A Linear Hybrid Concentrated Photovoltaic Solar Collector: A Methodology Proposal of Optical and Thermal Analysis

Abstract

:1. Introduction

2. Materials and Methods

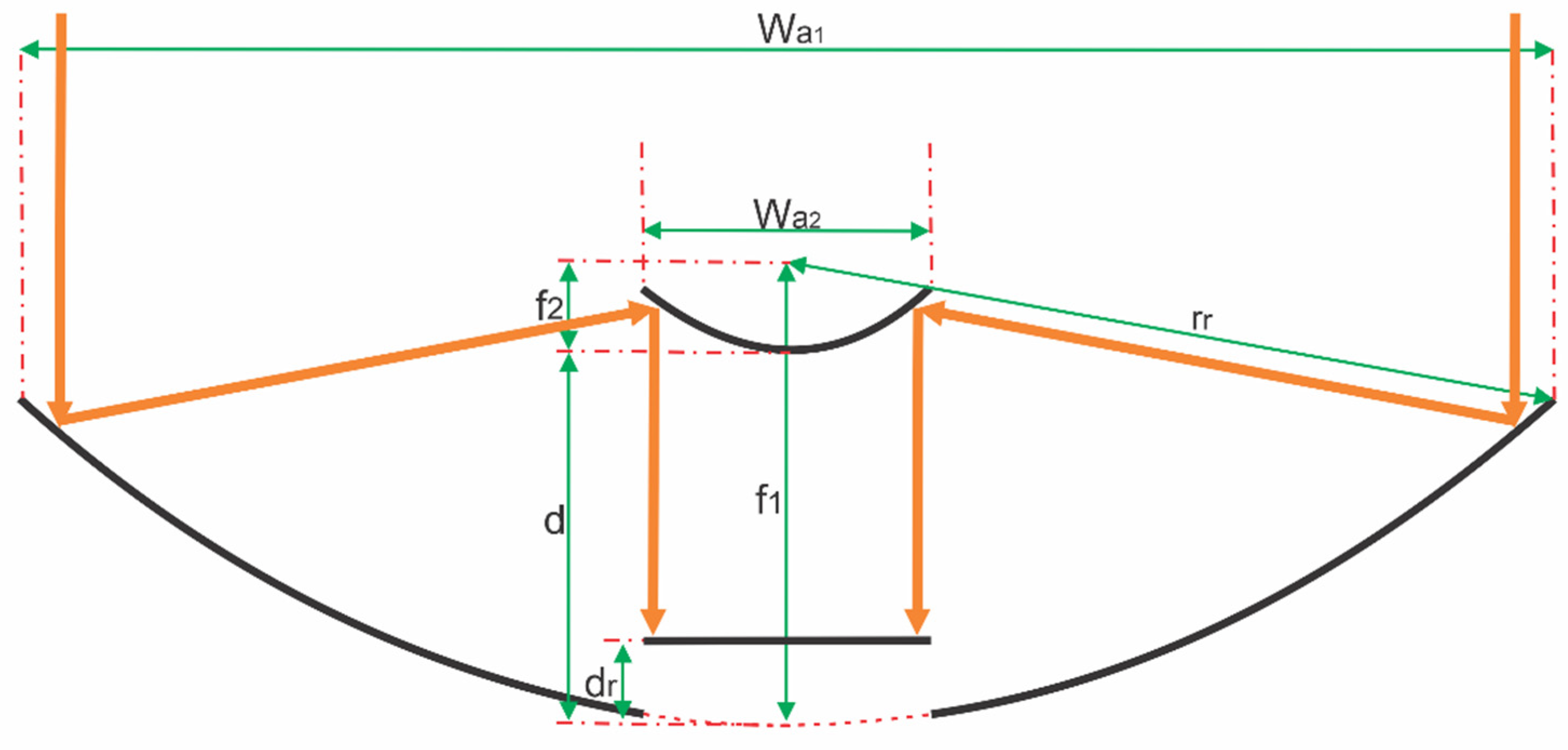

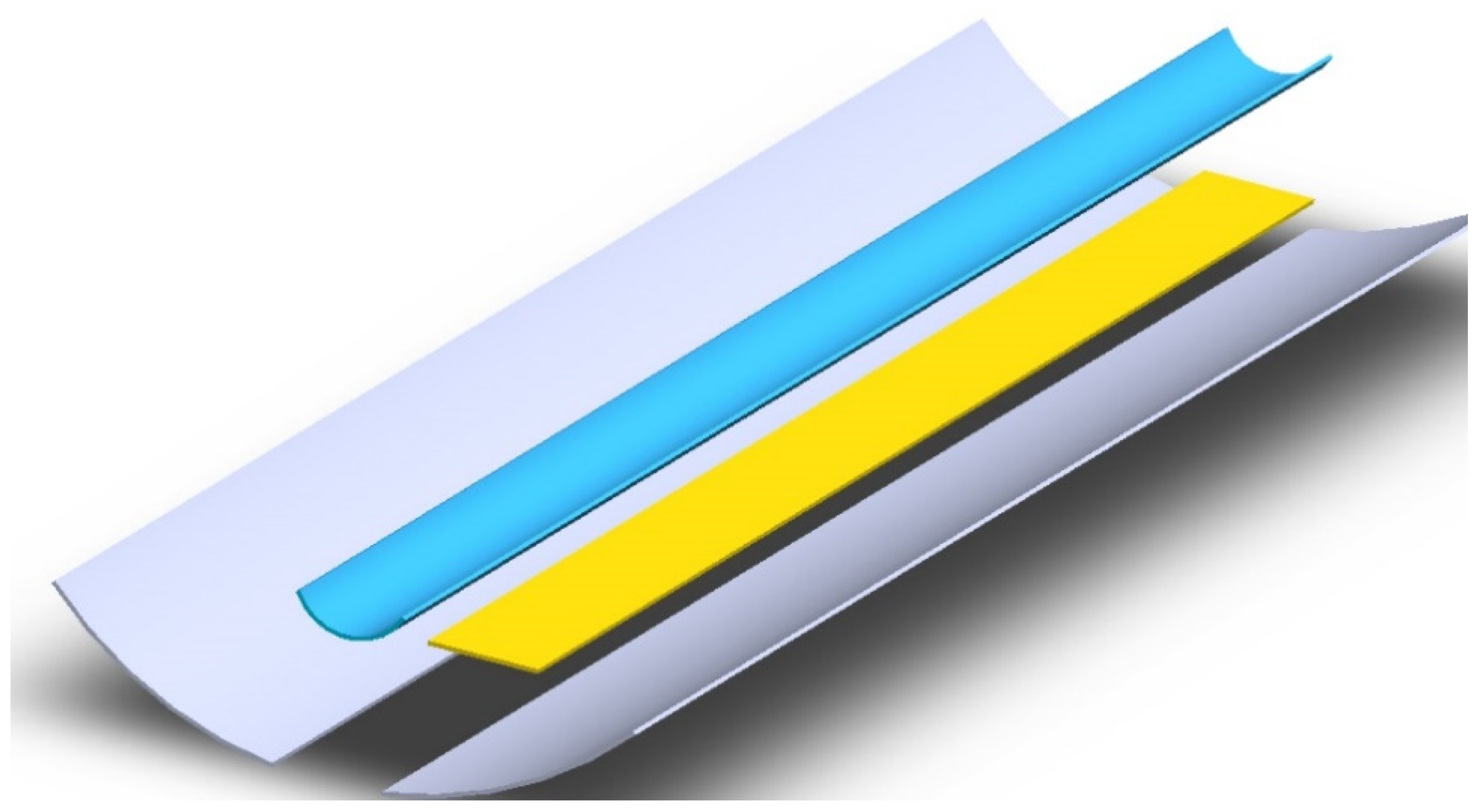

2.1. Geometry and Case Study

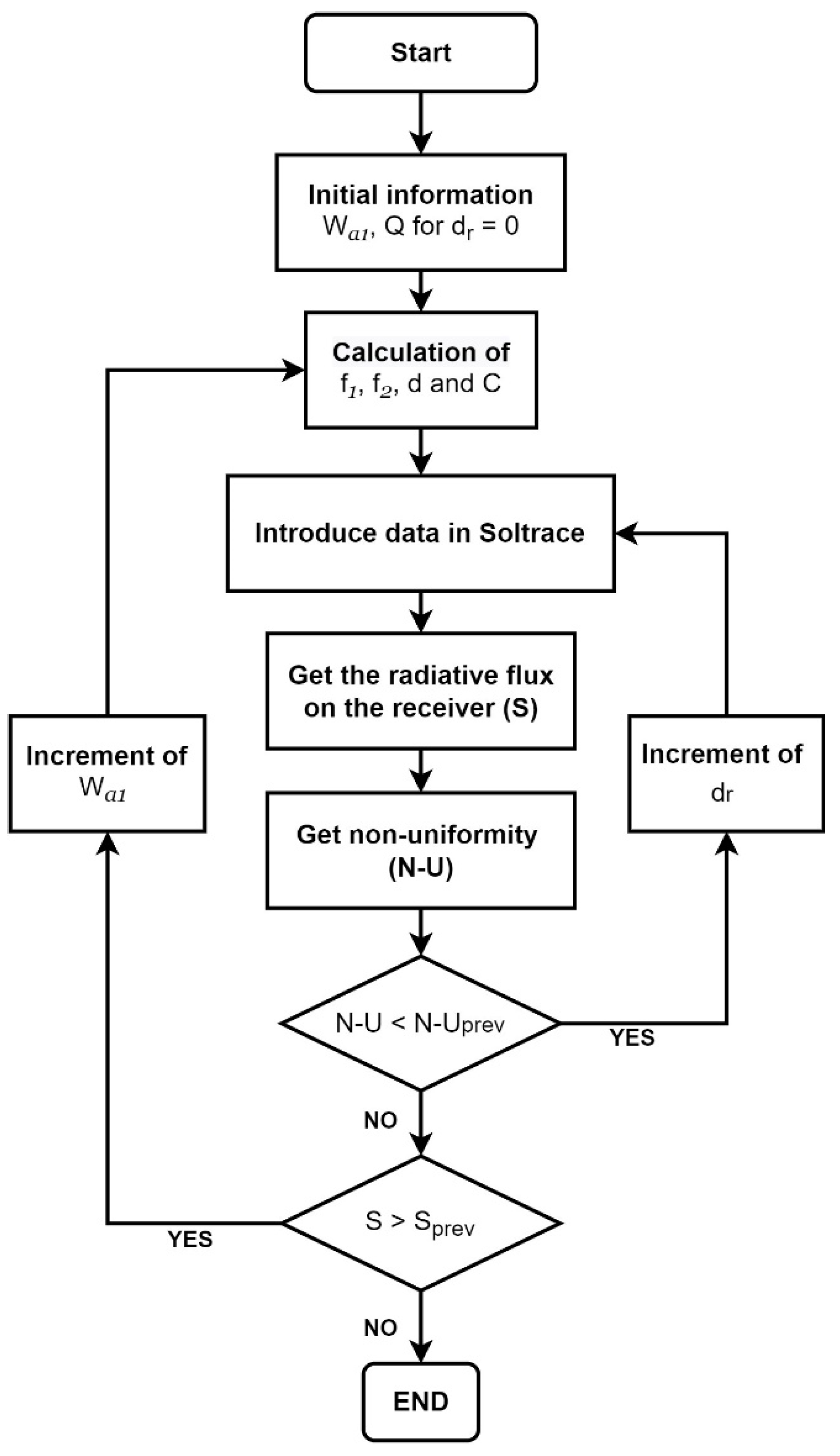

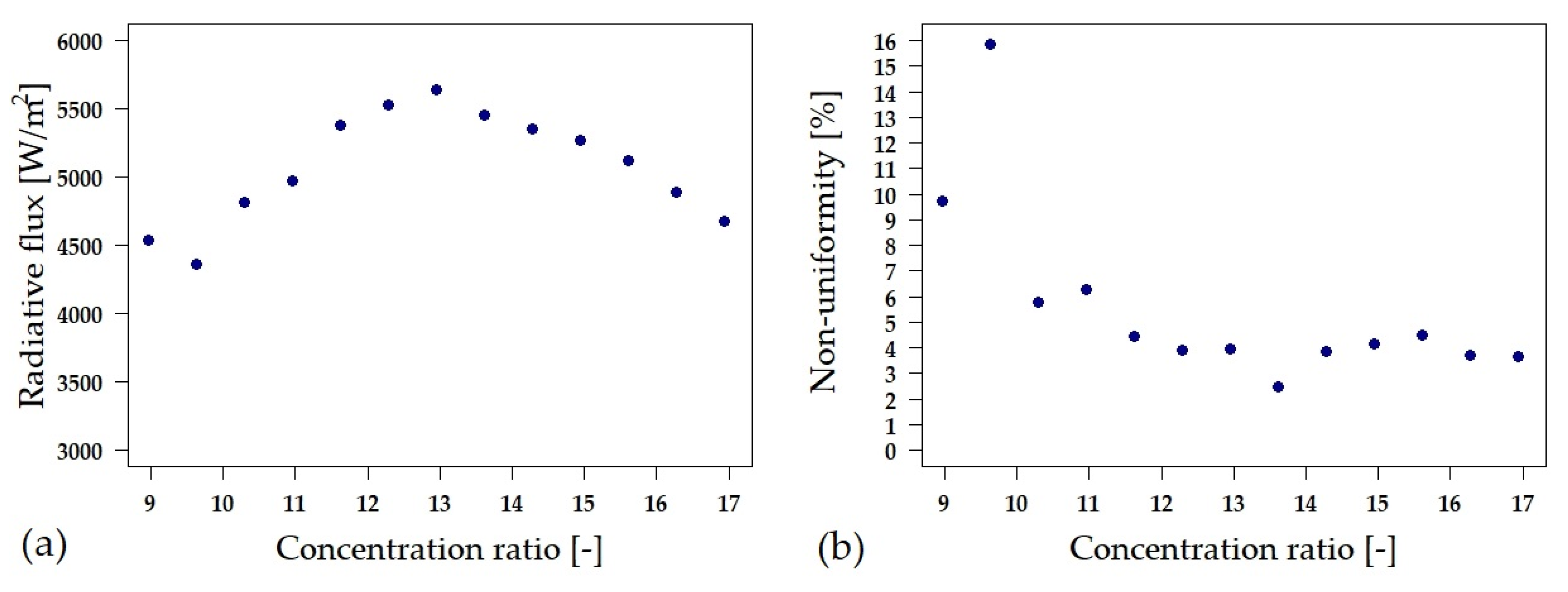

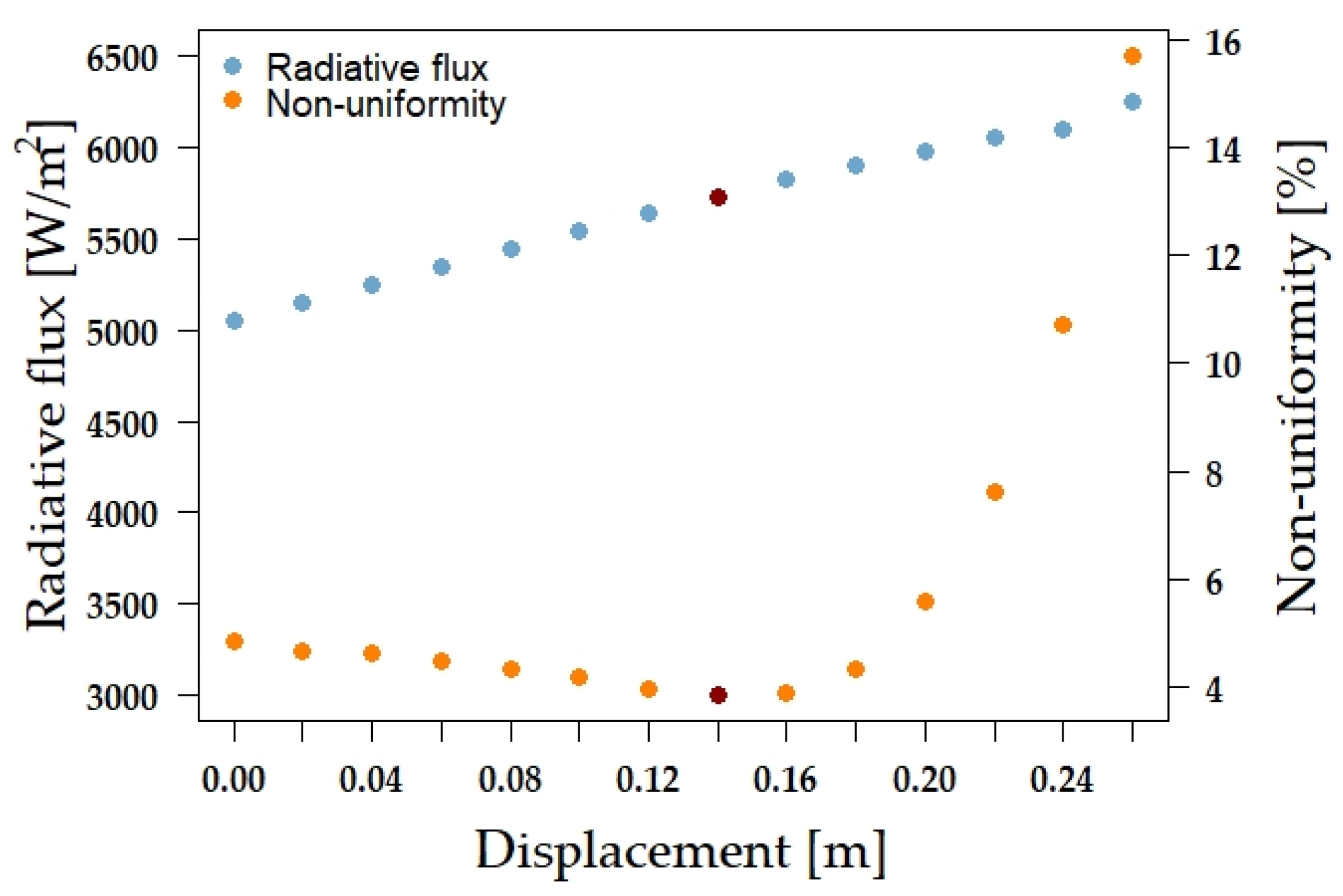

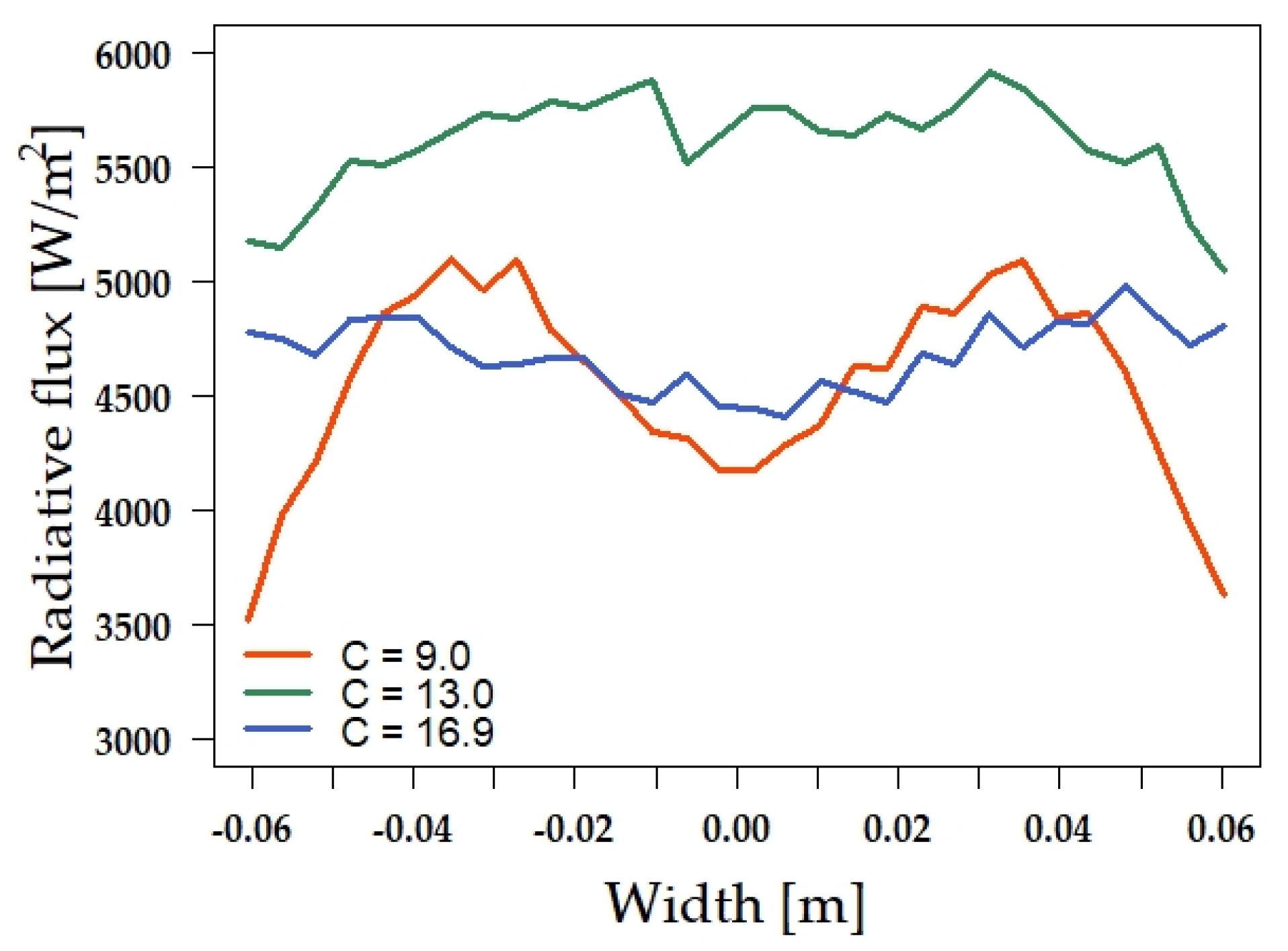

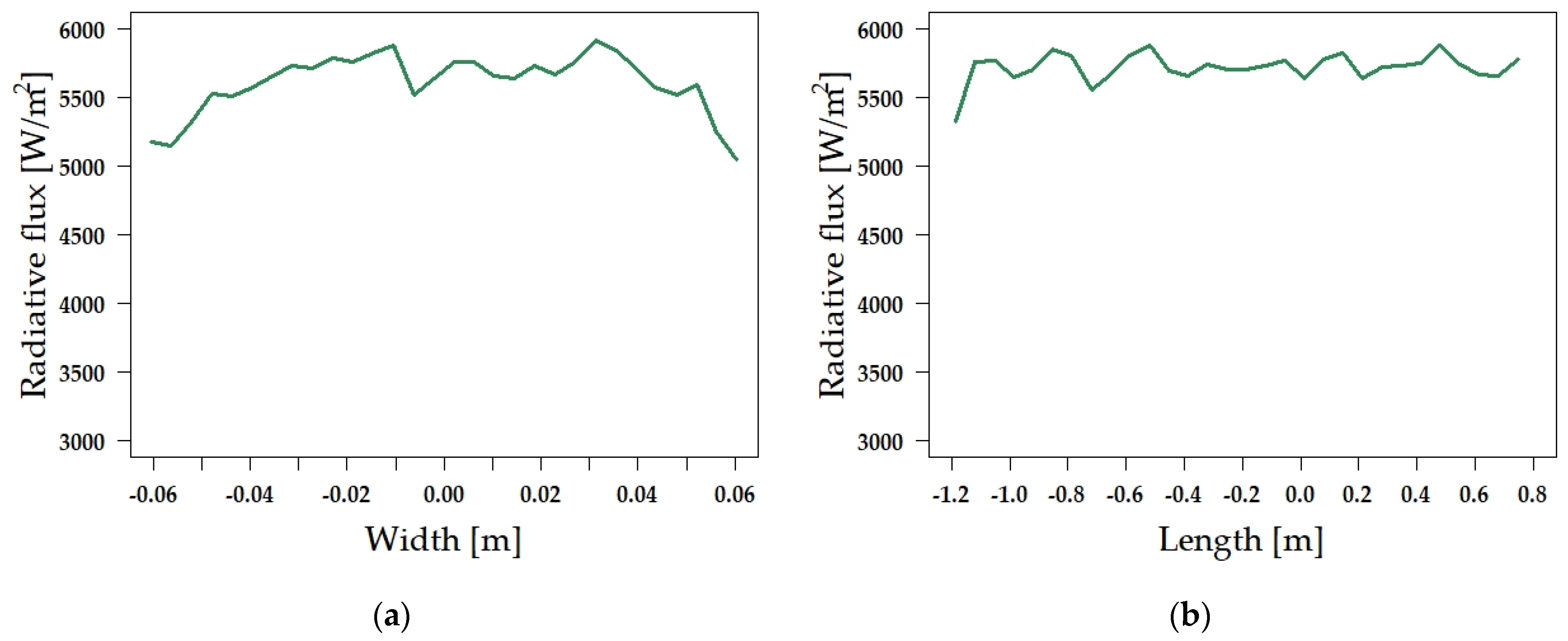

2.2. Optical Performance: Uniformity and Flux Analysis

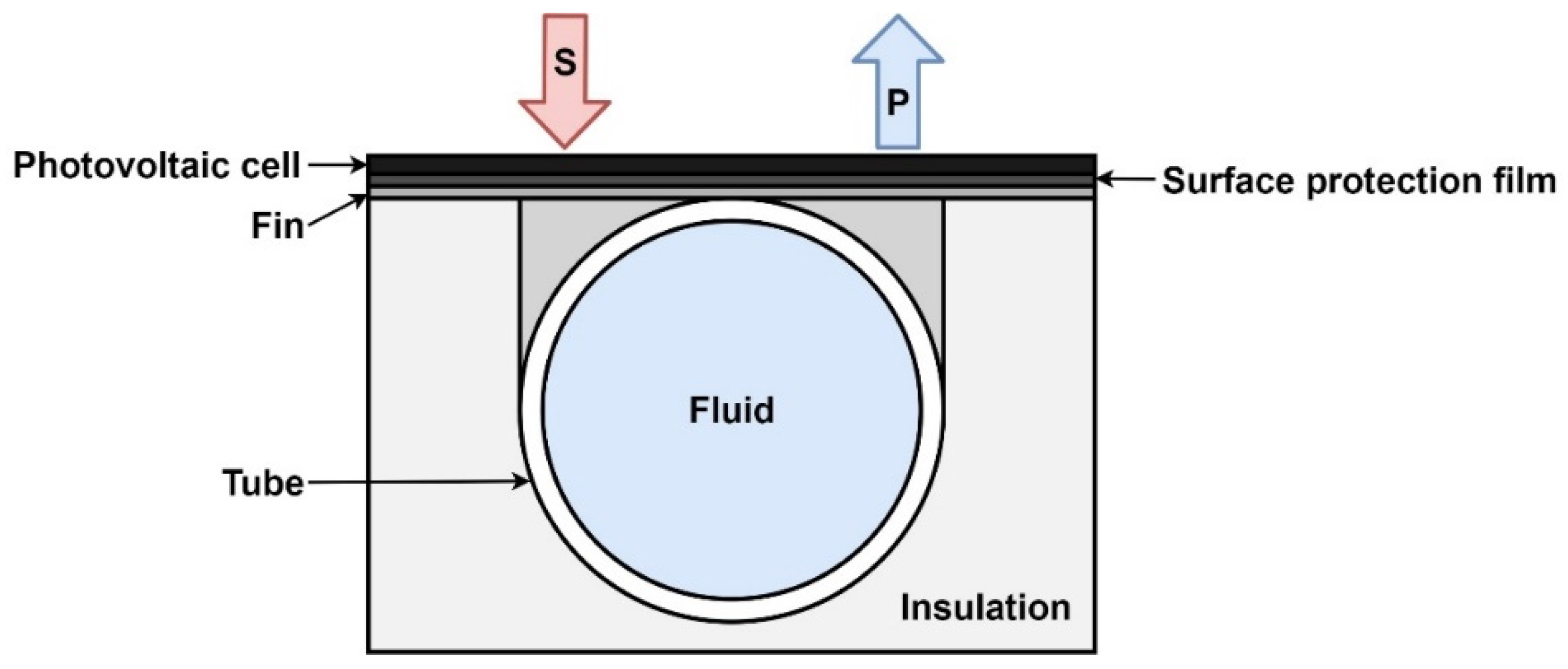

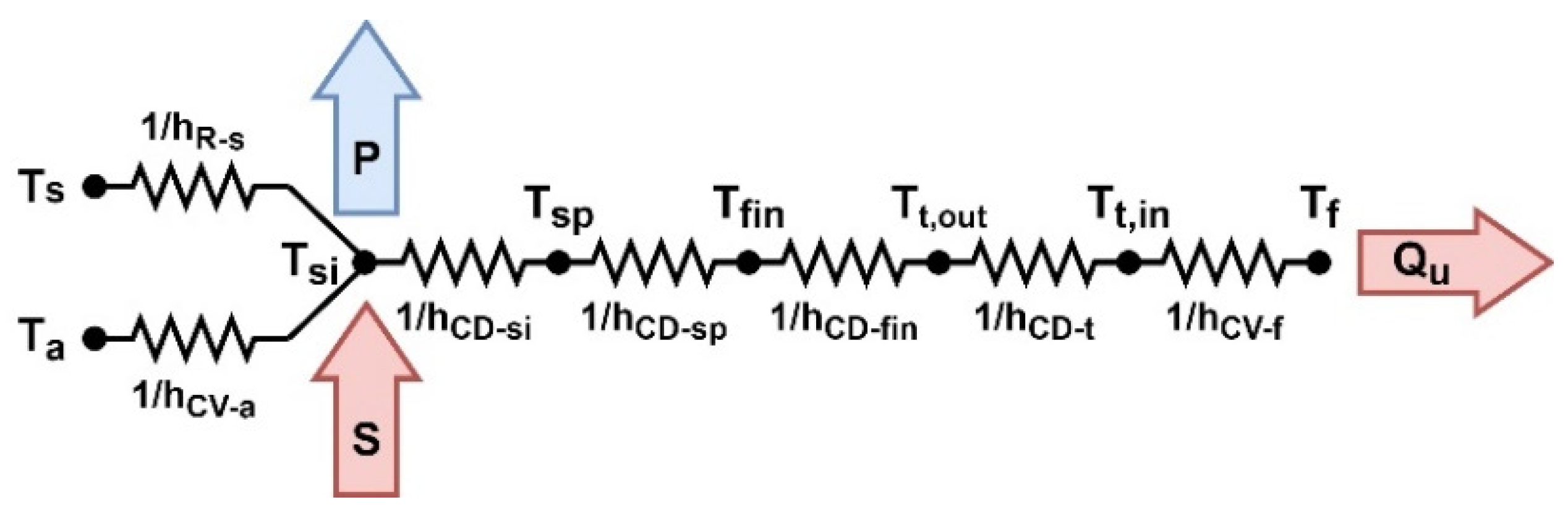

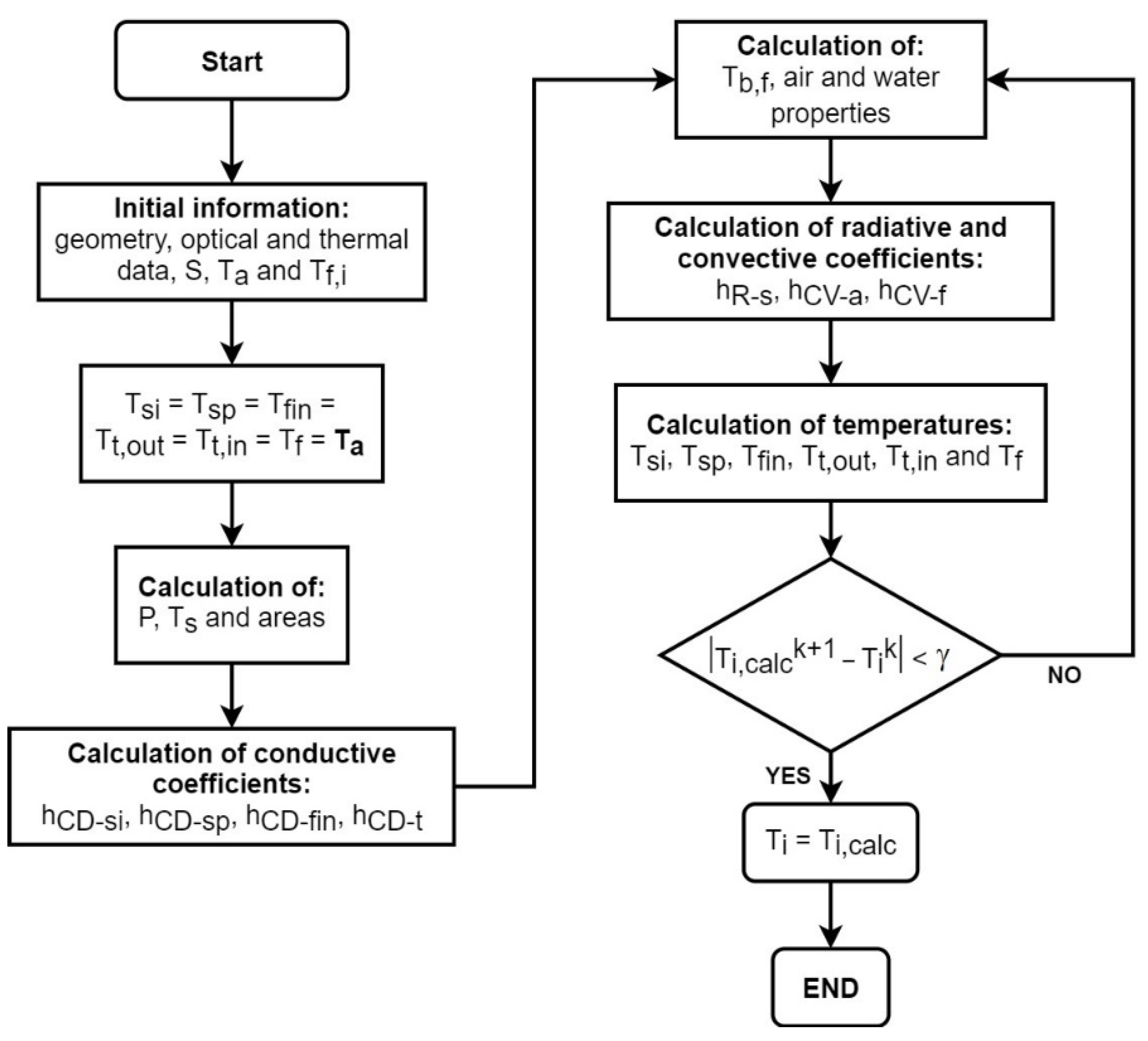

2.3. Thermal Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Area (m2) | |

| Solar concentration (dimensionless) | |

| Specific heat (J/(kg K)) | |

| Distance between the optical elements (m) | |

| Displacement of the receiver (m) | |

| Diameter (m) | |

| Thickness (m) | |

| Friction factor (dimensionless) | |

| Focal length of the primary concentrator (m) | |

| Focal length of the secondary reflector (m) | |

| Irradiance over the primary aperture (W) | |

| Heat transfer coefficient (W/(m2 K)) | |

| Thermal conductivity (W/(m K)) | |

| Length (m) | |

| Mass flow rate (m/s) | |

| Nusselt number (dimensionless) | |

| Power (W) | |

| Prandtl number (dimensionless) | |

| Energy per unit time (W) | |

| Mirror radius (m) | |

| Reynolds number (dimensionless) | |

| Absorbed solar radiation (W) | |

| Temperature (K) | |

| Velocity (m/s) | |

| Width (m) | |

| Parabola’s width of the primary concentrator (m) | |

| Parabola’s width of the secondary reflector (m) | |

| Greek symbols | |

| Temperature coefficient (1/K) | |

| Convergence criteria (K) | |

| Emissivity (dimensionless) | |

| Rim angle (°) | |

| Efficiency (dimensionless) | |

| Density (kg/m3) | |

| Dynamic viscosity (kg/(m s)) | |

| Stephan-Boltzman constant (5.67 × 10−8 W/(m2 K4)) | |

| Subscript | |

| Ambient | |

| Primary concentrator aperture | |

| Secondary reflector aperture | |

| Air | |

| Aperture | |

| Bulk | |

| Conductive | |

| Concentrated | |

| Convective | |

| Electrical | |

| Fluid | |

| Fin | |

| Inlet | |

| Inner | |

| Iteration number | |

| Laminar | |

| Nominal operation | |

| Optical | |

| Outer | |

| Previous value | |

| Photovoltaic cell | |

| Radiative | |

| Reference | |

| Sky | |

| Silicon | |

| Surface protection film | |

| Temperature | |

| Tube | |

| Transient | |

| Turbulent | |

| Useful | |

| Water | |

Appendix A. Evaluation of the Heat Transfer Coefficients

References

- IEA—International Energy Agency World: Energy Consumption, Electricity Consumption. Available online: https://www.iea.org/data-and-statistics/data-browser?country=WORLD&fuel=Energyconsumption&indicator=TotElecCons (accessed on 19 October 2021).

- Bouckaert, S.; Pales, A.; Fernandez, M.; Christophe, R.; Uwe, W.; Brent, V.; Laszlo D’, A.; Davide, S.T. IEA—International Energy Agency Net Zero by 2050. A Roadmap for the Global Energy Sector 2021; TRID: Paris, France, 2021; p. 222. [Google Scholar]

- Laura, C.; Tim, G. IEA—International Energy Agency World Energy Outlook 2021; IEA: Paris, France, 2021; p. 386. [Google Scholar]

- Besheer, A.H.; Smyth, M.; Zacharopoulos, A.; Mondol, J.; Pugsley, A. Review on recent approaches for hybrid PV/T solar technology. Int. J. Energy Res. 2016, 40, 2038–2053. [Google Scholar] [CrossRef]

- Yazdanifard, F.; Ameri, M. Exergetic advancement of photovoltaic/thermal systems (PV/T): A review. Renew. Sustain. Energy Rev. 2018, 97, 529–553. [Google Scholar] [CrossRef]

- Ju, X.; Xu, C.; Han, X.; Du, X.; Wei, G.; Yang, Y. A review of the concentrated photovoltaic/thermal (CPVT) hybrid solar systems based on the spectral beam splitting technology. Appl. Energy 2017, 187, 534–563. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Mustafa, R.J.; Rezk, H.; Al-Dhaifallah, M.; Al-Salaymeh, A. Sizing methodology of a multi-mirror solar concentrated hybrid PV/thermal system. Energies 2018, 11, 3276. [Google Scholar] [CrossRef] [Green Version]

- Yin, E.; Li, Q.; Xuan, Y. A novel optimal design method for concentration spectrum splitting photovoltaic–thermoelectric hybrid system. Energy 2018, 163, 519–532. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Al-Dhaifallah, M.; Alahmer, A.; Rezk, H. Design, modeling, and experimental investigation of activewater cooling concentrating photovoltaic system. Sustainability 2020, 12, 5392. [Google Scholar] [CrossRef]

- Yang, F.; Wang, H.; Zhang, X.; Tian, W.; Hua, Y.; Dong, T. Design and experimental study of a cost-effective low concentrating photovoltaic/thermal system. Sol. Energy 2018, 160, 289–296. [Google Scholar] [CrossRef]

- Othman, Y.; Hussain, F. Designs of various hybrid photovoltaic-thermal (PV/T) solar collectors. In Photovoltaics for Sustainable Electricity and Buildings; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–186. [Google Scholar]

- Guo, J.; Zheng, L. Numerically study on a new hybrid photovoltaic thermal (PVT) collectors with natural circulation. Appl. Sol. Energy (English Transl. Geliotekhnika) 2017, 53, 316–321. [Google Scholar] [CrossRef]

- Haloui, H.; Touafek, K.; Zaabat, M.; El Hocine, H.B.C.; Khelifa, A. Modelling of a hybrid photovoltaic thermal collector based on CdTe. Appl. Sol. Energy (English Transl. Geliotekhnika) 2016, 52, 27–31. [Google Scholar] [CrossRef]

- Othman, Y.; Hussain, F.; Sopian, K.; Yatim Baharuddin, R.H. Design of various hybrid single-pass photovoltaic–thermal (PV/T) solar collector. In Renewable Energy in the Service of Mankind Vol II; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Wang, G.; Yao, Y.; Lin, J.; Chen, Z.; Hu, P. Design and thermodynamic analysis of a novel solar CPV and thermal combined system utilizing spectral beam splitter. Renew. Energy 2020, 155, 1091–1102. [Google Scholar] [CrossRef]

- Ben Youssef, W.; Maatallah, T.; Menezo, C.; Ben Nasrallah, S. Modeling and optimization of a solar system based on concentrating photovoltaic/thermal collector. Sol. Energy 2018, 170, 301–313. [Google Scholar] [CrossRef]

- Aste, N.; Del Pero, C.; Leonforte, F.; Manfren, M. Performance monitoring and modeling of an uncovered photovoltaic-thermal (PVT) water collector. Sol. Energy 2016, 135, 551–568. [Google Scholar] [CrossRef]

- Khelifa, A.; Touafek, K.; Ben Moussa, H. Approach for the modelling of hybrid photovoltaic-thermal solar collector. IET Renew. Power Gener. 2015, 9, 207–217. [Google Scholar] [CrossRef]

- Vardanyan, R.R.; Dallakyan, V.K.; Travajyan, M.G. Temperature dependent performance of solar photovoltaic and thermal hybrid systems. J. Contemp. Phys. 2020, 55, 339–344. [Google Scholar] [CrossRef]

- Han, X.; Xu, C.; Pan, X.Y.; Ju, X.; Du, X.Z. Dynamic analysis of a concentrating photovoltaic/concentrating solar power (CPV/CSP) hybrid system. Sci. China Technol. Sci. 2019, 62, 1987–1998. [Google Scholar] [CrossRef]

- Afzali Gorouh, H.; Salmanzadeh, M.; Nasseriyan, P.; Hayati, A.; Cabral, D.; Gomes, J.; Karlsson, B. Thermal modelling and experimental evaluation of a novel concentrating photovoltaic thermal collector (CPVT) with parabolic concentrator. Renew. Energy 2022, 181, 535–553. [Google Scholar] [CrossRef]

- Herrando, M.; Ramos, A.; Zabalza, I.; Markides, C.N. A comprehensive assessment of alternative absorber-exchanger designs for hybrid PVT-water collectors. Appl. Energy 2019, 235, 1583–1602. [Google Scholar] [CrossRef] [Green Version]

- Nasseriyan, P.; Gorouh, H.A.; Gomes, J.; Cabral, D.; Salmanzadeh, M.; Lehmann, T.; Hayati, A. Numerical and experimental study of an asymmetric CPC-PVT solar collector. Energies 2020, 13, 1669. [Google Scholar] [CrossRef] [Green Version]

- Cabral, D.; Gomes, J.; Hayati, A.; Karlsson, B. Experimental investigation of a CPVT collector coupled with a wedge PVT receiver. Sol. Energy 2021, 215, 335–345. [Google Scholar] [CrossRef]

- Wang, G.; Yao, Y.; Chen, Z.; Hu, P. Thermodynamic and optical analyses of a hybrid solar CPV/T system with high solar concentrating uniformity based on spectral beam splitting technology. Energy 2019, 166, 256–266. [Google Scholar] [CrossRef]

- Herez, A.; El Hage, H.; Lemenand, T.; Ramadan, M.; Khaled, M. Review on photovoltaic/thermal hybrid solar collectors: Classifications, applications and new systems. Sol. Energy 2020, 207, 1321–1347. [Google Scholar] [CrossRef]

- Joshi, S.S.; Dhoble, A.S. Photovoltaic -Thermal systems (PVT): Technology review and future trends. Renew. Sustain. Energy Rev. 2018, 92, 848–882. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. Concentrated photovoltaic thermal (CPVT) solar collector systems: Part I—Fundamentals, design considerations and current technologies. Renew. Sustain. Energy Rev. 2015, 50, 1500–1565. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. Concentrated photovoltaic thermal (CPVT) solar collector systems: Part II—Implemented systems, performance assessment, and future directions. Renew. Sustain. Energy Rev. 2015, 50, 1566–1633. [Google Scholar] [CrossRef]

- Alzahrani, M.; Shanks, K.; Mallick, T.K. Advances and limitations of increasing solar irradiance for concentrating photovoltaics thermal system. Renew. Sustain. Energy Rev. 2021, 138, 110517. [Google Scholar] [CrossRef]

- Mauk, C.E.; Prengle, H.W.; Sun, E.C.H. Optical and thermal analysis of a cassegrainian solar concentrator. Sol. Energy 1979, 23, 157–167. [Google Scholar] [CrossRef]

- Wu, S.; Tang, R.; Wang, C. Numerical calculation of the intercept factor for parabolic trough solar collector with secondary mirror. Energy 2021, 233, 121175. [Google Scholar] [CrossRef]

- Granata, J.E.; Sorensen, N.R.; Riley, D.; Judkins, Z.; Olsen, S. Design for reliability: A low concentration PV case study. Conf. Rec. IEEE Photovolt. Spec. Conf. 2012, 1739–1743. [Google Scholar]

- Venegas-Reyes, E.; Jaramillo, O.A.; Castrejón-García, R.; Aguilar, J.O.; Sosa-Montemayor, F. Design, construction, and testing of a parabolic trough solar concentrator for hot water and low enthalpy steam generation. J. Renew. Sustain. Energy 2012, 4, 053103. [Google Scholar] [CrossRef]

- Rabl, A. Active Solar Collectors and Their Applications, 1st ed.; Oxford University Press Inc.: New York, NY, USA, 1985. [Google Scholar]

- Kalogirou, S.A. Solar Energy Engineering: Processes and Systems, 2nd ed.; Academic Press: Cambridge, ME, USA, 2014. [Google Scholar]

- Riverola, A.; Mellor, A.; Alonso Alvarez, D.; Ferre Llin, L.; Guarracino, I.; Markides, C.N.; Paul, D.J.; Chemisana, D.; Ekins-Daukes, N. Mid-infrared emissivity of crystalline silicon solar cells. Sol. Energy Mater. Sol. Cells 2018, 174, 607–615. [Google Scholar] [CrossRef] [Green Version]

- Hammami, M.; Torretti, S.; Grimaccia, F.; Grandi, G. Thermal and performance analysis of a photovoltaic module with an integrated energy storage system. Appl. Sci. 2017, 7, 1107. [Google Scholar] [CrossRef] [Green Version]

- SunPower Corporation MAXEON TM. GEN III SOLAR CELLS Electrical Characteristics of a Typical Maxeon Gen III Cell; Sunpower: San Jose, CA, USA, 2017. [Google Scholar]

- Swinbank, W.C. Long-wave radiation from clear skies. Q. J. R. Meteorol. Soc. 1963, 89, 339–348. [Google Scholar] [CrossRef]

- Hewitt, G.F. Heat Exchanger Design Handbook. Volume 2: Fluid Mechanics and Heat Transfer. In; Hemisphere Publishing Corporation: San Francisco, CA, USA, 1983. [Google Scholar]

- Engel, Y.A. Heat Transfer: A Practical Approach, 2nd ed.; Mcgraw-Hill: Blacklick, OH, USA, 2002. [Google Scholar]

| Component | Length (m) | Width (m) | Focal Length (m) | Coordinates |

|---|---|---|---|---|

| PPC | 2.44 | 1.121 | 0.297 | (0,0) |

| SPR | 2.44 | 0.125 | 0.024 | (0,0.027) |

| Receiver | 2.00 | 0.125 | --- | (0,dr) |

| Component | Material | Thickness (mm) | Thermal Conductivity (W/(m K)) |

|---|---|---|---|

| Photovoltaic cell | Silicon | 1.5 | 150 1 |

| Surface protection film | Tedlar | 1.0 | 0.35 1 |

| Fin | Cooper | 4.6 | 401 |

| Tube | Cooper | 7.1 | 401 |

| Parameter | Value |

|---|---|

| Technology | Monocrystalline silicon |

| Dimensions (mm) | 125 × 125 |

| Thickness (μm) | 150 ± 30 |

| Nominal operation temperature (°C) | 45 |

| Reference temperature (°C) | 25 |

| Reference irradiance (W/m2) | 1000 |

| Efficiency at standard test conditions (%) | 24.3 |

| Temperature power coefficient (%/°C) | 0.29 |

| Maximum solar concentration supported (W/m2) | 7000 |

| Displacement (m) | Non-Uniformity (%) | Radiative Flux (W/m2) |

|---|---|---|

| 0.00 | 4.85 | 5046.8 |

| 0.02 | 4.68 | 5149.2 |

| 0.04 | 4.62 | 5246.9 |

| 0.06 | 4.50 | 5342.9 |

| 0.08 | 4.32 | 5441.1 |

| 0.10 | 4.17 | 5538.1 |

| 0.12 | 3.98 | 5635.7 |

| 0.14 | 3.84 | 5728.2 |

| Parameter | Result |

|---|---|

| Silicon cell temperature (K) | 353.0 |

| Outlet fluid temperature (K) | 299.8 |

| Produced power (W) | 287.9 |

| Fluid extracted heat (W) | 905.9 |

| Optical efficiency (%) | 35.7 |

| Electrical efficiency (%) | 7.3 |

| Thermal efficiency (%) | 22.9 |

| Overall efficiency (%) | 30.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venegas-Reyes, E.; Ortega-Avila, N.; Peña-Cruz, M.I.; García-Ortiz, O.J.; Rodríguez-Muñoz, N.A. A Linear Hybrid Concentrated Photovoltaic Solar Collector: A Methodology Proposal of Optical and Thermal Analysis. Energies 2021, 14, 8155. https://doi.org/10.3390/en14238155

Venegas-Reyes E, Ortega-Avila N, Peña-Cruz MI, García-Ortiz OJ, Rodríguez-Muñoz NA. A Linear Hybrid Concentrated Photovoltaic Solar Collector: A Methodology Proposal of Optical and Thermal Analysis. Energies. 2021; 14(23):8155. https://doi.org/10.3390/en14238155

Chicago/Turabian StyleVenegas-Reyes, Eduardo, Naghelli Ortega-Avila, Manuel I. Peña-Cruz, Omar J. García-Ortiz, and Norma A. Rodríguez-Muñoz. 2021. "A Linear Hybrid Concentrated Photovoltaic Solar Collector: A Methodology Proposal of Optical and Thermal Analysis" Energies 14, no. 23: 8155. https://doi.org/10.3390/en14238155

APA StyleVenegas-Reyes, E., Ortega-Avila, N., Peña-Cruz, M. I., García-Ortiz, O. J., & Rodríguez-Muñoz, N. A. (2021). A Linear Hybrid Concentrated Photovoltaic Solar Collector: A Methodology Proposal of Optical and Thermal Analysis. Energies, 14(23), 8155. https://doi.org/10.3390/en14238155