A CUSUM-Based Approach for Condition Monitoring and Fault Diagnosis of Wind Turbines

Abstract

1. Introduction

2. Testing for Structural Change/Break in Economic Time Series

2.1. Introduction

2.2. CUSUM Test for Structural Change

Calculation of the Critical Region

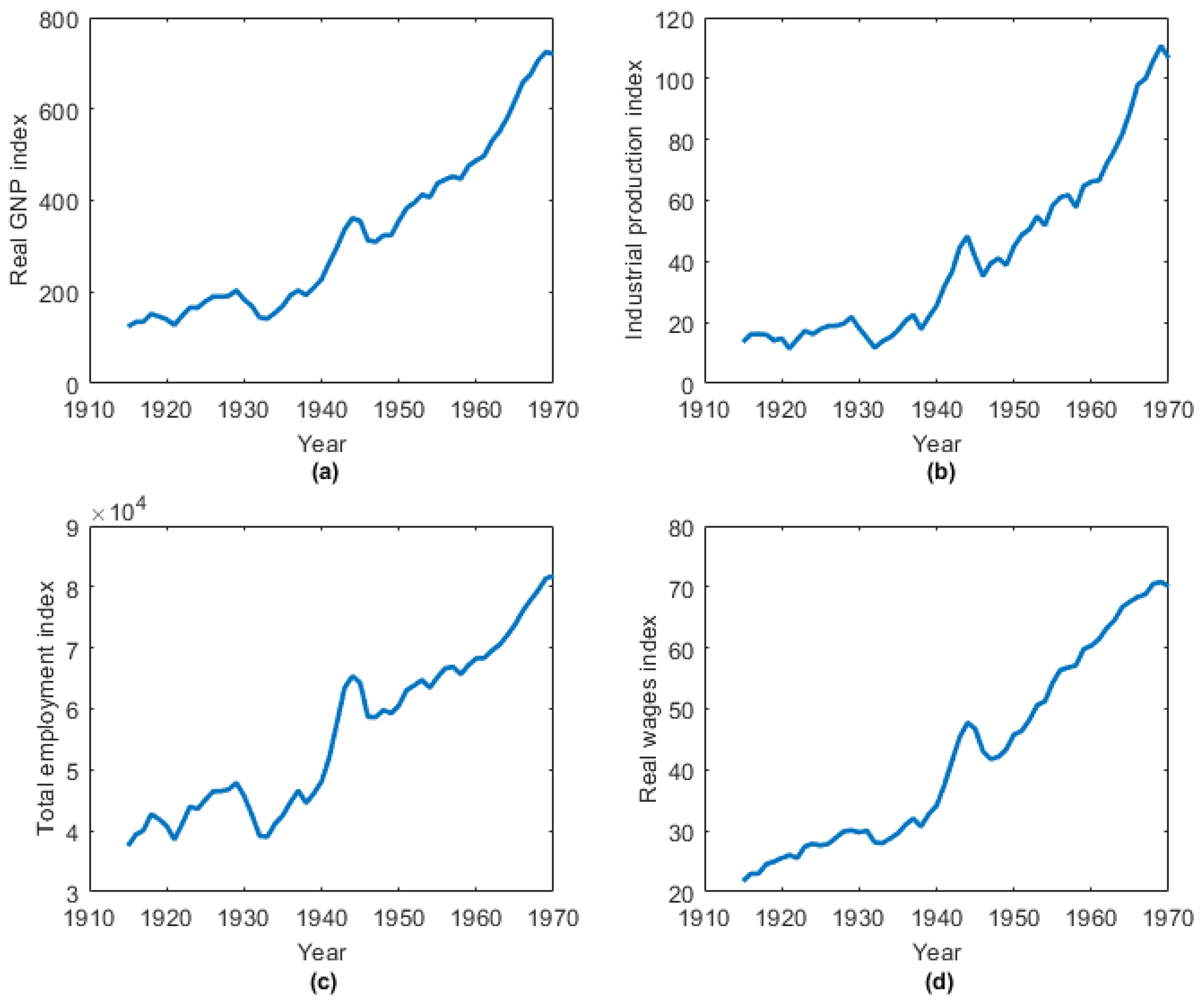

2.3. Example of CUSUM Tests for Structural Break Detection Using Economic Data

3. Condition Monitoring and Fault Diagnosis of Engineering Systems and/or Structures Based on CUSUM Tests

- Define the null hypothesis ()—i.e., what is known as true for the regression model formed in Step 1. In other words, is what we want to test. Essentially, represents the fact that there are not structural changes in the model. This implies in the point of view of condition monitoring that the engineering system and/or structure of interest has no fault or abnormal problems. On the contrary, the alternative hypothesis ()—i.e., what we need to accept if the null hypothesis is not true—means that an abnormal problem would appear in the system.

- Specify the significance level (or confidence level) for the statistical hypothesis testing, which is performed in Step 3. It is well known that, for statistical hypothesis tests, the significance level is the probability of rejecting the null hypothesis.

- If the sequence of the CUSUM test statistics crosses into the critical region after some recursive regression iterations, then it indicates the occurrence of a fault or an abnormal problem in the engineering system or structure at the current data sample. Consequently, send the warning information about the possible occurrence of a fault. After the fault/abnormality is identified, a waiting time period must be spent until a certain data sample when the system or structure completely returns to the normal operating state. Then the calculation procedure can start again from Step 1.

- If the sequence of the CUSUM test statistics does not cross into the critical region after all recursive regression iterations, then it is an indication that there is no fault or abnormality in the engineering system or structure from the beginning of the monitoring process till the current data sample. In this case, the calculation procedure returns to Step 3 and continues.

4. Case Study Using Temperature-Related Wind Turbine SCADA Data

- (1)

- The abnormal operating state F1 occurred during a time interval (80 min) between the data samples 410 and 418 (see Figure 7). This abnormality happened while the wind speed dropped down from 4.4 meters per second (mps), then stayed around 3.5 mps, and finally increased up to 4.75 mps. In response to the wind speed variations, the generator speed dropped down from 800 revolutions per minute (rpm) to almost stationary state (standstill), then suddenly increased up to more than 600 rpm and afterward rapidly decreased again to 0 rpm, and finally boosted up to the speed nearly 800 rpm. It can be observed that the generator speed varied abnormally with respect to the conditions of the wind speed. It is expected that this abnormality would be early identified to guarantee a proper operating condition of the WT and avoid more serious problems.

- (2)

- The gearbox fault F2 occurred at the data sample 1232 (see Figure 7). It happened when the generator speed was abruptly dropped down to the zero value, while the wind speed was still stable around 5.6 mps (i.e., normal range of wind speed for WT operation). It was reported that this fault might be caused by a bearing failure or damage in the gearbox. So, it is important to detect this fault accurately at the early stage of its occurrence.

5. Results and Discussion

5.1. Implementation of The Proposed Method for The Case Study

- The null hypothesis () is defined as that the regression coefficients in the multiple linear regression model given by Equation (7) are identical (or stable) across all sequential subsamples. In a simple description, if the null hypothesis is true then it implies that the wind turbine is in the normal operation condition (no fault). Otherwise, the null hypothesis is rejected in favor of the alternative hypothesis (), which indicates that a fault occurs in the wind turbine.

- The 1% level of significance is chosen for statistical hypothesis tests.

- If at least a value of the sequence of the CUSUM test statistics goes into the critical region, it suggests structural change in the model over time (i.e., the null hypothesis is rejected at the chosen level of significance). This indicates the occurrence of a fault or an abnormal problem in the wind turbine at the current data sample.

- If all values of the test statistics stay out of the critical region (or the test statistics do not cross into the critical region), it indicates failure to reject the null hypothesis, i.e., there is no structural break in the observed data, or in other words, the model is stable. If this is the case then there is no fault or abnormality in the wind turbine from the beginning of the monitoring process till the current data sample, or in other words, the wind turbine is still in the normal operation condition.

5.2. Condition Monitoring and Fault Detection Results

5.3. Discussion

6. Further Discussion and Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andrews, D.W.K. Tests for parameter instability and structural change with unknown change point. Econometrica 1993, 61, 821–856. [Google Scholar] [CrossRef]

- Chu, C.S.J.; Stinchcombe, M.; White, H. Monitoring structural change. Econometrica 1996, 64, 1045–1065. [Google Scholar] [CrossRef]

- Zeileis, A.; Leisch, F.; Kleiber, C.; Hornik, K. Monitoring structural change in dynamic econometric models. J. Appl. Econom. 2005, 20, 99–121. [Google Scholar] [CrossRef]

- Wang, C.S.H.; Xie, Y.M. Structural change and monitoring tests. In Handbook of Financial Econometrics and Statistics; Lee, C.F., Lee, J.C., Eds.; Springer: New York, NY, USA, 2015; pp. 873–902. [Google Scholar]

- Kleiber, C. Structural change in (economic) time series. In Complexity and Synergetics; Müller, S., Plath, P., Radons, G., Fuchs, A., Eds.; Springer: Cham, Switzerland, 2018; pp. 275–286. [Google Scholar]

- Antoch, J.; Hanousek, J.; Horváth, L.; Hušková, M.; Wang, S. Structural breaks in panel data: Large number of panels and short length time series. Econom. Rev. 2019, 38, 828–855. [Google Scholar] [CrossRef]

- Lewis, L.T.; Monarch, R.; Sposi, M.; Zhang, J. Structural Change and Global Trade; Globalization Institute Working Paper No. 333; Federal Reserve Bank of Dallas: Dallas, TX, USA, 2020. [Google Scholar]

- Comin, D.A.; Lashkari, D.; Mestieri, M. Structural Change with Long-Run Income and Price Effects; NBER Working Paper No. 21595; National Bureau of Economic Research: Cambridge, MA, USA, 2020. [Google Scholar]

- Chow, G.C. Tests of equality between sets of coefficients in two linear regressions. Econometrica 1960, 28, 591–605. [Google Scholar] [CrossRef]

- Brown, R.L.; Durbin, J.; Evans, J.M. Techniques for testing the constancy of regression relationships over time. J. R. Stat. Soc. Ser. B 1975, 37, 149–192. [Google Scholar] [CrossRef]

- Krämer, W.; Ploberger, W.; Alt, R. Testing for structural change in dynamic models. Econometrica 1988, 56, 1355–1369. [Google Scholar] [CrossRef]

- Turner, P. Power properties of the CUSUM and CUSUMSQ tests for parameter instability. Appl. Econ. Lett. 2010, 17, 1049–1053. [Google Scholar] [CrossRef]

- Ilott, P.W.; Griffiths, A.J. Development of a Pumping System Decision Support Tool Based on Artificial Intelligence. In Proceedings of the 8th IEEE International Conference on Tools with Artificial Intelligence (ICTAI 1996), Toulouse, France, 16–19 November 1996; pp. 260–267. [Google Scholar]

- Leger, R.P.; Garland, W.J.; Poehlman, W.F.S. Fault detection and diagnosis using statistical control charts and artificial neural networks. Artif. Intell. Eng. 1998, 12, 35–47. [Google Scholar] [CrossRef]

- Bin Shams, M.A.; Budman, H.M.; Duever, T.A. Fault detection, identification and diagnosis using CUSUM based PCA. Chem. Eng. Sci. 2011, 66, 4488–4498. [Google Scholar] [CrossRef]

- Bin Shams, M.A.; Budman, H.M.; Duever, T.A. Fault Detection Using CUSUM Based Techniques with Application to The Tennessee Eastman Process. In Proceedings of the 9th International Symposium on Dynamics and Control of Process Systems (DYCOPS 2010), Leuven, Belgium, 5–7 July 2010; pp. 109–114. [Google Scholar]

- Du, Y.; Du, D. Fault detection and diagnosis using empirical mode decomposition based principal component analysis. Comput. Chem. Eng. 2018, 115, 1–21. [Google Scholar] [CrossRef]

- Zhou, F.; Park, J.H.; Wen, C.; Hu, P. Average accumulative based time variant model for early diagnosis and prognosis of slowly varying faults. Sensors 2018, 18, 1804. [Google Scholar] [CrossRef] [PubMed]

- Lampreia, S.P.G.F.d.S.; Requeijo, J.F.G.; Dias, J.A.M.; Vairinhos, V.M.; Barbosa, P.I.S. Condition monitoring based on modified CUSUM and EWMA control charts. J. Qual. Maint. Eng. 2018, 24, 119–132. [Google Scholar] [CrossRef]

- Baghli, M.; Delpha, C.; Diallo, D.; Hallouche, A.; Mba, D.; Wang, T. Three-level NPC inverter incipient fault detection and classification using output current statistical analysis. Energies 2019, 12, 1372. [Google Scholar] [CrossRef]

- Xu, Q.; Lu, S.; Zhai, Z.; Jiang, C. Adaptive fault detection in wind turbine via RF and CUSUM. IET Renew. Power Gener. 2020, 14, 1789–1796. [Google Scholar] [CrossRef]

- Page, E.S. Continuous inspection scheme. Biometrika 1954, 41, 100–115. [Google Scholar] [CrossRef]

- Nelson, C.R.; Plosser, C.I. Trends versus random walks in macroeconomic time series: Some evidence and implications. J. Monet. Econ. 1982, 10, 139–162. [Google Scholar] [CrossRef]

- Global Wind Energy Council. Global Wind Report: Annual Market Update 2018. 2019. Available online: https://gwec.net/global-wind-report-2018/ (accessed on 31 January 2021).

- Hyers, R.W.; McGowan, J.G.; Sullivan, K.L.; Manwell, J.F.; Syrett, B.C. Condition monitoring and prognosis of utility scale wind turbines. Energy Mater. 2006, 1, 187–203. [Google Scholar] [CrossRef]

- Kusiak, A.; Li, W. The prediction and diagnosis of wind turbine faults. Renew. Energy 2011, 36, 16–23. [Google Scholar] [CrossRef]

- Qian, P.; Ma, X.; Zhang, D. Estimating health condition of the wind turbine drivetrain system. Energies 2017, 10, 1583. [Google Scholar] [CrossRef]

- Hameed, Z.; Hong, Y.S.; Cho, Y.M.; Ahn, S.H.; Song, C.K. Condition monitoring and fault detection of wind turbines and related algorithms: A review. Renew. Sustain. Energy Rev. 2009, 13, 1–39. [Google Scholar] [CrossRef]

- Salameh, J.P.; Cauet, S.; Etien, E.; Sakout, A.; Rambault, L. Gearbox condition monitoring in wind turbines: A review. Mech. Syst. Signal Process. 2018, 111, 251–264. [Google Scholar] [CrossRef]

- Wang, T.; Han, Q.; Chu, F.; Feng, Z. Vibration based condition monitoring and fault diagnosis of wind turbine planetary gearbox: A review. Mech. Syst. Signal Process. 2019, 126, 662–685. [Google Scholar] [CrossRef]

- Stetco, A.; Dinmohammadi, F.; Zhao, X.; Robu, V.; Flynn, D.; Barnes, M.; Keane, J.; Nenadic, G. Machine learning methods for wind turbine condition monitoring: A review. Renew. Energy 2019, 133, 620–635. [Google Scholar] [CrossRef]

- Hossain, M.L.; Abu-Siada, A.; Muyeen, S.M. Methods for advanced wind turbine condition monitoring and early diagnosis: A literature review. Energies 2018, 11, 1309. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, D. A survey of condition monitoring and fault diagnosis toward integrated O&M for wind turbines. Energies 2019, 12, 2801. [Google Scholar]

- Zaher, A.; McArthur, S.D.J.; Infield, D.G.; Patel, Y. Online wind turbine fault detection through automated SCADA data analysis. Wind Energy 2009, 12, 574–593. [Google Scholar] [CrossRef]

- Kusiak, A.; Zhang, Z. Analysis of wind turbine vibrations based on SCADA data. ASME J. Sol. Energy Eng. 2010, 132, 031008. [Google Scholar] [CrossRef]

- Wilkinson, M.; Darnell, B.; Delft, T.V.; Harman, K. Comparison of methods for wind turbine condition monitoring with SCADA data. IET Renew. Power Gener. 2014, 8, 390–397. [Google Scholar] [CrossRef]

- Sun, P.; Li, J.; Wang, C.; Lei, X. A generalized model for wind turbine anomaly identification based on SCADA data. Appl. Energy 2016, 168, 550–567. [Google Scholar] [CrossRef]

- Dao, P.B.; Staszewski, W.J.; Barszcz, T.; Uhl, T. Condition monitoring and fault detection in wind turbines based on cointegration analysis of SCADA data. Renew. Energy 2018, 116, 107–122. [Google Scholar] [CrossRef]

- Tautz-Weinert, J.; Watson, S.J. Using SCADA data for wind turbine condition monitoring—A review. IET Renew. Power Gener. 2017, 11, 382–394. [Google Scholar] [CrossRef]

- Zolna, K.; Dao, P.B.; Staszewski, W.J.; Barszcz, T. Nonlinear cointegration approach for condition monitoring of wind turbines. Math. Probl. Eng. 2015, 2015, 1–11. [Google Scholar] [CrossRef]

- Vidal, Y.; Pozo, F.; Tutivén, C. Wind turbine multi-fault detection and classification based on SCADA data. Energies 2018, 11, 3018. [Google Scholar] [CrossRef]

- Astolfi, D.; Castellani, F. Wind turbine power curve upgrades: Part II. Energies 2019, 12, 1503. [Google Scholar] [CrossRef]

- Feng, Y.; Qiu, Y.; Crabtree, C.J.; Long, H.; Tavner, P.J. Monitoring wind turbine gearboxes. Wind Energy 2013, 16, 728–740. [Google Scholar] [CrossRef]

- Schlechtingen, M.; Santos, I.F. Comparative analysis of neural network and regression based condition monitoring approaches for wind turbine fault detection. Mech. Syst. Signal Process. 2011, 25, 1849–1875. [Google Scholar] [CrossRef]

- Guo, P.; Infield, D.; Yang, X. Wind turbine generator condition-monitoring using temperature trend analysis. IEEE Trans. Sustain. Energy 2012, 3, 124–133. [Google Scholar] [CrossRef]

- Abdusamad, K.B.; Gao, D.W.; Muljadi, E. A Condition Monitoring System for Wind Turbine Generator Temperature by Applying Multiple Linear Regression Model. In Proceedings of the 2013 North American Power Symposium (NAPS), Manhattan, KS, USA, 22–24 September 2013. [Google Scholar]

- Astolfi, D.; Castellani, F.; Terzi, L. Fault prevention and diagnosis through SCADA temperature data analysis of an onshore wind farm. Diagnostyka 2014, 15, 71–78. [Google Scholar]

- Dao, P.B. Condition monitoring of wind turbines based on cointegration analysis of gearbox and generator temperature data. Diagnostyka 2018, 19, 63–71. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Q.; Yang, X.; Zeng, B. Condition monitoring of wind turbines based on analysis of temperature-related parameters in supervisory control and data acquisition data. Meas. Control. 2020, 53, 164–180. [Google Scholar] [CrossRef]

- Econometrics ToolboxTM; Release 2019b; The MathWorks Inc.: Natick, MA, USA, 2019.

- Dao, P.B.; Staszewski, W.J. Cointegration approach for temperature effect compensation in Lamb wave based damage detection. Smart Mater. Struct. 2013, 22, 095002. [Google Scholar] [CrossRef]

- Basseville, M.; Nikiforov, I. Detection of Abrupt Changes: Theory and Application; Prentice-Hall: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dao, P.B. A CUSUM-Based Approach for Condition Monitoring and Fault Diagnosis of Wind Turbines. Energies 2021, 14, 3236. https://doi.org/10.3390/en14113236

Dao PB. A CUSUM-Based Approach for Condition Monitoring and Fault Diagnosis of Wind Turbines. Energies. 2021; 14(11):3236. https://doi.org/10.3390/en14113236

Chicago/Turabian StyleDao, Phong B. 2021. "A CUSUM-Based Approach for Condition Monitoring and Fault Diagnosis of Wind Turbines" Energies 14, no. 11: 3236. https://doi.org/10.3390/en14113236

APA StyleDao, P. B. (2021). A CUSUM-Based Approach for Condition Monitoring and Fault Diagnosis of Wind Turbines. Energies, 14(11), 3236. https://doi.org/10.3390/en14113236