1. Introduction

The recent development in the digitalization of industries is becoming the digital transformation system of the whole market. The fundamental nature of the digitalization procedure in the framework of the Fourth Industrial Revolution’s deployment is the method of understanding information communication and devices into the processes and industry practices of the actual segment of the economy [

1]. The fourth industrial revolution and the fundamental digital transformation, established as Industry 4.0, is growing exponentially. The digital transformation is reforming the way people living and working fundamentally, and the community stays positive concerning the prospects Industry 4.0 can propose for sustainability [

2]. The development of new digital technologies in the era of Industrial Revolution 4.0, such as machine learning, big data, smart sensors, drones, cloud computing, robotics, artificial intelligence, augmented reality, and the Internet of Things (IoT) [

2]. Industrial Revolution 4.0, according to [

3] describes an approach to create a transformation from machine-leading industrial to digital production. Industry 4.0 specifications must be realized to accomplish a productive transformation, and a strong plan is to be created and implemented. The physical interaction in Industrial Revolution (IR 4.0) 4.0 is replaced with digital technologies that increase efficiency and develop workflows [

4]. The innovative technologies participating in Industry 4.0 are streamlining complete manufacturing methods by transforming traditional and integrated systems into digital and decentralized production procedures.

The revolutionized manufacturing industry due to the significant development in the digitalization, manufacturing, and industrial revolution has entirely reshaped individuals’ social and economic life. With the invention of simple steam engines to modern-day robotics today, the seventeenth century brings a breakthrough in technological development to transform the manufacturing industry’s face [

5]. Björkdahl [

6] suggested manufacturing and digitalization; digitalization can make manufacturing companies’ product development more effective. Digitalization of product development lowers the requirement for physical objects and models; devices used to model and image, and mathematical calculation systems are progressively more advanced and collaborative, producing the product. However, the application in manufacturing firms appears to be dimmer. Most manufacturing firms are even in the early phases of executing digital technologies and are consequently at a more fundamental level of technology use than is usually linked with Industry 4.0 [

7]. The effective execution of digital technologies in manufacturing is frequently pushed as the next enabler of manufacturing progress and a need for manufacturers to stay viable—the concept of intelligent factories fully equipped with digital technologies and IoT with minimum physical interaction. The intelligent factory’s overall production processes, data analysis, and scientific decisions are used to achieve production schedules, equipment service, and quality control [

8].

The current novel idea of evaluating the overall literature published on digital manufacturing and digital technologies improves the efficiency of manufacturing processes. The current study aims at digital technologies’ efficiency in the entire manufacturing process. The manufacturing industry is seeking sustainable processes to produce efficient products. The achievement of sustainable manufacturing is a challenge for manufacturers and policymakers. The second objective for the current study also collaborative research work on digital manufacturing among the different countries. How the different countries are collaborating to adopt the digital technologies. The current novel idea of evaluating the overall literature published on digital manufacturing and digital technologies improves the efficiency of manufacturing processes.

2. Review Methodology

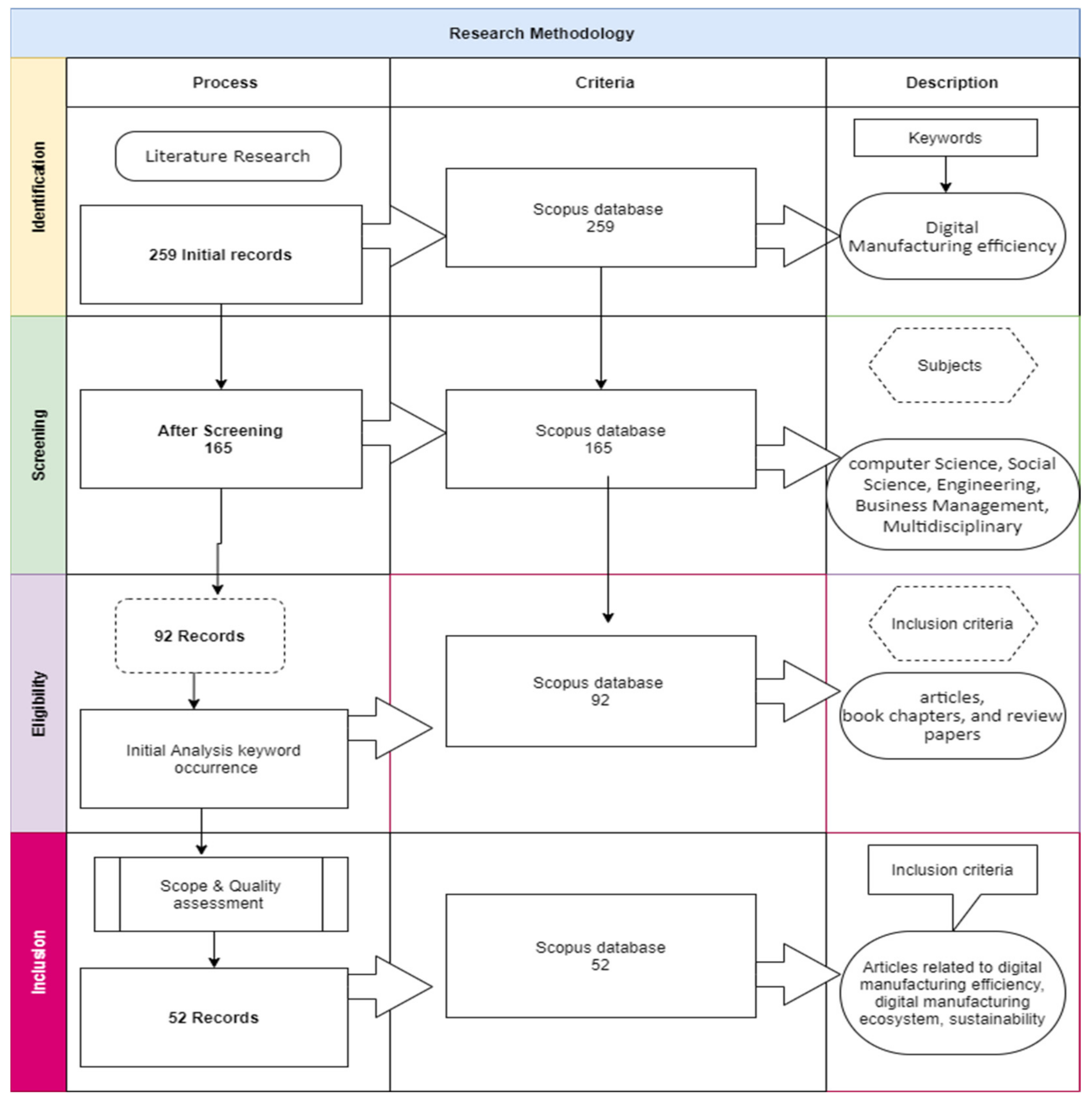

This paper followed the 2015 Preferred Reporting Items for Systematic Review and Meta-Analysis Protocols (PRISMA) framework for reviewing current literature [

9]. Following the PRISMA guidelines, the scoping process was used to obtain the most relevant literature on digital manufacturing efficiency and digital manufacturing ecosystem indicators and evaluation. This method enabled the vital lessons required settings and categorized the potential investigate keywords [

10]. They were expanding the nature of digital manufacturing, a comprehensive literature review done using the Scopus database to find suitable scientific journals and articles. Multiple keyword grouping searches were performed to gather the relevant published literature from the most distinguished and reliable research databases—the keyword Digital Manufacturing efficiency used in the Scopus database to search the appropriate literature. The document search was improved by applying predefined quality standards of PRISMA statement 2015 inclusion and exclusion criteria. The following section will discuss the inclusion and exclusion procedure with quality standards. The literature pursuit is that no publication time follows. At first, a total of 259 documents were shown. The subjects for the review are selected computer Science, Social Science, Engineering, Business Management, and Multidisciplinary; results are limited to 165; however, this contained all types of records, e.g., research articles, reviews, editorials, book chapters, and others. This study limited literature search to research articles, book chapters, review papers, and 92 papers chosen. The final literature hunting resulted up in 52 records from the Scopus database. The records were then transferred to an Excel sheet to carry on a further systematic review process. The PRISMA statement 2015 framework execution in this review is showing in

Figure 1.

2.1. Quality Evaluation

This study covers already published articles and review papers to discover the most acceptable findings and an excellent indication of the published research. Results, abstracts, and conclusions were split to restrict the records. Additionally, it also considered cited references in the assessed articles. The records frequently examined to prevent duplication and enhance the required results; irrelevant studies were also eliminated.

2.2. Eligibility and Inclusion Articles

Inclusion and exclusion criteria following adopted among the selected research articles: To confirm correct assortment, examine articles in the English language chosen. Furthermore, papers were designated, providing they were published in the Scopus database. This article reviews digital manufacturing ecosystem literature, indicates past studies, and plans to progress digital technologies.

2.3. Studies Included in Qualitative Synthesis

After choosing the papers, two successive steps were used to ensure the analysis’s quality was completed on the chosen documents. At first, the reliable metadata was taken into Microsoft Excel to examine digital manufacturing ecosystem literature, such as the segment and settings. In the subsequent phase, systematic content analysis is completed to classify and observe key examination streams, write recent research through numerous subjects, and highlight possible problems and probabilities for future study. Using content analysis method and texts that follow to label and degree the apparent statement content about planned groups following an organized technique, authorizing replicable and valid texts’ suggestions.

3. Results

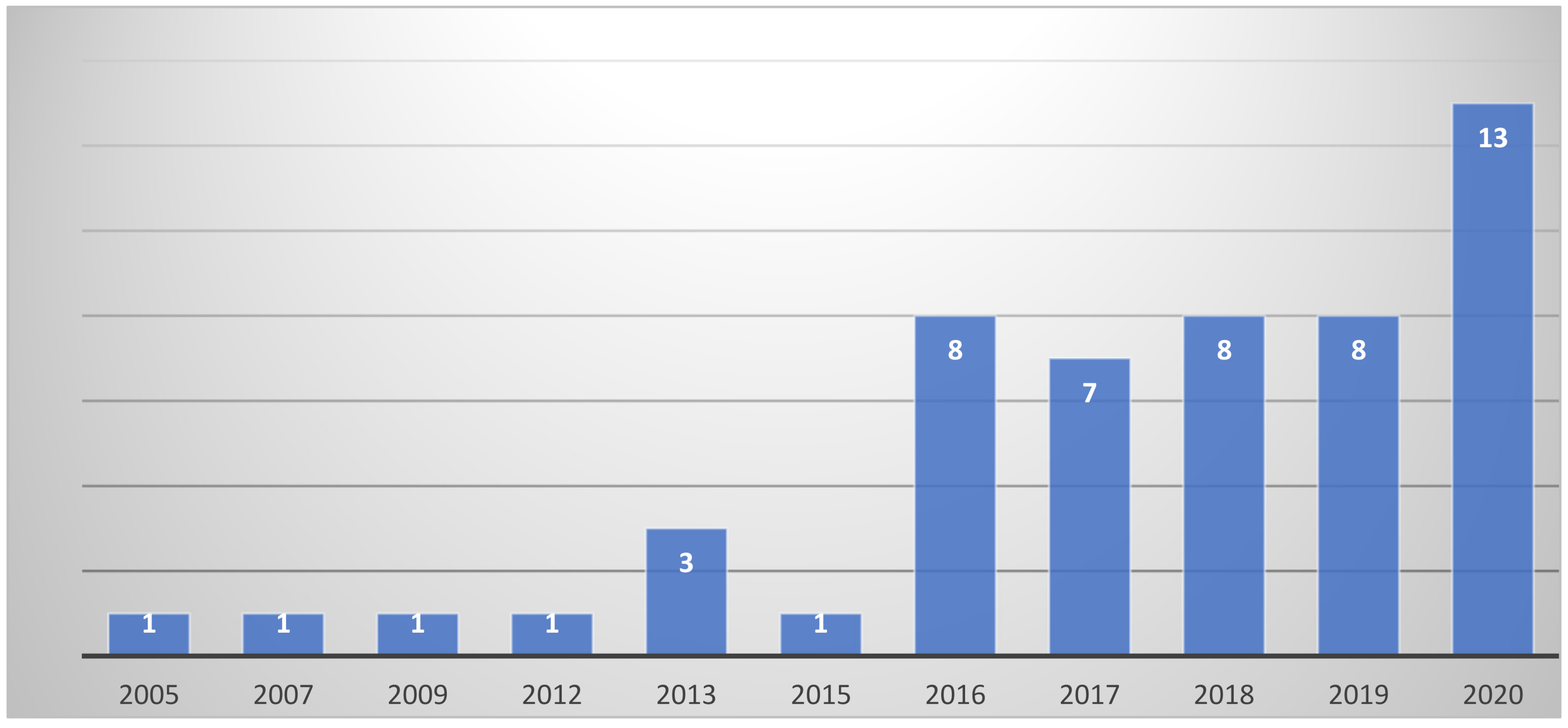

Several articles published per year on the digital manufacturing ecosystem. The plan was to discover digital manufacturing revisions and measures from the published documents. With the time, exploration in this area established gradually between 2016 and 2020, achieving a peak in 2020s.

Figure 2 shows that most works on digital manufacturing done in recent years.

Figure 2 indicates that in the years 2016–2020, there was a rise in a publication related to the digital manufacturing ecosystem. However, the preceding years’ efficiency in research literature was slight.

The citation report of the studies is showing in

Table 1. The most-cited journal was

Engineering Science and Technology, an International Journal, with 137 citations. The article’s name is “Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems”. After that, the second most-cited study was “Science of the Total Environment”, cited 66 times in 3 years. The article titled “Service engineering for the internet of services” was the third high cited article, with 65 citations—the article published in

Lecture Notes in Business Information Processing. The fourth study was “Towards a sustainable interoperability in networked enterprise information systems: Trends of knowledge and model-driven technology”. It was cited 58 times in 2 years and published in

Joule. Some other cited studies are shown in

Figure 3.

The journals that published the most articles on the digital manufacturing ecosystem are reporting in

Figure 4.

IEEE Transactions on Services Computing and Computers in Industry was at the top of the list with three publications, respectively.

Procedia Manufacturing is the second largest on the list with two studies and the

Science of the Total Environment with the same number of published articles on the digital manufacturing ecosystem. The rest of the list is also shown in

Figure 3.

4. Review of Literature

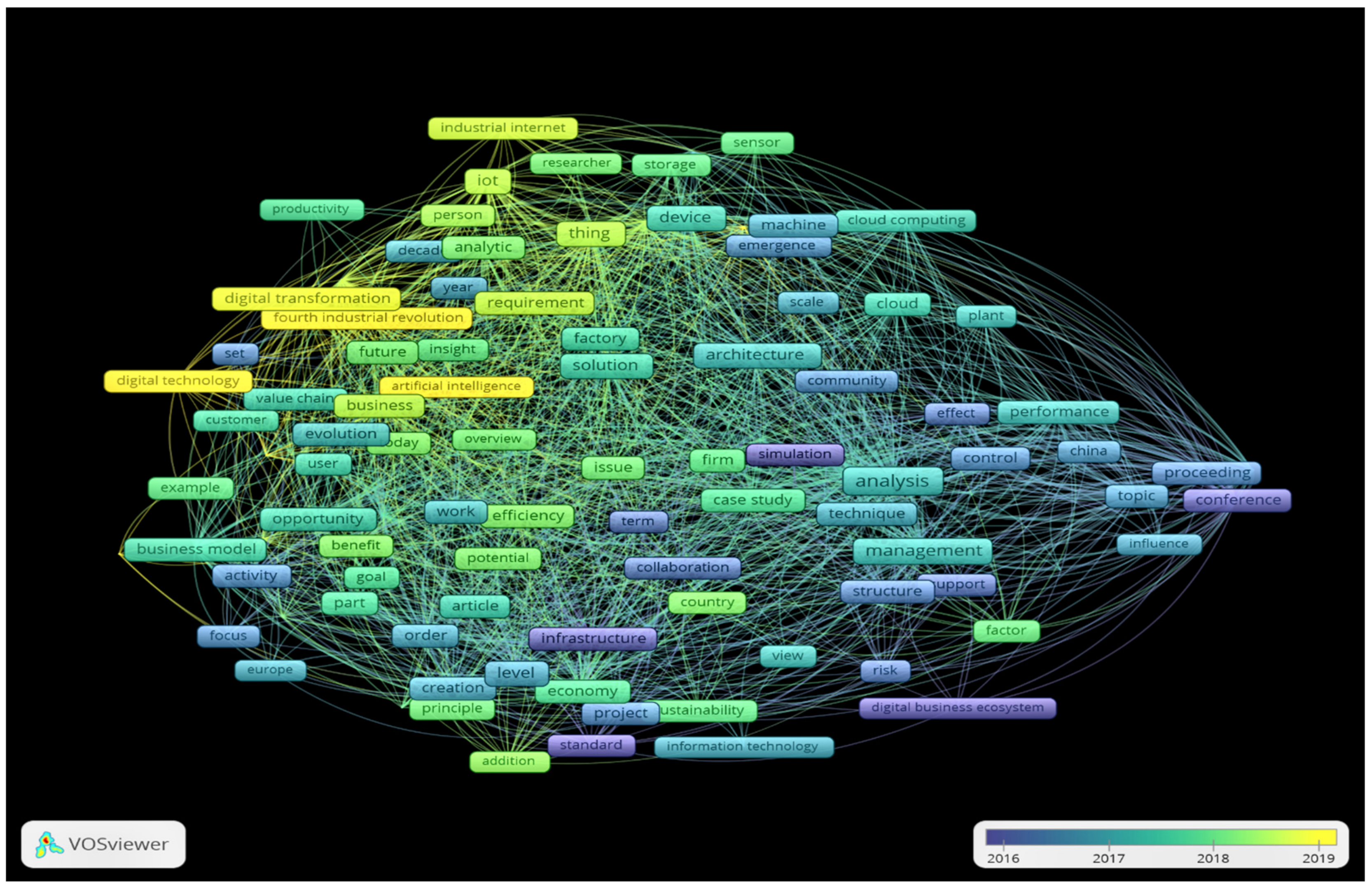

Digital manufacturing is expanding continuously in manufacturing industries, and researchers are looking deep into these technological changes step by step. Different digital technologies are used in the manufacturing technological era—the current study evaluating the digital technologies efficiency for the manufacturing sector. Further classification of literature drives the published literature and researcher perspective toward digital manufacturing efficiency adaptation in the manufacturing sector. We used the keywords digital manufacturing ecosystem, digital transformation, management performance, and sustainability to identify the most frequent keywords used in the studies. As mentioned above, there were 255 studies included in the keywords at literature review stage 1; further, these studies were used to identify the literature classifications from these keywords, as

The records were further analyzed through content analysis to determine the categories of the research. VOSViewer software analyzes the published literature’ content—data groups created on the text formed to cluster the associated concepts. Current research established that researchers’ keywords and keywords further in the journals’ indexation procedure in the databases are similarly actual for bibliometric analysis intended to discover the constructions of investigating field. Therefore, we engaged both classes of keywords for the co-occurrence analysis inside the research area linked to digital manufacturing efficiency. In total, 52 documents were contained in the study, and the data delivered 2401 keywords. We thoroughly developed and chosen only the most numerous 200 keywords monotonous in a minimum of 10 documents.

Figure 5 shows the outcomes of the content analysis. The group demonstrated four significant clusters, characterized in distinct colors in

Figure 5. The cluster represented in orange shows Digital transformation research, Industry Revolution 4.0, and the Internet of Things (IoT). The cluster in blue is mainly attributed to digital business ecosystem, collaboration, and community. The green cluster indicates business model, management, and performance. Finally, the purple cluster is indicating sustainability. Each cluster is further examined in the following sections to pinpoint the digital manufacturing ecosystem.

4.1. Digital Transformation

The digitalization era is due to Industry 4.0; every operation and function is digital, business start-ups, production environment, operations, machines, services, and products. The virtual representation makes it interconnected due to the digital environment. The transformation of face-to-face and physical operations is mapping on digital models at a consistent level. Industry 4.0 is operationalizing the higher level of auto achieving operational production and efficiency in the processes, interacting from physical to digital world. Industry 4.0 aims to work with a higher level of automatization, achieving a higher level of operational productivity and efficiency, connecting the physical to the virtual world [

11,

12].

IR 4.0 symbolizes a model move from centralized to decentralized manufacturing. It can change over the conventional role of manufacturing processes. Industry 4.0 concentrates on the end-to-end digital of all tangible resources and assimilation into digital ecosystems with value chain collaborators [

13]. China is still dependent on importing essential technologies and equipment [

14,

15]. Faulty industrial composition and the shortage of feature capacity are two disincentives to the growth of its manufacturing [

16,

17]. They enhance manufacturing industry processes and encourage innovation capability with Industry 4.0 to deliver practical methods and significant support for transforming China’s manufacturing [

18]. The development of technologies is opening the opportunities and forces for the manufacturing industries [

19].

Table 2 shows the classification details of the literature.

With industrial manufacturing growth with digital networks, intelligent factories gather large amounts of data from sensors and other devices. The internet of things (IoT) is also replacing the manufacturing parts to replacing the physical attraction of the operations in plants to gather the data and information [

20,

21]. The large amount of data collected in the manufacturing industries is used to monitor and optimize the production process. Billions of wireless devices are anticipating to be installed around the upcoming decade, with nearly partial to situating within manufacturing plants [

22,

23]. The manufacturing platforms digital manufacturing platforms empower the requirement of essential services linked with gathering, storage, processing, and supplying data. This information also explains the manufactured products or connects to the manufacturing procedures and resources that make manufacturing materialize [

24]. From manufacturing to everyday related issues, IOTs provide a great deal of data storage, connectivity of devices, and reliable data transformation in every segment of the process. Cloud computing is anticipated to deliver the backbone for worldwide information distribution, data analytics, and storage [

25]. The transformation of the devices from manual and physical operations to digital platforms is a great opportunity and challenge for organizations. It is reducing the time and needs a considerable amount of investment for the infrastructure installation.

4.2. Digital Manufacturing Ecosystem

Manufacturers are starting to react to the digital revolution’s opportunities in design, fabrication, production, Service, and supply chain processes. The incorporation of digital manufacturing technology throughout the product lifecycle is becoming its approach set down to the physical machines on the production floor due to innovations produced in hardware and software results in manufacturing plants [

26]. Information and Communication Technologies is converting more and more valuable in the manufacturing units, and businesses are confronting an increasing density of digital business ecosystem that is to be involved in new products development. Competitiveness involves providing the product and providing best-related services for business, care, and assistance [

27]. According to Cui et al. [

28], the appearance of the idea of cyber-physical system (CPS) and big data peremptorily allow manufacturing to develop more intelligent and modest between states. Smart manufacturing increases actionable information in actual time with the synthesis of big data and manufacturing awareness. As big data are collecting and analyzing to excerpt appropriate data, the manufacturing industry might motionless not know which method to custom, and their influences deprived of the area information. The environmental constraints are a reason for today’s world; environmentally friendly and fewer carbon footprints are the world’s premier agenda. Progressively robust social stresses, restraints, and ecological reflections. That straight manufacturing actions and product custom to be additional energy exchangeable and ecologically benevolent. With a focus on maximum and price of ownership and socioenvironmental effects, the social manufacturing worldwide community essential to accept a process of collaborative product development processes, and it must accomplish an excellent development level in procurement and arranging information and expertise from exterior and interior sources [

29,

30].

Table 3 is showing the classifications detail of literature from digital manufacturing eco-system.

The innovation ecosystem must achieve global market trends and requirements for the community’s sustainable development. The formation of the states’ innovation ecosystem is tactically significant to twitch with the regions, field important locations on digital awareness, innovative capacity, and highly technological industries [

31]. Technology, especially current developments in digital-enabled devices based on internet connectivity, is essential for building sustainable development globally. That can make the availability of water, land, and energy sources for large communities worldwide improve living standards. Sustainable manufacturing is not only crucial for resource generation and product development; other sectors like the agricultural food process are also linked to the supply chain process [

32]. According to Lin et al., [

33] speedy development of markets is delivering chances for new industrialists and early individuals who have high-tech, corporate, and relational assistances—to shape businesses based on new digital technologies. Digital technologies are more competently and efficiently using resources and individuals to connect nourishment, water, energy, nutrition, and human health. That resolve also contributes to the growth of a circular economy designed to be healing and reformative—diminishing waste and exploiting recycling and recycling to shape economic, natural, and social capital. The sustainable manufacturing process can be achieved using intelligent production ideas and digital technology involved in the overall manufacturing process. Smart factories are one of the very significant contributions to overcoming the ecological footprints and environmental damage. Digital technologies can influence the manufacturing process through quick response, efficient working, and minimal waste production processing [

34].

4.3. Management Performance

Digital technologies are used in the manufacturing process in their inbound outrebound operations related to the integration and cross-fertilization in firm processes. Digitalization in manufacturing brings drastic changes in the business model and management structure to gain value in a competitive market. In easy words, digitalization can be viewed as enhanced production, assessment, and use of information in demand, on the one hand, to increase the firm’s interior productivity, and on the other hand to expand the organization by improving value for consumers around the shift from conventional to digital systems. The tasks, openings, and impacts of digitalization need a significant effect on both industry leaders and governments [

35]. In the Industrial Revolution (IR 4.0) era, conventional ways of manufacturing no longer provide expected influence anymore. Firms do not endure and flourish exclusively over their efforts and inaccessible information [

36]. Fast-moving up the manufacturing transformation rate to great additional price products, procedures, and service industries consumes remained the critical communication of policymakers and manufacturing road-mapping enterprises for the last decade [

37]. For the digital instant, a manufacturing firm usually outsources non-core and upstream activities or resources to collaborators or external partners. Besides, the manufacturing process is downstream of the strategic events [

38]. The manufacturing organizations in a particular business ecosystem are weak or strong; the organizations in a business ecosystem are strong or weak, they eventually contribute to a similar outcome as that of the overall system. A company ecosystem can be classified into several business areas, and a sphere may be divided by other ecosystems. Robustness describes the capability of an ecosystem to face sudden effects and modifications [

39]. An organization in a robust ecosystem is comparatively able to foresee the future, and the interactions in the ecosystem can resolve future effects.

Table 4 is showing the classification details of the authors.

From the foundation of the Industrial Revolution, manufacturing has confronted a sequence of alterations in concept: amount of manufacture, cost reduction, worth of production, customization, lean industrial, information- and collaboration-leaning manufacturing, and recently, crowdsourcing and cloud-based manufacturing. The manufacturing atmosphere is typically complicated, tough to forecast, and comprises many symbiotic systems; it is also described by quick change and ambiguity, making analyzing and planning procedures rather challenging. Manufacturing demand and supply systems in dense socioeconomic structures usually showing traits. The multi-scale collaborations with high eventuality and nonlinearity, evolving behavior, model development, and self-organization [

40]. Key businesses’ push in the direction of “smart mobility solution” firms reveal the digital ecosystem’s significance. The tasks face the intelligent mobility solution business model, showing the collective innovations necessary for the digital ecosystem. Digital manufacturing is significantly establishing the idea of sustainable manufacturing in recent periods. The ecological footprint and environmental issues are relatively very vital for sustainable manufacturing processes [

41,

42]. However, the massive and growing amounts of machines at the global level generate further anxiety regarding their end-of-life removal to avoid toxic waste of air, water, and soil anticipated to their deprivation and leak, if not appropriately controlled. The end-of-life management of waste during manufacturing has been the focus of intense discussion in recent times [

43]. Their environmental effects are so enormous that they must be contemplated dangerous waste and controlled by a devoted and specific regulation at international and national levels [

44].

The digital manufacturing ecosystem will become a highly linked and collaborative system involving thousands of organizations that will apply persistent standards for innovative technological processes in the supply chain and manufacturing output model. The digital manufacturing model collaborates within a popular virtual workspace, allowing engineers and manufacturers to work together on tasks by distributing data and documents to achieve sustainability [

45].

4.4. Sustainability

Research direction investments in sustainable manufacturing processes from raw materials, supply chain, and final product outcome process during recent years. Driven continuously by simultaneous manufacturing, collaborative invention design in the practical operation, or digital behavioral, it is capitalized through establishing technology and advancement in the process. The achievement of sustainable manufacturing is impossible without creating a viable and active collaborative foundation for manufacturing digital business ecosystems [

46]. The Rajala et al study [

47] explains sustainability, an increasing figure out the investigation consideration to value formation in closed-loop manufacturing practices since conservational apprehensions are influential organizations across productions to reconsideration their business models. Besides, the ownership, recycling, and distribution of raw material supplies bring new structures to increase the circular economy. Closing industrial loops by creating improved materials and converting waste into energy and elements for restored goods provides environmental sustainability and offers new industry openings for manufacturing performers. The sustainability of manufacturing processes data represents a higher level of outputs responsible for the nutritious, greenhouse gas emission, and packaging affects appraisals [

48,

49]. Sustainable manufacturing is a significant element for today’s manufacturing environment; digital fusion makes the possibilities to achieve the input and output form of manufacturing with less physical attraction and minimum waste [

50,

51].

Table 5 is showing the classification details of the literature.

Over the present decade, economic growth and large-scale manufacturing are causing excessive carbon emissions and environmental degradation with severe water pollution in countries like China. The environmental issues are not limited only to China; large manufacturing industries in any country are responsible for the environmental degradation [

52]. Digital technologies are an intelligent addition to the development of sustainable manufacturing processes. The overall manufacturing process is operationalized using the IoTs, and devices are connected through the internet. Manufacturing input and output processes are monitors be the digital technologies lead to minimum involvement of human. The devices handle the supply chain processes, input and output procedures during the manufacturing [

53].

4.5. Collaborative Work on Digital Manufacturing Ecosystem

This paper’s second objective was to analyze the collaborative exploration of the digital manufacturing efficiency and ecosystem—a bibliometric analysis to establish collaborative work among the countries. The review submitted the research collaborations into three major segments. First, the clusters signified in

Figure 6 suggest the most influential countries with robust research collaborative working.

Figure 6 illustrates European and U.S. prominent the field in terms of exterior research collaborations.

That reveals that countries with high GDP and developed infrastructure are increasingly adopting digital technologies in manufacturing processes. However, the cooperation arrangements improved over the years.

Figure 6 suggests the research collaboration models from different continents. The colors in

Figure 6 show the tendency of research alliances in ASIA and Africa, like Malaysia, India and Egypt, to put effort into digital technologies. The more analogous the states’ color is, the more likely they are to collaborate.

Finally, it is equally vital to evaluate the attempts produced by each country in the world in establishing collaborative research systems.

Figure 6 underscores the number of collaborative actions taken out by each nation and suggests that the U.S., China, Germany, Netherland, Italy, Portugal, Russian Federation and Finland dominates with the maximum number of international collaborations developing nations.

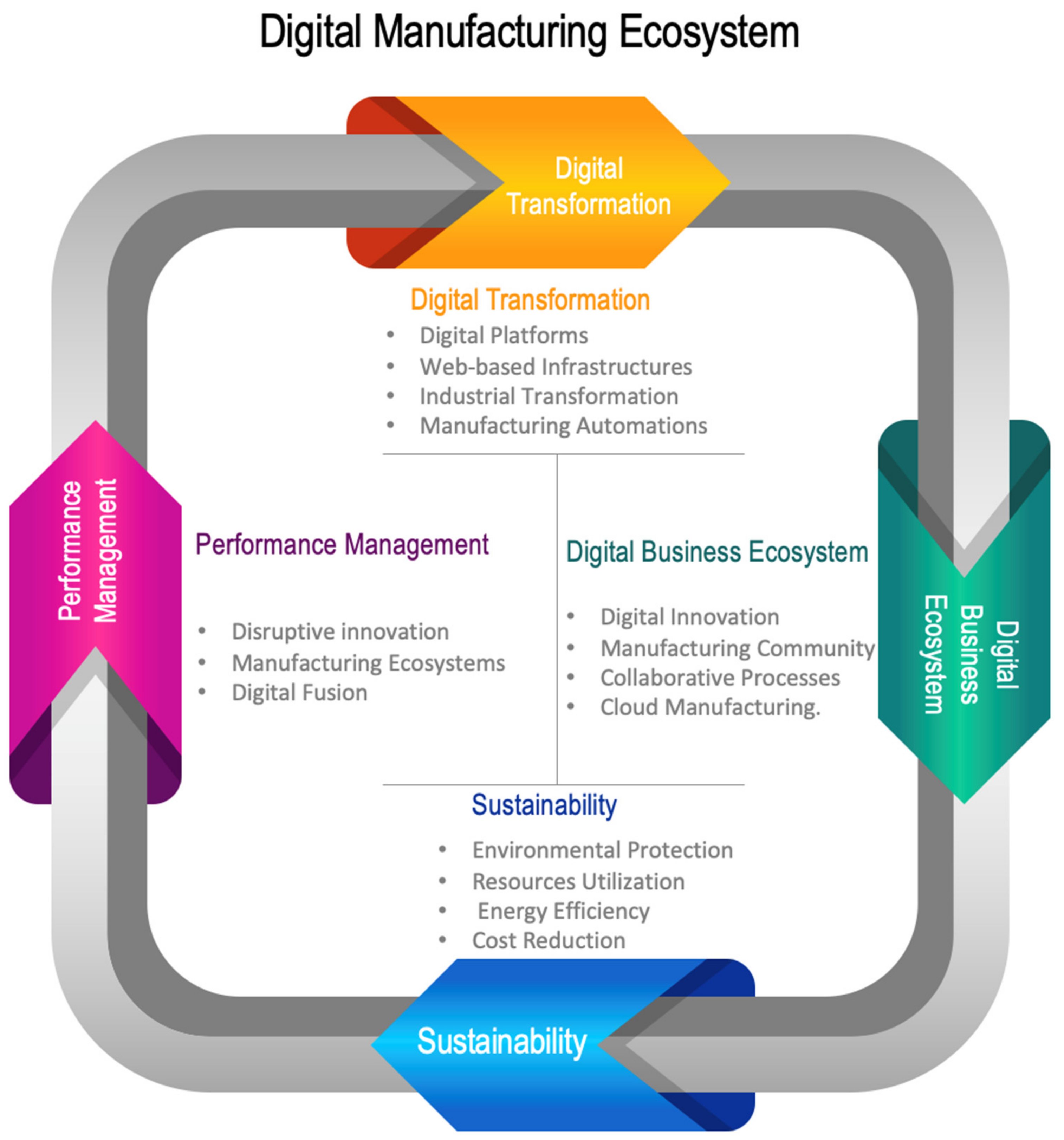

5. Results and Discussion

Summing up, the performed literature review analysis permits us to reply to the research questions of the study. The systematic literature review and bibliometric analysis were concentrating on two significant objectives. The first was digital technologies’ efficiency in the entire manufacturing process. The initial distribution of literature using VOS viewer and authors keyword classify the literature in four significant streams, and discussions are done according to these distributions. The strength of this publication is its rigorous inclusion standards and approach using the quality assessment. What motivates us to look back on simple published ideas, thoughts, and instead highlights in published literature been developed, analyzed, and explored. However, this study gives a great outline of what has recently been examined in the academic world. The review does not depict the whole image of the development in the digital manufacturing area. There are encouraging developments in sustainability in other digital manufacturing areas that are not included in the included publications for this review. The study’s scope is limited to the digital technologies and manufacturing ecosystem that enables the entire manufacturing processes under the digital technologies. To achieve the first objective, we reviewed digital manufacturing literature. Past research showed that quality work in digital manufacturing, especially manufacturing procedures and supply-chain channels, moves to use digital technologies. The robust manufacturing processes are still in the starting stages of technology advancement and adaptation.

The physical interaction in the Industrial Revolution 4.0 is minimal and bright factories are fully operationalized in the manufacturing sector. The supply chain process during the input and output manufacturing is integrated with the production process. The efficient manufacturing processes considerable for minor environmental damage due to Waste minimization, remanufacturing, and recycling procedures. Moreover, these ideas were categorized into the linked cluster—most of the primary research concentrating on digital transformation and the technologies efficiency in manufacturing. However, the overall manufacturing using digital technologies is still not entirely possible due to the digitalization infrastructure availability [

54]. Supply chain processes are not as much controlled and operationalized using digital technologies, and the overall ecosystem still has a gap between adopting the digital technologies. Significant barriers in adopting the technologies are relevant both to the ownership of the different processes, the supply chain or raw material is companies are hiring from external sources, which creates a gap to adopt digital technologies in manufacturing processes. Besides, several researchers have established supportive measures for developing the overall digital manufacturing ecosystem. Still, much work is required for the development of the process [

55]. The outcomes of this research are showing in

Figure 7 in detail and digital technologies penetration in literature very clearly.

The study’s second objective is related to the collaborative research work on digital manufacturing, showing that developed and advanced nations are working together. Researchers from established countries like the U.S., China, Italy, Portugal, Germany, and Switzerland are putting more effort on the local and international level to minimize the human interaction in the manufacturing processes. Collaborative research reveals that countries with high GDP and developed infrastructure are increasingly adopting digital technologies in manufacturing processes [

17]. The collaborative work in underdeveloped countries is still limited, and one primary reason is the limited resources available in these countries.

6. Conclusions

In this paper, we first introduce the basic concepts of digital manufacturing, which help bring process efficiency with major promising digital technologies. Then we review the current solutions to digital manufacturing, including smart factories, digital devices, and the digital manufacturing ecosystem. The gap between the digital manufacturing ecosystem is mainly discussed. The findings indicate that digital manufacturing research is focused on processes of manufacturing. However, manufacturing at the sector level and its economic elements related to the digital ecosystem that enables manufacturing efficiency in the manufacturing are not examined. More effort is needed to make manufacturing industries from developed and underdeveloped countries for a better and robust comparison. The study’s findings highlight that digital manufacturing is a complete methodology and demands enhanced manufacturing operations. For the achievement of this, digital manufacturers should consider and analyses beyond environmental and sustainable ecosystems. Digital manufacturing efficiency is discussed in a minimal number of studies; researchers must work on technology’s advanced concepts to improve the manufacturing efficiency in the manufacturing processes and supply chain processes using digital technologies.

Future Agenda

Most of the effort in this respect has been taken out in established and technologically revolutionize countries, while the other countries’ contribution is meager. This study introduces some new concepts such as the digital manufacturing ecosystem in some research and innovative manufacturing models for sustainability. Academicians must focus on hybrid procedures and IR 4.0 to determine sustainable manufacturing processes. More attempts are also required to produce cooperative and economic evaluations more workable and relevant to manufacturing activities. Ecological concerns in the manufacturing industries are becoming severe, and climate change presents an acute danger. Environment shift is triggering tragedies that humanity has never encountered in the past. However, digital technology’s introduction needs to analyze the issues solving related to sustainability and climate change.

Author Contributions

This work was the output of collaborative research between researchers from different institutions in Malaysia. N.K. and M.I.Q. were responsible for the conceptualization of the idea, manuscript preparation and data analysis, and revision of the manuscript. The prepared manuscript was reviewed and amended by A.F.S.A.-M. and S.S.H. contributed to the revised manuscript and secured article processing charges to facilitate publication of the research article. M.S.M.S. and Y.V. helped with reviewing and proofreading the final manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

No human or animals subjects were involved in the research.

Informed Consent Statement

This work was a result of collaborative research between researchers from the Azman Hashim International Business School, Universiti Teknologi Malaysia, Jalan Iman, Skudai 81310, Johor, Malaysia; Faculty of Technology Management and Technopreneurship, Universiti Teknikal Malaysia Melaka, Durian Tunggal 76100, Melaka, Malaysia; Faculty of Business, Social Science & Hospitality, Segi University, Kota Damansara, Petaling Jaya 47810, Selangor, Malaysia; UniKL Business School, Universiti Kuala Lumpur, Kuala Lumpur 50300, Malaysia.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tolkachev, S.A.; Bykov, A.A.; Morkovkin, D.E.; Borisov, O.I.; Gavrilin, A.V. Digitalization of manufacturing in Russia, Belarus and the European Union. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 421, p. 032041. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; Jabbour, A.B.L.D.S.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Núñez-Merino, M.; Maqueira-Marín, J.M.; Moyano-Fuentes, J.; Martínez-Jurado, P.J. Information and digital technologies of Industry 4.0 and Lean supply chain management: A systematic literature review. Int. J. Prod. Res. 2020, 58, 5034–5061. [Google Scholar] [CrossRef]

- Sharma, A.; Jain, D.K. Development of Industry 4.0. In Plant-Microbes-Engineered Nano-Particles (PM-ENPs) Nexus in Agro-Ecosystems; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019; pp. 23–38. [Google Scholar]

- Björkdahl, J. Strategies for Digitalization in Manufacturing Firms. Calif. Manag. Rev. 2020, 62, 17–36. [Google Scholar] [CrossRef]

- Buer, S.-V.; Strandhagen, J.W.; Semini, M. The digitalization of manufacturing: Investigating the impact of production environment and company size. J. Manuf. Technol. Manag. 2020. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; PRISMA-P Group. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 statement. Syst. Rev. 2015, 4, 1. [Google Scholar] [CrossRef]

- McInnes, M.D.F.; Moher, D.; Thombs, B.D.; McGrath, T.A.; Bossuyt, P.M.; Clifford, T.; Cohen, J.F.; Deeks, J.J.; Gatsonis, C.; Hooft, L.; et al. Preferred Reporting Items for a Systematic Review and Meta-analysis of Diagnostic Test Accuracy Studies. JAMA 2018, 319, 388–396. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Cardoso, J.; Winkler, M.; Voigt, K.; Berthold, H. IoS-Based Services, Platform Services, SLA and Models for the Internet of Services; Springer: Berlin/Heidelberg, Germany, 2011; Volume 50, pp. 3–17. [Google Scholar]

- Sandström, C.G. The non-disruptive emergence of an ecosystem for 3D Printing—Insights from the hearing aid industry’s transition 1989–2008. Technol. Forecast. Soc. Chang. 2016, 102, 160–168. [Google Scholar] [CrossRef]

- Mathews, I.; Kantareddy, S.N.; Buonassisi, T.; Peters, I.M. Technology and Market Perspective for Indoor Photovoltaic Cells. Joule 2019, 3, 1415–1426. [Google Scholar] [CrossRef]

- Götz, M.; Jankowska, B. Clusters and Industry 4.0—Do they fit together? Eur. Plan. Stud. 2017, 25, 1633–1653. [Google Scholar] [CrossRef]

- Bai, L.; Hu, M.; Liu, M.; Wang, J. BPIIoT: A Light-Weighted Blockchain-Based Platform for Industrial IoT. IEEE Access 2019, 7, 58381–58393. [Google Scholar] [CrossRef]

- Li, G.; Zakari, A.; Tawiah, V. Does environmental diplomacy reduce CO2 emissions? A panel group means analysis. Sci. Total Environ. 2020, 722, 137790. [Google Scholar] [CrossRef]

- Mourtzis, D.; Milas, N.; Vlachou, A. An Internet of Things-Based Monitoring System for Shop-Floor Control. J. Comput. Inf. Sci. Eng. 2018, 18, 021005. [Google Scholar] [CrossRef]

- Bechtold, S.; Höfle, B. Helios: A multi-purpose lidar simulation framework for research, planning and training of laser scanning operations with airborne, ground-based mobile and stationary platforms. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, III-3, 161–168. [Google Scholar] [CrossRef]

- Iqbal, M.F.; Riaz Khan, M.; Malik, A.H. Land use change detection in the limestone exploitation area of Margalla Hills National Park (MHNP), Islamabad, Pakistan using geo-spatial techniques. J. Himal. Earth Sci. 2013, 46, 89–98. [Google Scholar]

- Fraile, F.; Sanchis, R.; Poler, R.; Ortiz, A. Reference Models for Digital Manufacturing Platforms. Appl. Sci. 2019, 9, 4433. [Google Scholar] [CrossRef]

- Ying, W.; Pee, L.G.; Jia, S. Social informatics of intelligent manufacturing ecosystems: A case study of KuteSmart. Int. J. Inf. Manag. 2018, 42, 102–105. [Google Scholar] [CrossRef]

- West, S.; Gaiardelli, P.; Rapaccini, M. Exploring technology-driven service innovation in manufacturing firms through the lens of Service Dominant logic. IFAC-PapersOnLine 2018, 51, 1317–1322. [Google Scholar] [CrossRef]

- Seyedghorban, Z.; Tahernejad, H.; Meriton, R.; Graham, G. Supply chain digitalization: Past, present and future. Prod. Plan. Control. 2020, 31, 96–114. [Google Scholar] [CrossRef]

- Borrero, J.D. Agri-food supply chain traceability for fruit and vegetable cooperatives using Blockchain technology. CIRIEC España Rev. Econ. Pública, Soc. Coop. 2019, 95, 71–94. [Google Scholar] [CrossRef]

- Singh, S.; Angrish, A.; Barkley, J.; Starly, B.; Lee, Y.-S.; Cohen, P. Streaming Machine Generated Data to Enable a Third-Party Ecosystem of Digital Manufacturing Apps. Procedia Manuf. 2017, 10, 1020–1030. [Google Scholar] [CrossRef]

- Figay, N.; Ghodous, P.; Khalfallah, M.; Barhamgi, M. Interoperability framework for dynamic manufacturing networks. Comput. Ind. 2012, 63, 749–755. [Google Scholar] [CrossRef]

- Abdul-Rashid, S.H.; Sakundarini, N.; Ghazilla, R.A.R.; Thurasamy, R. The Impact of Sustainable Manufacturing Practices on Sustainability Performance: Empirical Evidence from Malaysia. Available online: https://www.emerald.com/insight/content/doi/10.1108/IJOPM-04-2015-0223/full/html (accessed on 14 February 2021).

- Goossenaerts, J.; Possel-Dolken, F.; Popplewell, K. Vision, Trends, Gaps, and a Broad Road Map for Future Engineering. Int. J. e-Collab. 2007, 3, 1–20. [Google Scholar] [CrossRef]

- Golova, I.M.; Sukhovey, A.F. Innovation and Technological Development of Industrial Regions in the Conditions of Socio-Economic Insecurity. Econ. Reg. 2015, 1, 131–144. [Google Scholar] [CrossRef]

- Xue, X.; Guo, Y.; Chen, S.; Wang, S. Analysis and Controlling of Manufacturing Service Ecosystem: A research Framework based on the Parallel System Theory. IEEE Trans. Serv. Comput. 2019, 1. [Google Scholar] [CrossRef]

- Davies, F.T.; Garrett, B. Technology for Sustainable Urban Food Ecosystems in the Developing World: Strengthening the Nexus of Food–Water–Energy–Nutrition. Front. Sustain. Food Syst. 2018, 2, 84. [Google Scholar] [CrossRef]

- Lin, K.F.; Cheng, H.M.; Hsu, H.C.; Lin, L.J.; Hsieh, W.F. Band gap variation of size-controlled ZnO quantum dots synthesized by sol-gel method. Chem. Phys. Lett. 2005, 409, 208–211. [Google Scholar] [CrossRef]

- Susanto, H.; Leu, F.-Y.; Caesarendra, W.; Ibrahim, F.; Haghi, P.K.; Khusni, U.; Glowacz, A. Managing Cloud Intelligent Systems over Digital Ecosystems: Revealing Emerging App Technology in the Time of the COVID19 Pandemic. Appl. Syst. Innov. 2020, 3, 37. [Google Scholar] [CrossRef]

- Hung, C.-Y.; Lee, W.-Y.; Wang, D.-S. Strategic foresight using a modified Delphi with end-user participation: A case study of the iPad’s impact on Taiwan’s PC ecosystem. Technol. Forecast. Soc. Chang. 2013, 80, 485–497. [Google Scholar] [CrossRef]

- Huikkola, T.; Rabetino, R.; Kohtamäki, M.; Gebauer, H. Firm boundaries in servitization: Interplay and repositioning practices. Ind. Mark. Manag. 2020, 90, 90–105. [Google Scholar] [CrossRef]

- Bergvall-Kareborn, B.; Howcroft, D. The Apple business model: Crowdsourcing mobile applications. Account. Forum 2013, 37, 280–289. [Google Scholar] [CrossRef]

- Leang, B.; Ean, S.; Ryu, G.-A.; Yoo, K.-H. Improvement of Kafka Streaming Using Partition and Multi-Threading in Big Data Environment. Sensors 2019, 19, 134. [Google Scholar] [CrossRef]

- Puca, A.; Carrano, M.; Liu, G.; Musella, D.; Ripa, M.; Viglia, S.; Ulgiati, S. Energy and eMergy assessment of the production and operation of a personal computer. Resour. Conserv. Recycl. 2017, 116, 124–136. [Google Scholar] [CrossRef]

- Fayoumi, A. Ecosystem-inspired enterprise modelling framework for collaborative and networked manufacturing systems. Comput. Ind. 2016, 80, 54–68. [Google Scholar] [CrossRef]

- Choi, P.K. A Need for Co-Evolution between Technological Innovations and Social Innovations. J. Open Innov. Technol. Mark. Complex. 2020, 6, 54. [Google Scholar] [CrossRef]

- Beckmann, B.; Giani, A.; Carbone, J.; Koudal, P.; Salvo, J.; Barkley, J. Developing the Digital Manufacturing Commons: A National Initiative for US Manufacturing Innovation. Procedia Manuf. 2016, 5, 182–194. [Google Scholar] [CrossRef]

- Beltagui, A.; Rosli, A.; Candi, M. Exaptation in a digital innovation ecosystem: The disruptive impacts of 3D printing. Res. Policy 2020, 49, 103833. [Google Scholar] [CrossRef]

- Heidel, N.D.; Usechak, N.G.; Dohrman, C.L.; Conway, J.A.; Conway, J.A. A Review of Electronic-Photonic Heterogeneous Integration at DARPA. IEEE J. Sel. Top. Quantum Electron. 2016, 22, 1. [Google Scholar] [CrossRef]

- Agostinho, C.; Ducq, Y.; Zacharewicz, G.; Sarraipa, J.; Lampathaki, F.; Poler, R.; Jardim-Goncalves, R. Towards a sustainable interoperability in networked enterprise information systems: Trends of knowledge and model-driven technology. Comput. Ind. 2016, 79, 64–76. [Google Scholar] [CrossRef]

- Tchoffa, D.; Figay, N.; Ghodous, P.; Expósito, E.; Kermad, L.; Vosgien, T.; El Mhamedi, A. Digital factory system for dynamic manufacturing network supporting networked collaborative product development. Data Knowl. Eng. 2016, 105, 130–154. [Google Scholar] [CrossRef]

- Rajala, R.; Hakanen, E.; Mattila, J.; Seppälä, T.; Westerlund, M. How Do Intelligent Goods Shape Closed-Loop Systems? Calif. Manag. Rev. 2018, 60, 20–44. [Google Scholar] [CrossRef]

- Martindale, W.; Duong, L.; Hollands, T.; Swainson, M. Testing the data platforms required for the 21st century food system using an industry ecosystem approach. Sci. Total Environ. 2020, 724, 137871. [Google Scholar] [CrossRef]

- Qureshi, M.; Khan, N.; Qayyum, S.; Malik, S.; Sanil, H.; Ramayah, T. Classifications of Sustainable Manufacturing Practices in ASEAN Region: A Systematic Review and Bibliometric Analysis of the Past Decade of Research. Sustainability 2020, 12, 8950. [Google Scholar] [CrossRef]

- Tuffnell, C.; Kral, P.; Siekelova, A.; Horak, J. Cyber-physical smart manufacturing systems: Sustainable industrial networks, cognitive automation, and data-centric business models. Econ. Manag. Financ. Mark. 2019, 14, 58–63. [Google Scholar]

- Millard, J.; Sorivelle, M.N.; Deljanin, S.; Unterfrauner, E.; Voigt, C. Is the Maker Movement Contributing to Sustainability? Sustainability 2018, 10, 2212. [Google Scholar] [CrossRef]

- Arai, T.; Fuji, K.; Yanagida, M. Moderating Effect of Social Support on the Relationship between Psychopathic Traits and Immoral Behaviors. Available online: https://tohoku.pure.elsevier.com/en/publications/moderating-effect-of-social-support-on-the-relationship-between-p (accessed on 14 February 2021).

- Cau, A.; Moccia, D.; Follesa, M.C.; Alvito, A.; Canese, S.; Angiolillo, M.; Cuccu, D.; Bo, M.; Cannas, R. Coral forests diversity in the outer shelf of the south Sardinian continental margin. Deep. Sea Res. Part I Oceanogr. Res. Pap. 2017, 122, 60–70. [Google Scholar] [CrossRef]

- Zemtsov, S.; Barinova, V.; Semenova, R. The Risks of Digitalization and the Adaptation of Regional Labor Markets in Russia. Foresight STI Gov. 2019, 13, 84–96. [Google Scholar] [CrossRef]

- Wang, B. The Future of Manufacturing: A New Perspective. Engineering 2018, 4, 722–728. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).