Planform Geometry and Excitation Effects of PVDF-Based Vibration Energy Harvesters

Abstract

1. Introduction

2. Materials and Methods

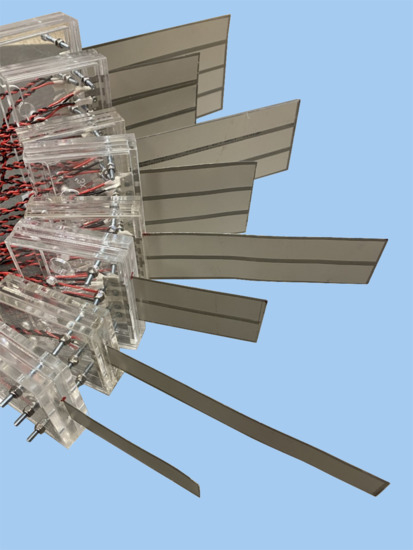

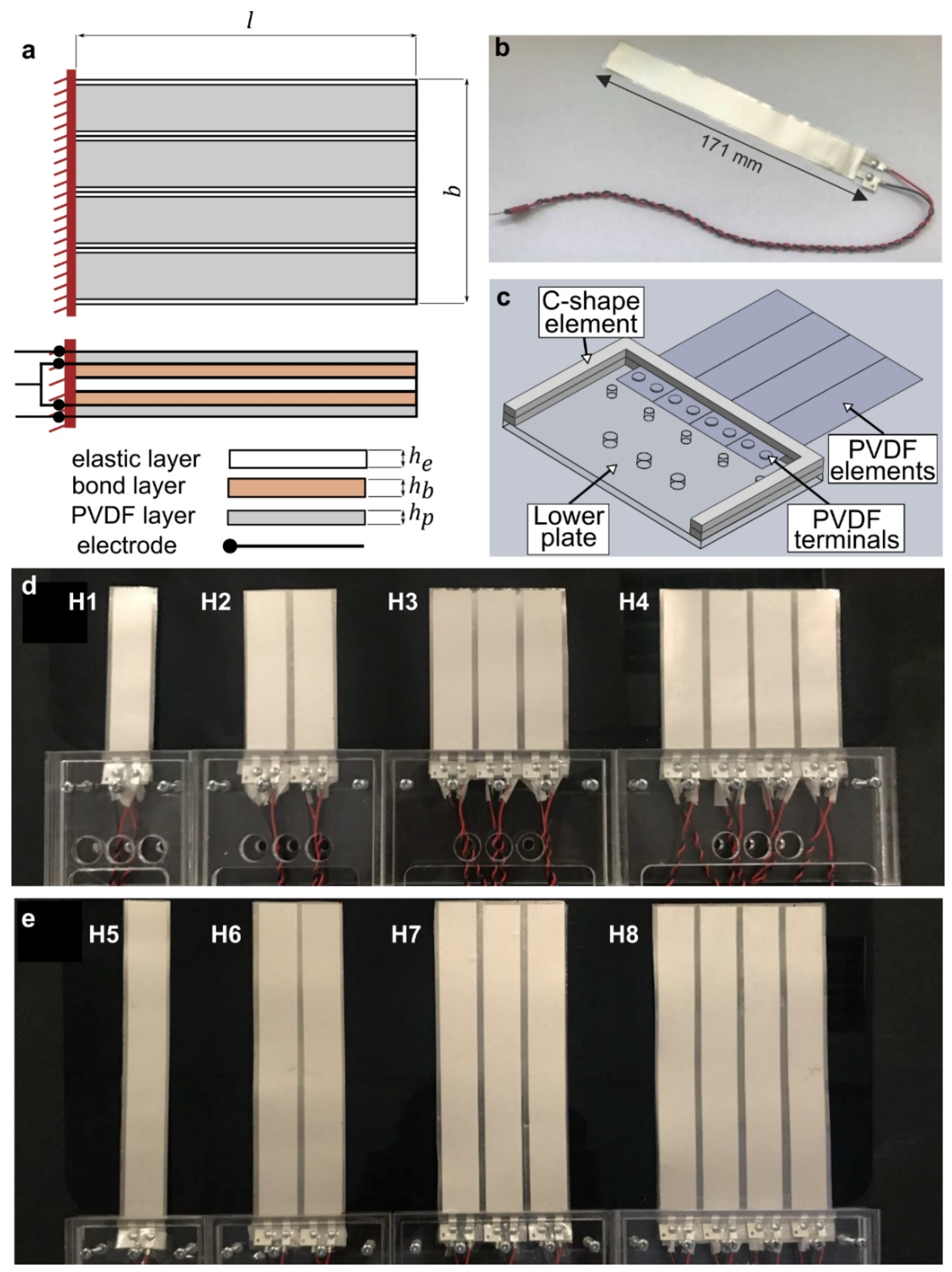

2.1. Harvesters’ Design and Realization

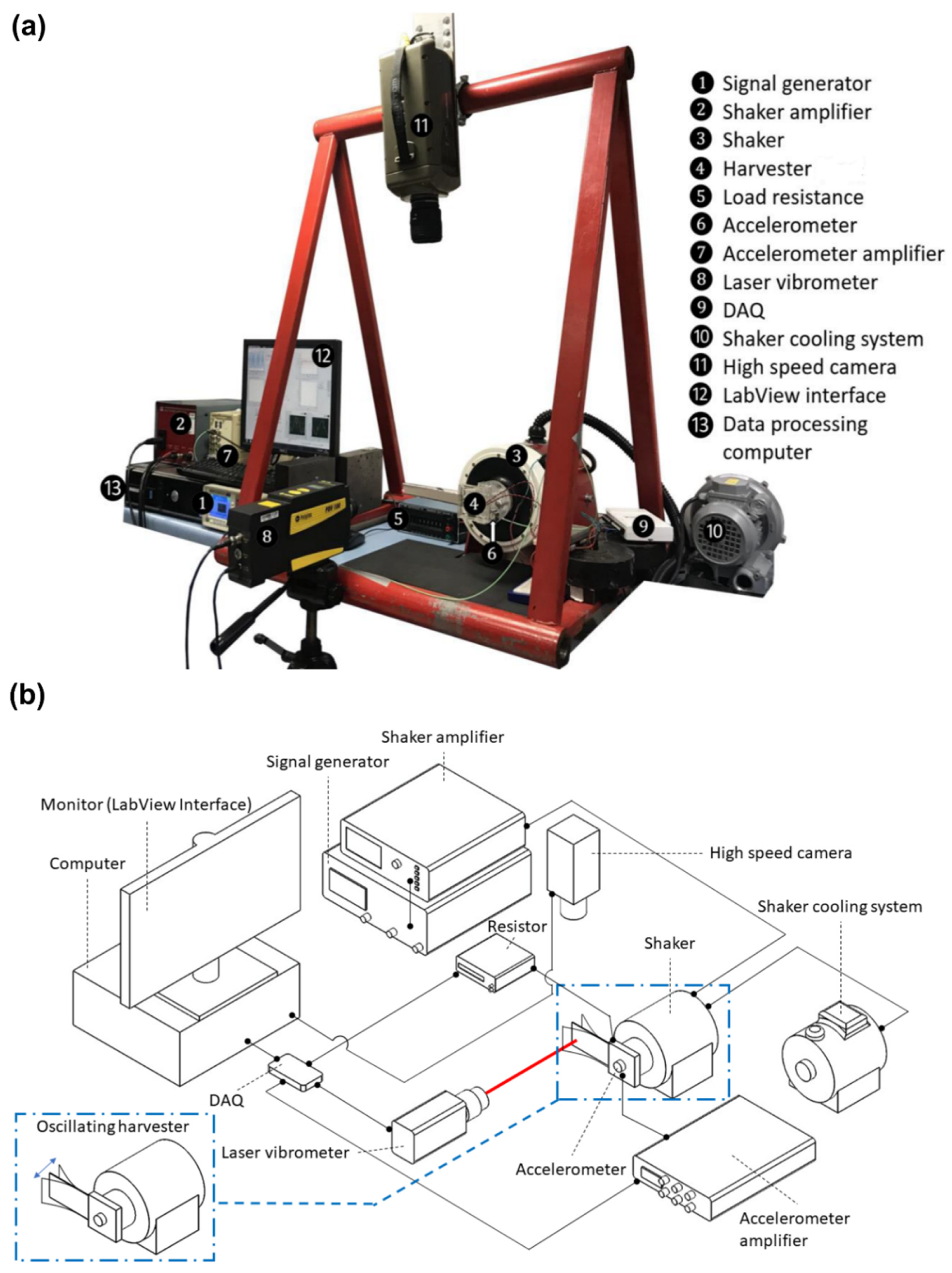

2.2. Experimental Setup

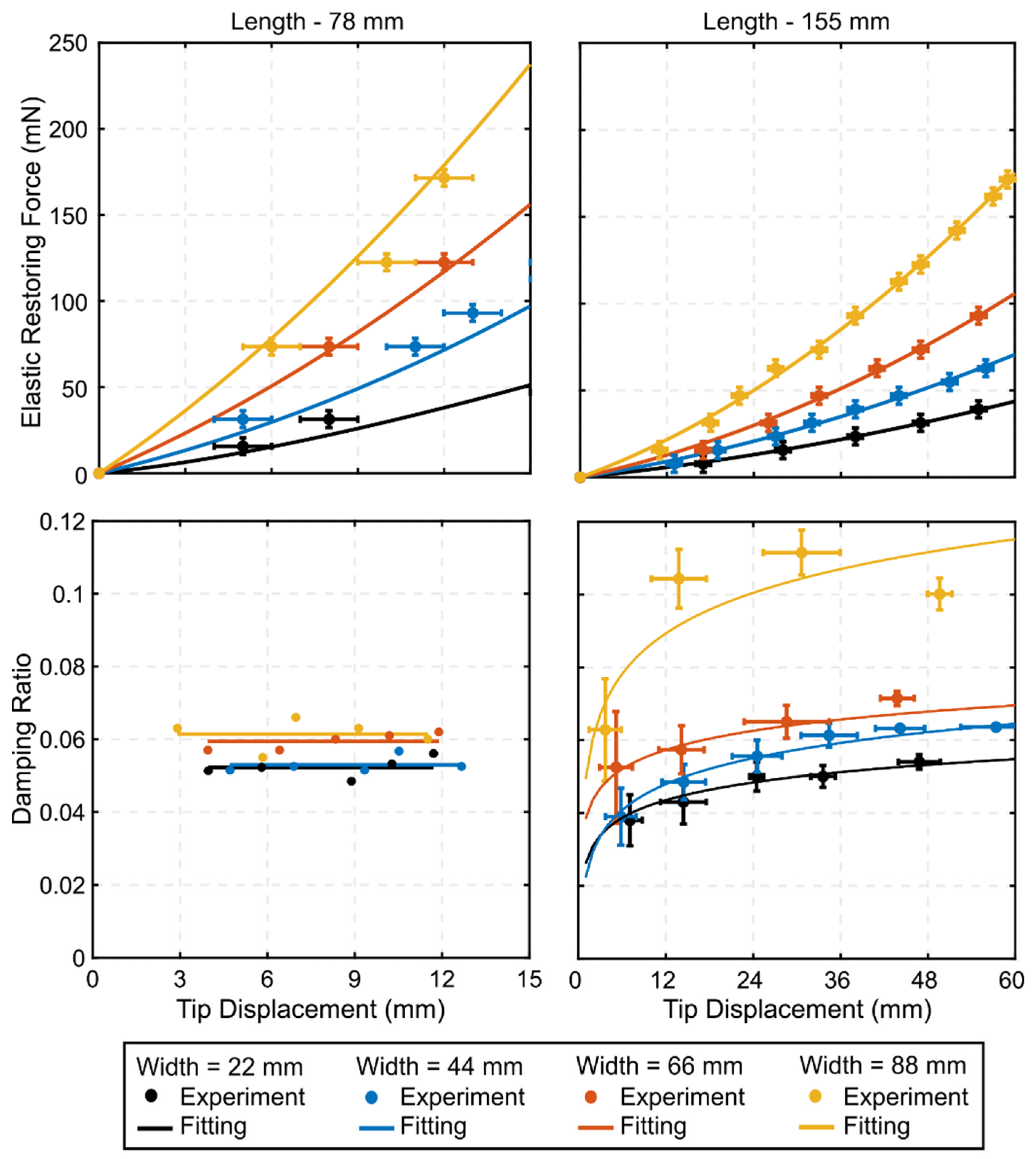

2.3. Characterization of Harvesters

3. Results and Discussion

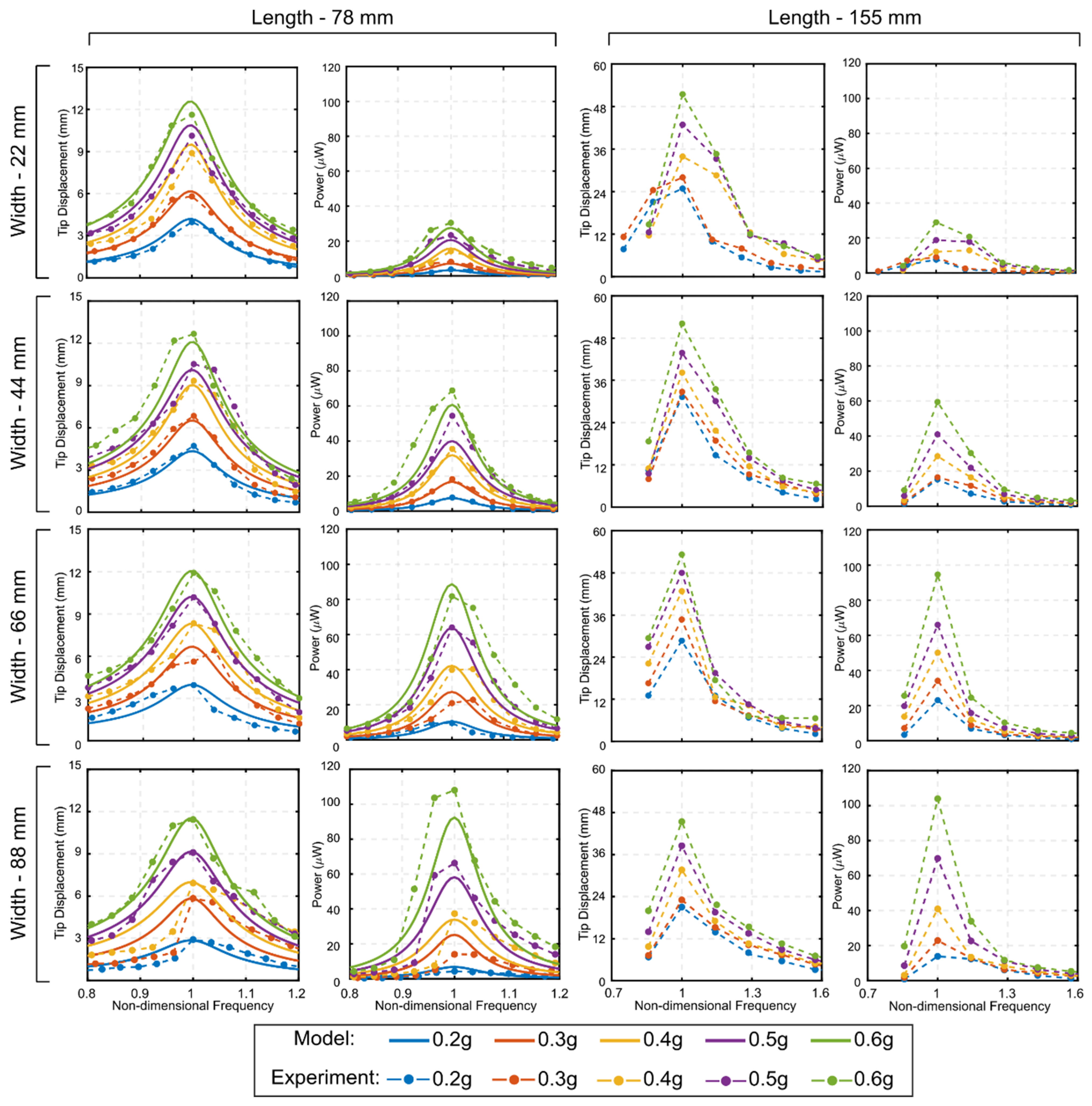

3.1. Dynamics and Power Generation Measurements

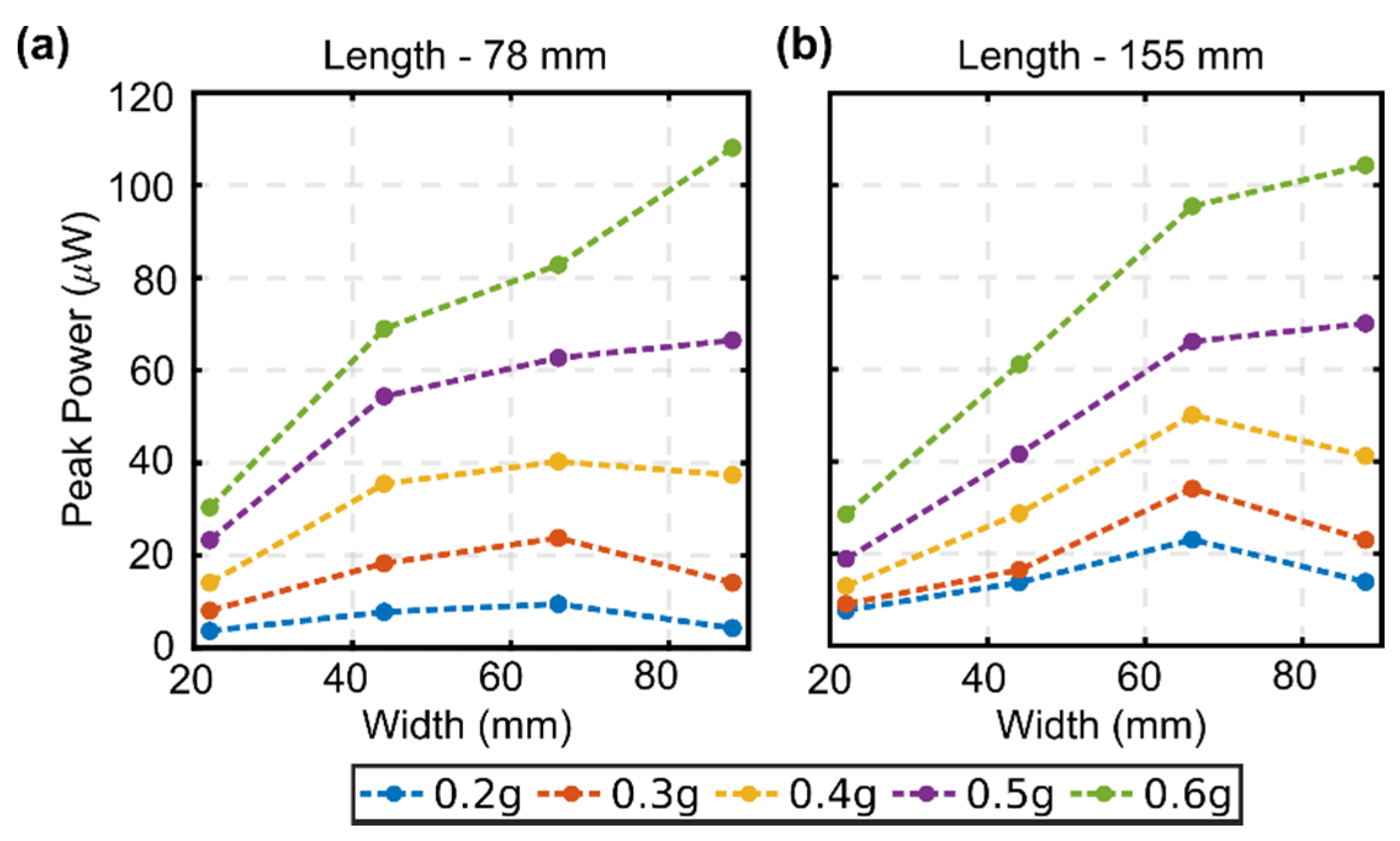

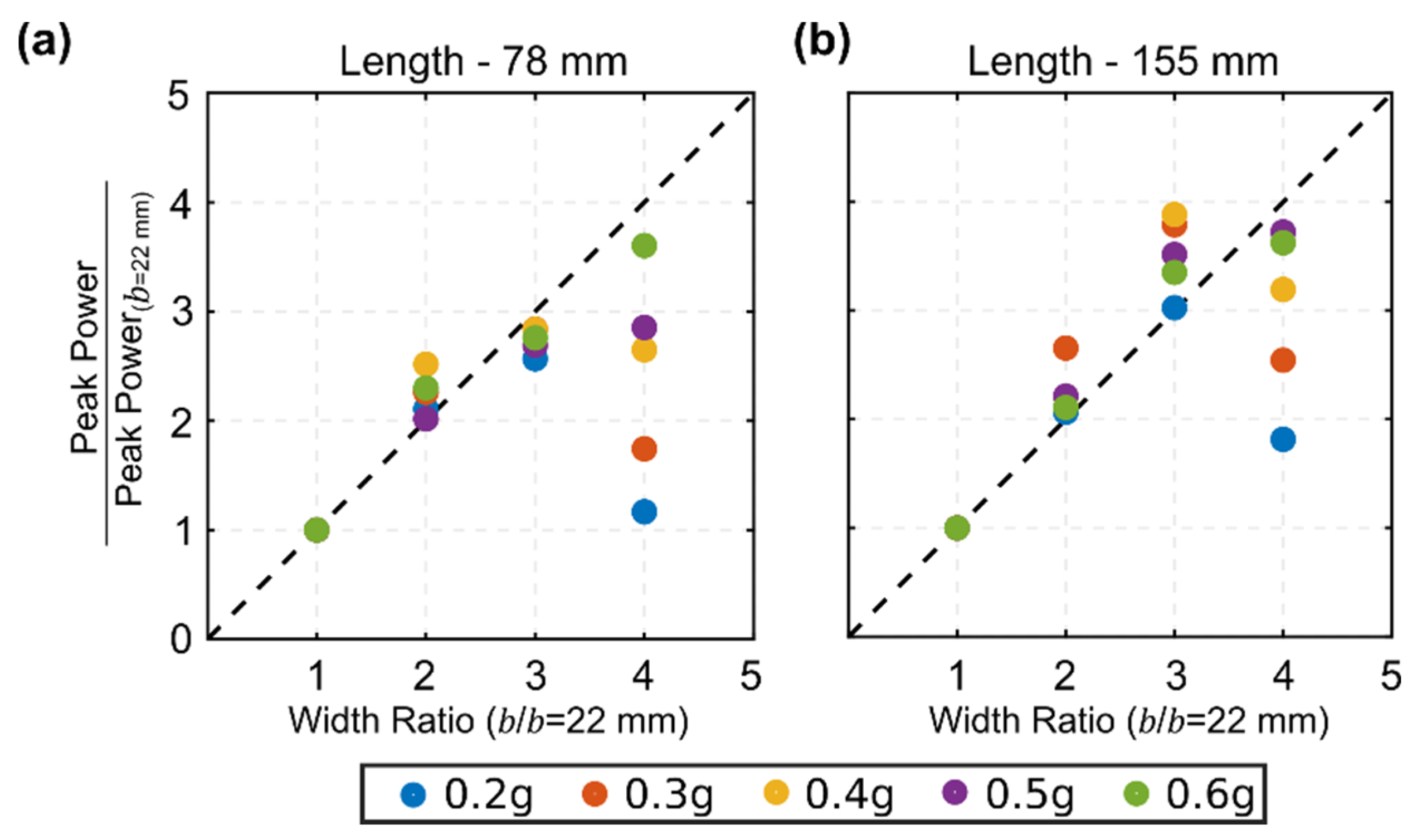

3.2. Planform Effects

3.3. Power Indicator Parameter

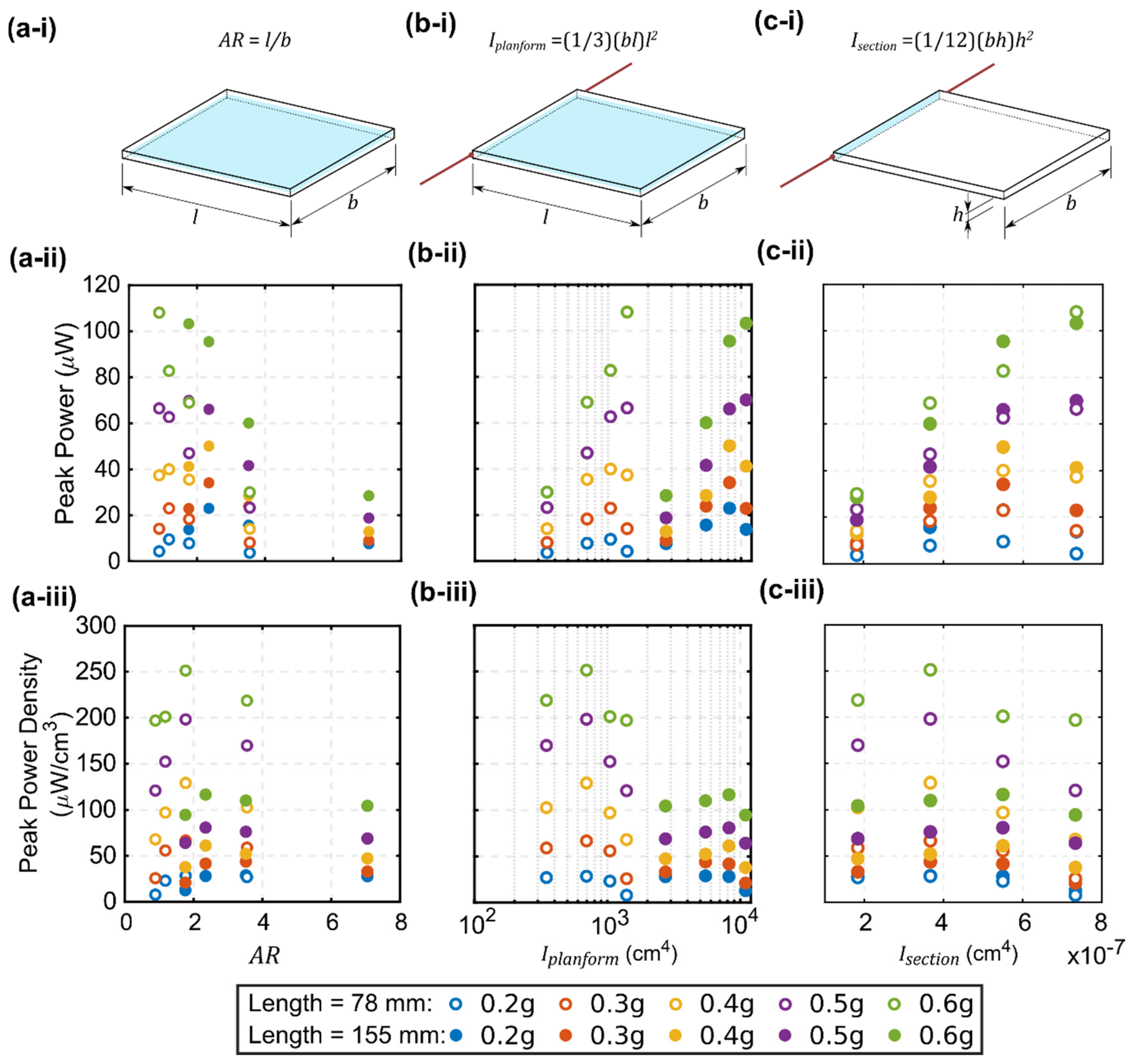

3.3.1. Aspect Ratio

3.3.2. Second Moment of Area

4. Concluding Remarks

- We show that there is an optimal width for this class of harvesters where the output power is maximized. This optimal width value depends on the excitation amplitude in such a way that narrower harvesters are more suited for small excitations, whereas wider harvesters perform better upon experiencing large excitations. Whilst this conclusion may well be anticipated, this work provides confirmation of this behavior for this class of harvesters through detailed, quantitative measurements;

- We show that for low excitation levels it is convenient to size the harvester at the optimum width, whereas at high excitation levels, multiple narrower harvesters would outperform one single harvester sized at the optimum width;

- We show that the selection of the harvester length is critical and should be determined to ensure a linear device response to the operation excitation, as if non-linear effects are triggered, they will drastically deteriorate the power density performance;

- We demonstrate the value of using the second moment of planform area to capture the geometric effect on the power density, i.e., to inform design/optimization studies. This is of significant importance from a practical perspective, in sizing such a class of harvesting devices for low-frequency vibration applications, and can open the door for further investigation and uptake of this metric when assessing harvester performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

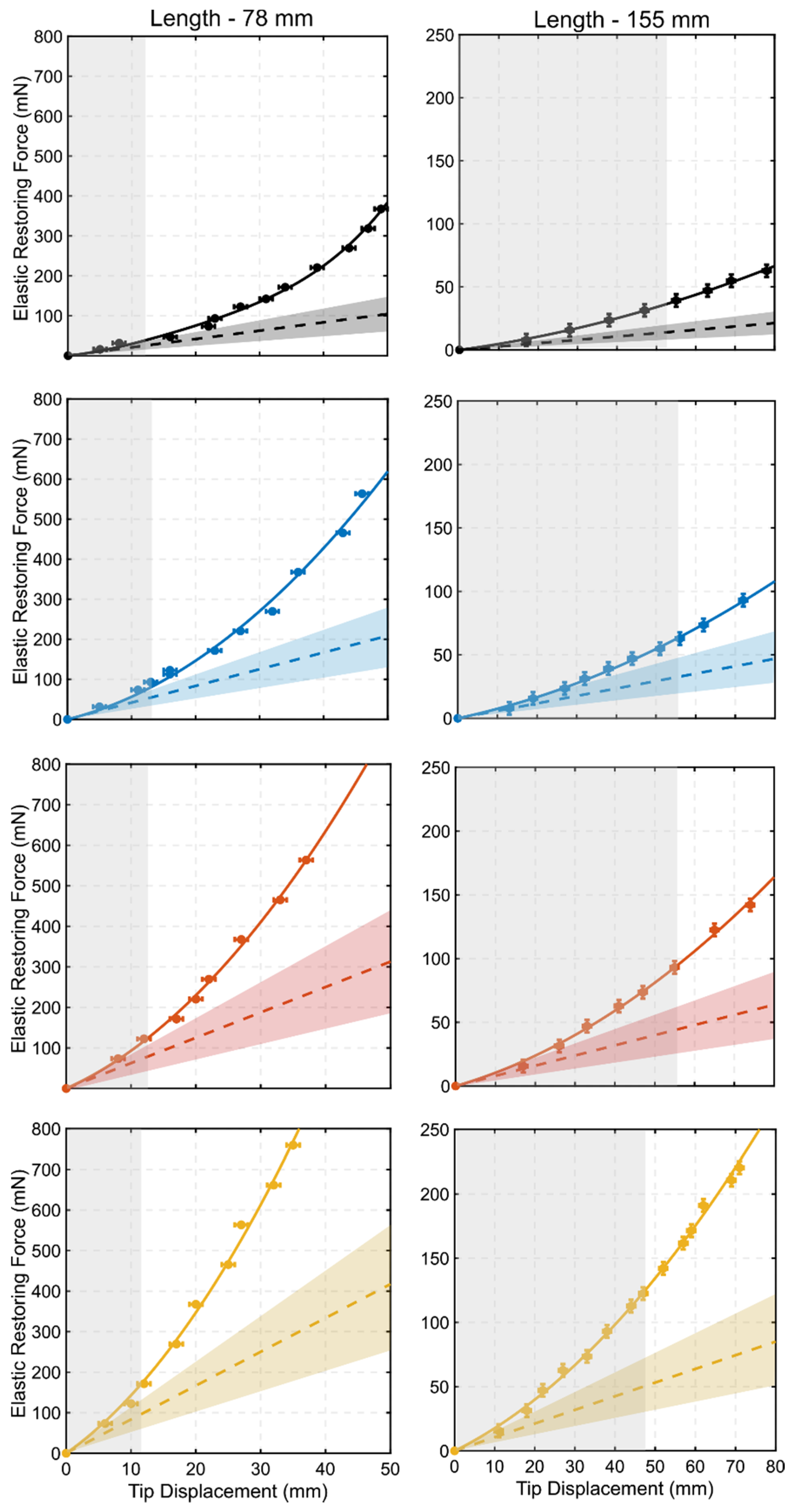

Appendix A. Static Deflection Testing of Harvesters

Appendix B. Linear Electro-Mechanical Dynamic Model

References

- Zhao, G. Wireless sensor networks for industrial process monitoring and control: A survey. Netw. Protoc. Algorithms 2011, 3, 46–63. [Google Scholar] [CrossRef]

- Aponte-Luis, J.; Gómez-Galán, J.A.; Gómez-Bravo, F.; Sánchez-Raya, M.; Alcina-Espigado, J.; Teixido-Rovira, P.M. An efficient wireless sensor network for industrial monitoring and control. Sensors 2018, 18, 182. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, Z.; Kim, K.; Lee, H. A cooperative wireless sensor network for indoor industrial monitoring. IEEE Trans. Ind. Inform. 2017, 13, 482–491. [Google Scholar] [CrossRef]

- Whelan, M.; Janoyan, K. Design of a robust, high-rate wireless sensor network for static and dynamic structural monitoring. J. Intell. Mater. Syst. Struct. 2008, 20, 849–863. [Google Scholar] [CrossRef]

- Avci, O.; Abdeljaber, O.; Kiranyaz, S.; Hussein, M.; Inman, D. Wireless and real-time structural damage detection: A novel decentralized method for wireless sensor networks. J. Sound Vib. 2018, 424, 158–172. [Google Scholar] [CrossRef]

- Yi, W.; Lo, K.; Mak, T.; Leung, K.; Leung, Y.; Meng, M. A survey of wireless sensor network based air pollution monitoring systems. Sensors 2015, 15, 31392–31427. [Google Scholar] [CrossRef]

- Kingsy Grace, R.; Manju, S. A comprehensive review of wireless sensor networks based air pollution monitoring systems. Wirel. Pers. Commun. 2019, 108, 2499–2515. [Google Scholar] [CrossRef]

- Adu-Manu, K.; Tapparello, C.; Heinzelman, W.; Katsriku, F.; Abdulai, J. Water quality monitoring using wireless sensor networks. ACM Trans. Sens. Netw. 2017, 13, 1–41. [Google Scholar] [CrossRef]

- Lin, Y.P.; Mukhtar, H.; Huang, K.T.; Petway, J.R.; Lin, C.M.; Chou, C.F.; Liao, S.W. Real-time identification of irrigation water pollution sources and pathways with a wireless sensor network and blockchain framework. Sensors 2020, 20, 3634. [Google Scholar] [CrossRef]

- Bouabdellah, K.; Noureddine, H.; Larbi, S. Using wireless sensor networks for reliable forest fires detection. Procedia Comput. Sci. 2013, 19, 794–801. [Google Scholar] [CrossRef]

- Silvani, X.; Morandini, F.; Innocenti, E.; Peres, S. Evaluation of a wireless sensor network with low cost and low energy consumption for fire detection and monitoring. Fire Technol. 2015, 51, 971–993. [Google Scholar] [CrossRef]

- Erdelj, M.; Król, M.; Natalizio, E. Wireless sensor networks and multi-UAV systems for natural disaster management. Comput. Netw. 2017, 124, 72–86. [Google Scholar] [CrossRef]

- Harne, R.L.; Wang, K.W. A review of the recent research on vibration energy harvesting via bistable systems. Smart Mater. Struct. 2013, 22, 023001. [Google Scholar] [CrossRef]

- Zuo, L.; Tang, X. Large-scale vibration energy harvesting. J. Intell. Mater. Syst. Struct. 2013, 24, 1405–1430. [Google Scholar] [CrossRef]

- Twiefel, J.; Westermann, H. Survey on broadband techniques for vibration energy harvesting. J. Intell. Mater. Syst. Struct. 2013, 24, 1291–1302. [Google Scholar] [CrossRef]

- Wei, C.; Jing, X. A comprehensive review on vibration energy harvesting: Modelling and realization. Renew. Sustain. Energy Rev. 2017, 74, 1–18. [Google Scholar] [CrossRef]

- Liu, D.K.C.; Friend, J.; Yeo, L. A brief review of actuation at the micro-scale using electrostatics, electromagnetics and piezoelectric ultrasonics. Acoust. Sci. Technol. 2010, 31, 115–123. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D. Piezoelectric Energy Harvesting; John Wiley and Sons, Ltd.: West Sussex, UK, 2011. [Google Scholar]

- Hirst, J.; Wang, J.; Nabawy, M.R.A.; Cioncolini, A. Long-term power degradation testing of piezoelectric vibration energy harvesters for low-frequency applications. Eng. Res. Express 2020, 2, 035026. [Google Scholar] [CrossRef]

- Wang, J.; Nabawy, M.R.A.; Cioncolini, A.; Revell, A. Solar panels as tip masses in low frequency vibration harvesters. Energies 2019, 12, 3815. [Google Scholar] [CrossRef]

- Li, S.; Yuan, J.; Lipson, H. Ambient wind energy harvesting using cross-flow fluttering. J. Appl. Phys. 2011, 109, 026104. [Google Scholar] [CrossRef]

- Jackson, N.; O’Keeffe, R.; O’Neill, M.; Waldron, F.; Mathewson, A. CMOS compatible low-frequency aluminium nitride MEMS piezoelectric energy harvesting device. In Proceedings of the SPIE Microtechnologies, Smart Sensors, Actuators, and MEMS VI, Grenoble, France, 17 May 2013; p. 87631I. [Google Scholar]

- Sharma, A.; Olszewski, O.Z.; Torres, J.; Mathewson, A.; Houlihan, R. Fabrication, simulation and characterisation of MEMS piezoelectric vibration energy harvester for low frequency. Procedia Eng. 2015, 120, 645–650. [Google Scholar] [CrossRef][Green Version]

- Shadoufa, M.; Emad, A.; Ghoneima, M.; Mahmoud, M.A.; Dessouky, M. Structure optimization for efficient AlN piezoelectric energy harvesters. In Proceedings of the IEEE International Conference on Electronics, Circuits, and Systems (ICECS), Cairo, Egypt, 6–9 December 2015; pp. 527–530. [Google Scholar]

- Heidrich, N.; Knöbber, F.; Sah, R.E.; Pletschen, W.; Hampl, S.; Cimalla, V.; Lebedev, V. Biocompatible AlN-based piezo energy harvesters for implants. In Proceedings of the IEEE International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 6–9 June 2011; pp. 1642–1644. [Google Scholar]

- Li, Y.; Çelik-Butler, Z.; Butler, D.P. An integrated piezoelectric zinc oxide nanowire micro-energy harvester. Nano Energy 2016, 26, 456–465. [Google Scholar] [CrossRef]

- Poulin-Vittrant, G.; Oshman, C.; Opoku, C.; Dahiya, A.S.; Camara, N.; Alquier, D.; Lethiecq, M. Fabrication and characterization of ZnO nanowire-based piezoelectric nanogenerators for low frequency mechanical energy harvesting. Phys. Procedia 2015, 70, 909–913. [Google Scholar] [CrossRef]

- Li, H.; Tian, C.; Deng, Z.D. Energy harvesting from low frequency applications using piezoelectric materials. Appl. Phys. Rev. 2014, 1, 041301. [Google Scholar] [CrossRef]

- Jiang, Y.; Hamada, H.; Shiono, S.; Kanda, K.; Fujita, T.; Higuchi, K.; Maenaka, K. A PVDF-based flexible cardiorespiratory sensor with independently optimized sensitivity to heartbeat and respiration. Procedia Eng. 2010, 5, 1466–1469. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, J.; Kuwano, H. Vibration energy harvesting characterization of 1 cm2 poly(vinylidene fluoride) generators in vacuum. Jpn. J. Appl. Phys. 2011, 50, 09ND15. [Google Scholar] [CrossRef]

- Rammohan, S.; Ramya, C.; Kumar, J.; Jain, A.; Pratap, R. Low frequency vibration energy harvesting using arrays of PVDF piezoelectric bimorphs. J. Intell. Mater. Syst. Struct. 2014, 3, 18–27. [Google Scholar]

- Song, J.; Zhao, G.; Li, B.; Wang, J. Design optimization of PVDF-based piezoelectric energy harvesters. Heliyon 2017, 3, e00377. [Google Scholar] [CrossRef]

- Tsukamoto, T.; Umino, Y.; Shiomi, S.; Yamada, K.; Suzuki, T. Bimorph piezoelectric vibration energy harvester with flexible 3D meshed-core structure for low frequency vibration. Sci. Technol. Adv. Mater. 2018, 19, 660–668. [Google Scholar] [CrossRef]

- Chandwani, J.; Somkuwar, R.; Deshmukh, R. Multi-band piezoelectric vibration energy harvester for low-frequency applications. Microsyst. Technol. 2019, 25, 3867–3877. [Google Scholar] [CrossRef]

- Roundy, S.; Wright, P.; Rabaey, J. A study of low level vibrations as a power source for wireless sensor nodes. Comput. Commun. 2003, 26, 1131–1144. [Google Scholar] [CrossRef]

- Boisseau, S.; Despesse, G.; Seddik, B. Nonlinear H-shaped springs to improve efficiency of vibration energy harvesters. J. Appl. Mech. 2013, 80, 061013. [Google Scholar] [CrossRef]

- Casiano, M.; Marshall, G. Extracting Damping Ratio from Dynamic Data and Numerical Solutions; NASA Technical Memorandum No 218227; NASA Langley Research Center: Hampton, VA, USA, 2016.

- Inman, D. Engineering Vibration; Prentice-Hall, Inc.: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Blevins, R. Flow-Induced Vibration, 2nd ed.; Krieger Publishing Company: Malabar, FL, USA, 2001. [Google Scholar]

- Elliott, S.; Tehrani, M.; Langley, R. Nonlinear damping and quasi-linear modelling. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140402. [Google Scholar] [CrossRef] [PubMed]

- Fearnow, D. Investigation of the Structural Damping of a Full-Scale Airplane Wing; NACA Research Memorandum No L51A04; National Advisory Committee for Aeronautics: Washington, DC, USA, 1951. Available online: https://digital.library.unt.edu/ark:/67531/metadc58765/m1/ (accessed on 1 January 2021).

- Nabawy, M.R.A.; Parslew, B.; Crowther, W.J. Dynamic performance of unimorph piezoelectric bending actuators. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2014, 229, 118–129. [Google Scholar] [CrossRef]

- Dagdeviren, O.; Miyahara, Y.; Mascaro, A.; Enright, T.; Grütter, P. Amplitude dependence of resonance frequency and its consequences for scanning probe microscopy. Sensors 2019, 19, 4510. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y. Review of nonlinear vibration energy harvesting: Duffing, bistability, parametric, stochastic and others. J. Intell. Mater. Syst. Struct. 2020, 31, 921–944. [Google Scholar] [CrossRef]

- Tran, N.; Ghayesh, M.; Arjomandi, M. Ambient vibration energy harvesters: A review on nonlinear techniques for performance enhancement. Int. J. Eng. Sci. 2018, 127, 162–185. [Google Scholar] [CrossRef]

- Zhang, H.; Corr, L.; Ma, T. Issues in vibration energy harvesting. J. Sound Vib. 2018, 421, 79–90. [Google Scholar] [CrossRef]

- Ramlan, R.; Brennan, M.; Mace, B.; Kovacic, I. Potential benefits of a non-linear stiffness in an energy harvesting device. Nonlinear Dyn. 2009, 59, 545–558. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Q.; Wang, W. Low-frequency wideband vibration energy harvesting by using frequency up-conversion and quin-stable nonlinearity. J. Sound Vib. 2017, 399, 169–181. [Google Scholar] [CrossRef]

- Zhang, L.; Abdelkefi, A.; Dai, H.; Naseer, R.; Wang, L. Design and experimental analysis of broadband energy harvesting from vortex-induced vibrations. J. Sound Vib. 2017, 408, 210–219. [Google Scholar] [CrossRef]

- Gammaitoni, L.; Neri, I.; Vocca, H. Nonlinear oscillators for vibration energy harvesting. Appl. Phys. Lett. 2009, 94, 164102. [Google Scholar] [CrossRef]

- Nabawy, M.R.A.; Crowther, W.J. Is Flapping Flight Aerodynamically Efficient? In Proceedings of the 32nd AIAA Applied Aerodynamics Conference, AIAA Aviation and Aeronautics Forum and Exposition, Atlanta, GA, USA, 16–20 June 2014; pp. 2014–2277. [Google Scholar]

- Nabawy, M.R.A.; ElNomrossy, M.M.; Abdelrahman, M.M.; ElBayoumi, G.M. Aerodynamic shape optimisation, wind tunnel measurements and CFD analysis of a MAV wing. Aeronaut. J. 2012, 116, 685–708. [Google Scholar] [CrossRef]

- Cioncolini, A.; Nabawy, M.R.A.; Silva-Leon, J.; O’Connor, J.; Revell, A. An experimental and computational study on inverted flag dynamics for simultaneous wind–solar energy harvesting. Fluids 2019, 4, 87. [Google Scholar] [CrossRef]

- Ojo, O.; Tan, D.; Wang, Y.; Shoele, K.; Erturk, A. Aspect ratio effects in wind energy harvesting using piezoelectric inverted flags. In Proceedings of the SPIE 10967, Active and Passive Smart Structures and Integrated Systems XIII, Denver, CO, USA, 27 March 2019; p. 109670Q. [Google Scholar]

- Orrego, S.; Shoele, K.; Ruas, A.; Doran, K.; Caggiano, B.; Mittal, R.; Kang, S. Harvesting ambient wind energy with an inverted piezoelectric flag. Appl. Energy 2017, 194, 212–222. [Google Scholar] [CrossRef]

- Silva-Leon, J.; Cioncolini, A.; Nabawy, M.R.A.; Revell, A.; Kennaugh, A. Simultaneous wind and solar energy harvesting with inverted flags. Appl. Energy 2019, 239, 846–858. [Google Scholar] [CrossRef]

- Nabawy, M.R.A.; Crowther, W.J. Dynamic electromechanical coupling of piezoelectric bending actuators. Micromachines 2016, 7, 12. [Google Scholar] [CrossRef]

| Harvester | Length, (mm) | Width, (mm) | Aspect Ratio, | Second Moment of Plan-form Area, | Optimum Load Resistance, |

|---|---|---|---|---|---|

| H1 | 78 | 22 | 3.55 | 348 | 1000 |

| H2 | 78 | 44 | 1.77 | 696 | 600 |

| H3 | 78 | 66 | 1.18 | 1044 | 400 |

| H4 | 78 | 88 | 0.89 | 1392 | 250 |

| H5 | 155 | 22 | 7.05 | 2731 | 2400 |

| H6 | 155 | 44 | 3.52 | 5462 | 1200 |

| H7 | 155 | 66 | 2.35 | 8192 | 800 |

| H8 | 155 | 88 | 1.76 | 10,923 | 600 |

| Excitation | H1 | H2 | H3 | H4 | H5 | H6 | H7 | H8 |

|---|---|---|---|---|---|---|---|---|

| 0.2 g | 13.5 | 13 | 13 | 14.5 | 4 | 3.5 | 3.5 | 3.5 |

| 0.3 g | 13.5 | 13 | 12.5 | 13.5 | 4 | 3.5 | 3.5 | 3.5 |

| 0.4 g | 13 | 13 | 12.5 | 13 | 3.5 | 3.5 | 3.5 | 3.5 |

| 0.5 g | 13 | 13 | 12.5 | 13 | 3.5 | 3.5 | 3.5 | 3.5 |

| 0.6 g | 13 | 13.5 | 12.5 | 13 | 3.5 | 3.5 | 3.5 | 3.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Nabawy, M.R.A.; Cioncolini, A.; Revell, A.; Weigert, S. Planform Geometry and Excitation Effects of PVDF-Based Vibration Energy Harvesters. Energies 2021, 14, 211. https://doi.org/10.3390/en14010211

Wang J, Nabawy MRA, Cioncolini A, Revell A, Weigert S. Planform Geometry and Excitation Effects of PVDF-Based Vibration Energy Harvesters. Energies. 2021; 14(1):211. https://doi.org/10.3390/en14010211

Chicago/Turabian StyleWang, Jie, Mostafa R. A. Nabawy, Andrea Cioncolini, Alistair Revell, and Samuel Weigert. 2021. "Planform Geometry and Excitation Effects of PVDF-Based Vibration Energy Harvesters" Energies 14, no. 1: 211. https://doi.org/10.3390/en14010211

APA StyleWang, J., Nabawy, M. R. A., Cioncolini, A., Revell, A., & Weigert, S. (2021). Planform Geometry and Excitation Effects of PVDF-Based Vibration Energy Harvesters. Energies, 14(1), 211. https://doi.org/10.3390/en14010211