1. Introduction

The rapid consumption of fossil fuel and accelerating global warming raises a worldwide concern of energy crisis and environmental problems. In this case, electric vehicles (EVs) are rapidly appreciated by governments, automobile manufacturers, consumers, and research institutions [

1]. EVs can be divided into battery electric vehicles (BEVs), hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs) and fuel cell electric vehicles (FCEVs) [

2]. BEV accounts for the most substantial proportion of new energy vehicle production and sales. Besides, BEV owns a broad market potential because of its exceptional advantages of zero emission, low noise, and high efficiency. Compared with other types of batteries, the lithium-ion battery has the benefit of greater energy density, longer cycle life, and higher discharge rate [

3]. Therefore, the lithium-ion battery is broadly used in EVs. Battery pack is the critical component of EVs and determines the driving range. To meet EV’s huge energy demand, battery packs usually comprise of numerous cells. The pack must be appropriately managed to prolong cycle life, avoid safety accidents, and maximize available energy [

4]. Therefore, a high-end battery management system (BMS) is critical to enhancing EV’s performance. The functional module of BMS includes safety protection, battery state parameters estimation, and battery equalization.

The inconsistency of cells in a battery pack is inevitable due to manufacturing tolerance, ambient temperature variation and aging rate divergence. The cells vary in internal resistance, self-discharge rate, and capacity, leading to the state of charge (SoC) diversity aggravating along with cyclic charging and discharging [

5]. Cells’ inconsistency degrades battery pack performance significantly thereby reducing the driving range of EVs.

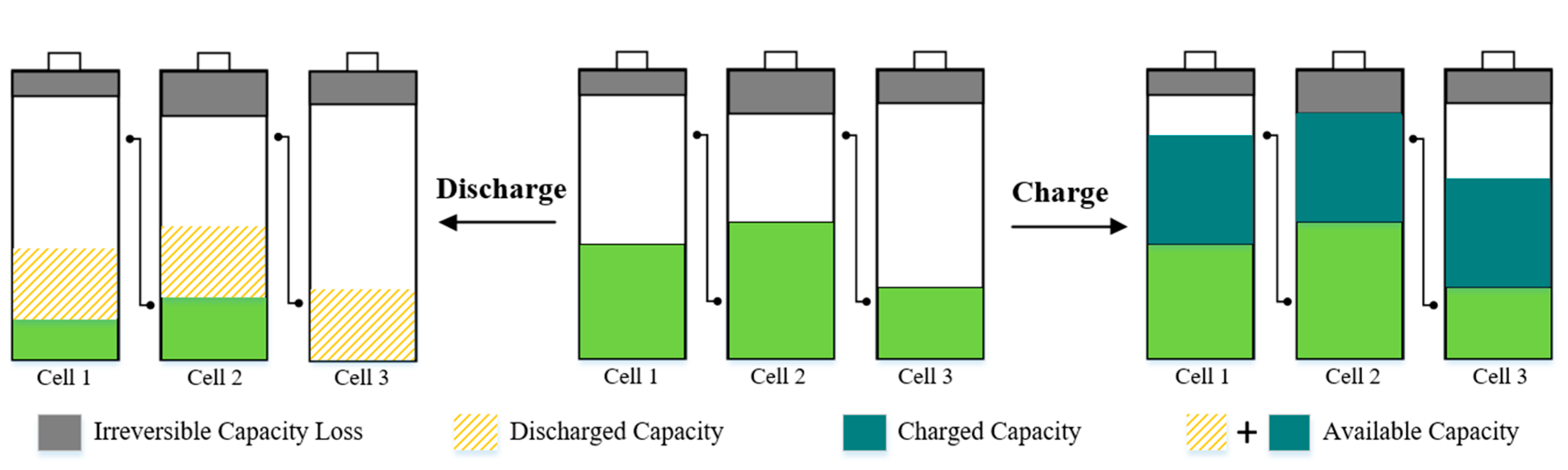

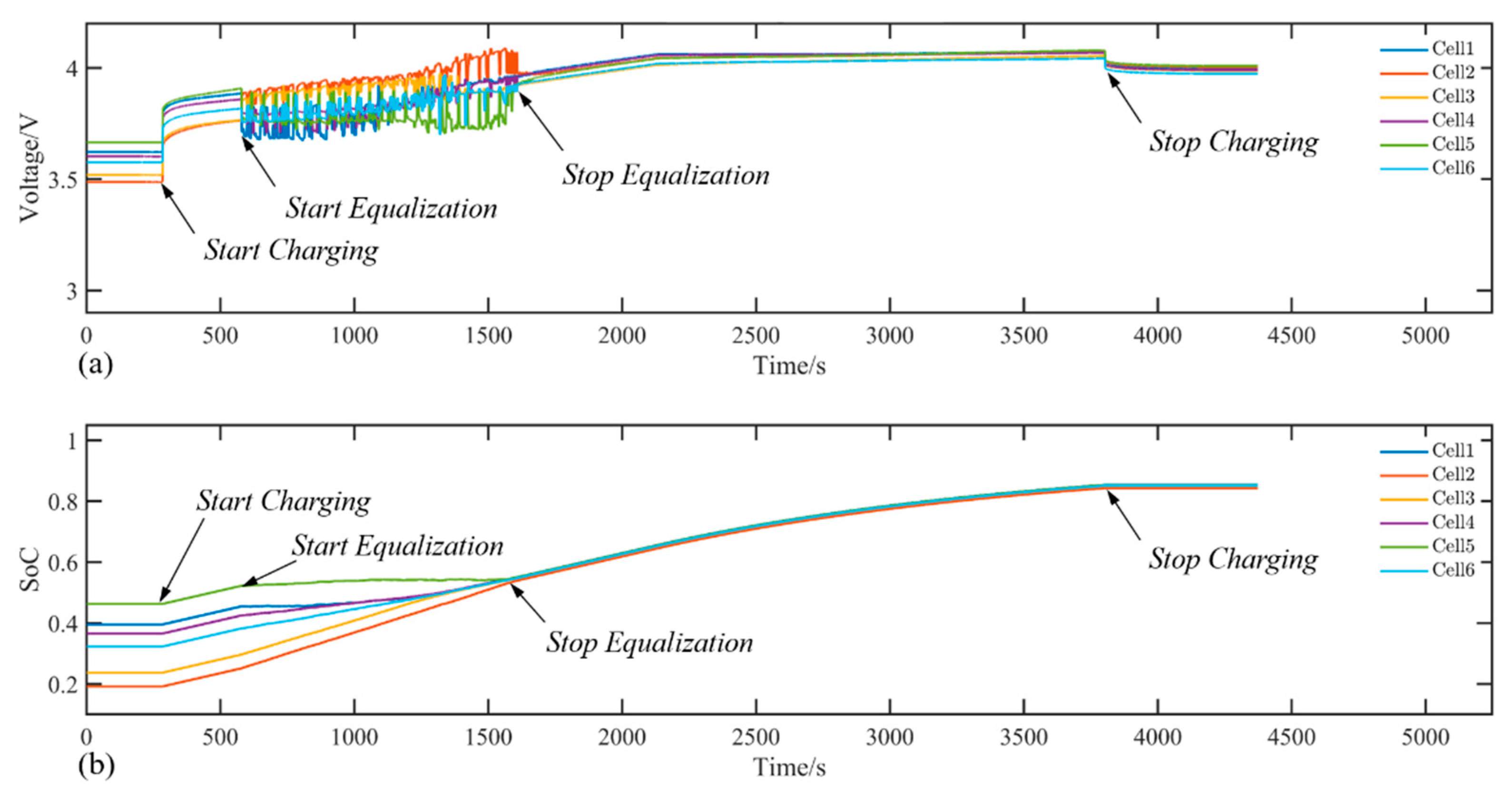

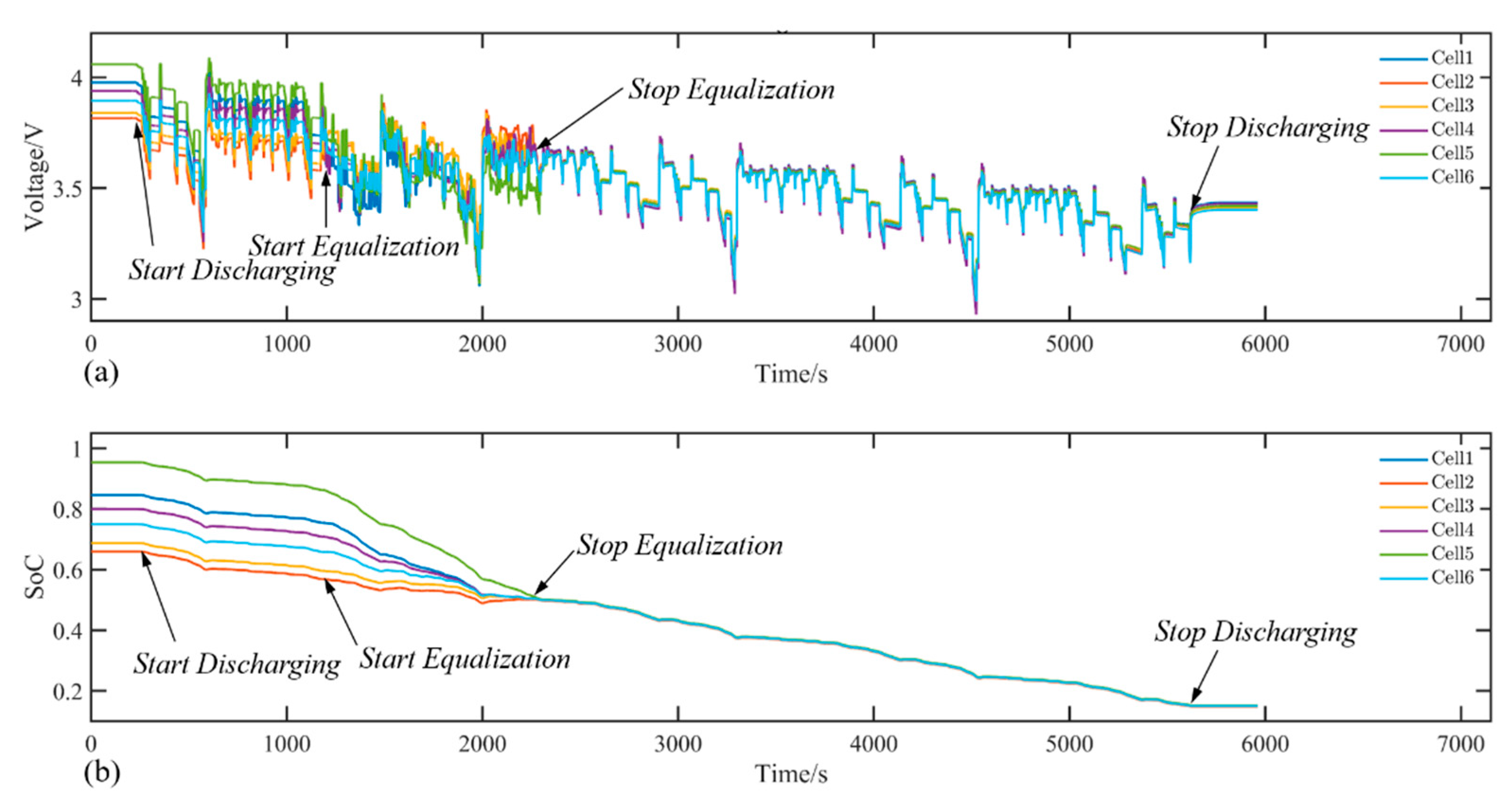

Figure 1 shows the charge and discharge process of the unbalanced battery string, which corresponds to EVs’ charging and driving states. As the range of cells’ SoCs enlarges, the total available capacity of the battery pack diminishes proportionally, leading to the degradation of EVs’ driving range. Furthermore, the inconsistency of SoCs causes unbalanced charge and discharge depths. Those cells in a larger depth of charge (Cell 2,

Figure 1) or discharge (Cell 3,

Figure 1) are on the edge of overcharging and overdischarging for a longer period, which accelerates the cycle life decay rate of specific cells and ultimately leads to degradation of pack useful life. Accordingly, the service life of EVs decreases. Therefore, the Equalization technology should be applied in series-connected batteries to lessen unbalanced levels of batteries, expand the available capacity of battery packs, and improve the overall performance of EVs.

Battery equalizers are widely used in multi-battery systems to maintain balanced charge among cells [

6]. Equalization topologies can be categorized into passive and active methods by the management of surplus energy [

7]. The passive methods transform energy from cell to heat by shunting resistor. Fixed shunting resistor equalizer is the simplest method to implement due to its unnecessary control [

8]. Switch shunting resistor equalizer connected or disconnect with cells by switches and therefore is more efficient than fixed shunting resistor equalizer [

7]. Analog shunting resistor equalizer controls the resistors’ connection status by voltage reference [

9]. It has the advantage of unnecessary control but requires a relatively higher cost. The passive method is widely employed in the EV industry because of its low-cost, simple structure and convenient implementation. However, considerable heat emission caused by energy dissipation is the major setbacks of the passive method, which triggers a significant challenge of temperature management of the pack. Besides, the slow equalization speed makes the passive method unsuitable for the equalization of large-capacity power batteries.

Various non-dissipative active equalizers have been proposed to overcome the setbacks raised by passive methods. Categorized by energy transfer media, active equalizers can be classified in capacitor, inductor, and transformer based. Capacitor-based equalizers include switch capacitor equalizer, single-switch capacitor equalizer, and double-tiered switch capacitor equalizer. Switch capacitor equalizer has the advantages of a straightforward control strategy while it has multiple capacitors [

10,

11,

12]. Single-switch capacitor equalizer has only one capacitor but requires complex control [

13,

14]. Double-tiered switch capacitor equalizer has an additional capacitor tiered for energy transfer, thereby increasing the equalization speed [

15,

16]. Capacitor-based equalizers have the advantages of good low-temperature characteristics, wide operating temperature range, high power density, and long cycle life. However, the practical application of capacitor-based equalizers is hindered by a relatively larger volume. Inductor-based equalizers operate on the principle of Buck-Boost. Single-inductor equalizers connect the highest and lowest cells with inductor alternately to transfer energy between cells but require complex and precise control [

17]. Multi-inductor equalizers can only transfer energy from adjacent batteries and yet is no need for complex control relatively [

18]. In spite of the advantages of relatively higher balancing current and shorter operation time, inductor-based equalizers are challenging for the practical implementation of large-scale packs due to their high cost and inevitable magnetic losses [

13]. Transformer-based equalizers include single-winding transformer equalizers, multi-winding transformer equalizers. Single-winding transformer equalizers contain only one transformer, which can reduce volume and cost, but has multiple switches, which lead to complex control [

19,

20]. Multi-winding transformer equalizers have fewer switches and require simpler control, but the large volume and, respectively, high cost should be concerned [

13,

21]. Besides, flyback structure [

22] are generally selected for the primary and second winding of the transformer-based equalizers. The foremost challenge of transformer-based equalizers is winding matching which increases the complexity of equalizer design. Furthermore, the necessity of precise control in transformer-based equalizer enhances the difficulties of devising controllers. The high magnetic loss is also a limitation of transformer-based equalizer.

Flyback transformer is a special application of transformer. The flyback transformer is capable of providing high voltages using relatively few turns of windings. The main feature of flyback transformer is that its output gets energy when the primary winding is disconnected from the power supply. The flyback transformer is competent for DC-DC energy transfer due to its advantages of circuit simplicity, electric isolation, high efficiency and small turn ratio [

23]. Under its advantages, flyback transformer has been utilized in numerous application areas, e.g., energy storage, energy supply and transfer, galvanic isolation [

24] and photovoltaic application [

25]. Thus, considering its strength in energy conversion, this paper devises the equalizer based on flyback transformer.

Equalization strategies play a significant role in pack balancing management since they determine the performance of the equalizer during the equalization process. Numerous strategies for equalization have been proposed based on the corresponding balancing topologies. For switch shunting resistor equalizer of passive methods, fuzzy logic control, which considers the thermal effect of the shunting resistors in the equalization process, can reduce equalization time and improve energy efficiency while maintaining low heat emission of the shunting resistors [

26]. In the field of active methods, fixed duty cycle (FDC) methods [

27,

28] are used in transformer-based equalizers. FDC method is the most straightforward strategy but has no idea of regulating the balancing current. Those cells whose SoCs are higher or lower than the average value are discharged or charged at the maximum equalization current, respectively. The variable duty cycle (VDC) methods [

29,

30] have been employed to control the transformer-based equalizer. The main idea of VDC is regulating the balancing current and the applied duty cycles of VDC are proportional to SoC deviations from the average value. Besides, some intelligent control methods have been proposed to control the equalizers. Fuzzy logic control [

31,

32] has been applied for transformer- and inductor-based equalizers, achieving voltage balancing in a short period. Model predictive control [

22,

33] proves its competence in controlling transformer-based equalizers. This method improves the efficiency of equalization circuit and prolongs cell life. Game theory [

34] has been successfully applied in inductor-based equalizer to realize SoC consistency in battery string, which reduces control complexity.

Equalization strategies can be further subdivided into voltage, SoC and remaining-capacity-based according to equalization reference. Voltage-based equalization strategies operate with the target of voltage uniformity. Fuzzy logic control strategy [

31] applied in transformer-based equalizers considers voltage as reference. Battery cell voltage balancing control [

35] employed in a modular bridge equalizer aims at voltage consistency. The control strategy of active hierarchical equalization circuits [

36] achieves voltage consistency. Voltage-based equalization strategies are convenient to execute and greatly streamline the implementation of strategies because cells’ voltages can be acquired straightforwardly. However, as the inconsistency of internal resistance in a battery string gradually grows due to aging rate divergence, the terminal voltage is no longer competent as equalization standard. During equalization procedures, those cells with larger internal resistance appear to output higher terminal voltage under the same charging balancing current, or vice versa, making the terminal voltage an unreliable equalization criterion. Remaining-capacity-based strategies consider cell remaining capacity as balancing standard. An active equalization method based on the remaining capacity [

37] is applied in transformers-based equalizers and an on-line equalization algorithm [

38] which is embedded with the remaining-capacity estimation is used to balance the strings. The main challenge of remaining-capacity-based strategies is the unavailability of the cells’ remaining capacities which are estimated by complicated online parameter identification algorithms. SoC-based equalization strategies take cells’ SoCs as reference. Model predictive control, which is used in bidirectional transformer-based equalizer [

22,

33], takes SoC as reference. Fuzzy logic control [

39] conducted in inductor-based equalizer aims to balance cell’ SoCs. A data-stream-mining-based strategy [

40] applied in single-switch capacitor equalizer attempts to equalize SoCs. By maintaining cells charging or discharging depth consistency, SoC-based equalization strategies can competently retard the aging of packs. Although SoC estimation precision influences the effect of equalization, SoC-based equalization strategies are preferable in virtue of its significant strength.

The research on the equalization method in this paper is aimed at the practical application in EVs. The working conditions of EVs can be generally divided into three states: parking, driving, and charging. First of all, the parking condition is the one with the longest time among the three states. The passive equalizer, which is vastly employed in practical application, provides small equalization currents thereby emerging a low speed [

7]. Therefore, in practical applications, the passive equalizer runs during the parking condition. In this case, the proposed equalization method is researched and verified during the parking condition to study the energy transfer efficiency and speed of the equalizer under the control of the proposed equalization strategy. Secondly, EVs’ performance of driving range is demonstrated in the driving condition. For the complex realistic driving environment [

41], international standards stipulate a variety of experimental test methods to simulate realistic driving conditions, such as The Extra Urban Driving Cycle (EUDC), The Federal Urban Driving Schedule (FUDS) and The New European Driving Cycle (NEDC). When the battery pack is not uniform, the capacity cannot be completely released, leading to a decline in EVs’ driving range. For the problem under the driving states, this research also applies the design and verification of the equalizer to the driving process to prolong the driving range of EVs. Finally, the commonly used charging method for EVs in charging conditions is the constant current constant voltage (CC-CV) method [

42]. When the battery pack is under-charged and unbalanced, the battery cannot be fully charged because cells are limited by the charge cut-off voltage for safety. To study and address this problem, the proposed equalization method is also applied in the charging process to verify the effect of increasing the overall available capacity.

Under the conditions discussed above for the realistic application environment of EVs, the battery pack is separated from the electric vehicle as a studied object of the equalization method. The working conditions of the battery pack can be summarized as static, discharging, charging, which correspond to the parking, driving and charging states of EVs, respectively. Among them, the discharge condition is verified by EUDC, and the charging condition is tested in CC-CV. Besides, the large-scale battery pack in a realistic application of EVs enhances the design and research difficulty of equalizer [

43]. To simplify the research complexity and simulate the actual use of large battery packs as much as possible, this study employed a series-connected battery string as the object of equalizer design and verification. In this environment, the key research and engineering aspects are to design the equalizer based on flyback transformer for battery string, study the energy transfer efficiency and speed under the control of equalization strategy in the static condition, and verify the applicability of the equalizer during the discharging and charging process to improve the maximum discharged capacity and available capacity.

The outline of this paper is as follows:

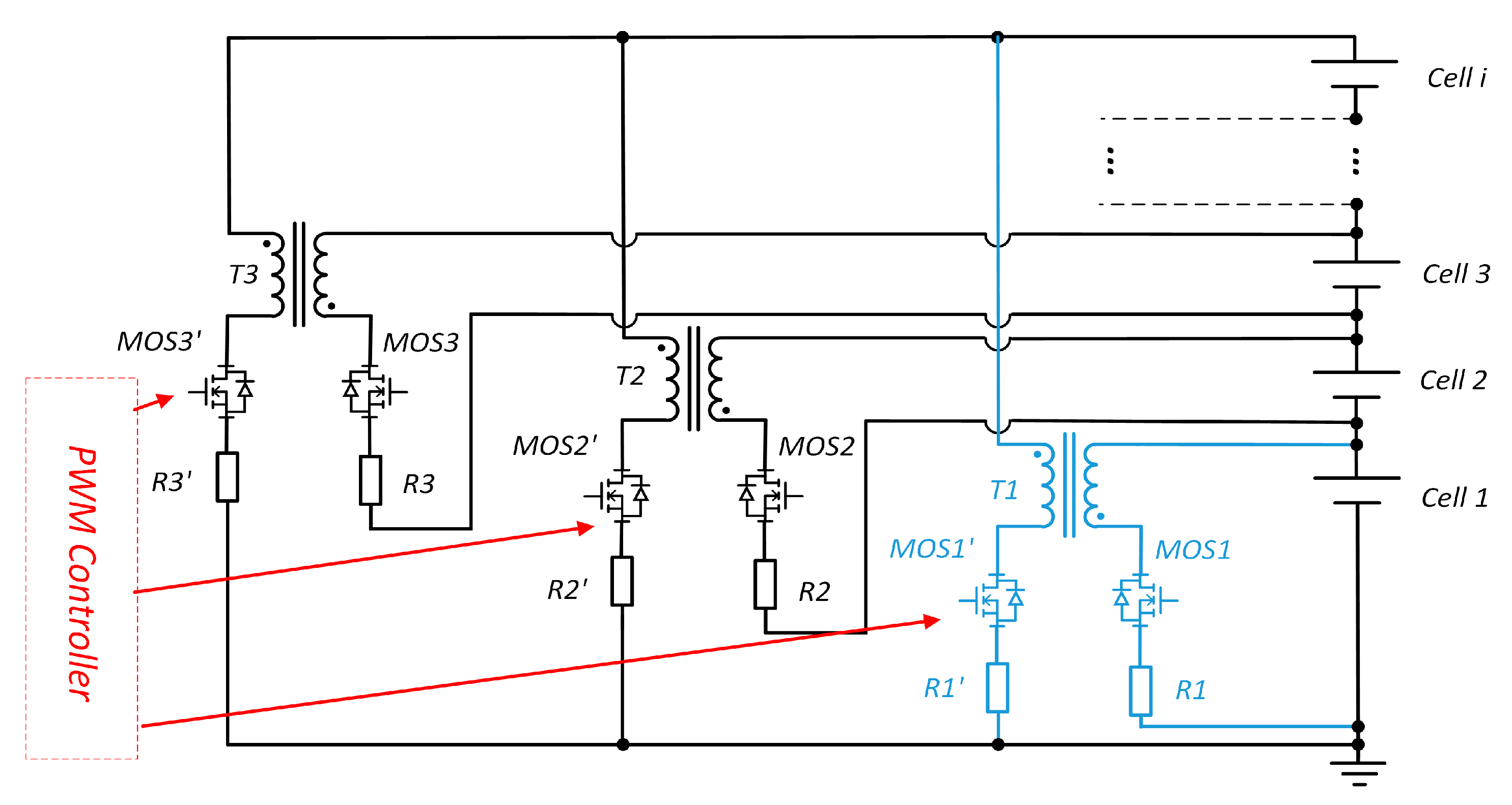

Section 2 introduces the architecture and operating principles of BFTE.

Section 3 presents the control of the equalizer.

Section 4 designs the VSSGPC strategy improved from traditional GPC.

Section 5 describes the experiment bench and discusses experiment results.

Section 6 summarizes this article.

4. Variable Step Size Generalize Predictive Control

This section introduces the proposed variable step size generalized predictive control (VSSGPC) strategy in the following order. Firstly,

Section 4.1 discusses the basic derivation of generalized predictive control (GPC) for the equalization system. Secondly,

Section 4.2 solves the optimum control law of GPC with constrained inputs. Thirdly,

Section 4.3 settles the problem of undetermined system parameters in CARIMA model. Finally,

Section 4.4 introduces the principles of the improved VSSGPC and the physical significant of the introduced Step Size Factor.

4.1. Generalized Predictive Control

4.1.1. The Basic Concept of GPC

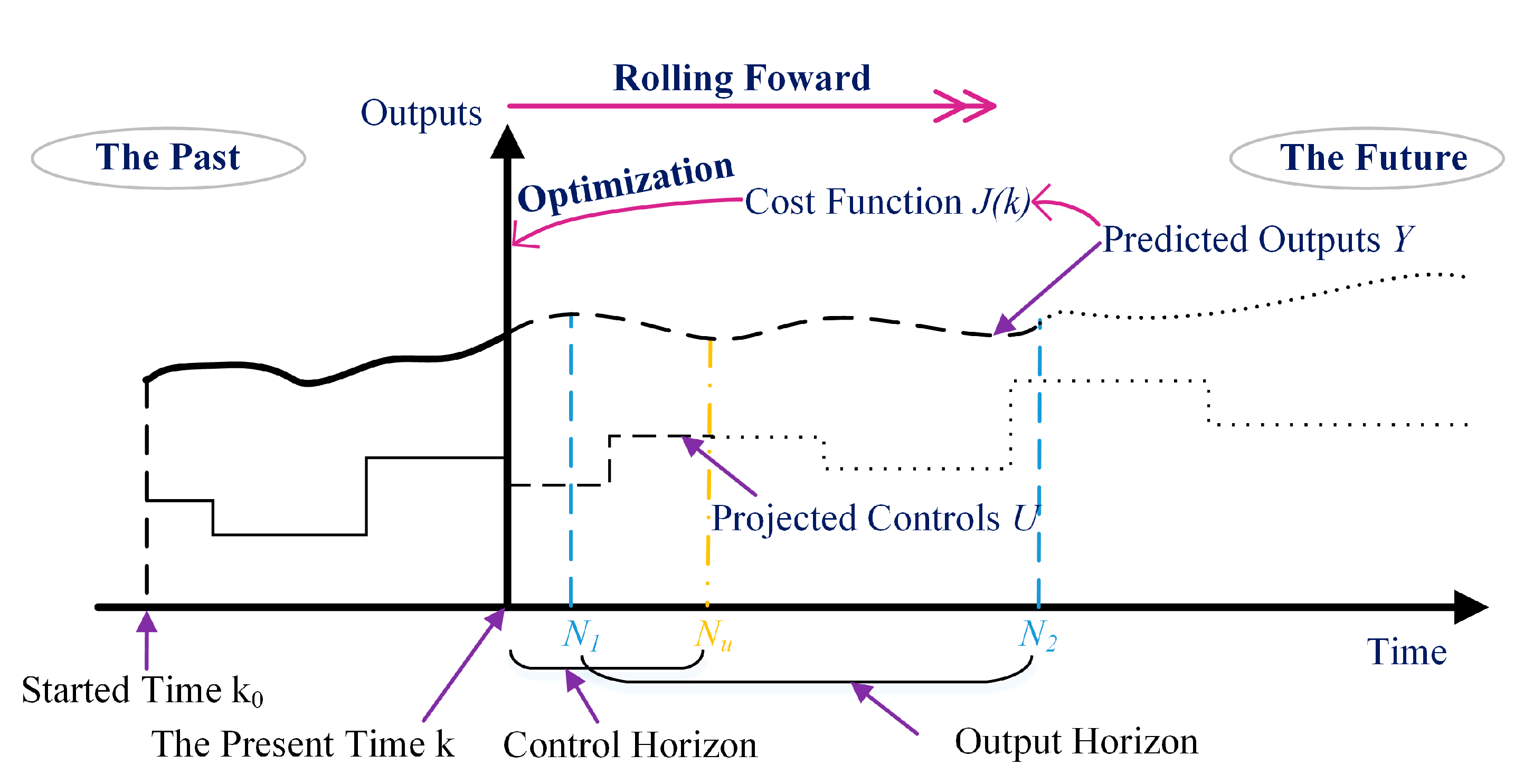

The schematic of GPC is illustrated in

Figure 4. Limited control and output horizons are adopted to stand for the global control process. At time

k, the cost function

is calculated based on predicted outputs

. With a target of minimizing

, projected controls

are obtained by optimization algorithms discussed in

Section 4.2. The first row of projected controls matrix

at present time

k is accepted as the optimum control law for the current moment. As the process rolls to the next moment

k+1, the optimum control law is acquired by the same method.

4.1.2. GPC of SISO System

For clarity, GPC of single-input-single-output (SISO) system is discussed first. SISO CARIMA model can be described by the following difference equation:

where

and

represent output and input of the controlled object, respectively.

is white noise sequence with zero mean.

is backward shift operator, that is

.

is difference operator, defined as

.

represents the present moment.

,

and

represent the orders of Equation (15)

The following Diophantine Equation (16) is considered.

The SISO prediction model, derived from Equations (14) and (16), is expressed as Equation (17). Reference [

44] has given out detailed derivation of SISO prediction model, and the recursion of the Diophantine Equation. In order to avoid repetition, the derivation of the SISO prediction model and the recursion of the matrices

G,

H and

F is not discussed in this article.

where

and

represent the minimum and maximum output horizons.

is the control horizon. At the present moment

k,

and

are the output and input in the future. Specifically,

is considered as the predicted output

at future time

calculated by the present and previous input and output.

and

are the output and input in the past, which were recorded.

4.1.3. GPC of MIMO System

As described in

Section 3, BFTE should be considered as a multi-input-multi-output (MIMO) system. Therefore, the MIMO CARIMA model is built and described as:

where

and

represent the numbers of inputs and outputs of the equalization system.

,

,

and

are the system parameters recognized by recursive least-squares discussed in

Section 4.3.

The GPC prediction model of MIMO system is an extension of SISO model. Based on the idea of the superposition principle, the derivation of MIMO prediction model is discussed in three steps.

Step 1: Under the assumption that only the input j changes and other inputs remain zero, the prediction model of output i is considered as:

Output

i represents the SoC of

Cell i. Noted that the predicted output

is independent from other outputs

(

) in the past. Therefore, the matrix

is considered as:

Considering Equation (22), the prediction model (21) can be simplified as:

Equation (23) describes the prediction model of input j and output i. By analogy with prediction model (17), the relationship can be considered as a SISO system as shown in Equation (24). For each pair of input and output combination, the form of SISO prediction model is adopted. Therefore, as discussed in

Section 4.1.2, the matrixes

,

,

can be solved.

Step 2: Under the assumption that all inputs change, and the superposition principle is considered. Output i can be described as:

where

Step 3: All inputs and outputs are considered. The prediction model can be expressed as:

where

is the predicted output.

is the future input.

and

are the past output and input, respectively. The elements

,

and

in matrixes

,

and

can be calculated separately from Equation (24) as a SISO model. Therefore, the prediction model is settled.

The prediction model (27) is used to generate a set of predicted output depend in part on future input which are to be determined.

4.1.4. Cost Function

The cost function, which is the optimization target of the balancing process, is calculated by the predicted output

and future input

of Equation (27), and is defined as:

where

In the consideration of the ultimate goal of SoC unification, the reference output is set to the average of current SoCs. and represent energy transfer loss ratio matrix and cell terminal voltage matrix, respectively. is the weighting sequence.

The physical significance of is maximizing the equalization speed at a lower cost of energy loss. Explicitly, the former and latter items of the cost function (30), which is weighted by , indicate the variance of SoCs from time to time , and the energy loss of equalization process from time to time , respectively.

Table 1 summarizes the major parameters adopted in GPC.

4.2. Constraints Management and Optimum Control Law Solution

The solution to the optimum control law under constraints is introduced. The optimum control law at the present time

k cannot be deduced directly because of the constrained inputs. Specifically, inputs of the equalization system are restricted by amplitude and interactions.

The optimization problem can be expressed as:

: The cost function described by Equation (30).

: The amplitude restriction of inputs.

: The mutual influence between the inputs. The maximum number () of equalizer sub-modules operating synchronously is limited for safety. is set to 4.

The optimization problem described by Equation (32) is a quadratic programming problem. There are plenty of methods to solve the quadratic problem with constraints, such as penalty function method, feasible direction method and active set method. However, they are competent to cope with , but not . This study employs the multi-population genetic algorithm (MPGA) to cope with optimization problems with both and . The competences of MPGA lie in two aspects. Firstly, the encoding of inputs solves automatically. Secondly, can be dealt with by introducing the Fatal Factor in the fitness function.

Fatal Factor is defined as:

where

NG is the generations of genetic algorithm.

The fitness function of MPGA is defined as:

Under the influence of the Fatal Factor , which is exponential function of the generations , the fitness function creates lower selective pressure in the initial stage of evolution. However, creates increasing pressure as the population evolves, eliminating those individuals out of constraints in the late stage of evolution. As a consequence, the optimization problem with is settled.

The basic steps of genetic algorithm can be sorted as encoding, crossover, mutation, selection, which will not be described in detail in this paper.

Table 2 and

Table 3 display the choices of methods and parameters.

4.3. Adaptive Control and Parameter Estimation

Since the parameters of CARIMA model (19) in previous discussion remain undetermined, this section introduces the estimation method of the system parameters. GPC has the characteristics of adaptive control. The idea of adaptive control in this study lies in two aspects. Firstly, the initial parameters of CARIMA model need to be estimated for the construction of the prediction model (27). Secondly, the parameters should be adjusted due to the inevitable model errors and environmental interference during the control process. This paper adopts recursive least-squares to estimate the parameters of CARIMA model.

The data vector

and parameter vector

are defined as:

The Equation (19) can be rewritten as:

Recursive least-squares (RLS) are used to estimate the parameter vector

.

where

is the estimation of data vector

.

The iteration initial values are set as:

4.4. Variable Step Size

This section proposes the variable step size generalized predictive control (VSSGPC) to improve the control effect of GPC.

The limitation of GPC is that it optimizes the overall control process by applying the optimum input of limited horizons, leading to a non-global optimization of the control process. The parameters , and can be increased to expand the control and output horizons and consequently better control effect of the whole equalization process can be obtained. However, due to the curse of dimensionality, the enlargement of horizons will result in an exponential growth of computation, increasing the real-time implementation difficulty.

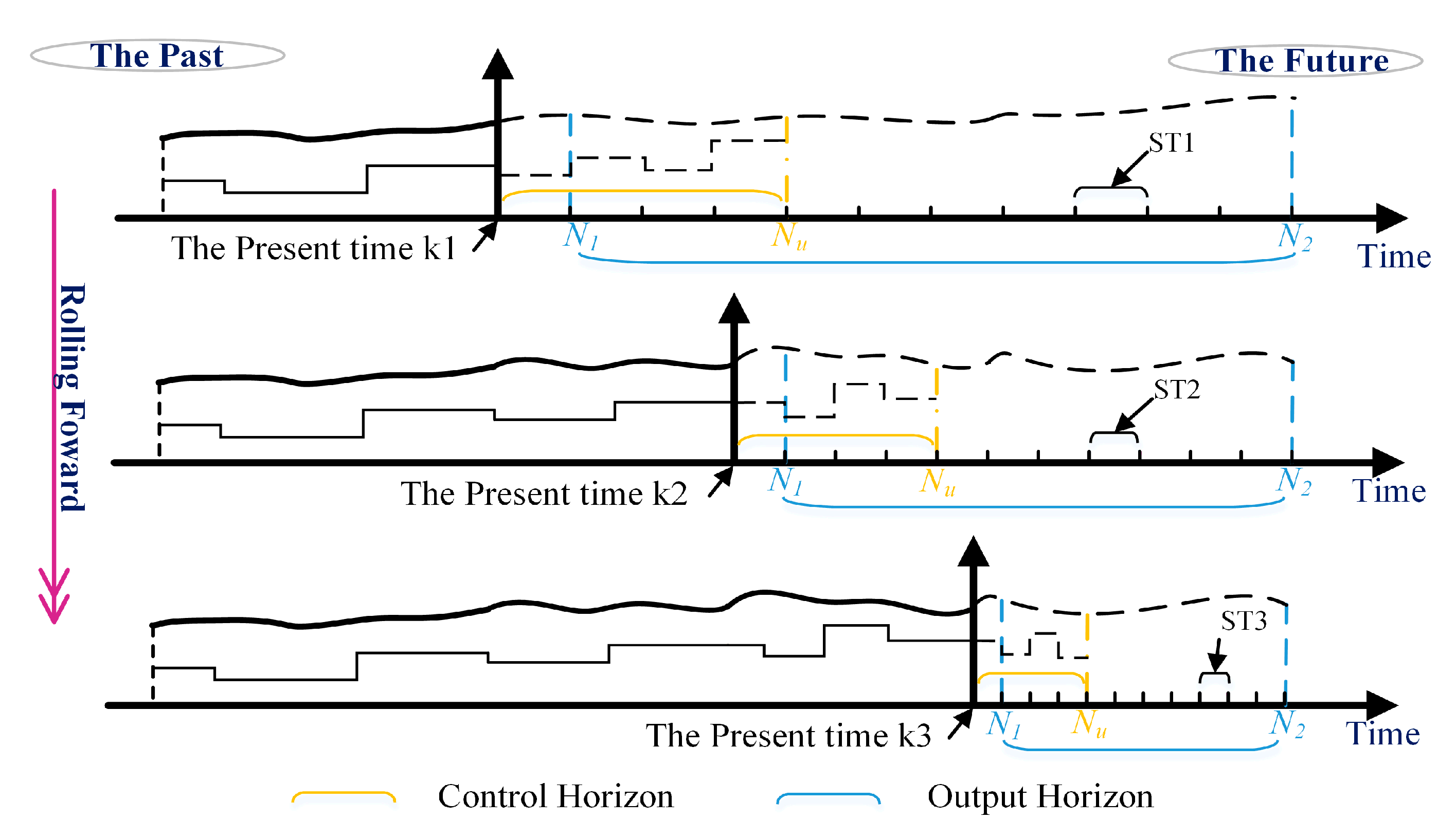

To solve the intractable dilemma of GPC, VSSGPC is proposed to enlarge the control and output horizons while maintaining a relatively low computation. The Step Size Factor

ST is introduced in GPC to adjust the steps of horizons. The schematic of VSSGPC is illustrated in

Figure 5. At the early stage of the control process (time k1), the step is enlarged by

ST. Consequently, the control and output horizons are stretched. As time moves forward (time k2, k3), the control and output horizons are adjusted.

The physical significance and rationality of

is discussed.

represents the expected terminal time. According to the definition of SoC (the output

),

can be calculated by the maximum deviation of outputs, typical capacity of cells

, and maximum channel balancing current

, as described by Equation (41).

represents the average step size of reaching

in

steps.

is introduced to the prediction model (27) and the Equation (29) is rewritten as:

where

Equation (42) indicates that the time domains of the past and future are extended backward and forwards, respectively. The predicted output can be stretched to the expected terminal time , resulting in the global optimization of the control process.

The cost function (30) is revised as:

where

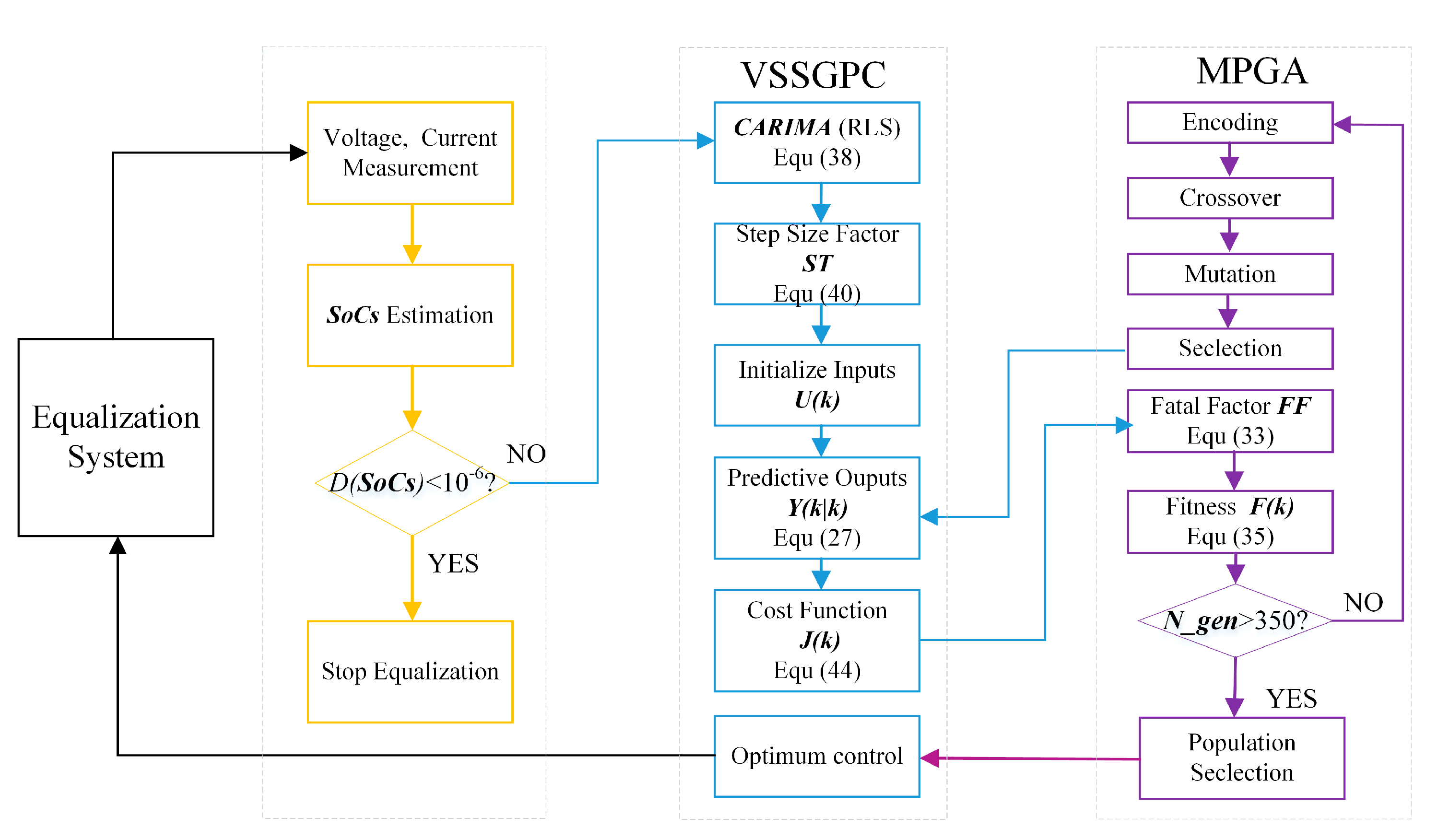

The flow chart of VSSGPC is shown in

Figure 6.