Numerical Modeling and Safety Design for Lithium-Ion Vehicle Battery Modules Subject to Crush Loading

Abstract

1. Introduction

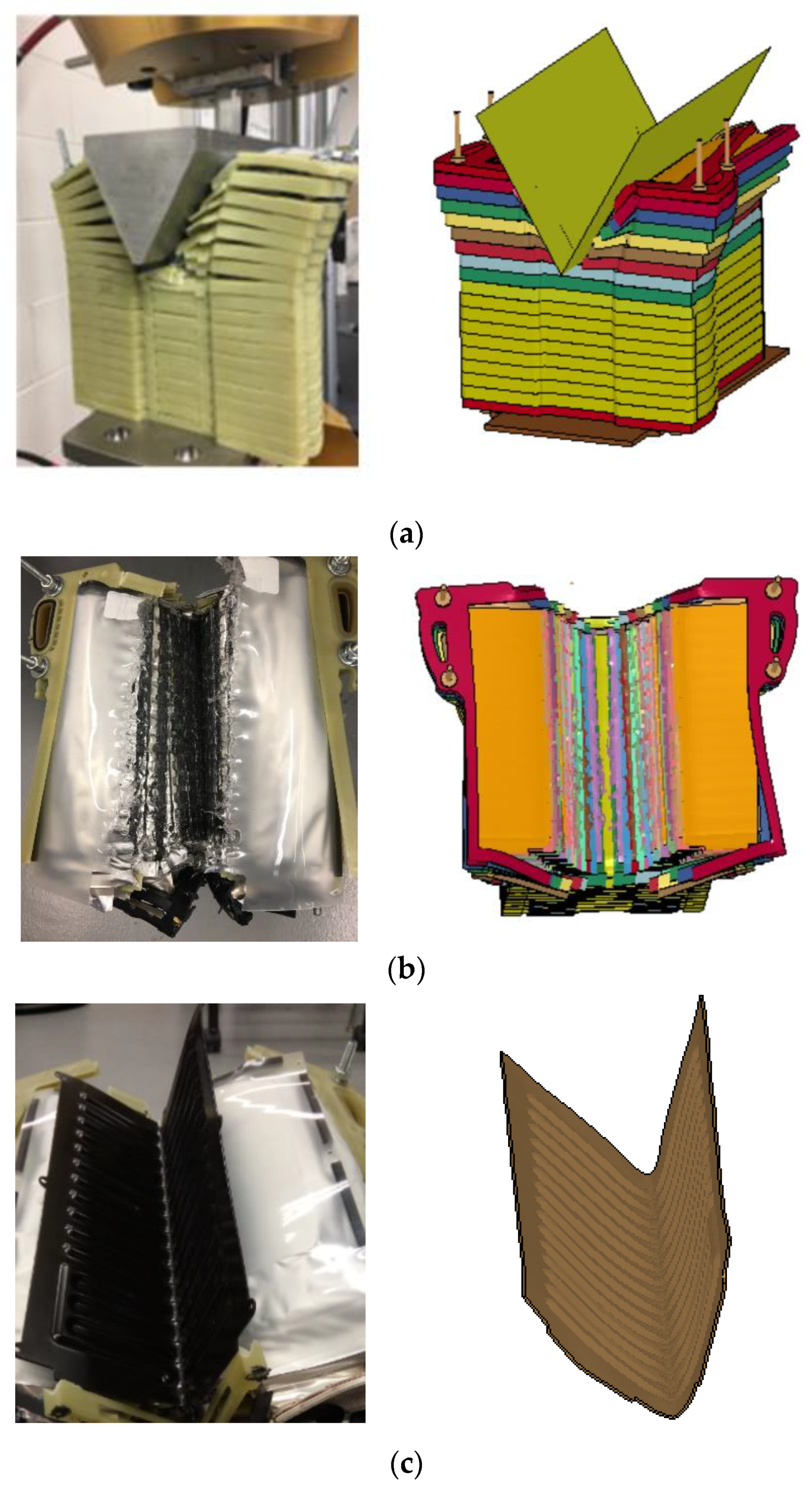

2. Battery Module and Wedge Indentation Tests

3. Numerical Model Development and Validation

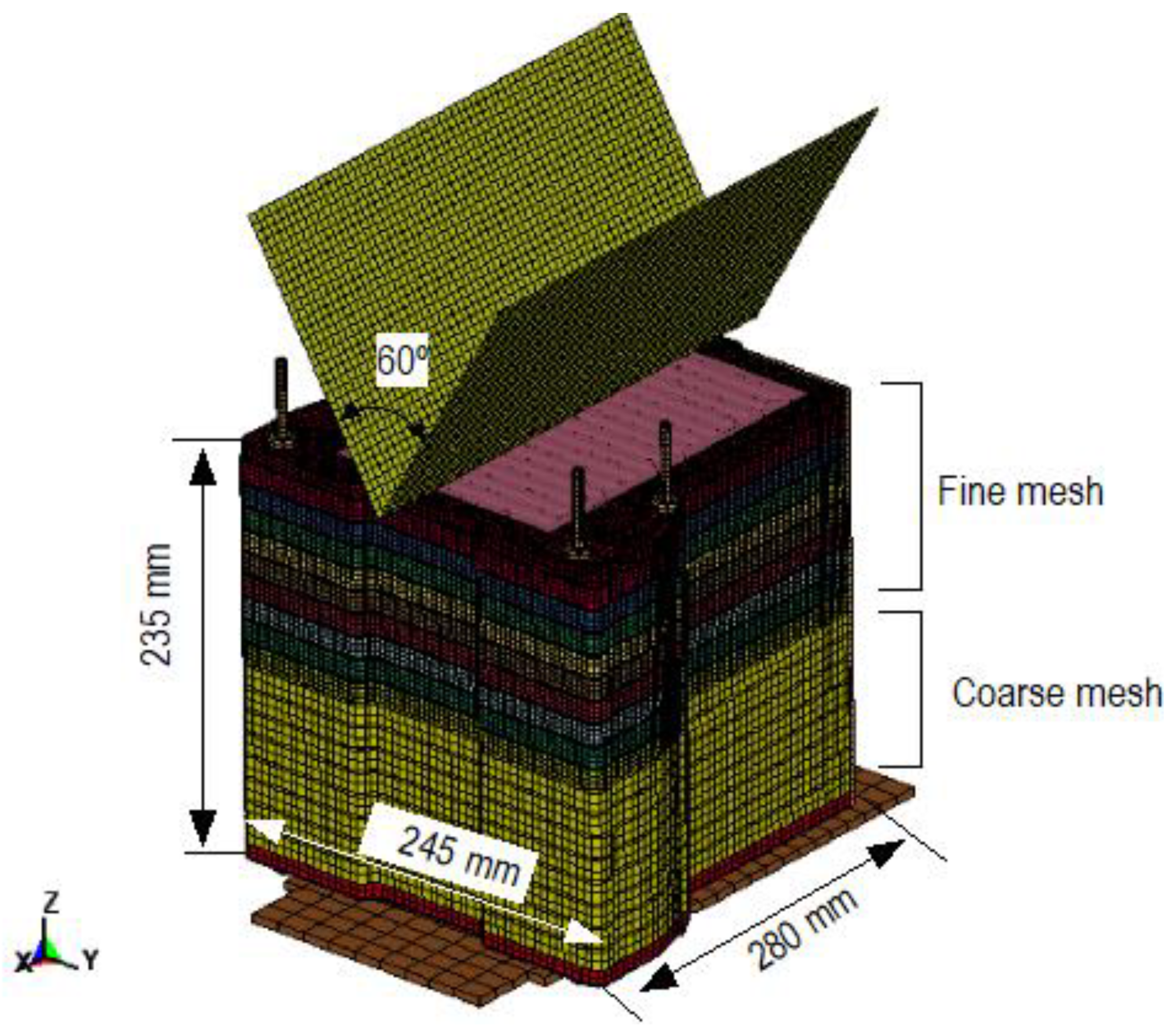

3.1. CAD Modeling and Mesh Development

3.2. Material Modeling

3.3. Model Validation

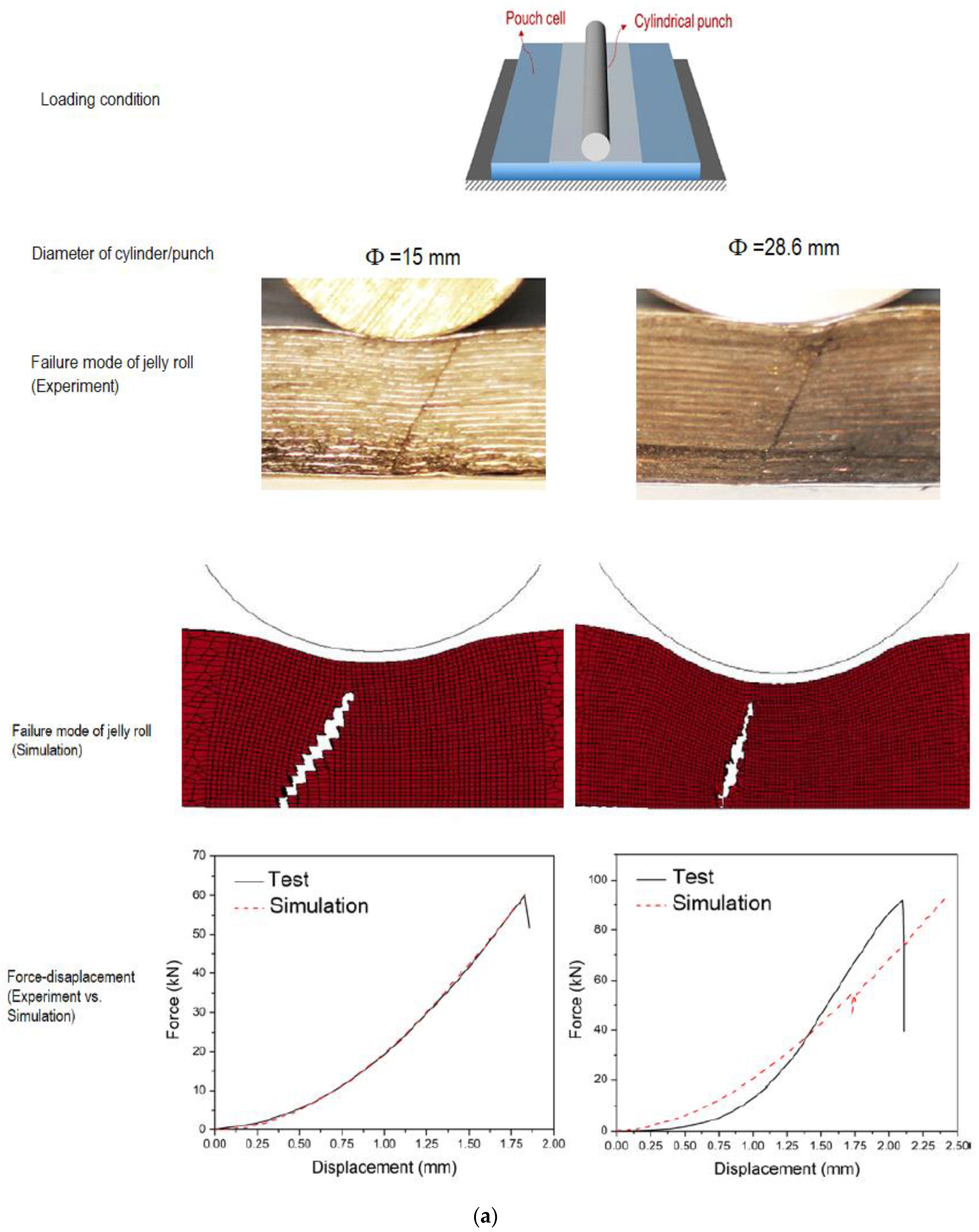

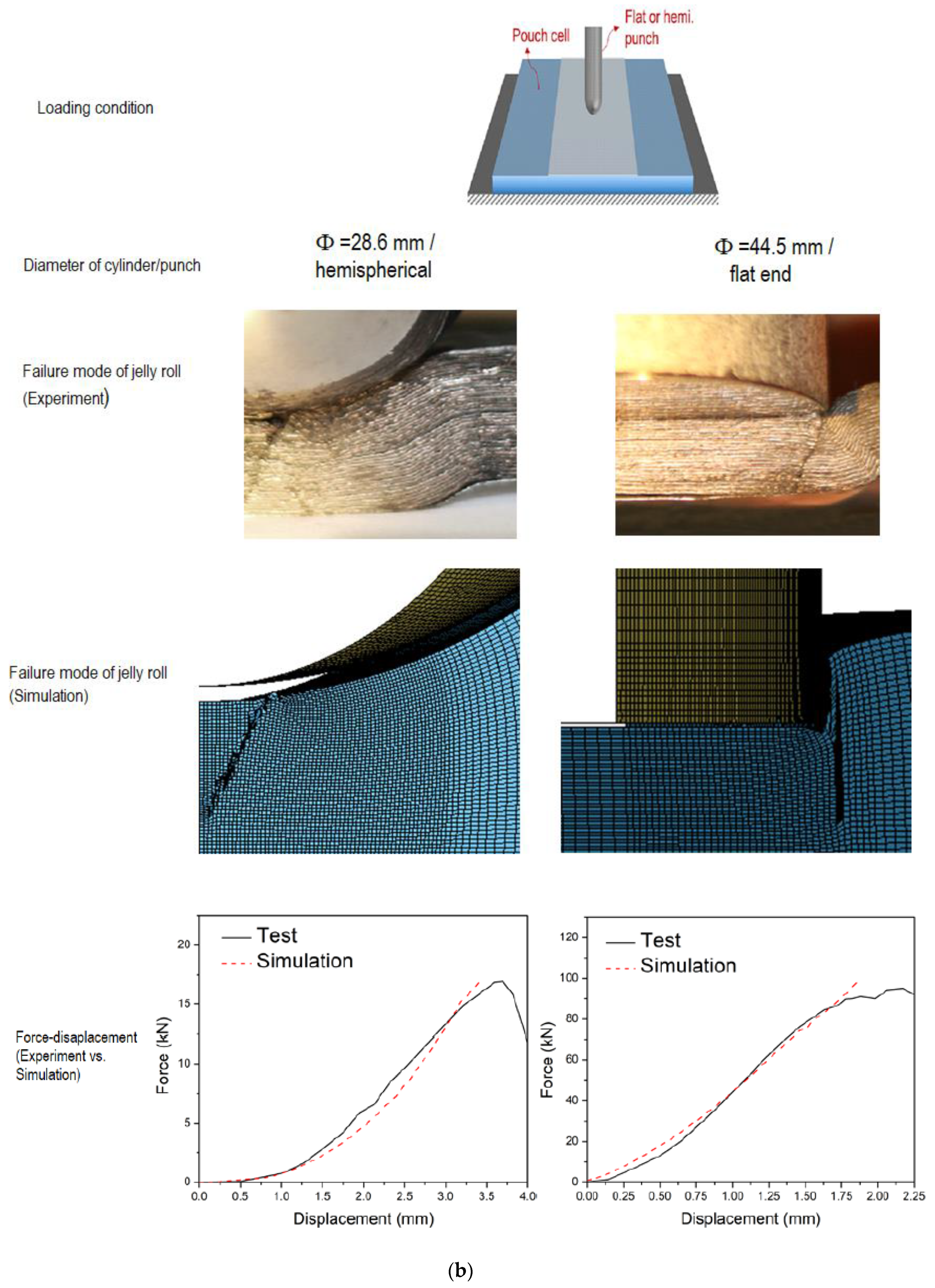

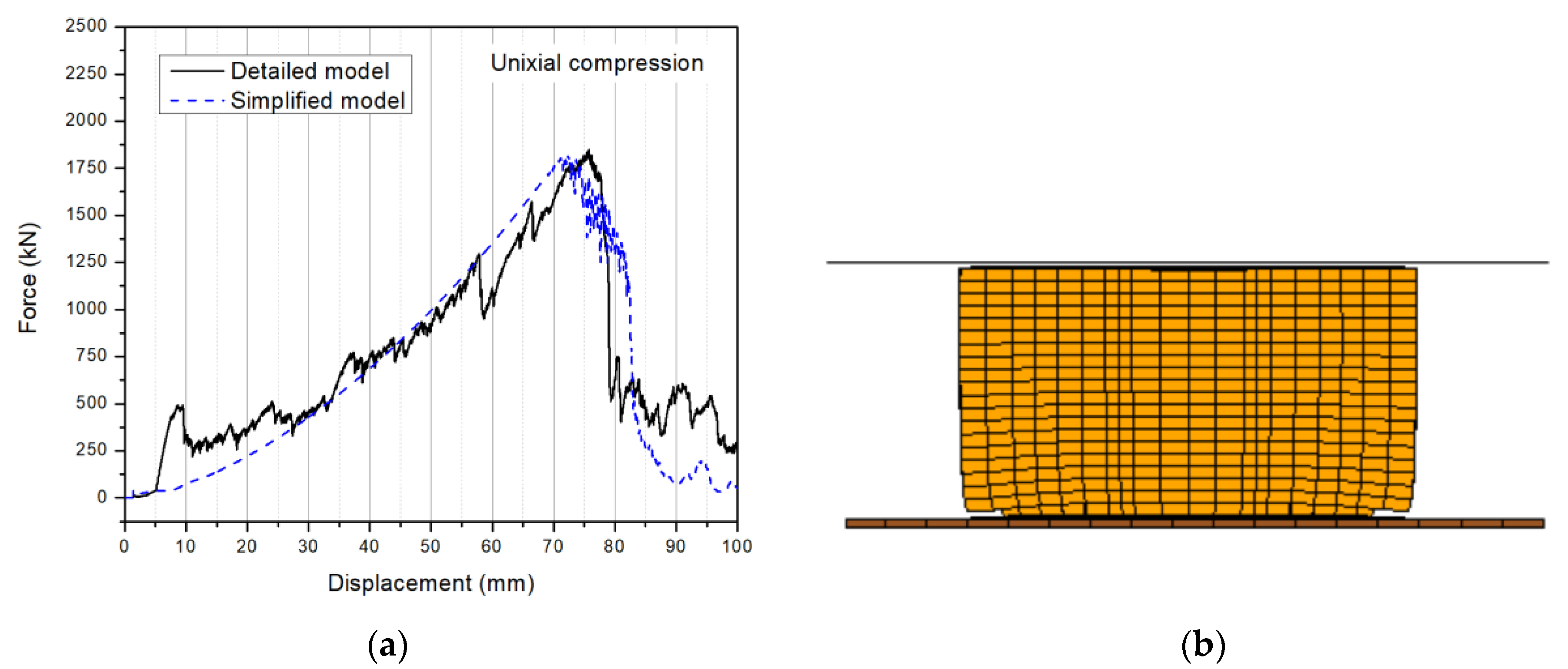

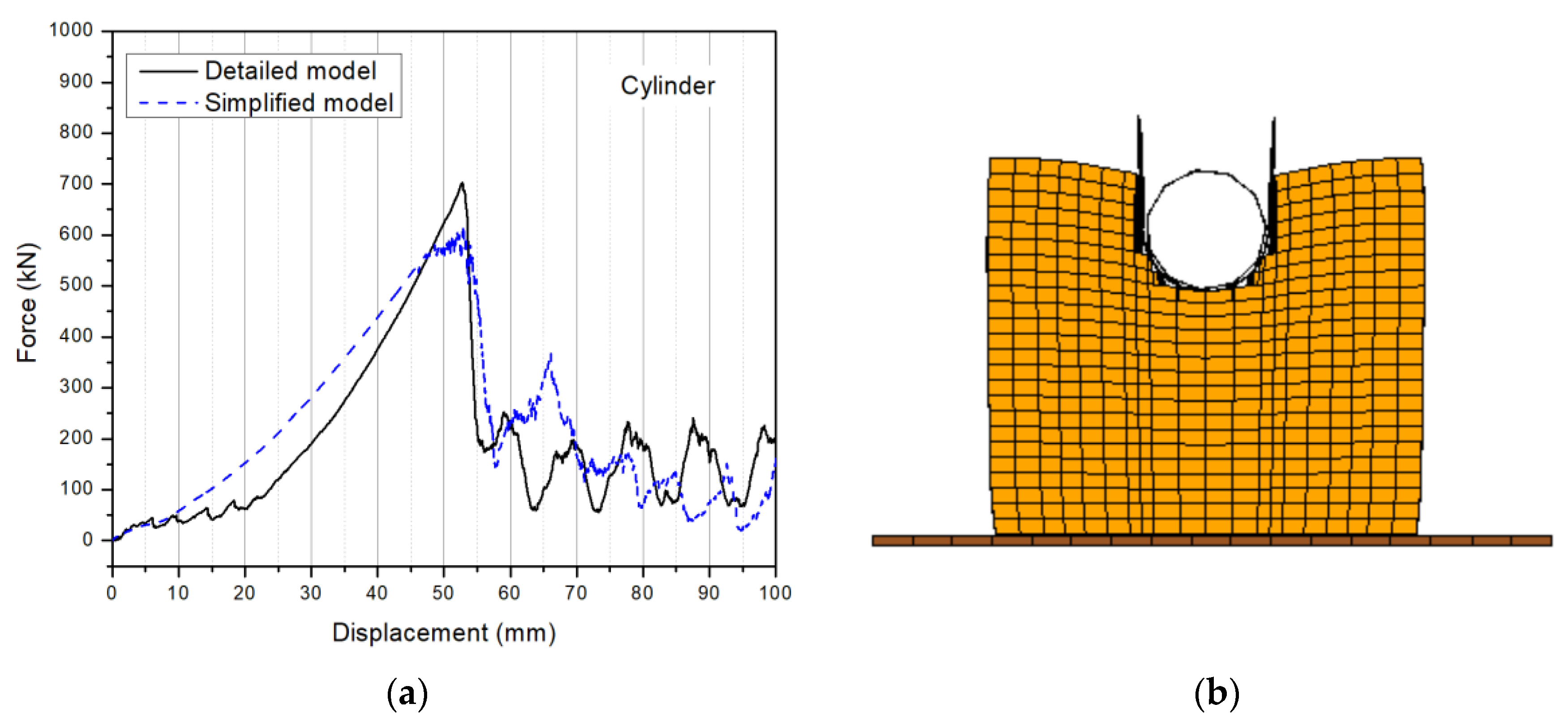

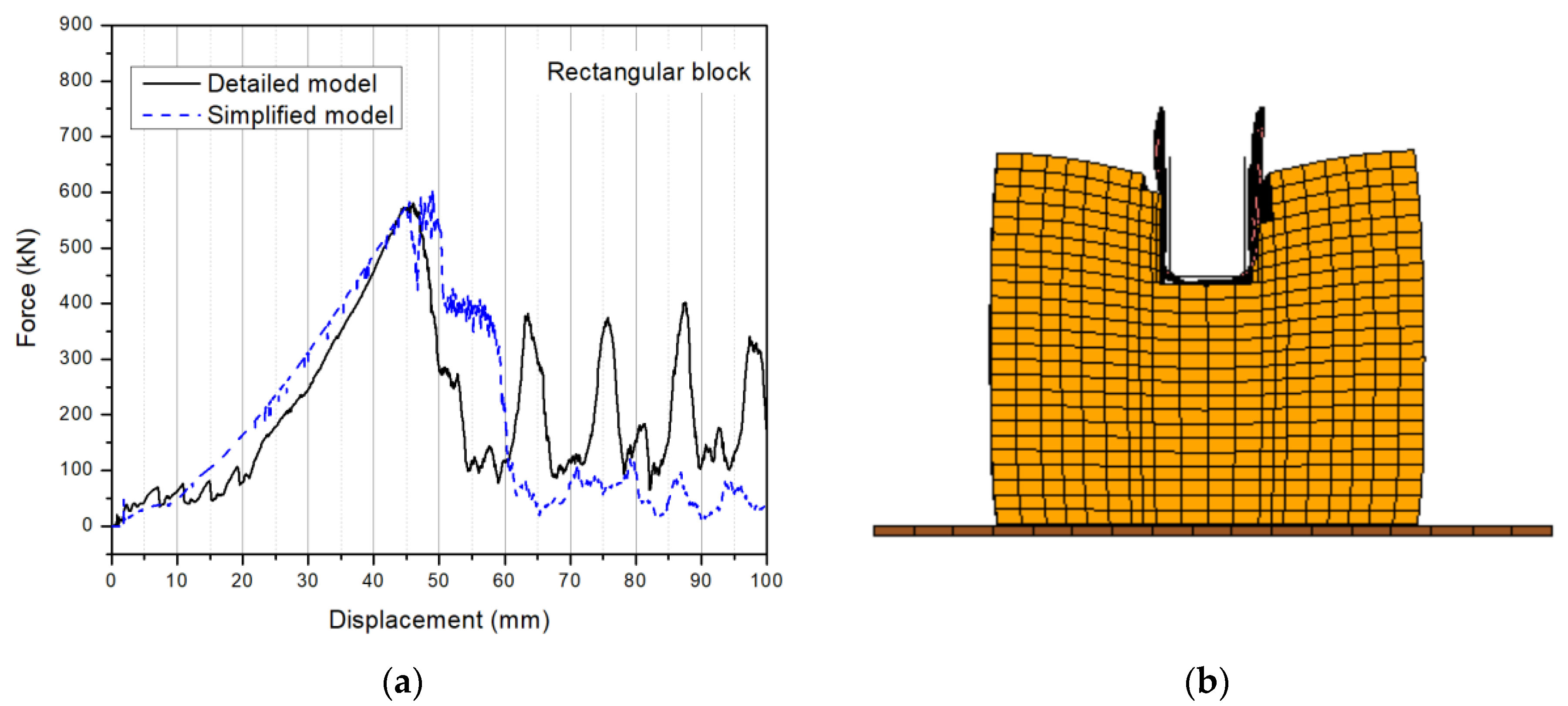

3.3.1. Cell level Validation

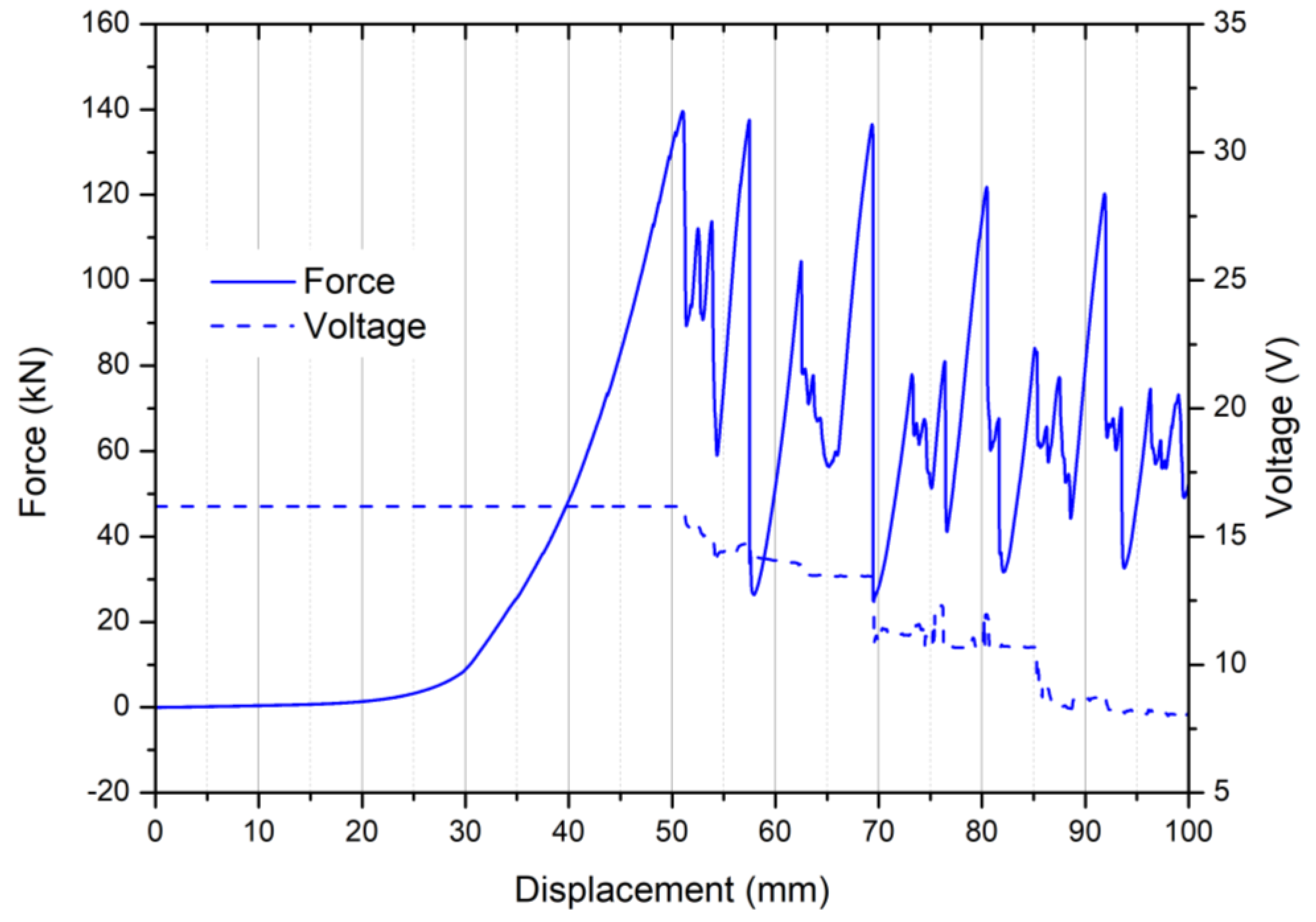

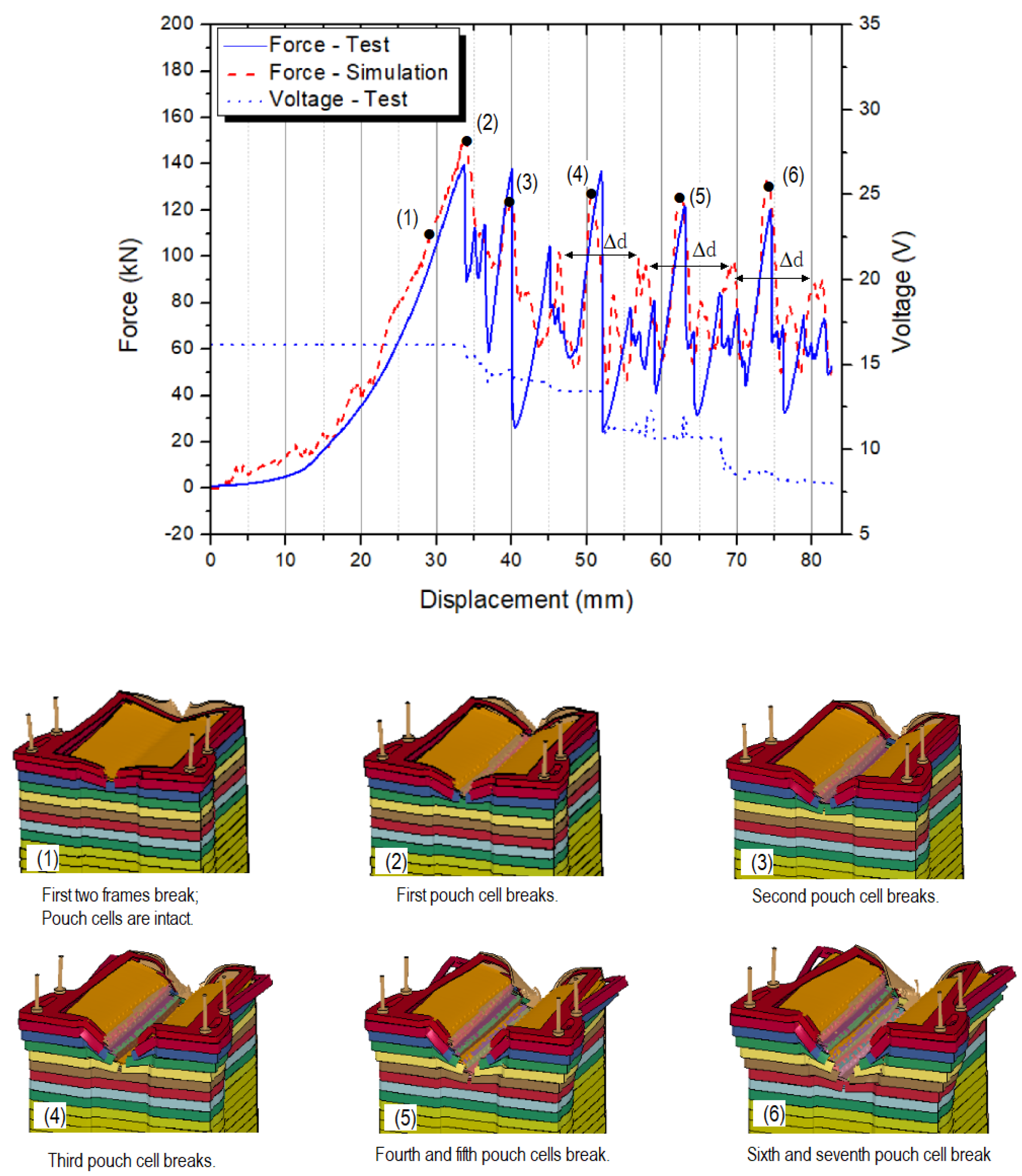

3.3.2. Module Level Validation

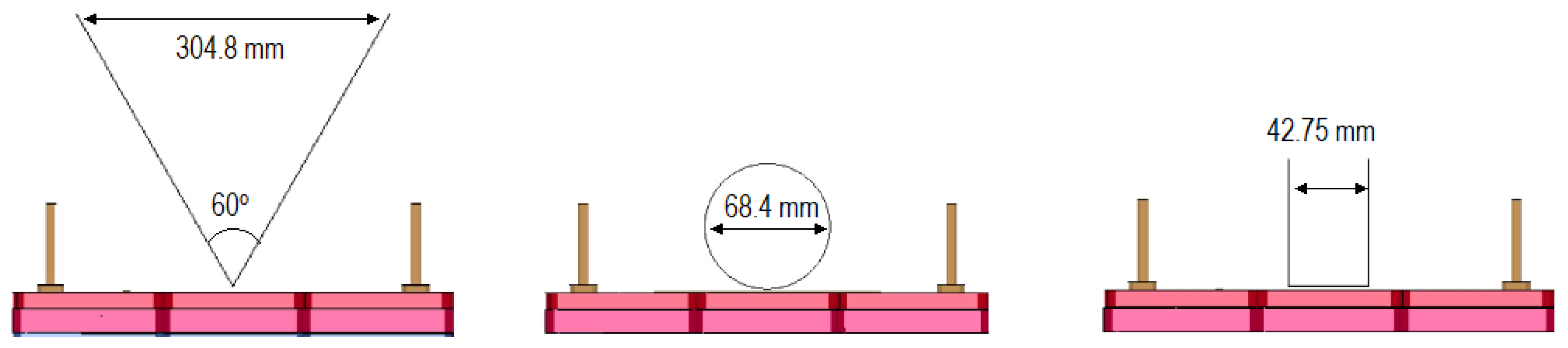

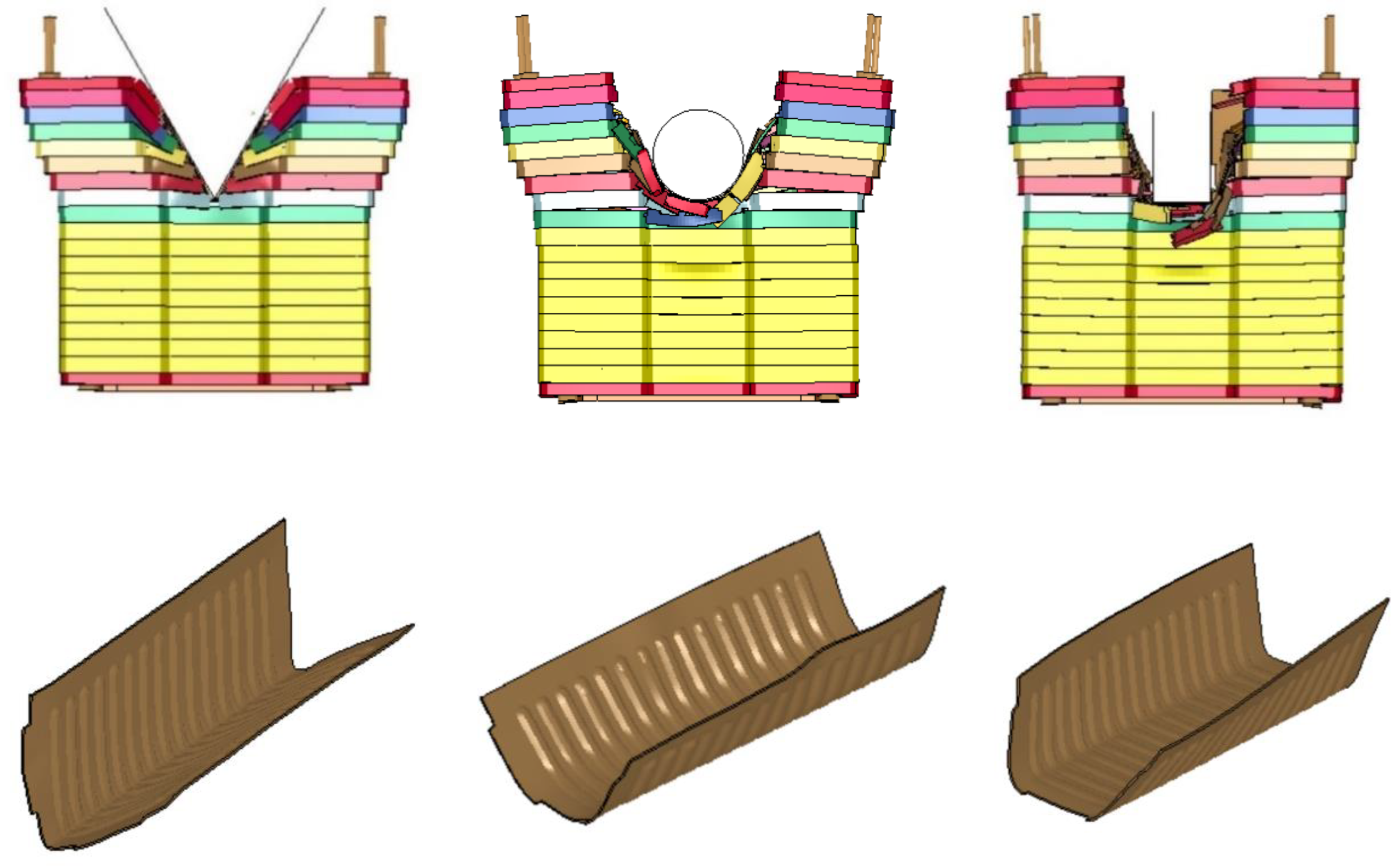

4. Model Application—Effect of Indenter Shape

4.1. Failure Modes and Force Response

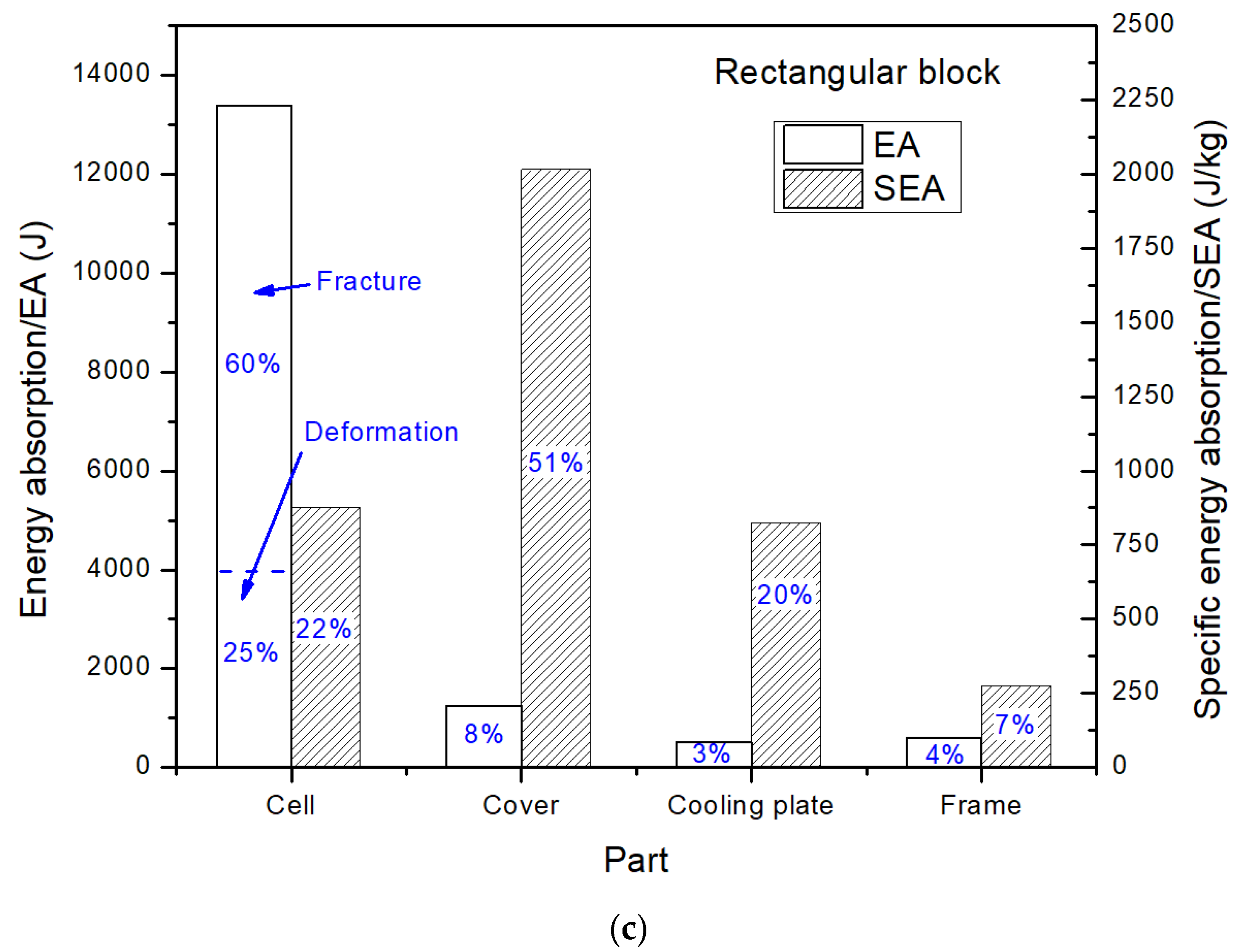

4.2. Energy Absorption

5. Safety Design Considerations for the Battery Module Components

5.1. Design Modification of Aluminum Cooling Plates

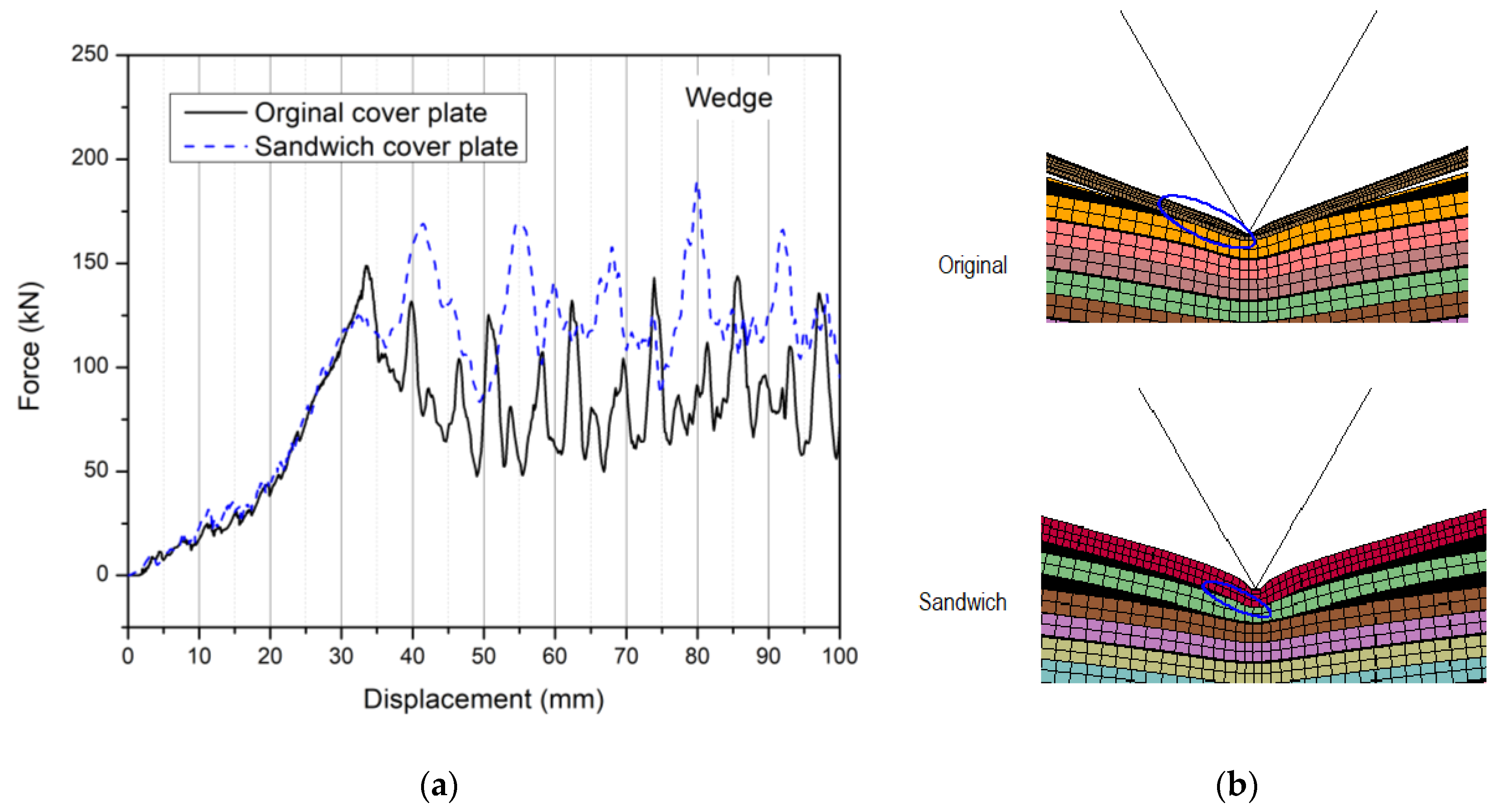

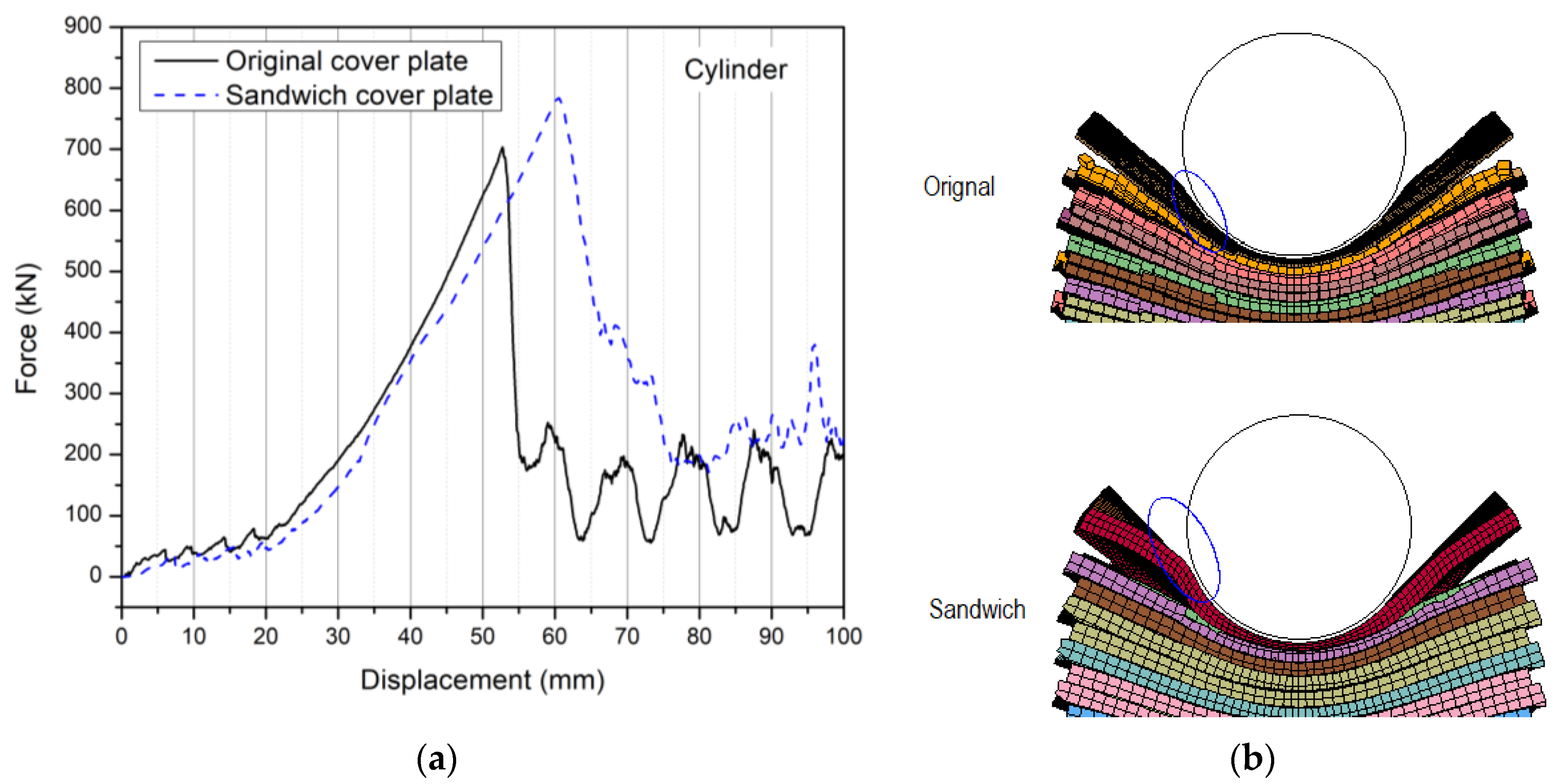

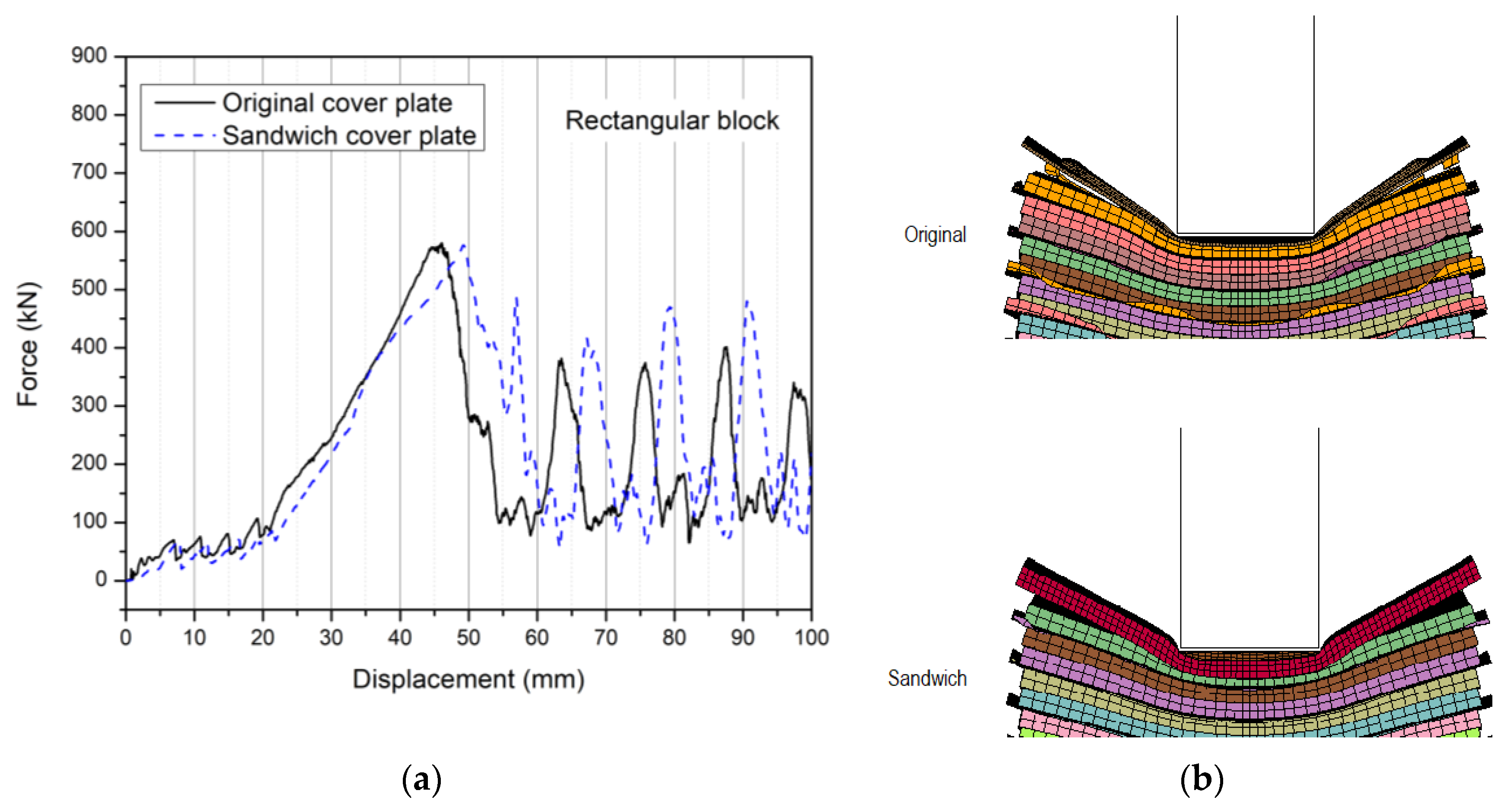

5.2. Design Modification of the Cover Plate

6. Module FE Model Simplification

7. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vehicles—Department of Energy: Energy.gov. Available online: energy.gov (accessed on 5 March 2014).

- Zhu, J.; Wierzbicki, T.; Li, W. A review of safety-focused mechanical modeling of commercial lithium-ion batteries. J. Power Sources 2018, 378, 153–168. [Google Scholar] [CrossRef]

- Deng, J.; Bae, C.; Marcicki, J.; Masias, A.; Miller, T. Safety modelling and testing of lithium-ion batteries in electrified vehicles. Nat. Energy 2018, 3, 261–266. [Google Scholar] [CrossRef]

- Kermani, G.; Sahraei, E. Review: Characterization and modeling of the mechanical properties of lithium-ion batteries. Energies 2017, 10, 1730. [Google Scholar] [CrossRef]

- Liu, B.; Jia, Y.; Yuan, C.; Wang, L.; Gao, X.; Yin, S.; Xu, J. Safety issues and mechanisms of lithium-ion battery cell upon mechanical abusive loading: A review. Energy Storage Mater. 2020, 24, 85–112. [Google Scholar] [CrossRef]

- Lai, W.J.; Ali, M.Y.; Pan, J. Mechanical behavior of representative volume elements of lithium-ion battery modules under various loading conditions. J. Power Sources 2014, 248, 789–808. [Google Scholar] [CrossRef]

- Kalnaus, S.; Wang, H.; Watkins, T.R.; Kumar, A.; Simunovic, S.; Turner, J.A.; Gorney, P. Effect of package and cooling plates on mechanical response and failure characteristics of Automotive Li-ion battery modules. J. Power Sources 2018, 403, 20–26. [Google Scholar] [CrossRef]

- Xia, Y.; Wierzbicki, T.; Sahraei, E.; Zhang, X. Damage of cells and battery packs due to ground impact. J. Power Sources 2014, 267, 78–97. [Google Scholar] [CrossRef]

- Xia, Y.; Chen, G.; Zhou, Q.; Shi, X.; Shi, F. Failure behavior of 100% SOC lithium-ion battery modules under different impact loading conditions. Eng. Fail. Anal. 2017, 82, 149–160. [Google Scholar] [CrossRef]

- Chen, G.; Li, W.; Luo, H.; Xia, Y. Influence of mechanical interaction between lithium-ion pouch cells in a simplified battery module under impact loading. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition (IMECE 2017), Tampa, FL, USA, 3–9 November 2017. [Google Scholar]

- Shi, Z.; Chen, G.; Zhu, L.; Li, J.; Xia, Y. Sandwich structure design of a cooling fin for battery modules against impact loads. Automot. Innov. 2020, 3, 260–269. [Google Scholar] [CrossRef]

- Zhu, F.; Du, X.; Lei, J.; Audisio, L.; Sypeck, D. Experimental study on the crushing behavior of lithium-ion battery modules. Int. J. Crashworthiness 2020. [Google Scholar] [CrossRef]

- Sahraei, E.; Meier, J.; Wierzbicki, T. Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells. J. Power Sources 2014, 247, 503–516. [Google Scholar] [CrossRef]

- Sahraei, E.; Kahn, M.; Meier, J.; Tomasz, W. Modelling of cracks developed in lithium-ion cells under mechanical loading. RSC Adv. 2015, 5, 80369–80380. [Google Scholar] [CrossRef]

- Wang, H.; Kumar, A.; Simunovic, S.; Allu, S.; Kalnaus, S.; Turner, J.A.; Helmers, J.C.; Rules, E.T.; Winchester, C.S.; Gorney, P. Progressive mechanical indentation of large-format Li-ion cells. J. Power Sources 2017, 341, 156–164. [Google Scholar] [CrossRef]

- Sahraei, E.; Campbell, J.; Wierzbicki, T. Modeling and short circuit detection of 18650 Li-ion cells under mechanical abuse conditions. J. Power Sources 2012, 220, 360–372. [Google Scholar] [CrossRef]

- LS-DYNA Keyword User’s Manual, Volume II: Materials Models; Livermore Software Technology Corp.: Livermore, CA, USA, 2018.

- Zhu, F.; Du, X.; Lei, J.; Audisio, L.; Sypeck, J. Numerical Modeling of Lithium-Ion Battery Cells and Modules Subjected to Low Speed Indentation; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Chung, S.H.; Tancogne-Dejean, T.; Zhu, J.; Luo, H.; Wierzbicki, T. Failure in lithium-ion batteries under transverse indentation loading. J. Power Sources 2018, 389, 148–159. [Google Scholar] [CrossRef]

- Zhang, J.; Ashby, M.F. The out-of-plane properties of honeycombs. Int. J. Mech. Sci. 1992, 34, 475–489. [Google Scholar] [CrossRef]

- Cote, F.; Deshpande, V.S.; Fleck, N.A.; Evans, A.G. The out-of-plane compressive behavior of metallic honeycombs. Mater. Sci. Eng. A 2004, 380, 272–280. [Google Scholar] [CrossRef]

- Sypeck, D.J. Highly Vented Truss Wall Honeycomb Structures. U.S. Patent 9,845,600 B2, 19 December 2017. [Google Scholar]

| Component | Mass (kg) | Element Type | Element Size (mm) | Number of Elements | Material Law |

|---|---|---|---|---|---|

| Pouch cell | 15.25 | Hex (Solid) | 2~9 | 98,162 | MAT-63 |

| Steel cover plate | 0.62 | Hex and Penta (Solid) | 0.45~5.4 | 41,892 | MAT-24 |

| Plastic frame | 2.18 | Hex (Solid) | 0.9~10 | 93,320 | |

| Aluminum cooling plate | 0.62 | Quad (Shell) | 2~9.8 | 35,316 | |

| Steel rods and screws | 0.21 | Hex (Solid) | 1~5.6 | 5632 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, F.; Zhou, R.; Sypeck, D.J. Numerical Modeling and Safety Design for Lithium-Ion Vehicle Battery Modules Subject to Crush Loading. Energies 2021, 14, 118. https://doi.org/10.3390/en14010118

Zhu F, Zhou R, Sypeck DJ. Numerical Modeling and Safety Design for Lithium-Ion Vehicle Battery Modules Subject to Crush Loading. Energies. 2021; 14(1):118. https://doi.org/10.3390/en14010118

Chicago/Turabian StyleZhu, Feng, Runzhou Zhou, and David J. Sypeck. 2021. "Numerical Modeling and Safety Design for Lithium-Ion Vehicle Battery Modules Subject to Crush Loading" Energies 14, no. 1: 118. https://doi.org/10.3390/en14010118

APA StyleZhu, F., Zhou, R., & Sypeck, D. J. (2021). Numerical Modeling and Safety Design for Lithium-Ion Vehicle Battery Modules Subject to Crush Loading. Energies, 14(1), 118. https://doi.org/10.3390/en14010118