The Effect of Tab Attachment Positions and Cell Aspect Ratio on Temperature Difference in Large-Format LIBs Using Design of Experiments

Abstract

:1. Introduction

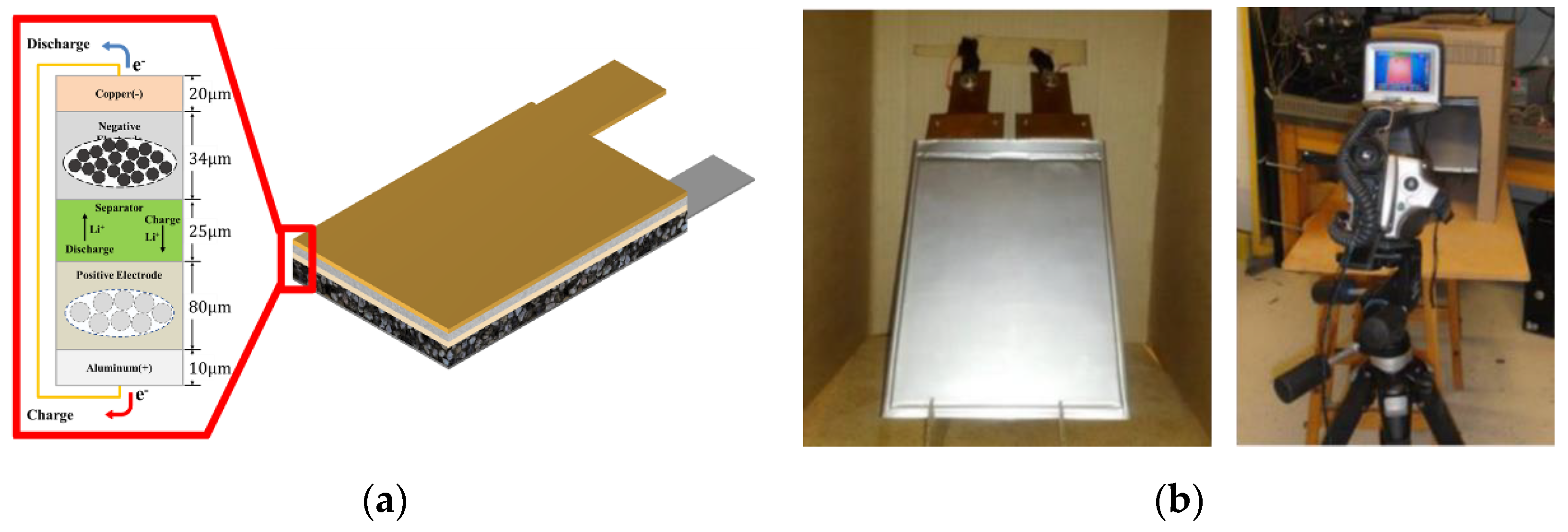

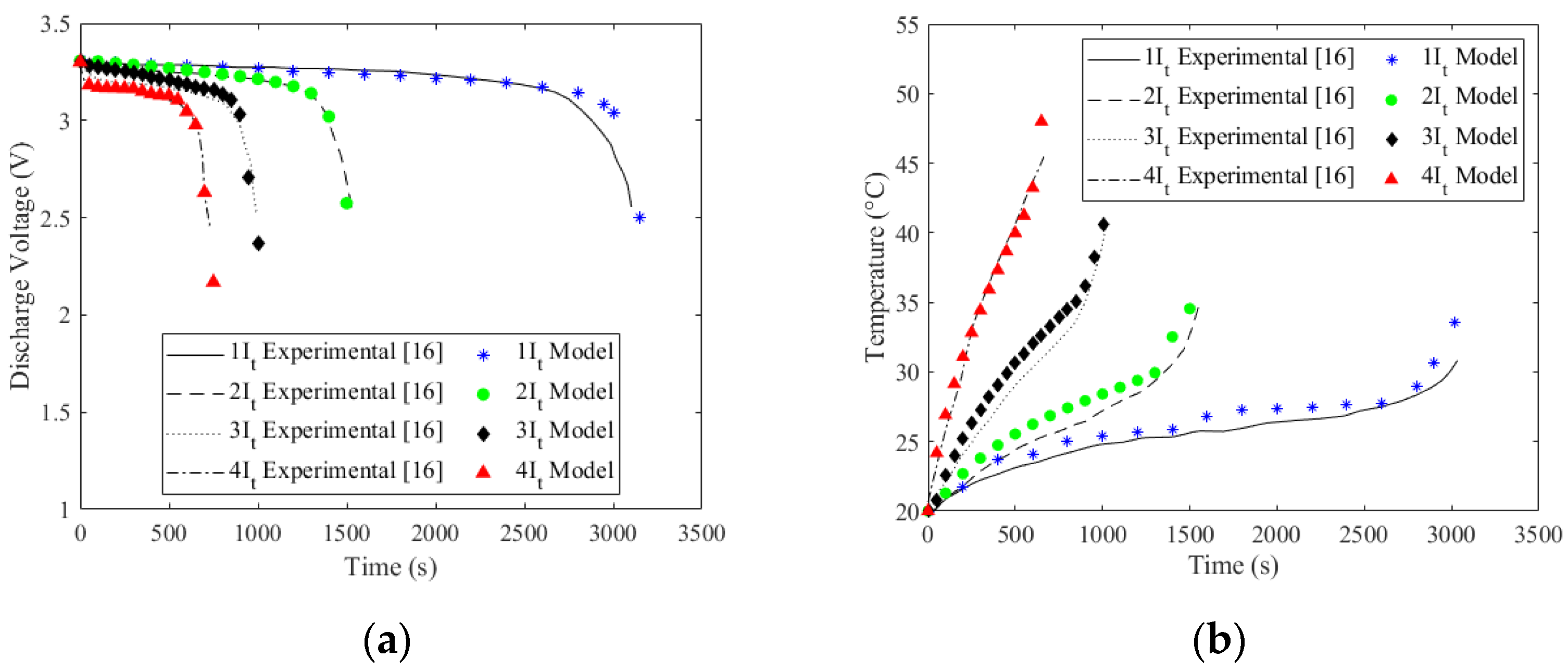

2. Three-Dimensional Electrochemical–Thermal Coupled Model of the 45-Ah LFP/Graphite Cell

3. Analyzing the Effect of Each Design Factor on Temperature Distribution by Applying the Design of Experiments

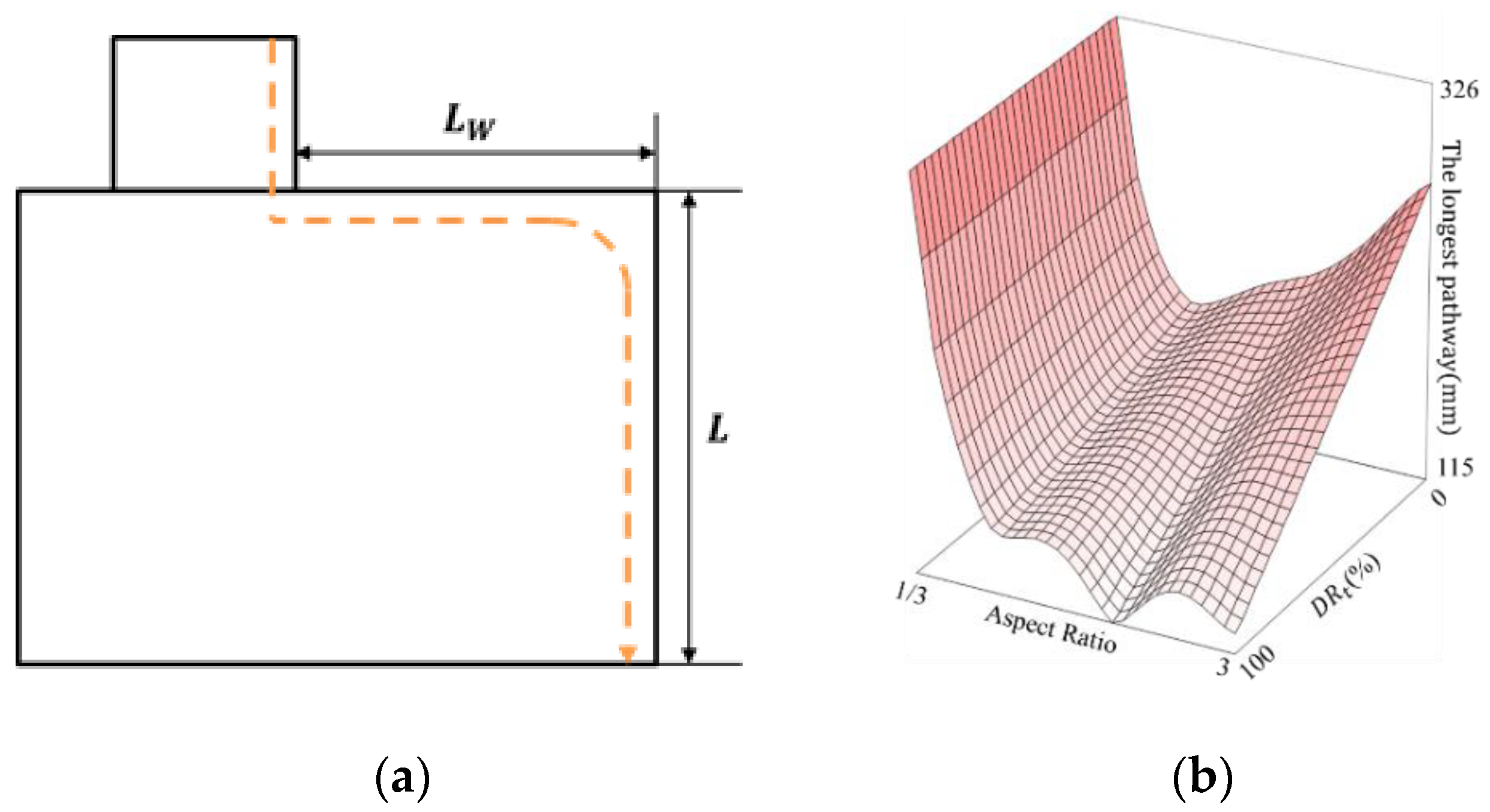

3.1. Design Factors and Responses

3.2. Design of Experiments Methodology

4. Results and Discussion

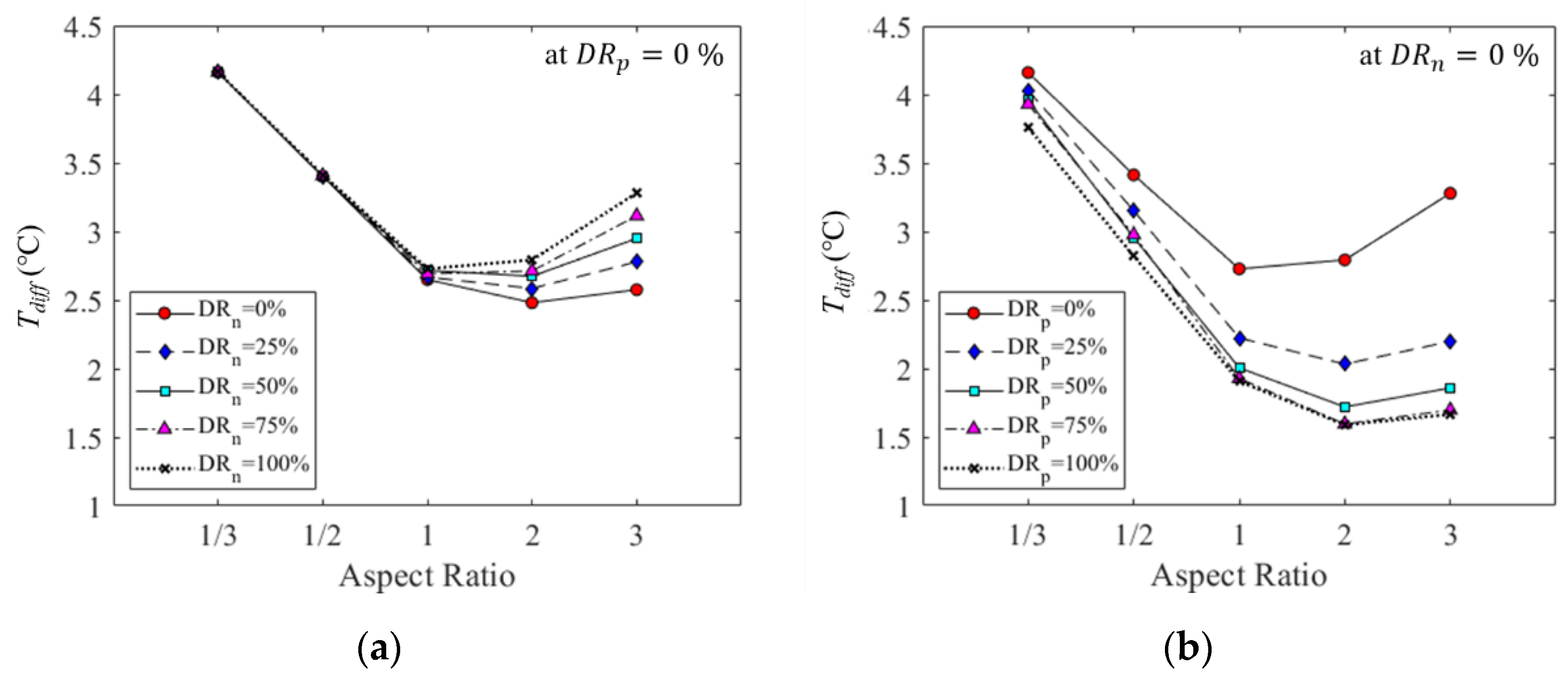

4.1. Effect of Cell Aspect Ratio and Tab Attachment Positions on the Temperature Distribution in LIB Cell

4.2. Analysis of Variance

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ion number | |

| charge coefficient | |

| Li concentration (mol/m3) | |

| diffusivity (m2/s) | |

| distance ratio of the total distance to the negative tab location | |

| distance ratio of the total distance to the positive tab location | |

| distance between the right edge of the negative tab and the nearest edge of the LIB cell | |

| distance between the right edge of the positive tab and the nearest edge of the LIB cell | |

| average molar activity coefficient | |

| F | Faraday’s constant, 96487 (C/mol) |

| current density (A/m2) | |

| local current density (A/m2) | |

| k | electronic conductivity (S/m) |

| L | Length of the LIB cell (mm) |

| Li+ flux (mol/m2s1) | |

| gas constant, 8.314 (J/(mol K)) | |

| radial distance from the center of the electrode active particle (μm) | |

| absolute temperature (K) | |

| thickness (m) | |

| transport number of Li+ | |

| W | Width of the LIB cell (mm) |

| porosity | |

| local surface overpotential (V) | |

| electrical potential (V) | |

| Subscripts and superscripts | |

| 1 | solid phase |

| 2 | liquid phase |

| app | applied |

| eff | effective value |

| el | electrolyte |

| init | initial value |

| n | negative electrode |

| p | positive electrode |

| s | separator |

References

- Scrosati, B.; Garche, J. Lithium batteries: Status, prospects and future. J. Power Sources 2010, 195, 2419–2430. [Google Scholar] [CrossRef]

- Curry, C. Lithium-Ion Battery Costs and Market, Bloomberg New Energy Finance 2017. Available online: https://data.bloomberglp.com/bnef/sites/14/2017/07/BNEF-Lithium-ion-battery-costs-and-market.pdf (accessed on 17 December 2020).

- Pillot, C. Lithium Ion Battery Raw Material Supply & Demand 2016–2025. Avicenne Energy. Available online: http://cii-resource.com/cet/AABE-03-17/Presentations/BRMT/Pillot_Christophe.pdf (accessed on 17 December 2020).

- EEI, Electric Vehicle Sales: Facts & Figures. Available online: https://www.eei.org/issuesandpolicy/electrictransportation/Documents/FINAL_EV_Sales_Update_April2019.pdf (accessed on 17 December 2020).

- Veth, C.; Dragicevic, D.; Merten, C. Thermal characterizations of a large-format lithium ion cell focused on high current discharges. J. Power Sources 2014, 267, 760–769. [Google Scholar] [CrossRef]

- Song, W.; Chen, M.; Bai, F.; Lin, S.; Chen, Y.; Feng, Z. Non-uniform effect on the thermal/aging performance of Lithium-ion pouch battery. Appl. Therm. Eng. 2018, 128, 1165–1174. [Google Scholar] [CrossRef]

- Kim, H.-K.; Kim, C.-J.; Kim, C.-W.; Lee, K.-J. Numerical analysis of accelerated degradation in large lithium-ion batteries. Comput. Chem. Eng. 2018, 112, 82–91. [Google Scholar] [CrossRef]

- Doyle, M.; Fuller, T.F.; Newman, J.S. Modeling of Galvanostatic Charge and Discharge of the Lithium/Polymer/Insertion Cell. J. Electrochem. Soc. 1993, 140, 1526–1533. [Google Scholar] [CrossRef]

- Rao, L.; Newman, J. Heat-Generation Rate and General Energy Balance for Insertion Battery Systems. J. Electrochem. Soc. 1997, 144, 2697–2704. [Google Scholar] [CrossRef]

- Gerver, R.E. 3D Thermal-Electrochemical Lithium-Ion Battery Computational Modeling. Master’s Thesis, The University of Texas at Austin, Austin, TX, USA, 2009. [Google Scholar]

- Kim, G.-H.; Smith, K.; Lee, K.-J.; Santhanagopalan, S.; Pesaran, A.A. Multi-Domain Modeling of Lithium-Ion Batteries Encompassing Multi-Physics in Varied Length Scales. J. Electrochem. Soc. 2011, 158, A955–A969. [Google Scholar] [CrossRef]

- Du, S.; Jia, M.; Cheng, Y.; Tang, Y.; Zhang, H.; Ai, L.; Zhang, K.; Lai, Y. Study on the thermal behaviors of power lithium iron phosphate (LFP) aluminum-laminated battery with different tab configurations. Int. J. Therm. Sci. 2015, 89, 327–336. [Google Scholar] [CrossRef]

- Kosch, S.; Rheinfeld, A.; Erhard, S.V.; Jossen, A. An extended polarization model to study the influence of current collector geometry of large-format lithium-ion pouch cells. J. Power Sources 2017, 342, 666–676. [Google Scholar] [CrossRef]

- Lee, D.-C.; Lee, J.-J.; Kim, J.-S.; Cho, S.; Kim, C.-W. Thermal behaviors analysis of 55 Ah large-format lithium-ion pouch cells with different cell aspect ratios, tab locations, and C-rates. Appl. Therm. Eng. 2020, 175, 115422. [Google Scholar] [CrossRef]

- Zhao, W.; Luo, G.; Wang, C.-Y. Effect of tab design on large-format Li-ion cell performance. J. Power Sources 2014, 257, 70–79. [Google Scholar] [CrossRef]

- Samba, A.; Omar, N.; Gualous, H.; Capron, O.; Bossche, P.V.D.; Van Mierlo, J. Impact of Tab Location on Large Format Lithium-Ion Pouch Cell Based on Fully Coupled Tree-Dimensional Electrochemical-Thermal Modeling. Electrochim. Acta 2014, 147, 319–329. [Google Scholar] [CrossRef]

- Lee, J.-J.; Kim, J.-S.; Lee, D.-C.; Chang, H.; Kim, C.-W. Design optimization of tab attachment positions and cell aspect ratio to minimize temperature difference in 45-Ah LFP large-format Lithium-ion pouch cells. Appl. Therm. Eng. 2020, 182, 116143. [Google Scholar] [CrossRef]

- Panchal, S.; Mathewson, S.; Fraser, R.; Culham, R.; Fowler, M. Measurement of Temperature Gradient (dT/dy) and Temperature Response (dT/dt) of a Prismatic Lithium-Ion Pouch Cell with LiFePO4 Cathode Material. SAE Tech. Pap. Ser. 2017. [Google Scholar] [CrossRef]

- COMSOL Multiphysics 3.3. Available online: http://www.comsol.com (accessed on 11 January 2012).

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

| Name | Value |

|---|---|

| Aspect ratio | 0.65 |

| Area (mm2) | 34,500 |

| (mm) | 70 |

| (mm) | 30 |

| Positive tab width (mm) | 40 |

| Negative tab width (mm) | 50 |

| Tab length (mm) | 75 |

| Nominal capacity (Ah) | 0.58 |

| Nominal voltage (V) | 3.2 |

| Cut-off voltage (V) | 2 |

| Design Factors | Cell Aspect Ratio | ||

|---|---|---|---|

| Lower bound | 1/3 | 0 | 0 |

| Upper bound | 3 | 100 | 100 |

| Design Factors | Cell Aspect Ratio | ||

|---|---|---|---|

| Level 1 | 1/3 | 0 | 0 |

| Level 2 | 1/2 | 25 | 25 |

| Level 3 | 1 | 50 | 50 |

| Level 4 | 2 | 75 | 75 |

| Level 5 | 3 | 100 | 100 |

| Design Factors | Sum of Squares | DOF | Mean Square | % Contribution | F-Value | p-Value ※ |

|---|---|---|---|---|---|---|

| Cell Aspect Ratio | 91.7 | 4.0 | 22.93 | 86.84 | 534.92 | << 0.001 |

| (%) | 0.6 | 4.0 | 0.15 | 0.57 | 3.5 | |

| (%) | 13.3 | 4.0 | 3.33 | 12.59 | 77.58 | << 0.001 |

| Error | 4.8 | 112.0 | 0.04 | 0.16 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-J.; Kim, J.-S.; Chang, H.-K.; Lee, D.-C.; Kim, C.-W. The Effect of Tab Attachment Positions and Cell Aspect Ratio on Temperature Difference in Large-Format LIBs Using Design of Experiments. Energies 2021, 14, 116. https://doi.org/10.3390/en14010116

Lee J-J, Kim J-S, Chang H-K, Lee D-C, Kim C-W. The Effect of Tab Attachment Positions and Cell Aspect Ratio on Temperature Difference in Large-Format LIBs Using Design of Experiments. Energies. 2021; 14(1):116. https://doi.org/10.3390/en14010116

Chicago/Turabian StyleLee, Jeong-Joo, Ji-San Kim, Hyuk-Kyun Chang, Dong-Chan Lee, and Chang-Wan Kim. 2021. "The Effect of Tab Attachment Positions and Cell Aspect Ratio on Temperature Difference in Large-Format LIBs Using Design of Experiments" Energies 14, no. 1: 116. https://doi.org/10.3390/en14010116

APA StyleLee, J.-J., Kim, J.-S., Chang, H.-K., Lee, D.-C., & Kim, C.-W. (2021). The Effect of Tab Attachment Positions and Cell Aspect Ratio on Temperature Difference in Large-Format LIBs Using Design of Experiments. Energies, 14(1), 116. https://doi.org/10.3390/en14010116