Approaches for Modelling the Physical Behavior of Technical Systems on the Example of Wind Turbines

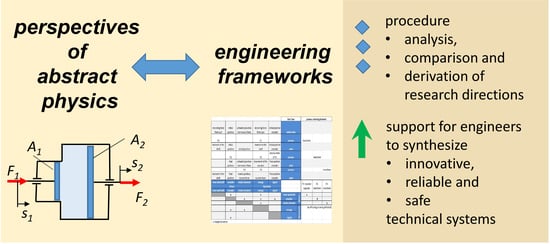

Abstract

1. Introduction

1.1. Research-Question Development

1.2. Scientfic Contribution

1.3. Paper Structure

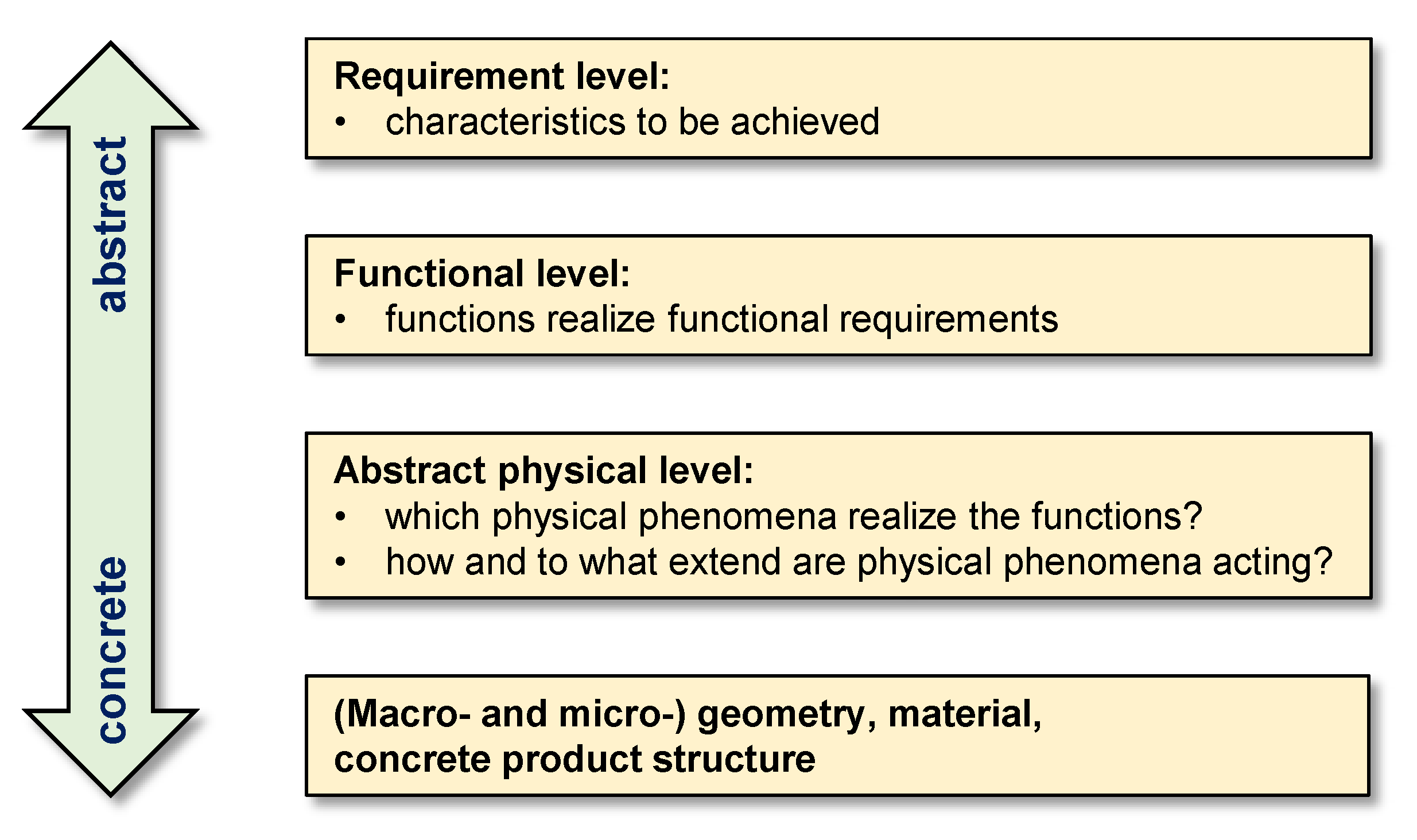

2. Abstract Physics—Background

3. Modelling Perspectives of Abstract Physics

3.1. Phenomenon-Oriented Perspective

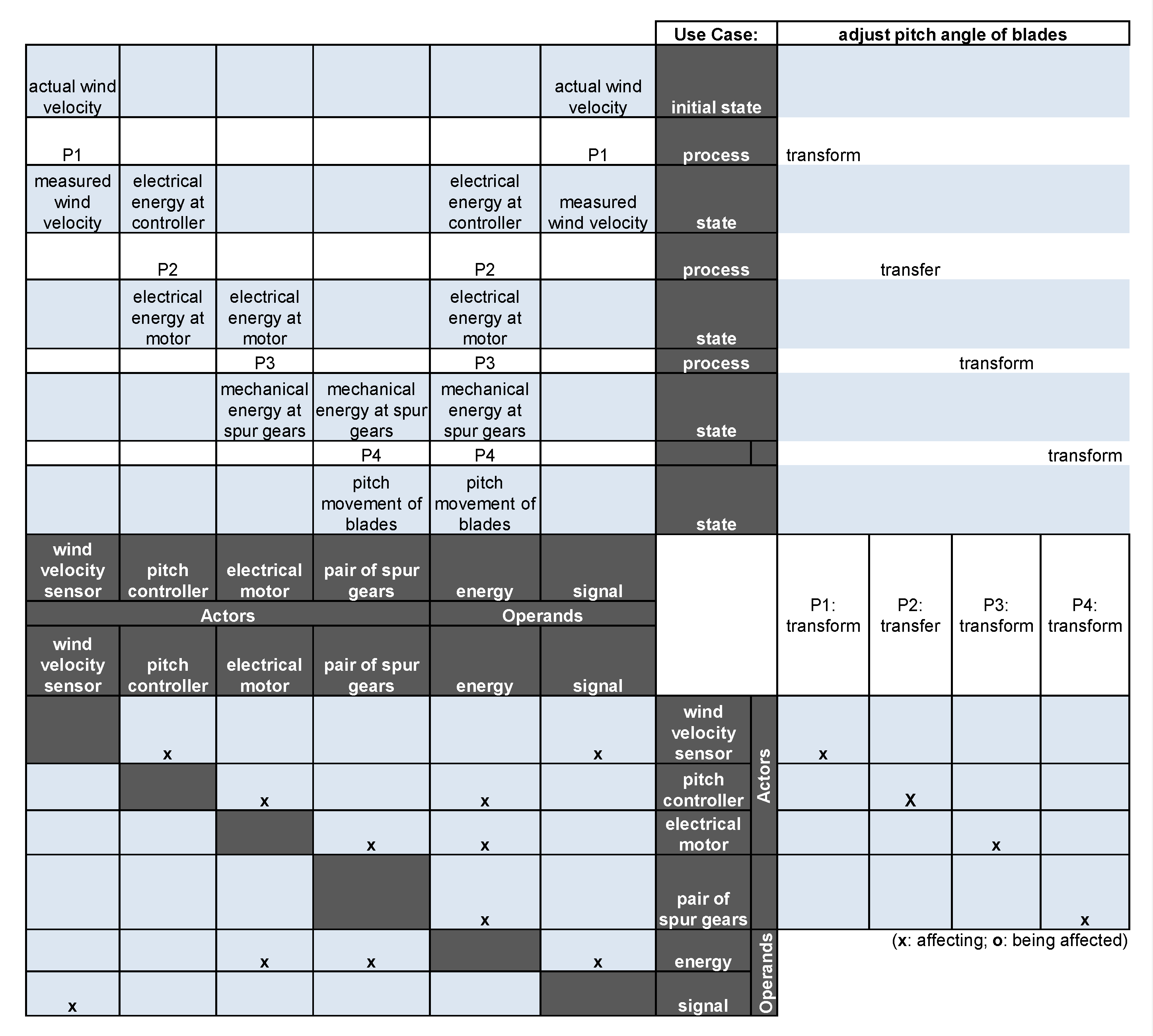

3.2. Behavior-Oriented Perspective

3.3. Interface-Oriented Perspective

- working surface pairs (WSP) that stand for interfaces between physical structures;

- channel and support structures (CSS) that permanently or occasionally represent interacting physical structures of solid bodies, liquids, gases, or fields; and

- connectors (C), which model elements that denote the effect and state properties of the environment that is relevant for the function of a system.

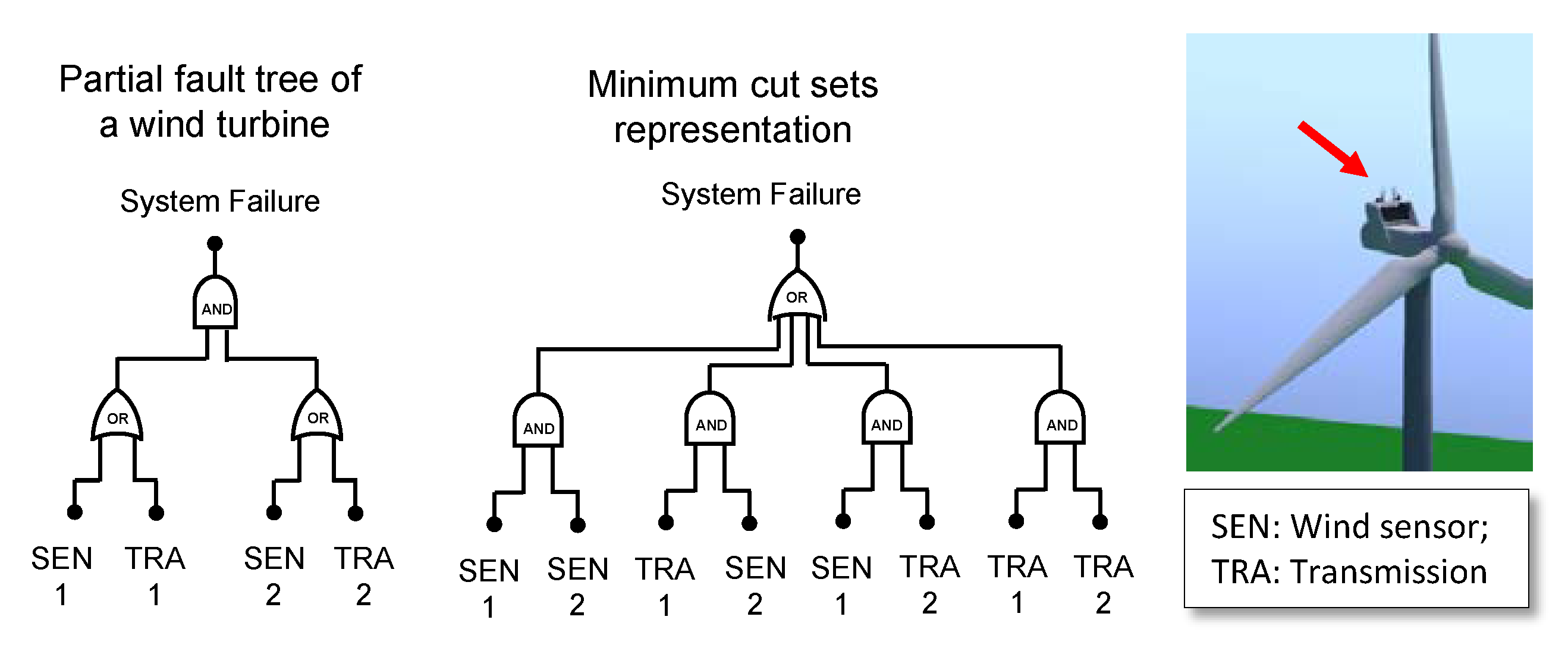

3.4. Logic-Oriented Perspective

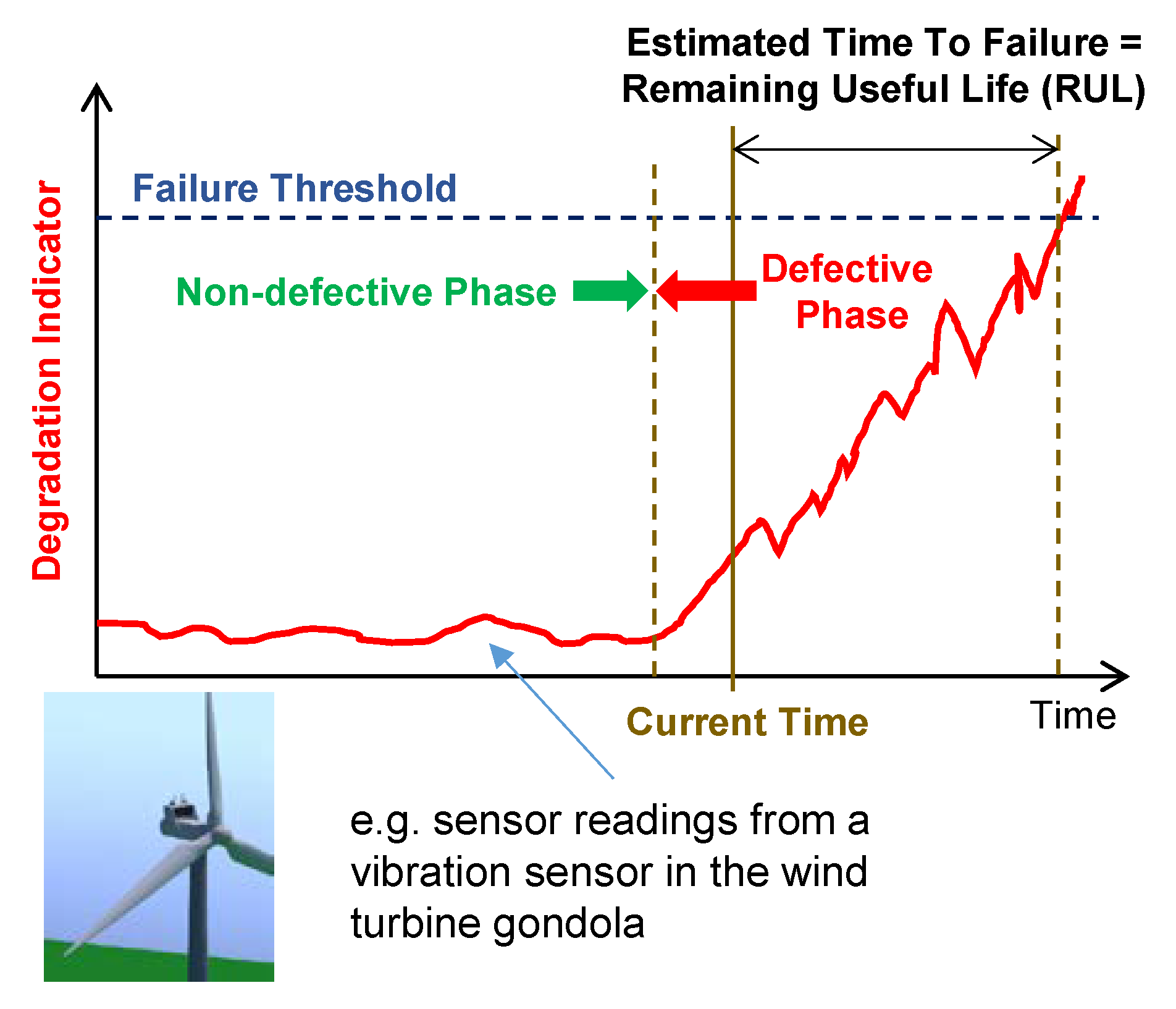

3.5. Control-Oriented Perspective

3.6. Summary

4. Integration of Perspectives

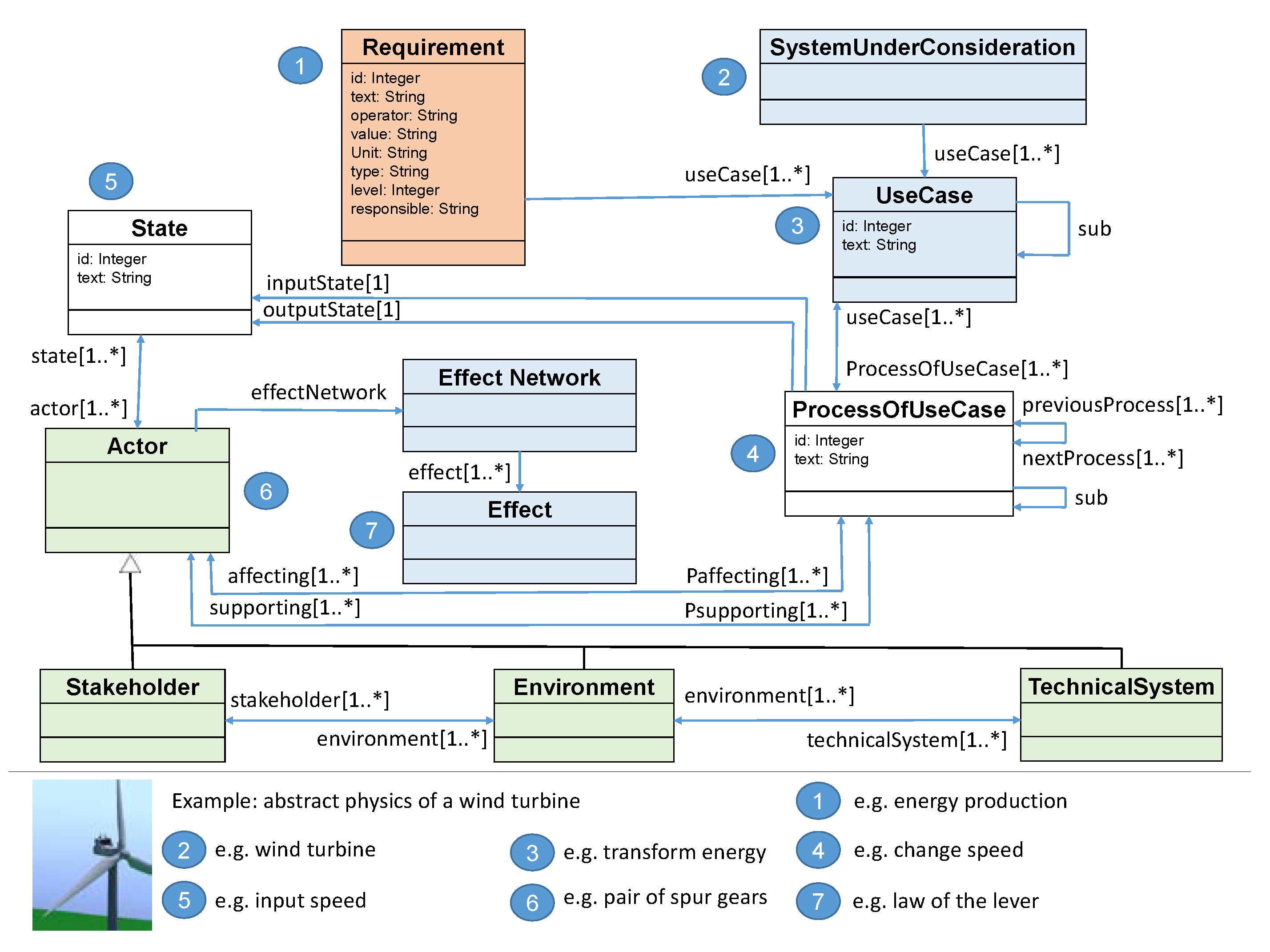

4.1. Expansion of Integrated-Function-Modelling Framework

4.2. Integration in Computational-Design Synthesis Framework

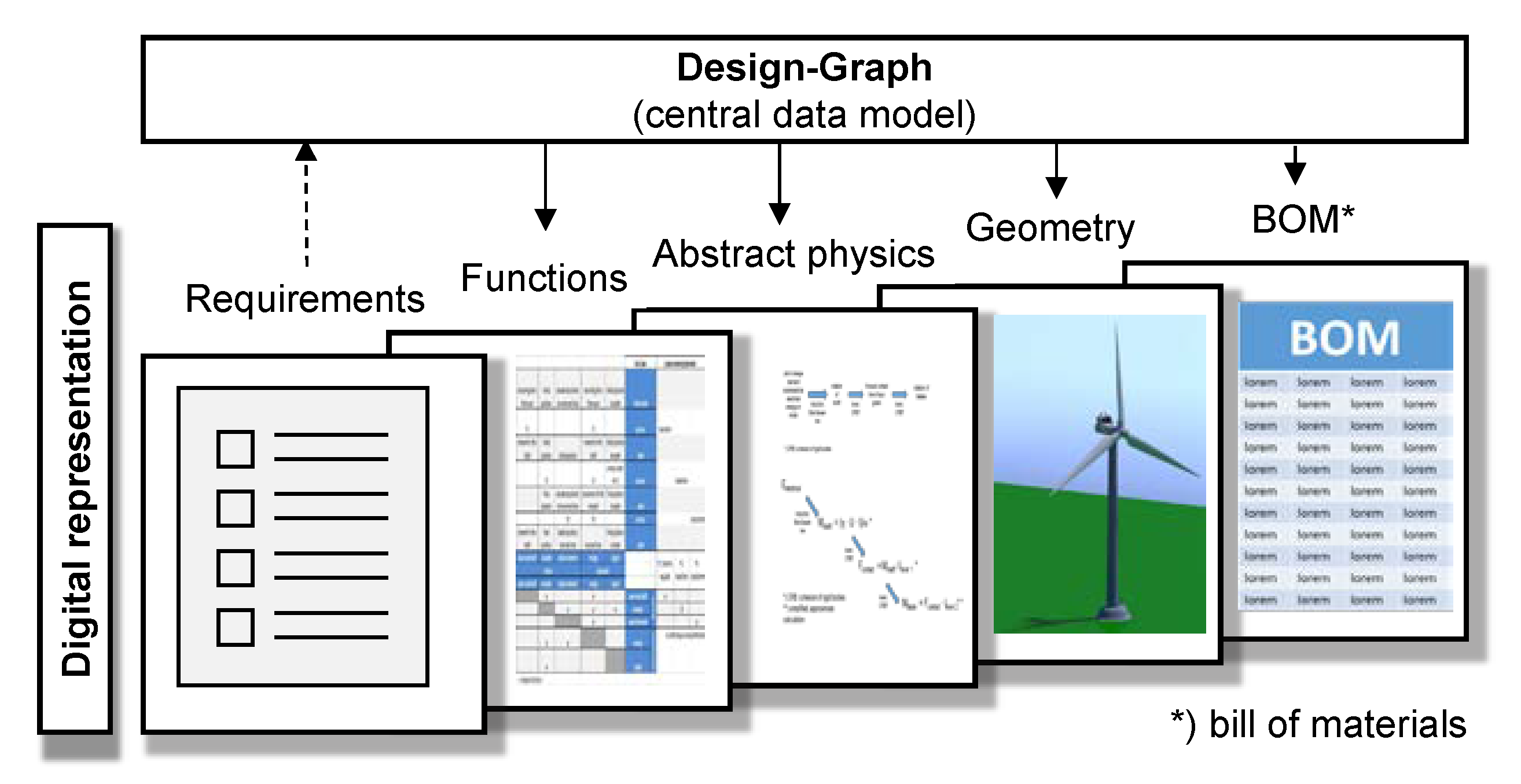

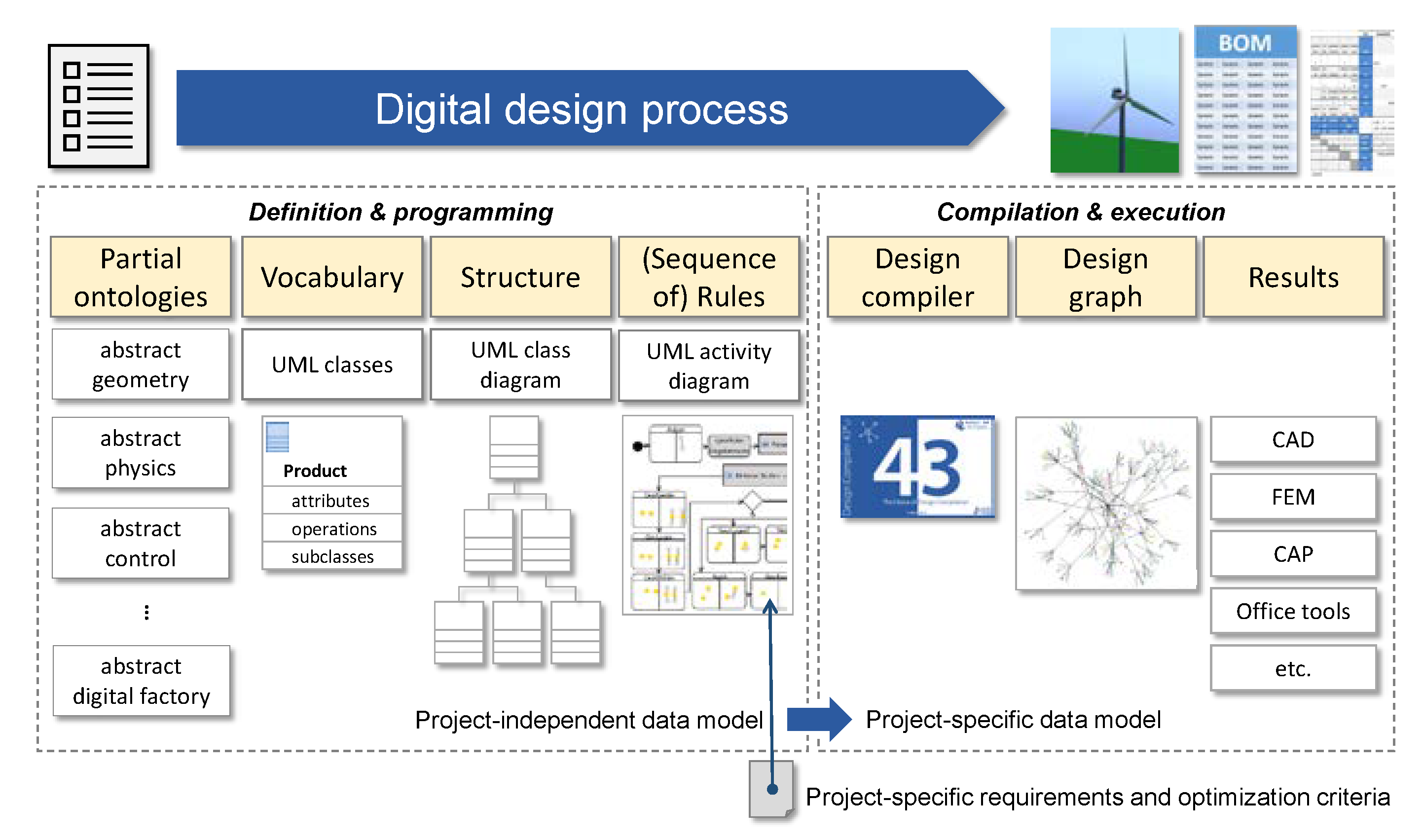

4.3. Integration in Frameworks Based on Graph-Based Design Languages

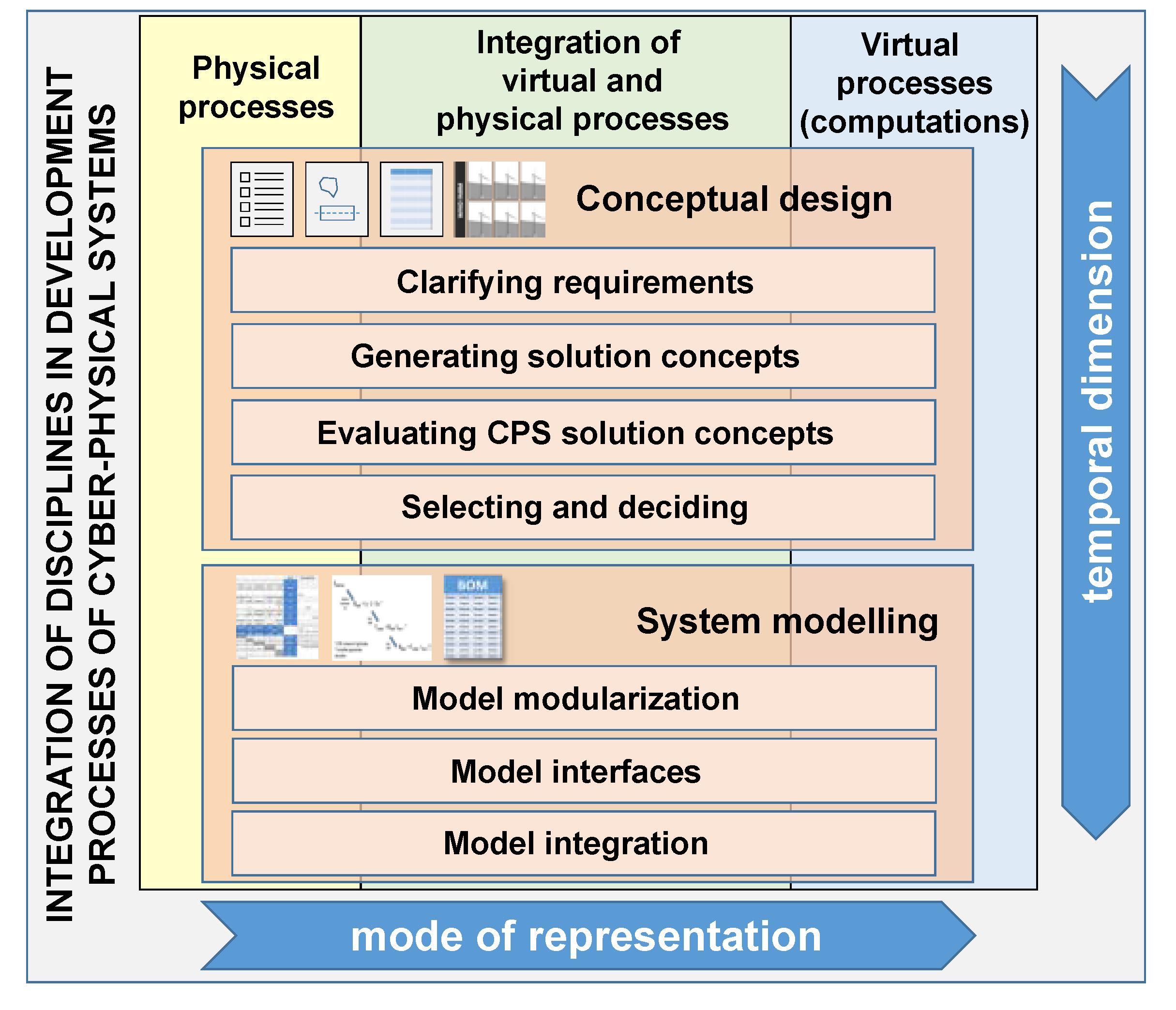

4.4. Integration in Frameworks for Cyber–Physical-System Development

4.5. Summary

5. Conclusions and Recommendations for Further Research

- The phenomenon-oriented perspective was proposed by design science and has its unique merits but is usually weakly represented in integrated modelling approaches. Initial approaches for the digital modelling of this perspective were proposed in the last few years; however, it remains a promising field for further research.

- For the behavior perspective, a multitude of modelling possibilities are available, but only some are integrated in existing engineering frameworks. Additionally, abstract representations of the behavior perspective are sparse and rarely employed; in this area, further scientific activities are desirable.

- Research concerning the interface-oriented perspective is relatively new; the connection with other modelling attempts and the integration in engineering frameworks is a field for future scientific activities.

- The logic-oriented perspective is relatively well-researched and frequently applied in engineering practice for reliability and safety analyses; links to other system-modelling possibilities are usually still rather weak.

- Numerous modelling possibilities concerning the control-oriented perspective were developed and successfully applied in the last few decades; similar to the logic-oriented perspective, links to other system-modelling possibilities are usually still rather weak.

- Strong links to the requirements concerning a technical system to the functional domain and structural domain are highly desirable in order to avoid repetitive work, inconsistencies, and fault possibilities.

- Engineering frameworks that connect several views in the functional domain may allow an expansion towards a more concrete modelling of abstract physics; further research in this area is desirable.

- In research activities in the area of computational design synthesis, several perspectives concerning the physical behavior of future technical systems are already incorporated.

- Engineering frameworks based on graph-based design languages may allow an expansion towards the more concrete modelling of abstract physics; further scientific activities concerning this expansion have large potential.

- Ontologies and metamodels play a central role in all modelling endeavors; frequently, their investigation is not explicitly addressed, but it is mandatory for the development of future holistic and integrated modelling possibilities in the field of abstract physics.

- As most future complex technical systems are cyber–physical or even cloud-based, the vertical and horizontal integration of information, models, and processes in this field is inevitable; future research has to address this need.

Funding

Conflicts of Interest

References

- Chamas, M.; Paetzold, K. Modeling of Requirement-Based Effect Chains of Mechatronic Systems in Conceptual Stage. Int. J. Electr. Electron. Eng. Telecommun. 2018, 7, 127–134. [Google Scholar] [CrossRef]

- Hruschka, P. Business Analysis und Requirements Engineering: Produkte und Prozesse Nachhaltig Verbessern; Hanser: Munich, Germany, 2019. [Google Scholar] [CrossRef]

- Bernard, R.; Irlinger, R. About watches and cars: Winning R&D strategies in two branches. In Proceedings of the Presentation at the International Symposium “Engineering Design—The Art of Building Networks”, Garching, Germany, 4 April 2016. [Google Scholar]

- Lang, H. Die Methodische Integration Empirischer Analysen in die Frühen Phasen Eines Entwicklungsprozesses. Ph.D. Thesis, Technischen Universität Graz, Graz, Austria, 2016. [Google Scholar]

- Zhang, Z.; Li, X.; Liz, Z. A Closed-loop Based Framework for Design Requirement Management. In Moving Integrated Product Development to Service Clouds in the Global Economy; IOS Press: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Holder, K.; Zech, A.; Ramsaier, M.; Stetter, R.; Niedermeier, H.-P.; Rudolph, S.; Till, M. Model-Based Requirements Management in Gear Systems Design based on Graph-Based Design Languages. Appl. Sci. 2017, 7, 1112. [Google Scholar] [CrossRef]

- Eisenbart, B.; Gericke, K.; Blessing, L.; McAloone, T. A DSM-based Framework for Integrated Function Modeling: Concept, Application and Evaluation. Res. Eng. Des. 2016, 28, 25–51. [Google Scholar] [CrossRef]

- Elwert, M.; Ramsaier, M.; Eisenbart, B.; Stetter, R. Holistic Digital Function Modelling with Graph-Based Design Languages. In Proceedings of the Design Society: International Conference on Engineering Design, Delft, The Netherlands, 5–8 August 2019; Cambridge University Press: Cambridge, UK, 2019; Volume 1, pp. 1523–1532. [Google Scholar] [CrossRef]

- Atkin, R.H. Abstract Physics. In Il Nuovo Cimento; Springer: Berlin, Germany, 1965; Volume XXXVIII, pp. 496–517. [Google Scholar] [CrossRef]

- Gero, J.; Kannengiesser, U. The Function-Behaviour-Structure Ontology of Design. In An Anthology of Theories and Models of Design; Chakrabarti, A., Blessing, L.T.M., Eds.; Springer: Berlin, Germany, 2014. [Google Scholar] [CrossRef]

- Ehrlenspiel, K.; Meerkamm, H. Integrierte Produktentwicklung. Denkabläufe, Methodeneinsatz, Zusammenarbeit; Carl Hanser: Munich, Germany, 2013. [Google Scholar] [CrossRef]

- Lindemann, U. Methodische Entwicklung Technischer Produkte; Methoden flexibel und situationsgerecht anwenden; Springer: Berlin, Germany, 2009. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design: A Systematic Approach; Springer: Berlin, Germany, 2007. [Google Scholar] [CrossRef]

- Ponn, J.; Lindemann, U. Konzeptentwicklung und Gestaltung Technischer Produkte: Systematisch von Anforderungen zu Konzepten und Gestaltlösungen; Springer: Berlin, Germany, 2011. [Google Scholar] [CrossRef]

- Stetter, R.; Niedermeier, M. Approaches towards Lean Products. In DS 42: Proceedings of ICED 2007, the 16th International Conference on Engineering Design, Paris, France, 28–31 July 2007; Bocquet, J.-C., Ed.; Design Society: Paris, France, 2007. [Google Scholar]

- Wulf, J. Elementarmethoden zur Lösungssuche. Ph.D. Thesis, Technischen Universität München, Munich, Germany, 2001. [Google Scholar]

- Schmitz, J.; Diepeveen, N.F.B.; Vatheuer, N.; Murrenhoff, H. Dynamic transmission response of a hydrostatic transmission measured on a test bench. In Proceedings of the European Wind Energy Conference and Exhibition (EWEA 2012), Copenhagen, Denmark, 16–19 April 2012. [Google Scholar]

- Liu, Z.; Tao, Y.; Wei, L.; Zhan, P.; Yue, D. Analysis of Dynamic Characteristics of a 600 kW Storage Type Wind Turbine with Hybrid Hydraulic Transmission. Processes 2019, 7, 397. [Google Scholar] [CrossRef]

- Mathias, J.; Eifler, T.; Engelhardt, R.; Kloberdanz, H.; Birkhofer, H.; Bohn, A. Selection of Physical Effects Based on Disturbances and Robustness Ratios in the Early Phases of Robust Design. In DS 68-1: Proceedings of the 18th International Conference on Engineering Design (ICED 11), Impacting Society through Engineering Design, Vol. 1: Design Processes, Lyngby/Copenhagen, Denmark, 15–19 August 2011; Culley, S.J., Hicks, B.J., McAloone, T.C., Howard, T.J., Clarkson, J., Eds.; Design Society: Glasgow, UK, 2011. [Google Scholar]

- Helms, B. Object-Oriented Graph Grammars for Computational Design Synthesis. Ph.D. Thesis, Technischen Universität München, Munich, Germany, 2013. [Google Scholar]

- Wagner, C. Funktionsintegration im Rahmen Einer Fertigungsgetriebenen Produktentwicklung. Ph.D. Thesis, Technische Universität, Darmstadt, Germany, 2018. [Google Scholar]

- Williams, J.H. Fundamentals of Applied Dynamics; John Wiley and Sons: Hoboken, NJ, USA, 2004. [Google Scholar] [CrossRef]

- Jafri, S.M.; Eltaher, A.; Paul, J. Dynamics of Offshore Wind Turbines. In Proceedings of the Twenty-first International Offshore and Polar Engineering Conference, Maui, HI, USA, 19–24 June 2011; International Society of Offshore and Polar Engineers (ISOPE): Mountain View, CA, USA, 2011. [Google Scholar]

- Jiang, Z.; Yang, L.; Gao, Z.; Moan, T. Numerical Simulation of a Wind Turbine with a Hydraulic Transmission System. Energy Procedia 2014, 53, 44–55. [Google Scholar] [CrossRef]

- Ramakrishnan, V. Analysis of Wind Turbine Blade Vibration and Drivetrain Loads. Ph.D. Thesis, Michigan State University, East Lansing, MI, USA, 2017. [Google Scholar]

- Ansoategui, I.; Zulueta, E.; Fernandez-Gamiz, U.; Lopez-Guede, J.M. Mechatronic Modeling and Frequency Analysis of the Drive Train of a Horizontal Wind Turbine. Energies 2019, 12, 613. [Google Scholar] [CrossRef]

- Ismaiel, A.; Yoshida, S. Aeroelastic Analysis of a Coplanar Twin-Rotor Wind Turbine. Energies 2019, 12, 1881. [Google Scholar] [CrossRef]

- Chu, J.; Yuan, L.; Hu, Y.; Pan, C.; Pan, L. Comparative Analysis of Identification Methods for Mechanical Dynamics of Large-Scale Wind Turbine. Energies 2019, 12, 3429. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Zhang, Y.; Fan, Y.; Bao, G.; Wang, X. Multi-Period Generation Expansion Planning for Sustainable Power Systems to Maximize the Utilization of Renewable Energy Sources. Sustainability 2020, 12, 1083. [Google Scholar] [CrossRef]

- Ramsaier, M.; Stetter, R.; Till, M.; Rudolph, S.; Schumacher, A. Automatic Definition of Density-driven Topology Optimization with Graph-based Design Languages. In Advances in Structural and Multidisciplinary Optimization; Proceedings of the 12th World Congress of Structural and Multidisciplinary Optimization (WCSMO12), Braunschweig, Germany, 5–9 June 2017; Schumacher, A., Vietor, T., Fiebig, S., Bletzinger, K.U., Maute, K., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Fritzson, P. Principles of Object-Oriented Modeling and Simulation with Modelica 3.3: A Cyber-Physical Approach; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Vogel, S. An application-independent continuum mechanics interface for virtual engineering. Eng. Comput. 2019, 35, 551–565. [Google Scholar] [CrossRef]

- Münzer, C.; Shea, K. A Simulation-Based CDS Approach: Automated Generation of Simulation Models Based from Generated Concept Model Graphs. In Proceedings of the ASME 2015 International Design Engineering Technical Conference & Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Albers, A.; Wintergerst, E. The Contact and Channel Approach (C&C2-A): Relating a system’s physical structure to its functionality, In An Anthology of Theories and Models of Design; Chakrabarti, A., Blessing, L.T.M., Eds.; Springer: London, UK, 2014; pp. 151–171. [Google Scholar] [CrossRef]

- Gladysz, B.; Spandl, L.; Albers, A. A Function- and Embodiment-Based Failure Analysis Method for an In-Depth Understanding of Failure Mechanisms. In Proceedings of the 21st International Conference on Engineering Design ICED17, Vancouver, BC, Canada, 21–25 August 2017; Maier, A., Skec, S., Kim, H., Kokkolaras, M., Oehmen, J., Fadel, G., Salustri, F., Van der Loos, M., Eds.; The Design Society: Glasgow, UK, 2017. [Google Scholar]

- Li, J.; Wang, Z.; Ren, Y.; Yang, D.; Lv, X. A Novel Reliability Estimation Method of Multi-State System Based on Structure Learning Algorithm. Eksploatacja i Niezawodnosc - Maintenance and Reliability 2020, 22, 170–178. [Google Scholar] [CrossRef]

- Gausemeier, J.; Pöschl, M.; Deyter, S.; Kaiser, L. Modeling and Analyzing Fault-tolerant Mechatronic Systems. In DS 58-1: Proceedings of ICED 09, the 17th International Conference on Engineering Design, Vol. 1, Design Processes, Palo Alto, CA, USA, 24–27 August 2009; Norell Bergendahl, M., Grimheden, M., Leifer, L., Skogstad, P., Lindemann, U., Eds.; The Design Society: Glasgow, UK, 2009. [Google Scholar]

- Dorociak, R.; Gausemeier, J. Modeling of the Failure Propagation of an Advanced Mechatronic System within the Specification of its Principle Solution. In Proceedings of the international design conference DESIGN 2012, Dubrovnik, Croatia, 21–24 May 2012; Marjanovic, D., Storga, M., Pavkovic, P., Bojcetic, N., Eds.; The Design Society: Glasgow, UK, 2012. [Google Scholar]

- Mhenni, F.; Choley, J.Y.; Rivière, A.; Nguyen, N.; Kadima, H. SysML and Safety Analysis for Mechatronic Systems. In Proceedings of the 2012 9th France-Japan & 7th Europe-Asia Congress on Mechatronics (MECATRONICS)/13th International Workshop on Research and Education in Mechatronics (REM), Paris, France, 21–23 November 2012. [Google Scholar]

- Mhenni, F. Safety Analysis Integration in a Systems Engineering Approach for Mechatronic Systems Design. Ph.D. Thesis, Ecole Centrale Paris, Châtenay-Malabry, France, 2014. [Google Scholar]

- Stetter, R. Fault-Tolerant Design and Control of Automated Vehicles and Processes; Insights for the Synthesis of Intelligent Systems; Springer: Berlin, Germany, 2020. [Google Scholar] [CrossRef]

- Kececioglu, D. Reliability Engineering Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2002; Volume 2. [Google Scholar]

- Vedachalam, N.; Umapathy, A.; Ramadass, G.A. Fault-Tolerant Design Approach for Reliable Offshore Multi-Megawatt Variable Frequency Converters. J. Ocean Eng. Sci. 2016, 1, 226–237. [Google Scholar] [CrossRef]

- Dubrova, E. Fault-Tolerant Design; Springer: Berlin, Germany, 2013. [Google Scholar] [CrossRef]

- Song, X.; Zhai, Z.; Liu, Y.; Han, J. A Stochastic Approach for the Reliability Evaluation of Multi-State Systems with Dependent Components. Reliab. Eng. Syst. Saf. 2018, 170, 257–266. [Google Scholar] [CrossRef]

- Bruch, C. Handling Undesired Functions during Conceptual Design—A State and State Transition-based Approach. In DS 32: Proceedings of DESIGN 2004, the 8th International Design Conference, Dubrovnik, Croatia, 18–21 May 2004; Marjanovic, D., Ed.; The Design Society: Glasgow, UK, 2004. [Google Scholar]

- Peng, R. Reliability of Interdependent Networks with Cascading Failures. Eksploatacja i Niezawodnosc 2018, 20, 273–277. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y. Common Cause and Load-Sharing Failures-Based Reliability Analysis for Parallel Systems. Eksploatacja i Niezawodnosc 2020, 22, 26–34. [Google Scholar] [CrossRef]

- Njindam, T.S.; Paetzold, K. Design for Reliability: An Event- and Function-Based Framework for Failure Behavior Analysis in the Conceptual Design of Cognitive Products. In DS 68-1: Proceedings of the 18th International Conference on Engineering Design (ICED 11), Impacting Society through Engineering Design, Vol. 1: Design Processes, Lyngby/Copenhagen, Denmark, 15–19 August 2011; Culley, S.J., Hicks, B.J., McAloone, T.C., Howard, T.J., Clarkson, J., Eds.; The Design Society: Glasgow, UK, 2011. [Google Scholar]

- Witczak, M. Fault Diagnosis and Fault-Tolerant Control Strategies for Non-Linear Systems; Analytical and Soft Computing Approaches; Springer: Berlin, Germany, 2014. [Google Scholar]

- Hackl, C.; Jané-Soneira, P.; Pfeifer, M.; Schechner, K.; Hohmann, S. Full- and Reduced-Order State-Space Modeling of Wind Turbine Systems with Permanent Magnet Synchronous Generator. Energies 2018, 11, 1809. [Google Scholar] [CrossRef]

- Adams, D. Health Monitoring of Structural Materials and Components: Methods with Applications; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Farrar, C.R.; Worden, K. An Introduction to Structural Health Monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 303–315. [Google Scholar] [CrossRef]

- Isermann, R. Fault Diagnosis Systems. An Introduction from Fault Detection to Fault Tolerance; Springer: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Ramsaier, M.; Holder, K.; Zech, A.; Stetter, R.; Rudolph, S.; Till, M. Digital representation of product functions in multicopter design. In Proceedings of the 21st International Conference on Engineering Design (ICED 17) Vol 1: Resource Sensitive Design, Design Research Applications and Case Studies, Vancouver, BC, Canada, 21–25 August 2017; Maier, A., Škec, S., Kim, H., Kokkolaras, M., Oehmen, J., Fadel, G., Salustri, F., Van der Loos, M., Eds.; The Design Society: Glasgow, UK, 2017. [Google Scholar]

- Wu, Y.; Peng, G.; Wang, H.; Zhang, H. Two-Stage Fault Tolerance Method for Large-Scale Manufacturing Network. IEEE Access 2019, 7, 81574–81592. [Google Scholar] [CrossRef]

- Habibi, H.; Nohooji, H.R.; Howard, I.; Simani, S. Fault-Tolerant Neuro Adaptive Constrained Control of Wind Turbines for Power Regulation with Uncertain Wind Speed Variation. Energies 2019, 12, 4712. [Google Scholar] [CrossRef]

- Hehenberger, P.; Vogel-Heuser, B.; Bradley, D.; Eynard, B.; Tomiyama, T.; Achiche, S. Design, Modelling, Simulation and Integration of Cyber Physical Systems: Methods and Applications. Comput. Ind. 2016, 82, 273–289. [Google Scholar] [CrossRef]

- Rigger, E.; Münzer, C.; Shea, K. Estimating the Potential of State of the Art Design Automation—Tasks, Methods, and Benefits. In Proceedings of the DESIGN 2016, 14th International Design Conference, Dubrovnik, Croatia, 16–19 May 2016; Marjanovic, D., Storga, M., Neven, G., Bojcetic, N., Stanko, S., Eds.; The Design Society: Glasgow, UK, 2016; Volume 1, pp. 421–432. [Google Scholar]

- Bolognini, F.; Jauregui Becker, J.M.; Schotborch, W.O. An investigation into limited integration of computational design synthesis in common design practice. In DS 70: Proceedings of DESIGN 2012, the 12th International Design Conference, Dubrovnik, Croatia, 21–24 May 2012; Marjanovic, D., Storga, M., Pavkocic, P., Bojcetic, B., Eds.; The Design Society: Glasgow, UK, 2012; pp. 727–736. [Google Scholar]

- Entner, D.; Prante, T.; Vosgien, T.; Zăvoianu, A.; Saminger-Platz, S.; Schwarz, M.; Fink, K. Potential Identification and Industrial Evaluation of an Integrated Design Automation Workflow. J. Eng. Des. Technol. 2019, 17, 1085–1109. [Google Scholar] [CrossRef]

- Antonsson, E.K.; Cagan, J. Formal Engineering Design Synthesis; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

- Wölkl, S.; Shea, K. A Computational Product Model for Conceptual Design using SYSML. In Proceedings of the ASME 2009 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, IDETC/CIE 2009, San Diego, CA, USA, 30 August–2 September 2009. [Google Scholar] [CrossRef]

- Muenzer, C.; Shea, K. Simulation-Based Computational Design Synthesis using Automated Generation of Simulation Models from Concept Model Graphs. J. Mech. Des. 2017, 139, 071101. [Google Scholar] [CrossRef]

- Münzer, C.; Helms, B.; Shea, K. Automatically Transforming Object-Oriented Graph-Based Representations into Boolean Satisfiability Problems for Computational Design Synthesis. J. Mech. Des. 2013, 135. [Google Scholar] [CrossRef]

- Königseder, C.; Stankovic, T.; Shea, K. Improving Design Grammar Development and Application Through Network-Based Analysis of Transition Graphs. Des. Sci. 2016, 2, 1–34. [Google Scholar] [CrossRef][Green Version]

- Rigger, E.; Vosgien, T. Design Automation State of Practice—Potential and Opportunities. In DS 92: Proceedings of the DESIGN 2018 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; Marianovic, D., Štorga, M., Škec, S., Bojčetić, N., Pavković, N., Eds.; The Design Society: Glasgow, UK, 2018. [Google Scholar] [CrossRef]

- Rigger, E.; Lutz, A.; Shea, K.; Stankovic, T. Estimating the Impact of Design Automation: The Influence of Knowledge on Potential Estimation. In DS 94: Proceedings of the Design Society: 22nd International Conference on Engineering Design (ICED19) Responsible Design for Our Future, Delft, The Netherlands, 5–8 August 2019; The Design Society: Glasgow, UK, 2019. [Google Scholar]

- Rudolph, S. Übertragung von Ähnlichkeitsbegriffen. Habilitationsschrift, Fakultät Luft- und Raumfahrttechnik und Geodäsie. Habilitation thesis, Universität Stuttgart, Stuttgart, Germany, 2002. [Google Scholar]

- Alber, R.; Rudolph, S. On a Grammar-Based Design Language That Supports Automated Design Generation and Creativity. In Knowledge Intensive Design Technology; Borg, J.C., Farrugia, P.J., Camilleri, K.P., Eds.; Springer: Boston, MA, USA, 2004; pp. 19–35. [Google Scholar] [CrossRef]

- Groß, J. Aufbau und Einsatz von Entwurfssprachen zur Auslegung von Satelliten. Doctoral dissertation, Institut für Statik und Dynamik der Luft- und Raumfahrtkonstruktionen. Universität Stuttgart, Stuttgart, Germany, 2013. [Google Scholar]

- Wünsch, F.; Ramsaier, M.; Breckle, T.; Stetter, R.; Till, M.; Rudolph, S. Executable Cost-Sensitive Product Development of a Self-Balancing Two-Wheel Scooter with Graph-Based Design Languages. In DS 92: Proceedings of the DESIGN 2018 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; Marjanović, D., Štorga, M., Škec, S., Bojčetić, N., Pavković, N., Eds.; The Design Society: Glasgow, UK, 2018. [Google Scholar] [CrossRef]

- Walter, B.; Kaiser, D.; Rudolph, S. Machine-executable Model-based Systems Engineering with design languages. In Complex Systems Design & Management; Banach, R., Razavi, J., Lesecq, S., Debicki, O., Mareau, N., Foucault, J., Correvon, M., Dudnik, G., Eds.; Springer: Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Zech, A.; Stetter, R.; Holder, K.; Rudolph, S.; Till, M. Novel approach for a holistic and completely digital represented product development process by using graph-based design languages. Procedia CIRP 2019, 79, 568–573. [Google Scholar] [CrossRef]

- Ramsaier, M.; Spindler, C.; Stetter, R.; Rudolph, S.; Till, M. Digital representation in multicopter design along the product life-cycle. Procedia CIRP 2017, 62, 559–564. [Google Scholar] [CrossRef]

- IILS mbH. Design Compiler 43. Available online: https://www.iils.de (accessed on 18 March 2020).

- Ramsaier, M.; Stetter, R.; Till, M.; Rudolph, S. Abstract Physics Representation of a Balanced Two-Wheel Scooter in Graph-Based Design Languages. In Proceedings of the Accepted for the 16th international design conference DESIGN 2020 and publication in the proceedings published by the Design Society, Cavtat, Croatia, 26–29 October 2020. [Google Scholar]

- Kiefer, J.; Stetter, R.; Rudolph, S.; Till, M. Graphenbasierte Entwurfssprachen für die digitale Konzeptplanung von Montageanlagen. Ingenieurspiegel 2018, 3, 47–49. [Google Scholar]

- Reichwein, A. Application-specific UML Profiles for Multidisciplinary Product Data Integration. Doctoral Dissertation, Universität Stuttgart, Stuttgart, Germany, 2011. [Google Scholar]

- Pietrusewicz, K. Metamodelling for Design of Mechatronic and Cyber-Physical Systems. Appl. Sci. 2019, 9, 376. [Google Scholar] [CrossRef]

- Rajkumar, R. A Cyber-physical Future. Proc. IEEE 2012, 100, 1309–1312. [Google Scholar] [CrossRef]

- Zheng, C.; Hehenberger, P.; Le Duigou, J.; Bricogne, M.; Eynard, B. Multidisciplinary Design Methodology for Mechatronic Systems Based on Interface Model. Res. Eng. Des. 2017, 28, 333–356. [Google Scholar] [CrossRef]

- Barbieri, G.; Fantuzzi, C.; Borsare, R. A Model-Based Design Methodology for The Development of Mechatronic Systems. Mechatronics 2014, 24, 833–843. [Google Scholar] [CrossRef]

- Guerineau, B.; Zheng, C.; Bricogne, M.; Durupt, A.; Rivest, L.; Rowson, H.; Eynard, B. Management of Heterogeneous Information for Integrated Design of Multidisciplinary Systems. Procedia CIRP 2017, 60, 320–325. [Google Scholar] [CrossRef]

- Nazari, S.; Sonntag, C.; Engell, S. A Modelica-Based Modeling and Simulation Framework for Large-Scale Cyber Physical Systems of Systems. IFAC PapersOnLine 2015, 48, 920–921. [Google Scholar] [CrossRef]

- Chen, C.; Cao, H.; Su, S.; Chen, H.; Gong, Y.; Chen, G. A Unified Modelling Method for Cyber-Physical Systems Based on Modelica. Int. J. Wirel. Mob. Comput. 2019, 16, 350–357. [Google Scholar] [CrossRef]

- Mazidi, P.; Tohidi, Y.; Sanz-Bobi, M.A. Strategic Maintenance Scheduling of an Offshore Wind Farm in a Deregulated Power System. Energies 2017, 10, 3. [Google Scholar] [CrossRef]

| Perspective | Characterization | Specific Merit |

|---|---|---|

| Phenomenon-oriented perspective | Describes demarcated physical phenomena | Supports deeper understanding and breakthrough innovations |

| Behavior-oriented perspective | Quantitatively describes behavior based on analytical and numerical mathematics | Supports simulation and optimization |

| Interface-oriented perspective | Describes how surfaces and support structures realize technical function | Supports detailed analyses of effect surfaces and interactions |

| Logic-oriented perspective | Describes logical relationships that determine reliability and safety | Supports analyses of unintended-behavior possibilities |

| Control-oriented perspective | Describes potential for and activities of a control system | Supports development of complex control systems including fault-tolerant control |

| Integration Approach | Characterization | Specific Merit |

|---|---|---|

| Expansion of integrated-function-modelling (IFM) framework | Integrates physical phenomena in multi-view framework for function representation | Allows linking to concise function modelling framework |

| Integration in computational-design-synthesis (CDS) framework | Integrates physical phenomena and behavior descriptions in design framework for abstract, early phases of design | Allows linking to large framework for design automation, even in early phases |

| Integration in frameworks based on graph-based design languages (GBDL) | Integrates physical phenomena and behavior descriptions in a framework spanning the whole product life cycle | Allows linking to an engineering framework with the ability to compile numerous instances of information including geometry |

| Integration in frameworks for cyber–physical system (CPS) development | Integrates behavior descriptions in a framework, including locally and organizationally distributed processes and cloud solutions | Allows linking to an engineering framework that includes vertical integration |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stetter, R. Approaches for Modelling the Physical Behavior of Technical Systems on the Example of Wind Turbines. Energies 2020, 13, 2087. https://doi.org/10.3390/en13082087

Stetter R. Approaches for Modelling the Physical Behavior of Technical Systems on the Example of Wind Turbines. Energies. 2020; 13(8):2087. https://doi.org/10.3390/en13082087

Chicago/Turabian StyleStetter, Ralf. 2020. "Approaches for Modelling the Physical Behavior of Technical Systems on the Example of Wind Turbines" Energies 13, no. 8: 2087. https://doi.org/10.3390/en13082087

APA StyleStetter, R. (2020). Approaches for Modelling the Physical Behavior of Technical Systems on the Example of Wind Turbines. Energies, 13(8), 2087. https://doi.org/10.3390/en13082087