The Possible Roles of Wastewater Treatment Plants in Sector Coupling

Abstract

1. Introduction

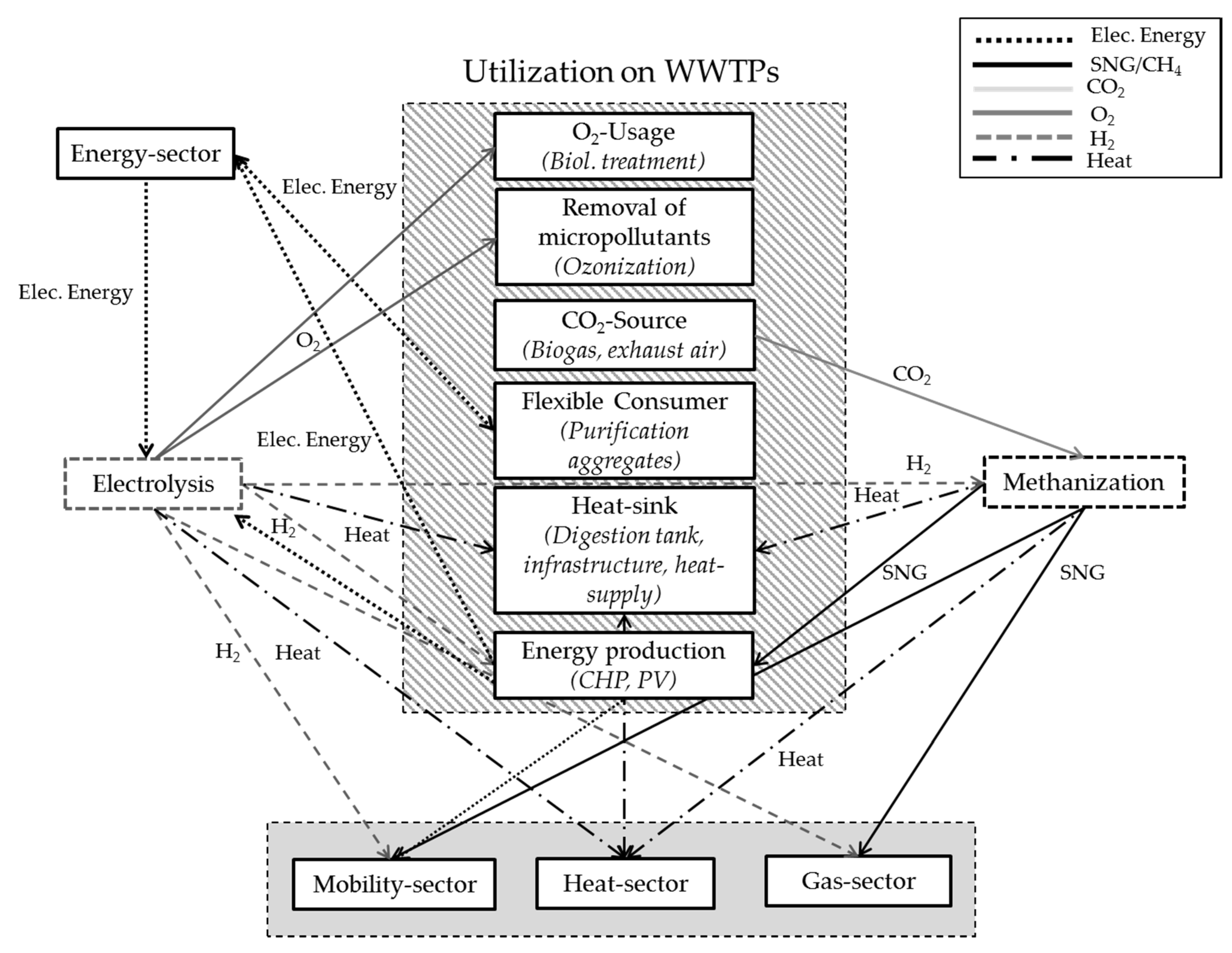

2. Sector Coupling with WWTPs

3. Gas-Sector

3.1. Power-to-Gas in WWTPs

3.1.1. CH4 Utilization

3.1.2. O2-Utilization: Usage of O2 From Electrolysis in Wastewater Treatment

3.1.3. O2 Utilization: Micropollutant Removal via Ozone Produced from Renewable O2

4. Heat-Sector

5. Mobility Sector and Power-to-Fuel

6. Conclusions

7. Outlook and Further Approach

- The upcoming needed technical knowledge of every sector is very diverse and causes many interconnections. This requires interdisciplinary expertise, with challenging tasks for every specialist in his field, which cannot be handled by a single player.

- Whilst every expert group can handle their specific field the best, the interconnections can rise up to major problems due to missing experiences and require a very close cooperation.

- Coordination and handling of the utilization path among each other of the competing available resources and their data management is very challenging in terms of gas flow rates, energy production, heat demands and storage management.

- Linking new components with significant impacts on plant processes to existing systems is difficult, e.g., coordination of the electrolysis gases: O2 production, O3 generation and O3 demand for wastewater treatment or the use of H2 by supplying public transportation and feeding into the NGI.

- The plant operators and the political decision-makers have to be involved and convinced from the start to carry out and promote such big municipal implementations and investments.

- Only a motivated and reliable team is able to keep up with a challenging and difficult regulatory environment.

- Local and/or federal funding is up-to-now mandatory to use the potential of sector coupling in WWTPs.

Author Contributions

Funding

Conflicts of Interest

References

- Friedrich, E.; Pillay, S.; Buckley, C.A. Environmental life cycle assessments for water treatment processes—A South African case study of an urban water cycle. Water SA 2009, 2009, 73–84. [Google Scholar] [CrossRef]

- U.S. Department of Energy. The Water-Energy Nexus: Challenges and Opportunities. 2014. Available online: https://www.energy.gov/downloads/water-energy-nexus-challenges-and-opportunities (accessed on 13 March 2020).

- Beca Consultants Pty Ltd (Beca). Opportunities for Renewable Energy in the Australian Water Sector. 2015. Available online: https://arena.gov.au/assets/2016/01/Opportunities-for-renewable-energy-in-the-Australian-water-sector.pdf (accessed on 13 March 2020).

- Economic and Social Council, United Nations. Special Edition: Progress Towards the Sustainable Development Goals. 2019. Available online: https://undocs.org/E/2019/68 (accessed on 13 March 2020).

- UNFCCC. Paris Agreement. 2016. Available online: https://unfccc.int/files/meetings/paris_nov_2015/application/pdf/paris_agreement_english_.pdf (accessed on 13 March 2020).

- Renewable Energy Policy Network for the 21st Century (REN21). Renewables 2019—Global Status Report. 2019. Available online: https://www.ren21.net/wp-content/uploads/2019/05/gsr_2019_full_report_en.pdf (accessed on 13 March 2020).

- BNetzA. Flexibilität im Stromversorgungssystem. Bestandsaufnahme, Hemmnisse und Ansätze zur Verbesserten Erschließung von Flexibilität. 2017. Available online: https://www.bundesnetzagentur.de/SharedDocs/Downloads/DE/Sachgebiete/Energie/Unternehmen_Institutionen/NetzentwicklungUndSmartGrid/BNetzA_Flexibilitaetspapier.pdf?__blob=publicationFile&v=1 (accessed on 13 March 2020).

- Deutsche Energie-Agentur GmbH (DENA). dena-Netzflexstudie. Optimierter Einsatz von Speichern für Netz- und Marktanwendungen in der Stromversorgung. 2017. Available online: https://www.dena.de/fileadmin/dena/Dokumente/Pdf/9191_dena_Netzflexstudie.pdf (accessed on 13 March 2020).

- Sterner, M.; Stadler, I. Energiespeicher—Bedarf, Technologien, Integration; 2.Auflage 2016; Springer: Berlin, Germany, 2016; ISBN 978-3-642-37379-4. [Google Scholar]

- Müller-Syring, G.; Henel, M.; Köppel, W.; Sterner, M.; Höcher, T. Entwicklung von Modularen Konzepten zur Erzeugung, Speicherung und Einspeisung von Wasserstoff und Methan ins Erdgasnetz. 2013. Available online: https://www.dvgw.de/medien/dvgw/forschung/berichte/g1_07_10.pdf (accessed on 15 April 2020).

- Lensch, D.; Schaum, C.; Cornel, P.; Lensch, D.; Schaum, C.; Cornel, P. Examination of food waste co-digestion to manage the peak in energy demand at wastewater treatment plants. Water Sci. Technol. 2016, 73, 588–596. [Google Scholar] [CrossRef] [PubMed]

- Seier, M.; Schebek, L. Model-based investigation of residual load smoothing through dynamic electricity purchase: The case of wastewater treatment plants in Germany. Appl. Energy 2017, 205, 210–224. [Google Scholar] [CrossRef]

- Mauky, E.; Weinrich, S.; Jacobi, H.-F.; Nägele, H.-J.; Liebetrau, J.; Nelles, M. Demand-driven biogas production by flexible feeding in full-scale—Process stability and flexibility potentials. Anaerobe 2017, 46, 86–95. [Google Scholar] [CrossRef] [PubMed]

- Schäfer, M.; Hobus, I.; Schmitt, T.G. Energetic flexibility on wastewater treatment plants. Water Sci. Technol. 2017, 76, 1225–1233. [Google Scholar] [CrossRef]

- Schmitt, T.G.; Schäfer, M.; Gretzschel, O.; Knerr, H.; Hüesker, F.; Kornrumpf, T.; Zdrallek, M.; Salomon, D.; Bidlingmaier, A.; Simon, R.; et al. Abwasserreinigungsanlagen als Regelbaustein in intelligenten Verteilnetzen mit Erneuerbarer Energieerzeugung—arrivee. 2017. Available online: www.erwas-arrivee.de (accessed on 25 June 2018).

- Schäfer, M. Ein Methodischer Ansatz zur Bereitstellung Energetischer Flexibilität Durch Einen Anpassungsfähigen Kläranlagenbetrieb. Ph.D. Thesis, Technische Universität Kaiserslautern, Kaiserslautern, Germany, February 2019. Available online: https://nbn-resolving.org/urn:nbn:de:hbz:386-kluedo-56084 (accessed on 13 March 2020).

- ASUE. Power to Gas. Erzeugung von Regenerativem Erdgas. 2014. Available online: https://asue.de/sites/default/files/asue/themen/umwelt_klimaschutz/2014/broschueren/07_06_14_Power_to_Gas.pdf (accessed on 13 March 2020).

- Forschungsstellefür Energiewirtschaft e.V. (FfE). Kurzstudie Power-to-X. Ermittlung des Potenzials von PtX-Anwendungen für die Netzplanung der Deutschen ÜNB. 2017. Available online: https://www.netzentwicklungsplan.de/de/ermittlung-des-potenzials-von-power-x-anwendungen-fuer-die-netzplanung-zu-kapitel-251 (accessed on 13 March 2020).

- Peyer, T.; Rene, N.; Thomas, H.; Monika, R. Kläranlagen-Ideal für Power-to-Gas: Swisspower identifiziert 100 Kläranlagen in der Nähe von Gasnetzen. AQUA GAS 2016, 7–8, 42–46. [Google Scholar]

- Schäfer, M.; Gretzschel, O.; Schütz, S.; Schuhmann, E.; Raabe, T. The natural gas grid infrastructure as a suitable storage for renewable energy produced by wastewater treatment plants. In Proceedings of the 10th International Renewable Energy Storage Conference (IRES), Düsseldorf, Germany, 15–16 March 2016. [Google Scholar]

- Wulf, C.; Linßen, J.; Zapp, P. Review of Power-to-Gas Projects in Europe. Energy Procedia 2018, 155, 367–378. [Google Scholar] [CrossRef]

- Schäfer, M.; Gretzschel, O.; Schmitt, T.G.; Knerr, H. Wastewater Treatment Plants as System Service Provider for Renewable Energy Storage and Control Energy in Virtual Power Plants—A Potential Analysis. Energy Procedia 2015, 73, 87–93. [Google Scholar] [CrossRef]

- Hien, S. Approaches for Supportive Prediction of Biogas Production Rate and Control Strategies to Provide Flexible Power Production. Ph.D. Thesis, University of Luxembourg, Esch-sur-Alzette, Luxemburg, May 2017. Available online: http://hdl.handle.net/10993/31245 (accessed on 13 March 2020).

- Smolinka, T.; Günther, M.; Garche, J. Stand und Entwicklungspotenzial der Wasserelektrolyse zur Herstellung von Wasserstoff aus regenerativen Energien: NOW-Studie: Kurzfassung des Abschlussberichts—Redakionsstand: 22.12.2010 (Revision 1 vom 05.07.2011). 2011. Available online: https://www.tib.eu/de/suchen/id/TIBKAT%3A872387518/Stand-und-Entwicklungspotenzial-der-Wasserelektrolyse/ (accessed on 16 March 2020).

- DENA. Power to Gas. Eine Innovative Systemlösung auf dem Weg zur Marktreife; Deutsche Energie-Agentur GmbH, DENA: Berlin, Germany, 2013. [Google Scholar]

- Graf, F.; Götz, M.; Henel, M.; Schaaf, T.; Tichler, R. Technoökonomische Studie von Power-to-Gas-Konzepten. 2014. Available online: https://www.dvgw.de/medien/dvgw/forschung/berichte/g3_01_12_tp_b_d.pdf (accessed on 16 March 2020).

- DWA. DWA-M 363—Herkunft, Aufbereitung und Verwertung von Biogasen; DWA, Ed.; DWA: Hennef, Germany, 2010; ISBN 978-3-941897-52-6. [Google Scholar]

- Graf, F.; Krajete, A.; Schmack, U. Techno-ökonomische Studie zur Biologischen Methanisierung bei Power-to-Gas-Konzepten. 2014. Available online: https://www.dvgw.de/themen/forschung-und-innovation/forschungsprojekte/dvgw-forschungsbericht-g-30113/ (accessed on 16 March 2020).

- Reuter, M. Power-to-Gas: Biological methanization; first at a municipal sewage plant. In Proceedings of the 8th International Renewable Energy Storage Conference, Düsseldorf, Germany, 18–20 November 2013. [Google Scholar]

- Dröge, S.; Pacan, B. Erfahrungen mit der Power-to-Gas Pilotanlage im Energiepark Pirmasens-Winzeln. In Proceedings of the Fachgespräch: Biologische Methanisierung, Berlin, Germany, 25 April 2017. [Google Scholar]

- Trautmann, N.; Nelting, K.; Vogel, B.; Weichgrebe, D.; Stopp, P.; Cuff, G. Methan aus Erneuerbaren Energien—Biologische Umwandlung von Wasserstoff aus der Elektrolyse zu Methan. 2018. Available online: https://www.dbu.de/OPAC/ab/DBU-Abschlussbericht-AZ-33505-01.pdf (accessed on 16 March 2020).

- Lardon, L.; Thorberg, D.; Krosgaard, L. Biogas valorization and efficient energy management—Technical and economic analysis of biological methanation. In Powerstep: Your Flush, Our Energy; Kompetenzzentrum Wasser Berlin: Berlin, Germany, 2018; Available online: http://powerstep.eu/system/files/generated/files/resource/d3-2-technical-and-economic-analysis-of-biological-methanationdeliverable.pdf (accessed on 16 March 2020).

- Gandiglio, M.; Lanzini, A.; Soto, A.; Leone, P.; Santarelli, M. Enhancing the Energy Efficiency of Wastewater Treatment Plants through Co-digestion and Fuel Cell Systems. Front. Environ. Sci. 2017, 5, 221. [Google Scholar] [CrossRef]

- Wang, H.; Gu, Y.; Li, Y.; Li, X.; Luo, P.; Robinson, Z.P.; Wang, X.; Wu, J.; Li, F. The feasibility and challenges of energy self-sufficient wastewater treatment plants. Appl. Energy 2017, 204, 1463–1475. [Google Scholar] [CrossRef]

- Pinnekamp, J.; Schröder, M.; Bolle, F.-W.; Gramlich, E.; Gredigk-Hoffmann, S.; Koenen, S.; Loderhose, M.; Miethig, S.; Ooms, K.; Riße, H.; et al. Energie in Abwasseranlagen. Handbuch NRW. 2018. Available online: https://www.umwelt.nrw.de/fileadmin/redaktion/Broschueren/energie_abwasseranlagen.pdf (accessed on 16 March 2020).

- Gretzschel, O.; Schmitt, T.G.; Hansen, J.; Siekmann, K.; Jakob, J. Sludge digestion instead of aerobic stabilisation—A cost benefit analysis based on experiences in Germany. Water Sci. Technol. 2014, 69, 430–437. [Google Scholar] [CrossRef]

- ASUE. BHKW Kennzahlen 2014/2015. Module, Anbieter, Kosten. Arbeitsgemeinschaft für Sparsamen und Umweltfreundlichen Energieverbrauch e.V.; ASUE: Berlin, Germany, 2014. [Google Scholar]

- Strauss, K. Kraftwerkstechnik. Zur Nutzung Fossiler, Nuklearer und Regenerativer Energiequellen, 7. Auflage; Springer Vieweg: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-662-53029-0. [Google Scholar] [CrossRef]

- Erbe, V.; Kolisch, G.; Feldmann, N. Studie zur Aufbereitung und Einspeisung von Faulgas auf Kommunalen Kläranlagen. 2011. Available online: https://www.lanuv.nrw.de/landesamt/forschungsvorhaben/sonstiges?tx_cartproducts_products%5Bproduct%5D=741&cHash=baebeccab6c9a99fb823b8f435fc00a2 (accessed on 16 March 2020).

- Electrochea. Electrochea Realisiert Power-to-Gas-Anlage für ein Nachhaltiges Pfaffenhofen. 2017. Available online: http://www.electrochaea.com/wp-content/uploads/2017/11/20171113_PM-Electrochaea_PtoG_fuer_Pfaffenhofen_DE_FIN.pdf (accessed on 16 March 2020).

- Zutter, R.; Nijsen, R.; Peyer, T. Studie Potential zur Effizienzsteigerung in Kläranlagen mittels Einspeisung oder Verstromung des Klärgases. 2015. Available online: https://swisspower.ch/themen-und-standpunkte/potential-zur-effizienzsteigerung-in-kl%C3%A4ranlagen-mittels-einspeisung-oder-verstromung-des-kl%C3%A4rgases (accessed on 16 March 2020).

- Ryser Ingenieure AG. Klärgas-Verstromung oder Aufbereitung und Einspeisung. Entscheidhilfe für Betreiber und Planer. 2019. Available online: http://www.infrawatt.ch/sites/default/files/2019_02_20_Energie%20in%20ARA_Kap._Kl%C3%A4rgas%20Verstromen%20oder%20Einspeisen.pdf (accessed on 16 March 2020).

- Kolisch, G.; Taudien, Y.; Osthoff, T. Projekt Nr. 2: Verbesserung der Klärgasnutzung, Steigerung der Energieausbeute auf kommunalen Kläranlagen (Zusatzbericht). 2014. Available online: https://www.lanuv.nrw.de/fileadmin/forschung/wasser/klaeranlage_abwasser/2014_Abschlussbericht_TP2.pdf (accessed on 16 March 2020).

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Biotechnol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Jentsch, M.; Büttner, S. Dezentrale Umsetzung der Energie- und Verkehrswende mit Waserstoffsystemen auf Kläranlagen. gwf Gas + Energie 2019, 6, 28–39. [Google Scholar]

- Rudolph, K.-U.; Müller-Czygan, G.; Bombeck, M. Reinsauerstoffbelüftung auf kleinen Industriekläranlagen—Energieeinsparpotenziale und Kapazitätssteigerungen am Beispiel der Kläranlage der Fa. Emsland Frischgeflügel GmbH: Meschede, Germany. Available online: https://www.dbu.de/OPAC/ab/DBU-Abschlussbericht-AZ-26353.pdf (accessed on 15 April 2020).

- Büttner, S.; Jentsch, M.; Hörnlein, S.; Hubner, B. Sektorenkopplung im Rahmen der Energiewende—Einsatz von Elektrolysesauerstoff auf kommunalen Kläranlagen. In Nutzung Regenerativer Energiequellen und Wasserstofftechnik 2018; Luschtinetz, T., Lehmann, J., Eds.; Fachhochschule Stralsund: Stralsund, Germany, 2018; pp. 22–41. ISBN 978-3-9817740-4-7. Available online: https://www.hochschule-stralsund.de/storages/hs-stralsund/FAK_ETI/Dateien/REGWA/TagungsBaende/Tagungsband_2018-11-04.pdf (accessed on 16 March 2020).

- CETAQUA. Greenlysis—Final Report. 2013. Available online: https://ec.europa.eu/environment/life/project/Projects/index.cfm?fuseaction=home.showFile&rep=file&fil=LIFE08_ENV_E_000118_AfterLIFE.pdf (accessed on 16 March 2020).

- Schmid-Schmieder, V. Alternative Energiequellen auf Kläranlagen: Elektrolytische Wasserstoff- und Sauerstoffnutzung auf Kläranlagen—Wasserstoffproduktion aus Faul- und Biogas. In wwt Wasserwirtschaft Wassertechnik; HUSS-Verlag: Munich, Germany, 2007; Volume 11–12. [Google Scholar]

- Haas, F.; Jain, A.; Lehmann, J.; Luschtinetz, O.; Schefler, R. The hydrogen-oxygen project in Barth. Int. J. Hydrog. Energy 2004, 30, 555–557. [Google Scholar] [CrossRef]

- Hansen, J.; Steinmetz, H.; Zettl, U. Betriebsergebnisse zum Einsatz der Reinsauerstoffbegasung zur weitergehenden Stickstoffelimination bei einer Anlage mit Weinbaueinfluß. Abwassertechnik 1996, 2, 32–36. [Google Scholar]

- Margot, J.; Urfer, D. Sicherheitsaspekte zum Umgang mit Sauerstoff auf Kläranlagen. 2016. Available online: https://www.micropoll.ch/fileadmin/user_upload/Redaktion/Dokumente/02_Faktenblaetter/Faktenblatt_Sauerstoff_DE_FINAL_21112016.pdf (accessed on 16 March 2020).

- Strässle, M. Anwendungspotentiale der Wasserstofftechnologie auf Kläranlagen. Master’s Thesis, Leibnitz University Hannover, Hannover, Germany, October 2017. [Google Scholar]

- CETAQUA. GREENLYSIS—Hydrogen and Oxygen Production via Electrolysis Powered by Renewable Energies to Reduce Environmental Footprint of a WWTP 2012. Available online: http://ec.europa.eu/environment/life/project/Projects/index.cfm?fuseaction=search.dspPage&n_proj_id=3416 (accessed on 16 March 2020).

- SUN. Das Klärwerk 1 in Nürnberg. Eine Kurzbeschreibung. 2017. Available online: https://www.nuernberg.de/imperia/md/sun/dokumente/sun/kw1_kurz.pdf (accessed on 16 March 2020).

- DWA. DWA-A 131—Bemessung von Einstufigen Belebungsanlagen, Juni 2016; Deutsche Vereinigung für Wasserwirtschaft Abwasser und Abfall: Hennef, Germany, 2016; ISBN 978-3-88721-331-2. [Google Scholar]

- Gewässerschutzverordnung. Schweizerische Bundesrat. GSchV, 2018. Law Text (AS 1998 2863). Available online: https://www.admin.ch/opc/de/classified-compilation/19983281/index.html (accessed on 28 September 2018).

- Hillenbrand, T.; Tettenborn, F. Empfehlungen des Stakeholder-Dialogs “Spurenstoffstrategie des Bundes”. An die Politik zur Reduktion von Spurenstoffeinträgen in die Gewässer. 2017. Available online: https://www.bmu.de/fileadmin/Daten_BMU/Download_PDF/Binnengewaesser/spurenstoffstrategie_policy_paper_bf.pdf (accessed on 16 March 2020).

- Pinnekamp, J.; Bolle, F.-W.; Palmowski, L.; Veltmann, K.; Mousel, D.; Mauer, C.; Eckers, S. Energiebedarf von Verfahren zur Elimination von organischen Spurenstoffen. Final Report. 2011. Available online: https://www.lanuv.nrw.de/fileadmin/lanuv/wasser/abwasser/forschung/pdf/Abschlussbericht_ENVELOS.pdf (accessed on 20 March 2020).

- Schäfer, M.; Schmitt, T.G.; Gretzschel, O.; Steinmetz, H. Integration of fluctuating Renewable Energies on WWTPs to remove micropollutants due ozonation. In Proceedings of the 12th International Renewable Energy Storage Conference—IRES 2018, Düsseldorf, Germany, 13–15 March 2018. [Google Scholar]

- UBA. Maßnahmen zur Verminderung des Eintrages von Mikroschadstoffen in die Gewässer 85/2014. 2014. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/378/publikationen/texte_85_2014_massnahmen_zur_verminderung_des_eintrages_von_mikroschadstoffen_in_die_gewaesser_0.pdf (accessed on 16 March 2020).

- DWA. Möglichkeiten der Elimination von Anthropogenen Spurenstoffen; DWA, Ed.; DWA: Hennef, Germany, 2015; ISBN 978-3-88721-210-0. [Google Scholar]

- Wunderlin, P.; Abegglen, C.; Durisch-Kaiser, E.; Götz, C.; Joss, A.; Kienle, C.; Langer, M.; Peter, A.; Santiago, S.; Soltermann, F.; et al. Abklärungen Verfahrenseignung Ozonung. Available online: https://www.micropoll.ch/fileadmin/user_upload/Redaktion/Dokumente/03_Vollzugshilfen/Abkl%C3%A4rungenVerfahrenseignungOzonung_DE_FINAL_20042017.pdf (accessed on 16 March 2020).

- Margot, J.; Urfer, D. Sicherheitsaspekte zum Umgang mit Ozon auf Kläranlagen. 2016. Available online: https://www.micropoll.ch/fileadmin/user_upload/Redaktion/Dokumente/02_Faktenblaetter/Faktenblatt_Ozon_DE_Final_09092016.pdf (accessed on 16 March 2020).

- Steinmetz, H.; Schmitt, T.G.; Schäfer, M.; Gretzschel, O.; Krieger, S.; Alt, K.; Zydorczyk, S.; Bender, V.; Pick, E. Konzeptstudie. Klimafreundliche und ressourceneffiziente Anwendung der Wasserelektrolyse zur Erzeugung von regenerativen Speichergasen kombiniert mit einer weitergehenden Abwasserbehandlung zur Mikroschadstoffelimination auf Kläranlagen. Unpublished work. 2018. [Google Scholar]

- Steinmetz, H.; Schmitt, T.G.; Schäfer, M.; Gretzschel, O.; Krieger, S.; Alt, K.; Zydorczyk, S.; Bender, V.; Pick, E. Ergänzende Betrachtungen zur Konzeptstudie. Unpublished work. 2019. [Google Scholar]

- DWA KEK-10.4. Wärme- und Kältekonzepte auf Kläranlagen: Arbeitsbericht der DWA-Arbeitsgruppe 10.4 “Wärme- und Kältekonzepte auf Kläranlagen”; Arbeitsbericht. Korrespondenz Abwasser, Abfall; DWA: Hennef, Germany, 2016; pp. 704–713. [Google Scholar]

- AWEL—Amt für Abfall, wasser, Energie und Luft. Baudirektion Kanton Zürich. Heizen und Kühlen mit Abwasser. Leitfaden für die Planung, Bewilligung und Realisierung von Anlagen zur Abwasserenergienutzung. 2010. Available online: https://awel.zh.ch/internet/baudirektion/awel/de/energie_radioaktive_abfaelle/waermenutzung_ausuntergrundwasser/abwasser/_jcr_content/contentPar/downloadlist/downloaditems/1596_1433140855118.spooler.download.1433141005406.pdf/Heizen_Kuehlen_Abwasser.pdf (accessed on 16 March 2020).

- Alekseiko, L.N.; Slesarenko, V.V.; Yudakov, A.A. Combination of wastewater treatment plants and heat pumps. Pac. Sci. Rev. 2014, 16, 36–39. [Google Scholar] [CrossRef]

- Mitsdoerffer, R. Wärme- und Kältekonzepte auf Kläranlagen, München. 2017. Available online: https://www.gfm-ingenieure.de/fileadmin/Daten/Referenzen/Klaeranlage/Energie/Vortrag-Mitsdoerffer-20170115-mi.pdf (accessed on 16 March 2020).

- DWA. DWA-M 114—Abwasserwärmenutzung. Merkblatt, Entwurf September 2018; Deutsche Vereinigung für Wasserwirtschaft Abwasser und Abfall: Hennef, Germany, 2018; ISBN 978-3-88721-635-1. [Google Scholar]

- Seyfried, C.F.; Kroiss, H.; Rosenwinkel, K.-H.; Dichtl, N.; Weiland, P. Anaerobtechnik. Abwasser-, Schlamm- und Reststoffbehandlung, Biogasgewinnung; 3., neu bearbeitete Auflage; Springer Vieweg: Berlin, Germany, 2015; ISBN 978-3-642-24895-5. [Google Scholar]

- Hubert, C.; Steiniger, B.; Schaum, C.; Michel, M.; Spallek, M. Variation of the digester temperature in the annual cycle—Using the digester as heat storage. Water Pract. Technol. 2019, 14, 471–481. [Google Scholar] [CrossRef]

- Bousková, A.; Dohányos, M.; Schmidt, J.E.; Angelidaki, I. Strategies for changing temperature from mesophilic to thermophilic conditions in anaerobic CSTR reactors treating sewage sludge. Water Res. 2005, 39, 1481–1488. [Google Scholar] [CrossRef]

- Barrington, S.; Ortega, L.; Guiot, S.R. Thermophilic adaptation of a mesophilic anaerobic sludge for food waste treatment. J. Environ. Manage. 2007, 88, 517–525. [Google Scholar] [CrossRef]

- DWA. DWA-M 368—Biologische Stabilisierung von Klärschlamm; DWA, Ed.; DWA: Hennef, Germany, 2014; ISBN 978-3-944328-60-7. [Google Scholar]

- Aprile, M.; Scoccia, R.; Dénarié, A.; Kiss, P.; Dombrovszky, M.; Gwerder, D.; Schuetz, P.; Elguezabal, P.; Arregi, B. District power-to-heat/cool complemented by sewage heat recovery. Energies 2019, 12, 364. [Google Scholar] [CrossRef]

- Kollmann, R.; Neugebauer, G.; Kretschmer, F.; Truger, B.; Kindermann, H.; Stoeglehner, G.; Ertl, T.; Narodoslawsky, M. Renewable energy from wastewater—Practical aspects of integrating a wastewater treatment plant into local energy supply concepts. J. Clean. Prod. 2016, 155, 119–129. [Google Scholar] [CrossRef]

- Hamburg-Wasser. Unterirdischer Waermespeicher Erfolgreich Getestet. 2017. Available online: https://www.hamburgwasser.de/privatkunden/unternehmen/presse/unterirdischer-waermespeicher-erfolgreich-getestet/ (accessed on 16 March 2020).

- Hansen, G.; Giese, T. “Mach 3”: Umweltwärme aus Wasser für eine erneuerbare Fernwärmeversorgung in Hamburg—ein Projekt mit vielen Möglichkeiten. In Proceedings of the 31th Hamburger Kolloquium zur Abwasserwirtschaft: Themenschwerpunkte: Mikroschadstoffe, Mikroplastik, Antibiotikaresistenzen; Industrieabwasserbehandlung; Niederschlagswasser, Umweltwärme; Klärschlammentsorgung, Gewässerschutz, Hamburg, Germany, 18–19 September 2019; Available online: https://cgi.tu-harburg.de/~awwweb/downloads/TagungsbandAbwasserkolloquium2019.pdf (accessed on 16 March 2020).

- Neugebauer, G.; Kretschmer, F.; Kollmann, R.; Narodoslawsky, M.; Ertl, T.; Stoeglehner, G. Mapping Thermal Energy Resource Potentials from Wastewater Treatment Plants. Sustainability 2015, 7, 12988–13010. [Google Scholar] [CrossRef]

- BHKW-Infozentrum. Grundlagen der Kraft-Wärme-Kälte-Kopplung. Available online: https://www.bhkw-infozentrum.de/allgemeine-erlaeuterungen-bhkw-kwk/kwkk-grundlagen.html (accessed on 6 April 2020).

- IPCC. Climate change 2014. Synthesis Report. Available online: https://archive.ipcc.ch/pdf/assessment-report/ar5/syr/SYR_AR5_FINAL_full_wcover.pdf (accessed on 16 March 2020).

- IEA. World Energy Outlook. 2018. Available online: https://webstore.iea.org/download/summary/190?fileName=English-WEO-2018-ES.pdf (accessed on 16 March 2020).

- Pietzcker, R.C.; Longden, T.; Chen, W.; Fu, S.; Kriegler, E.; Kyle, P.; Luderer, G. Long-term transport energy demand and climate policy: Alternative visions on transport decarbonization in energy-economy models. Energy 2014, 64, 95–108. [Google Scholar] [CrossRef]

- Bundesministerium für Verkehr und digitale Infrastruktur (BMVI). Initiative klimafreundlicher Straßengüterverkehr. Fahrplan für einen klimafreundlichen Straßengüterverkehr. 2017. Available online: https://www.bmvi.de/SharedDocs/DE/Anlage/G/MKS/initiative-klimafreundlicher-strassengueterverkehr.pdf?__blob=publicationFile (accessed on 16 March 2020).

- Unnerstall, T. Verkehr—Die Zukunft des Autos. In Energiewende verstehen: Die Zukunft von Autoverkehr, Heizen und Strompreisen; Unnerstall, T., Ed.; Springer: Berlin, Germany, 2018; pp. 57–69. ISBN 978-3-662-57786-8. [Google Scholar]

- Sternberg, A.; Hank, C.; Hebling, C. Treibhausgas-Emissionen für Batterie- und Brennstoffzellenfahrzeuge mit Reichweiten über 300 km: Studie im Auftrag der H2 Mobility. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/news/2019/ISE_Ergebnisse_Studie_Treibhausgasemissionen.pdf (accessed on 11 March 2020).

- Bolle, F.-W.; Genzowsky, K.; Gredigk-Hoffmann, S.; Reinders, M.; Riße, H.; Schröder, M.; Manja, S.; Wöffen, B.; Illing, F.; Jagemann, P.; et al. WaStraK NRW “Einsatz der Wasserstofftechnologie in der Abwasserbeseitigung”—Phase I. Band I: Kompendium Wasserstoff. 2012. Available online: https://www.lanuv.nrw.de/landesamt/forschungsvorhaben/klaeranlage-abwasserbeseitigung?tx_cartproducts_products%5Bproduct%5D=654&cHash=f6ef363dd1a75575207fe2fa142d5e95 (accessed on 16 March 2020).

- Scandinavian Biogas. Henriksdal and Bromma, Sweden. Available online: http://scandinavianbiogas.com/en/project/henriksdal-and-bromma/ (accessed on 16 March 2020).

- Schattenhofer, S. Pfaffenhofen gibt Gas—erneuerbar: Neues Projekt der Bürger-Energiegenossenschaft: Überschüssiger Öko-Strom wird Biomethan. 2017. Available online: https://www.donaukurier.de/nachrichten/wirtschaft/lokalewirtschaft/Pfaffenhofen-Pfaffenhofen-gibt-Gas-erneuerbar;art1735,3569895 (accessed on 16 March 2020).

- Meier, B. Kläranlage Kaisersesch soll Wasserstofftankstelle speisen. Rhein-Zeitung. 2017. Available online: https://www.rhein-zeitung.de/region/aus-den-lokalredaktionen/kreis-cochem-zell_artikel,-klaeranlage-kaisersesch-soll-wasserstofftankstelle-speisen-_arid,1606117.html (accessed on 29 January 2018).

- Bolle, F.-W.; Reinders, M.; Riße, H.; Schröder, M.; Bernhard, W.; Illing, F. WaStraK NRW “Einsatz der Wasserstofftechnologie in der Abwasserbeseitigung”—Phase I. Band II: Methanolsynthese. 2012. Available online: https://www.lanuv.nrw.de/landesamt/forschungsvorhaben/klaeranlage-abwasserbeseitigung?tx_cartproducts_products%5Bproduct%5D=654&cHash=f6ef363dd1a75575207fe2fa142d5e95 (accessed on 16 March 2020).

- Mariakakis, I. A Two Stage Process for Hydrogen and Methane Production by the Fermentation of Molasses. Ph.D. Thesis, Stuttgarter Berichte zur Siedlungswasserwirtschaft, Stuttgart, Germany, 2013. [Google Scholar]

- Chen, G.; Zhao, L.; Qi, Y. Enhancing the productivity of microalgae cultivated in wastewater toward biofuel production: A critical review. Appl. Energy 2015, 137, 282–291. [Google Scholar] [CrossRef]

- 2synfuel. Turning Sweage Sluidge into Fuels and Hydrogen. 2018. Available online: http://www.tosynfuel.eu (accessed on 16 March 2020).

- Energbieangentor.NRW Wasserstoff—Schlüssel zur Energiewende. Beispiele aus Nordrhein-Westfalen von der Herstellung bis zur Nutzung. 2018. Available online: https://broschueren.nordrheinwestfalendirekt.de/broschuerenservice/energieagentur/wasserstoff-schluessel-zur-energiewende-beispiele-aus-nordrhein-westfalen-von-der-herstellung-bis-zur-nutzung/2833 (accessed on 16 March 2020).

- Wietschel, M.; Plötz, P.; Pfluger, B.; Klobasa, M.; Eßer, A.; Haendel, M.; Müller-Kirchenbauer, J.; Kochems, J.; Hermann, L.; Grosse, B.; et al. Sektorkopplung—Definition, Chancen und Herausforderungen. Working Paper Sustainability and Innovation No. S 01/2018; Fraunhofer ISI: Arlsruhe, Germany, 2018. [Google Scholar]

- Reuter, B.; Hendrich, A.; Hengstler, J.; Kupferschmid, S.; Schwenk, M. Rohstoffe für innovative Fahrzeugtechnologien. Herausforderungen und Lösungsansätze. 2019. Available online: https://www.e-mobilbw.de/fileadmin/media/e-mobilbw/Publikationen/Studien/Material-Studie_e-mobilBW.pdf (accessed on 16 March 2020).

| Power-to-Gas(-H2) | Power-to-Gas(-CH4) | |

|---|---|---|

| Chemical equation (simplified) | ||

| Efficiency * | 54%–84% | 49%–79% |

| Advantages |

|

|

| Drawbacks |

|

|

| Electrical Energy Production on-Site | Feeding into the NGI |

|---|---|

| (+) use for self-sufficiency purposes (reduced fees in power purchasing) | (+) full use of the energy content of the digestion gas |

| (+) heat demand of the WWTP fully covered | (+) substitution of fossil CH4 in the NGI |

| (+) local production of renewable energy | (+) separated CO2 due to the gas treatment usable as a green CO2 source for PtX systems |

| (+) usable surplus heat for local district heating | (+) new opportunities for alternative heat concepts |

| (+) emergency power generation | |

| (+) providing control energy for energy grids | (−) gas treatment installations required |

| (-) excess heat possibly not usable | (-) new heat management required |

| (-) lower efficiency than utilization in bigger power plants | (-) higher costs for electricity purchase due to not fitting taxation systems |

| (-) no incentives for a utilization of otherrenewable heat sources (e.g., heat recovery) | (-) highly dependent on the local boundary conditions (e.g. connection and distance to the NGI) |

| Benefits | Drawbacks |

|---|---|

|

| Type of Drive | Type of Fuel | Efficiency of Drive Concept (%) | Life-Cycle Greenhouse Gas Emissions * (g CO2-eq/km) |

|---|---|---|---|

| Battery electric vehicle + battery | Electrical energy | 75–85 | 40–80 |

| Fuel cell + electric vehicle | Hydrogen | 25–35 | 50–70 |

| Combustion engine | Synthetic fuel | 10–20 | - |

| Combustion engine | Biofuel | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schäfer, M.; Gretzschel, O.; Steinmetz, H. The Possible Roles of Wastewater Treatment Plants in Sector Coupling. Energies 2020, 13, 2088. https://doi.org/10.3390/en13082088

Schäfer M, Gretzschel O, Steinmetz H. The Possible Roles of Wastewater Treatment Plants in Sector Coupling. Energies. 2020; 13(8):2088. https://doi.org/10.3390/en13082088

Chicago/Turabian StyleSchäfer, Michael, Oliver Gretzschel, and Heidrun Steinmetz. 2020. "The Possible Roles of Wastewater Treatment Plants in Sector Coupling" Energies 13, no. 8: 2088. https://doi.org/10.3390/en13082088

APA StyleSchäfer, M., Gretzschel, O., & Steinmetz, H. (2020). The Possible Roles of Wastewater Treatment Plants in Sector Coupling. Energies, 13(8), 2088. https://doi.org/10.3390/en13082088