Occurrence of Linear Discontinuous Deformations in Upper Silesia (Poland) in Conditions of Intensive Mining Extraction—Case Study

Abstract

1. Introduction

- ▪

- Cracks, when the continuity of the surface is interrupted and the horizontal displacement is not greater than 1 cm, without any vertical displacement.

- ▪

- Fissures, when the continuity of the surface is interrupted and the horizontal displacement is greater than 1 cm, without any vertical displacement.

- ▪

- Faults (steps), when the surface is cut and there is mutual vertical displacement.

- ▪

- Humps, when there is an uplift of the terrain due to high-value horizontal deformations.

- ▪

- Grabens, when a narrow hollow in the soil is created at a certain length.

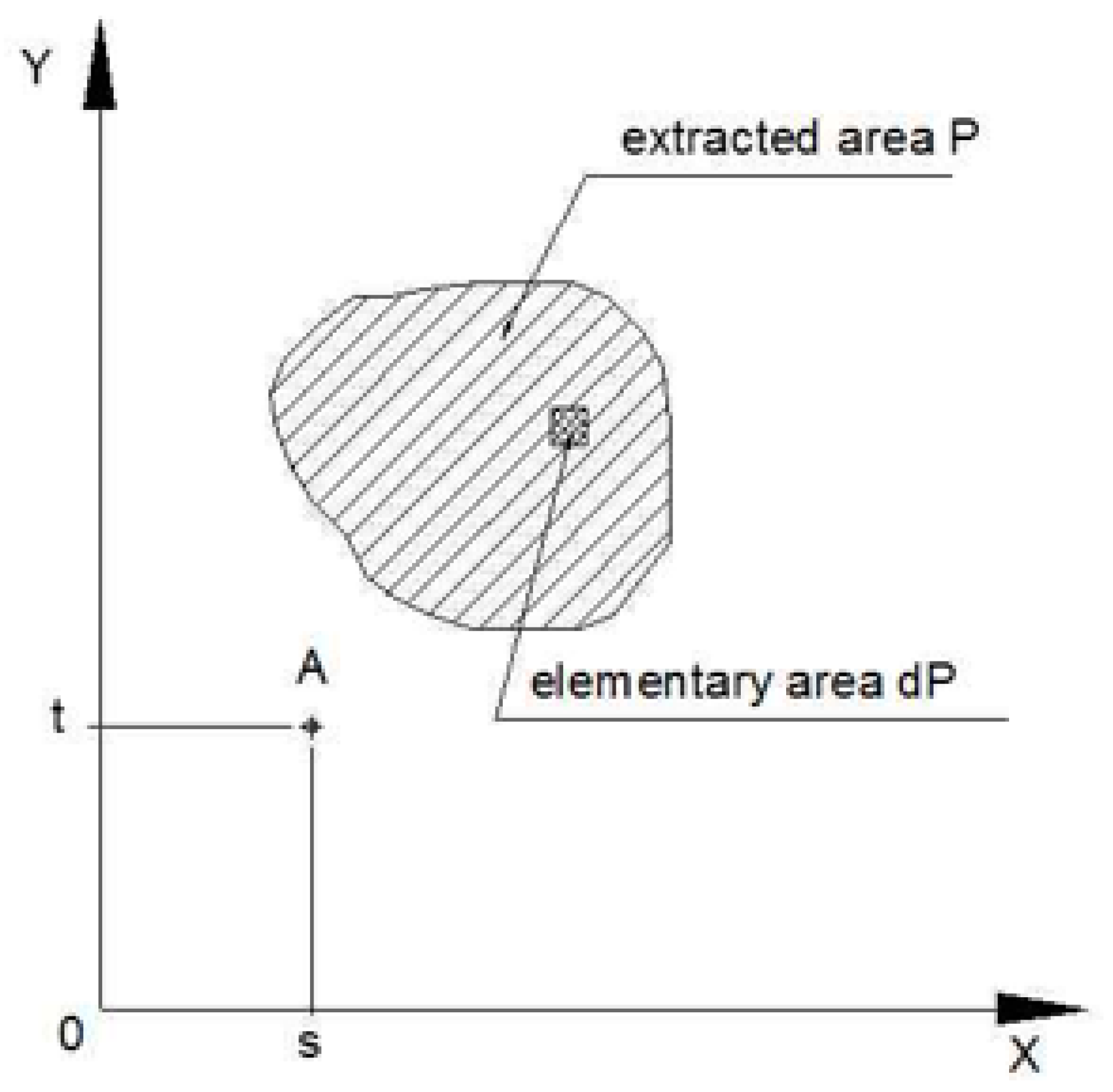

2. Material and Methods

- Geometric-integral theories utilizing a special function called the “influence function” that describes the distribution of land surface subsidence around the elementary extraction area. In Poland, there are several methods of this group, e.g., by W. Budryk–S. Knothe and T. Kochmański. The W. Budryk–S. Knothe theory, especially, has found widespread applications because of its clarity in the description of the deformation process, particularly in the transient state. It has been the subject of various modifications by other authors, aiming at its improvement—mainly in the scope of transient subsidence.

- Theories (methods) based on continuum mechanics. In these methods, the state of stress and displacement is described by a system of differential equations and a state equation that depends on the type of the considered medium. The works of A. Sałustowicz et al. are widely known in Poland.

- Solutions based on the so-called “theory of stochastic medium” created by J. Litwiniszyn and later developed by H. Smolarski.

- Numerical methods that, generally speaking, use the assumptions of FEM (Finite Element Method) methods.

- —the thickness of the coal seam, m.

- ,—the coordinates of point A in the Cartesian coordinate system, m.

- ,—the coordinates of the elementary extraction field , m.

- —the extracted area of the coal seam, m2.

- —the main impact range, m.

3. Results

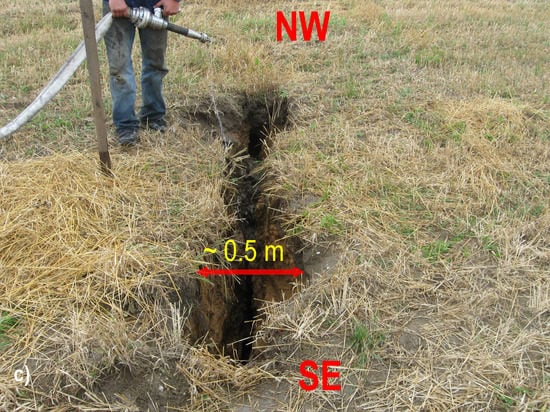

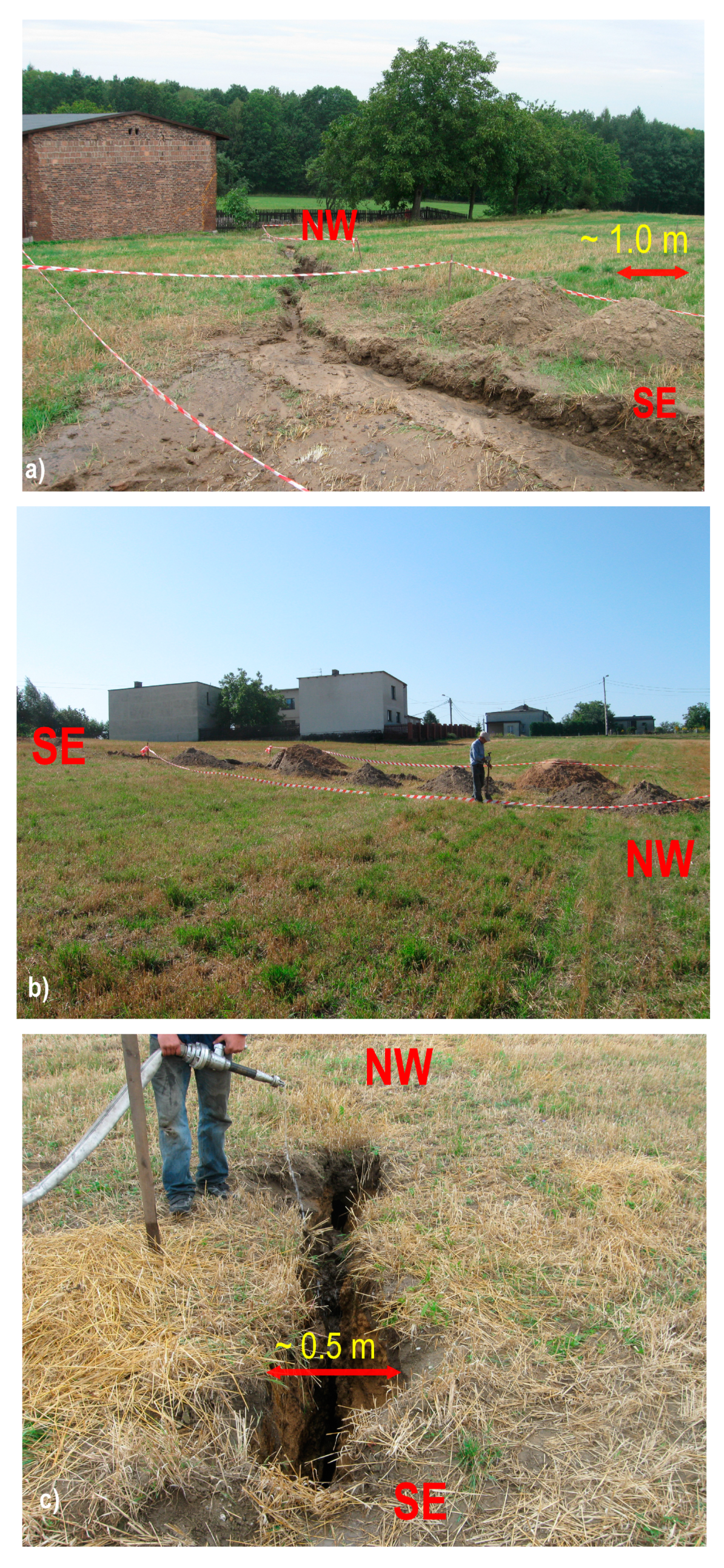

3.1. Description of the Deformation

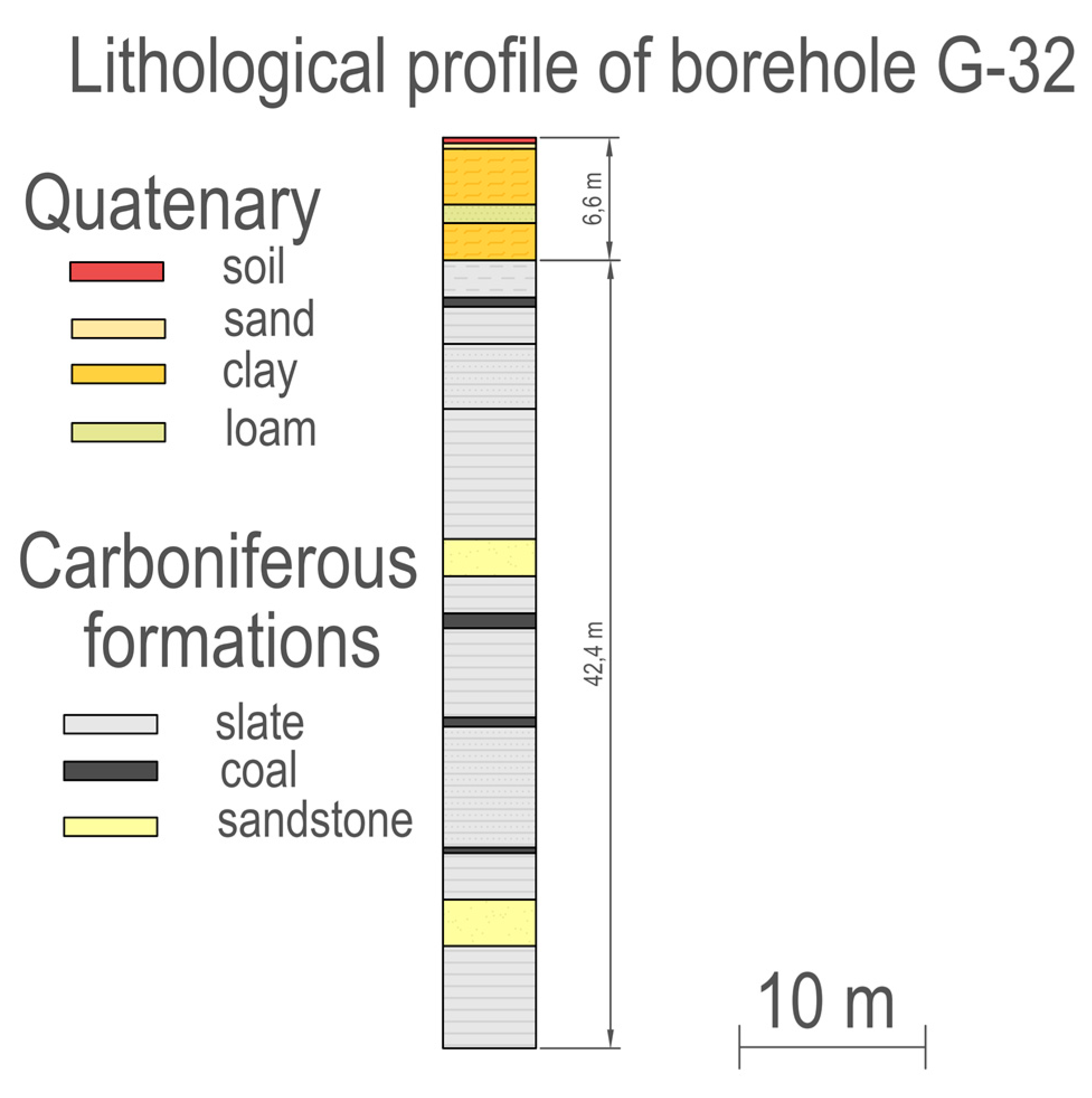

3.2. Rock Mass Structure

3.3. Tectonics

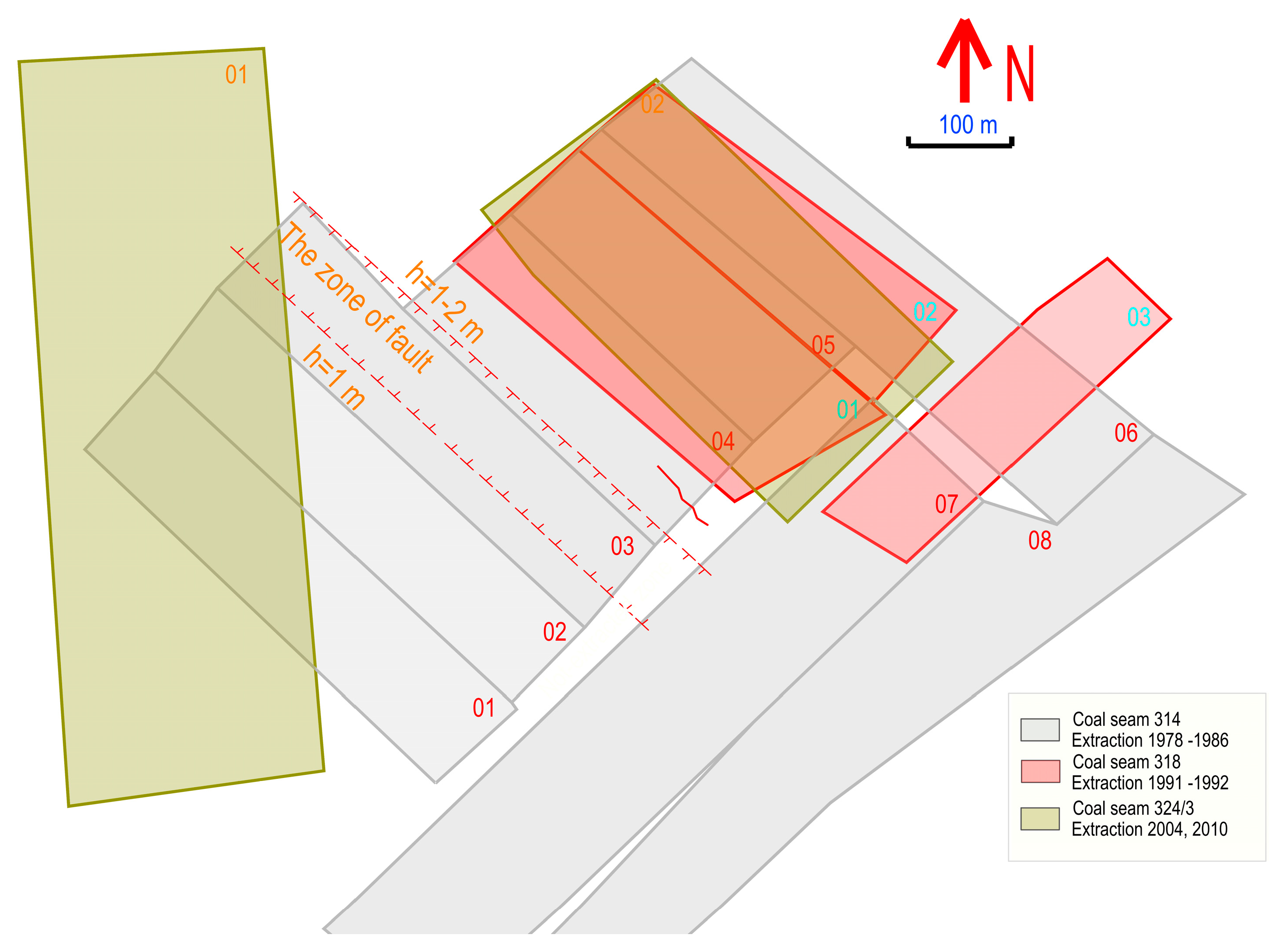

3.4. Former Mining Exploitation

3.5. Selected Analysis Method

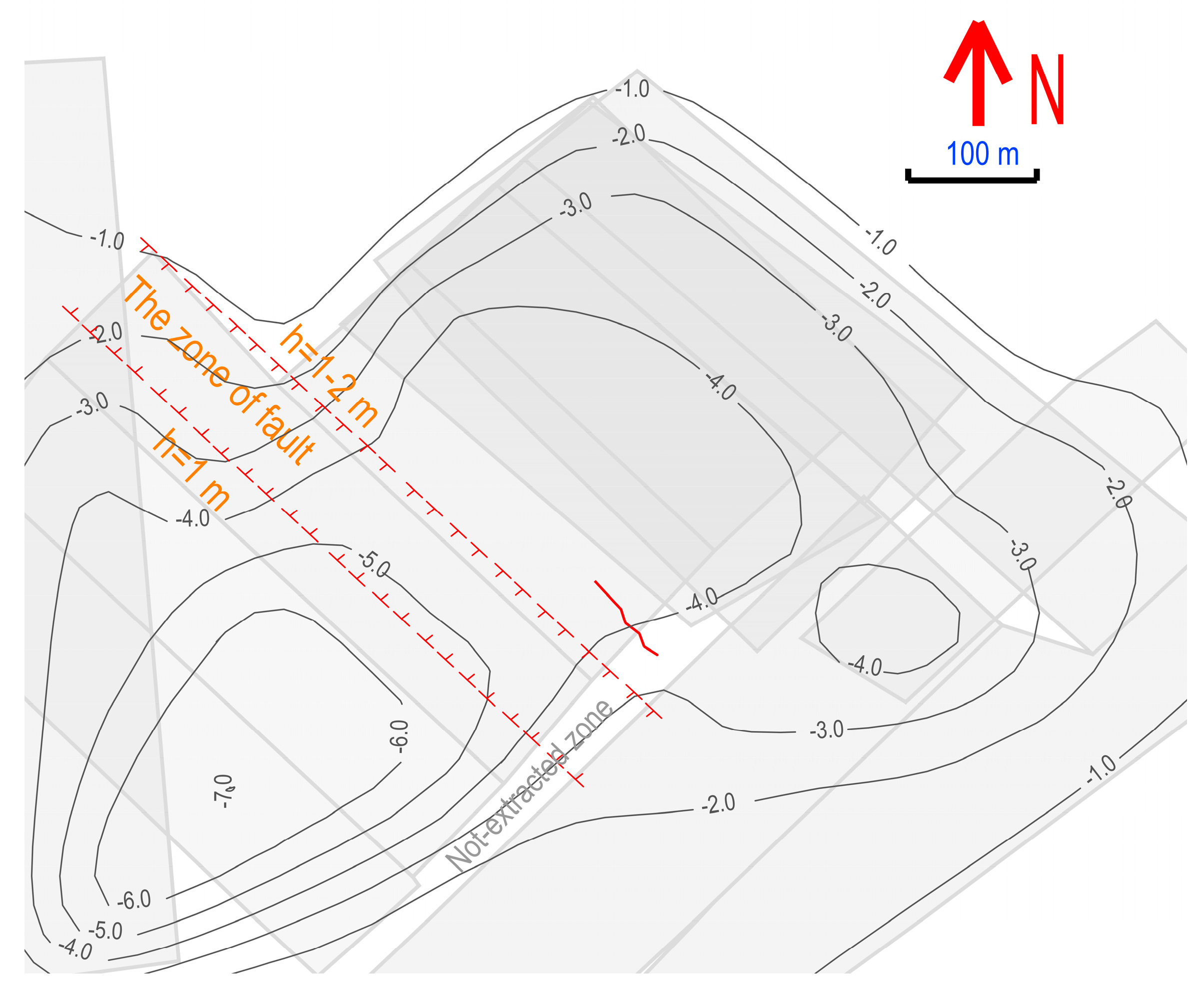

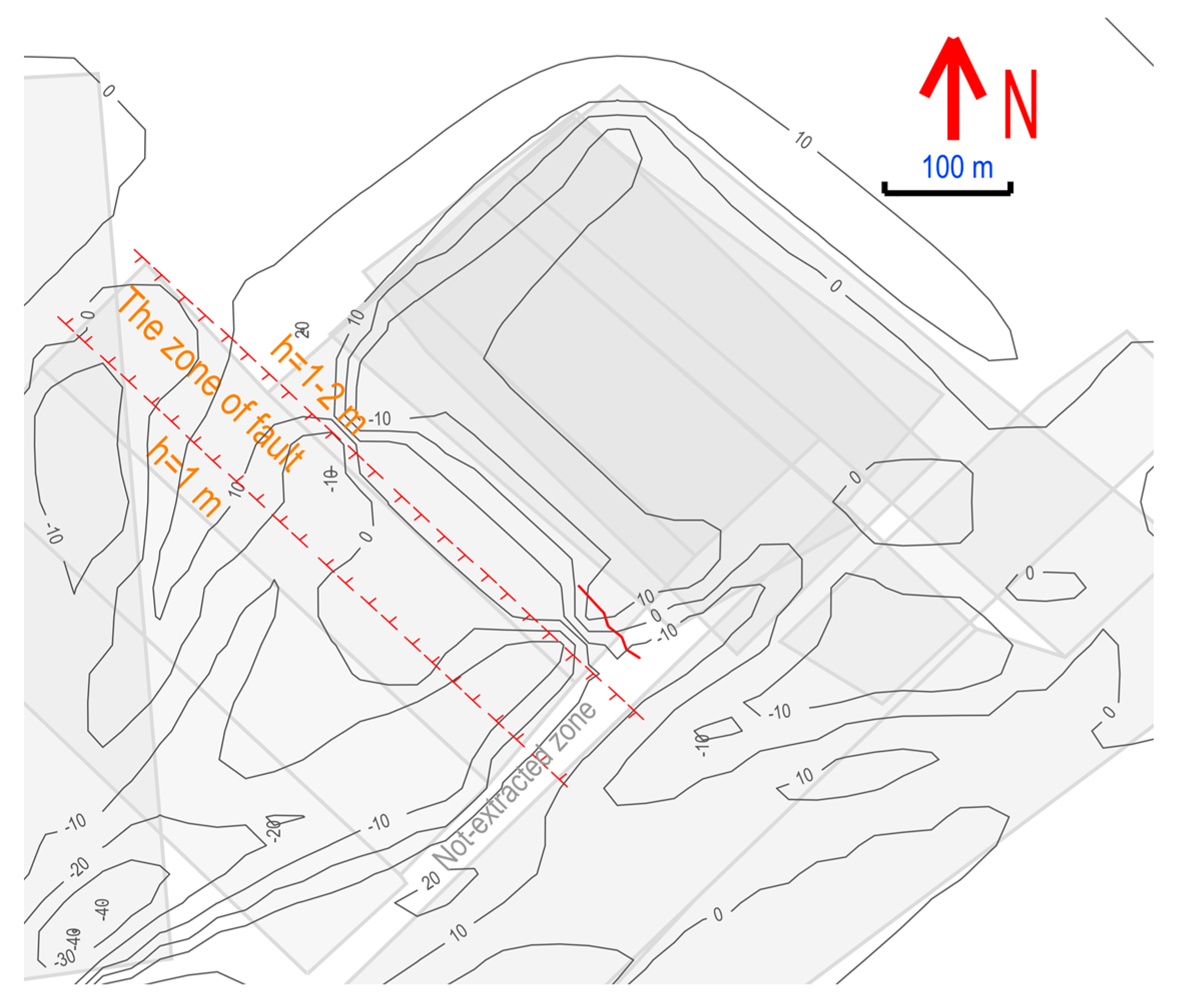

- The determination of the distribution of maximal horizontal strains, maximal inclinations, and horizontal displacements in the area of the deformation.

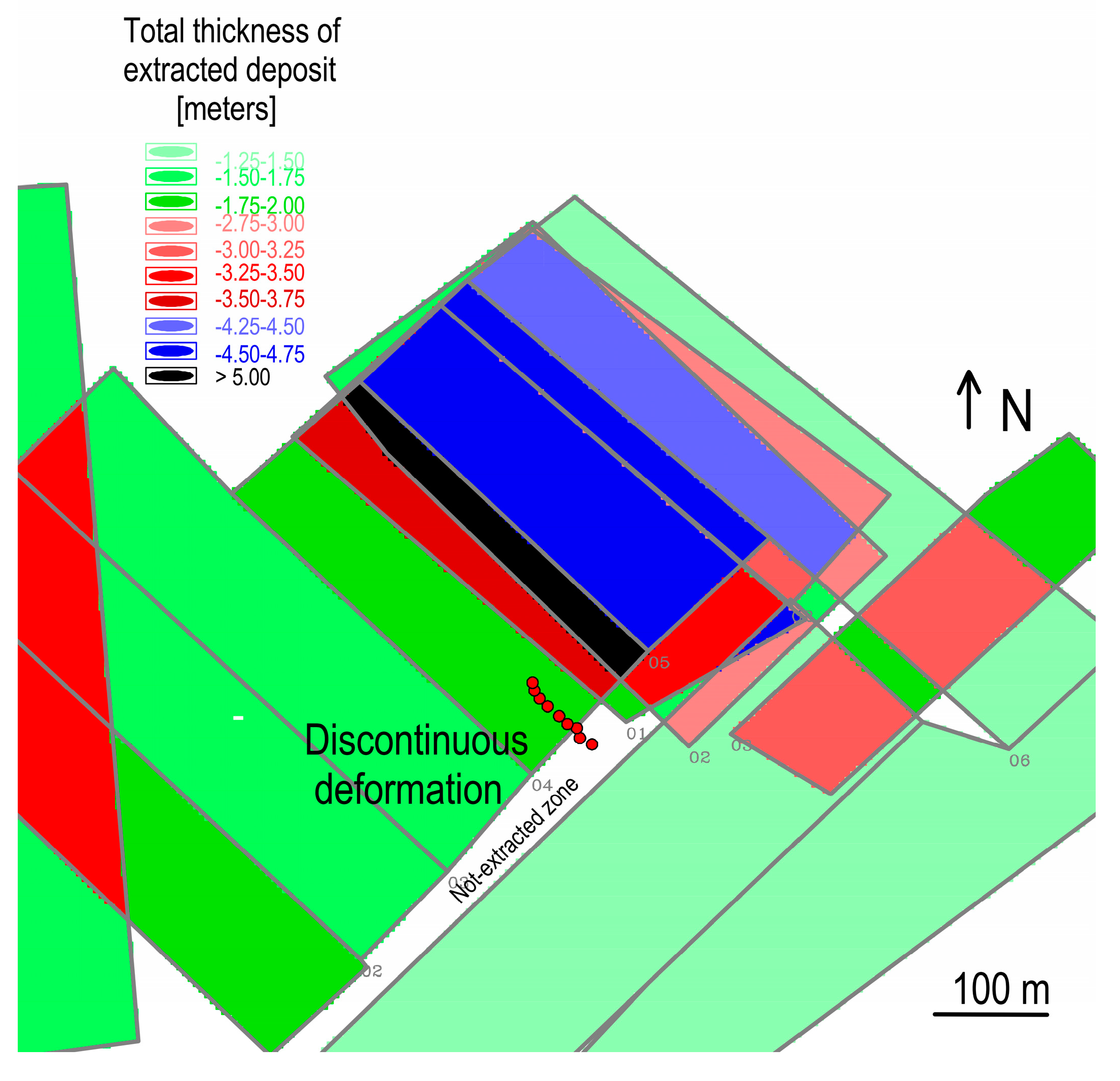

- The creations of a map of the thickness of the extracted deposit.

- The examination of the correlation between the course of the linear strains, the thicknesses of the selected deposit and the tectonic fault, and the location of the deformation on the surface.

- Roof control coefficient = 0.8.

- Tangent of the main impact range angle β = 2.0.

- Proportionality coefficient determining the horizontal strains = 0.32.

- Extraction boundary = 0 m.

3.6. Obtained Calculation Results and Their Review

4. Conclusions

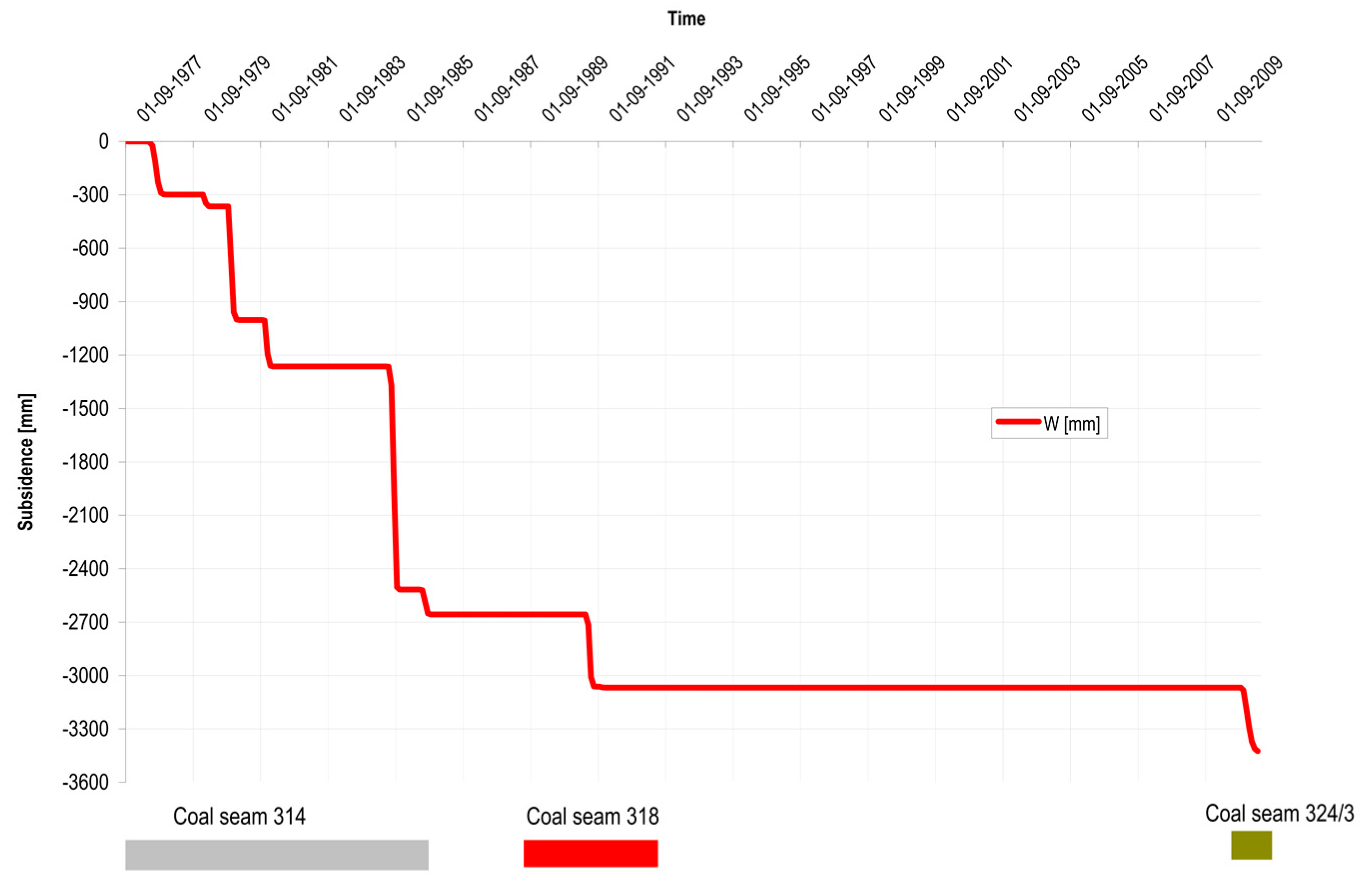

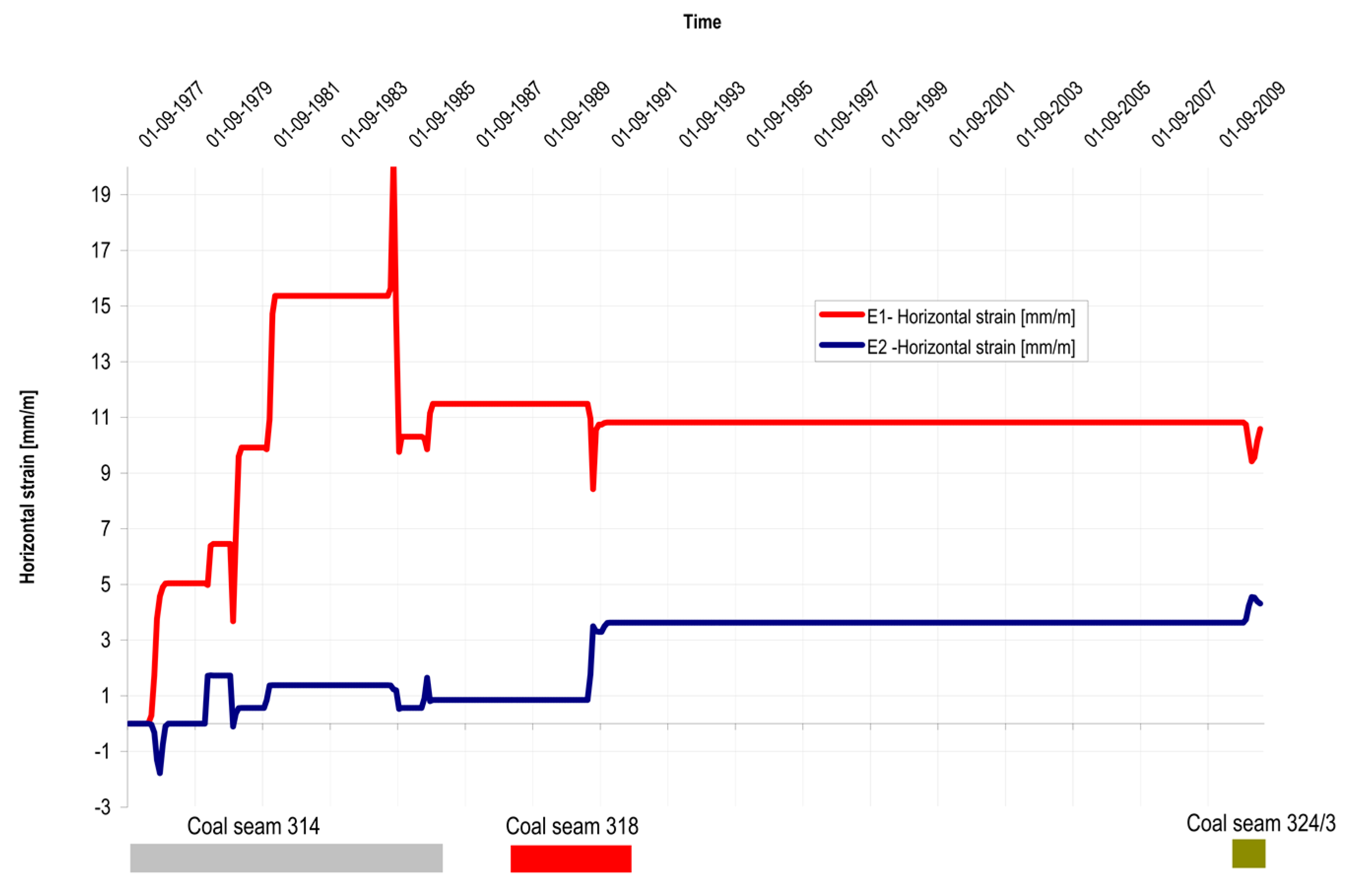

- The main and basic cause of the occurrence of the deformation was the conducted mining exploitation with caving in three coal seams at the depths between 200 and 545 m. This exploitation caused significant (i.e., exceeding 10 mm/m) horizontal tensile strain values. The obtained results confirmed the known conclusions drawn from studies conducted by other authors. However, the cases described in the literature only presented the occurrence of ground steps and cracks in the rock mass—not grabens (as was the instance in the analyzed case).

- A factor that could have contributed to the formation of the deformation was the occurrence of a tectonic fault in the area of the deformation. Its course overlapped with the direction of the resulting deformation, which confirmed this view. Another convincing argument was the fact that no discontinuous deformations occurred in places where the values of the horizontal tensile strain were the same, but there were no tectonic faults. Here, it should be noted that the fault throw was of small value—as opposed to the cases known from the literature. This suggests that the activation of even a small fault can cause dangerous and extensive deformations.

- The way to avoid the dangers associated with the occurrence of linear deformations is to design the exploitation in such a way as to limit the occurrence of high-value horizontal strain or at least to allow for their occurrence in undeveloped zones.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, C.; Xu, J.; Wang, F.; Wang, F. Movement Boundary Shape of Overburden Strata and Its Influencing Factors. Energies 2018, 11, 742. [Google Scholar] [CrossRef]

- Peng, S. Coal Mine Ground Control, 3rd ed.; West Virginia University: Morgantown, WV, USA, 2008; p. 750. [Google Scholar]

- Ścigała, R.; Szafulera, K. Linear discontinuous deformations created on the surface as an effect of underground mining and local geological conditions—Case study. Bull. Eng. Geol. Environ. 2019, 1–10. [Google Scholar] [CrossRef]

- Orwat, J. Causes analysis of occurrence of the terrain surface discontinuous deformations of a linear type. J. Phys. 2020, 1426, 1–9. [Google Scholar] [CrossRef]

- Kowalski, A.; Kotyrba, A. Linear discontinuous deformation of A4 highway within mining area Halemba. Miner. Resour. Manag. 2009, 25, 303–317. [Google Scholar]

- Chudek, M. Rock Mass Mechanics with Basics of Environment Management in Mining and Post-Mining Areas; Publishing House of Silesian University of Technology: Gliwice, Poland, 2010; p. 499. [Google Scholar]

- Strzałkowski, P. Overview of Mining Areas Protection; Publishing House of Silesian University of Technology: Gliwice, Poland, 2015; p. 192. [Google Scholar]

- Bell, F.G.; Stacey, T.R.; Genske, D.D. Mining subsidence and its effect on the environment: Some differing examples. Environ. Geol. 2000, 40, 135–152. [Google Scholar] [CrossRef]

- Strzałkowski, P.; Ścigała, R. The causes of mining induced ground steps occurrence—Case study from Upper Silesia in Poland. Acta Geodyn. Geomater. 2017, 14, 305–312. [Google Scholar] [CrossRef][Green Version]

- Li, X.; Wang, S.J.; Liu, T.Y.; Ma, F.S. Engineering geology, ground surface movement and fissures induced by underground mining in the Jinchuan Nickel Mine. Eng. Geol. 2004, 76, 93–107. [Google Scholar] [CrossRef]

- Woo, K.; Eberhardt, E.; Elmo, D.; Stead, D. Empirical investigation and characterization of surface subsidence related to block cave mining. Int. J. Rock Mech. Min. Sci. 2013, 61, 31–42. [Google Scholar] [CrossRef]

- Donnelly, L.J. A review of international cases of fault reactivation during mining subsidence and fluid abstraction. Q. J. Eng. Geol. Hydrogeol. 2009, 42, 73–94. [Google Scholar] [CrossRef]

- Hellewell, E.G. Influence of faulting on ground movement due to coal mining. The UK and European experience. Min. Eng. 1988, 147, 334–337. [Google Scholar]

- Kratzsch, H. Mining Subsidence Engineering; Springer-Verlag: Berlin/Heidelberg, Germany; New York, NY, USA, 1983; p. 543ff. [Google Scholar]

- Ścigała, R. The identification of parameters of theories used for prognoses of post mining deformations by means of present software. Arch. Min. Sci. 2013, 58, 1347–1357. [Google Scholar] [CrossRef]

- Ścigała, R. The Influence of Deposit Tectonics on the Distribution on Mining Area Deformations; Publishing House of Silesian University of Technology: Gliwice, Poland, 2013; p. 160. [Google Scholar]

- Tajduś, A.; Cała, M.; Tajduś, K. Seismicity and rock burst hazard assessment in fault zones: A case study. Arch. Min. Sci. 2018, 63, 747–765. [Google Scholar] [CrossRef]

- Malinowska, A.A.; Hejmanowski, R. The impact of deep underground coal mining on Earth fissure occurrence. Acta Geodyn. Geomater. 2016, 13, 321–330. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, C.; Xia, K.; Pang, H.; Sun, C.; Yang, K.; Zheng, X. Investigation on the distribution characteristics of ground cracks in the Chengchao Iron Mine, China. Environ. Earth Sci. 2019, 78, 280. [Google Scholar] [CrossRef]

- Zhu, H.; He, F.; Fan, Y. Development mechanism of mining-induced ground fissure for shallow burial coal seam in the mountains area of southwestern China: A case study. Acta Geodyn. Geomater. 2018, 15, 329–362. [Google Scholar] [CrossRef]

- Kang, J. Analysis of effect of fissures in caused by underground mining on ground movement and deformation. Artic. Yanshilixue Yu Gongcheng Xuebao/Chin. J. Rock Mech. Eng. 2008, 27, 59–64. [Google Scholar]

- Peng, J.; Qiao, J.; Leng, Y.; Wang, F.; Xue, S. Distribution and mechanism of the ground fissures in Wei River Basin, the origin of the Silk Road Environ. Earth Sci. 2016, 75, 1–12. [Google Scholar] [CrossRef]

- Li, J.; Liu, C. Formation Mechanism and Reduction Technology of Mining-Induced Fissures in Shallow Thick Coal Seam Mining. Shock Vib. 2017, 6, 14. [Google Scholar] [CrossRef]

- Lian, X.; Hu, H. Terrestrial laser scanning monitoring and spatial analysis of ground disaster in Gaoyang coal mine in Shanxi, China: A technical note. Environ. Earth Sci. 2017, 76, 287. [Google Scholar] [CrossRef]

- Ścigała, R. Computer Aided Forecasting of Rock Mass and Surface Deformations; Publishing House of Silesian University of Technology: Gliwice, Poland, 2008; p. 127. [Google Scholar]

- Zych, J. The Method of Predicting Mining Exploitation Influences on the Ground Surface Taking into Account the Asymmetry of Deformation Process; Publishing House of Silesian University of Technology: Gliwice, Poland, 1987; p. 158. [Google Scholar]

- Knothe, S. Forecasting the Impact of Mining Exploitations; Publishing House ‘Śląsk’: Katowice, Poland, 1984; p. 122. [Google Scholar]

- Kryzia, K.; Majcherczyk, T.; Niedbalski, Z. Variability of exploitation coefficient of Knothe theory in relation to rock mass strata type. Arch. Min. Sci. 2018, 63, 767–782. [Google Scholar] [CrossRef]

- Strzałkowski, P. Some Remarks on Impact of Mining Based on an Example of Building Deformation and Damage Caused by Mining in Conditions of Upper Silesian Coal Basin. Pure Appl. Geophys. 2019, 176, 2595–2605. [Google Scholar] [CrossRef]

- Gabzdyl, W. Geology of Coal Deposits. Deposits of the World; Polska Agencja Ekologiczna: Warsaw, Poland, 1994; p. 400. [Google Scholar]

- Jureczka, J.; Ignatowicz, A.; Zdanowski, A. Polish hard coal basins—And overview of the history of the researche of the National Geological Institute. Przegląd Geologiczny 2019, 67, 578–583. [Google Scholar]

- Strzałkowski, P.; Szafulera, K. Mining—Geological Opinion Concerning Mining Extraction Influences on the Ground Surface in the Area of Marzankowicka Street in Mikołów; Unpublished Work; Silesian University of Technology: Gliwice, Poland, 2019. [Google Scholar]

| Coal Seam | Mining Longwall | Exploitation Commencement | Exploitation Completion | Thickness (m) | Depth (m) | Relative Direction of Deformations |

|---|---|---|---|---|---|---|

| 314 | 01 | 1 January 1978 | 30 September 1978 | 2.20 | 210 | down |

| 314 | 02 | 1 January 1979 | 30 September 1979 | 2.10 | 210 | NE |

| 314 | 03 | 1 January 1980 | 30 July 1980 | 2.15 | 210 | down |

| 314 | 04 | 1 October 1980 | 15 May 1981 | 2.20 | 210 | down |

| 314 | 05 | 1 October 1981 | 15 May 1982 | 1.80 | 205 | down |

| 314 | 06 | 1 April 1985 | 15 February 1986 | 1.70 | 200 | NE |

| 314 | 07 | 1 September 1977 | 15 December 1978 | 1.70 | 235 | E 2 |

| 314 | 08 | 1 January 1986 | 15 December 1986 | 1.70 | 255 | E |

| 318 | 01 | 1 May 1991 | 30 September 1991 | 2.20 | 285 | NE |

| 318 | 02 | 1 January 1990 | 30 September 1991 | 2.00 | 285 | NE |

| 318 | 03 | 1 October 1991 | 31 March 1992 | 2.20 | 292 | NE |

| 324/3 | 01 | 15 March 2004 | 31 December 2004 | 2.00 | 545 | N 1 |

| 324/3 | 02 | 1 October 2010 | 30 April 2011 | 1.9 | 530 | NE |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strzałkowski, P.; Szafulera, K. Occurrence of Linear Discontinuous Deformations in Upper Silesia (Poland) in Conditions of Intensive Mining Extraction—Case Study. Energies 2020, 13, 1897. https://doi.org/10.3390/en13081897

Strzałkowski P, Szafulera K. Occurrence of Linear Discontinuous Deformations in Upper Silesia (Poland) in Conditions of Intensive Mining Extraction—Case Study. Energies. 2020; 13(8):1897. https://doi.org/10.3390/en13081897

Chicago/Turabian StyleStrzałkowski, Piotr, and Katarzyna Szafulera. 2020. "Occurrence of Linear Discontinuous Deformations in Upper Silesia (Poland) in Conditions of Intensive Mining Extraction—Case Study" Energies 13, no. 8: 1897. https://doi.org/10.3390/en13081897

APA StyleStrzałkowski, P., & Szafulera, K. (2020). Occurrence of Linear Discontinuous Deformations in Upper Silesia (Poland) in Conditions of Intensive Mining Extraction—Case Study. Energies, 13(8), 1897. https://doi.org/10.3390/en13081897