Numerical Analysis on the Effectiveness of Gurney Flaps as Power Augmentation Devices for Airfoils Subject to a Continuous Variation of the Angle of Attack by Use of Full and Surrogate Models

Abstract

1. Introduction

1.1. Background

1.2. Objectives

1.3. Organization of the Study

2. Study Cases

2.1. Experimental Validation Benchmark

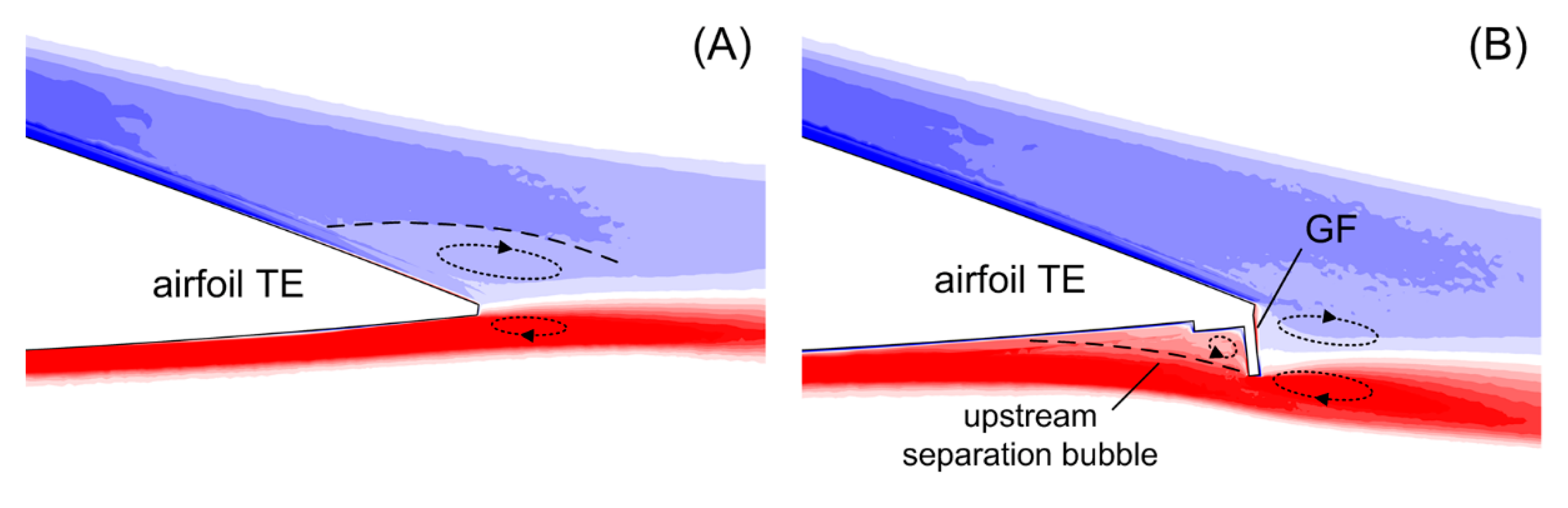

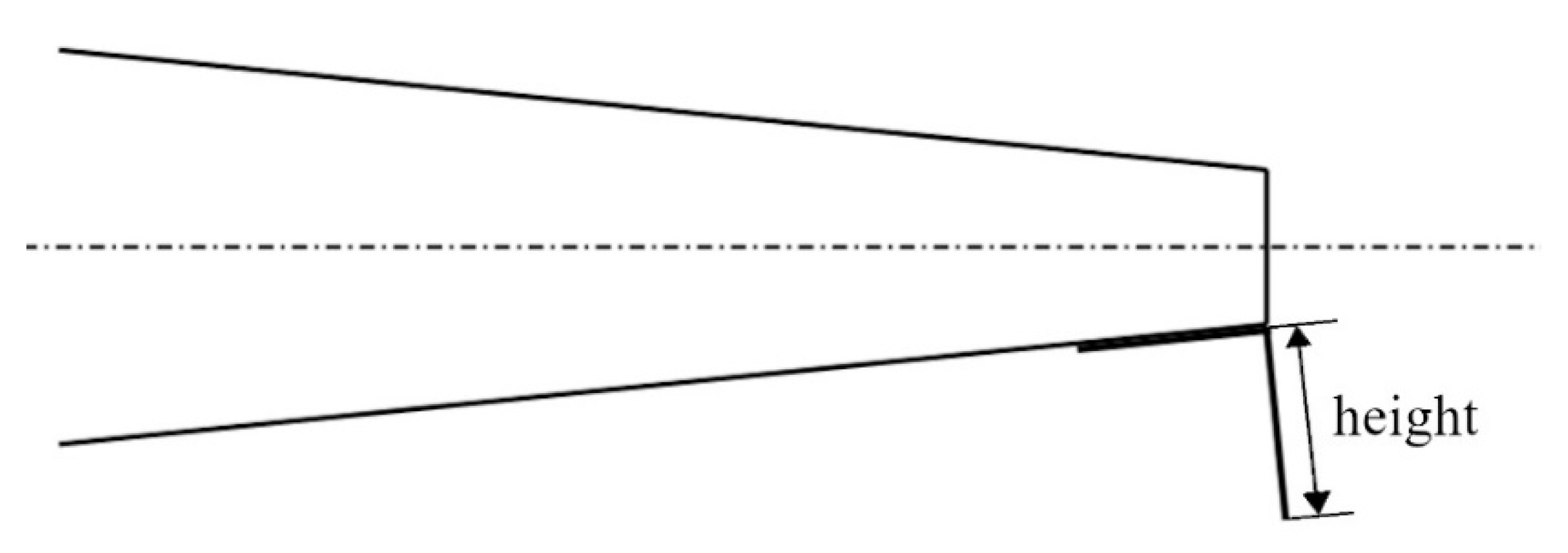

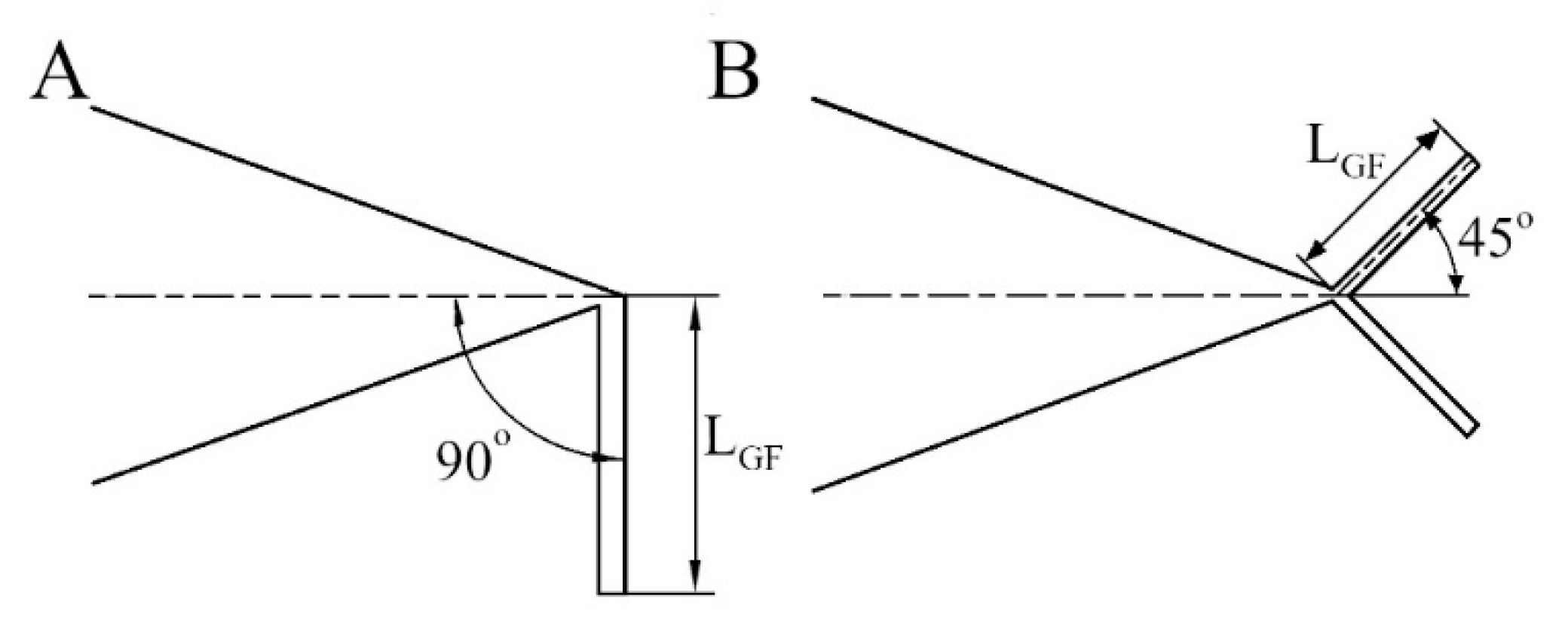

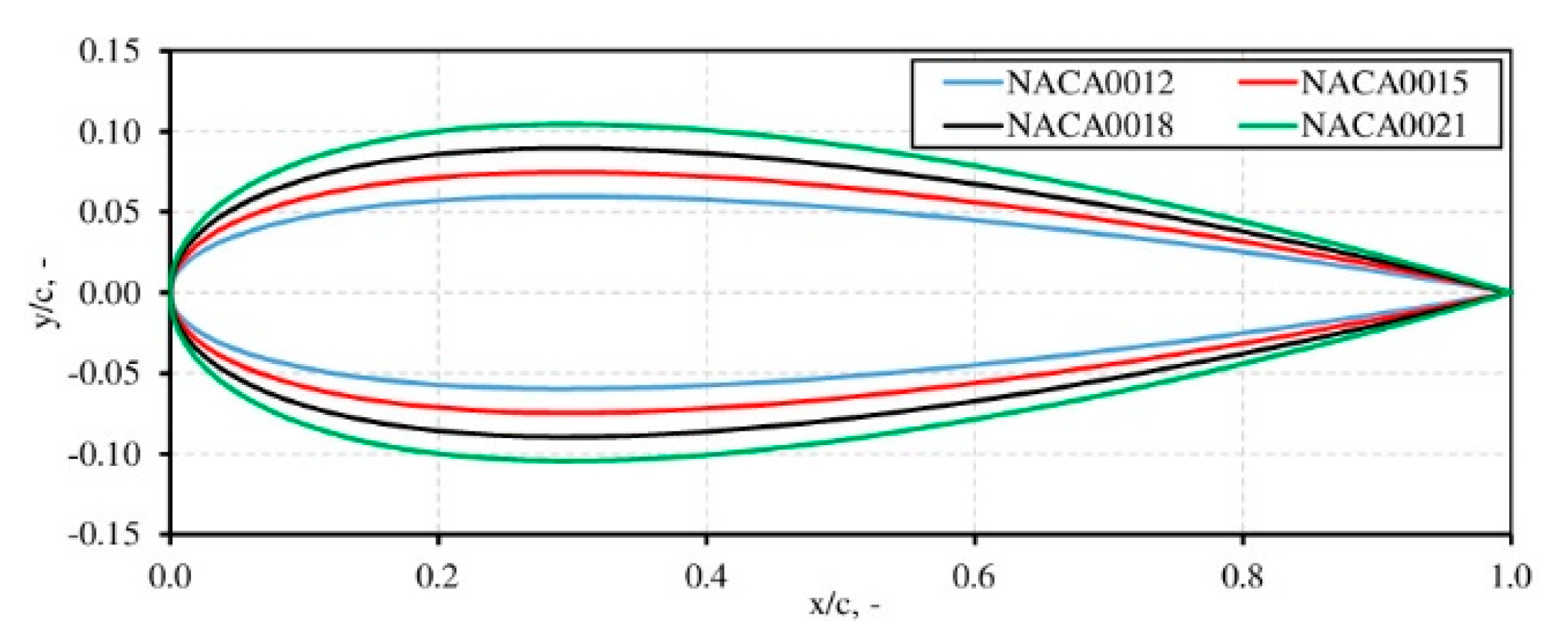

2.2. Gurney Flaps

2.3. Test Plan

3. Methods

3.1. Numerical CFD Simulations

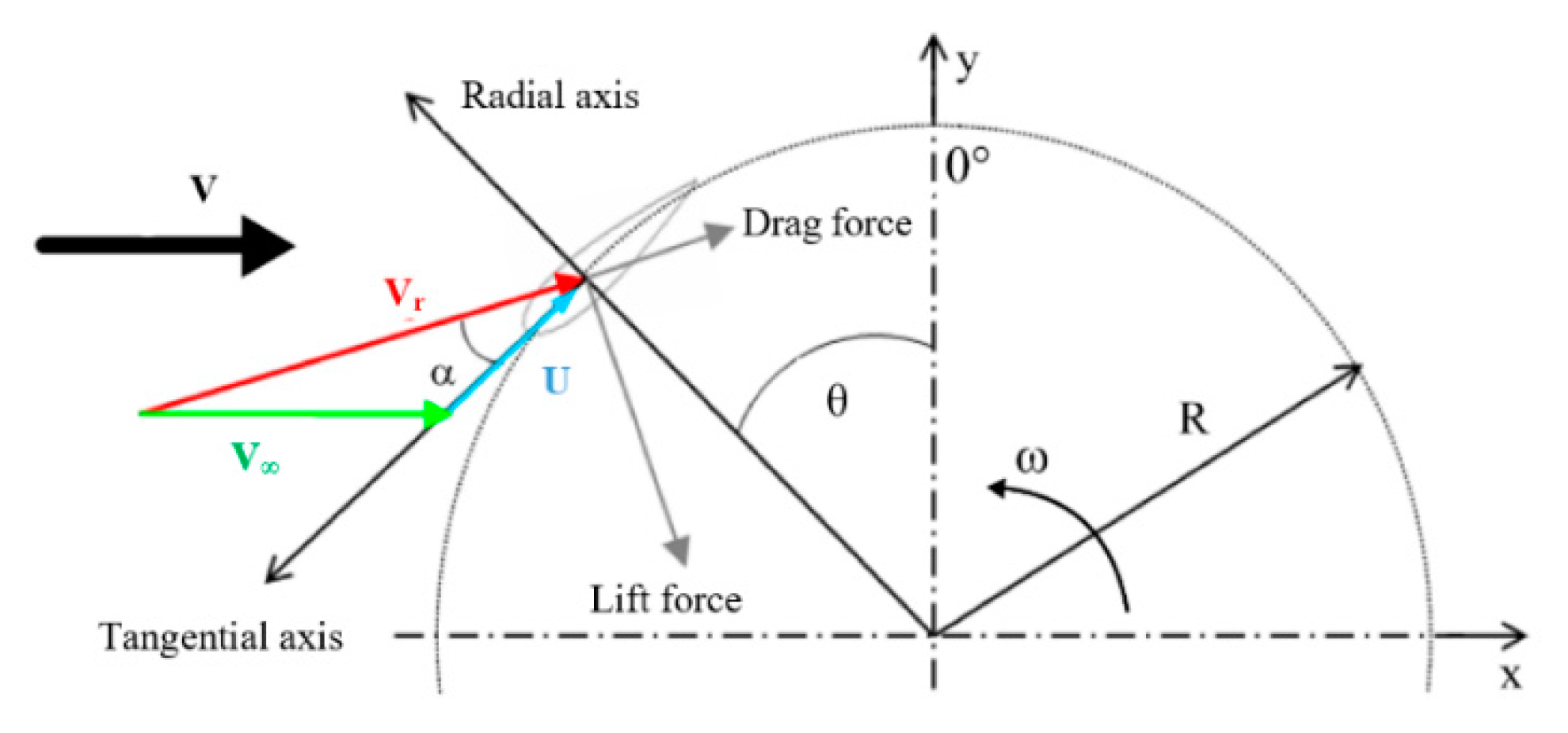

3.2. Pitching Movements and Conventions

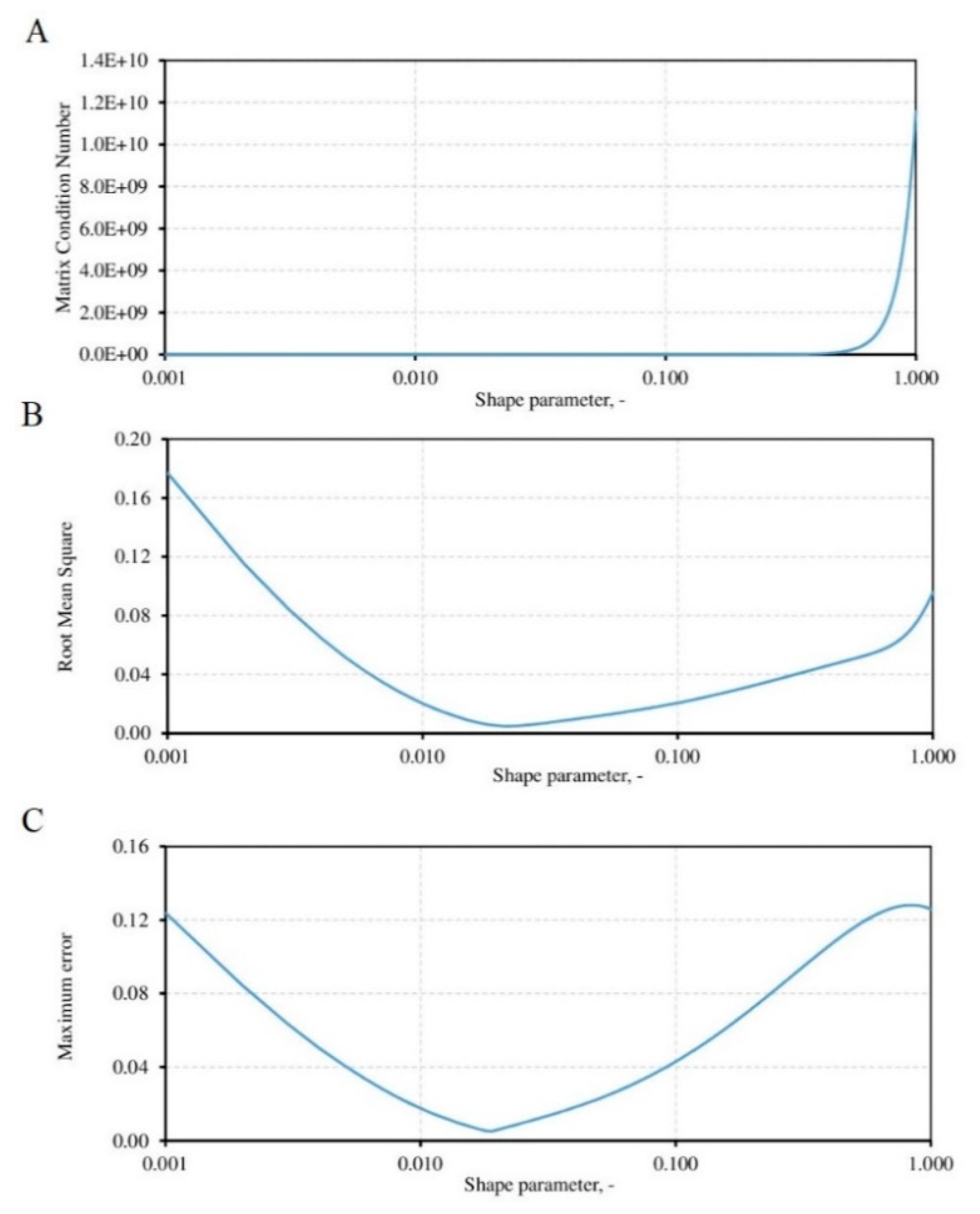

3.3. Radial Basis Functions (RBFs) Interpolation for Data Reduction

4. Results and Discussions

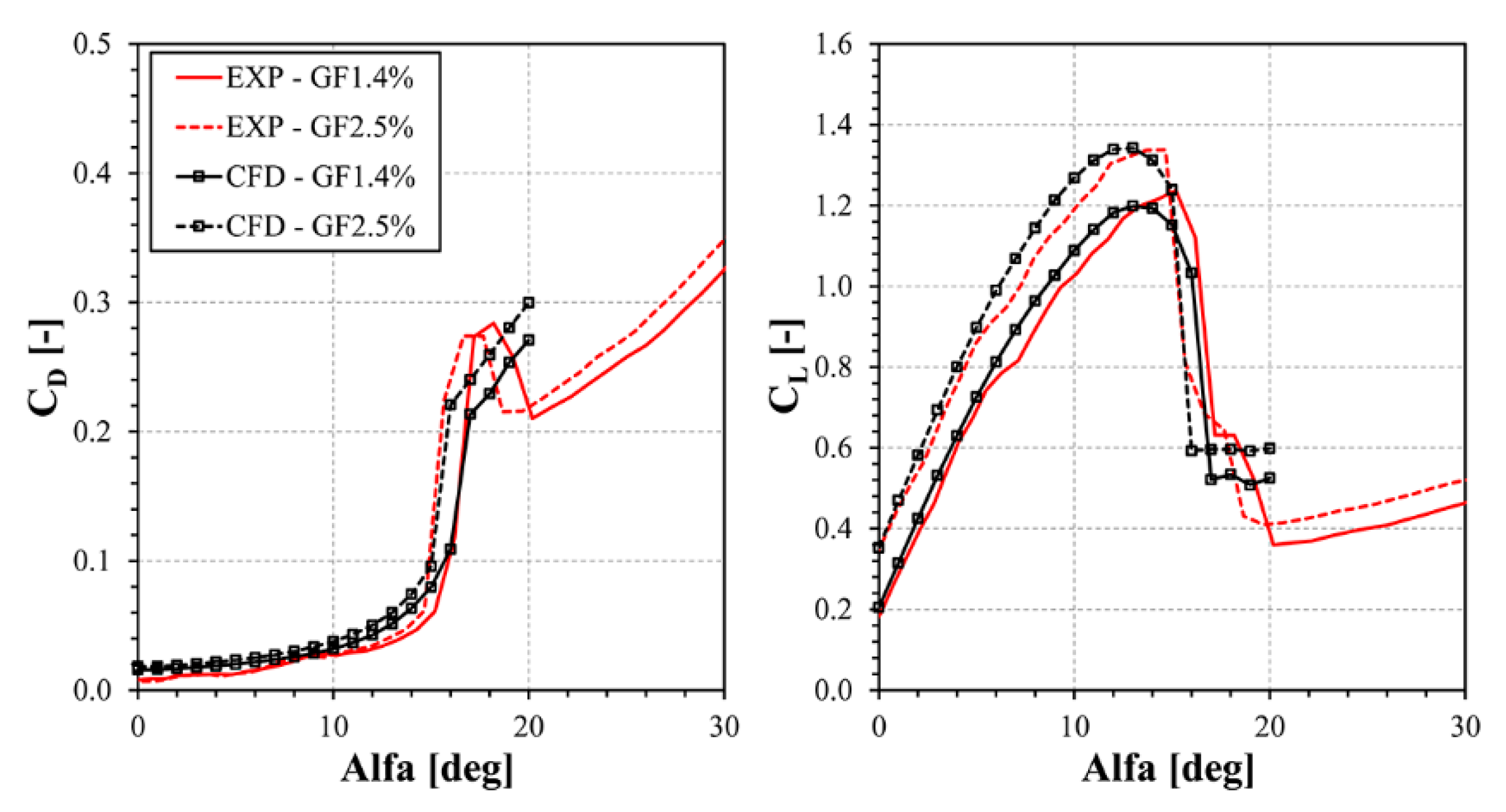

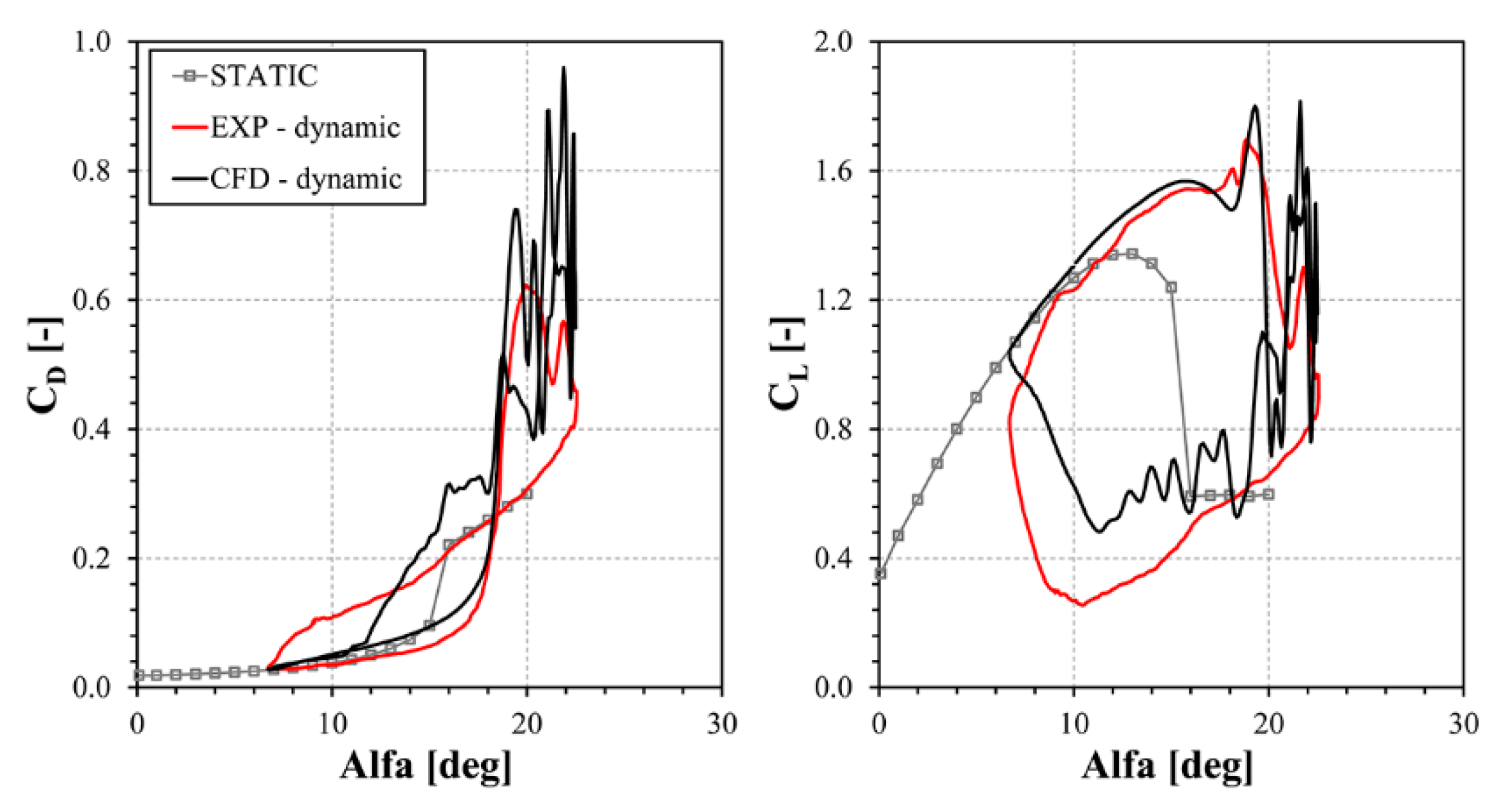

4.1. Experimental Assessment of the Numerical Model

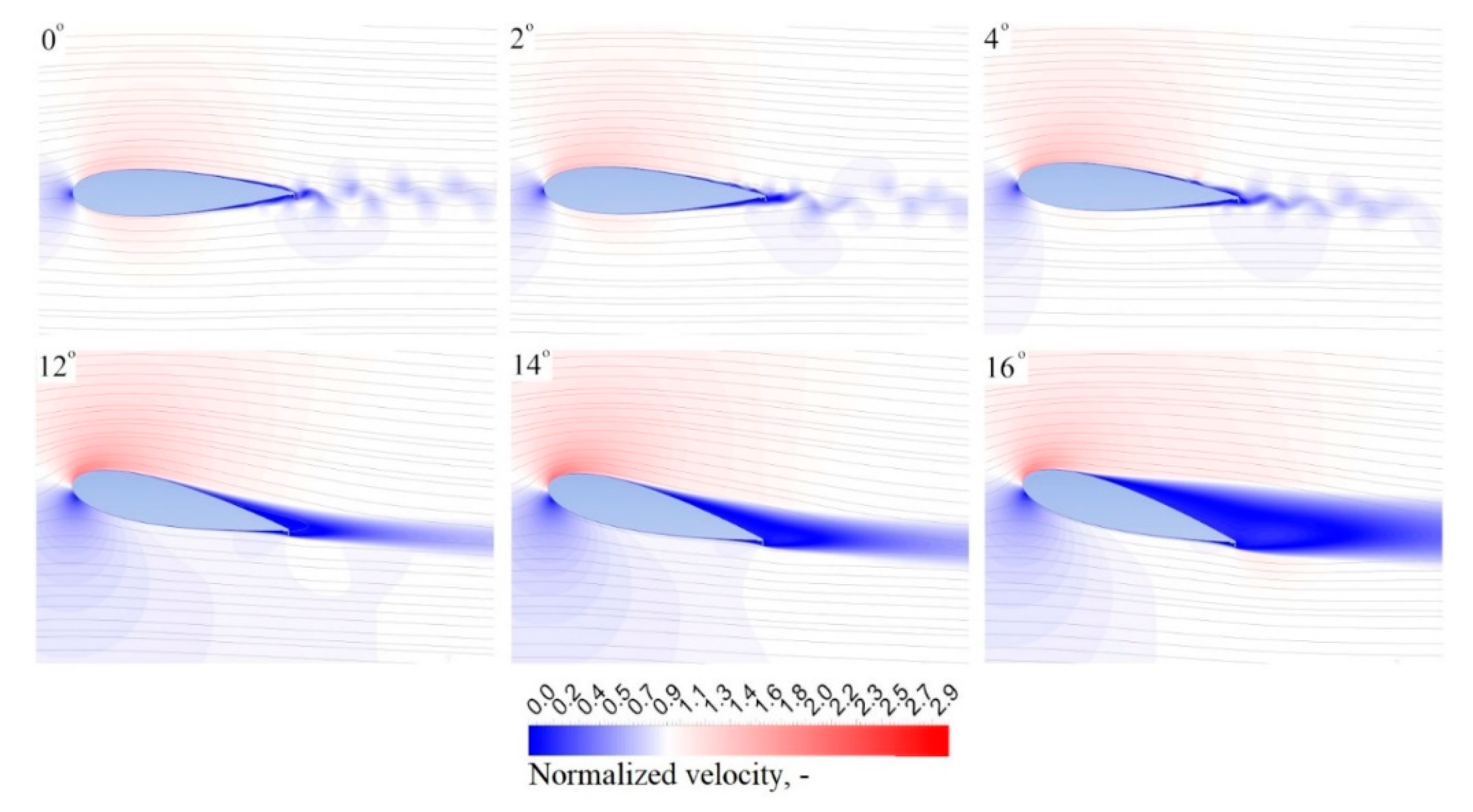

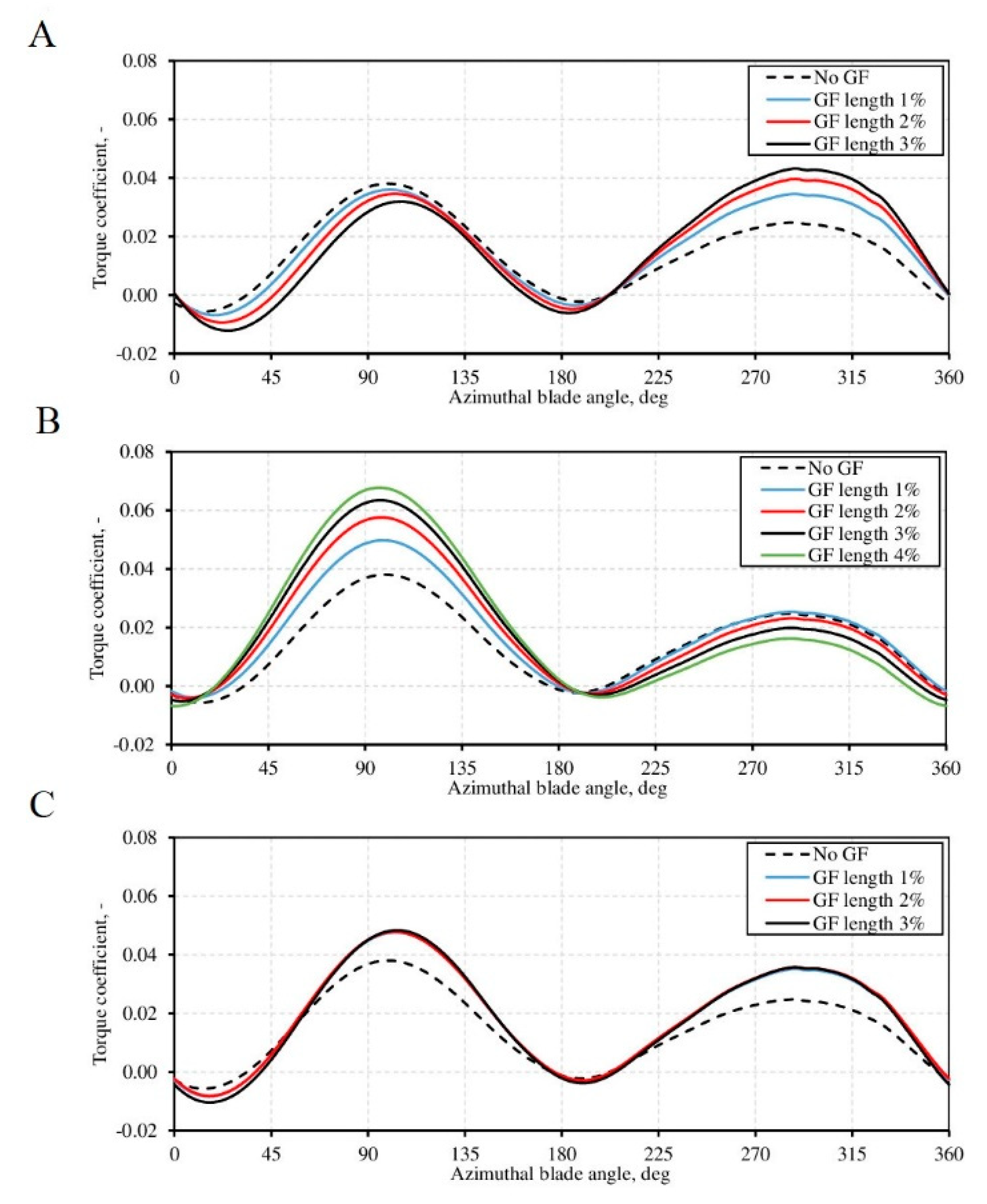

4.2. GF Effects in Cycloidal Motion: Impact on Torque Profiles

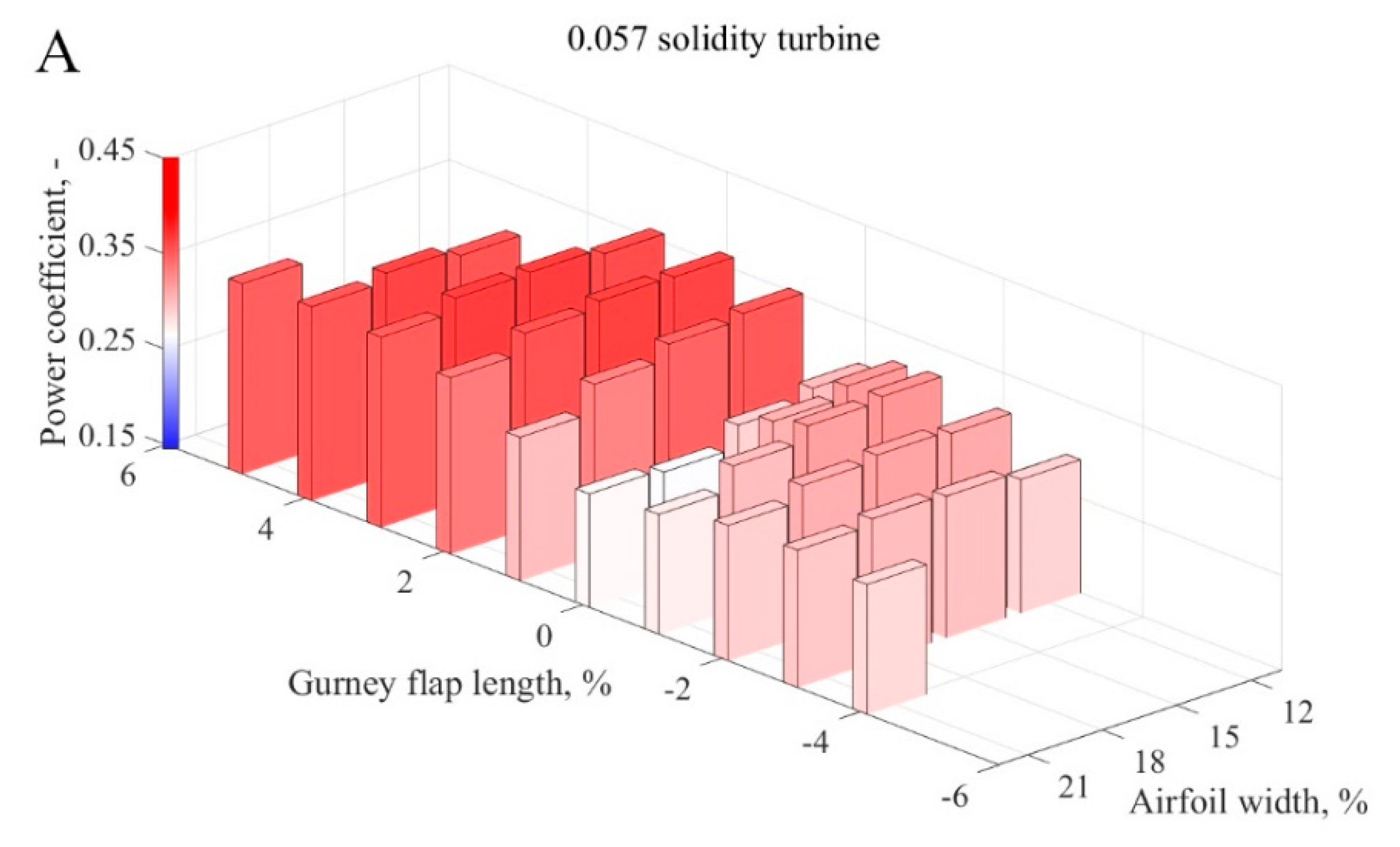

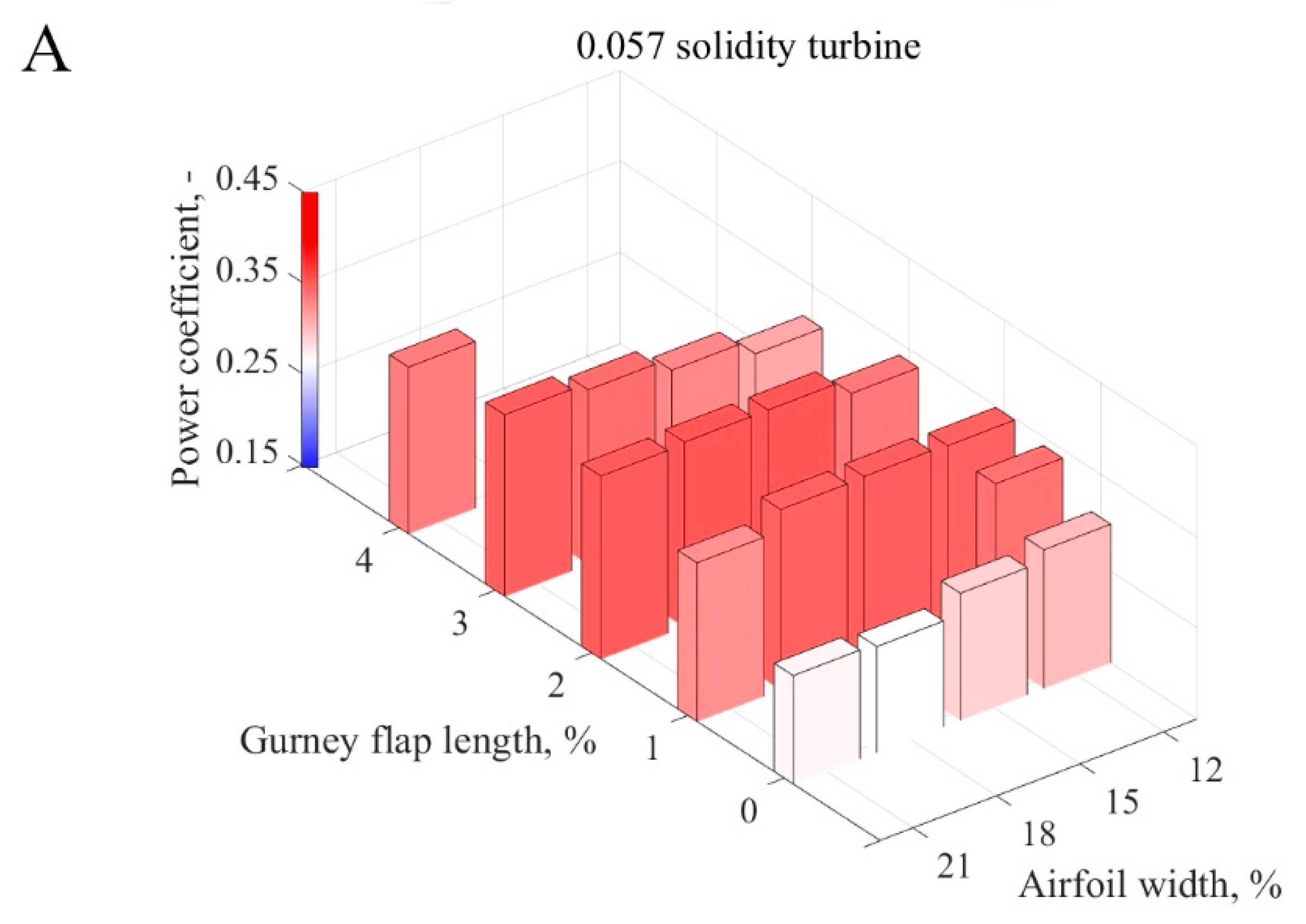

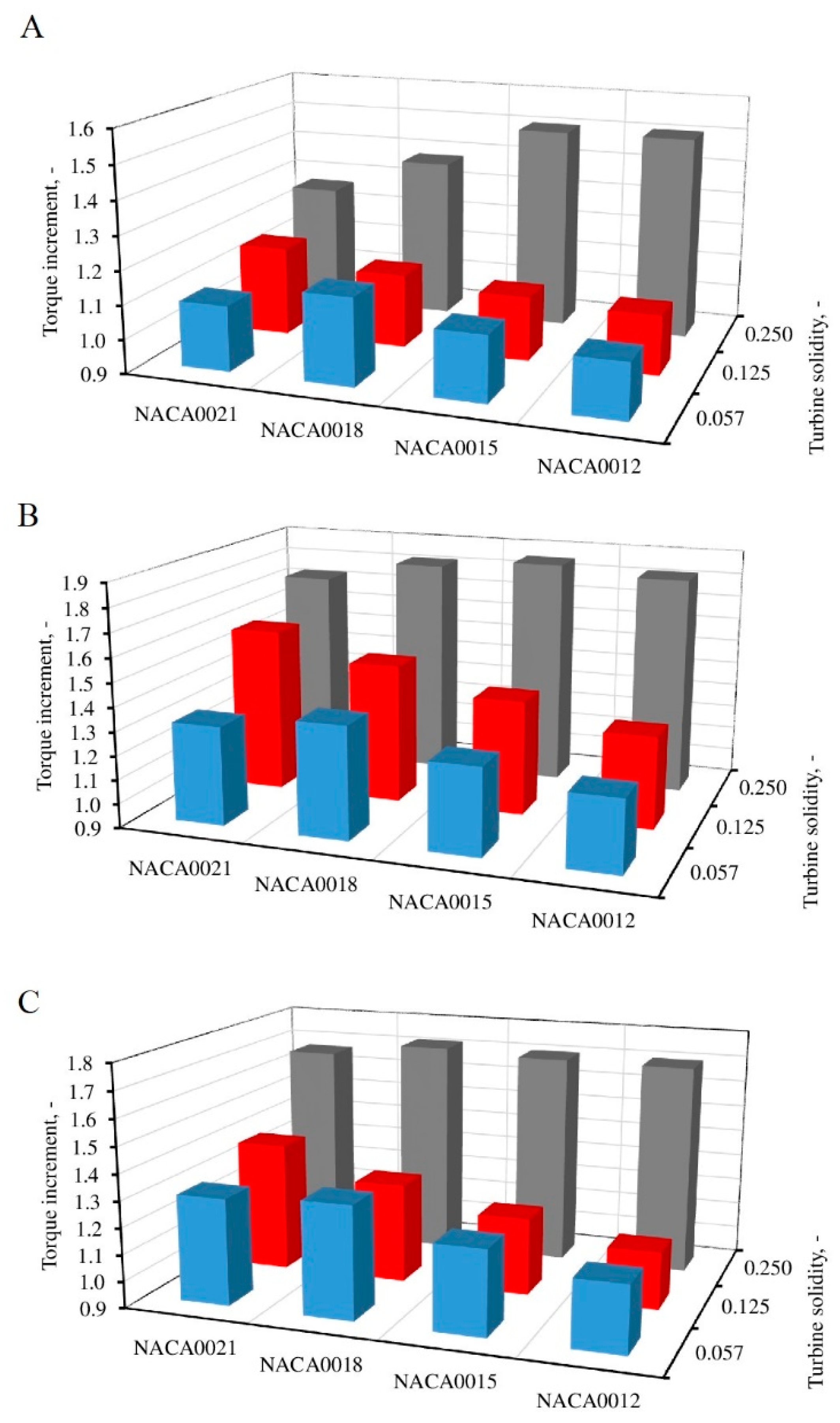

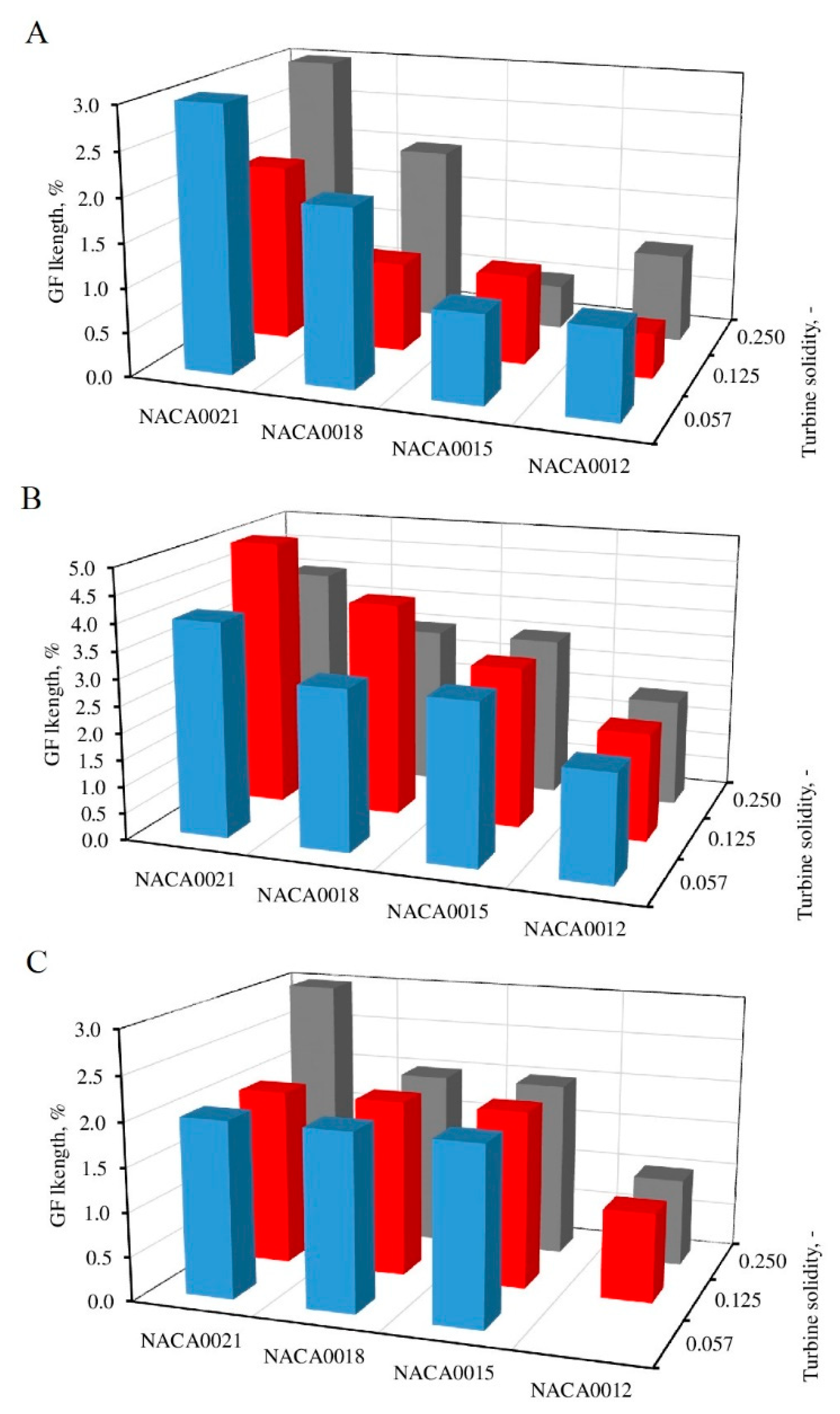

4.3. GF Effects in Cycloidal Motion: Sensitivity Analysis on GF Characteristics

- ■

- The outward positioning of the GF (if one-sided) always provided the largest power increase in a blade in cycloidal motion; however, as soon as the solidity increased, the possibility of having a more balanced energy extraction (i.e., with the inward positioning) became attractive;

- ■

- For higher solidities, the application of the GF seems to provide a constant increase of performance. This can be explained as follows: a) in case of the inward positioning, this is due to the discussed re-distribution of the energy extraction between the upwind and downwind halves. In a very solid turbine, indeed, the wind velocity oncoming to the downwind half of the revolution is very low, thus leading to small AoAs and then to a reduced torque production. In this view, adding a GF that is able to increase the performance in this region (where it acts on the pressure side of the airfoils) leads to potential benefits; b) in case of the outward positioning, the torque extraction is maximized in the upwind half (where the flow is more energized), sacrificing the performance downwind;

- ■

- For low solidities, this latter approach is the only one providing significant benefits. In this case, the torque profile is sufficiently balanced even in the original configuration and then it is more convenient to maximize the impact of the GF upwind, where the flow speeds are higher.

- ■

- In the case of the inward mounting, the maximum performance (presented as a torque increment with respect to no GF configuration) in the case of low solidity is monotonically increasing with the airfoil thickness-to-chord ratio, while for the high solidity, better performance is obtained with the medium NACA00018. The optimal GF height generally increases with the airfoil thickness.

- ■

- An opposite trend than the one above was noticed for the outward mounting of the Gurney flap. However, the optimal GF height kept increasing with the airfoil thickness;

- ■

- In the cases of the fish tail configurations quite thick airfoils are preferred, with the optimal GF height also increasing with the airfoil thickness.

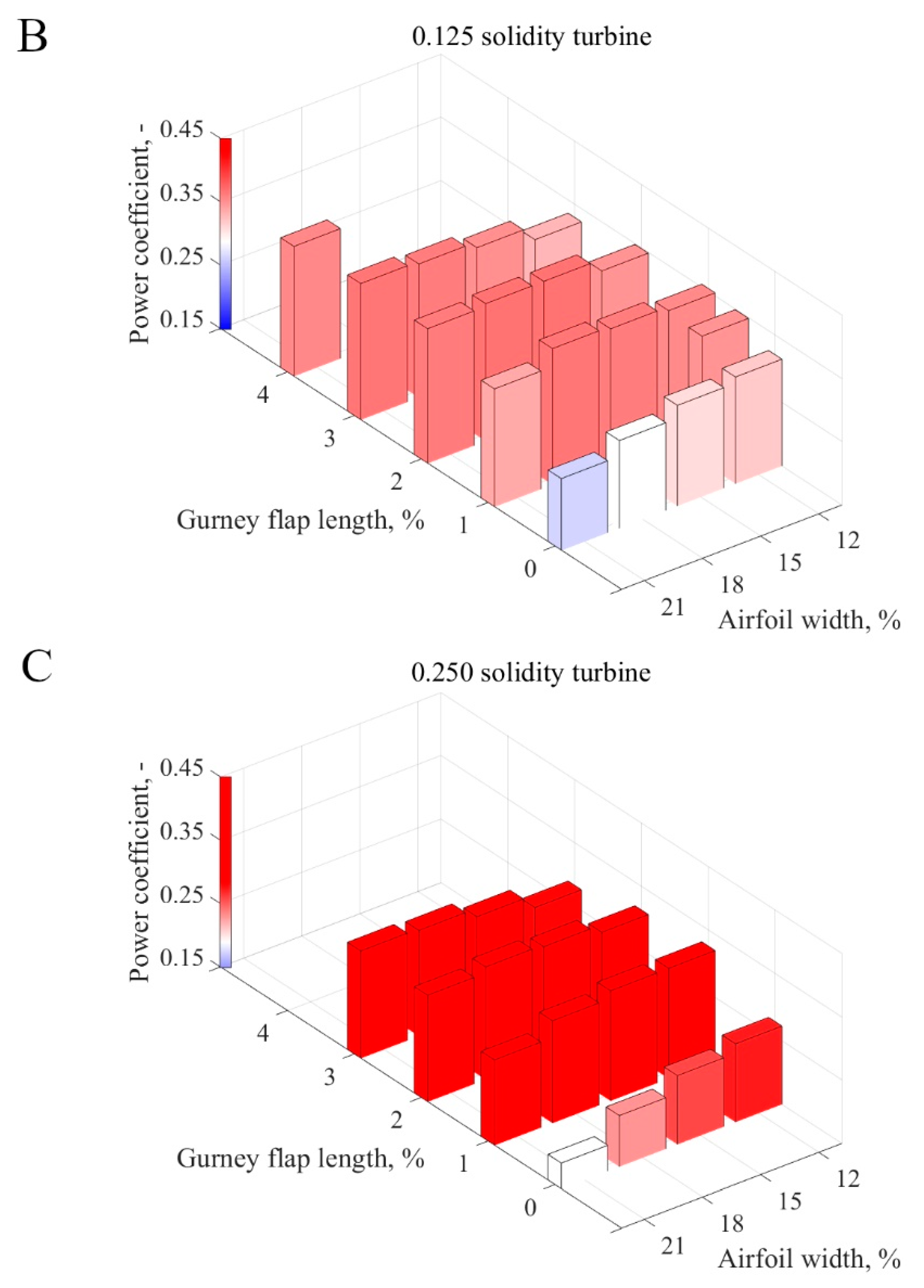

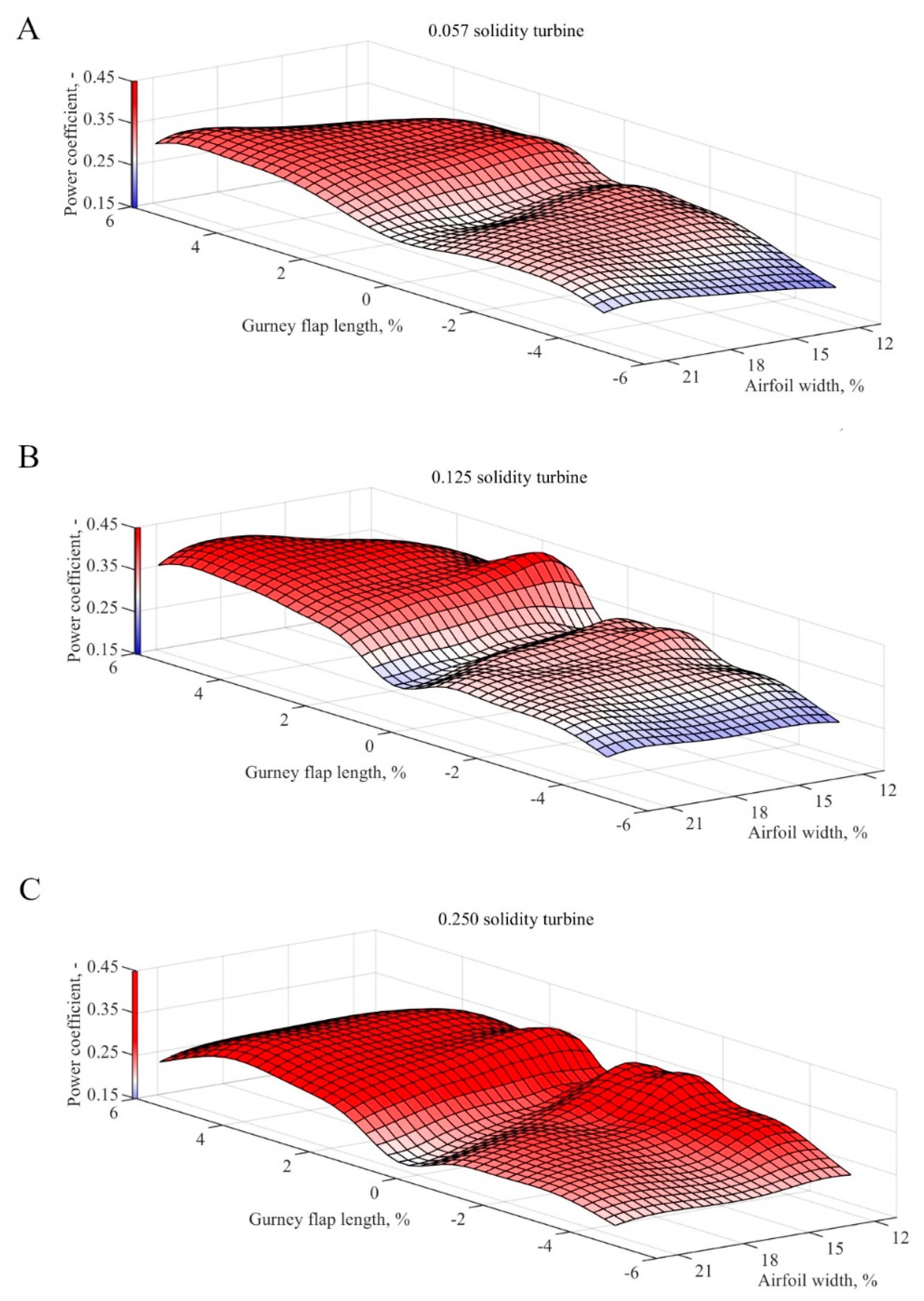

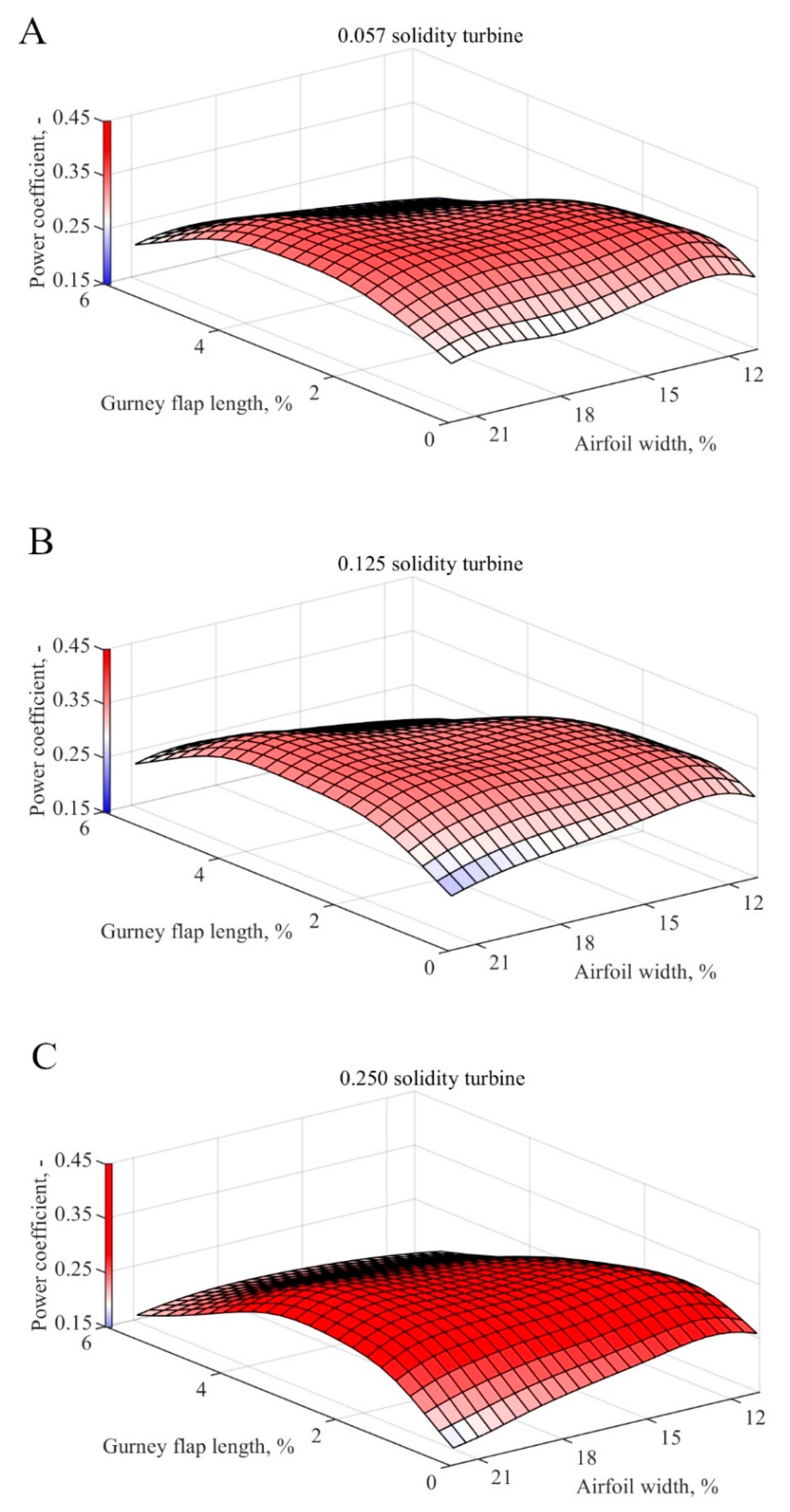

4.4. Response Surfaces

5. Conclusions

- ■

- A proper GF selection can indeed provide performance increases when used in a Darrieus wind turbine (possible benefits up to +89.5% when added in combination with the correct thickness of airfoil);

- ■

- The potential benefits are higher in case of more solid turbines;

- ■

- The introduction of a GF should be coupled with a re-optimization of the airfoil thickness to obtain the maximum performance. In case of medium-high solidity turbines, this would imply a reduction in the thickness-to-chord ratio;

- ■

- The one-sided Gurney flap allows obtaining the highest turbine efficiency, but it leads to a significant imbalance of the torque distribution between the upwind and the downwind part of the turbine;

- ■

- The Fish Tail Gurney flap configuration (both-sided GF with an inclination angle of 45°) provides a lower increment of the turbine power coefficient compared to the one-sided Gurney flap, but it results in a more balanced torque output.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bianchini, A. Trends, prospects, and R&D directions in wind turbine technology. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 978-0-12-409548-9. [Google Scholar]

- Paraschivoiu, I. Wind Turbine Design: With Emphasis on Darrieus Concept; Presses Internat Polytechnique: Montreal, QC, Canada, 2009; Reprinted; ISBN 978-2-553-00931-0. [Google Scholar]

- Molina, A.C.; Massai, T.; Balduzzi, F.; Bianchini, A.; Ferrara, G.; De Troyer, T.; Bartoli, G. Combined experimental and numerical study on the near wake of a Darrieus VAWT under turbulent flows. J. Phys. Conf. Ser. 2018, 1037, 072052. [Google Scholar] [CrossRef]

- Simão Ferreira, C.J.; Van Zuijlen, A.; Bijl, H.; Van Bussel, G.; Van Kuik, G. Simulating dynamic stall in a two-dimensional vertical-axis wind turbine: Verification and validation with particle image velocimetry data. Wind Energy 2010, 13, 1–17. [Google Scholar] [CrossRef]

- Islam, M.R.; Mekhilef, S.; Saidur, R. Progress and recent trends of wind energy technology. Renew. Sustain. Energy Rev. 2013, 21, 456–468. [Google Scholar] [CrossRef]

- Bianchini, A.; Balduzzi, F.; Di Rosa, D.; Ferrara, G. On the use of Gurney Flaps for the aerodynamic performance augmentation of Darrieus wind turbines. Energy Convers. Manag. 2019, 184, 402–415. [Google Scholar] [CrossRef]

- Amini, Y.; Liravi, M.; Izadpanah, E. The effects of Gurney flap on the aerodynamic performance of NACA 0012 airfoil in the rarefied gas flow. Comput. Fluids 2018, 170, 93–105. [Google Scholar] [CrossRef]

- Han, D.; Dong, C.; Barakos, G.N. Performance improvement of variable speed rotors by Gurney flaps. Aerosp. Sci. Technol. 2018, 81, 118–127. [Google Scholar] [CrossRef]

- Zhu, H.; Hao, W.; Li, C.; Ding, Q. Numerical study of effect of solidity on vertical axis wind turbine with Gurney flap. J. Wind Eng. Ind. Aerodyn. 2019, 186, 17–31. [Google Scholar] [CrossRef]

- Zhu, B.; Huang, Y.; Zhang, Y. Energy harvesting properties of a flapping wing with an adaptive Gurney flap. Energy 2018, 152, 119–128. [Google Scholar] [CrossRef]

- Aramendia, I.; Fernandez-Gamiz, U.; Ramos-Hernanz, J.A.; Sancho, J.; Lopez-Guede, J.M.; Zulueta, E. Flow control devices for wind turbines. In Energy Harvesting and Energy Efficiency; Bizon, N., Mahdavi Tabatabaei, N., Blaabjerg, F., Kurt, E., Eds.; Springer International Publishing: Cham, Switzerland, 2017; Volume 37, pp. 629–655. ISBN 978-3-319-49874-4. [Google Scholar]

- Saenz-Aguirre, A.; Fernandez-Gamiz, U.; Zulueta, E.; Ulazia, A.; Martinez-Rico, J. Optimal wind turbine operation by artificial neural network-based active gurney flap flow control. Sustainability 2019, 11, 2809. [Google Scholar] [CrossRef]

- Islam, M.; Ting, D.S.-K.; Fartaj, A. Desirable airfoil features for smaller-capacity straight-bladed VAWT. Wind Eng. 2007, 31, 165–196. [Google Scholar] [CrossRef]

- Bianchini, A.; Balduzzi, F.; Ferrara, G.; Ferrari, L. Critical analysis of dynamic stall models in low-order simulation models for vertical-axis wind turbines. Energy Procedia 2016, 101, 488–495. [Google Scholar] [CrossRef]

- Fernandez-Gamiz, U.; Gomez-Mármol, M.; Chacón-Rebollo, T. Computational modeling of gurney flaps and microtabs by POD method. Energies 2018, 11, 2091. [Google Scholar] [CrossRef]

- Holst, D.; Balduzzi, F.; Bianchini, A.; Church, B.; Wegner, F.; Pechlivanoglou, G.; Ferrari, L.; Ferrara, G.; Nayeri, C.N.; Paschereit, C.O. Static and dynamic analysis of a NACA 0021 airfoil section at low reynolds numbers based on experiments and computational fluid dynamics. J. Eng. Gas Turbines Power 2019, 141. [Google Scholar] [CrossRef]

- Balduzzi, F.; Holst, D.; Melani, P.F.; Wegner, F.; Nayeri, C.N.; Ferrara, G.; Paschereit, C.O.; Bianchini, A. Combined numerical and experimental study on the use of Gurney flaps for the performance enhancement of NACA0021 airfoil in static and dynamic conditions. In Proceedings of the ASME Turbo Expo, London, UK, 22–26 June 2020. [Google Scholar]

- Bianchini, A.; Balduzzi, F.; Ferrara, G.; Ferrari, L. A computational procedure to define the incidence angle on airfoils rotating around an axis orthogonal to flow direction. Energy Convers. Manag. 2016, 126, 790–798. [Google Scholar] [CrossRef]

- Bianchini, A.; Balduzzi, F.; Ferrara, G.; Persico, G.; Dossena, V.; Ferrari, L. A critical analysis on low-order simulation models for darrieus vawts: How much do they pertain to the real flow? J. Eng. Gas Turbines Power 2019, 141. [Google Scholar] [CrossRef]

- Balduzzi, F.; Bianchini, A.; Maleci, R.; Ferrara, G.; Ferrari, L. Critical issues in the CFD simulation of Darrieus wind turbines. Renew. Energy 2016, 85, 419–435. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Balduzzi, F.; Bianchini, A.; Ferrara, G.; Ferrari, L. Dimensionless numbers for the assessment of mesh and timestep requirements in CFD simulations of Darrieus wind turbines. Energy 2016, 97, 246–261. [Google Scholar] [CrossRef]

- Bianchini, A.; Balduzzi, F.; Ferrara, G.; Ferrari, L. Aerodynamics of Darrieus wind turbines airfoils: The impact of pitching moment. J. Eng. Gas Turbines Power 2017, 139. [Google Scholar] [CrossRef]

- Lazzaro, D.; Montefusco, L.B. Radial basis functions for the multivariate interpolation of large scattered data sets. J. Comput. Appl. Math. 2002, 140, 521–536. [Google Scholar] [CrossRef]

- Golub, G.H.; Loan, C.F.V. Matrix Computations; JHU Press: Baltimore, MD, USA, 2013; ISBN 978-1-4214-0794-4. [Google Scholar]

- Buliński, Z.; Nowak, A.J.; Šarler, B. Numerical Experiments with the Local RBF Collocation; International Conference on Computational Experimental Engineering and Science Special Symposium on Meshless Methods ICCES MM: Dubrovnik, Croatia, 2006. [Google Scholar]

| Profile | NACA0021 |

| Chord length | 0.14 m |

| Reynolds number | 180,000 |

| Gurney flap height | 2.5% |

| Geometrical Parameters | |||

| Diameter | 3.50 m | 1.60 m | 1.03 m |

| Number of blades | 1 | 1 | 3 |

| Chord | 0.200 m | 0.200 m | 0.086 m |

| Solidity | 0.057 | 0.125 | 0.250 |

| Original wing profile | NACA0018 | NACA0018 | NACA0021 |

| Working Conditions | |||

| Free stream velocity | 8.235 m/s | 8.0 m/s | 13.0 m/s |

| Air density | 1.20 kg/m3 | 1.20 kg/m3 | 1.20 kg/m3 |

| Air viscosity | 1.789 × 10−5 Pa∙s | 1.789 × 10−5 Pa∙s | 1.789 × 10−5 Pa∙s |

| TSR | 4.45 | 3.14 | 3.30 |

| Blade Reynolds Number | 482,000 | 386,000 | 250,000 |

| Functions Form | |

|---|---|

| Multiquadric (MQ) | |

| Inverse Quadratic (IQ) | |

| Inverse Multiquadric (IMQ) |

| IMQ | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Turbine solidity | 0.057 | 0.125 | 0.250 | ||||||

| Geometrical Parameters | |||||||||

| Ref. | One sided | Fish tail | Ref. | One sided | Fish tail | Ref. | One sided | Fish Tail | |

| Airfoil Thickness | 18.00 | 18.38 | 19.87 | 18.00 | 15.52 | 19.94 | 21.00 | 14.06 | 19.74 |

| Gurney flap length | 0.00 | 3.48 | 2.08 | 0.00 | 3.50 | 2.84 | 0.00 | 3.42 | 2.42 |

| Results | |||||||||

| Power coefficient | 0.27 | 0.37 | 0.36 | 0.29 | 0.43 | 0.37 | 0.19 | 0.36 | 0.33 |

| Increment, % | - | 37.04% | 33.33% | 48.28% | 27.59% | - | 89.47% | 73.68% | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiśniewski, P.; Balduzzi, F.; Buliński, Z.; Bianchini, A. Numerical Analysis on the Effectiveness of Gurney Flaps as Power Augmentation Devices for Airfoils Subject to a Continuous Variation of the Angle of Attack by Use of Full and Surrogate Models. Energies 2020, 13, 1877. https://doi.org/10.3390/en13081877

Wiśniewski P, Balduzzi F, Buliński Z, Bianchini A. Numerical Analysis on the Effectiveness of Gurney Flaps as Power Augmentation Devices for Airfoils Subject to a Continuous Variation of the Angle of Attack by Use of Full and Surrogate Models. Energies. 2020; 13(8):1877. https://doi.org/10.3390/en13081877

Chicago/Turabian StyleWiśniewski, Piotr, Francesco Balduzzi, Zbigniew Buliński, and Alessandro Bianchini. 2020. "Numerical Analysis on the Effectiveness of Gurney Flaps as Power Augmentation Devices for Airfoils Subject to a Continuous Variation of the Angle of Attack by Use of Full and Surrogate Models" Energies 13, no. 8: 1877. https://doi.org/10.3390/en13081877

APA StyleWiśniewski, P., Balduzzi, F., Buliński, Z., & Bianchini, A. (2020). Numerical Analysis on the Effectiveness of Gurney Flaps as Power Augmentation Devices for Airfoils Subject to a Continuous Variation of the Angle of Attack by Use of Full and Surrogate Models. Energies, 13(8), 1877. https://doi.org/10.3390/en13081877