Receding Horizon Control of Cooling Systems for Large-Size Uninterruptible Power Supply Based on a Metal-Air Battery System

Abstract

1. Introduction

2. UPS System Modeling

2.1. Prior Research

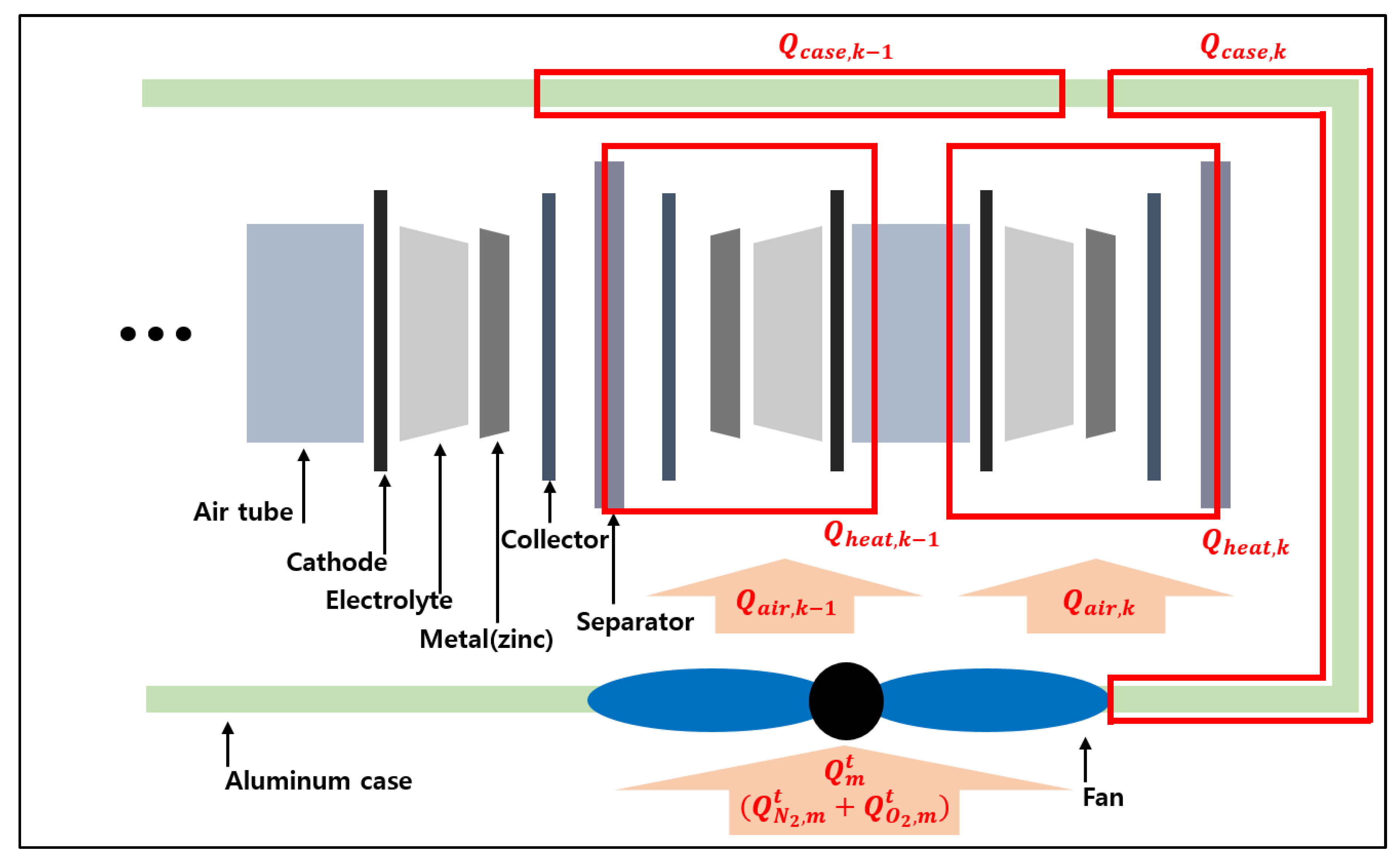

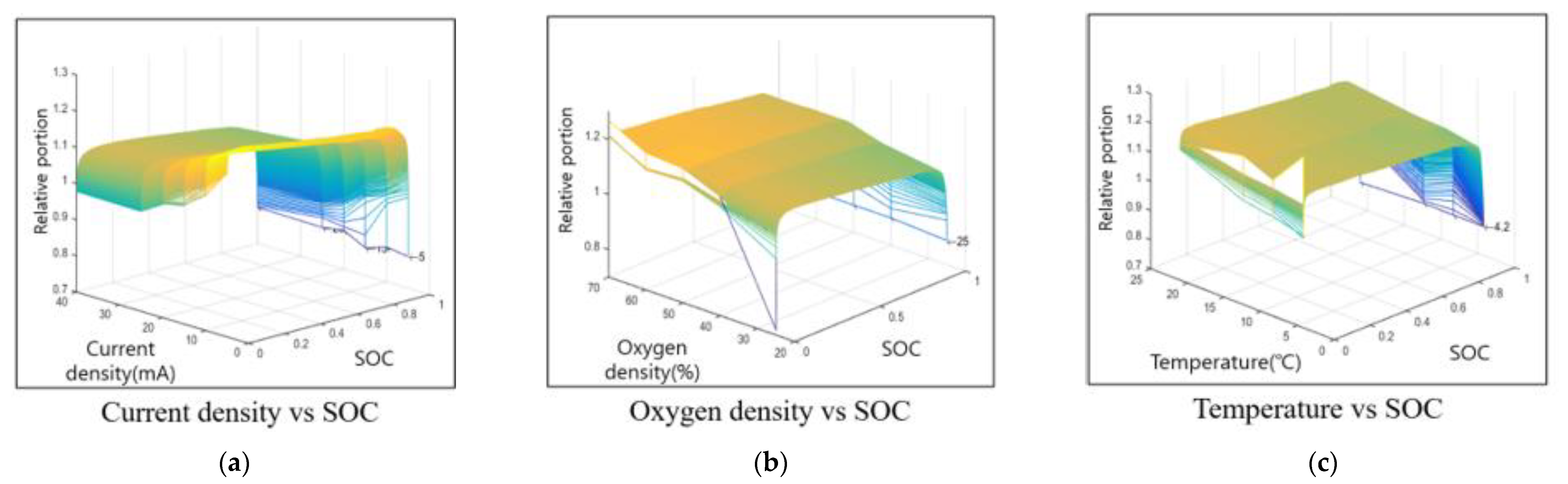

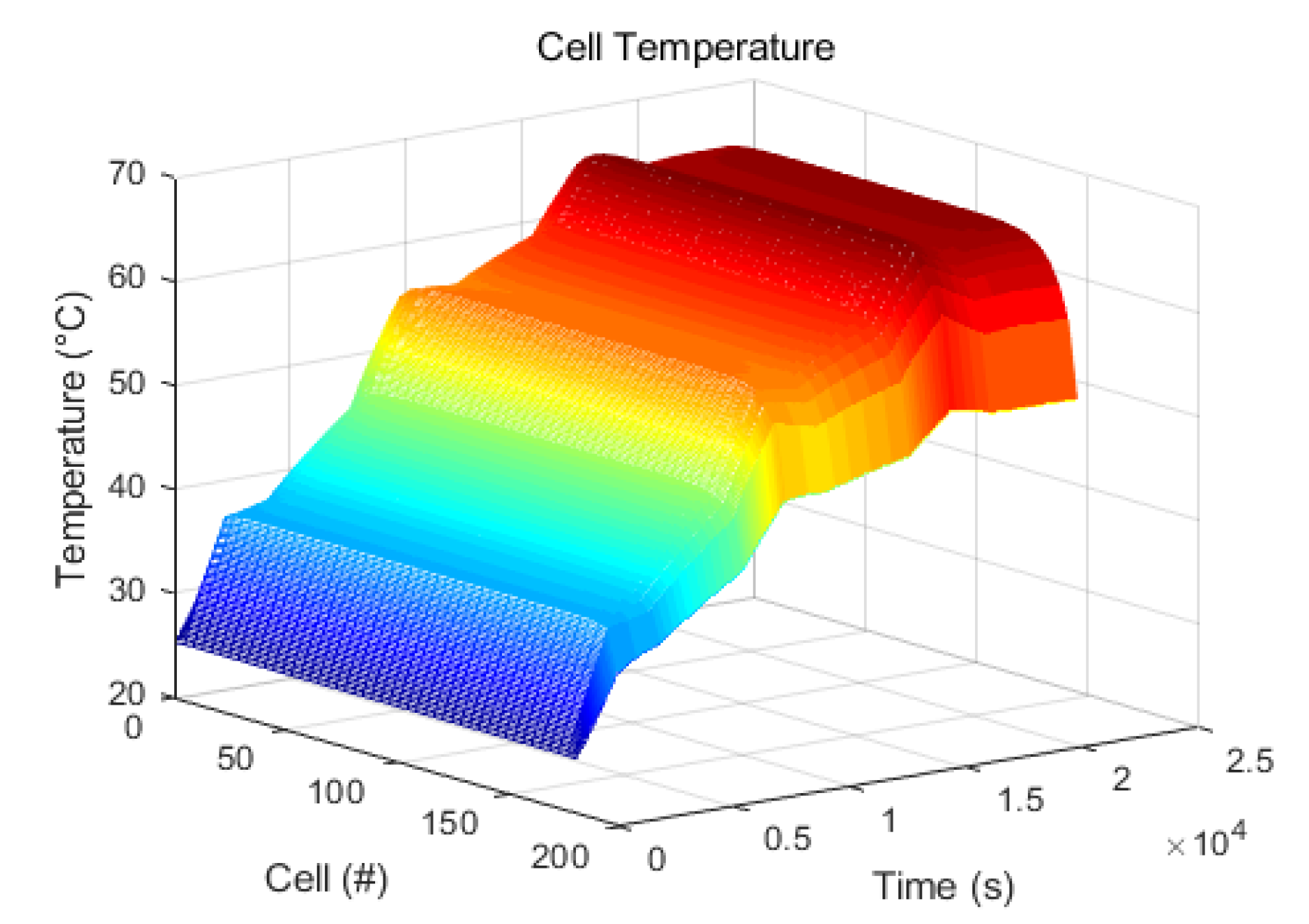

2.2. Thermodynamic Model

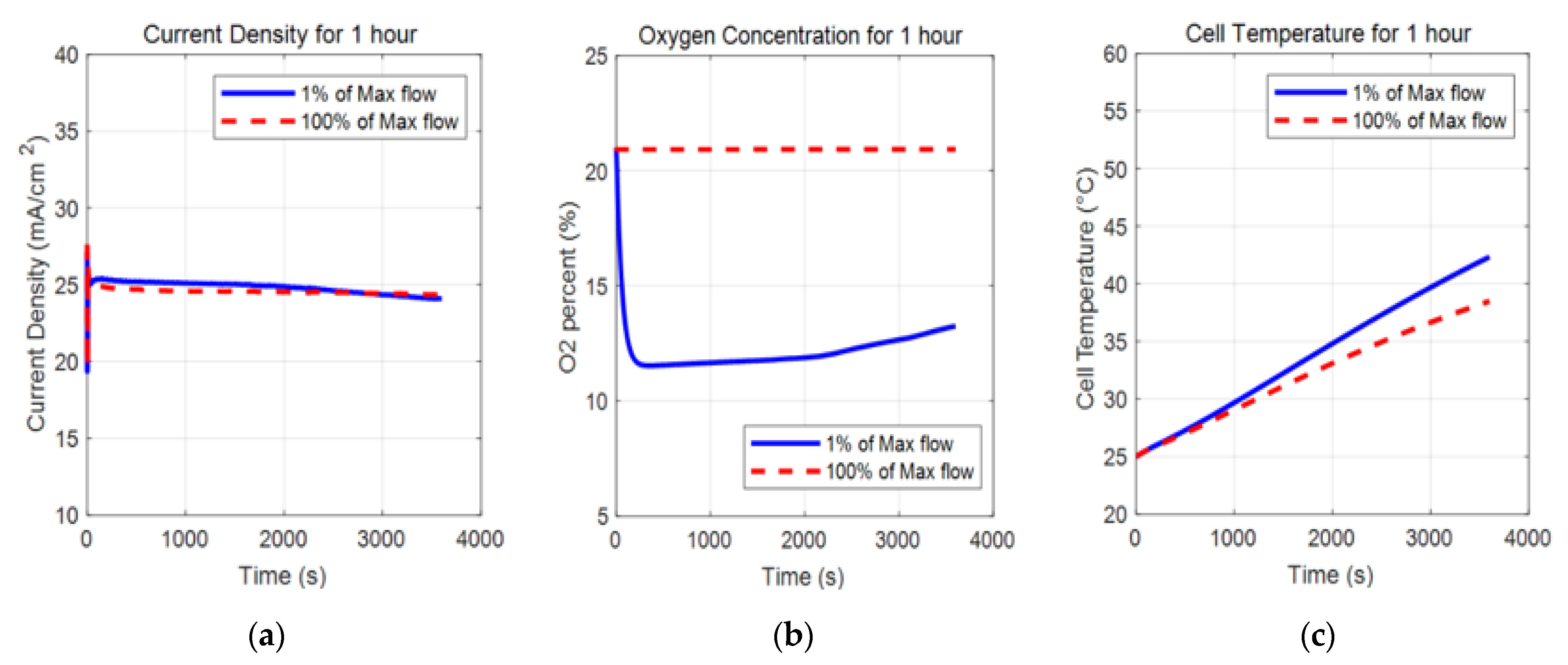

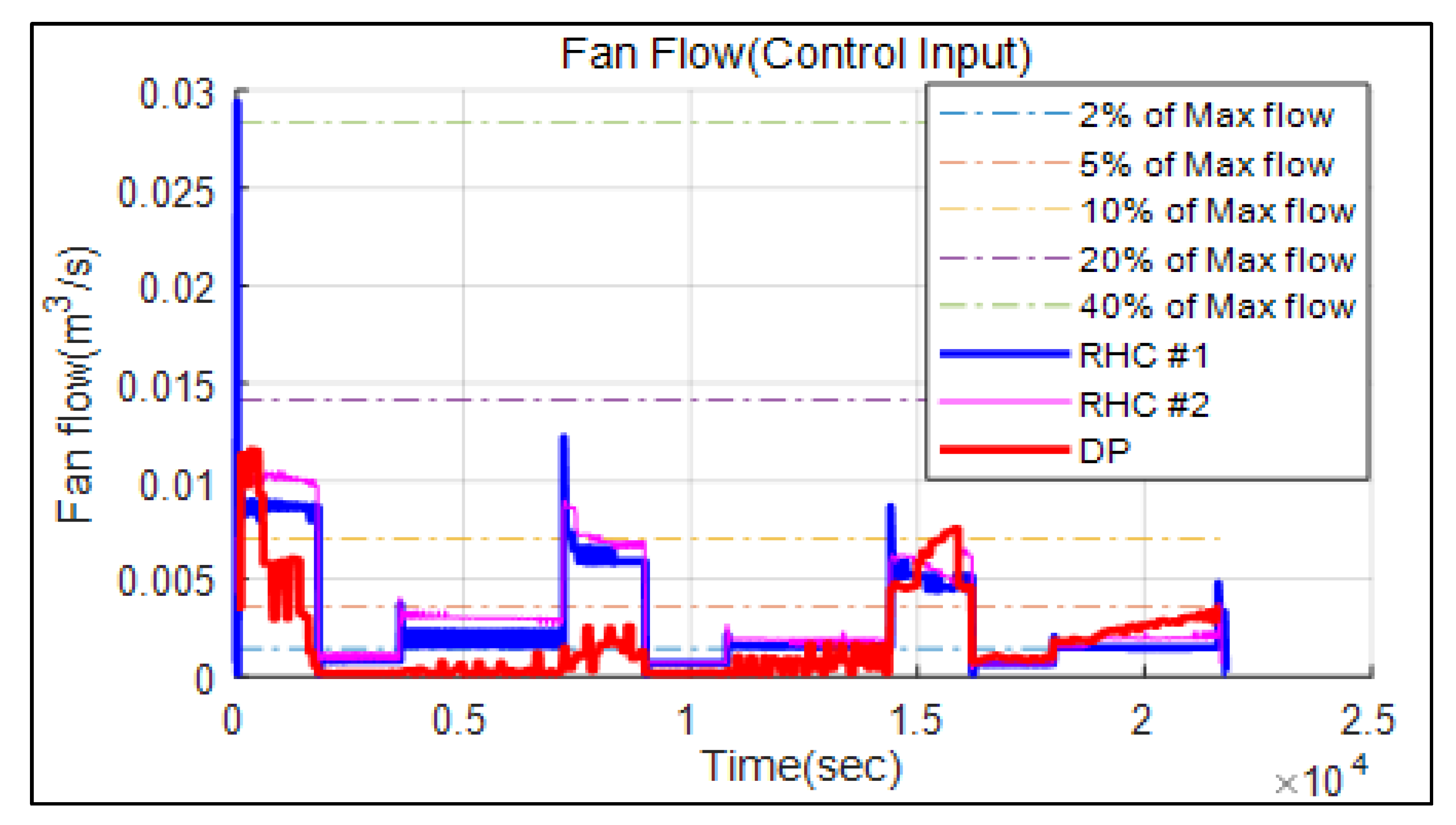

2.3. UPS Simulation and Fan Control

3. Control Modeling and Simulation

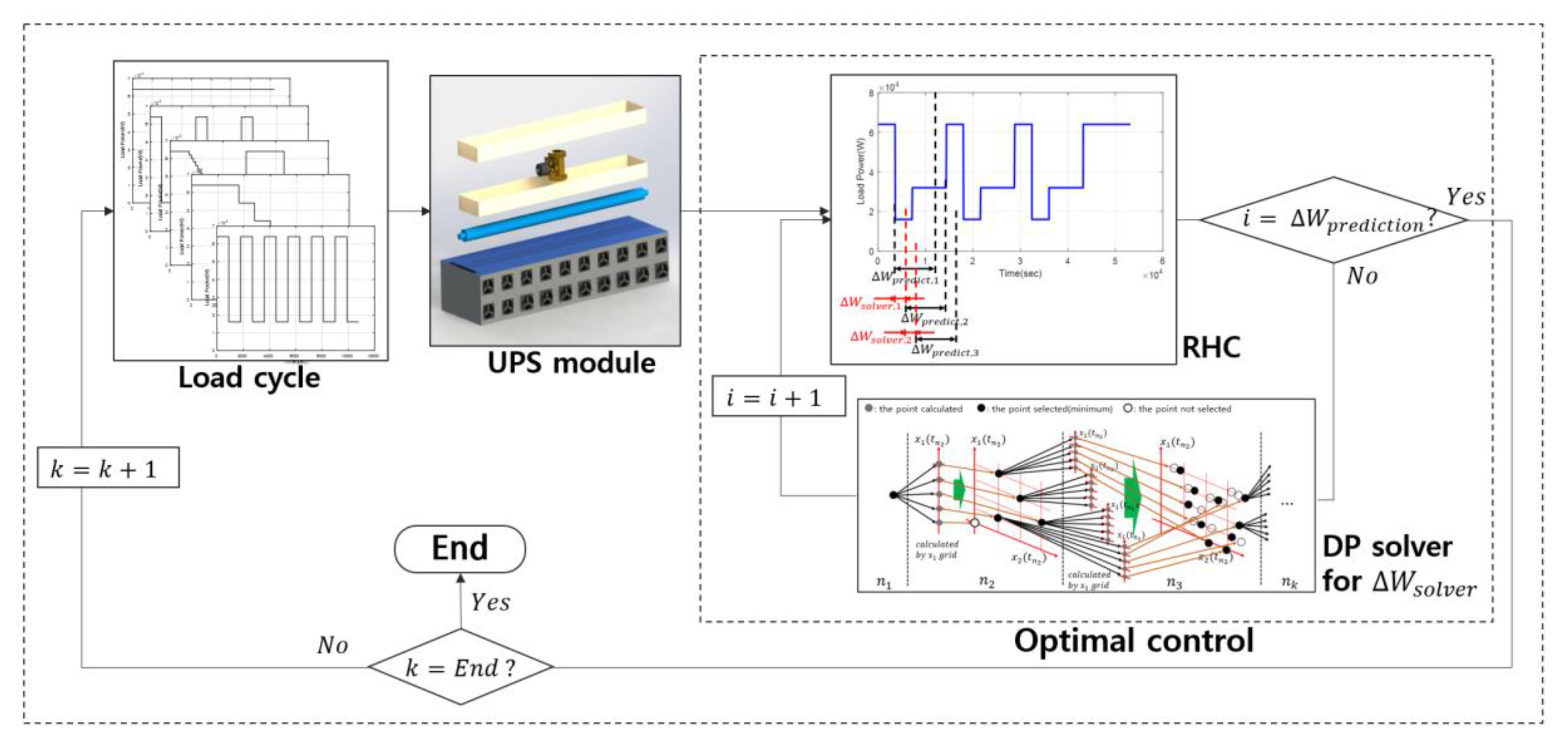

3.1. The Conceptual Framework

3.2. Receding Horizon Control

3.3. Dynamic Programming

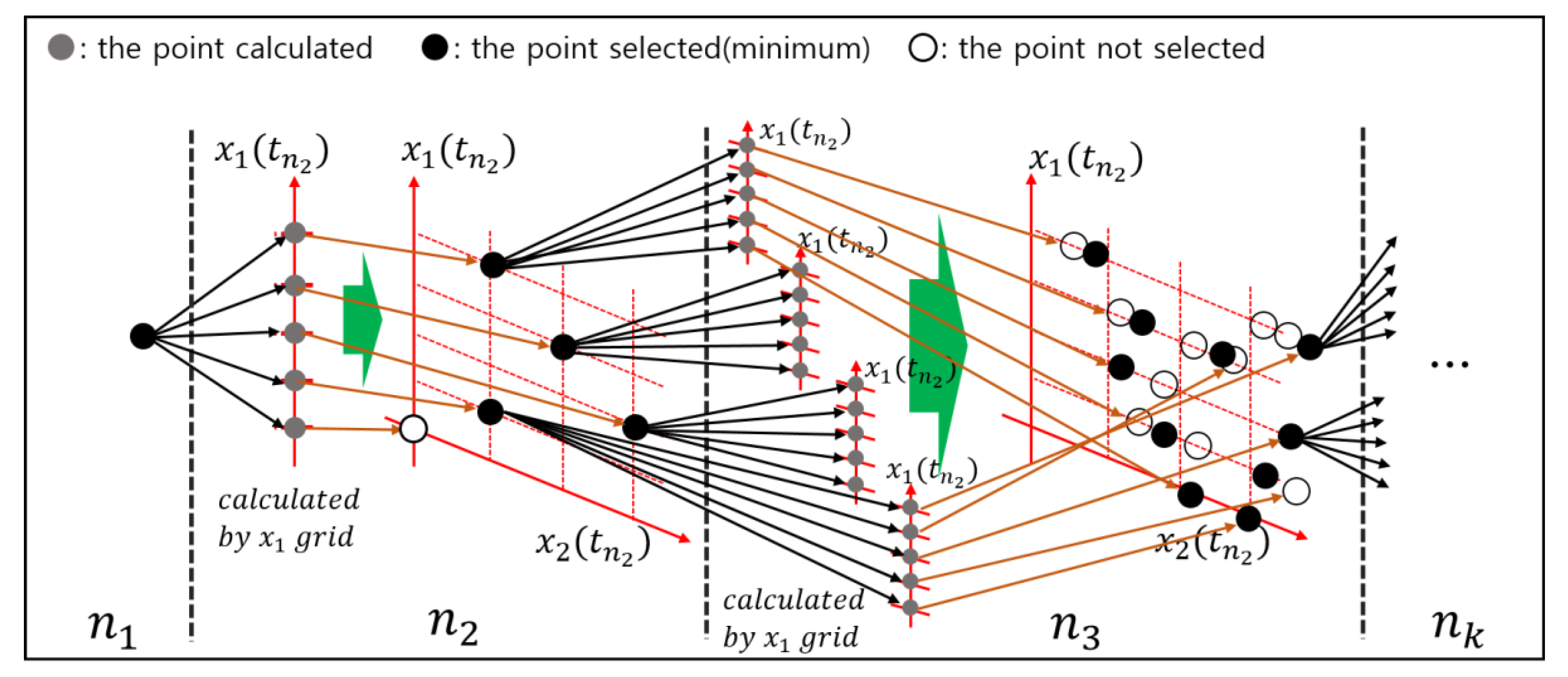

3.4. Solver Based on 1.5-Dimensional DP

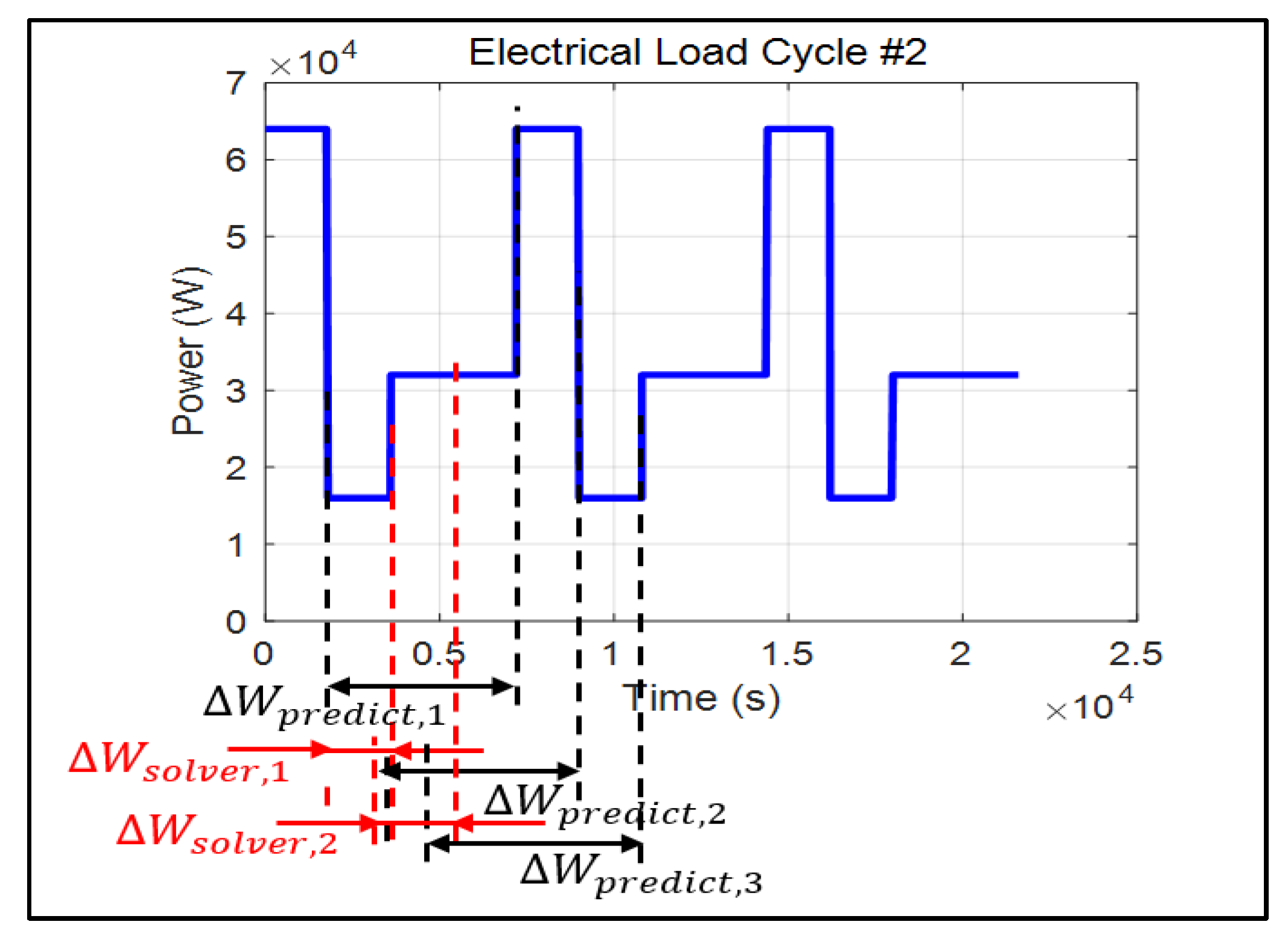

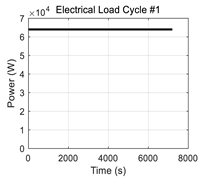

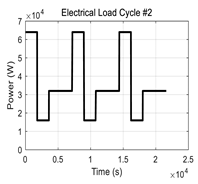

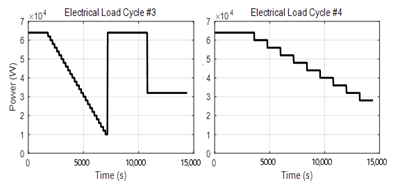

3.5. Electrical Load Cycle

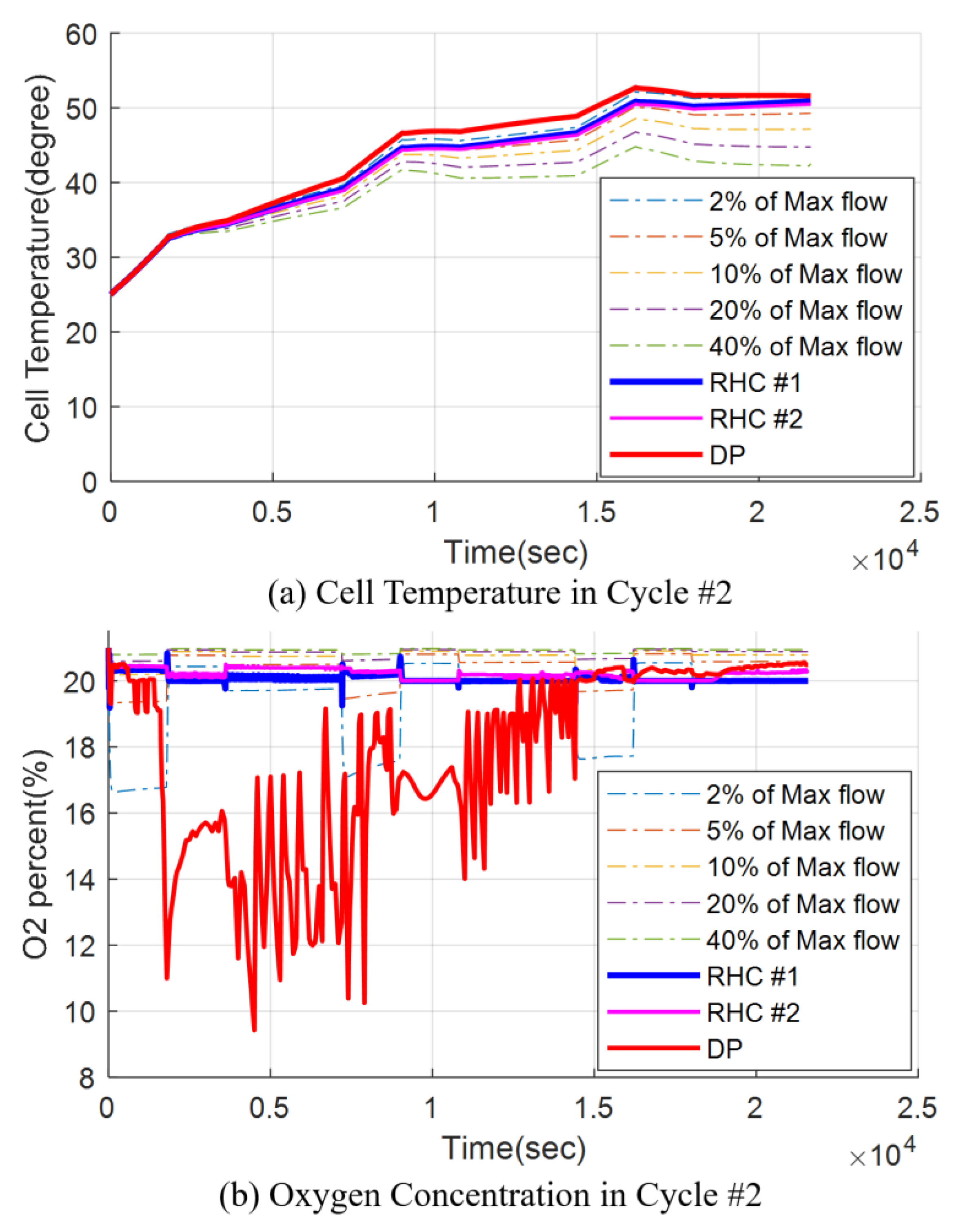

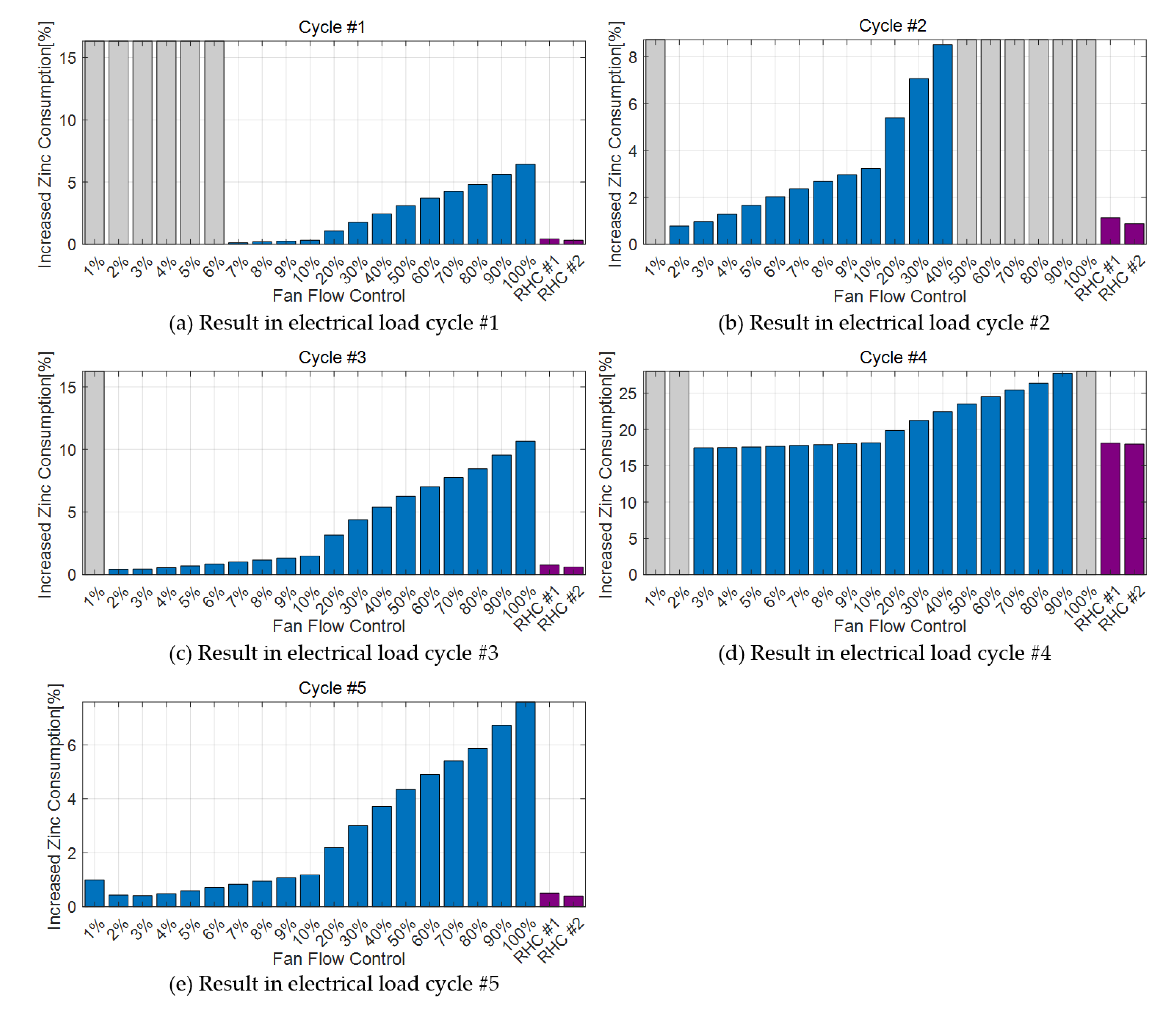

4. Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chew, C.; Rama, S.; Kondapalli, R. Optimization ( Genetic Algorithm ) of dc-dc converter for uninterruptible power supply applications | S S r-. Int. J. Pure Appl. Math. 2018, 118, 1530–1535. [Google Scholar]

- Narvaez, D.I.; Villalva, M.G. Modeling and control strategy of a single-phase uninterruptible power supply (UPS). In Proceedings of the 2015 IEEE PES Innovative Smart Grid Technologies Latin America (ISGT LATAM), Montevideo, Uruguay, 5–7 October 2015; pp. 355–360. [Google Scholar]

- Lahyani, A.; Venet, P.; Guermazi, A.; Troudi, A. Battery/Supercapacitors combination in uninterruptible power supply (UPS). IEEE Trans. Power Electron. 2013, 28, 1509–1522. [Google Scholar] [CrossRef]

- Chlodnicki, Z.; Koczara, W.; Al-Khayat, N. Hybrid UPS based on supercapacitor energy storage and adjustable speed generator. In Proceedings of the 2007 Compatibility in Power Electronics, Gdansk, Poland, 29 May–1 June 2007; Volume XIV, pp. 13–24. [Google Scholar]

- Mallika, S.; Kumar, R.S. Review on ultracapacitor- battery interface for energy management system. Int. J. Eng. Technol. 2011, 3, 37–43. [Google Scholar]

- Han, X.; Ji, T.; Zhao, Z.; Zhang, H. Economic evaluation of batteries planning in energy storage power stations for load shifting. Renew. Energy 2015, 78, 643–647. [Google Scholar] [CrossRef]

- Linden, D.; Reddy, T.B. Handbook of Batteries, 3rd ed.; McGraw-Hill Professional: New York, NY, USA, 2002. [Google Scholar]

- Lee, C.W.; Sathiyanarayanan, K.; Eom, S.W.; Kim, H.S.; Yun, M.S. Effect of additives on the electrochemical behaviour of zinc anodes for zinc/air fuel cells. J. Power Sources 2006, 160, 161–164. [Google Scholar] [CrossRef]

- Gu, B.; Yoon, S.H.; Park, S.K.; Byun, S.; Cha, S.W. A study on the application of metal–air battery to large size uninterruptible power supply with a hybrid system. JMST Adv. 2019, 1, 181–190. [Google Scholar] [CrossRef]

- Lee, J.; Yim, C.; Lee, D.W.; Park, S.S. Manufacturing and characterization of physically modified aluminum anodes based air battery with electrolyte circulation. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 53–57. [Google Scholar] [CrossRef]

- Wang, K.; Pei, P.; Wang, Y.; Liao, C.; Wang, W.; Huang, S. Advanced rechargeable zinc-air battery with parameter optimization. Appl. Energy 2018, 225, 848–856. [Google Scholar] [CrossRef]

- Xiao, Y.; Jing, R.; Song, H.; Zhu, N.; Yang, H. Design and experiment on zinc-air battery continuous power controller based on microcontroller. Chem. Eng. Trans. 2016, 51, 91–96. [Google Scholar]

- Li, Z.Z.; Cheng, T.H.; Xuan, D.J.; Ren, M.; Shen, G.Y.; de Shen, Y. Optimal design for cooling system of batteries using DOE and RSM. Int. J. Precis. Eng. Manuf. 2012, 13, 1641–1645. [Google Scholar] [CrossRef]

- Sabbah, R.; Kizilel, R.; Selman, J.R.; Al-Hallaj, S. Active (air-cooled) vs. passive (phase change material) thermal management of high power lithium-ion packs: Limitation of temperature rise and uniformity of temperature distribution. J. Power Sources 2008, 182, 630–638. [Google Scholar] [CrossRef]

- Ling, Z.; Wang, F.; Fang, X.; Gao, X.; Zhang, Z. A hybrid thermal management system for lithium ion batteries combining phase change materials with forced-air cooling. Appl. Energy 2015, 148, 403–409. [Google Scholar] [CrossRef]

- Xie, J.; Ge, Z.; Zang, M.; Wang, S. Structural optimization of lithium-ion battery pack with forced air cooling system. Appl. Therm. Eng. 2017, 126, 583–593. [Google Scholar] [CrossRef]

- Wang, Y.X.; Qin, F.F.; Ou, K.; Kim, Y.B. Temperature control for a polymer electrolyte membrane fuel cell by using fuzzy rule. IEEE Trans. Energy Convers. 2016, 31, 667–675. [Google Scholar] [CrossRef]

- Zhan, Y.; Wang, H.; Zhu, J. Modelling and control of hybrid UPS system with backup PEM fuel cell/battery. Int. J. Electr. Power Energy Syst. 2012, 43, 1322–1331. [Google Scholar] [CrossRef]

- Guerrero, J.M.; Alcala, J.M.; Miret, J.; de Vicuña, L.G.; Matas, J.; Castilla, M. Output impedance design of parallel-connected ups inverters with wireless load-sharing control control and management of single phase microgrids view project converter modelling and digital control view project output impedance design of parallel-connecte. IEEE Trans. Ind. Electr. 2005, 52, 1126–1135. [Google Scholar] [CrossRef]

- Pei, Y.; Jiang, G.; Yang, X.; Wang, Z. Auto-Master-Slave control technique of parallel inverters in distributed AC power systems and UPS. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference (IEEE Cat. No.04CH37551), Aachen, Germany, 20–25 June 2004; Volume 3, pp. 2050–2053. [Google Scholar]

- Guerrero, J.M.; Vásquez, J.C.; Matas, J.; Castilla, M.; de Vicuna, L.G. Control strategy for flexible microgrid based on parallel line-interactive UPS systems. IEEE Trans. Ind. Electron. 2009, 56, 726–736. [Google Scholar] [CrossRef]

- Rawlings, J.B.; Muske, K.R. The stability of constrained receding horizon control. IEEE Trans. Autom. Control 1993, 38, 1512–1516. [Google Scholar] [CrossRef]

- Mayne, D. Receding Horzion control of nonlienar system.pdf. IEEE Trans. Autom. Control 1990, 35, 814–824. [Google Scholar] [CrossRef]

- Low, K.S.; Cao, R. Model predictive control of parallel-connected inverters for uninterruptible power supplies. IEEE Trans. Ind. Electron. 2008, 55, 2884–2893. [Google Scholar]

- Kim, S.K.; Park, C.R.; Yoon, T.W.; Lee, Y.I. Disturbance-observer-based model predictive control for output voltage regulation of three-phase inverter for uninterruptible-power-supply applications. Eur. J. Control 2015, 23, 71–83. [Google Scholar] [CrossRef]

- Johannesson, L.; Nilsson, M.; Murgovski, N. Look-ahead vehicle energy management with traffic predictions. IFAC-PapersOnLine 2015, 28, 244–251. [Google Scholar] [CrossRef]

- Hellström, E.; Ivarsson, M.; Åslund, J.; Nielsen, L. Look-ahead control for heavy trucks to minimize trip time and fuel consumption. Control Eng. Pract. 2009, 17, 245–254. [Google Scholar] [CrossRef]

| Parameter | Basis | Value |

|---|---|---|

| Stack area | , load current 330 A | |

| Max load power | load current 330 A, boost converter efficiency | 370 A |

| Module quantity | load current 330 A, max current density | 0.16 , 8 modules |

| Stack voltage range | min voltage 0.8 V, max voltage 1.1 V | 180–200 V |

| Cell stack quantity | voltage range, cell voltage | 170 cells |

| Metal weight | simulation result, demanded current 576 A | 200 g/cell |

| Metal thickness | cell surface area, metal weight | 0.15 mm/cell |

| Electrolyte thickness | simulation result, other variables | 2 mm |

| Cathode thickness | simulation result, other variables | 0.7 mm |

| Separator thickness | simulation result, stack weight | 0.3 mm |

| Air tube thickness | cell array structure, airflow, air consumption | 16 mm |

| Module volume | cell, airflow |

| Max Power | |||

|---|---|---|---|

| 64 kW (Total Stack) | |||

| Run Time | Graph | Run Time | Graph |

| 7200 s |  | 21,600 s |  |

| 14,400 s |  | 11,800 s |  |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, B.; Lee, H.; Kang, C.; Sung, D.; Lee, S.; Yun, S.; Park, S.K.; Cho, G.-Y.; Kim, N.; Cha, S.W. Receding Horizon Control of Cooling Systems for Large-Size Uninterruptible Power Supply Based on a Metal-Air Battery System. Energies 2020, 13, 1611. https://doi.org/10.3390/en13071611

Gu B, Lee H, Kang C, Sung D, Lee S, Yun S, Park SK, Cho G-Y, Kim N, Cha SW. Receding Horizon Control of Cooling Systems for Large-Size Uninterruptible Power Supply Based on a Metal-Air Battery System. Energies. 2020; 13(7):1611. https://doi.org/10.3390/en13071611

Chicago/Turabian StyleGu, Bonhyun, Heeyun Lee, Changbeom Kang, Donghwan Sung, Sanghoon Lee, Sunghyun Yun, Sung Kwan Park, Gu-Young Cho, Namwook Kim, and Suk Won Cha. 2020. "Receding Horizon Control of Cooling Systems for Large-Size Uninterruptible Power Supply Based on a Metal-Air Battery System" Energies 13, no. 7: 1611. https://doi.org/10.3390/en13071611

APA StyleGu, B., Lee, H., Kang, C., Sung, D., Lee, S., Yun, S., Park, S. K., Cho, G.-Y., Kim, N., & Cha, S. W. (2020). Receding Horizon Control of Cooling Systems for Large-Size Uninterruptible Power Supply Based on a Metal-Air Battery System. Energies, 13(7), 1611. https://doi.org/10.3390/en13071611