Combustion and Emissions Characteristics of the Turbine Engine Fueled with HEFA Blends from Different Feedstocks

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of the Test Rig

2.2. Tested Fuels

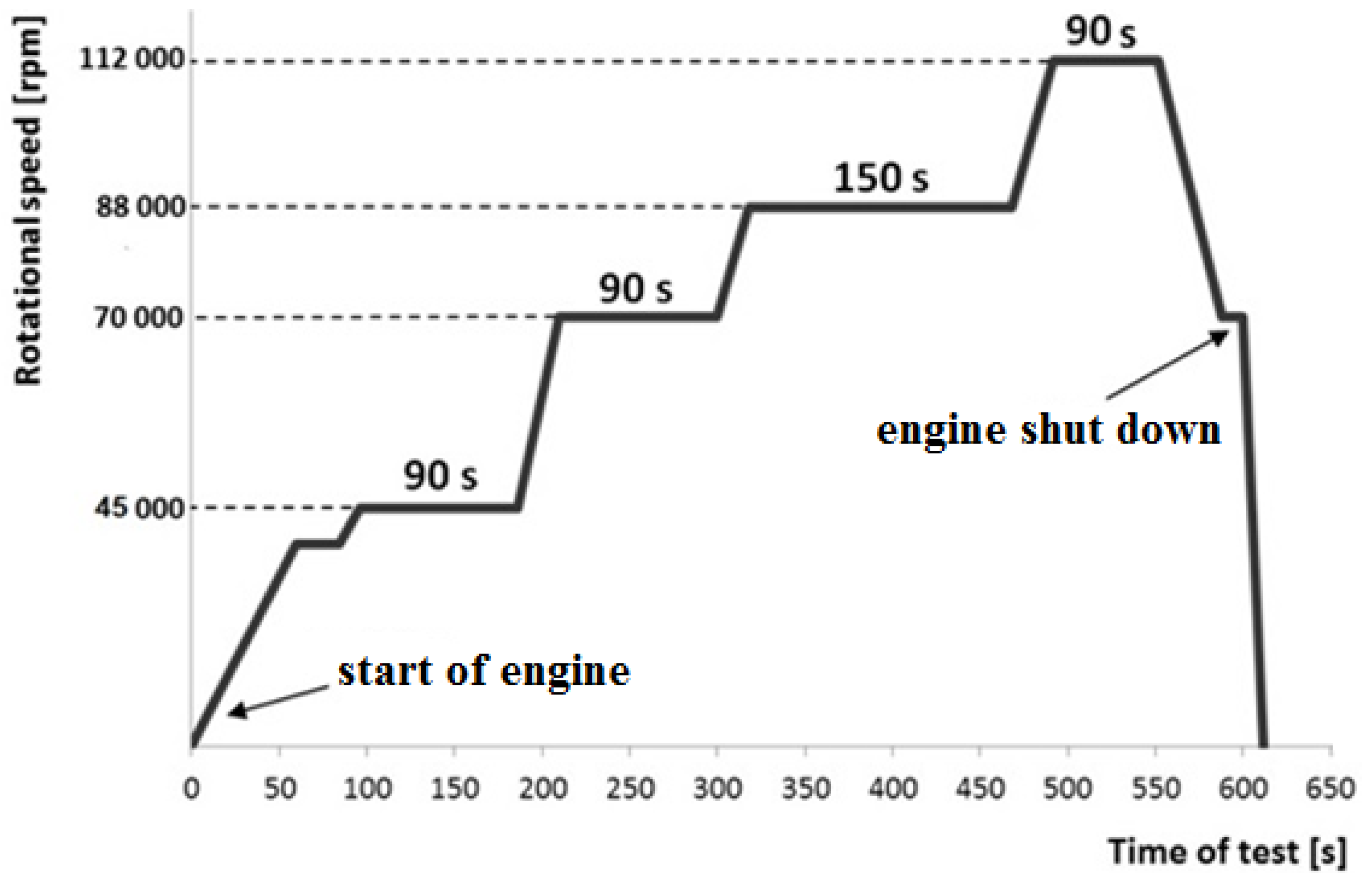

2.3. Procedure and Test Conditions

2.4. Uncertainty Analysis

3. Results and Discussion

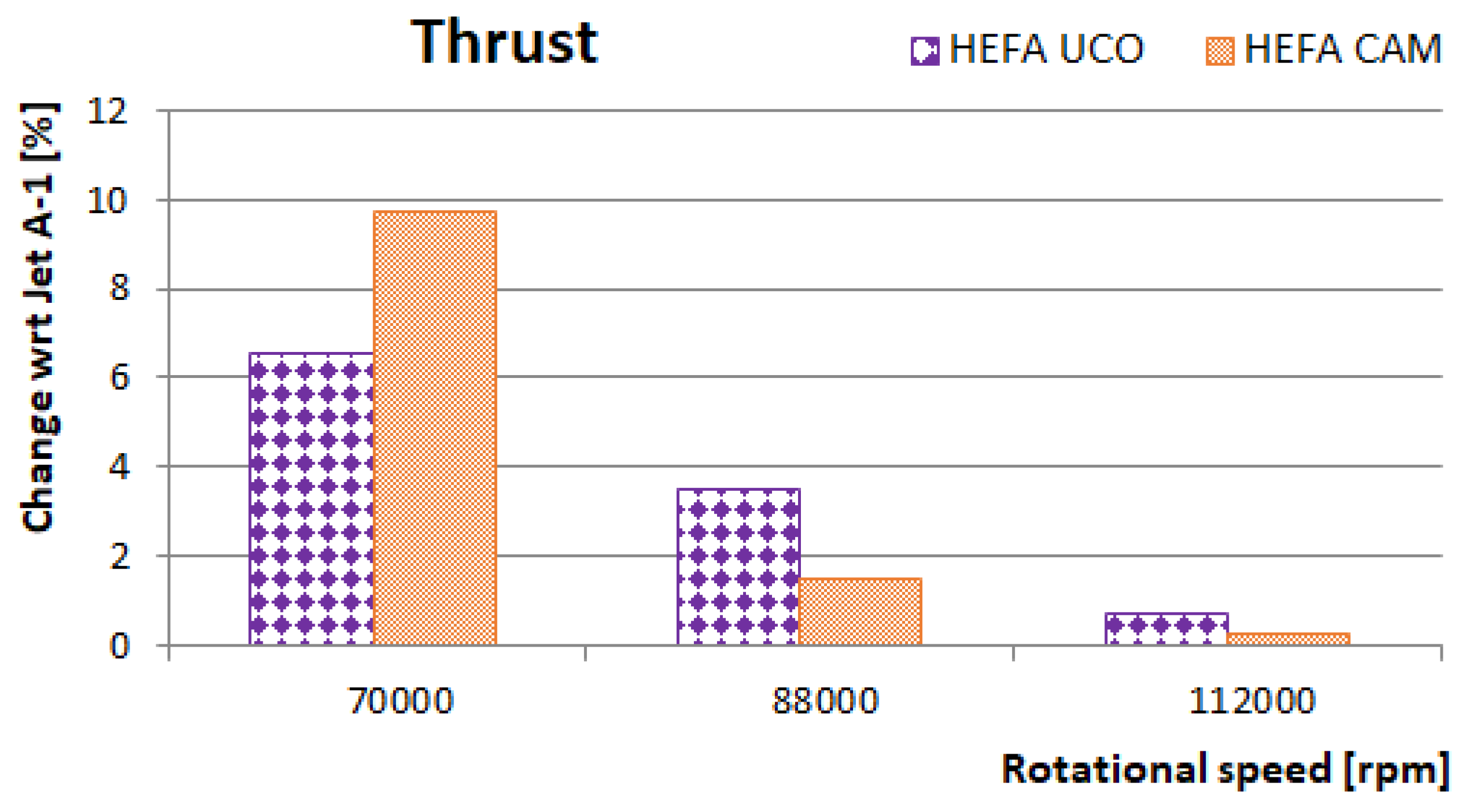

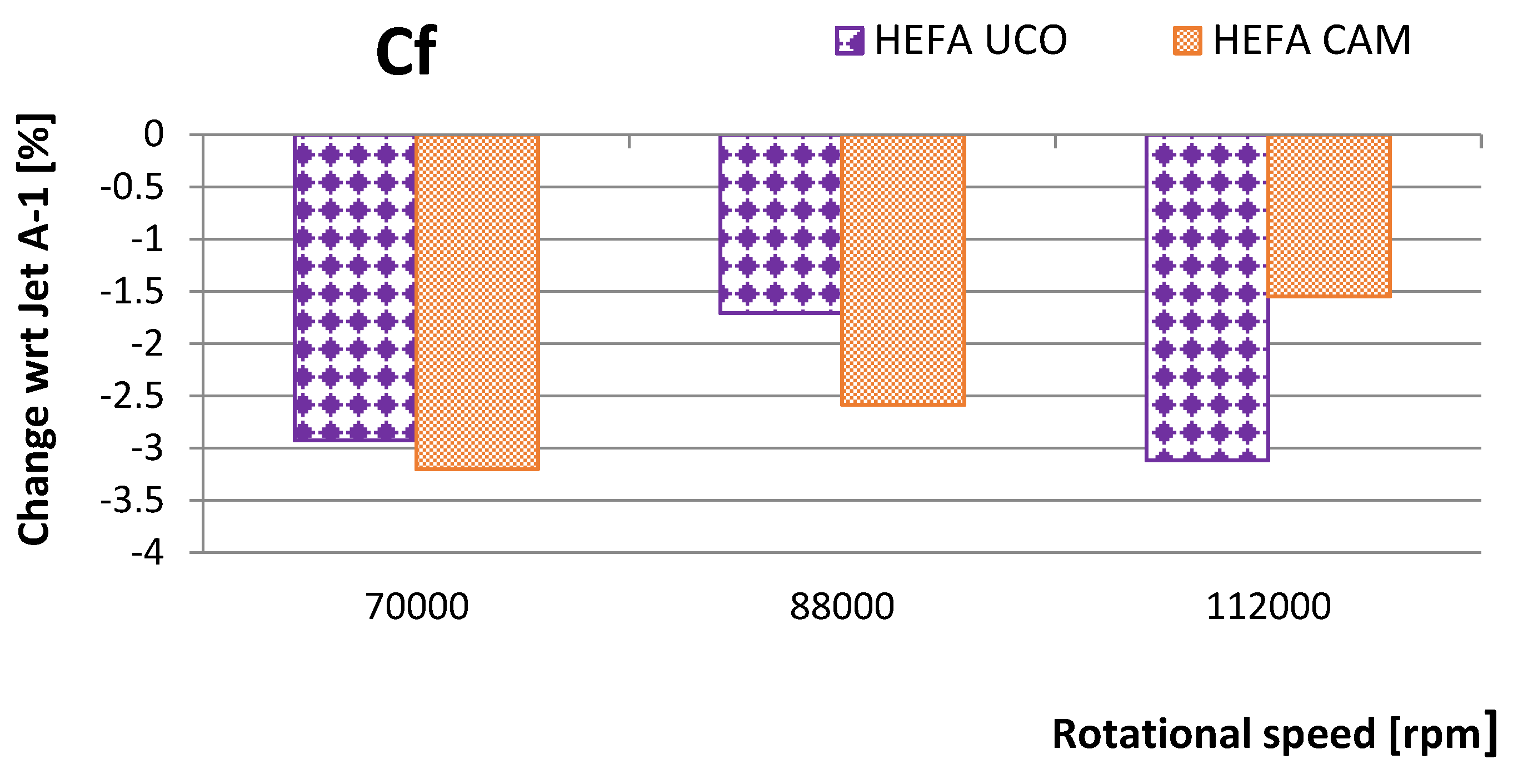

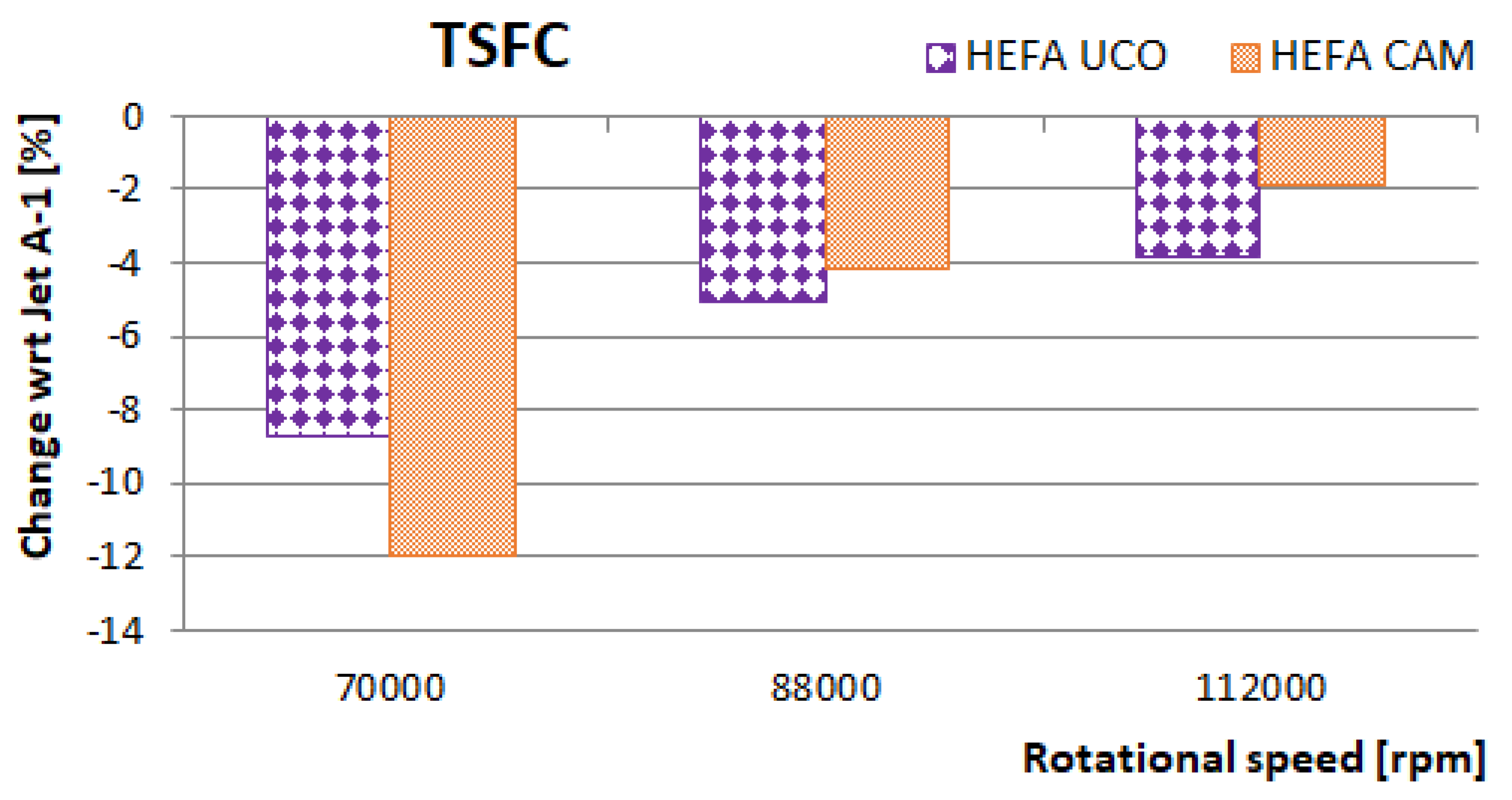

3.1. Combustion Characteristics

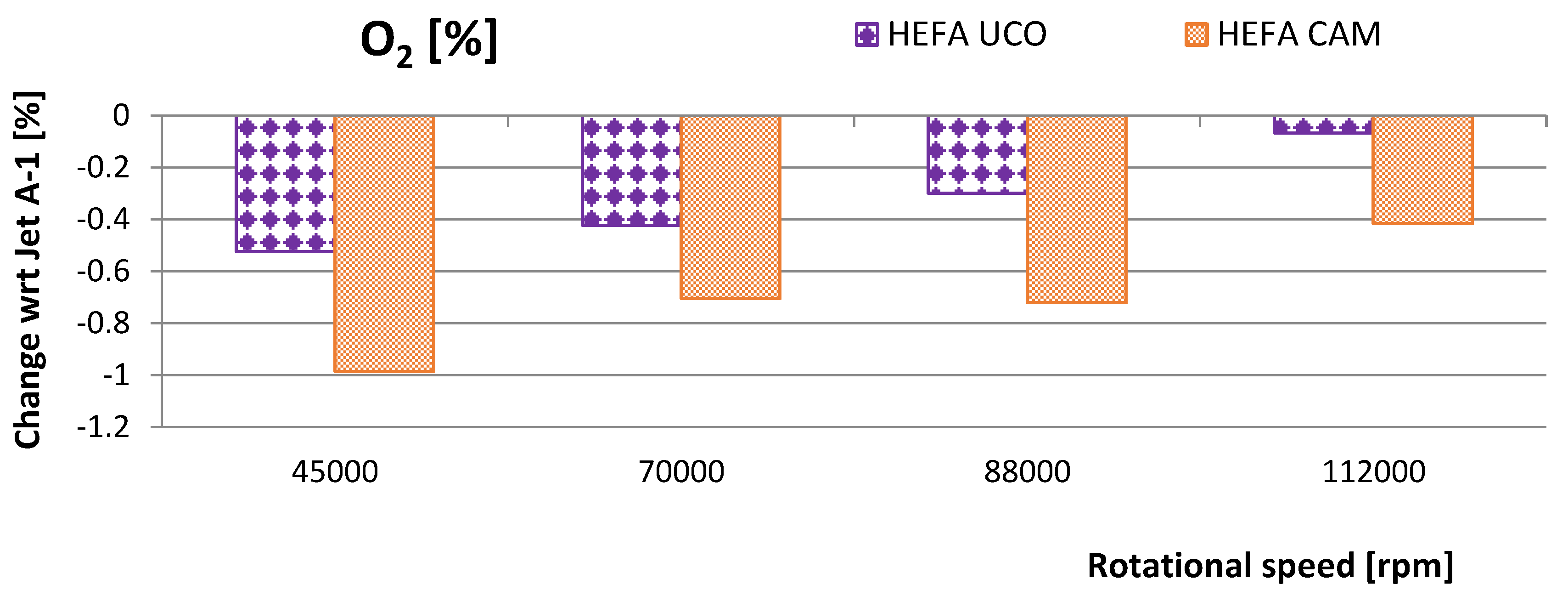

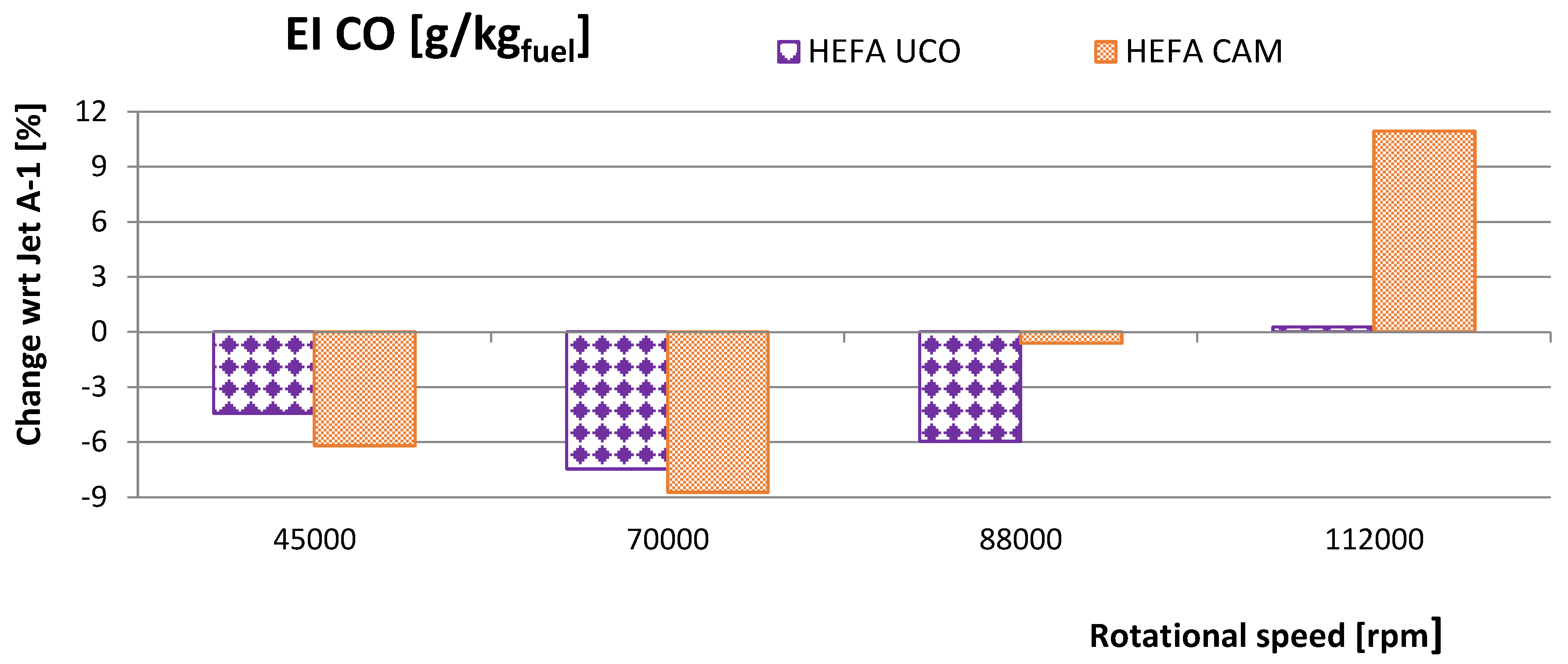

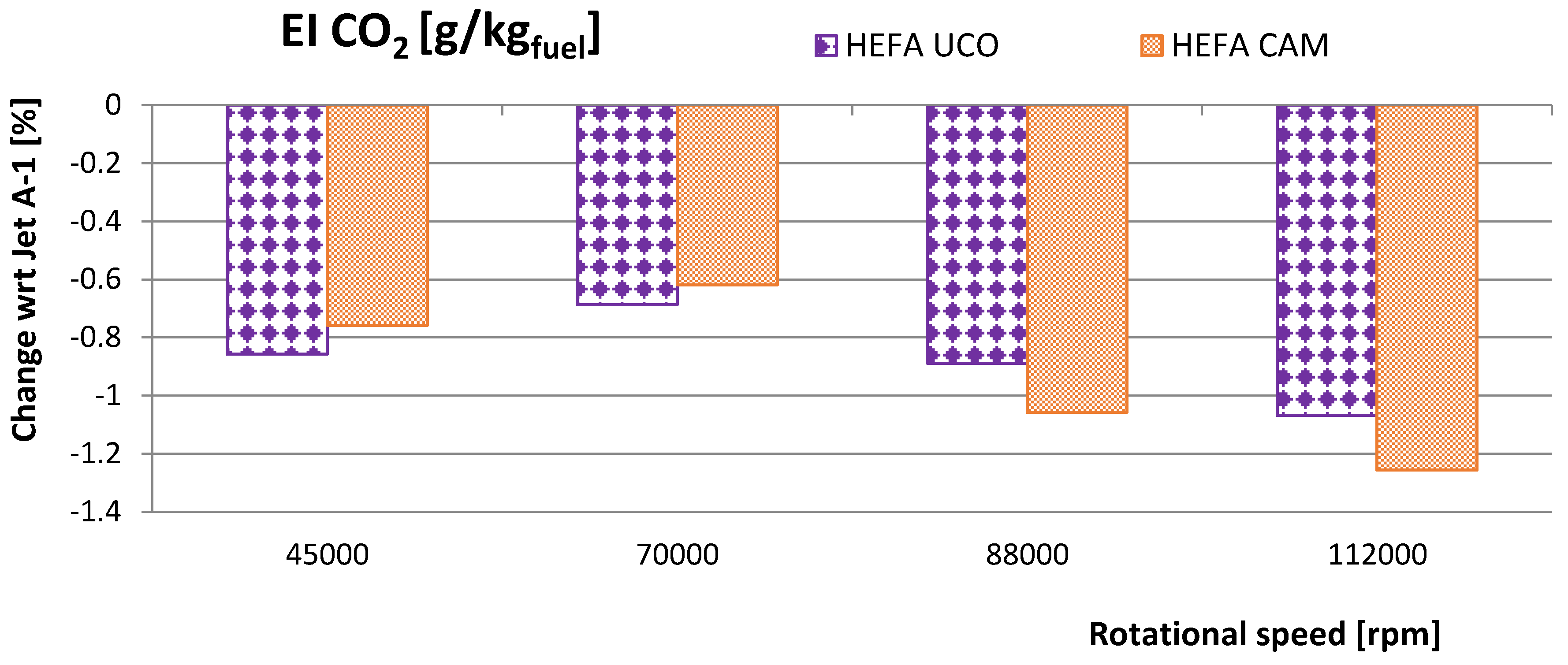

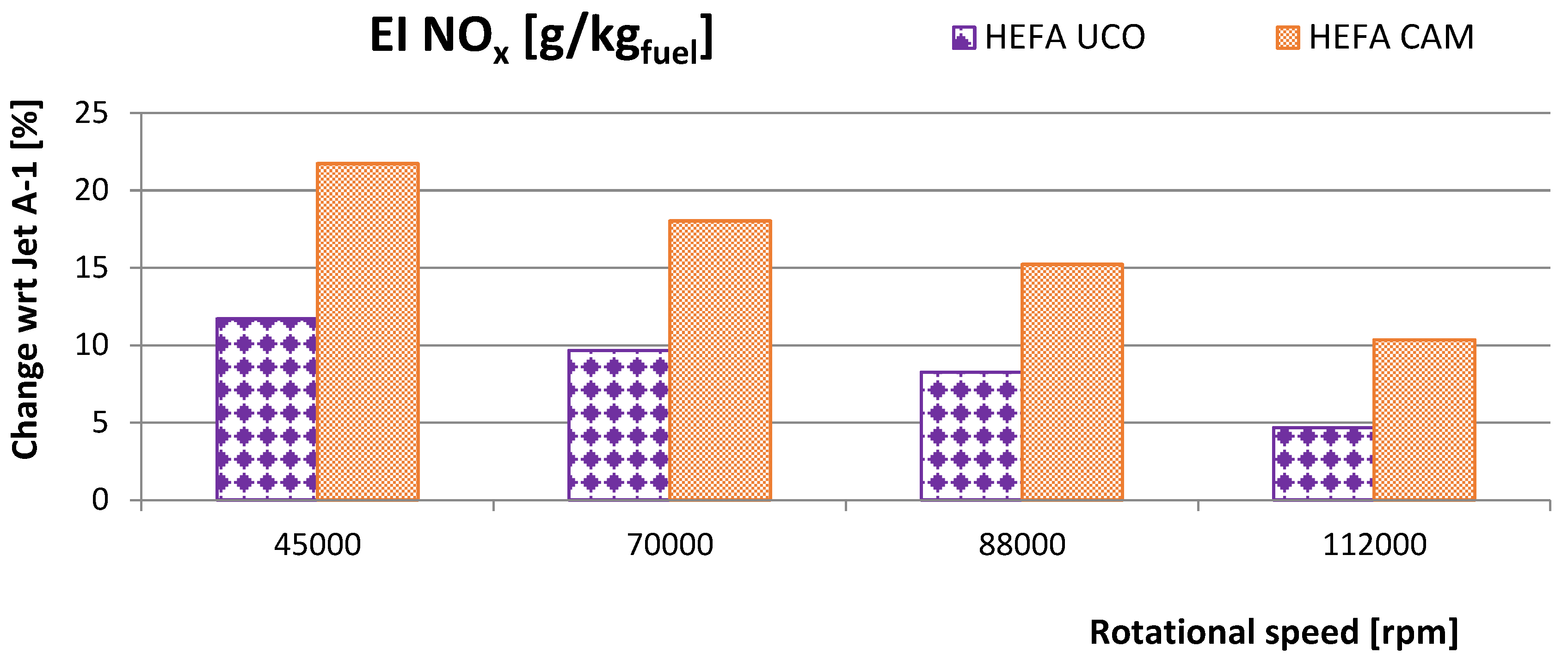

3.2. Exhaust Emissions Characteristics

4. Conclusions

- The analysis of experimental data indicates differences in the operation of the miniature jet engine if it runs on neat Jet A-1 or on HEFA blends, which shows especially in fuel consumption and CO emission. Fuel consumption and CO emission for HEFA blends are lower than Jet A-1. HEFA blends have a higher calorific value and lower density compared to neat jet fuel.

- No significant variations in the turbine temperature and CO2 emissions on all engine operating states for tested fuels.

- Significant differences for tested fuels are obtained for NOx emissions. HEFA component, for both camelina and used cooking oil, added to aviation fuel increases NOx emissions.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Symbol | Definition | Units |

| CO2 | carbon dioxide | % |

| K | thrust | N |

| Cf | fuel consumption | g/s |

| T4 | turbine temperature | °C |

| TSFC | thrust-specific fuel consumptions | kg/Nh |

| O2 | oxigen | % |

| EI CO | emission index of carbon monoxide | g/kgfuel |

| EI CO2 | emission index of carbon dioxide | g/kgfuel |

| EI NOx | emission index of nitrogen oxides | g/kgfuel |

References

- Intergovernmental Panel on Climate Change (IPPC), Fourth Assessment Report, “Climate Change 2007: Mitigation of Climate Change”. Available online: https://archive.ipcc.ch/publications_and_data/publications_ipcc_fourth_assessment_report_wg3_report_mitigation_of_climate_change.htm (accessed on 12 November 2019).

- Lee, D.; Fahey, D.W.; Forster, P.M.; Newton, P.J.; Wit, R.C.N.; Lim, L.L.; Owen, B.; Sausen, R. Aviation and global climate change in the 21st century. Atmos. Environ. 2009, 43, 3520–3537. [Google Scholar] [CrossRef]

- Fact Sheet. Climate Change & CORSIA. IATA. 2018. Available online: https://www.iata.org/en/iata-repository/pressroom/fact-sheets/fact-sheet---climate-change/ (accessed on 2 December 2019).

- ASTM D7566. Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Gutiérrez-Antonio, C.; Gómez-Castro, F.I.; de Lira-Flores, J.A.; Hernández, S. A review on the production processes of renewable jet fuel. Renew. Sustain. Energy Rev. 2017, 79, 709–729. [Google Scholar] [CrossRef]

- Rahmes, T.F.; Kinder, J.D.; Henry, T.M.; Crenfeldt, G.; Leduc, G.F.; Zombanakis, G.P.; Abe, Y.; Lambert, D.M.; Lewis, C.; Juenger, J.A.; et al. Sustainable Bio-derived Synthetic Paraffinic Kerosene (Bio-SPK) Jet Fuel Flight and Engine Tests Program Results. In Proceedings of the 9th AIAA Aviation Technology, Integration and Operations Conference, Hilton Head, SC, USA, 21–23 September 2009. [Google Scholar] [CrossRef]

- ASTM D1655. Standard Specification for Aviation Turbine Fuels; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Bolszo, C.D.; McDonell, V.G. Emissions optimization of a biodiesel fired gas turbine. Proc. Combust. Inst. 2009, 32, 2949–2956. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Z.; Lu, Y.; Zhang, C.; Zhang, X.; Zhang, C.; Roskilly, A.P. Experimental study of the gaseous and particulate matter emissions from a gas turbine combustor burning butyl butyrate and ethanol blends. Appl. Energy 2017, 195, 693–701. [Google Scholar] [CrossRef]

- Chong, C.T.; Hochgreb, S. Spray flame structure of rapeseed biodiesel and Jet A-1 fuel. Fuel 2014, 115, 551–558. [Google Scholar] [CrossRef]

- Chuck, C.J.; Donnelly, J. The compatibility of potential bioderived fuels with Jet A-1 aviation kerosene. Appl. Energy 2014, 118, 83–91. [Google Scholar] [CrossRef]

- Dzięgielewski, W.; Gawron, B.; Kulczycki, A. Low Temperature Properties of Fuel Blends of Kerosene and Fame Type Used to Supply Turbine Engines in Marine and Other Non-Aeronautical Applications. Pol. Marit. Res. 2015, 22, 101–105. [Google Scholar]

- Gawron, B.; Białecki, T.; Dzięgielewski, W.; Kaźmierczak, U. Performance and emission characteristic of miniature turbojet engine fed Jet A–1/alcohol blend. J. Kones 2016, 23, 123–129. [Google Scholar] [CrossRef]

- Badami, M.; Nuccio, P.; Pastrone, D.; Signoretto, A. Performance of a small-scale turbojet engine fed with traditional and alternative fuels. Energy Convers. Manag. 2014, 82, 219–228. [Google Scholar] [CrossRef]

- Hui, X.; Kumar, K.; Sung, C.J.; Edwards, T.; Gardner, D. Experimental studies on the combustion characteristics of alternative jet fuels. Fuel 2012, 98, 176–182. [Google Scholar] [CrossRef]

- Gaspar, R.M.P.; Sousa, M.M. Impact of alternative fuels on the operational and environmental performance of a small turbofan engine. Energy Convers. Manag. 2016, 130, 81–90. [Google Scholar] [CrossRef]

- Won, S.H.; Veloo, P.S.; Dooley, S.; Santner, J.; Haas, F.M.; Ju, Y.; Dryer, F.L. Predicting the global combustion behaviors of petroleum-derived and alternative jet fuels by simple fuel property measurements. Fuel 2016, 168, 34–46. [Google Scholar] [CrossRef]

- Xue, X.; Hui, X.; Singh, P.; Sung, C.J. Soot formation in non-premixed counterflow flames of conventional and alternative jet fuels. Fuel 2017, 210, 343–351. [Google Scholar] [CrossRef]

- Allen, C.; Valco, D.; Toulson, E.; Edwards, T.; Lee, T. Ignition behavior and surrogate modeling of JP-8 and of camelina and tallow hydrotreated renewable jet fuels at low temperatures. Combust. Flame 2013, 160, 232–239. [Google Scholar] [CrossRef]

- Buffi, M.; Valera-Medina, A.; Marsh, R.; Pugh, D.; Giles, A.; Runyon, J.; Chiaramonti, D. Emissions characterization tests for hydrotreated renewable jet fuel from used cooking oil and its blends. Appl. Energy 2017, 201, 84–93. [Google Scholar] [CrossRef]

- Gawron, B.; Białecki, T. Impact of a Jet A-1/HEFA blend on the performance and emission characteristics of a miniature turbojet engine. Int. J. Environ. Sci. Technol. 2018, 15, 1501–1508. [Google Scholar] [CrossRef]

- Hashimoto, N.; Nishida, H.; Ozawa, Y. Fundamental combustion characteristics of Jatropha oil as alternative fuel for gas turbines. Fuel 2014, 126, 194–201. [Google Scholar] [CrossRef]

- Liu, Y.C.; Savas, A.J.; Avedisian, C.T. The spherically symmetric droplet burning characteristics of Jet-A and biofuels derived from camelina and tallow. Fuel 2013, 108, 824–832. [Google Scholar] [CrossRef]

- Shila, J.J.; Johnson, M.E. Estimation and comparison of particle number emission factors for petroleum-based and camelina biofuel blends used in a Honeywell TFE-109 Turbofan Engine. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar]

- Zhang, C.; Hui, X.; Lin, Y.; Sung, C.J. Recent development in studies of alternative jet fuel combustion: Progress, challenges, and opportunities. Renew. Sustain. Energy Rev. 2016, 54, 120–138. [Google Scholar] [CrossRef]

- Yang, J.; Xin, Z.; He, Q.; Corscadden, K.; Niu, H. An overview on performance characteristics of bio-jet fuels. Fuel 2019, 237, 916–936. [Google Scholar] [CrossRef]

- Gawron, B.; Białecki, T. The laboratory test rig with miniature jet engine to research aviation fuels combustion process. J. Konbin 2015, 36, 79–90. [Google Scholar] [CrossRef]

- Gawron, B.; Białecki, T. Measurement of exhaust gas emissions from miniature turbojet engine. Combust. Engines 2016, 167, 58–63. [Google Scholar]

- SAE Aerospace Recommended Practice 1256. Procedure for the Continuous Sampling and Measurement of Gaseous Emissions from Aircraft Turbine Engines; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Gawron, B.; Białecki, T.; Górniak, A.; Janicka, A.; Zawiślak, M. An innovative method for exhaust gases toxicity evaluation in the miniature turbojet engine. Aircr. Eng. Aerosp. Technol. 2017, 89, 757–763. [Google Scholar] [CrossRef]

- Gawron, B.; Białecki, T.; Janicka, A.; Górniak, A.; Zawiślak, M. Exhaust toxicity evaluation in a gas turbine engine fueled by aviation fuel containing synthesized hydrocarbons. Aircr. Eng. Aerosp. Technol. 2020, 92, 60–66. [Google Scholar] [CrossRef]

- Janicka, A.; Zawiślak, M.; Zaczyńska, E.; Czarny, A.; Górniak, A.; Gawron, B.; Białecki, T. Exhausts toxicity investigation of turbojet engine, fed with conventional and biofuel, performed with aid of BAT-CELL method. Toxicol. Lett. 2017, 280, 202. [Google Scholar] [CrossRef]

| Parameter | Sensor Type | Range | Least Count | Accuracy |

|---|---|---|---|---|

| CO | electrochemical | 0–2000 | 0.1 ppm | ±5% measured value |

| CO2 | infrared | 0–25 | 0.01% | ±5% measured value |

| NO | electrochemical | 0–500 | 0.1 ppm | ±5% measured value |

| NO2 | electrochemical | 0–100 | 0.1 ppm | ±5 ppm |

| Property | Unit | Limits ASTM D1655/D7566 | Results | ||

|---|---|---|---|---|---|

| Jet A-1 | HEFA CAM | HEFA UCO | |||

| Density at 15 °C | kg/m3 | 775.0 ÷ 840.0 | 790.2 | 779.9 | 771.1 |

| Viscosity in −20 °C | mm2/s | Max 8.0 | 3.117 | 4.968 | 3.514 |

| Heat of combustion | MJ/kg | Min 42.8 | 43.307 | 43.691 | 43.744 |

| Flash point | °C | Min 38 | 42.0 | 44.5 | 43.5 |

| Freezing point | °C | Max −40 | −63.8 | −57.5 | −51.5 |

| Smoke point | mm | Min 18 | 25.0 | 25.0 | 26.0 |

| Naphthalenes | (v/v) % | Max 3.0 | 0.47 | 0.57 | 0.24 |

| Aromatics | (v/v) % | Max 25 | 15.0 | 9.1 | 7.2 |

| Fuel | Test No. | Po (hPa) | To (°C) | RH (%) |

|---|---|---|---|---|

| Jet A-1 | Test 1 | 995.2 | 27.9 | 62.0 |

| Test 2 | 995.1 | 28.8 | 60.3 | |

| HEFA CAM | Test 1 | 994.3 | 30.7 | 50.2 |

| Test 2 | 994.1 | 31.0 | 48.5 | |

| HEFA UCO | Test 1 | 994.8 | 29.4 | 55.9 |

| Test 2 | 994.7 | 29.9 | 52.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gawron, B.; Białecki, T.; Janicka, A.; Suchocki, T. Combustion and Emissions Characteristics of the Turbine Engine Fueled with HEFA Blends from Different Feedstocks. Energies 2020, 13, 1277. https://doi.org/10.3390/en13051277

Gawron B, Białecki T, Janicka A, Suchocki T. Combustion and Emissions Characteristics of the Turbine Engine Fueled with HEFA Blends from Different Feedstocks. Energies. 2020; 13(5):1277. https://doi.org/10.3390/en13051277

Chicago/Turabian StyleGawron, Bartosz, Tomasz Białecki, Anna Janicka, and Tomasz Suchocki. 2020. "Combustion and Emissions Characteristics of the Turbine Engine Fueled with HEFA Blends from Different Feedstocks" Energies 13, no. 5: 1277. https://doi.org/10.3390/en13051277

APA StyleGawron, B., Białecki, T., Janicka, A., & Suchocki, T. (2020). Combustion and Emissions Characteristics of the Turbine Engine Fueled with HEFA Blends from Different Feedstocks. Energies, 13(5), 1277. https://doi.org/10.3390/en13051277