1. Introduction

One of the greatest challenges in the 21st century is the continuous deterioration of the environment, characterized by climate change and other interdependent consequences assisted by policies in favor of fossil fuels [

1]. As the world population increases in the coming decades, the International Energy Agency predicted global energy demand will extend by 30% between 2016 and 2040 [

2].

The main source of inexhaustible energy is the sun, and its potential is 6500 TW [

3]. Irradiance has huge potential (e.g., 1500 kWh/m

2 year on a horizontal plane in Africa [

4]) to fulfill the world’s energy demands [

5], while humans can have an available technology for collecting and withdrawing the sun’s energy. Many countries have established policies to encourage users to consume renewable electricity. Policies include tariff privileges (cost credit for using renewable energy [

6,

7]), allocation rules (they should produce a specific rate of energy from sustainable sources [

8,

9]), pensions (gives economic support for sustainable energy management or energy efficient technology use [

10]), feed-in costs (gives monetary help for the purchaser), relationship of research institutes (gives research fellowships), planned implementation, measure, and/or inexhaustible power laws [

11].

At present, the European Commission has determined to reduce emissions by 2050 as one of its fundamental objectives. They have developed economic and social transition strategies [

12]. The European Union (EU) is working on “Pathways for the transition to a net-zero greenhouse gas emissions economy and strategic priorities”, and a subsection of this general line is “Maximize the deployment of renewables and electricity to fully decarbonize Europe’s energy supply”, underlining the European dependency on oil and gas, which in 2018 was 55% of the energy need. The EU aims to reduce 20% of the entire energy need by 2050. The Spanish plan of greenhouse gas (GHG) emissions, 10% reduction by 2020 compared to 2005, means conserving energy and emissions (as many as current consumption). According to the EU [

13], they expect that in 2020 Spain will meet the objectives, but not in 2030. So, we must make the first efforts to meet emission reduction targets. Energy production through renewable sources is equal to 20% [

13]. Spanish legislation on building construction imposes to cover 30–70% (depending on the zone in Spain) of energy demand with solar thermal energy [

14].

Solar water heaters are a convenient substitute to produce hot water for space heating and domestic hot water (DHW) supply [

15,

16], as solar thermal collectors can diminish the use of non-inexhaustible energy and can provide hot water at temperatures fluctuating from 40 to 80 °C. The leading states in solar water heater capacity (cumulated water collector) in 2019 were China, the United States, Turkey, and Germany (334.52, 17.76, 16.28 and 13.74 MW

2 respectively) [

17]. Heating is a very efficient use of solar thermal power, which could help to reduce fossil fuel consumption and minimize global carbon emissions for environmental, economic, and social reasons [

18].

Since exploring the warming and refrigerating loads at the construction design stage can lower energy consumption in families, researchers are handling more concerns on optimizing building envelopes, windows [

19], outline dimensions, direction, rubbing area, and thermophysical properties of structure elements [

15]. Solar irradiance received by a building depends on its orientation and glazing area [

20], acknowledging that buildings with great energy efficiency are oriented to capture irradiance from a variety of directions [

15].

Researchers developed simulation models for building integrated solar thermal elements [

21,

22] and for multiskin facades [

23,

24], but they are difficult to compare because authors did not present some information (the boundary conditions, fluid inlet temperature, the usage pattern) that affects the solar thermal performance [

25]. The major troubles in solar thermal systems are overheating and stagnation. Overheating occurs when the solar energy absorbed by a solar collector exceeds the capability of its heat transfer fluid circuit to cool it (the temperature of a thermal fluid during sluggishness can reach up to 180 °C) [

26]. Practitioners do not equip standard dwellings with meters to give the flow and temperature for energy-balance calculations, so the data are not available in most cases. Water meters register total water consumption in residences, but it does not discriminate between hot and cold-water utilization. A survey on the energy expenditure in households shows that the energy savings are moderate because of diverse active or passive energy-saving technologies [

27].

Green houses refer to architecture that is environmentally efficient and resource efficient [

28,

29,

30]. New approaches have determined that self-utilization systems are viable, but they associate economics to systems design. Several factors (such as load profile, solar production analysis, and the designs of the support schemes) influence the feasibility of self-expenditure. In the USA, some works investigated the large-scale implementation of solar water heating techniques on their utility [

31], which led to reduction of energy demands, energy expenditure, and carbon emissions.

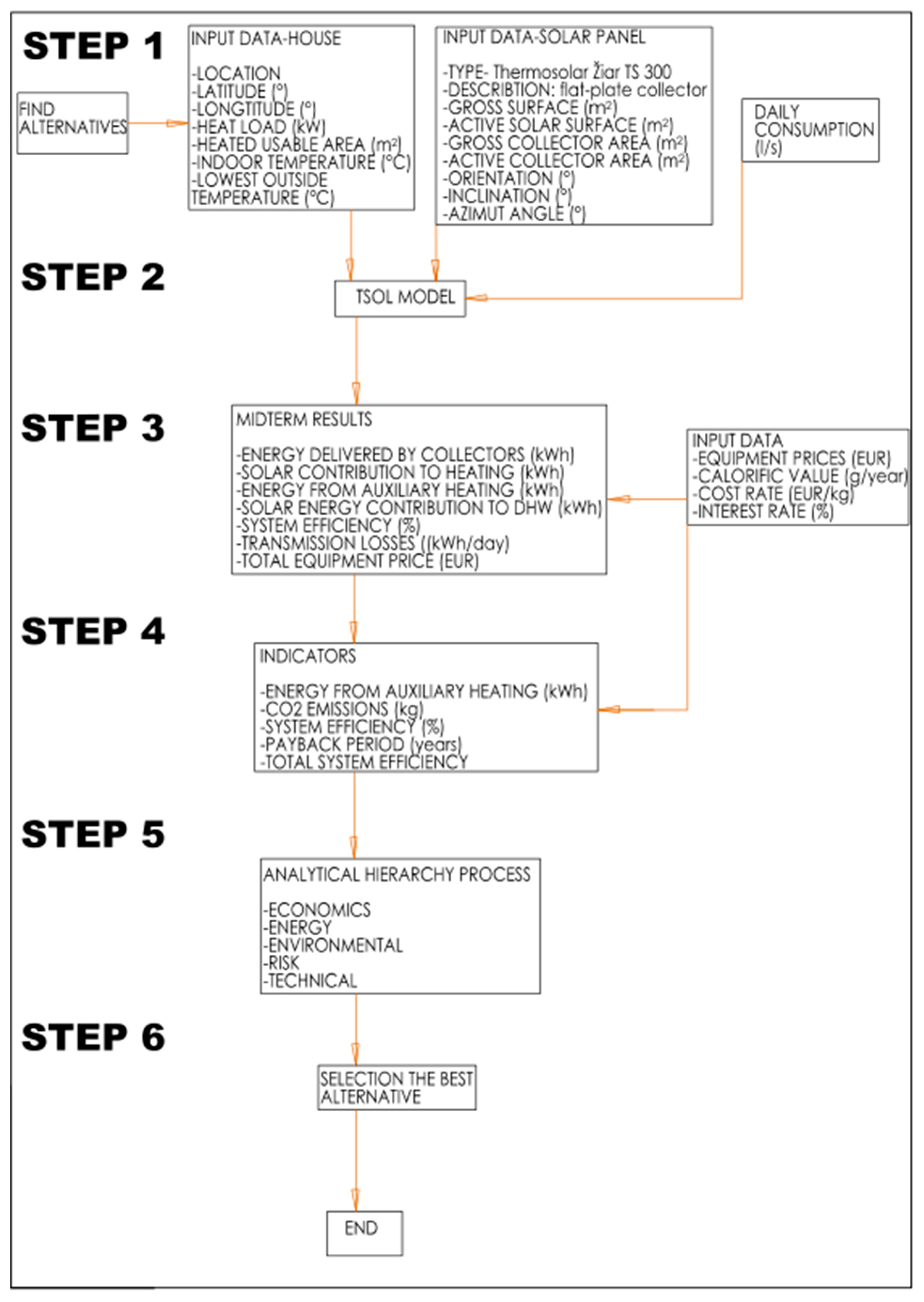

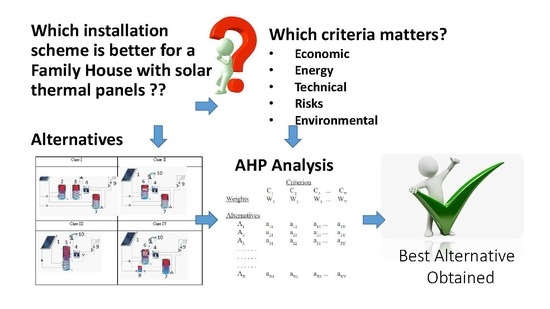

This work proposes a method to determine which design scheme is better for a building in which a solar thermal panel for space heating and (Domestic Hot Water are incorporated [

32,

33], something that has been performed in industries [

34] and offices buildings [

35], or focusing on the thermal energy performance of cool louvers of shutters [

36], ventilated double skin façades with venetian blinds [

37], or on the new materials and technologies that can improve the thermal comfort in buildings [

38]. We calculate energy and emissions savings comparing every scenario with the zero-case where only a gas boiler and a tank are used for domestic hot water and for floor/radiator heating (this zero-case does not consider renewable energies). In every scenario, we use the simulation software “T*SOL” (Valentin Software GmbH, 10243 Berlin, Germany) [

39] to calculate the efficiency of solar thermal equipment. T*SOL software returns the energy delivered to collectors, the solar contribution to heating and DHW, and the energy from auxiliary heating for every alternative. We prioritize alternatives considering multiple criteria (energy savings, economic availability, technical availability, and environmental standpoints) to find which solar energy installation in buildings is the best alternative in this decision support model to help decision-makers understand the trade-offs among alternatives.

We calculate the cost of alternatives (costs of Solar thermal panels, gas boilers, and water tanks) and compute the economic savings after this investment. From the economic perspective, we calculate the payback period to prioritize the solar installation schemes. As the software presents auxiliary gas consumption, we incorporate these data as environmental results for every alternative. Availability criteria consider that technological obsolescence involves higher transmission losses (from the ST systems, tanks, etc.).

To assess the weights of these criteria, we adopt the analytical hierarchy process (AHP), a robust management science tool that is helpful in structuring complex multiperson, multicriteria decisions [

40,

41]. AHP is a measurement (scoring) model that relies on personal managerial views on different criteria, applied in sustainable energy-related questions [

42,

43,

44]. We established the AHP model with precise benchmarks and metrics and converted these inputs into scores that were used to test each of the choices. AHP and the analytical network process were presented in [

45,

46], and we calculated the AHP procedure with a software developed in Microsoft Excel based on Macro (VBA- Visual Basic for Applications programming) [

47].

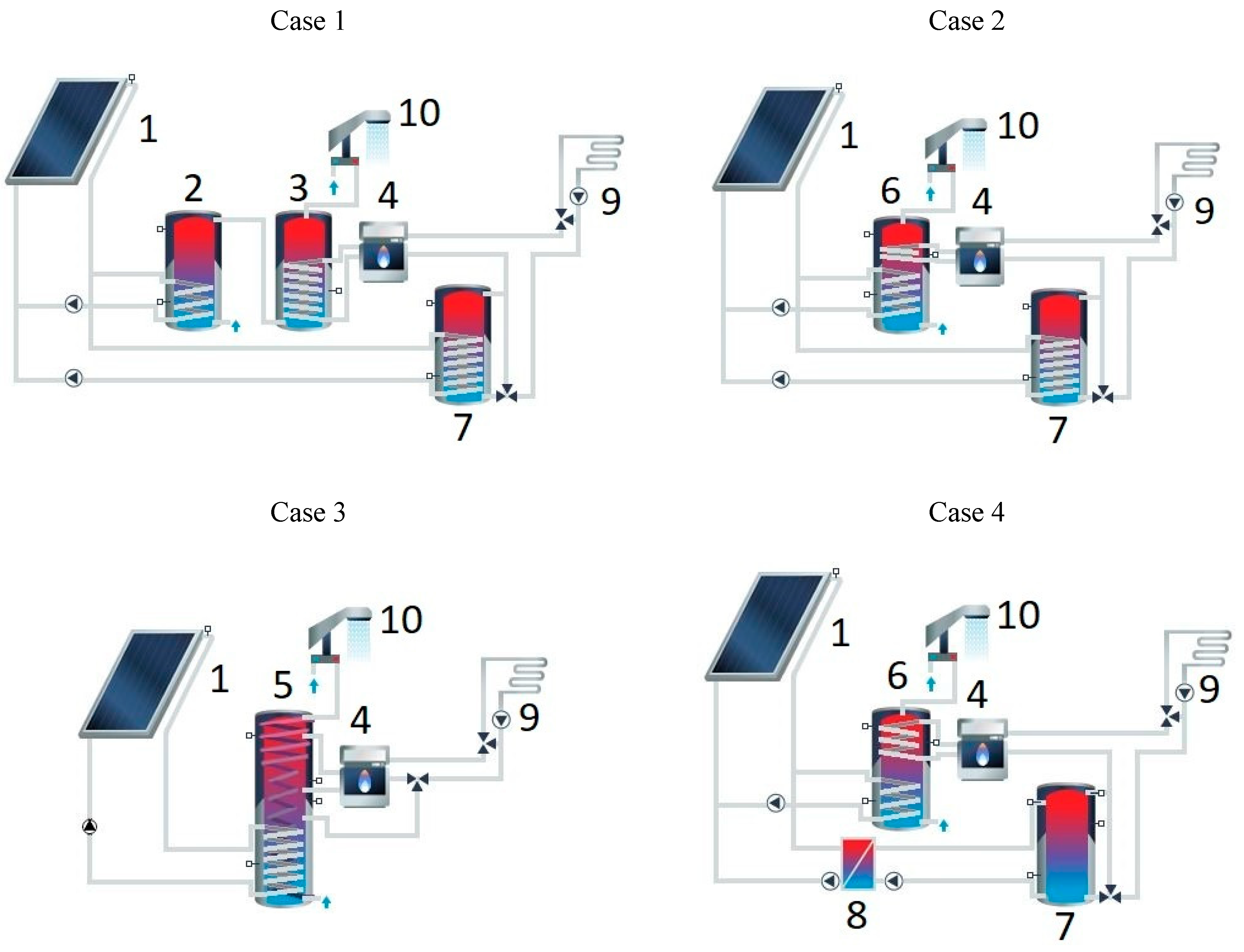

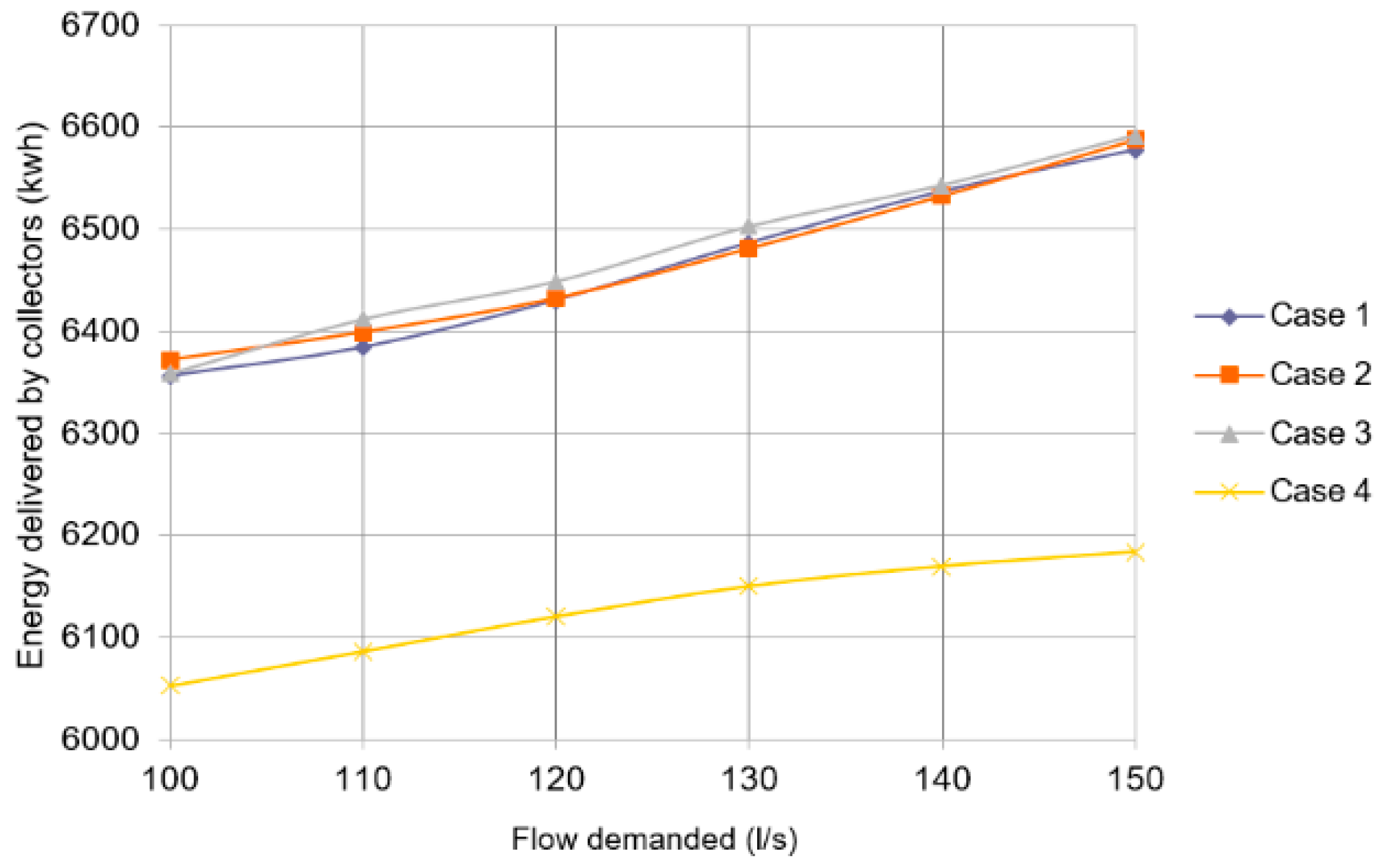

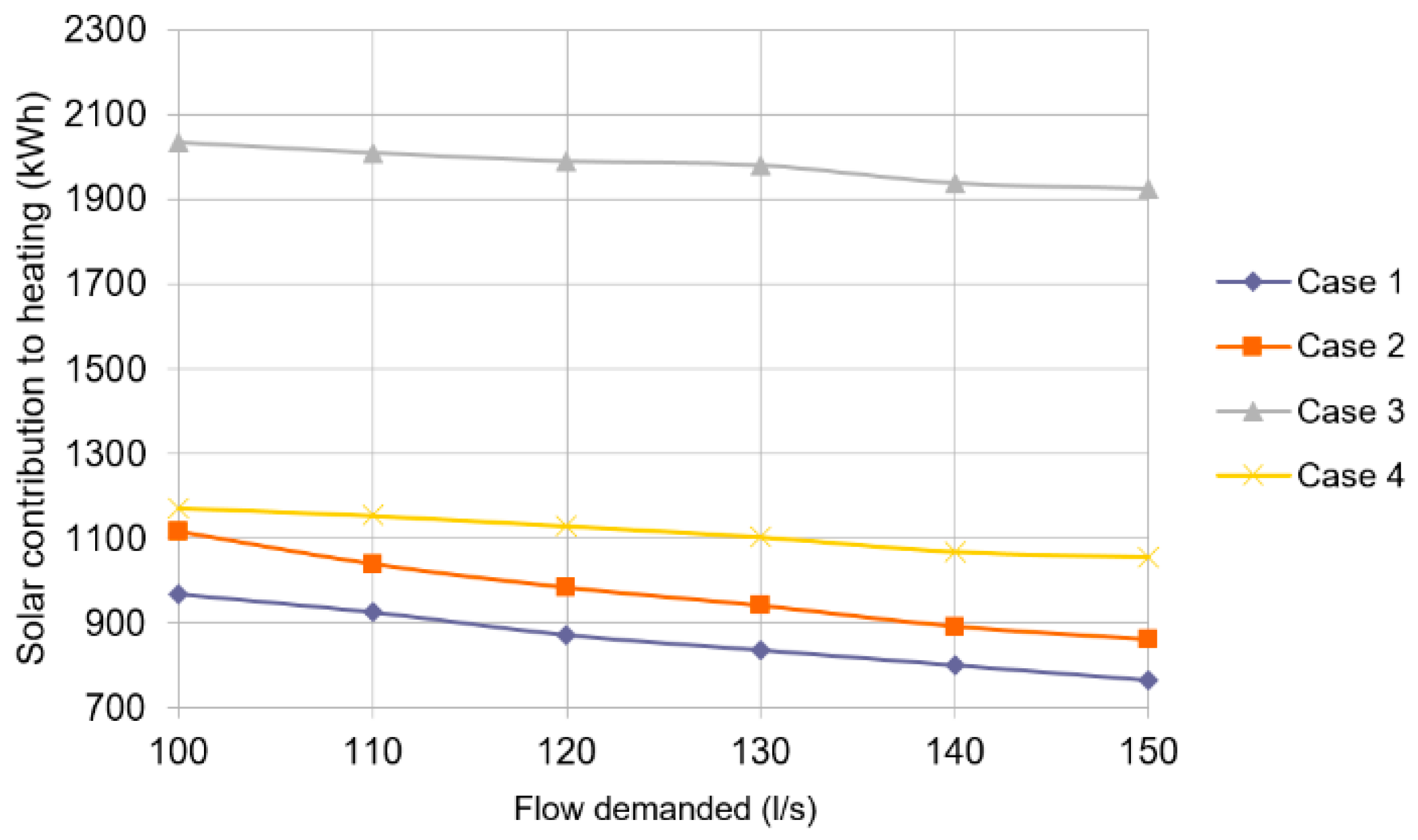

This software generates pair-wise matrixes (based on the criteria and based on the options) and it prioritizes a set of options from most to least acceptable (it offers a general score, where the best alternative has the greatest value). It determines the relative merit of members of a set of alternatives and calculates the inconsistency ratio for each criterion and for the total problem. We present here a real case study allocated in a house (four inhabitants) in Murcia (Spain). In this context, we propose four schemes with five solar panels and other differences that intend to represent the most common installation alternatives. We perform a sensitivity analysis to see how these cases work with daily water demand variations.

4. Conclusions

This work presents a method to create a multicriteria decision support system to compare solar energy systems in buildings considering energy, economical, technical, availability, and environmental issues. We computed the weight of the criteria selected considering the analytical hierarchy process to get a prioritization scheme for selecting the right solar panel system. We intend practitioners to set their own weights for the criteria (other scenarios can involve different weights, for example environmental, energy, or availability, if they are considered more than in our case) to make this a universal tool.

In the case study selected, we proposed four schemes to represent the most common installation alternatives in Spain. Among others, Case 1 which incorporated a gas boiler, a solar preheating tank, a buffer tank, and DHW tank, was the best alternative, as the economic criteria were much more important than in the other cases. We can state here that a universal best solar thermal scheme does not exist, as energy consumption depends on other features and limits as well as energy production, geographical latitude of the location, and so forth. For the other criteria, Case 3 (a gas boiler and a combination tank) resulted in the best alternative for reducing the energy required and CO2 emitted, it had the best energy efficiency of the installation, and it had the lowest transmission losses. In other scenarios when the economic criteria are not so relevant, this should be the best case in the prioritization scheme. The sensitivity analysis with regards the DHW consumption showed that an increase in hot water demand involved higher energy requirements. These schemes are more important in terms of energy and environmental savings; thus, it is appropriate to install a greater number of panels.

We will focus our future research works on experimental measurements of solar thermal installation schemes and on comparing modelled and measured parameters with the aim to confirm the results obtained with T*SOL software. It is important to highlight that as heat production varies in many locations (longitude and latitude, mean outside temperature, lowest outside temperature), we think the current method will show that different results are expected in every town or country.