Abstract

Lithium ion (Li-ion) batteries have been widely applied to portable electronic devices and hybrid vehicles. In order to further enhance performance, the search for advanced anode materials to meet the growing demand for high-performance Li-ion batteries is significant. Fe3C as an anode material can contribute more capacity than its theoretical one due to the pseudocapacity on the interface. However, the traditional synthetic methods need harsh conditions, such as high temperature and hazardous and expensive chemical precursors. In this study, a graphitic carbon encapsulated Fe/Fe3C (denoted as Fe/Fe3C@GC) composite was synthesized as an anode active material for high-performance lithium ion batteries by a simple and cost-effective approach through co-pyrolysis of biomass and iron precursor. The graphitic carbon shell formed by the carbonization of sawdust can improve the electrical conductivity and accommodate volume expansion during discharging. The porous microstructure of the shell can also provide increased active sites for the redox reactions. The in-situ-formed Fe/Fe3C nanoparticles show pseudocapacitive behavior that increases the capacity. The composite exhibits a high reversible capacity and excellent rate performance. The composite delivered a high initial discharge capacity of 1027 mAh g−1 at 45 mA g−1 and maintained a reversible capacity of 302 mAh g−1 at 200 mA g−1 after 200 cycles. Even at the high current density of 5000 mA g−1, the Fe/Fe3C@GC cell also shows a stable cycling performance. Therefore, Fe/Fe3C@GC composite is considered as one of the potential anode materials for lithium ion batteries.

1. Introduction

High-energy lithium ion batteries (LIBs) have been used in portable electronics and mobile communication devices due to their high energy density, long cycling life, and environmental friendliness [1,2]. Graphite has been commercially used as an anode material for LIBs with high electrical conductivity and good cyclability. However, it is difficult to develop advanced batteries due to low theoretical specific capacity (372 mAh g−1). Therefore, the development of advanced anode materials is important to meet the ever-growing demand for high-performance LIBs. Some attractive anode materials, such as Sn-based, Si-based, Sb-based, Fe-based oxides, Ti-based oxides, and transition metal sulfides, can provide high potential capacity by the conversion reaction or alloying process [3,4,5]. However, large volume changes during the lithiation and delithiation processes can cause rapid capacity fading and poor cycle life, which are serious drawbacks that hinder commercialization [6,7,8,9].

Recently, transition metal carbides (TMCs) have been investigated as potential anode candidates for LIBs due to the benefits of excellent chemical and thermal stability, good electrocatalytic performance, and reasonable economic efficiency [10,11,12]. However, the theoretical capacity is restricted and cycling stability is poor, which limits the application of TMCs in Li storage devices. There have been many attempts to mitigate these restrictions. One of the most promising attempts was to design a rational hybrid structure with TMC nanomaterials and carbonaceous materials. For example, Yang et al. developed Mo2C/N-doped carbon mesoporous heteronanowires in which Mo2C nanocrystallites are embedded in continuous 1D N-doped carbon matrix as an anode material to improve the rate capability and life span [13]. Liu et al. reported an onion-like, carbon-coated Fe3C nanocapsule embedded in porous carbon as an anode material, stabilizing electrochemical properties and extending the cycle life [14]. Su et al. reported a ternary hybrid system, core-shell Fe@Fe3C/C nanocomposite to enhance the electrochemical performance, where Fe provides good conductivity throughout the nanocomposite [15]. These superior hybrid structures have shown promising results. However, the sophisticated fabrication process is not only time consuming, but also wasteful of money, which is not useful for large-scale production. Therefore, it is necessary to explore a simple, low-cost, safe, and scalable synthesis strategy of TMC-based LIB anode materials.

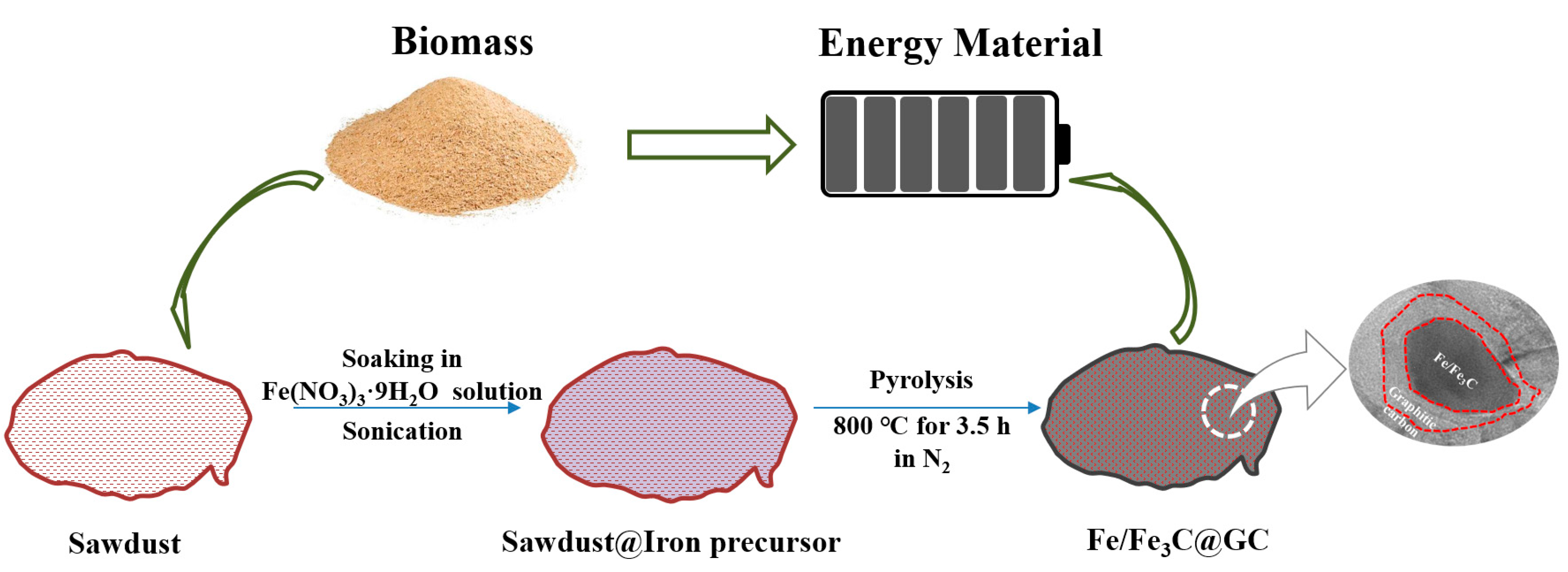

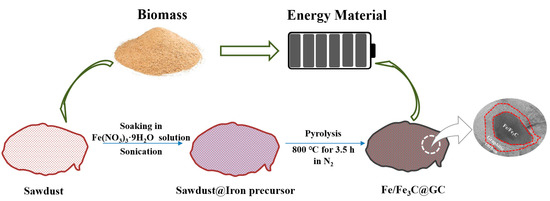

In this study, a simple one-step strategy was designed for the synthesis of a graphitic carbon encapsulated Fe/Fe3C (denoted as Fe/Fe3C@GC) composite by direct heat treatment of a mixture of sawdust and Fe(NO3)3. The detailed synthesis process is shown in Figure 1. Sawdust, a kind of industrial/agricultural waste product, has renewable, abundant, and eco-friendly properties, which can be graphitized with Fe-based nanohybrid catalysts at relatively low temperatures [16]. Fe(NO3)3 as an iron precursor can be in-situ converted into Fe/Fe3C nanoparticles encapsulated in graphitic carbon (GC) [17,18,19]. GC can not only increase the electrical conductivity and diffusion of ions and electrons in the cell, but also buffer volume changes during the charge and discharge processes, resulting in cycle stability. In addition, a porous structure can be formed during the pyrolysis process. This provides more active sites for Li-ions and more contact areas between the Fe/Fe3C nanoparticles and the electrolyte to improve the electrochemical performance of the electrodes. It is worth noting that biomass-derived graphitic carbon shells serve as an effective and scalable way to reduce costs and promote commercial production. Thus, the synthesized Fe/Fe3C@GC composite can not only enhance the electrochemical performance, but also enable low-cost, green, and industrial-grade production of anode materials for future advanced energy storage applications.

Figure 1.

Illustration of the sequential fabrication steps for Fe/Fe3C@GC composite.

2. Materials and Methods

2.1. Materials

Sawdust (JRS Co. Ltd.), iron nitrate nonahydrate (Fe(NO3)3·9H2O, 98%, Sigma-Aldrich), Poly(vinylidene fluoride) (PVdF, Sigma-Aldrich), and N-methyl-2-pyrrolidone (NMP, 99.5%, Samchun Pure Chemical Co., Ltd.) were used as received without further purification.

2.2. Synthesis of Graphitic Carbon Encapsulated Fe/Fe3C (Fe/Fe3C@GC) Composite

A solution of Fe(NO3)3·9H2O was prepared by dissolving 4.0 g of the iron salt in 40 ml of distilled water while stirring at room temperature. To the resulting solution was added 5.0 g of sawdust. The mixture was sonicated for 1 h to obtain a uniform dispersion, and then dried in an oven at 80 °C for 24 h. Finally, the mixture of Fe(NO3)3 and sawdust was carbonized at 800 °C for 3.5 h under a N2 atmosphere in a tubular furnace to obtain the Fe/Fe3C@GC composite material.

2.3. Characterization of Materials

Field emission scanning electron microscopy (FE-SEM, Philips XL30S FEG) and transmission electron microscopy (TEM, TF30ST-300 KV) images were recorded to observe surface and internal morphologies. The crystal structure of the Fe/Fe3C@GC was confirmed by X-ray diffractometer (XRD, D2 Phaser Bruker AXS). Thermogravimetric analysis (TGA, Q50 TA Instruments) was used to analyze the Fe/Fe3C content of the Fe/Fe3C@GC composite at a heating rate of 10 °C min−1 from room temperature to 800 °C in an air atmosphere. Brunner–Emmet–Teller analysis (BET, ASAP 2010) and the Barrett–Joyner–Halenda (BJH) method were used to determine the specific surface area, pore volume, and pore size distribution of the Fe/Fe3C@GC composite.

2.4. Electrochemical Characterization

An anode compartment was prepared with a slurry containing graphite carbon (GC) or Fe/Fe3C@GC composite, Super-P (SP) carbon black, and PVdF binder dissolved in NMP at a weight ratio of 80:10:10. The slurry was then coated onto a copper foil and dried at 60 °C for 24 h. A coated foil was cut into a circular disk with a diameter of 10 mm, for the anode. The total electrode mass was ~2.5 mg cm−2. The stainless steel (SS) Swagelok® cells were assembled in an argon-filled glove box. Celgard® 2400 microporous polypropylene membrane as the separator, 1 M lithium hexafluorophosphate (LiPF6) salt in a mixed solvent of ethylene carbonate and diethylene carbonate (1/1, v/v) as the electrolyte, and lithium foil as the counter electrodes were placed in the cell. The charge and discharge tests of cells were recorded on a WBCS3000 battery cycler (WonA Tech. Co.) at different current densities based on the total mass of the Fe/Fe3C@GC composite of the electrode. Cyclic voltammetry (CV) measurements from 0.01 to 3.0 V were performed at a scan rate of 0.05 mV s−1. To monitor the impedance changes of the cells, electrochemical impedance spectra (EIS) were obtained in the frequency range of 0.1 Hz to 2 MHz with an amplitude of 5 mV on an impedance analyzer (ZIVE SP2, WonA Tech. Co., Ltd).

3. Results and Discussion

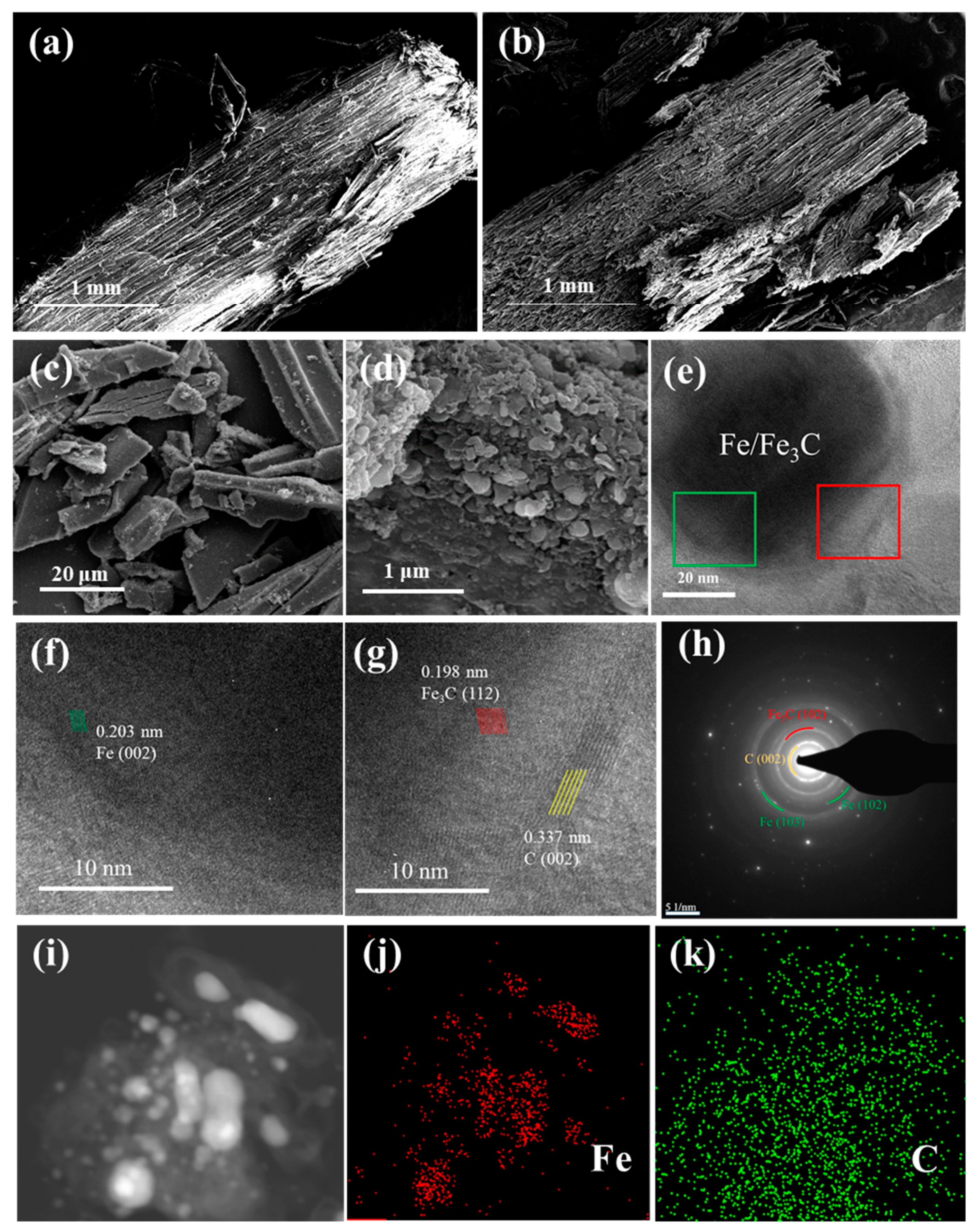

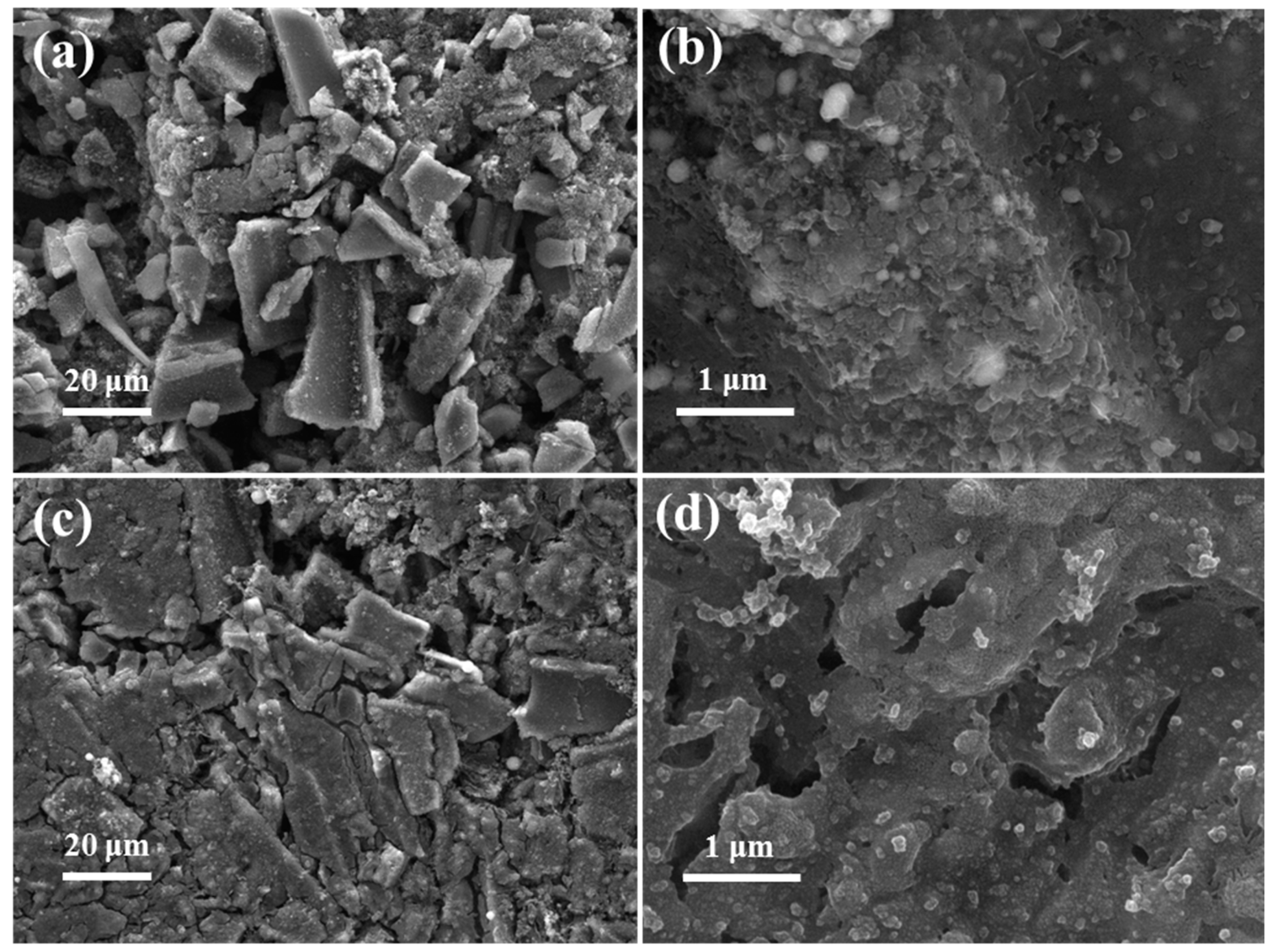

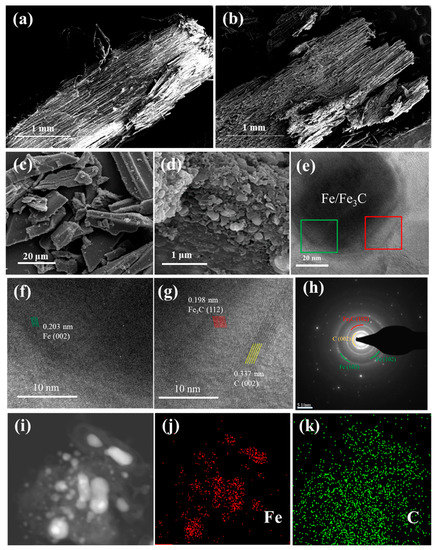

The surface morphologies of the raw sawdust, the sawdust@Fe(NO3)3, and the Fe/Fe3C@GC composites were recorded by FE-SEM as shown in Figure 2a–d. Raw sawdust looks like an agglomerated fiber bundle as shown in Figure 2a. No significant difference is observed in the shape of the sawdust@Fe(NO3)3 composite (Figure 2b), indicating that Fe(NO3)3 was absorbed into the sawdust. After pyrolysis, the Fe/Fe3C@GC composite presents as tile-like pieces (Figure 2c) and agglomerates with particles between 100 and 500 nm in size (Figure 2d). The internal structure of the Fe/Fe3C@GC composite is detailed in the TEM image in Figure 2e. Fe/Fe3C (dark contrast region) as the core of composite nanoparticles is surrounded by a graphitic carbon (GC) shell (bright contrast region). The enlarged images of the selected green (Figure 2f) and red (Figure 2g) regions in Figure 2e display different lattice spacing. Accordingly, the (002) plane of Fe (Figure 2f), the (112) plane of Fe3C and the (002) plane of graphitic carbon (Figure 2g) were detected, in agreement with the XRD pattern (Figure 3a). In the subsequent selected area electron diffraction (SAED) pattern of the Fe/Fe3C@GC composite material, diffraction rings that correspond to the (102) and (103) planes of Fe, the (103) plane of Fe3C, and the (002) plane of graphitic carbon can also be observed (Figure 2h). They are also in accordance with the XRD pattern. The elemental mappings of the composite measured with the energy dispersive X-ray spectroscopy (EDS) are shown in Figure 2i–k. The Fe signals overlap the highlight points of the TEM image of the Fe/Fe3C@GC composite, and it confirms that Fe/Fe3C nanoparticles are properly confined within the graphitic carbon.

Figure 2.

FE-SEM images of (a) raw sawdust, (b) the mixture of sawdust@Fe(NO3)3, (c–d) Fe/Fe3C@GC composite, (e–g) TEM image of Fe/Fe3C@GC composite, (h) selected area electron diffraction (SAED) pattern of Fe/Fe3C@GC composite, and (i–k) EDS mapping of Fe/Fe3C@GC composite.

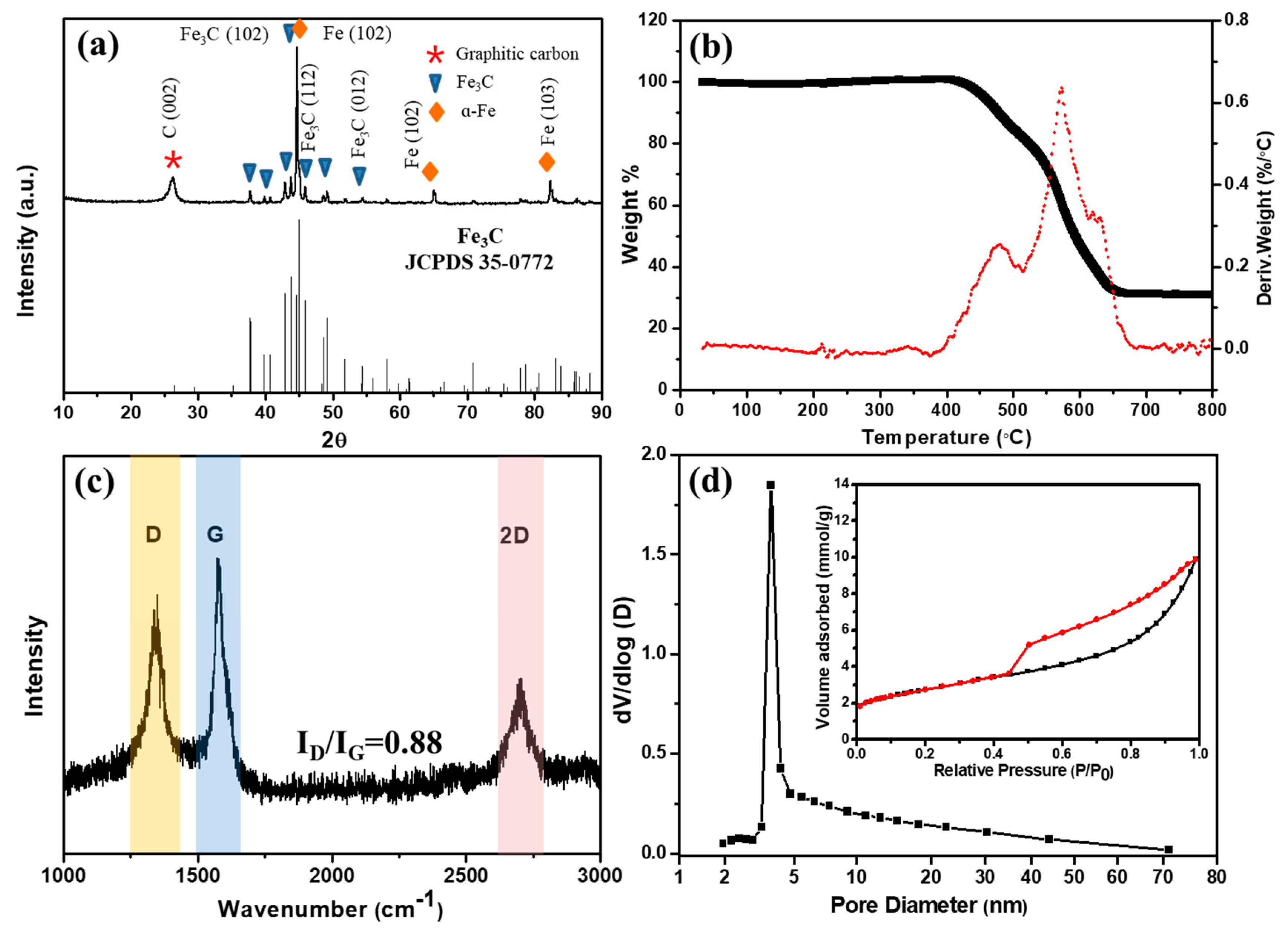

Figure 3.

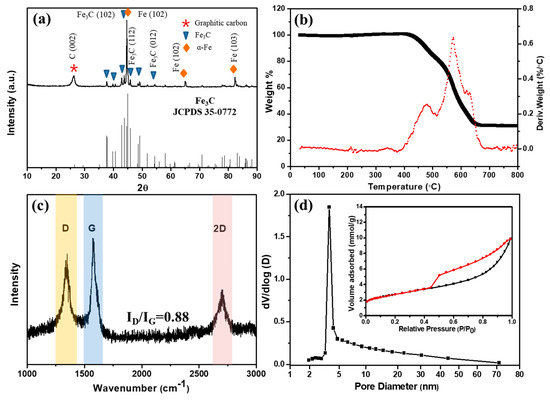

(a) XRD patterns, (b) TGA plot, (c) Raman spectroscopy, and (d) nitrogen adsorption–desorption isotherms and pore size distribution of the Fe/Fe3C@GC composite.

The phase of the Fe/Fe3C@GC composite was identified by X-ray diffraction, as shown in Figure 3a. The main diffraction peaks are consistent with Fe3C (JCPDS No. 35-0772) and Fe (JCPDS No. 65-5099), indicating the coexistence of Fe3C and Fe in the final product. The Fe nanoparticles incorporated in the composite can enhance the electronic conductance of the entire nanocomposite. The small sharp peak at 26.3° originates from the (002) plane of graphitic carbon. Thermogravimetric analysis (TGA) of the composite was also performed out in air from room temperature to 800 °C (Figure 3b). The significant mass loss was observed in the temperature range of 400–650 °C, which was related to the oxidation of Fe/Fe3C and carbon. Above 650 °C, the weight of the Fe/Fe3C@GC composite remained constant at 32 wt. % of the weight before heat treatment. Based on the mass loss in the TGA result and the preserved mass of the iron component, the Fe/Fe3C content in the composite can be estimated to be 23.2 ± 0.8 wt. % [15,20].

The typical Raman curve of the Fe/Fe3C@GC composite is shown in Figure 3c. Three distinct peaks are located at 1347, 1575, and 2699 cm−1, corresponding to D, G, and 2D bands, respectively. The D band is derived from structural defects or a lattice distortion in carbon atoms, and the G band originates from in-plane stretching vibration of sp2 hybrid carbon atoms [21,22]. The ratio of integrated intensity D to G band (ID/IG) is used to evaluate the degree of graphitization of carbon-based materials. The Fe/Fe3C@GC composite synthesized in this study shows a high degree of graphitization (ID/IG = 0.88), suggesting high electrical conductivity and rapid charge transfer in the anode. The 2D peak can also identify the presence of a multilayer graphitic structure in the sample. The porous microstructure of the Fe/Fe3C@GC composite was characterized by the N2 sorption isothermal curve and the pore size distribution plot in Figure 3d. The Fe/Fe3C@GC composite represents a typical type IV isotherm and type H3 hysteresis loop, indicating the presence of a plate-like mesoporous structure in the composite [23]. The specific surface area, pore volume, and average pore size are found to be 216 m2 g−1, 0.35 cm3 g−1, and 5.6 nm, respectively.

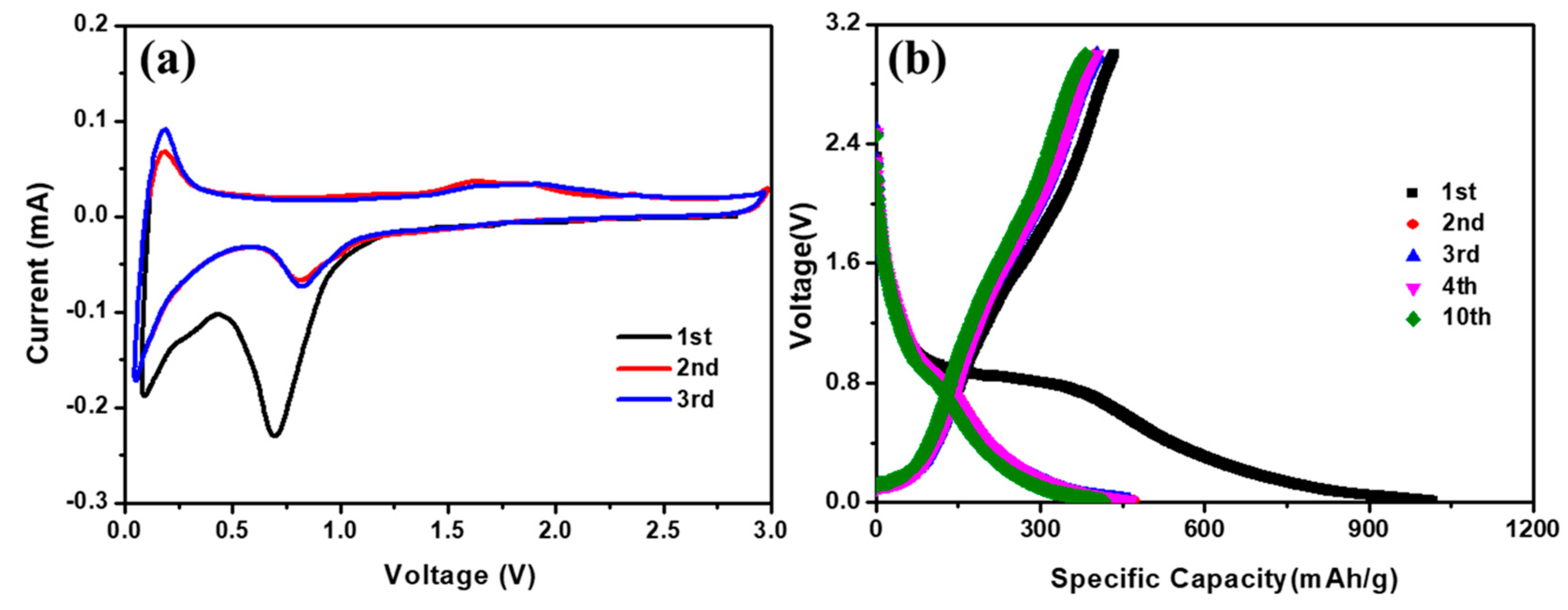

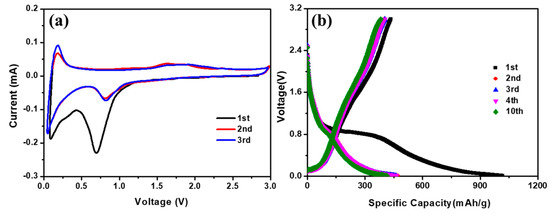

Figure 4a shows the CV curves of the cell using an Fe/Fe3C@GC composite as an anode. There is a clear difference between the first and subsequent CV curves. The initial curve has a strong peak at 0.7 V, which is not the reduction peak of Fe3+. Instead, the peak is assigned to the formation of a solid electrolyte interface (SEI) film [11]. The cathodic peak below 0.2 V and the anodic peak at 0.18 V represent the typical lithiation and delithiation processes for carbon materials. According to the previous report [14,20], the transformation from Fe to Fe3+ results in the peak around 1.8 V. Hence, during the charging process, the anodic peak located at 1.78 V represents the Li extraction from an SEI film [12,23] and a transformation from Fe to Fe3+. In the next two cycles, the cathodic peak at 0.7 V shifts positively to 0.82 V, which derives from the polarization associated with charge–discharge cycling [12,23,24]. From the second curve, the reduction and oxidation peaks were closely overlapped: this behavior indicates good reversibility and cycling stability of the Fe/Fe3C@GC cell for LIBs. The investigation of atomic bonding status and contents ratio with X-ray photoelectron spectroscopy to elucidate the interaction of Fe and Fe3C with lithium can be further considered [21].

Figure 4.

(a) Cyclic voltammetry (CV) profiles with the voltage window of 0.01–3.0 V and the scanning rate of 0.05 mV s−1, and (b) charge–discharge profiles of the Fe/Fe3C@GC cell at 45 mA g−1.

Figure 4b shows the charge–discharge curves of the Fe/Fe3C@GC composite at a current density of 45 mA g−1. In the first cycle, the discharge capacity reaches 1017 mAh g−1, but the charge capacity is 435 mAh g−1 with about 43% of the initial Coulombic efficiency. The high irreversibility of the initial cycle is frequently observed in previous studies. It is reported that this phenomenon can be caused by various reasons such as the formation of the SEI film, nature of the crystal structure, particle size, operating voltage, and the solvent reduction [11,14,25,26,27,28,29]. The plateau (0.6–0.8 V) in the first discharge curve was shifted to a higher position (0.7–0.9 V) in the subsequent discharge curves, which is in accordance with cyclic voltammogram. In subsequent cycles, the charge and discharge curves represent good consistency in capacity, indicating stable and reversible internal electrochemical reactions.

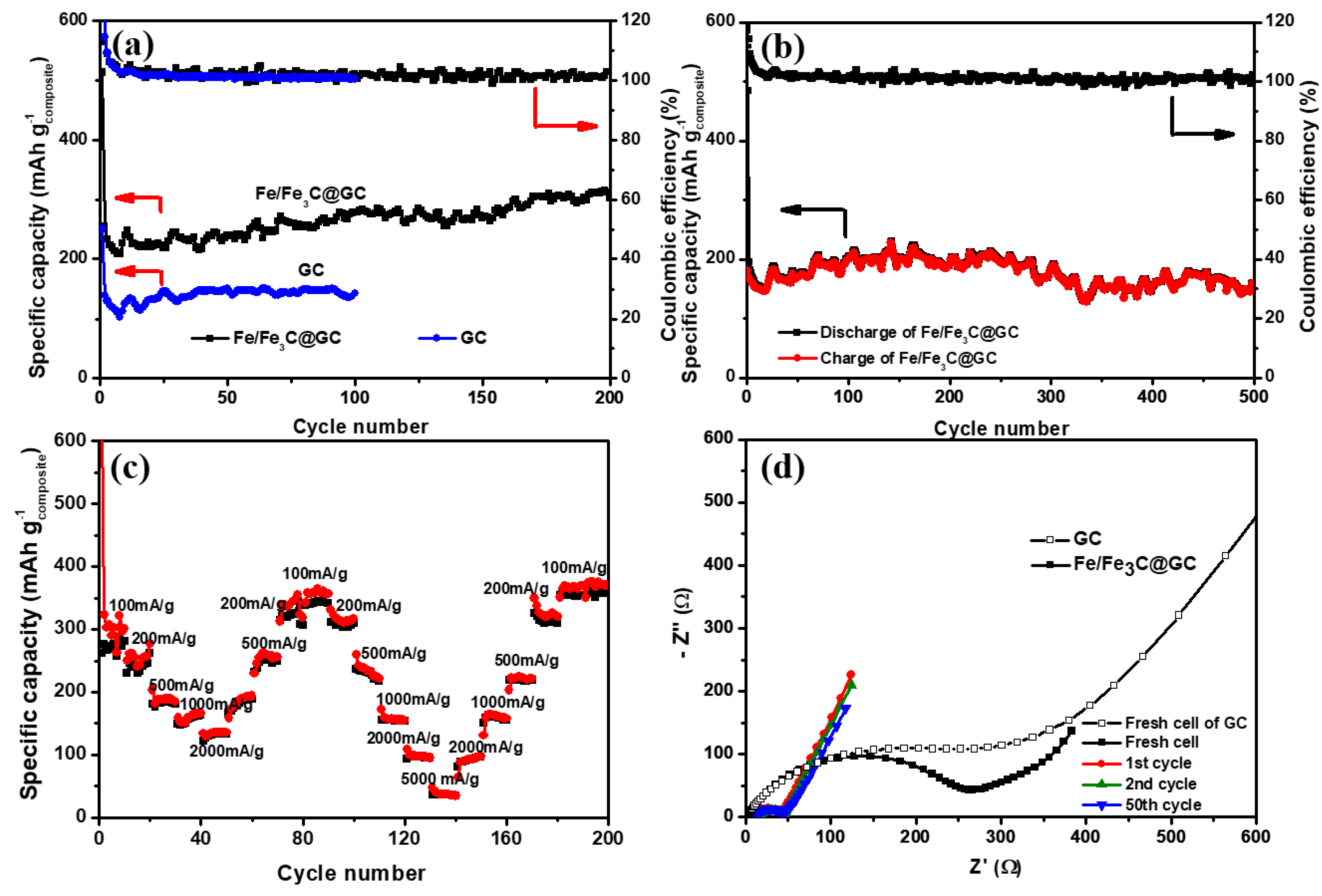

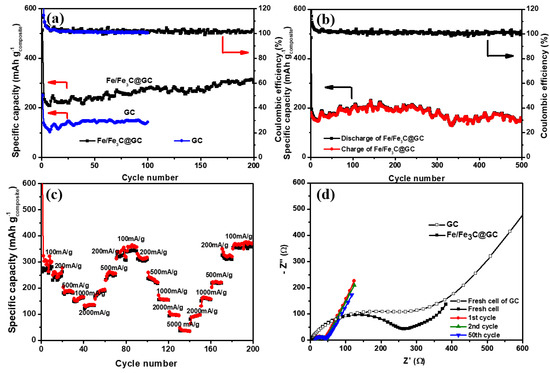

As shown in Figure 5a, the cycling performances of the Fe/Fe3C@GC and GC cells exhibit high Coulombic efficiency and excellent cycling stability at 200 mA g−1. Apparently, the discharge capacity of the Fe/Fe3C@GC cell was higher than that of the GC cell, which may be attributed to the pseudocapacitive behavior between the Fe/Fe3C nanoparticles and an electrolyte [11,26,28]. Interestingly, the discharge capacity gradually increased during the charging and discharging processes of the Fe/Fe3C@GC cell at 200 and 500 mA g−1 as shown in Figure 5a,b. The capacity increase can be brought about by two aspects: (a) the “pseudocapacity-type” phenomenon between an electrolyte and nanocomposites [11,26,28], and (b) the increased active sites for the ionic transport and storage which belong to the porous structure [14]. Figure 5b shows the long cycling stability of the Fe/Fe3C@GC cell with a capacity of 154 mAh g−1 and Coulombic efficiency of 100% even after 500 cycles at 500 mA g−1. The capacity fluctuation during charge–discharge cycling shown in Figure 5a,b may be attributed to the wettability between electrolyte and electrode, the stepwise evolution of pores in the active material, and the formation of a self-optimized stable SEI film [11,30,31].

Figure 5.

(a) Cycling performances and Coulombic efficiency of the Fe/Fe3C@GC and graphitic carbon (GC) cells at 200 mA g−1, (b) long cycling performance and Coulombic efficiency of the Fe/Fe3C@GC cell at 500 mA g−1, (c) rate performance of the Fe/Fe3C@GC cell at different current densities, and (d) electrochemical impedance spectra (EIS) spectra of the Fe/Fe3C@GC cell and the GC cell.

To further characterize the electrochemical performance, a rate performance of the Fe/Fe3C@GC cell was evaluated as shown in Figure 5c. Starting with a current density of 100 mA g−1 for 10 cycles, it was gradually increased to 2000 mA g−1 then decreased to 100 mA g−1, and then gradually increased to 5000 mA g−1 before finally being returned to 100 mA g−1. The cell maintained stable cycling performance and good Coulombic efficiency, indicating that the Fe/Fe3C@GC cell has excellent recovery and rate capability. For comparison, the electrochemical performances of LIBs using the Fe3C/C composite as an anode are summarized in Table S1. The Fe/Fe3C@GC composite in this study has advantages of cost-effective production, a simple co-pyrolysis with biomass and iron precursor, and competitive cell performances, i.e., high capacity retention with respect to cycle number. Therefore, the Fe/Fe3C@GC composite in this study has potential as an economical anode material for high-performance LIBs.

The electrochemical impedance spectra of the Fe/Fe3C@GC cell and the GC cell were measured after various cycles as shown in Figure 5d. The Nyquist plot consists of the ohmic bulk resistance, charge transfer resistances, and Warburg impedance [32,33]. The ohmic resistance at high frequency includes the electrolyte, separator, and electrical contacts. The semicircles in the middle frequency range depend on the charge transfer process. At the fresh state, the semicircle of the Fe/Fe3C@GC cell is obviously smaller than the GC cell due to the reduced charge transfer resistance and improved electrical conductivity. For the Fe/Fe3C@GC cell, the charge transfer resistances after cycling are much lower than in the initial state, clearly showing that the porous structure can provide more active sites, which can enhance electrolyte wettability and promote charge transfer. Furthermore, there is no significant difference in the semicircles after cycling, which means that the lithiation–delithiation reactions are stabilized. The sloping straight line represents the Warburg diffusion impedance at lower frequencies.

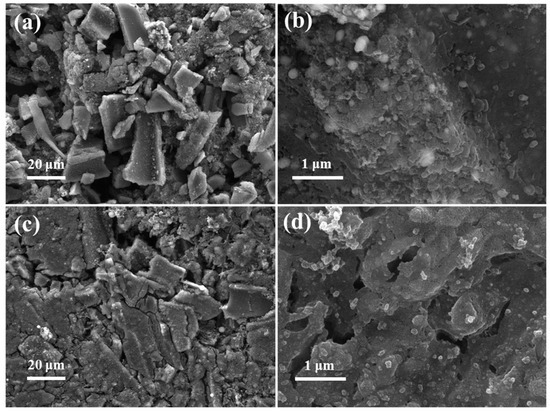

As shown in Figure 6, the surface morphologies of the Fe/Fe3C@GC electrode at the fresh state and fully-charged state after 500 cycles at 500 mA g−1 were observed with FE-SEM. Even after long cycles, the structural integrity of the Fe/Fe3C@GC electrode can be maintained as shown in Figure 6a and c. In the enlarged image (Figure 6d), the surface morphology of the Fe/Fe3C@GC electrode after long cycles showed an ambiguous surface due to the continuous charge–discharge processes, but the active substance particles are similar to the initial state (Figure 6b), indicating the structural stability of the Fe/Fe3C@GC composite.

Figure 6.

FE-SEM morphologies of (a,b) the fresh Fe/Fe3C@GC electrode and (c,d) the Fe/Fe3C@GC after 500 cycles at 500 mA g−1.

4. Conclusions

Graphitic carbon encapsulated Fe/Fe3C composite was developed as anode material for lithium-ion batteries in a simple and cost-effective way through co-pyrolysis of biomass and iron precursor under nitrogen atmosphere. The cell employing the novel composite exhibited a high initial discharge capacity of 1027 mAh g−1 at 45 mA g−1 and maintained a reversible capacity of 302 mA g−1 at 200 mA g−1 after 200 cycles. This noteworthy performance may be attributed to its unique microstructure. The graphitic carbon shell can not only increase the electrical conductivity but also mitigate volume change of the Fe/Fe3C nanoparticles during discharging. The porous microstructure formed by carbonization of sawdust can provide more active sites for lithium ion transport and storage and can improve the contact between Fe/Fe3C nanoparticles and an electrolyte, resulting in high capacity retention and stable cycling performance. The effect of pyrolysis temperature and dosage of the iron precursor will be further studied to improve cell performance. The synthetic strategy and the structure of Fe/Fe3C@GC anode material may open a new avenue for the development of anode material in Li-ion batteries.

Supplementary Materials

The following are available online at https://www.mdpi.com/1996-1073/13/4/827/s1: Table S1: Electrochemical performances of lithium-ion batteries with Fe3C/C composite as an anode active material.

Author Contributions

Composite synthesis, testing, data analysis and manuscript drafting were done by Y.L., while additional experiment and data analysis were done by X.L., A.K.H., Y.S., J.H., J.-H.A. and Y.L. supervised the entire work and checked the grammatical sentences of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the 2019 Gyeongsang National University Global Research Network Fund.

Acknowledgments

This work was supported by the 2019 Gyeongsang National University Global Research Network Fund.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tarascon, J.M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Armand, M.; Tarascon, J.M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef] [PubMed]

- Nithyadharseni, P.; Reddy, M.V.; Nalini, B.; Kalpana, M.; Chowdari, B.V.R. Sn-based intermetallic alloy anode materials for the application of lithium ion batteries. Electrochim. Acta 2015, 161, 261–268. [Google Scholar] [CrossRef]

- Nithyadharseni, P.; Reddy, M.V.; Nalini, B.; Ravindran, T.R.; Pillai, B.C.; Kalpana, M.; Chowdari, B.V.R. Electrochemical studies of CNT/Si-SnSb nanoparticles for lithium ion batteries. Mater. Res. Bull. 2015, 70, 478–485. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Zheleznov, V.V.; Opra, D.P.; Voit, E.I.; Modin, E.B.; Sokolov, A.A.; Ustinov, A.Y.; Sergienko, V.I. Effect of Hf-doping on electrochemical performance of anatase TiO2 as an anode material for lithium storage. Roy. Soc. Open Sci. 2018, 5, 171811. [Google Scholar] [CrossRef] [PubMed]

- Kuryavyi, V.G.; Ustinov, A.Y.; Opra, D.P.; Zverev, G.A.; Kaidalova, T.A. Composite containing nanosized titanium oxide and oxyfluoride and carbon synthesized in plasma of pulse high-voltage discharge. Mater. Lett. 2014, 137, 398–400. [Google Scholar] [CrossRef]

- Cho, S.; Jang, H.Y.; Jung, I.; Liu, L.; Park, S. Synthesis of embossing Si nanomesh and its application as anode for lithium ion batteries. J. Power Sources 2017, 362, 270–277. [Google Scholar] [CrossRef]

- Opra, D.P.; Gnedenkov, S.V.; Sinebryukhov, S.L.; Voit, E.I.; Sokolov, A.A.; Ustinov, A.Y.; Zheleznov, V.V. Zr4+/F- co-doped TiO2 (anatase) as high performance anode material for lithium-ion battery. Prog. Nat. Sci. 2018, 28, 542–547. [Google Scholar] [CrossRef]

- Opra, D.P.; Gnedenkov, S.V.; Sinebryukhov, S.L. Recent efforts in design of TiO2(B) anodes for high-rate lithium-ion batteries: A review. J. Power Sources 2019, 442, 227225. [Google Scholar] [CrossRef]

- Liu, X.; Li, Z.; Zhang, S.; Long, H.; Wei, H.; Zhang, H.; Li, H.; Zhao, C. Mo2C@onion-like carbon/amorphous carbon nanocomposites as outstanding anode materials for ideal lithium-ion batteries. Ceram. Int. 2017, 43, 14446–14452. [Google Scholar] [CrossRef]

- Chen, S.; Wu, J.; Zhou, R.; Zuo, L.; Li, P.; Song, Y.; Wang, L. Porous carbon spheres doped with Fe3C as an anode for high-rate lithium-ion batteries. Electrochim. Acta 2015, 180, 78–85. [Google Scholar] [CrossRef]

- Che, H.; He, Y.S.; Liao, X.Z.; Zhang, H.J.; Zhang, W.; Ma, Z.F. An active amorphous carbon material with Fe2C nanocrystals encapsulated as a high performance electrode for lithium-ion batteries. Chem. Sel. 2017, 2, 1854–1859. [Google Scholar] [CrossRef]

- Yang, L.; Li, X.; He, S.; Du, G.; Yu, X.; Liu, J.; Gao, Q.; Hu, R.; Zhu, M. Mesoporous Mo2C/N-doped carbon heteronanowires as high-rate and long-life anode materials for Li-ion batteries. J. Mater. Chem. A 2016, 4, 10842–10849. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.; Sun, Y.; Zhang, S.; Wu, Y. Onion-like carbon coated Fe3C nanocapsules embedded in porous carbon for the stable lithium-ion battery anode. Appl. Surf. Sci. 2019, 479, 318–325. [Google Scholar] [CrossRef]

- Su, L.; Zhou, Z.; Shen, P. Core-shell Fe@Fe3C/C nanocomposites as anode materials for Li ion batteries. Electrochim. Acta 2013, 87, 180–185. [Google Scholar] [CrossRef]

- Li, M.; Xiong, Y.; Liu, X.; Han, C.; Zhang, Y.; Bo, X.; Guo, L. Iron and nitrogen co-doped carbon nanotube@hollow carbon fibers derived from plant biomass as efficient catalysts for the oxygen reduction reaction. J. Mater. Chem. A 2015, 3, 9658–9667. [Google Scholar] [CrossRef]

- Xiao, M.; Zhu, J.; Feng, L.; Liu, C.; Xing, W. Meso/macroporous nitrogen-doped carbon architectures with iron carbide encapsulated in graphitic layers as an efficient and robust catalyst for the oxygen reduction reaction in both acidic and alkaline solutions. Adv. Mater. 2015, 27, 2521–2527. [Google Scholar] [CrossRef]

- Li, Q.; Xu, P.; Gao, W.; Ma, S.; Zhang, G.; Cao, R.; Cho, J.; Wang, H.L.; Wu, G. Graphene/graphene-tube nanocomposites templated from cage-containing metal-organic frameworks for oxygen reduction in Li-O2 batteries. Adv. Mater. 2014, 26, 1378–1386. [Google Scholar] [CrossRef]

- Li, J.S.; Li, S.L.; Tang, Y.J.; Han, M.; Dai, Z.H.; Bao, J.C.; Lan, Y.Q. Nitrogen-doped Fe/Fe3C@graphitic layer/carbon nanotube hybrids derived from MOFs: Efficient bifunctional electrocatalysts for ORR and OER. Chem. Commun. 2015, 51, 2710–2713. [Google Scholar] [CrossRef]

- Li, J.; Wen, W.; Xu, G.; Zou, M.; Huang, Z.; Guan, L. Fe-added Fe3C carbon nanofibers as anode for Li ion batteries with excellent low-temperature performance. Electrochim. Acta 2015, 153, 300–305. [Google Scholar] [CrossRef]

- Hou, Y.; Li, J.; Wen, Z.; Cui, S.; Yuan, C.; Chen, J. N-doped graphene/porous g-C3N4 nanosheets supported layered-MoS2 hybrid as robust anode materials for lithium-ion batteries. Nano Energy 2014, 8, 157–164. [Google Scholar] [CrossRef]

- Qin, J.; He, C.; Zhao, N.; Wang, Z.; Shi, C.; Liu, E.Z.; Li, J. Graphene networks anchored with Sn@graphene as lithium ion battery Anode. ACS Nano 2014, 8, 1728–1738. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.G.; Lin, X.L.; Zhang, X.H.; Pan, Q.C.; Yan, Z.X.; Wang, H.Q.; Chen, J.J.; Li, Q.Y. Fe3C@carbon nanocapsules/expanded graphite as anode materials for lithium ion batteries. Electrochim. Acta 2015, 178, 468–475. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, T.; Yang, T.; Wang, M.; Guo, J.; Yan, C. Nanomeshes of highly crystalline nitrogen-doped carbon encapsulated Fe/Fe3C electrodes as ultrafast and stable anodes for Li-ion batteries. J. Mater. Chem. A 2015, 3, 15008–15014. [Google Scholar] [CrossRef]

- Cresce, A.V.; Russell, S.M.; Baker, D.R.; Gaskell, K.J.; Xu, K. In situ and quantitative characterization of solid electrolyte interphases. Nano Lett. 2014, 14, 1405–1412. [Google Scholar] [CrossRef]

- Reddy, M.V.; Cai, Y.; Fan, J.H.; Kian, P.L.; Chowdari, B.V.R. Li-cycling properties of molten salt method prepared nano/submicrometer and micrometer-sized CuO for lithium batteries. ACS Appl. Mater. Interfaces 2013, 5, 4361–4366. [Google Scholar] [CrossRef]

- Reddy, M.V.; Wen, B.L.W.; Loh, K.P.; Chowdari, B.V.R. Energy storage studies on InVO4 as high performance anode material for Li-ion batteries. ACS Appl. Mater. Interfaces 2013, 5, 7777–7785. [Google Scholar] [CrossRef]

- Reddy, M.V.; Andreea, L.Y.T.; Ling, A.Y.; Hwee, J.N.C.; Lin, C.A.; Admas, S.; Loh, K.P.; Mathe, M.K.; Ozoemena, K.I.; Chowdari, B.V.R. Effect of preparation temperature and cycling voltage range on molten salt method prepared SnO2. Electrochim. Acta 2013, 106, 143–148. [Google Scholar] [CrossRef]

- Das, B.; Reddy, M.V.; Subba Rao, G.V.; Chowdari, B.V.R. Nano-phase tin hollandites, K2(M2Sn6)O16 (M=Co, In) as anodes for Li-ion batteries. J. Mater. Chem. 2011, 21, 1171–1180. [Google Scholar] [CrossRef]

- Wu, H.; Chan, G.; Choi, J.W.; Ryu, I.; Yao, Y.; McDowell, M.T.; Lee, S.W.; Jackson, A.; Yang, Y.; Hu, L.; et al. Stable cycling of double-walled silicon nanotube battery anodes through solid-electrolyte interphase control. Nat. Nanotechnol. 2012, 7, 310–315. [Google Scholar] [CrossRef]

- Sun, H.; Xin, G.; Hu, T.; Yu, M.; Shao, D.; Sun, X.; Lian, J. High-rate lithiation-induced reactivation of mesoporous hollow spheres for long-lived lithium-ion batteries. Nat. Commun. 2014, 5, 4526. [Google Scholar]

- Cherian, C.T.; Zheng, M.; Reddy, M.V.; Chowdari, B.V.R.; Sow, C.H. Zn2SnO4 nanowires versus nanoplates: Electrochemical performance and morphological evolution during Li-cycling. ACS Appl. Mater. Interfaces 2013, 5, 6054–6060. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Yu, J.; Cui, C.; Sun, Y.; Li, X.; Li, Z. Flower-like BiOI microspheres/Ni@C nanocapsule hybrid composites and their efficient microwave absorbing activity. J. Phys. D Appl. Phys. 2018, 51, 265002. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).