Design and Implementation of a Control Method for GaN-Based Totem-Pole Boost-Type PFC Rectifier in Energy Storage Systems

Abstract

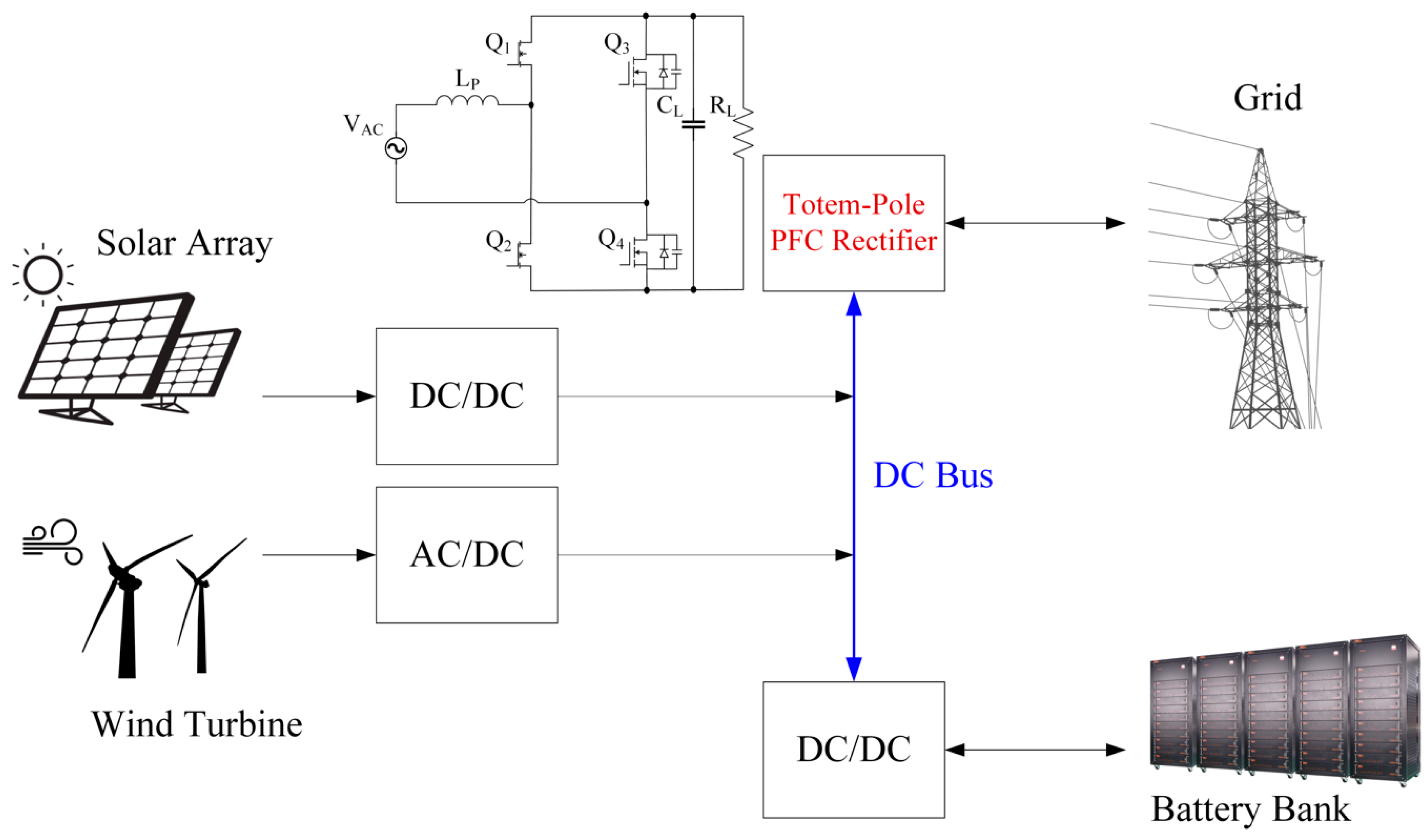

1. Introduction

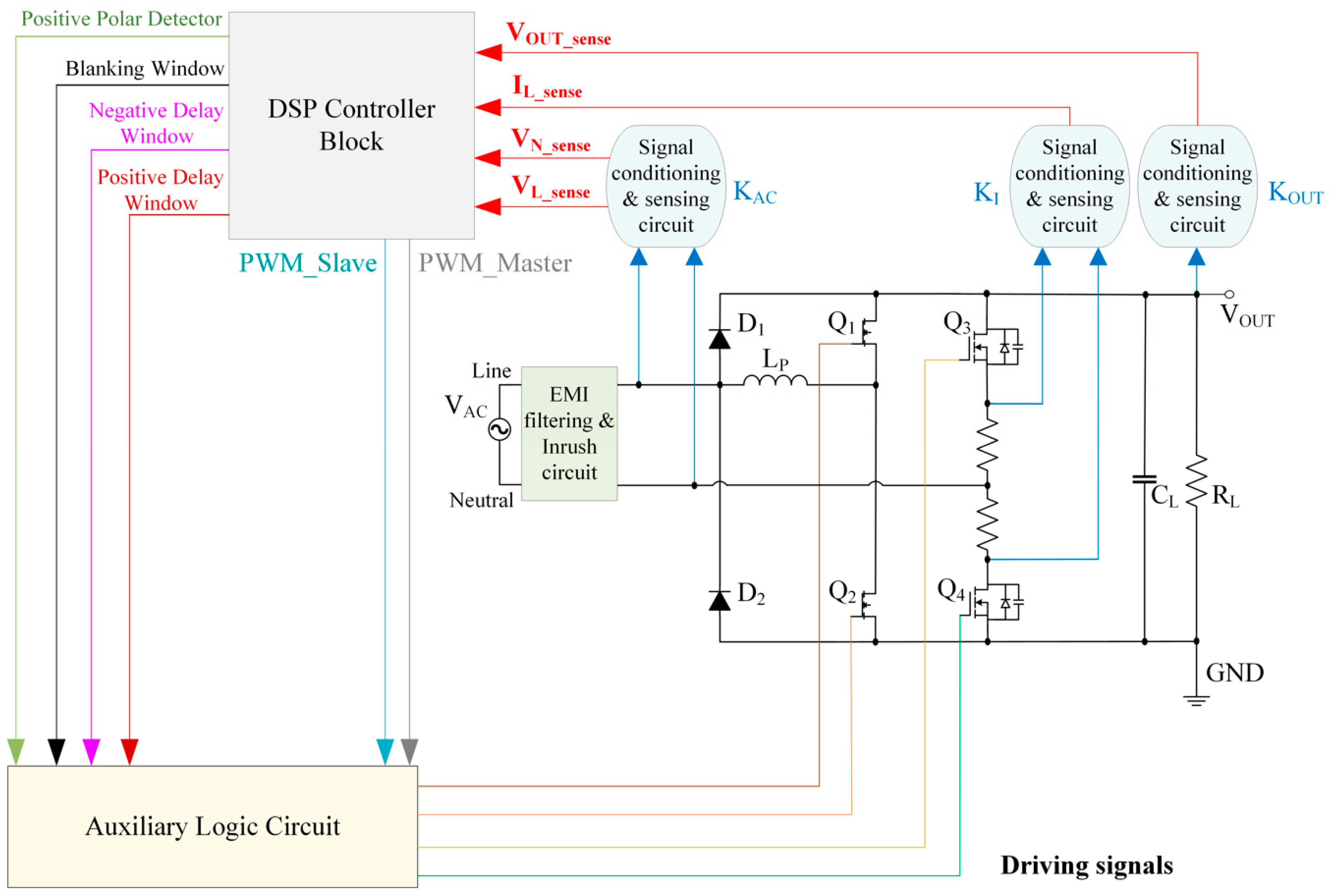

2. Proposed Control Structure

2.1. Block Diagram

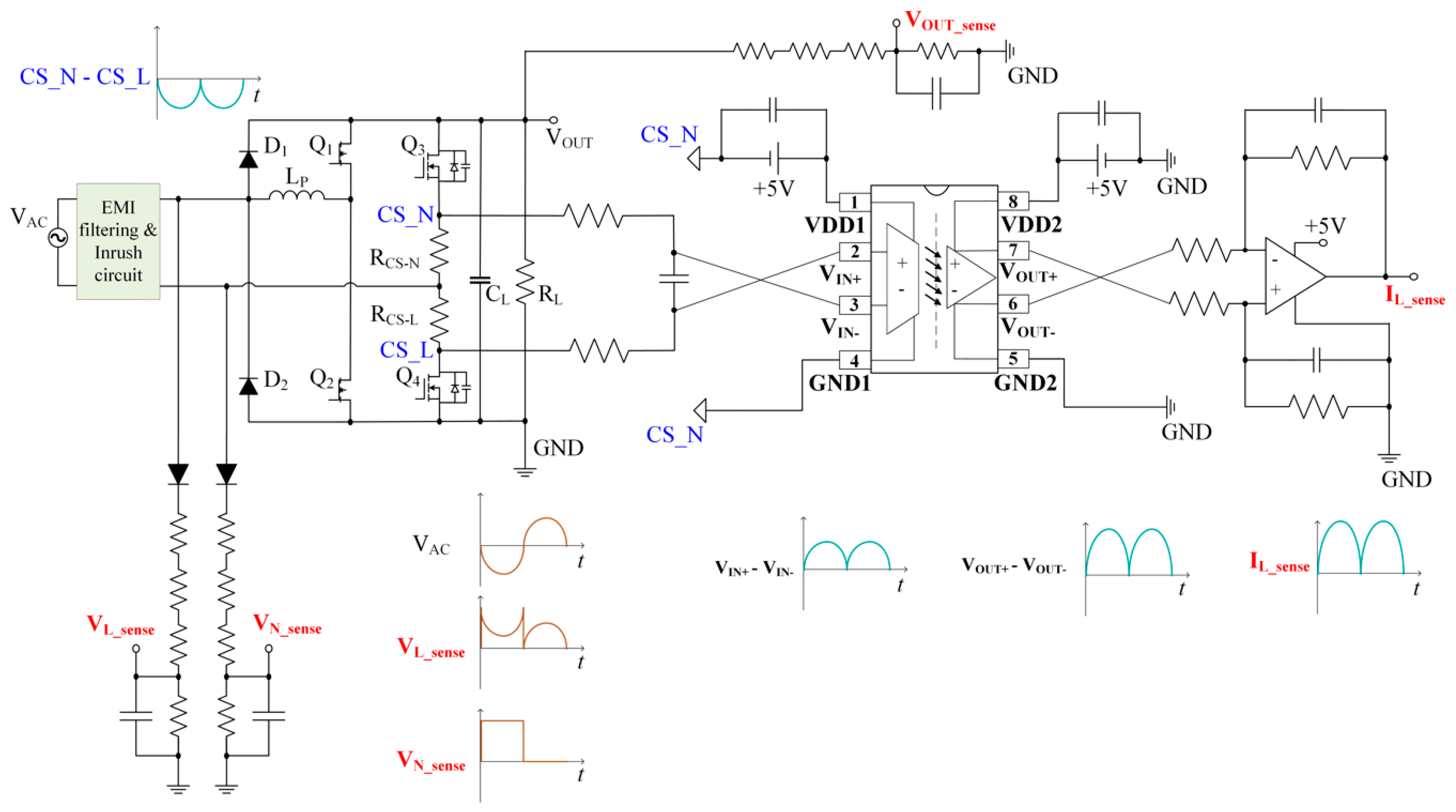

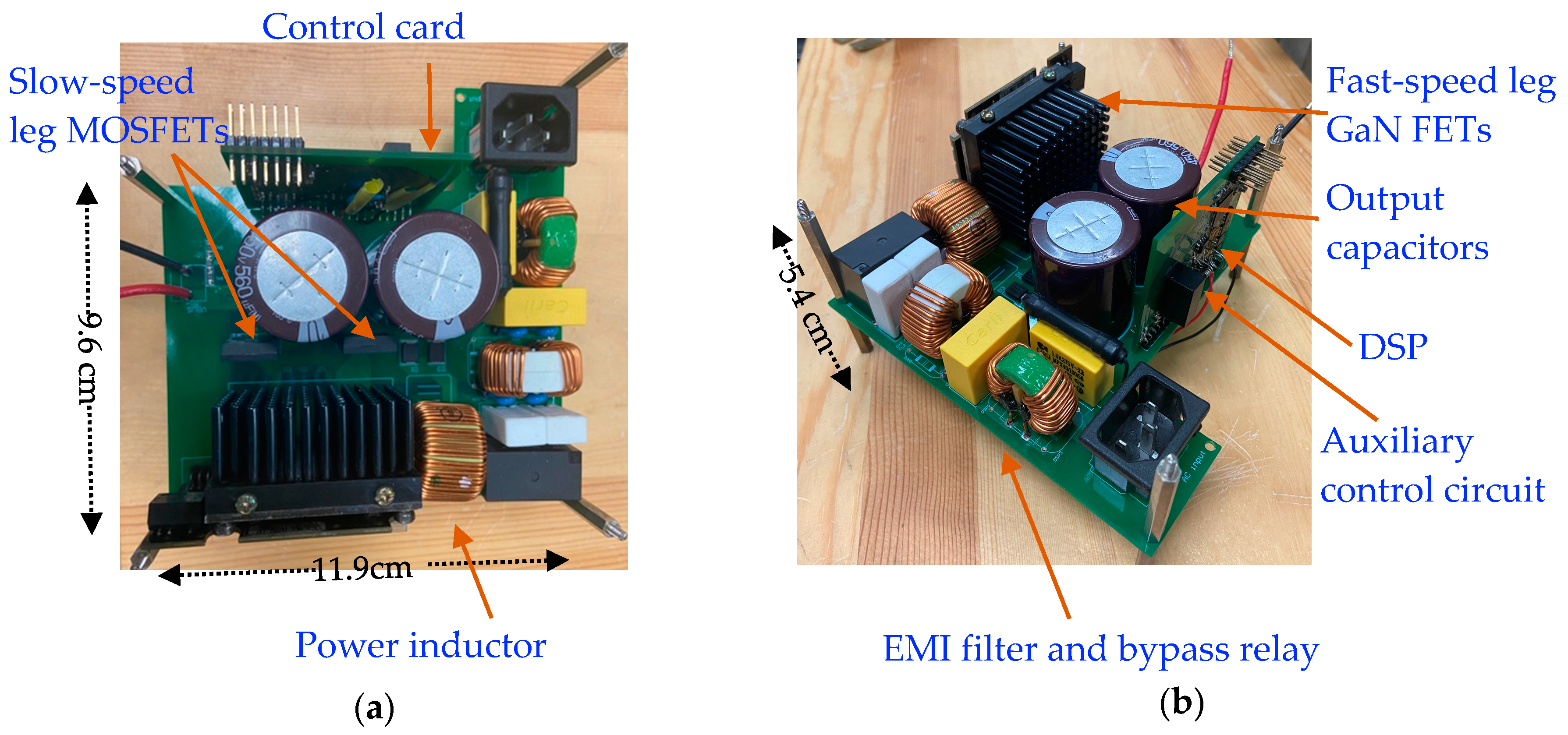

2.2. Power Stage and Sensing Circuit

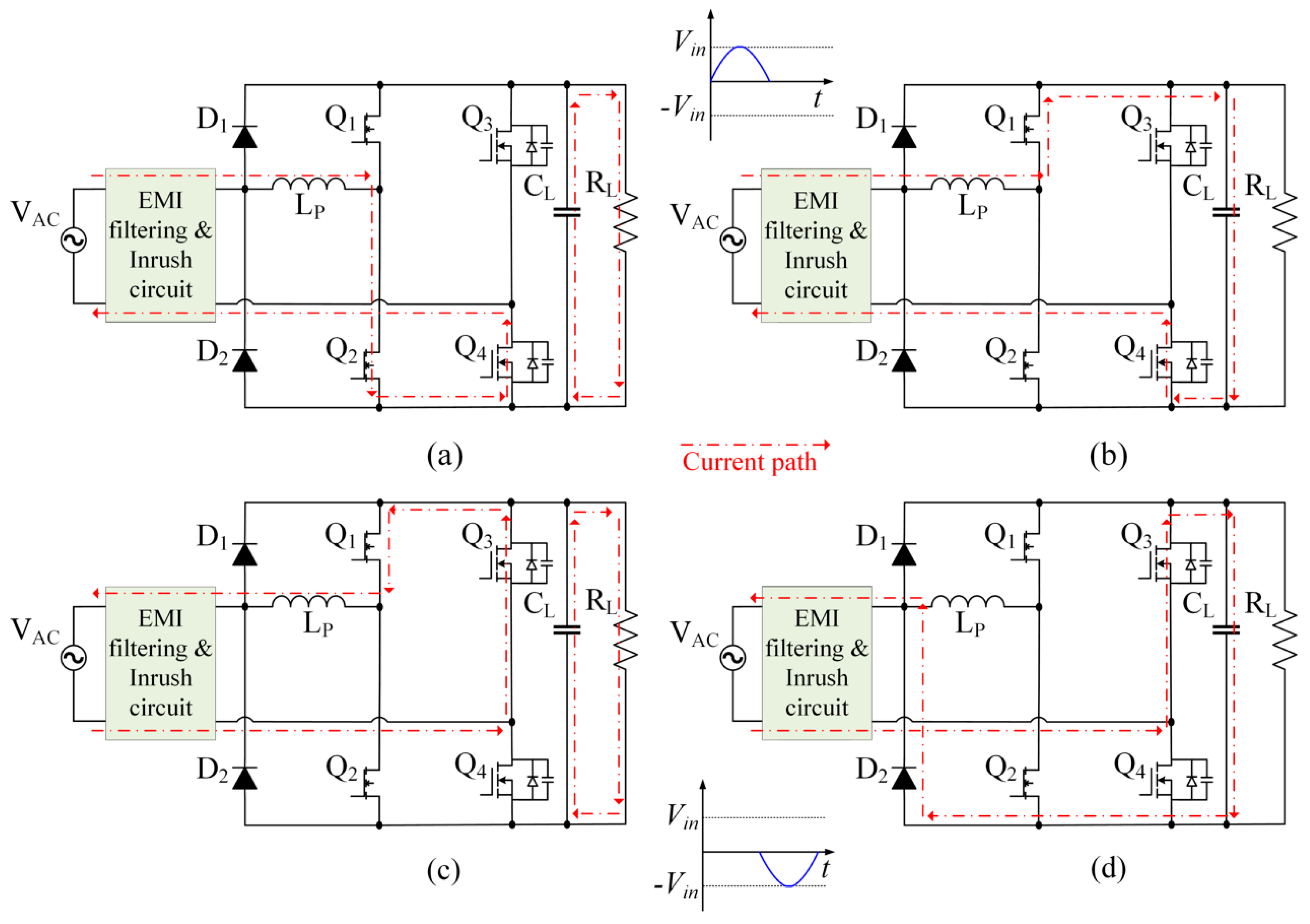

2.2.1. Power Stage

2.2.2. Signal Conditioning and Sensing Circuit

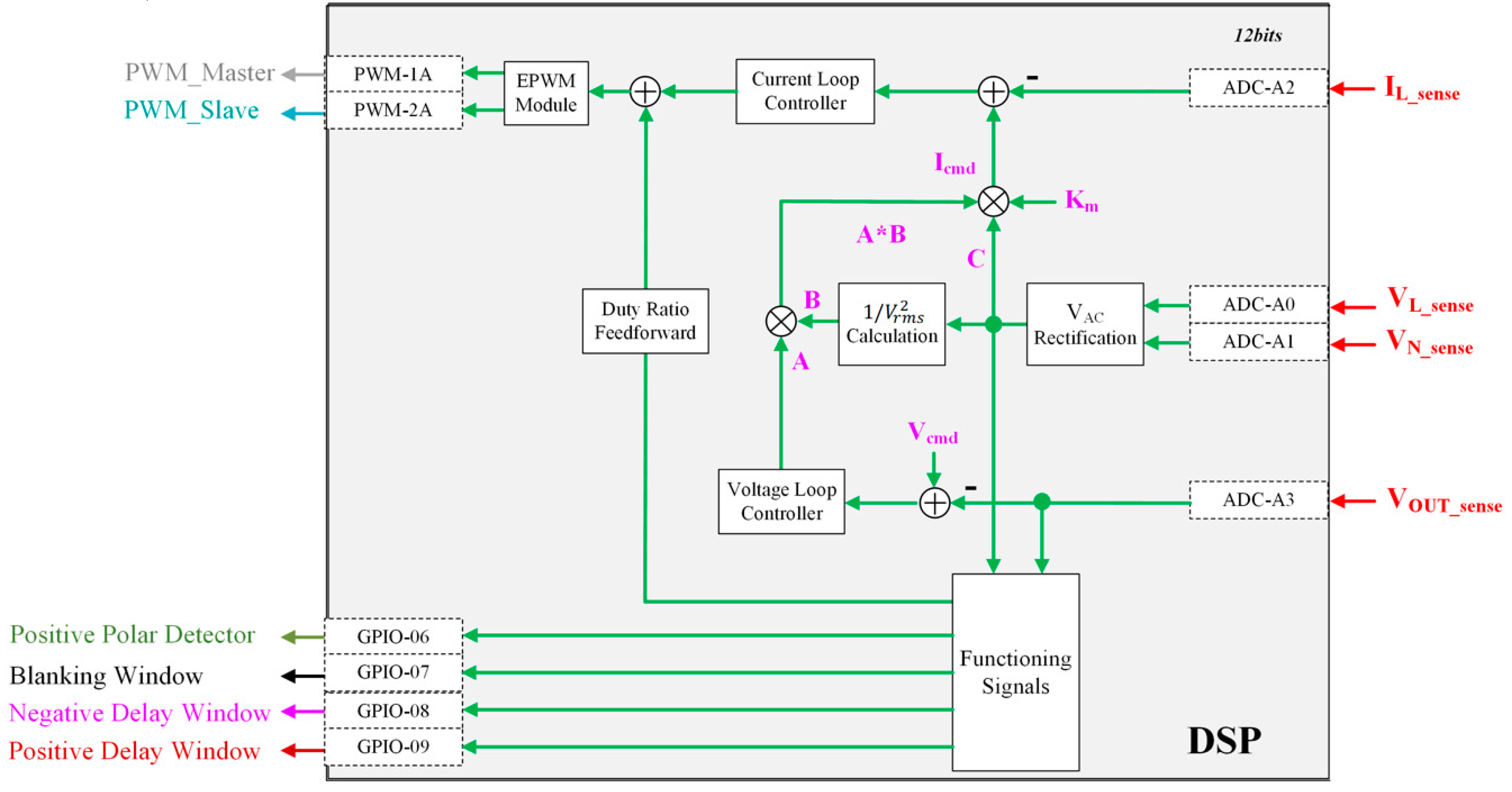

2.3. DSP Control Block

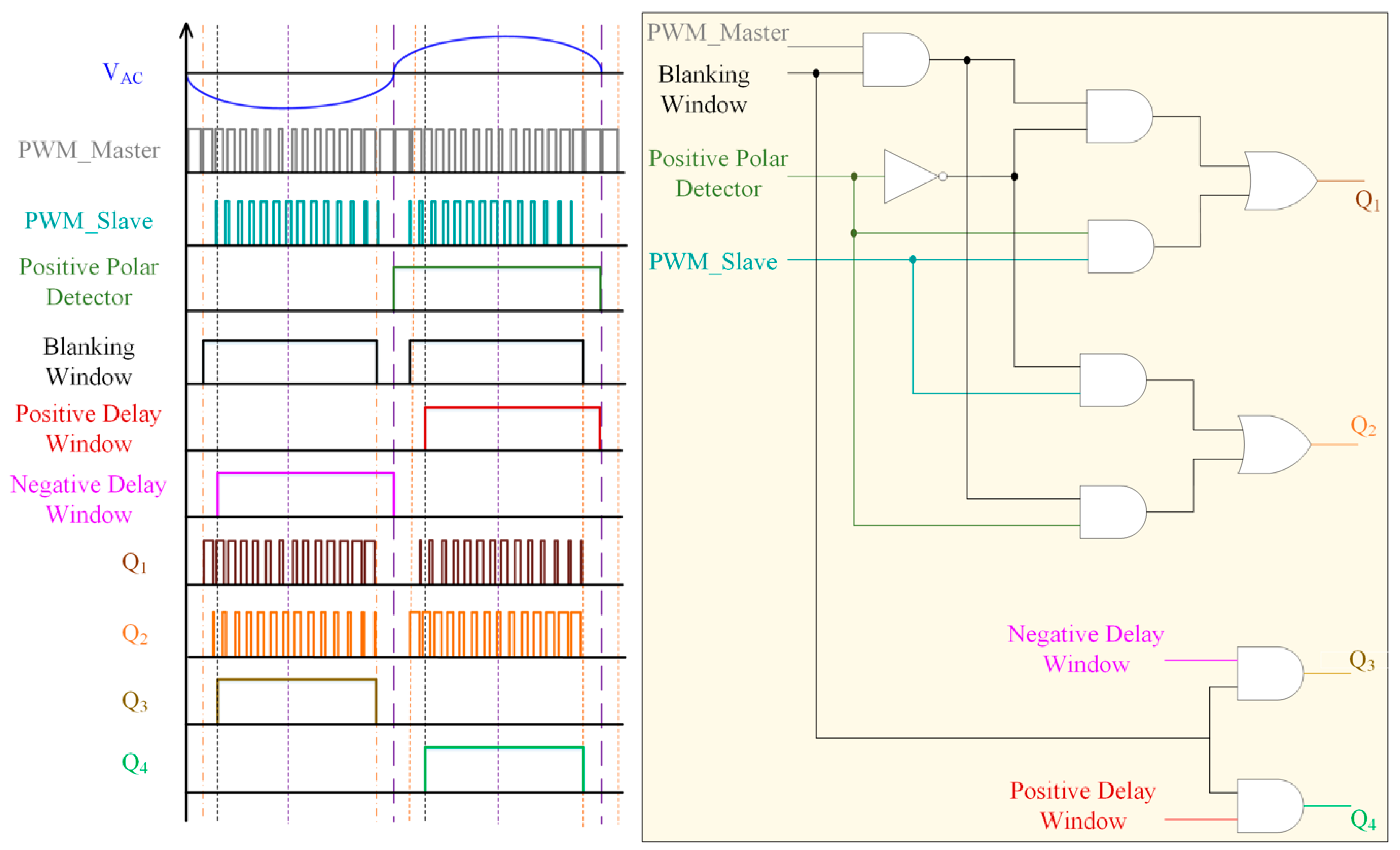

2.4. Auxiliary Logic Circuit

3. Firmware Design for the Control Strategy

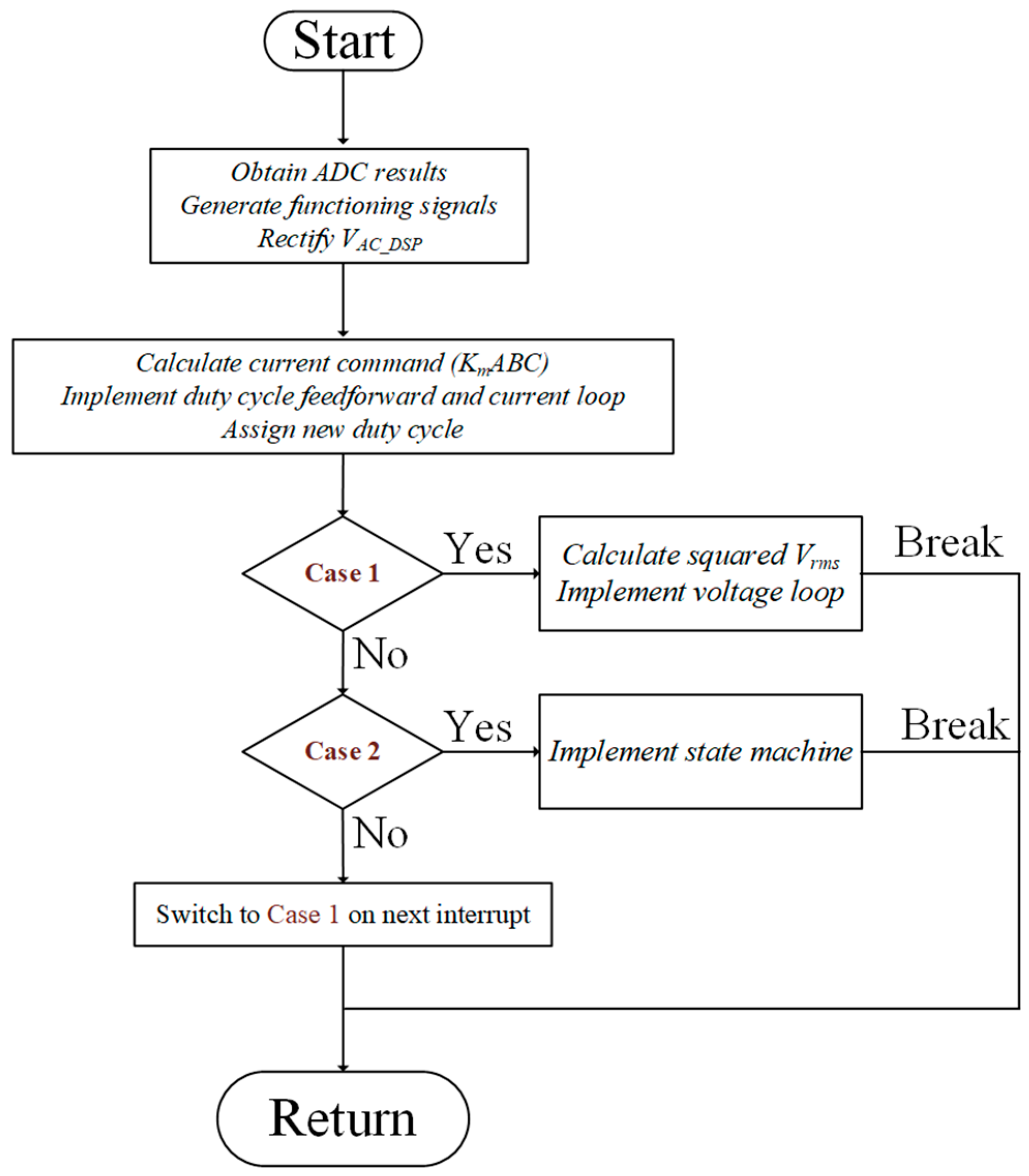

3.1. Algorithm Flowchart

- Obtain ADC results: The task aims at acquiring 4 ADC channel values comprising the line voltage sensing signal, the neutral voltage sensing signal, the inductor current sensing signal and the output voltage sensing signal.

- Generate functioning signals: In the hardware design, employing the proper driving signals at the auxiliary logic circuit for controlling GaN switches and MOSFETs results in the need of generating functioning signals such as positive polar detector, blanking window, negative delay window and positive delay window. Accordingly, this task creates these functioning signals based on the ADC results of the line voltage sensing signal, the neutral voltage sensing signal and the output voltage sensing signal as aforesaid in Section 2.3. Software counters are appropriately added to remove glitches or noises influencing these functioning signals adversely. For instance, in case of the positive polar detector signal changes the state from HIGH to LOW, but not at the zero-crossing zone, which enables the counter increment in a row, a threshold is programmed with such a higher value than this counter that the function can clear the improper signal. Otherwise, the controller will behave as if the AC grid swaps to a negative semicycle. Thus an enormous current spike will be produced by being shorted between the ground and output bus, resulting in the damage of the components.

- Rectify Vac_DSP: The task produces the rectified waveform (M-shape waveform) of the AC mains voltage sensing signal to prepare for calculating the current command.

- Calculate current command (ABCKm): The task calculates the current command Icmd where factors are established in corresponding as follows: The notation A is the output of the voltage loop controller whose maximum value and minimum value contain:

- Implement Duty-cycle feedforward and current loop: The current loop controller is designed and implemented by DSP to catch improved duty cycles for PWM_Master and PWM_Slave.

- Assign the new duty cycle: After implementing the duty feedforward and current loop controller, the new duty value is available. Afterward, an upper-end limitation is imposed on this updated duty ratio to prevent excessive current and instability when working at a high duty ratio. Therefore, the objective of this task is assigning the novel duty cycle value to assure the duty of EPWMs signals placed on the correct gate driver’s signal pin.

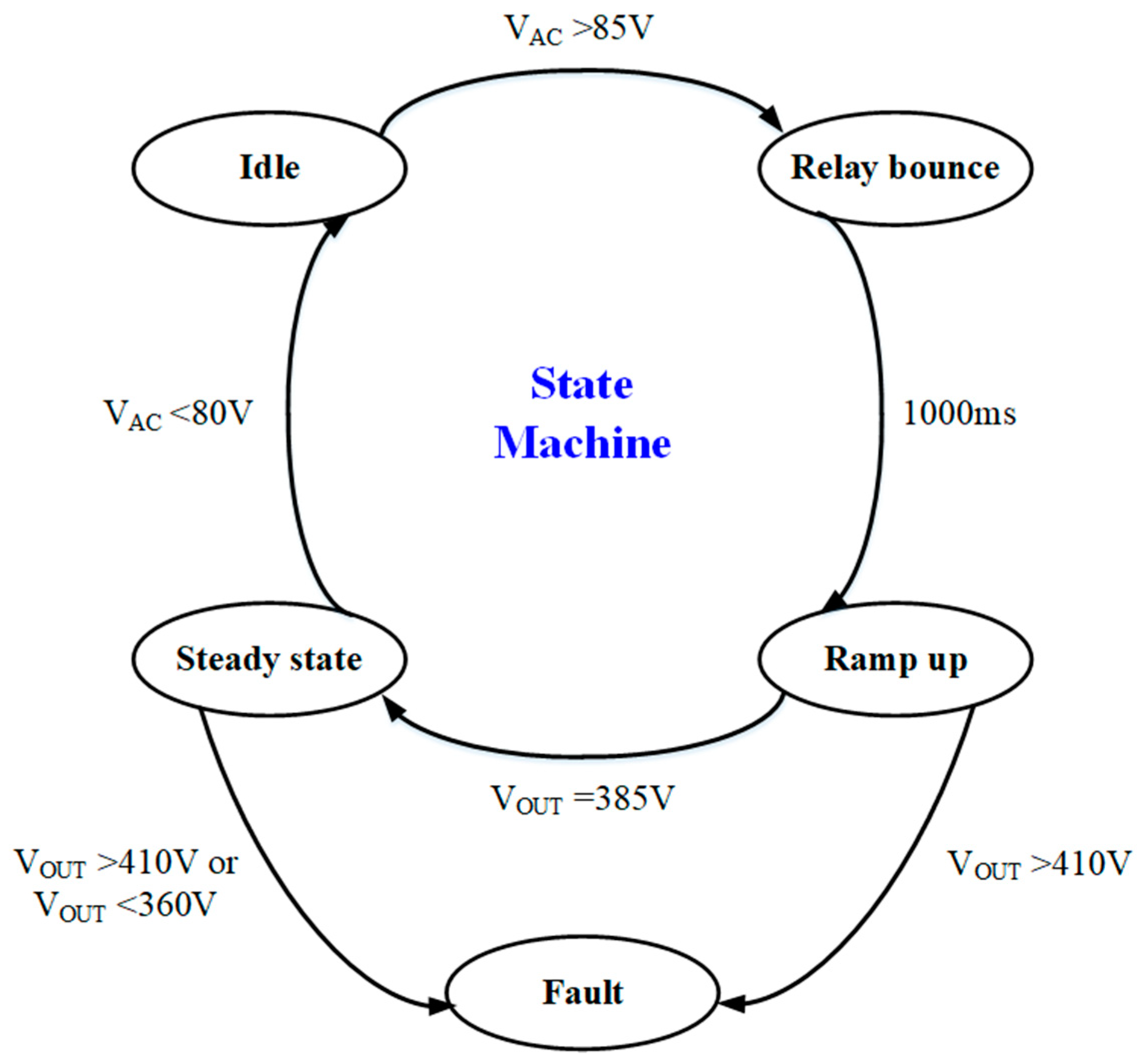

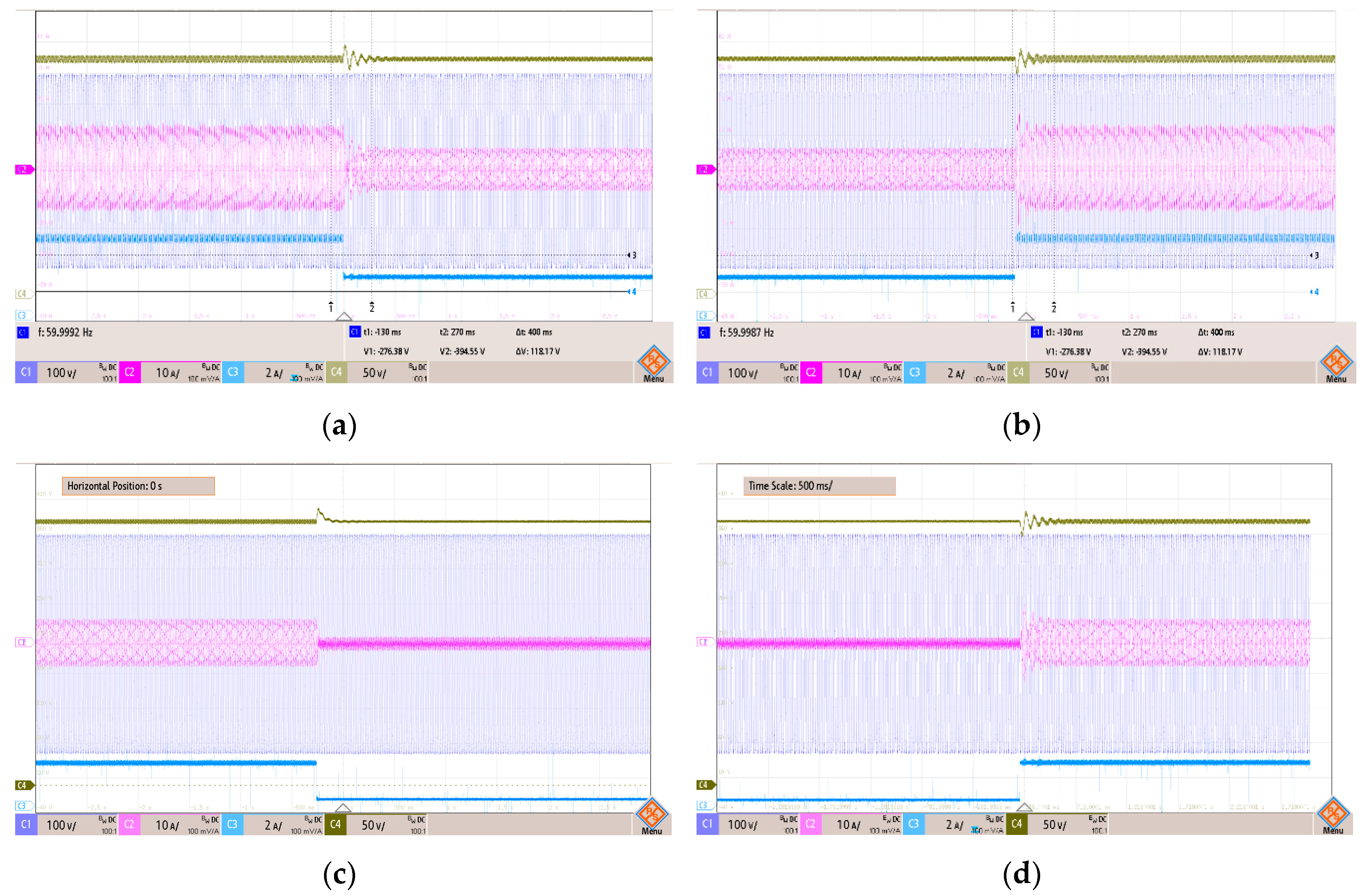

3.2. State Machine

- Idle: Inrush current relay is turned off rather than bypassing the inrush current resistor in the beginning. Inrush current relay is turned on (bypass the inrush current resistor) and moving to the next state if VAC is continually higher than 85 V during 100 ms. At the beginning of a start-up, both outputs of the voltage loop and control loop are zero.

- Relay bounce: Checking VAC is still higher than 85 V after the relay bounces. If VAC is stable in a duration of 1000 ms, the controller is enabled.

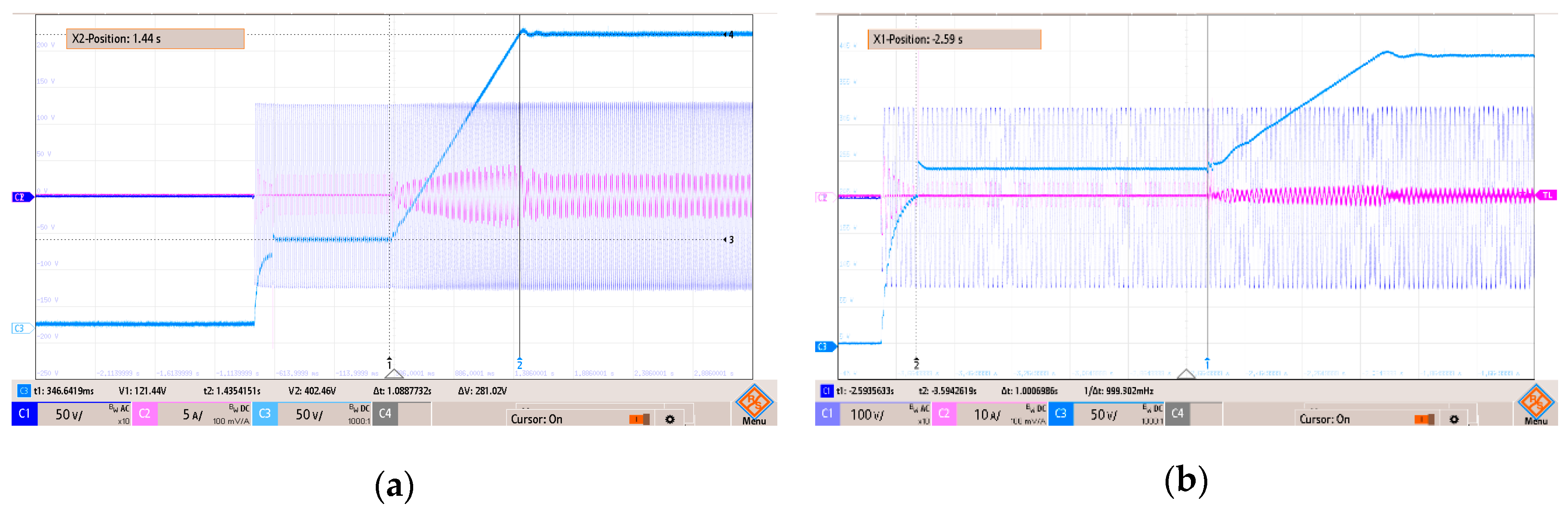

- Ramp-up: The output voltage value is elevated linearly. The controller forces the output voltage to follow the reference value until the output voltage reaches the demanded value. This leads to protecting the circuit from the excessive starting-up current.

- Steady state: The normal condition of PFC operation and checking of an overvoltage condition.

- Fault: The incidents of fault state concerning the output voltage are determined by being out of range. Once the voltage exceeds more or less than 6% of its nominal value, the controller will activate the overvoltage protection.

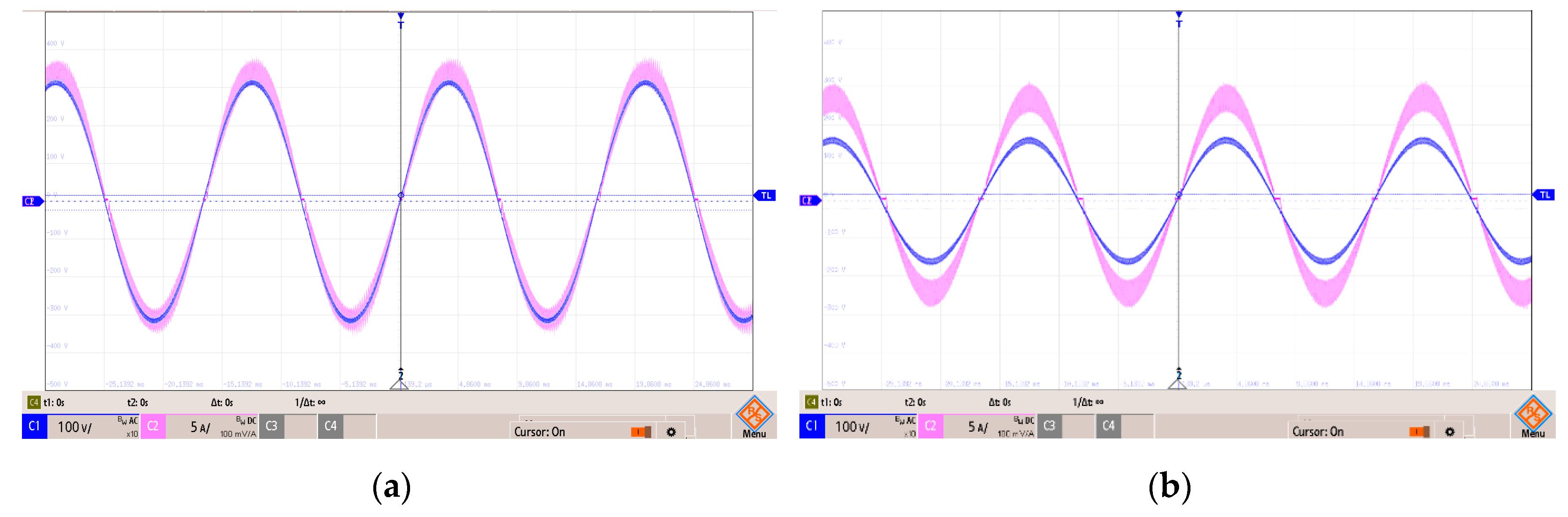

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Padmanabhan, N.; Ahmed, M.; Bhattacharya, K. Battery energy storage systems in energy and reserve markets. IEEE Trans. Power Syst. 2019, 35, 215–226. [Google Scholar] [CrossRef]

- Arani, A.K.; Gharehpetian, G.; Abedi, M. Review on energy storage systems control methods in microgrids. Int. J. Electr. Power Energy Syst. 2019, 107, 745–757. [Google Scholar] [CrossRef]

- Hannan, M.; Lipu, M.H.; Ker, P.J.; Begum, R.; Agelidis, V.G.; Blaabjerg, F. Power electronics contribution to renewable energy conversion addressing emission reduction: Applications, issues, and recommendations. Appl. Energy 2019, 251, 113404. [Google Scholar] [CrossRef]

- Vazquez, S.; Lukic, S.M.; Galvan, E.; Franquelo, L.G.; Carrasco, J.M. Energy storage systems for transport and grid applications. IEEE Trans. Ind. Electron. 2010, 57, 3881–3895. [Google Scholar] [CrossRef]

- Xue, F.; Yu, R.; Huang, A.Q. A 98.3% efficient GaN isolated bidirectional DC–DC converter for DC microgrid energy storage system applications. IEEE Trans. Ind. Electron. 2017, 64, 9094–9103. [Google Scholar] [CrossRef]

- Qian, H.; Zhang, J.; Lai, J.-S.; Yu, W. A high-efficiency grid-tie battery energy storage system. IEEE Trans. Power Electron. 2010, 26, 886–896. [Google Scholar] [CrossRef]

- Pahlevani, M.; Eren, S.; Guerrero, J.M.; Jain, P. A hybrid estimator for active/reactive power control of single-phase distributed generation systems with energy storage. IEEE Trans. Power Electron. 2015, 31, 2919–2936. [Google Scholar] [CrossRef]

- Bagawade, S.; Mousavian, H.; Jain, P.; Pahlevani, M. A novel bi-directional AC/DC converter used for Energy Storage Systems (ESSs). In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 459–466. [Google Scholar]

- Kwon, O.; Kim, J.-S.; Kwon, J.-M.; Kwon, B.-H. Bidirectional grid-connected single-power-conversion converter with low-input battery voltage. IEEE Trans. Ind. Electron. 2017, 65, 3136–3144. [Google Scholar] [CrossRef]

- Dragicevic, T.; Meng, L.; Blaabjerg, F.; Li, Y. Control of Power Converters in ac and dc Microgrids. In Wiley Encyclopedia of Electrical and Electronics Engineering; Wiley: Hoboken, NJ, USA, 2019. [Google Scholar]

- Shao, J.; Agrawal, B.; Bathula, V.S.; Mangal, N.; Moxey, G. Analog Based High Efficiency 2 KW Totem Pole PFC Converter Using Surface Mount SIC MOSFET’s. In Proceedings of the PCIM Europe 2018, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management. Nuremberg, Germany, 5–7 June 2018; pp. 1–6. [Google Scholar]

- Li, Q.; Andersen, M.A.; Thomsen, O.C. Conduction losses and common mode EMI analysis on bridgeless power factor correction. In Proceedings of the 2009 International Conference on Power Electronics and Drive Systems (PEDS), Taipei, Taiwan, 2–5 November 2009; pp. 1255–1260. [Google Scholar]

- Eren, S.; Pahlevani, M.; Bakhshai, A.; Jain, P. A digital current control technique for grid-connected AC/DC converters used for energy storage systems. IEEE Trans. Power Electron. 2016, 32, 3970–3988. [Google Scholar] [CrossRef]

- Firmansyah, E.; Tomioka, S.; Abe, S.; Shoyama, M.; Ninomiya, T. Totem-Pole Power-Factor-Correction Converter under Critical-Conduction-Mode Interleaved Operation. IEICE Trans. Commun. 2010, 93, 2250–2256. [Google Scholar] [CrossRef]

- Su, B.; Zhang, J.; Lu, Z. Totem-pole boost bridgeless PFC rectifier with simple zero-current detection and full-range ZVS operating at the boundary of DCM/CCM. IEEE Trans. Power Electron. 2011, 26, 427–435. [Google Scholar] [CrossRef]

- Marxgut, C.; Krismer, F.; Bortis, D.; Kolar, J.W. Ultraflat interleaved triangular current mode (TCM) single-phase PFC rectifier. IEEE Trans. Power Electron. 2013, 29, 873–882. [Google Scholar] [CrossRef]

- Huang, L.; Yao, W.; Lu, Z. Interleaved totem-pole bridgeless PFC rectifier with ZVS and low input current ripple. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 166–171. [Google Scholar]

- Keshmiri, N.; Wang, D.; Agrawal, B.; Hou, R.; Emadi, A. Current status and future trends of GaN HEMTs in electrified transportation. IEEE Access 2020, 8, 70553–70571. [Google Scholar] [CrossRef]

- Lidow, A.; De Rooij, M.; Strydom, J.; Reusch, D.; Glaser, J. GaN Transistors for Efficient Power Conversion, 3rd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2020; pp. 254–265. [Google Scholar]

- Mitova, R.; Ghosh, R.; Mhaskar, U.; Klikic, D.; Wang, M.-X.; Dentella, A. Investigations of 600-V GaN HEMT and GaN diode for power converter applications. IEEE Trans. Power Electron. 2013, 29, 2441–2452. [Google Scholar] [CrossRef]

- Monthéard, R.; Carcouët, S.; Cassarino, L.; Gavelle, M.; Marcault, E.; Périchon, P.; Sutto, T.; Moreau, E. A 1.5-kW totem-pole PFC converter using D-mode (normally-on) GaN HEMTs. In Proceedings of the 2019 IEEE 13th International Conference on Power Electronics and Drive Systems (PEDS), Toulouse, France, 9–12 July 2019; pp. 1–5. [Google Scholar]

- Hou, X.; Boroyevich, D.; Burgos, R. Characterization on latest-generation SiC MOSFET’s body diode. In Proceedings of the 2016 IEEE 4th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Fayetteville, AR, USA, 7–9 November 2016; pp. 247–252. [Google Scholar]

- Kaplar, R.; Marinella, M.; DasGupta, S.; Smith, M.A.; Atcitty, S.; Sun, M.; Palacios, T. Characterization and reliability of SiC-and GaN-based power transistors for renewable energy applications. In Proceedings of the 2012 IEEE Energytech, Cleveland, OH, USA, 29–31 May 2012; pp. 1–6. [Google Scholar]

- Zhu, K.; O’Grady, M.; Dodge, J.; Bendel, J.; Hostetler, J. 1.5 kW single phase CCM totem-pole PFC using 650V SiC cascodes. In Proceedings of the 2016 IEEE 4th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Fayetteville, AR, USA, 7–9 November 2016; pp. 90–94. [Google Scholar]

- Syu, Y.-L.; Liu, Y.-C.; Chen, M.-C.; Hsieh, Y.-C.; Ou, S.-Y.; Chiu, H.-J. High efficiency and low input current distortion Totem-Pole Bridgeless PFC. In Proceedings of the 2016 Asian Conference on Energy, Power and Transportation Electrification (ACEPT), Singapore, 25–27 October 2016; pp. 1–6. [Google Scholar]

- Wu, W. 1.5 kW Digital Totem Pole PFC Design for Air-Conditioner and Perforance Comparison Using IGBT, SiC and GaN. In Proceedings of the PCIM Europe 2017; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremburg, Germany, 16–18 May 2017; pp. 1–5. [Google Scholar]

- Brohlin, P.; Beheshti, M. Designing High-Density Power Solutions with GaN. In Proceedings of the PCIM Europe 2018, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management. Nuremberg, Germany, 5–7 June 2018; pp. 1–5. [Google Scholar]

- Zhang, R.; Liu, S.; Li, B.; Zhao, N.; Wang, G.; Xu, D. Totem-Pole Bridgeless Boost PFC Converter Based on GaN HEMT for Air Conditioning Applications. In Proceedings of the 2018 2nd IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 20–22 October 2018; pp. 1–9. [Google Scholar]

- Fan, J.W.-T.; Yeung, R.S.-C.; Chung, H.S.-H. Optimized hybrid PWM scheme for mitigating zero-crossing distortion in totem-pole bridgeless PFC. IEEE Trans. Power Electron. 2018, 34, 928–942. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Zhuang, Y.; Wang, C. Analysis to input current zero crossing distortion of bridgeless rectifier operating under different power factors. Energies 2018, 11, 2447. [Google Scholar] [CrossRef]

- Park, S.M.; Park, S.-Y. Versatile control of unidirectional AC–DC boost converters for power quality mitigation. IEEE Trans. Power Electron. 2014, 30, 4738–4749. [Google Scholar] [CrossRef]

- Zhang, B.; Lin, Q.; Imaoka, J.; Shoyama, M.; Tomioka, S.; Takegami, E. EMI Prediction and Reduction of Zero-Crossing Noise in Totem-Pole Bridgeless PFC Converters. J. Power Electron. 2019, 19, 278–287. [Google Scholar]

- Sun, B. Control challenges in a totem-pole PFC. Analog Appl. J. 2017, 2, 1–4. [Google Scholar]

- De Gusseme, K.; Van de Sype, D.M.; Van den Bossche, A.P.; Melkebeek, J.A. Digitally controlled boost power-factor-correction converters operating in both continuous and discontinuous conduction mode. IEEE Trans. Ind. Electron. 2005, 52, 88–97. [Google Scholar] [CrossRef]

| Item | Value/Model |

|---|---|

| Input supply voltage VAC | 90–264 Vac |

| Output voltage VOUT | 385 Vdc bus nominal |

| Input frequency fline | 43–63 Hz |

| Output power POUT | 1 kW @ 90–132 V, with 115 V nominal 2.6 kW @ 180–264 V, with 230 V nominal |

| Switching frequency fs | 65 kHz |

| Semiconductor device Q1, Q2 Semiconductor device Q3, Q4 | GaN System’s GS66516B as fast speed leg IXFH60N65X2 as slow speed leg |

| Power inductor LP | 604 µH |

| Output capacitor CL | 2*560 µF |

| Controller core | DSP TMS320F28035 |

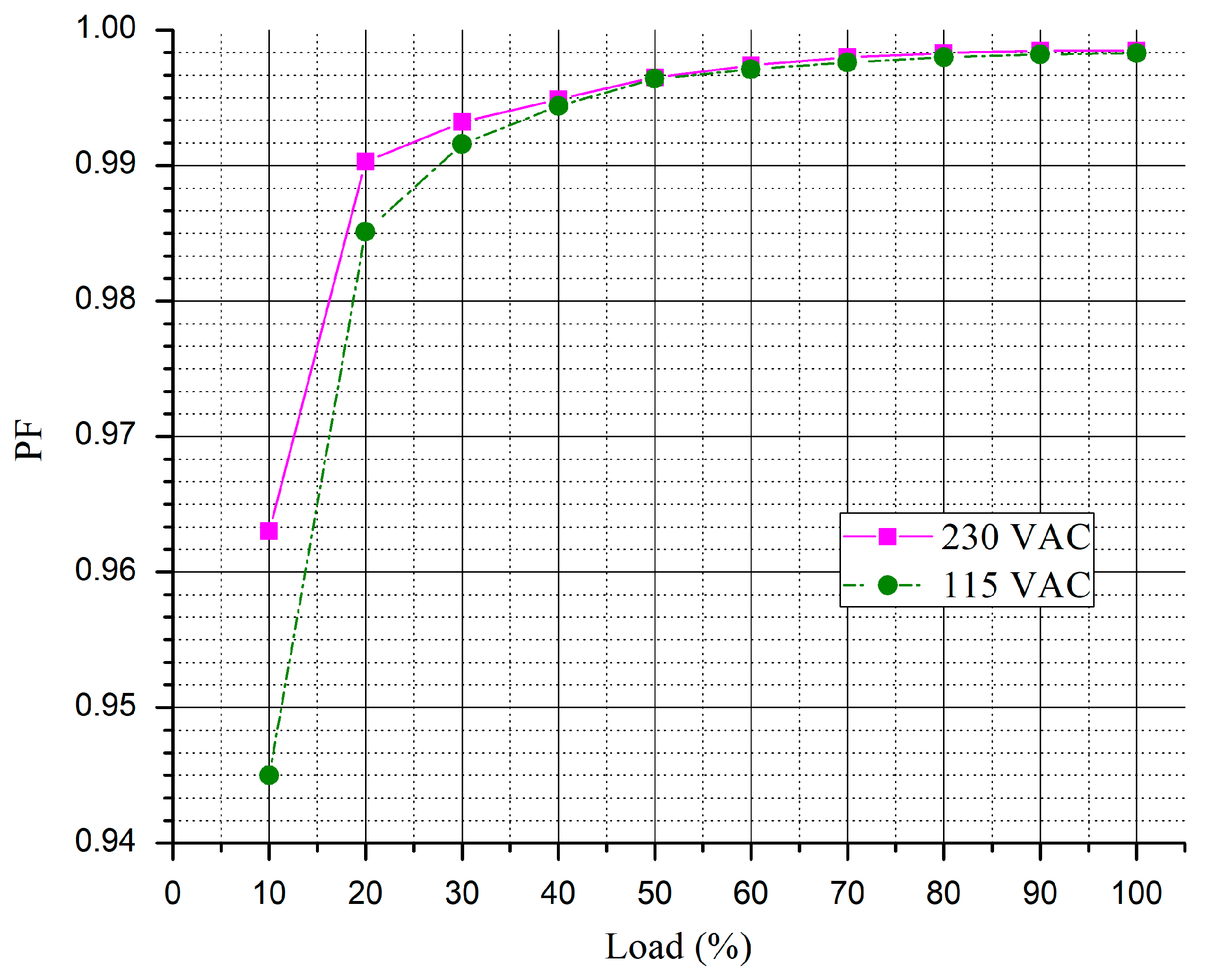

| Power factor | ≥0.99 |

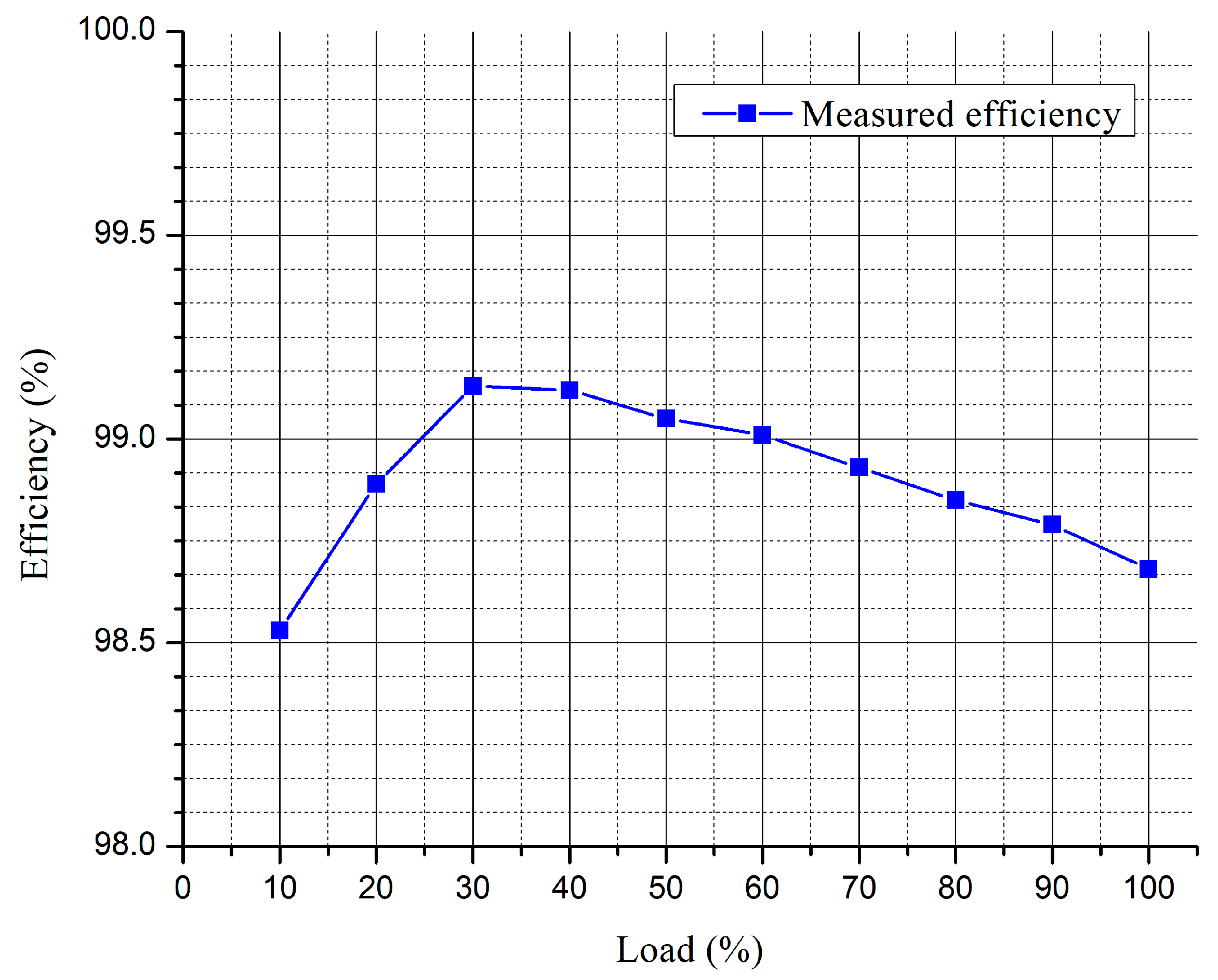

| Peak efficiency | >99.1% |

| Harmonic content | <2% at 230 V and full load |

| Load (%) | VAC = 90 V | VAC = 264 V | ||

|---|---|---|---|---|

| PF | THD (%) | PF | THD (%) | |

| 10 | 0.981 | 6.13 | 0.911 | 8.72 |

| 20 | 0.991 | 4.55 | 0.983 | 4.61 |

| 30 | 0.996 | 3.18 | 0.988 | 3.79 |

| 40 | 0.997 | 2.67 | 0.993 | 3.51 |

| 50 | 0.998 | 2.39 | 0.995 | 3.31 |

| 60 | 0.998 | 2.17 | 0.997 | 3.17 |

| 70 | 0.998 | 2.08 | 0.998 | 3.08 |

| 80 | 0.999 | 2.01 | 0.998 | 2.91 |

| 90 | 0.999 | 1.81 | 0.998 | 2.83 |

| 100 | 0.999 | 1.76 | 0.998 | 2.79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Do, N.-N.; Huang, B.-S.; Phan, N.-T.; Nguyen, T.-T.; Wu, J.-H.; Liu, Y.-C.; Chiu, H.-J. Design and Implementation of a Control Method for GaN-Based Totem-Pole Boost-Type PFC Rectifier in Energy Storage Systems. Energies 2020, 13, 6297. https://doi.org/10.3390/en13236297

Do N-N, Huang B-S, Phan N-T, Nguyen T-T, Wu J-H, Liu Y-C, Chiu H-J. Design and Implementation of a Control Method for GaN-Based Totem-Pole Boost-Type PFC Rectifier in Energy Storage Systems. Energies. 2020; 13(23):6297. https://doi.org/10.3390/en13236297

Chicago/Turabian StyleDo, Nguyen-Nghia, Bing-Siang Huang, Nhat-Truong Phan, Tan-Tung Nguyen, Jian-Hong Wu, Yu-Chen Liu, and Huang-Jen Chiu. 2020. "Design and Implementation of a Control Method for GaN-Based Totem-Pole Boost-Type PFC Rectifier in Energy Storage Systems" Energies 13, no. 23: 6297. https://doi.org/10.3390/en13236297

APA StyleDo, N.-N., Huang, B.-S., Phan, N.-T., Nguyen, T.-T., Wu, J.-H., Liu, Y.-C., & Chiu, H.-J. (2020). Design and Implementation of a Control Method for GaN-Based Totem-Pole Boost-Type PFC Rectifier in Energy Storage Systems. Energies, 13(23), 6297. https://doi.org/10.3390/en13236297