A Methodology for Long-Term Model Predictive Control of Hybrid Geothermal Systems: The Shadow-Cost Formulation

Abstract

1. Introduction

2. Literature Review

2.1. Model Predictive Control (MPC) Concept

2.2. MPC in (Hybrid) Geothermal Systems

3. Proposed Methodology

3.1. Cost Function

3.2. Building Long-Term Model

3.3. Energy System Long-Term Model

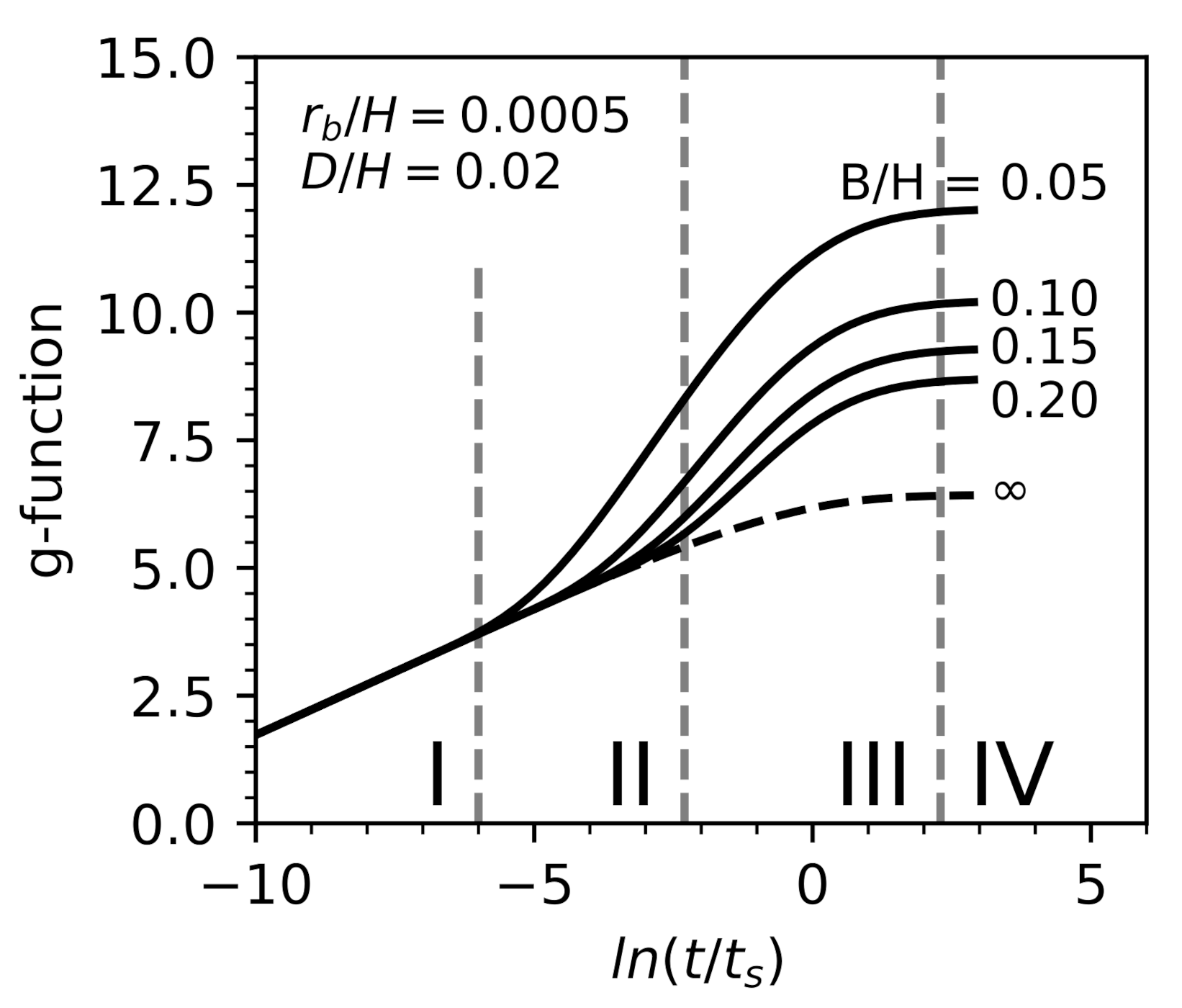

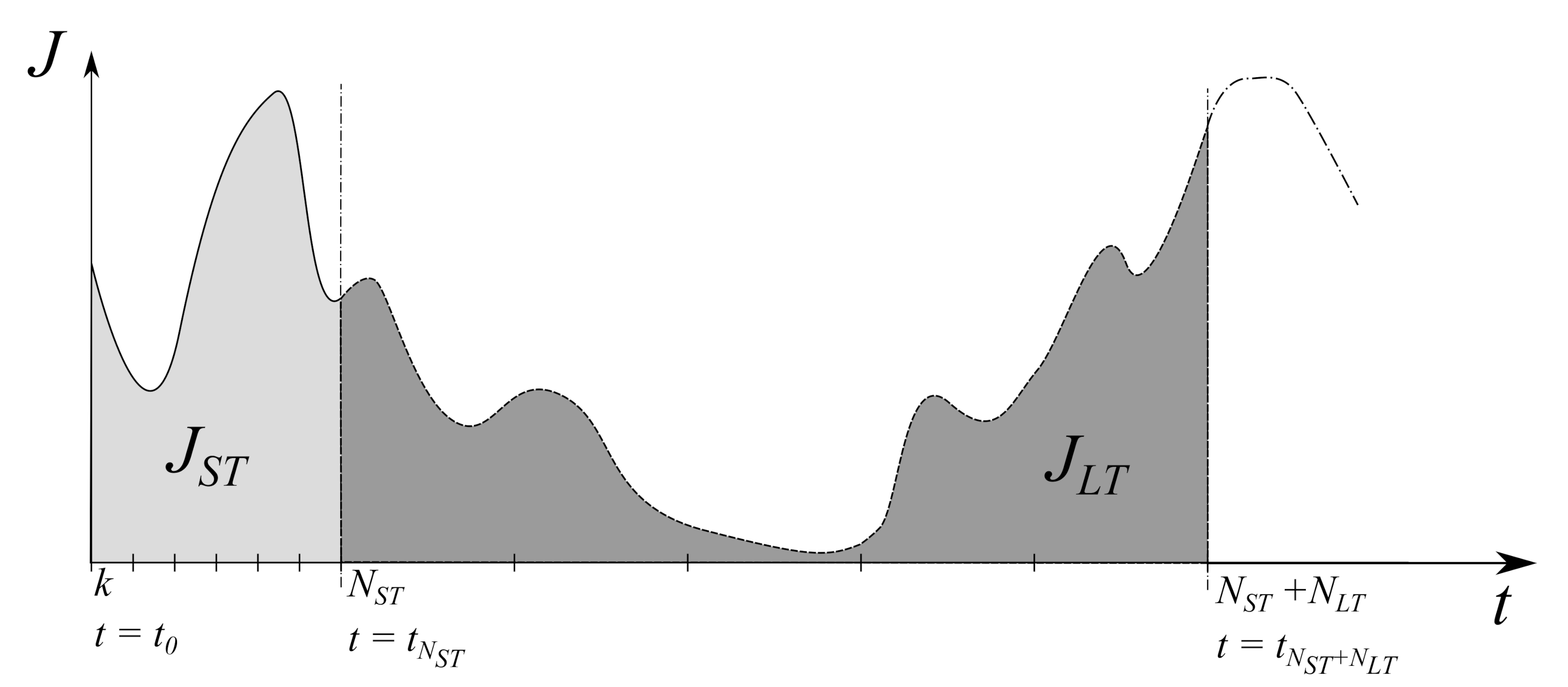

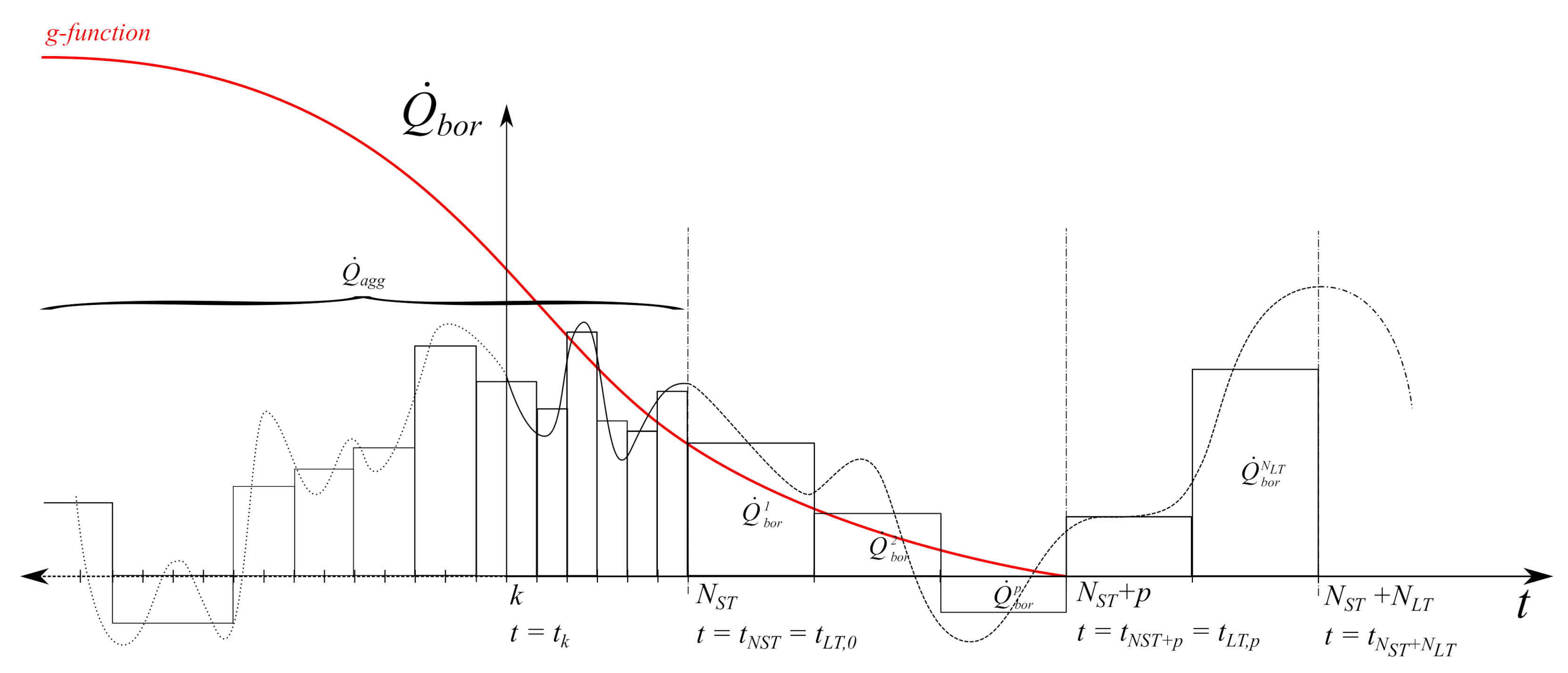

3.4. Borefield Long-Term Model

3.5. Formulation of the Shadow-Cost

4. Validation Case Study

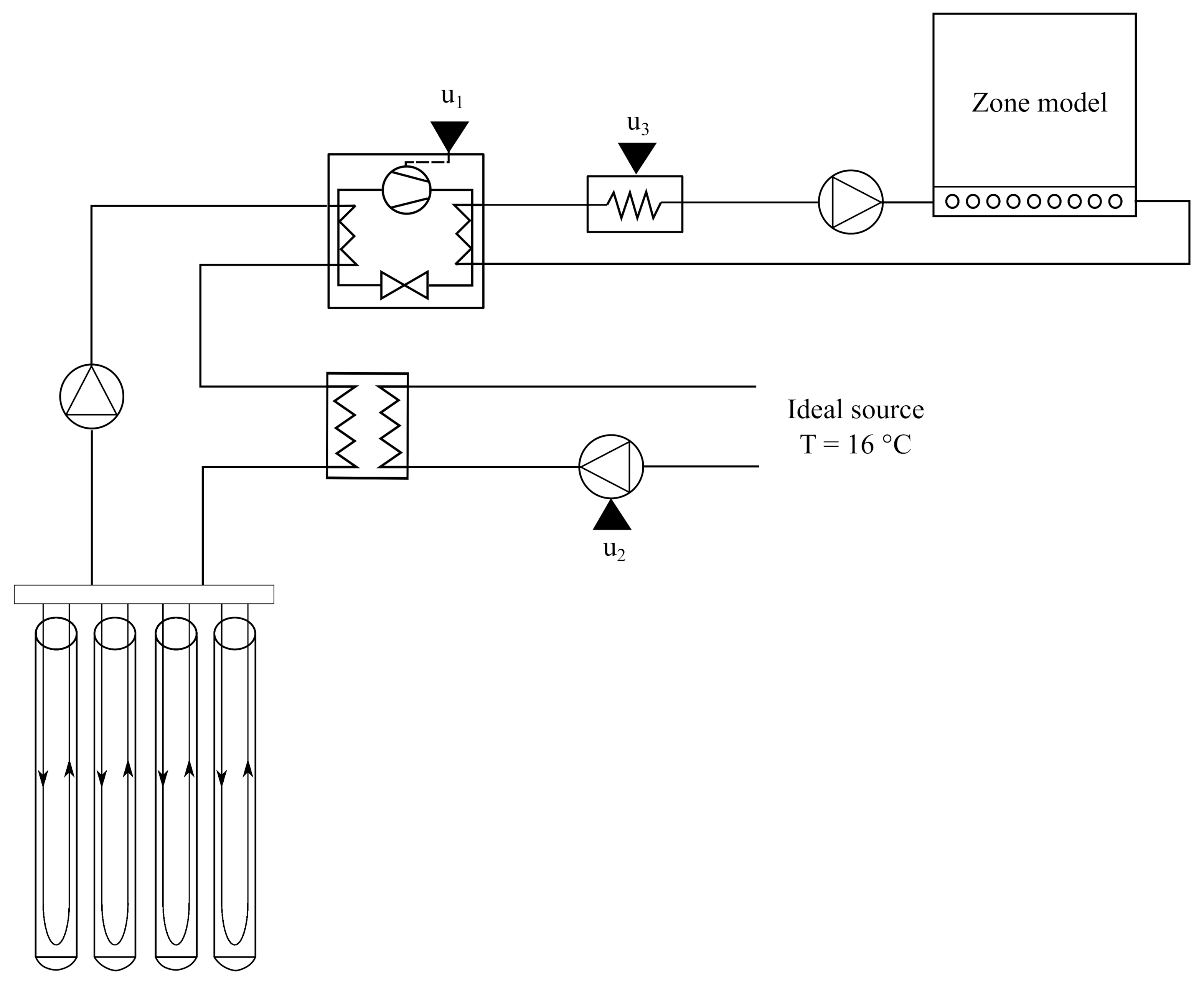

4.1. Building Envelope and Energy System Models

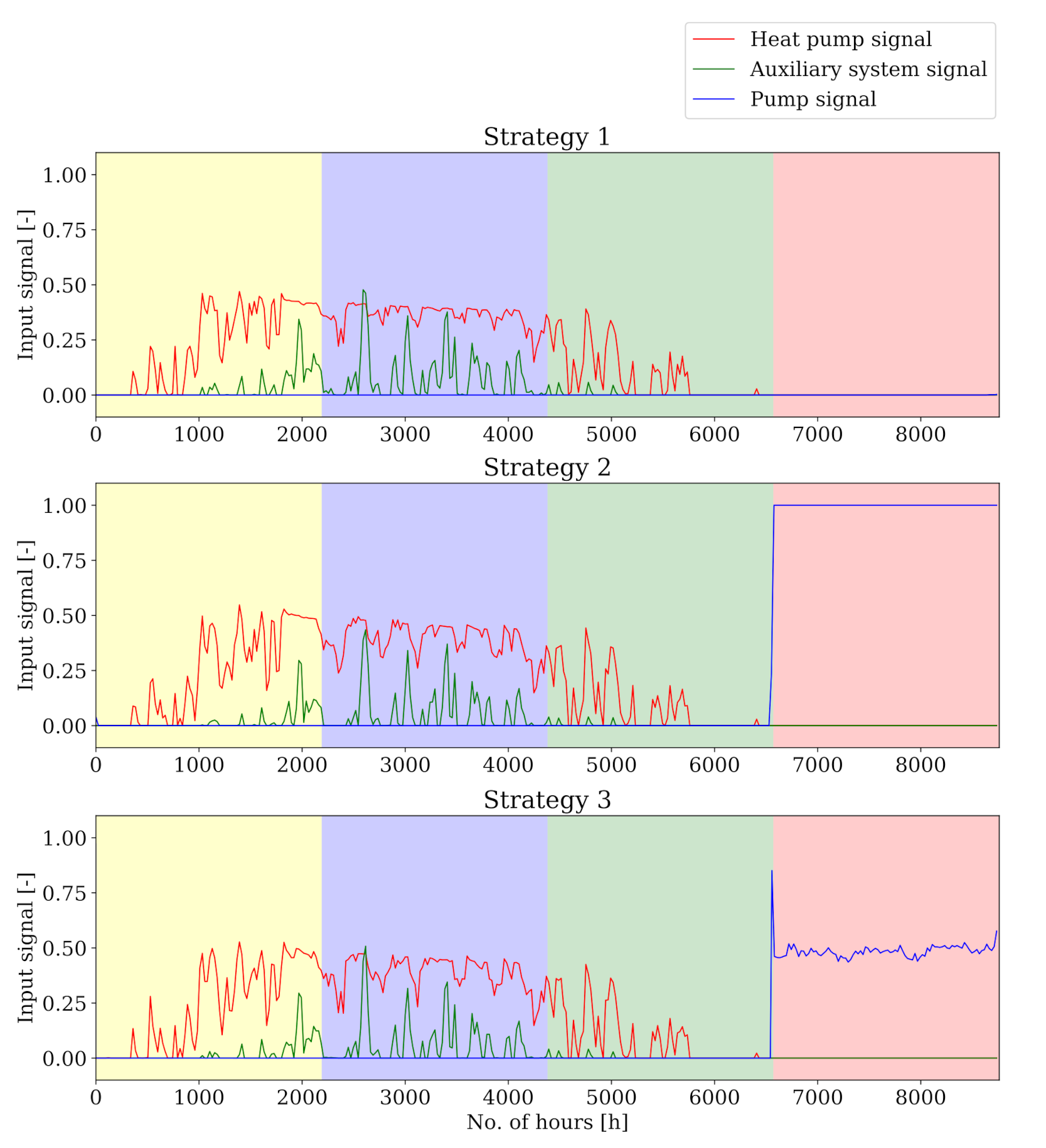

4.2. Control Strategies

- A state-of-the-art MPC for the whole system;

- A state-of-the-art MPC combined with an RBC that activates the regeneration pump during the summer period, i.e., maximizes the amount of regenerated heat;

- An MPC that includes the shadow-cost methodology.

5. Results and Discussion

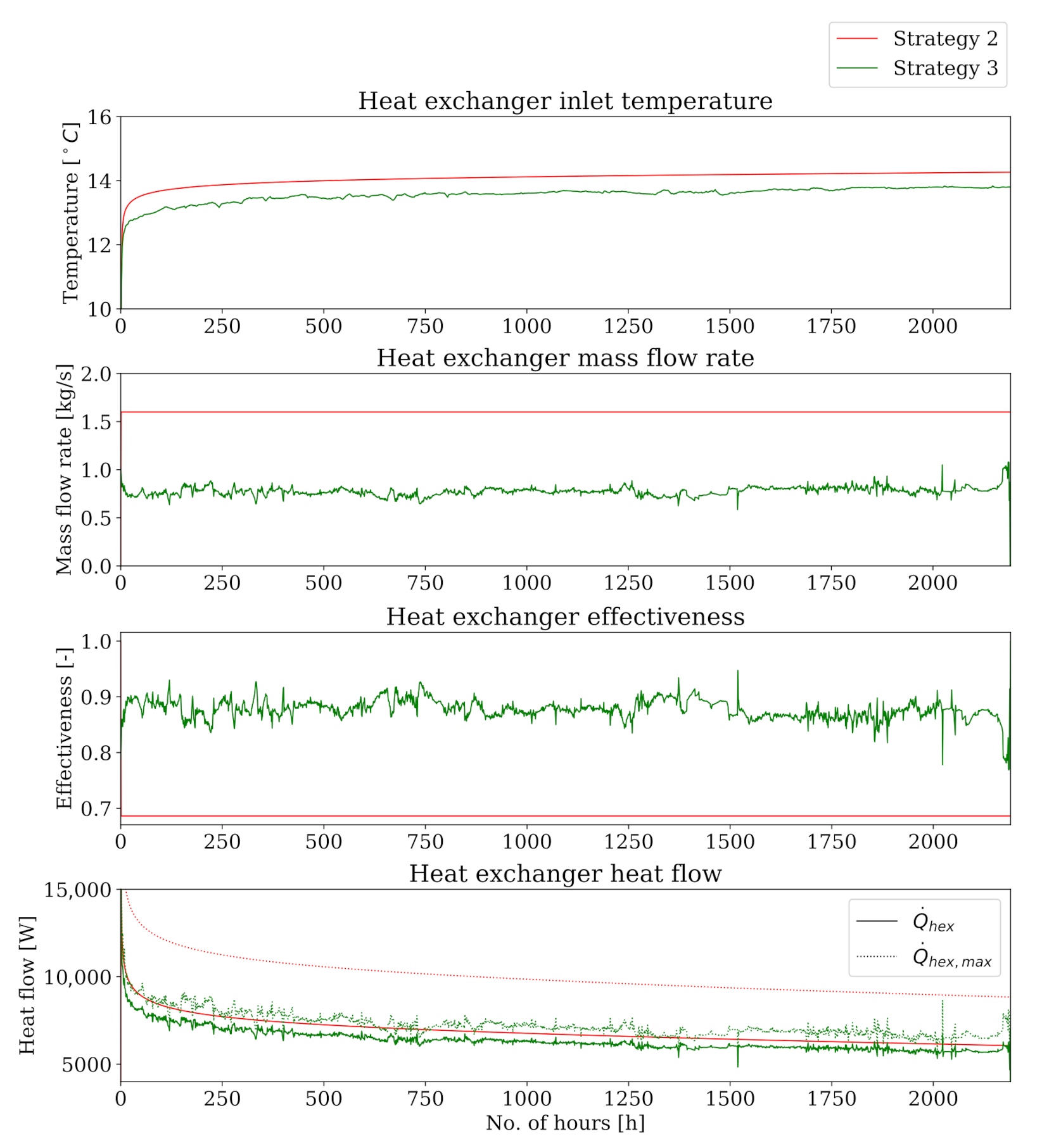

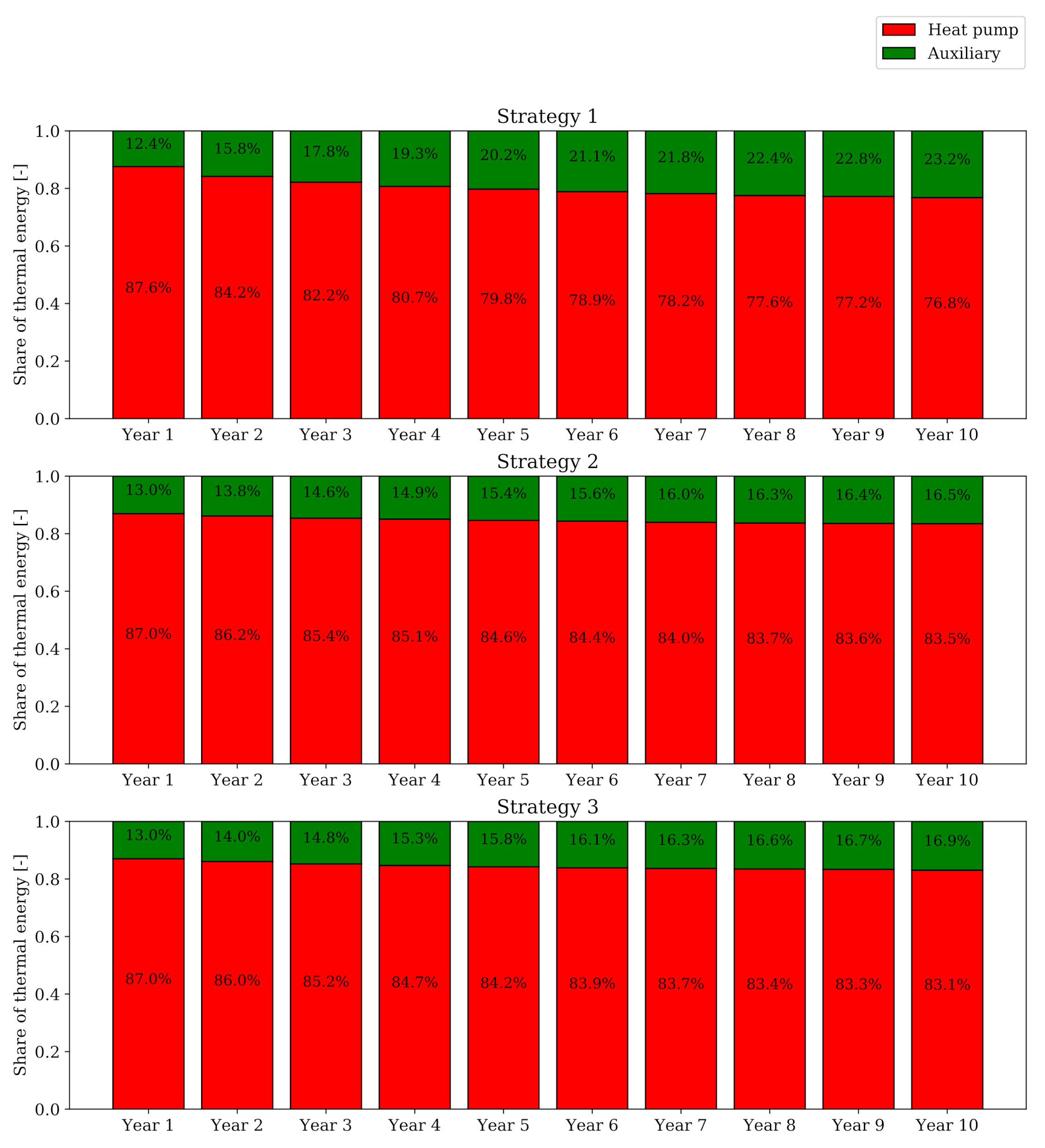

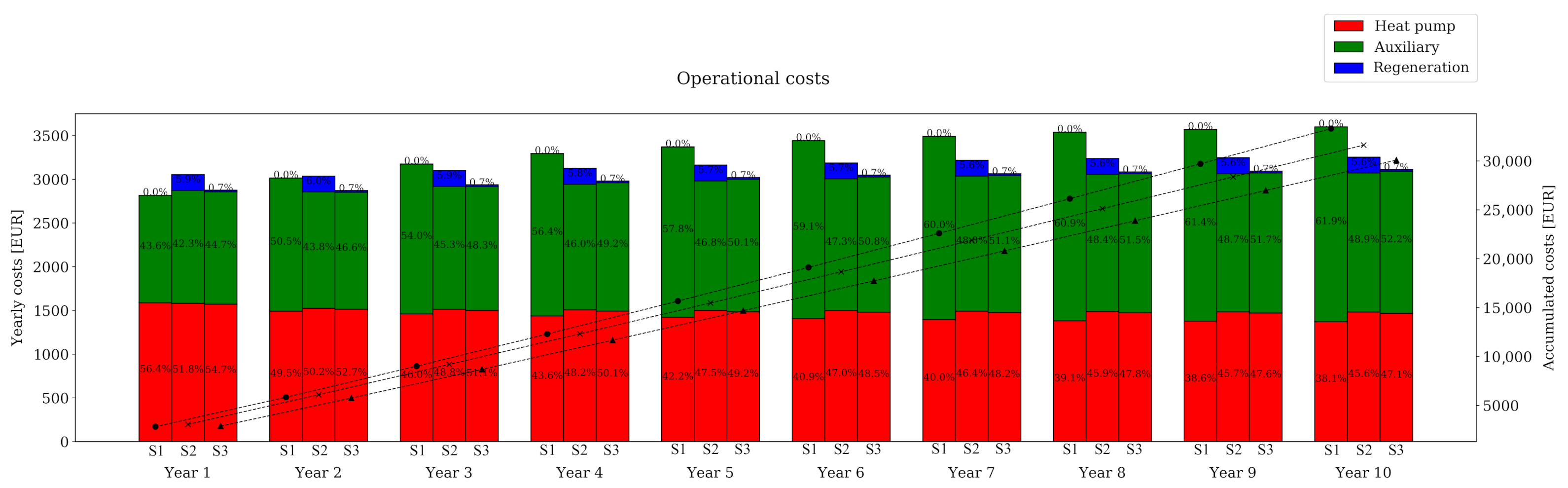

5.1. Comparison of Control Strategies

5.2. Effect of Different Long-Term Horizons

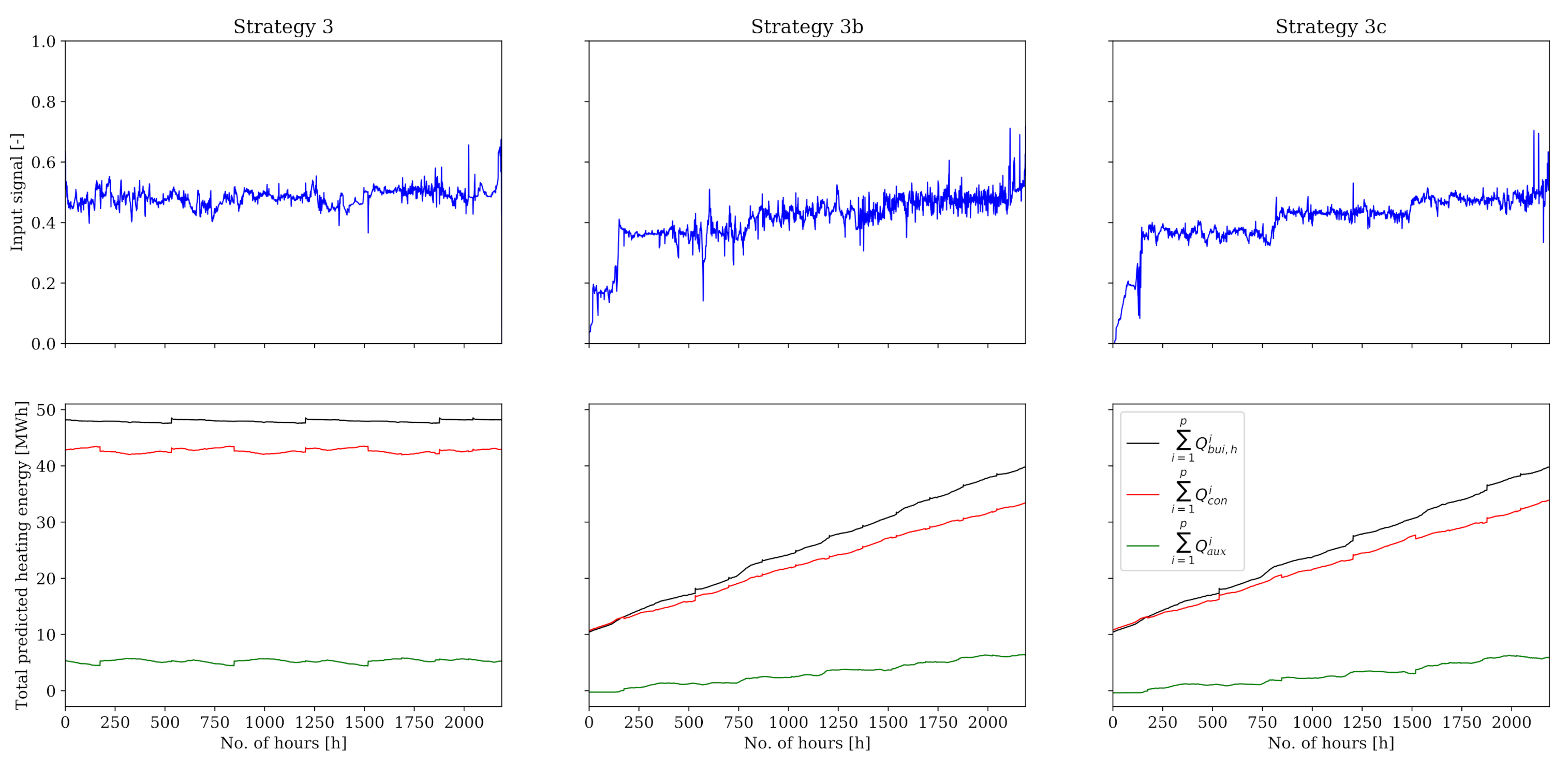

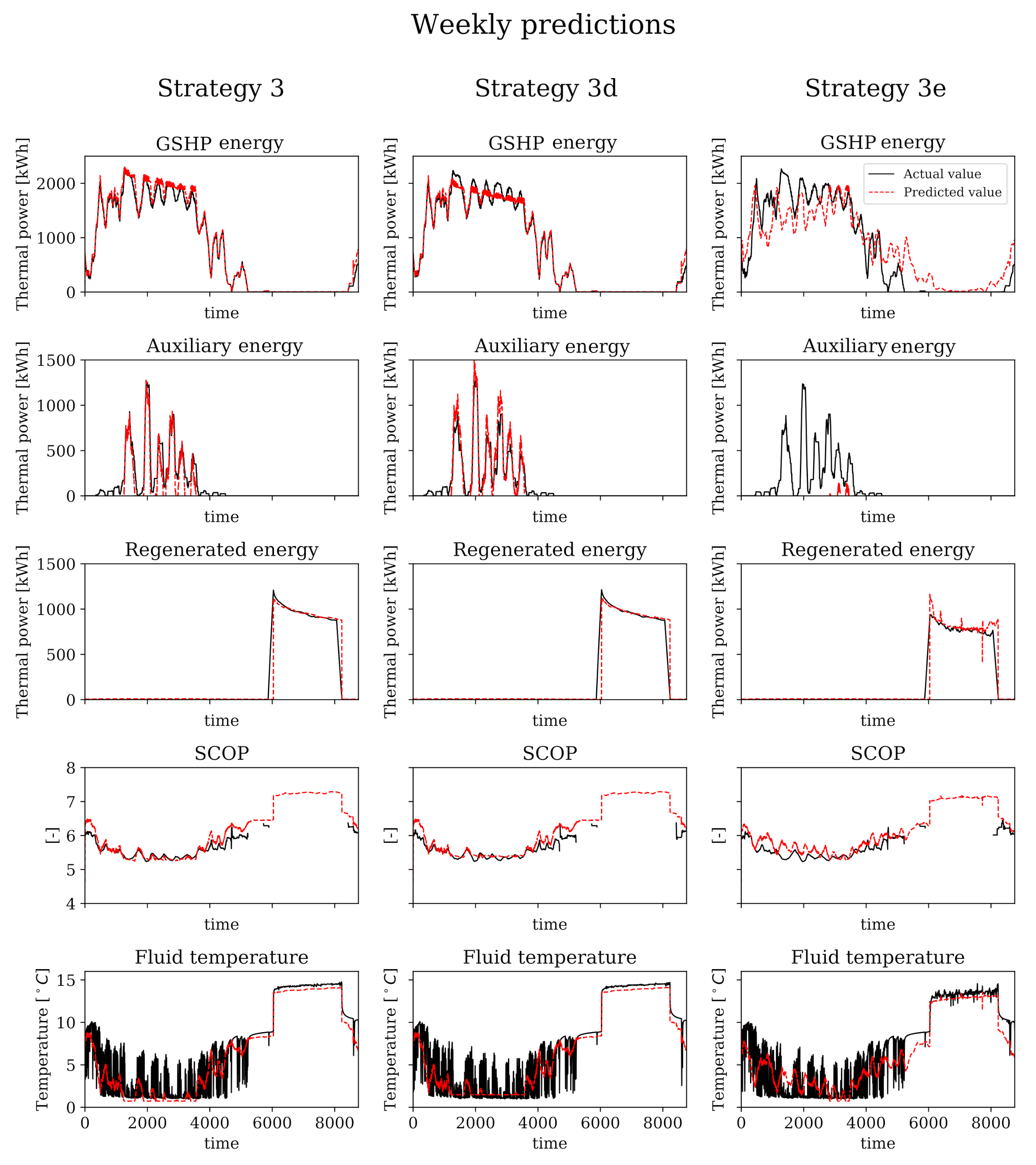

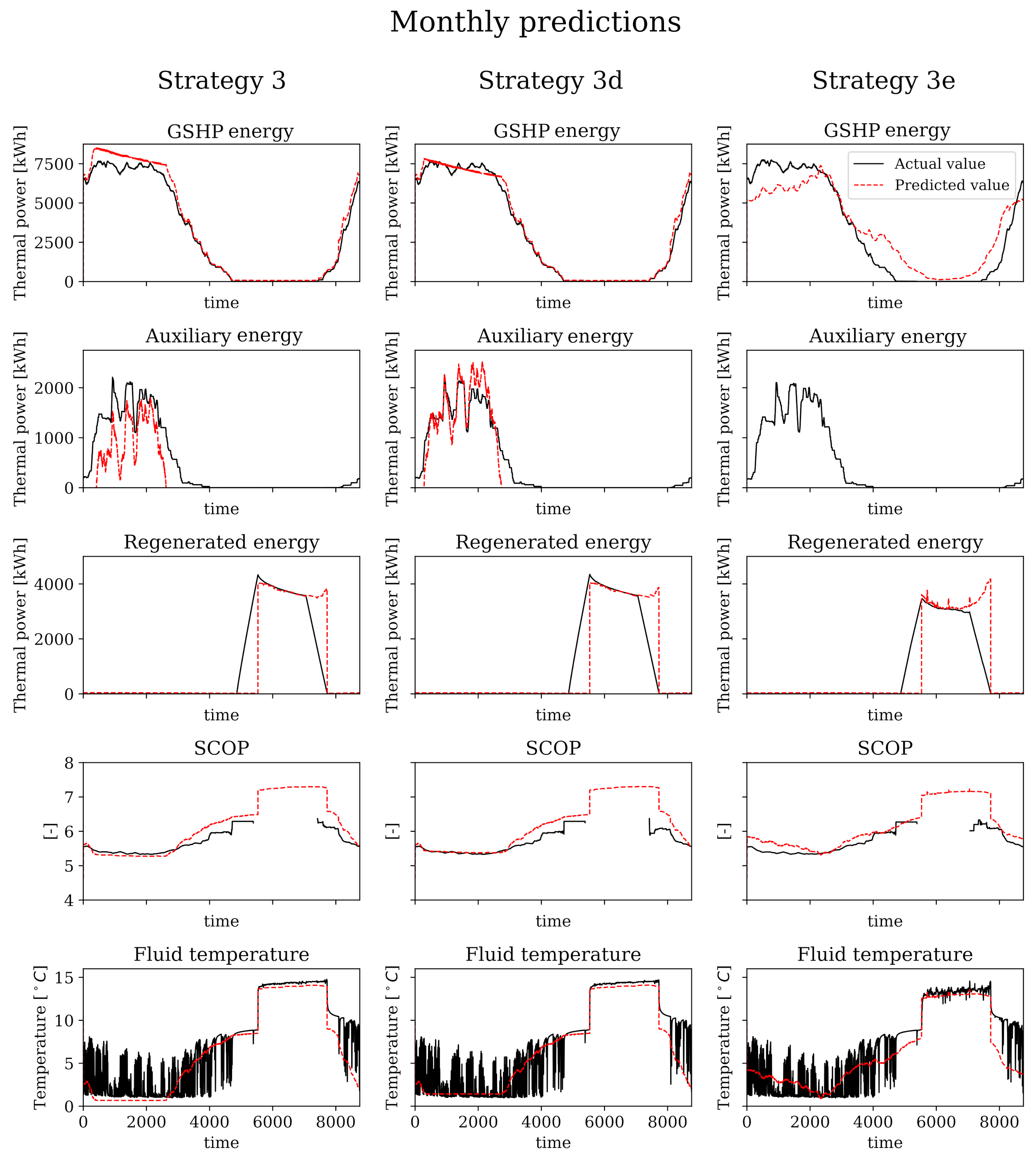

5.3. Effect of the Predictions Accuracy

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ANN | Artificial neural network |

| COP | Coefficient of performance |

| DST | Duct-storage model |

| EER | Energy efficienct ratio |

| GSHP | Ground source heat pump |

| HVAC | Heating, ventilation and air conditioning |

| LP | Linear problem |

| MILP | Mixed integer linear problem |

| MPC | Model predictive control |

| MOR | Model order reduction |

| NLP | Non-linear problem |

| NTU | Number of transfer units |

| OCP | Optimal control problem |

| POD | Proper orthogonal decomposition |

| QUICK | Quadratic upstream interpolation of convective kinetics |

| TABS | Thermally activated building systems |

| RBC | Rule based control |

| RC | Resistance-capacitance |

| RHC | Radiant heating and cooling |

| SALTO | Short- and long-term optimization |

| SCOP | Seasonal coefficient of performance |

| SEER | Seasonal energy efficiency ratio |

| TACO | Toolchain for automated control and optimization |

References

- De Coninck, R.; Helsen, L. Practical implementation and evaluation of model predictive control for an office building in Brussels. Energy Build. 2016, 111, 290–298. [Google Scholar] [CrossRef]

- Vana, Z.; Cigler, J.; Siroky, J.; Zacekova, E.; Ferkl, L. Model-based energy efficient control applied to an office ock. J. Process Control 2014, 24, 790–797. [Google Scholar] [CrossRef]

- West, S.R.; Ward, J.K.; Wall, J. Trial results from a model predictive control and optimisation system for commercial building HVAC. Energy Build. 2014, 72, 271–279. [Google Scholar] [CrossRef]

- Camacho, E.F.; Alba, C.B. Model Predictive Control; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Cupeiro Figueroa, I.; Cigler, J.; Helsen, L. Model Predictive Control formulation: A review with focus on hybrid GEOTABS buildings. In Proceedings of the REHVA Annual Meeting Conference Low Carbon Technologies in HVAC, Brussels, Belgium, 24 April 2018; pp. 1–9. [Google Scholar]

- Himpe, E.; Vercautere, M.; Boydens, W.; Helsen, L.; Laverge, J. GEOTABS concept and design: State-of-the-art, challenges and solutions. In Proceedings of the REHVA Annual Meeting Conference Low Carbon Technologies in HVAC, Brussels, Belgium, 24 April 2018. [Google Scholar]

- ASHRAE. Chapter 34: Geothermal Energy. In ASHRAE Handbook: Applications; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2015. [Google Scholar]

- Bernier, M.A. Closed-loop ground-coupled heat pump systems. Ashrae J. 2006, 48, 12–25. [Google Scholar]

- Atam, E.; Helsen, L. Ground-coupled heat pumps: Part 1—Literature review and research challenges in modeling and optimal control. Renew. Sustain. Energy Rev. 2016, 54, 1653–1667. [Google Scholar] [CrossRef]

- Hellström, G. Duct Ground Heat Storage Model, Manual for Computer Code; Department of Mathematical Physics, University of Lund: Lund, Sweden, 1989. [Google Scholar]

- Verhelst, C.; Helsen, L. Low-order state space models for borehole heat exchangers. HVAC R Res. 2011, 17, 928–947. [Google Scholar] [CrossRef]

- Eskilson, P. Thermal Analysis of Heat Extraction Boreholes. Ph.D. Thesis, University of Lund, Lund, Sweden, 1987. [Google Scholar]

- Verhelst, C. Model Predictive Control of Ground Coupled Heat Pump Systems for Office Buildings. Ph.D. Thesis, Katholieke University Leuven, Leuven, Belgium, 2012. [Google Scholar]

- Atam, E.; Verhelst, C.; Helsen, L. Development of a control-oriented model for borehole dynamics for buildings equipped with ground-coupled heat pumps. In Proceedings of the 13th Conference International Building Performance Simulation Association (BS 2013), Chambéry, France, 25–28 August 2013; pp. 2052–2059. [Google Scholar]

- Atam, E.; Helsen, L. A convex approach to a class of non-convex building HVAC control problems: Illustration by two case studies. Energy Build. 2015, 93, 269–281. [Google Scholar] [CrossRef]

- Atam, E.; Patteeuw, D.; Antonov, S.P.; Helsen, L. Optimal control approaches for analysis of energy use minimization of hybrid ground-coupled heat pump systems. IEEE Trans. Control Syst. Technol. 2015, 24, 525–540. [Google Scholar] [CrossRef]

- De Ridder, F.; Diehl, M.; Mulder, G.; Desmedt, J.; Bael, J.V. An optimal control algorithm for borehole thermal energy storage systems. Energy Build. 2011, 43, 2918–2925. [Google Scholar] [CrossRef]

- Atam, E.; Schulte, D.O.; Arteconi, A.; Sass, I.; Helsen, L. Control-oriented modeling of geothermal borefield thermal dynamics through Hammerstein-Wiener models. Renew. Energy 2018, 120, 468–477. [Google Scholar] [CrossRef]

- Schulte, D.O.; Rühaak, W.; Welsch, B.; Sass, I. BASIMO–borehole heat exchanger array simulation and optimization tool. Energy Procedia 2016, 97, 210–217. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M.; Sengur, A.; Esen, M. Performance prediction of a ground-coupled heat pump system using artificial neural networks. Expert Syst. Appl. 2008, 35, 1940–1948. [Google Scholar] [CrossRef]

- Sundbrandt, M. Control of a Ground Source Heat Pump Using Hybrid Model Predictive Control. Master’s Thesis, Department of Electrical Engineering, Automatic Control, Linköping University, Linköping, Sweden, 2011. [Google Scholar]

- Witte, H.J.; Cazorla-Marín, A.; Corberán, J.M. An efficient borehole heat exchanger model for the analysis of transient thermal response: Comparison with some existing models. In Proceedings of the 14th International Conference on Energy Storage, Adana, Turkey, 25–28 April 2018. [Google Scholar]

- Cupeiro Figueroa, I.; Picard, D.; Helsen, L. Short-term modeling of hybrid geothermal systems for Model Predictive Control. Energy Build. 2019, 25, 1095–1110. [Google Scholar] [CrossRef]

- Cupeiro Figueroa, I.; Drgoňa, J.; Helsen, L. State estimators applied to a linear white-box geothermal borefield controller model. In Proceedings of the International Building Simulation Conference 2019, Rome, Italy, 3–5 September 2019. [Google Scholar]

- Cupeiro Figueroa, I.; Cimmino, M.; Drgoňa, J.; Helsen, L. Fluid temperature predictions of geothermal borefields using load estimations via state observer. J. Build. Perform. Simul. 2020. [Google Scholar] [CrossRef]

- Cimmino, M. Pygfunction: An Open-Source Toolbox for the Evaluation of Thermal Response Factors for Geothermal Borehole Fields; Département de Génie Mécanique, Polytechnique Montréal: Montreal, QC, Canada, 2018. [Google Scholar]

- Cimmino, M.; Bernier, M. A semi-analytical method to generate g-functions for geothermal bore fields. Int. J. Heat Mass Transf. 2014, 70, 641–650. [Google Scholar] [CrossRef]

- Cimmino, M. Fast calculation of the g-functions of geothermal borehole fields using similarities in the evaluation of the finite line source solution. J. Build. Perform. Simul. 2018, 11, 655–668. [Google Scholar] [CrossRef]

- Bernier, M.A.; Pinel, P.; Labib, R.; Paillot, R. A multiple load aggregation algorithm for annual hourly simulations of GCHP systems. HVAC R Res. 2004, 10, 471–487. [Google Scholar] [CrossRef]

- Claesson, J.; Javed, S. A load-aggregation method to calculate extraction temperatures of borehole heat exchangers. Ashrae Trans. 2012, 118, 530–539. [Google Scholar]

- Weeratunge, H.; Narsilio, G.; de Hoog, J.; Dunstall, S.; Halgamuge, S. Model predictive control for a solar assisted ground source heat pump system. Energy 2018, 152, 974–984. [Google Scholar] [CrossRef]

- Ingersoll, L.; Plass, H. Theory of the ground pipe source for the heat pump. Ashrae Trans. 1948, 54, 339–348. [Google Scholar]

- Laferrière, A.; Cimmino, M. Model predictive control applied to residential self-assisted ground source heat pumps. In Proceedings of the International Ground Source Heat Pump Association Research Track, Stockholm, Sweden, 18–20 September 2018. [Google Scholar]

- Laferrière, A.; Cimmino, M. Linear model predictive control for the reduction of auxiliary electric heating in residential self-assisted ground-source heat pump systems. Sci. Technol. Built Environ. 2019, 25, 1095–1110. [Google Scholar] [CrossRef]

- Antonov, S. Should the optimization horizon in optimal control of ground-coupled heat-pump systems cover the interseasonal time scale? Ashrae Trans. 2014, 120, 346. [Google Scholar]

- Heating and Cooling Degree Days—European Environment Agency. Available online: https://www.eea.europa.eu/data-and-maps/indicators/heating-degree-days-2 (accessed on 19 May 2020).

- Picard, D.; Jorissen, F.; Helsen, L. Methodology for obtaining linear state space building energy simulation models. In Proceedings of the 11th International Modelica Conference, Versailles, France, 21–23 September 2015; pp. 51–58. [Google Scholar]

- Fritzson, P.; Engelson, V. Modelica—A Unified Object-Oriented Language for System Modeling and Simulation; Springer: Berlin/Heidelberg, Germany, 1998; pp. 67–90. [Google Scholar]

- Wetter, M.; Fuchs, M.; Grozman, P.; Helsen, L.; Jorissen, F.; Müller, D.; Nytsch-Geusen, C.; Picard, D.; Sahlin, P.; Thorade, M. IEA EBC annex 60 modelica library-an international collaboration to develop a free open-source model library for buildings and community energy systems. In Proceedings of the Building Simulation 2015, Hyderabad, India, 7–9 December 2015; pp. 395–402. [Google Scholar]

- Jorissen, F.; Reynders, G.; Baetens, R.; Picard, D.; Saelens, D.; Helsen, L. Implementation and Verification of the IDEAS Building Energy Simulation Library. J. Build. Perform. Simul. 2018, 11, 669–688. [Google Scholar] [CrossRef]

- Method for Calculation of the Design Heat Load—Part 1: Space Heating Load; International Organization for Standardization: Geneva, Switzerland, 2017.

- Picard, D.; Helsen, L. A new hybrid model for borefield heat exchangers performance evaluation. In Proceedings of the 2014 ASHRAE Annual Conference, Seattle, WA, USA, 28 June–2 July 2014. [Google Scholar]

- Laferrière, A.; Cimmino, M.; Picard, D.; Helsen, L. Development and validation of a full-time-scale semi-analytical model for the short- and long-term simulation of vertical geothermal bore fields. Geothermics 2020, 86, 101788. [Google Scholar] [CrossRef]

- Leonard, B. A stable and accurate convective modelling procedure based on quadratic upstream interpolation. Comput. Methods Appl. Mech. Eng. 1979, 19, 59–98. [Google Scholar] [CrossRef]

- Incropera, F.P.; Lavine, A.S.; Bergman, T.L.; DeWitt, D.P. Heat Exchanger Analysis: The Effectiveness-NTU Method. In Fundamentals of Heat and Mass Transfer; Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Wetter, M. Fan and pump model that has a unique solution for any pressure boundary condition and control signal. In Proceedings of the 13th Conference of International Building Performance Simulation Association, Chambéry, France, 25–28 August 2013; pp. 3505–3512. [Google Scholar]

- Åkesson, J. Optimica—An extension of modelica supporting dynamic optimization. In Proceedings of the 6th International Modelica Conference, Bielefeld, Germany, 3–4 March 2008; pp. 57–66. [Google Scholar]

- Jorissen, F.; Boydens, W.; Helsen, L. TACO, an automated toolchain for model predictive control of building systems: Implementation and verification. J. Build. Perform. Simul. 2019, 12, 180–192. [Google Scholar] [CrossRef]

- Andersson, J.; Åkesson, J.; Diehl, M. CasADi: A symbolic package for automatic differentiation and optimal control. In Recent Advances in Algorithmic Differentiation; Springer: Berlin/Heidelberg, Germany, 2012; pp. 297–307. [Google Scholar] [CrossRef]

- Heating & Cooling Degree Days—Free Worldwide Data Calculation. Available online: https://www.degreedays.net/ (accessed on 6 June 2020).

| Element | k [W/mK] | t [m] | U [W/mK] | [kg/m] | [J/kgK] |

|---|---|---|---|---|---|

| Outer wall | |||||

| Concrete block | 0.51 | 0.20 | 2.55 | 1400 | 1000 |

| Foam insulation | 0.04 | 0.17 | 0.235 | 10 | 1400 |

| Wood siding | 0.14 | 0.01 | 14.0 | 530 | 900 |

| Total | 0.195 | ||||

| Floor | |||||

| Concrete slab | 1.13 | 0.08 | 14.13 | 1400 | 1000 |

| Insulation | 0.04 | 0.20 | 0.2 | 10 | 10 |

| Concrete slab | 1.13 | 0.35 | 3.23 | 1400 | 1000 |

| Total | 0.123 | ||||

| Roof | |||||

| Plasterboard | 0.16 | 0.01 | 16.0 | 950 | 840 |

| Concrete slab | 1.13 | 0.08 | 14.13 | 1400 | 1000 |

| Fibreglass quilt | 0.04 | 0.15 | 0.266 | 12 | 840 |

| Roofdeck | 0.14 | 0.02 | 7.0 | 430 | 900 |

| Total | 0.184 | ||||

| Windows: | U-value: | 1.0 W/mK | g-factor: | 0.598 | |

| 1 | 2 | 3 | |

|---|---|---|---|

| A | 23,152 | 522.3 | −51.7 |

| B | 17,138 | 522.0 | −170.5 |

| C | −34.59 | 0.138 | 0.0071 |

| Borehole Parameters | Piping Parameters | ||||||

| Notation | Description | Value | Unit | Notation | Description | Value | Unit |

| Borehole radius | 75.0 | mm | Pipe radius | 20.0 | mm | ||

| Borehole height | 125.0 | m | Pipe conductivity | 0.5 | W/(mK) | ||

| Borehole burial depth | 0 | m | Pipe thickness | 2.0 | mm | ||

| Number of boreholes | 4 | - | Pipe spacing | 80.0 | mm | ||

| Ground Parameters | Grout Parameters | ||||||

| Notation | Description | Value | Unit | Notation | Description | Value | Unit |

| Ground conductivity | 2.0 | W/(mK) | Grout conductivity | 1.15 | W/(mK) | ||

| Ground heat capacity | 1200 | J/(kgK) | Grout heat capacity | 800 | J/(kgK) | ||

| Ground density | 1800 | kg/m | Grout density | 1600 | kg/m | ||

| Undisturbed ground temperature | 10 | C | |||||

| Geothermal gradient | 0.01 | C/m | |||||

| Notation | Description | Value | Unit |

|---|---|---|---|

| GSHP nominal capacity | 26 | kW | |

| Auxiliary system nominal power | 40 | kW | |

| Heat exchanger heat transfer coefficient | 10,000 | W/K | |

| Pump nominal pressure drop | 120 | kPa | |

| Pump nominal mass flow rate | 1.6 | kg/s | |

| Pump nominal power | 400 | W |

| Interval No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MPC (N) | ||||||||||||||

| Interval size | 1 h | 1 h | 1 h | 1 h | 2 h | 2 h | 4 h | 4 h | 8 h | 12 h | 12 h | 24 h | 48 h | 48 h |

| Time elapsed | 1 h | 2 h | 3 h | 4 h | 6 h | 8 h | 12 h | 16 h | 1 d | 1.5 d | 2 d | 3 d | 5 d | 7 d |

| Shadow cost (N) | ||||||||||||||

| Interval size | 1 w | 1 w | 1 w | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m |

| Time elapsed | 2 w | 3 w | 1 m | 2 m | 3 m | 4 m | 5 m | 6 m | 7 m | 8 m | 9 m | 10 m | 11 m | 12 m |

| Strategy 1: | Strategy 2: | Strategy 3: | ||

|---|---|---|---|---|

| Key Performance Indicator | Unit | MPC | MPC + RBC | MPC + Shadow Cost |

| GSHP condenser energy use | MWh | 380.01 | 401.18 | 398.85 |

| GSHP compressor energy use | MWh | 70.27 | 73.89 | 73.20 |

| SCOP | − | 5.41 | 5.43 | 5.45 |

| Auxiliary (thermal) energy use | MWh | 93.01 | 72.23 | 73.29 |

| Regeneration pump energy use | MWh | ~0 | 8.88 | 1.00 |

| Regenerated energy | MWh | 0.28 | 148.85 | 137.45 |

| Total operational costs | $ | 33,309 | 31,623 | 30,090 |

| Average number of iterations | − | 48.19 | 49.36 | 72.95 |

| Average time per iteration | s | 0.0115 | 0.0088 | 0.0311 |

| Interval No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Strategy 3 | ||||||||||||||

| Interval size | 1 w | 1 w | 1 w | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1 m | 1m |

| Time elapsed | 2 w | 3 w | 1 m | 2 m | 3 m | 4 m | 5 m | 6 m | 7 m | 8 m | 9 m | 10 m | 11 m | 12 m |

| Strategy 3b | ||||||||||||||

| Interval size | 1 w | 1 w | 1 w | 1 w | 1 w | 1 w | 1 w | 1 w | 1 w | 1 w | 1 w | 1 m | 1 m | 1 m |

| Time elapsed | 2 w | 3 w | 4 w | 5 w | 6 w | 7 w | 8 w | 9 w | 10 w | 11 w | 3 m | 4 m | 5 m | 6 m |

| Strategy 3c | ||||||||||||||

| Interval size | 1 w | 1 w | 1 w | 1 m | 1 m | 1 m | 1 m | 1 m | ||||||

| Time elapsed | 2 w | 3 w | 1 m | 2 m | 3 m | 4 m | 5 m | 6 m | ||||||

| Key Performance Indicator | Unit | Strategy 3 | Strategy 3b | Strategy 3c |

|---|---|---|---|---|

| GSHP condenser energy use | MWh | 398.85 | 398.65 | 398.21 |

| GSHP compressor energy use | MWh | 73.20 | 73.24 | 73.13 |

| SCOP | − | 5.45 | 5.45 | 5.45 |

| Auxiliary (thermal) energy use | MWh | 73.29 | 74.18 | 74.43 |

| Regeneration pump energy use | MWh | 1.00 | 0.69 | 0.66 |

| Regenerated energy | MWh | 137.45 | 130.69 | 129.48 |

| Total operational costs | $ | 30,090 | 30,214 | 30,239 |

| Average number of iterations | − | 72.95 | 72.82 | 61.01 |

| Average time per iteration | s | 0.0311 | 0.0312 | 0.0268 |

| Key Performance Indicator | Unit | Strategy 3 | Strategy 3d | Strategy 3e |

|---|---|---|---|---|

| GSHP condenser energy use | MWh | 398.85 | 398.24 | 397.45 |

| GSHP compressor use | MWh | 73.20 | 73.10 | 73.08 |

| SCOP | − | 5.45 | 5.45 | 5.45 |

| Auxiliary (thermal) energy use | MWh | 73.29 | 73.54 | 75.26 |

| Regeneration pump energy use | MWh | 1.00 | 1.06 | 0.26 |

| Regenerated energy | MWh | 137.45 | 137.85 | 118.28 |

| Total operational costs | $ | 30,090 | 30,132 | 30,316 |

| Average number of iterations | − | 72.95 | 73.64 | 74.76 |

| Average time per iteration | s | 0.0311 | 0.0314 | 0.0329 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cupeiro Figueroa, I.; Cimmino, M.; Helsen, L. A Methodology for Long-Term Model Predictive Control of Hybrid Geothermal Systems: The Shadow-Cost Formulation. Energies 2020, 13, 6203. https://doi.org/10.3390/en13236203

Cupeiro Figueroa I, Cimmino M, Helsen L. A Methodology for Long-Term Model Predictive Control of Hybrid Geothermal Systems: The Shadow-Cost Formulation. Energies. 2020; 13(23):6203. https://doi.org/10.3390/en13236203

Chicago/Turabian StyleCupeiro Figueroa, Iago, Massimo Cimmino, and Lieve Helsen. 2020. "A Methodology for Long-Term Model Predictive Control of Hybrid Geothermal Systems: The Shadow-Cost Formulation" Energies 13, no. 23: 6203. https://doi.org/10.3390/en13236203

APA StyleCupeiro Figueroa, I., Cimmino, M., & Helsen, L. (2020). A Methodology for Long-Term Model Predictive Control of Hybrid Geothermal Systems: The Shadow-Cost Formulation. Energies, 13(23), 6203. https://doi.org/10.3390/en13236203