Optimal Design of High-Frequency Induction Heating Apparatus for Wafer Cleaning Equipment Using Superheated Steam

Abstract

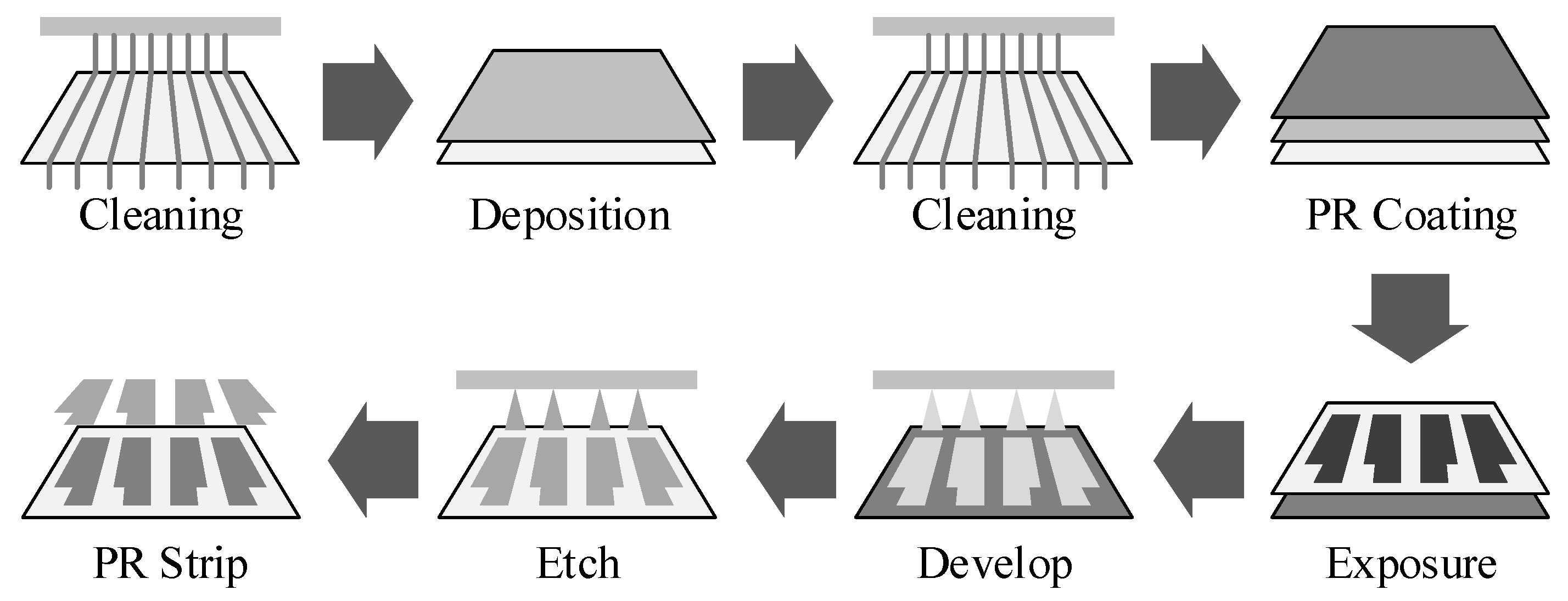

1. Introduction

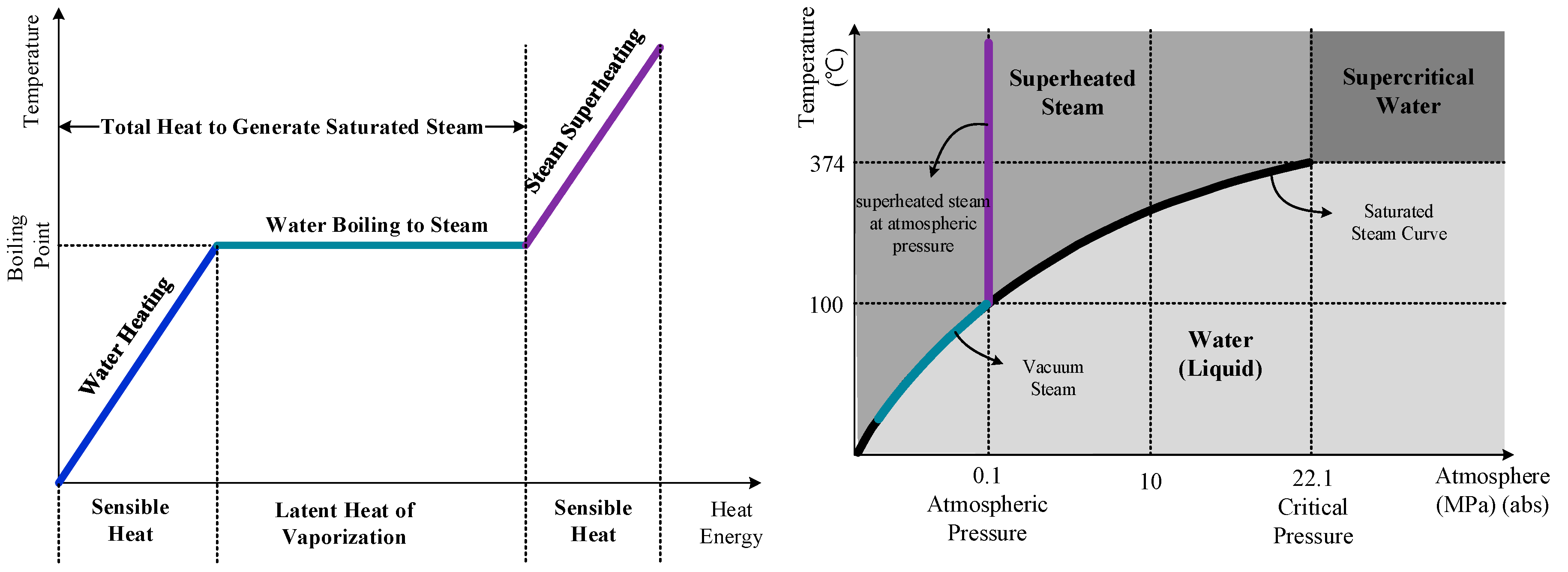

2. Analysis of Specific Enthalpy Steam and Titanium Characterization

2.1. Calculation of Steam Heat Capacity

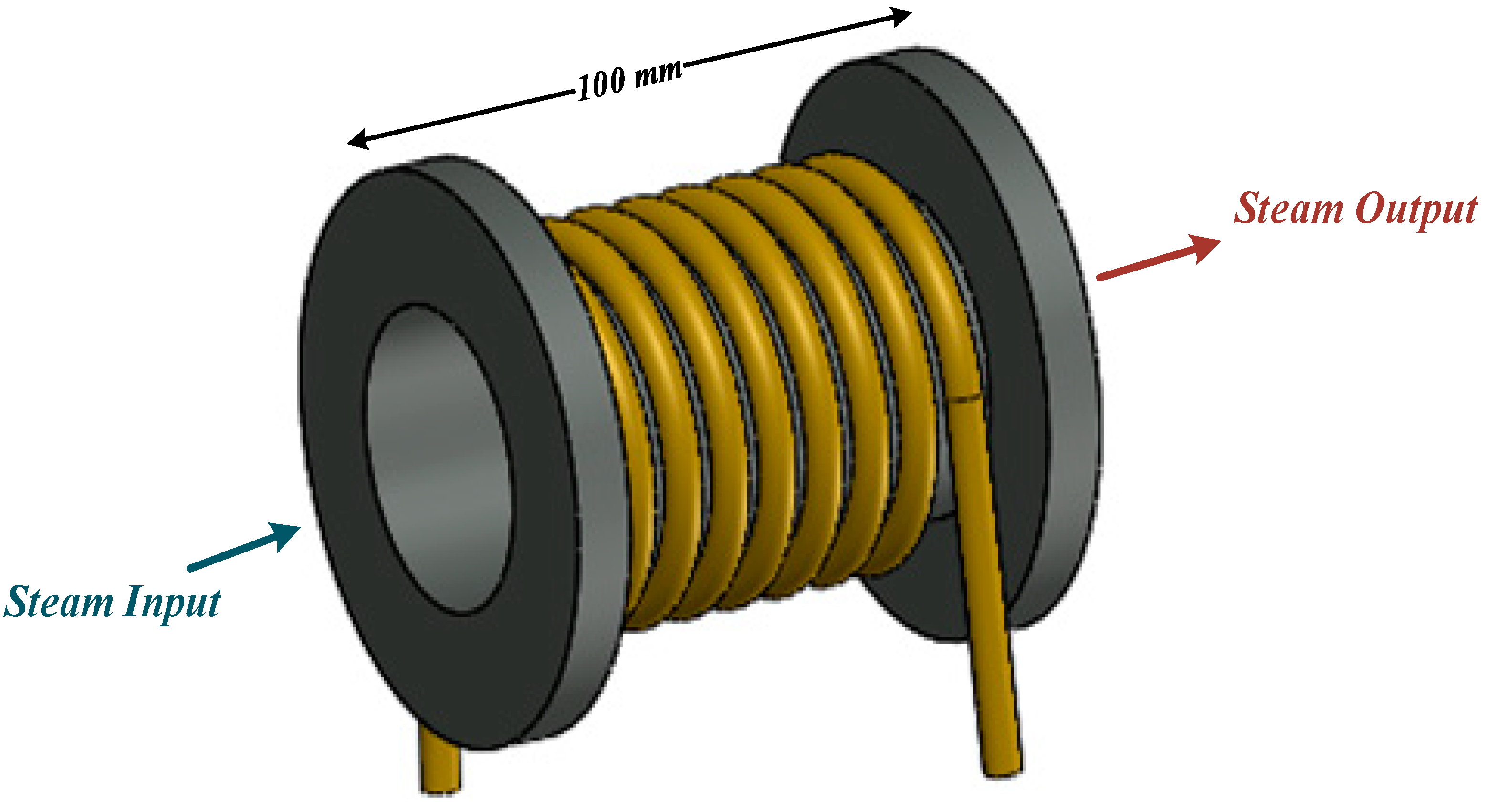

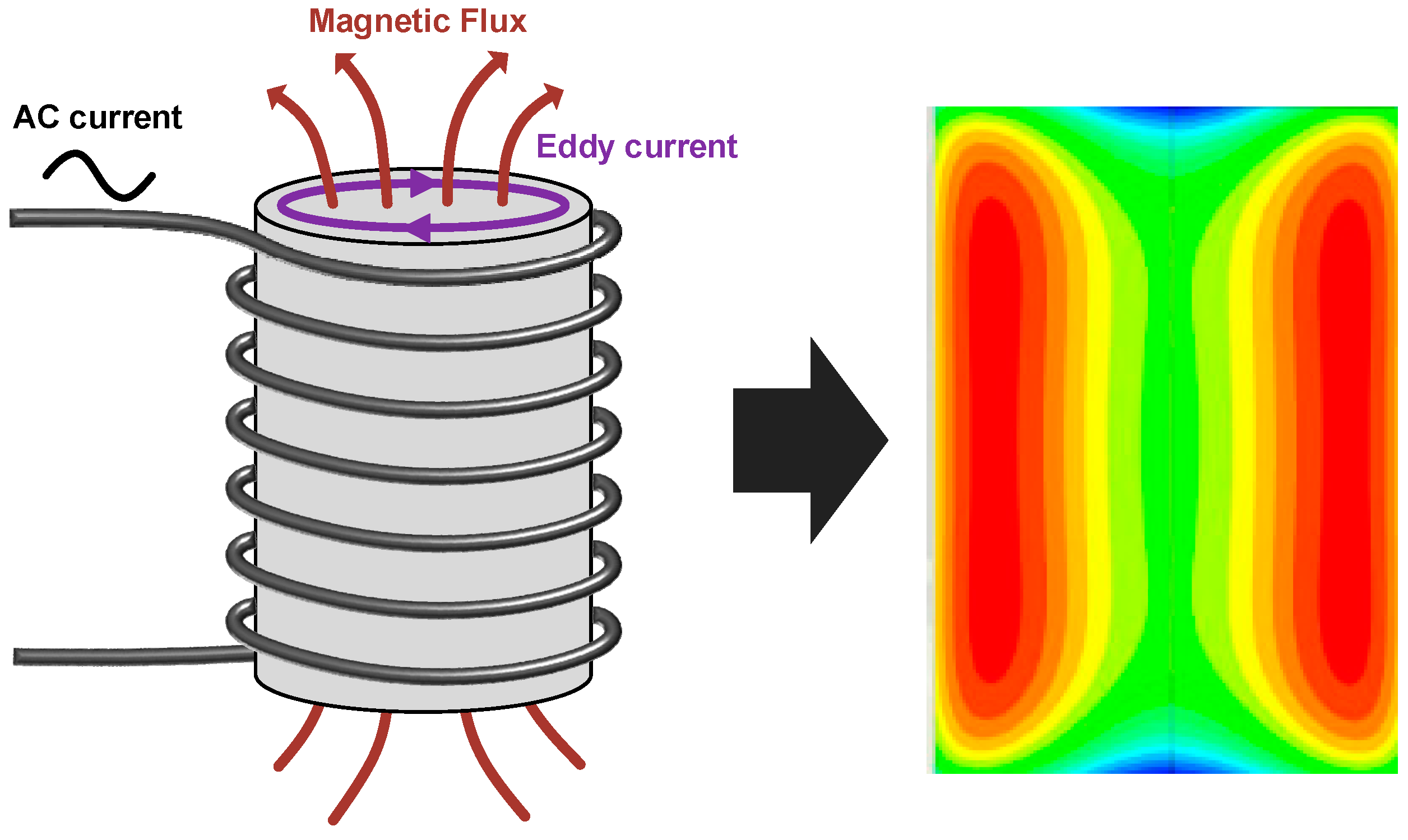

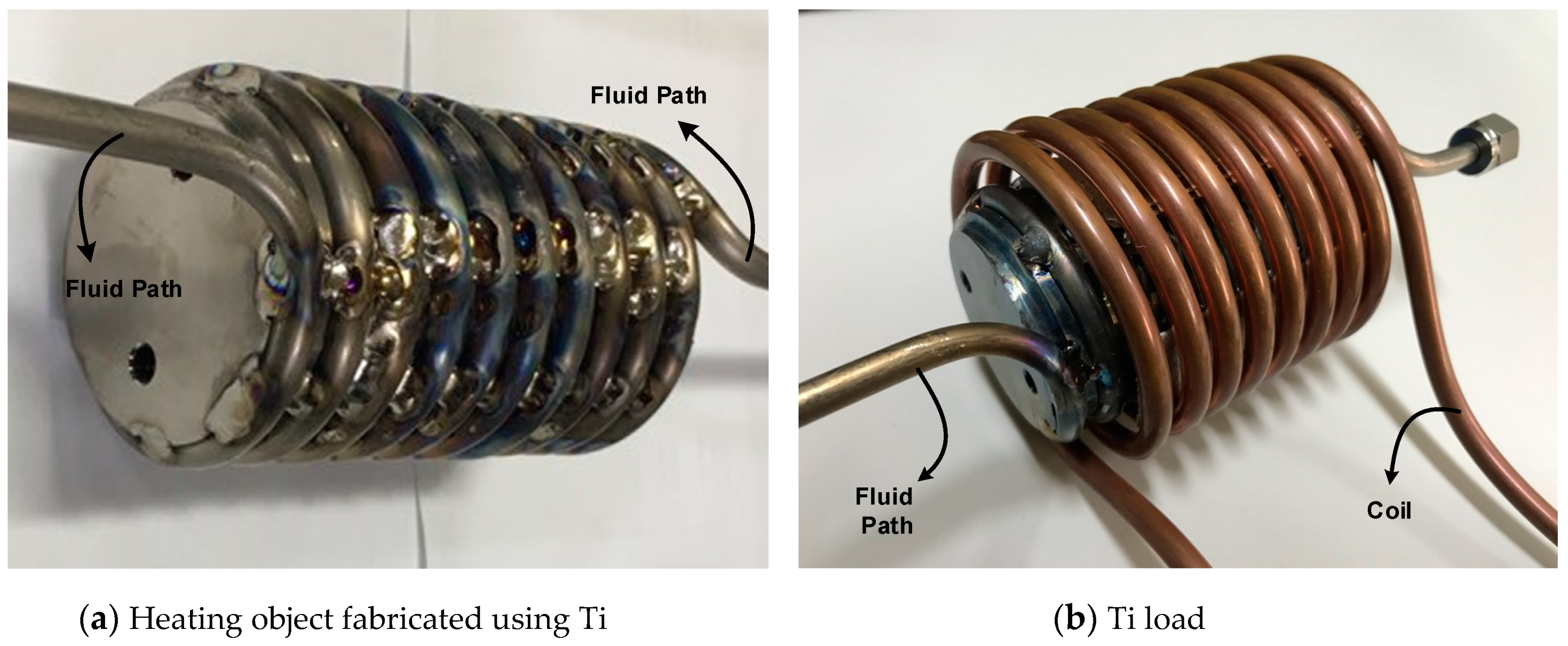

2.2. Design and Implementation of the Heating Object for Rapid Induction Heating

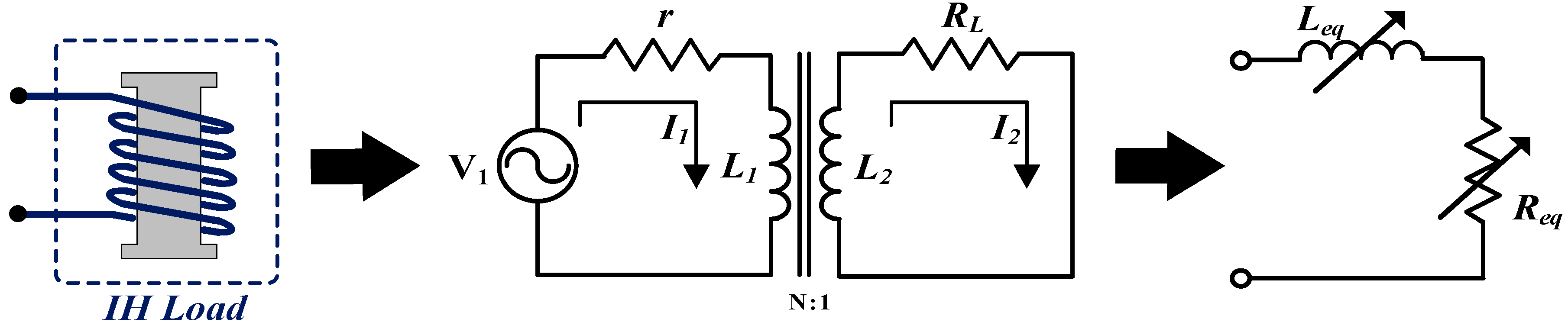

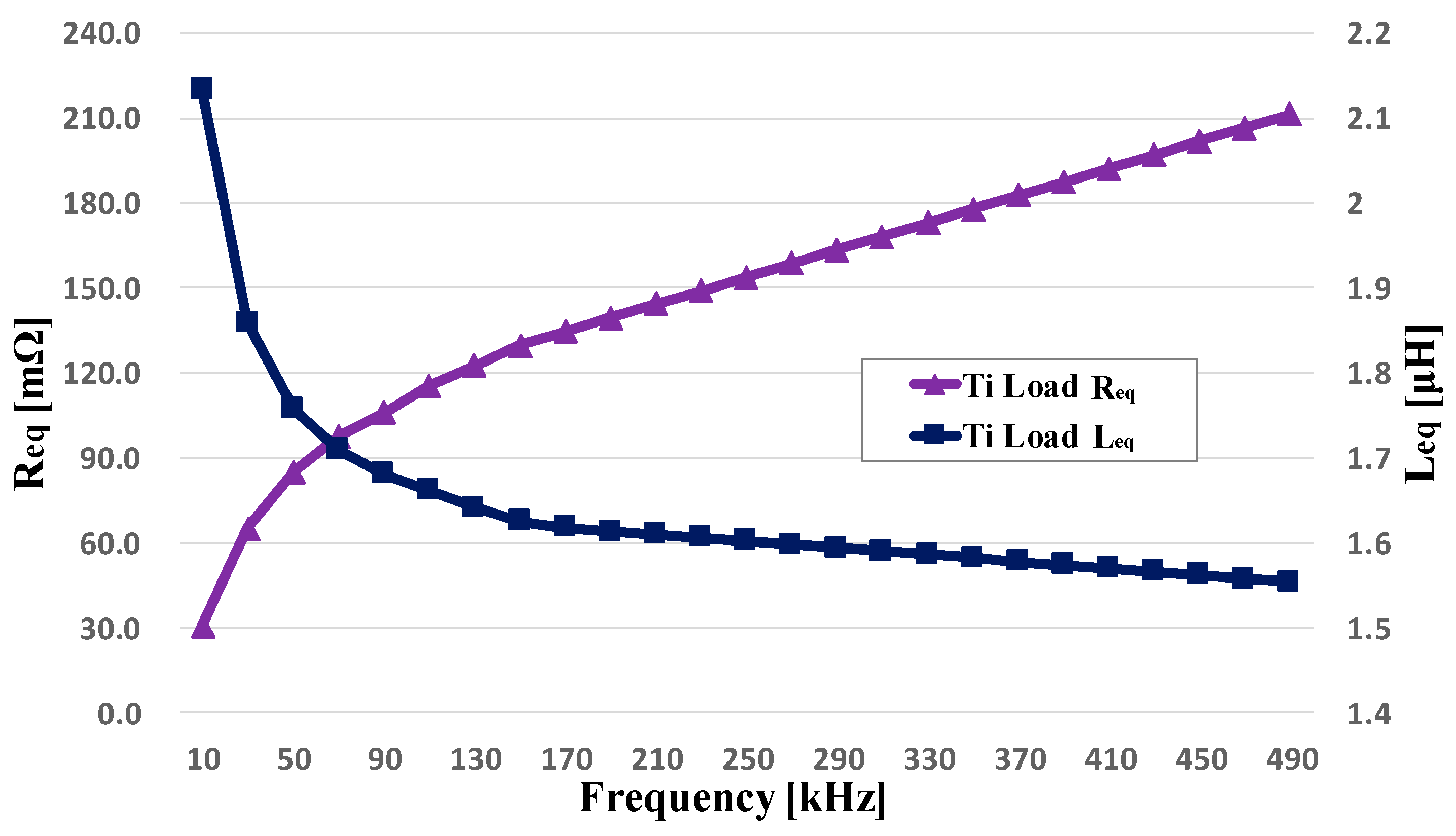

2.3. Parameter Analysis of the Titanium Load

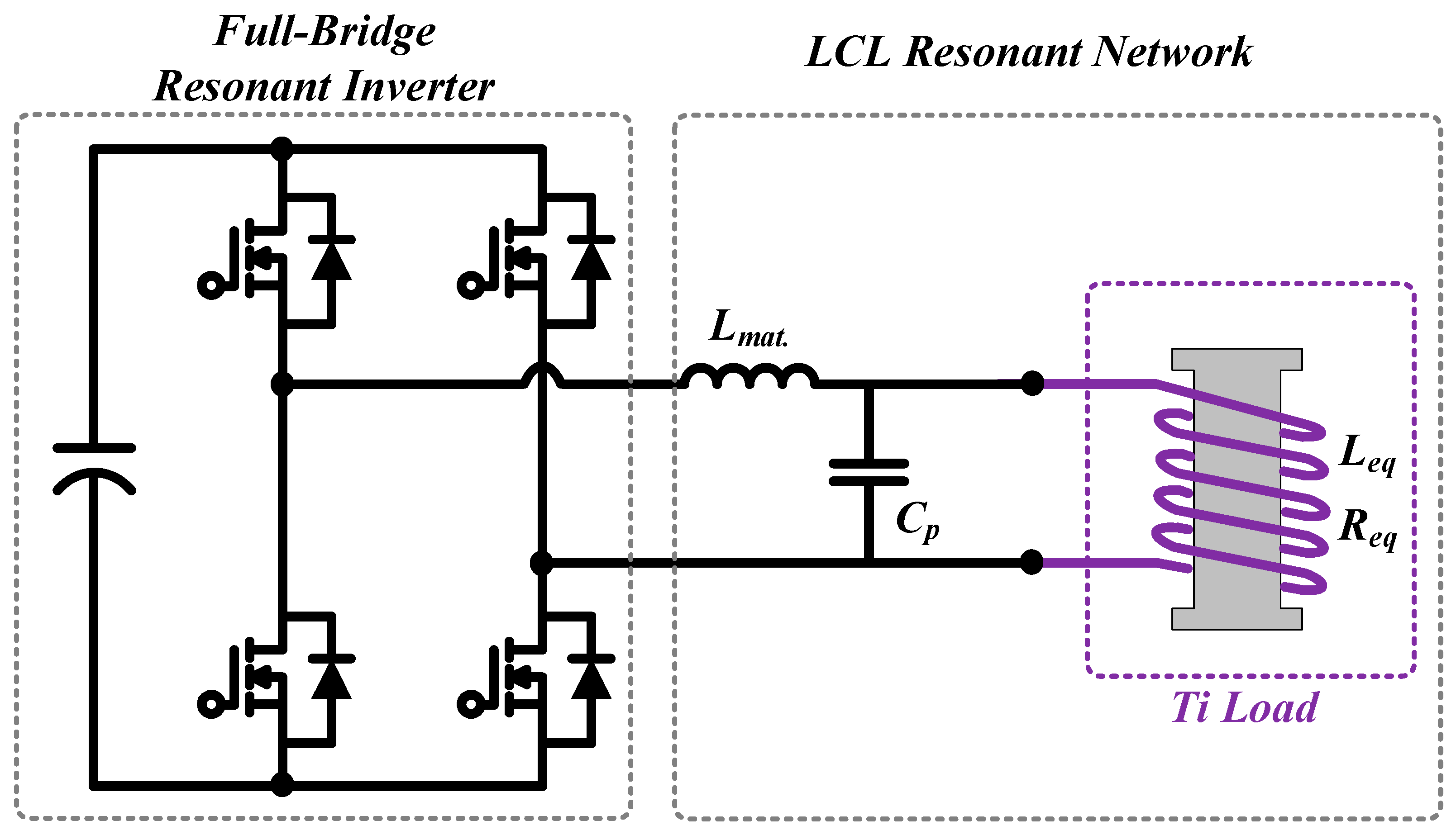

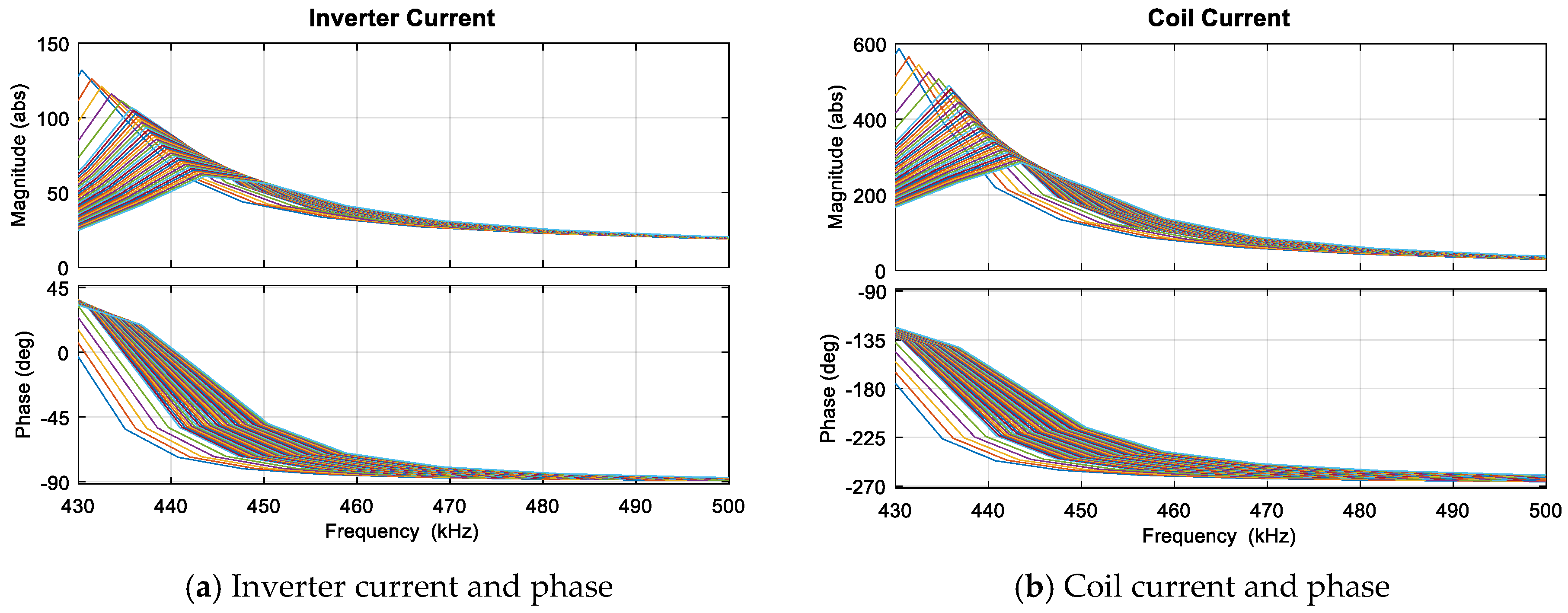

2.4. Design of Electric Power Converter Specifications and Simulation Verification

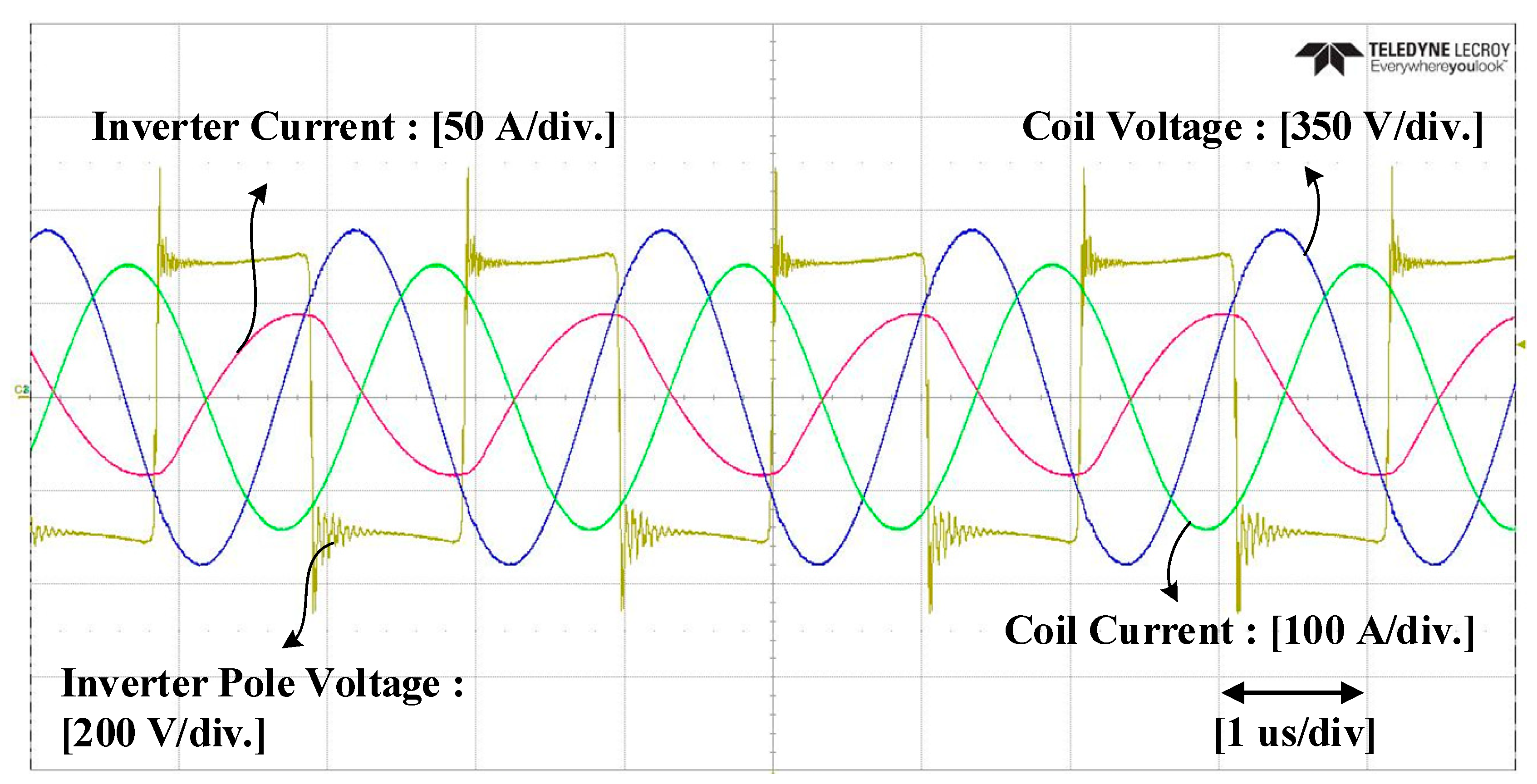

3. Experimental Verification

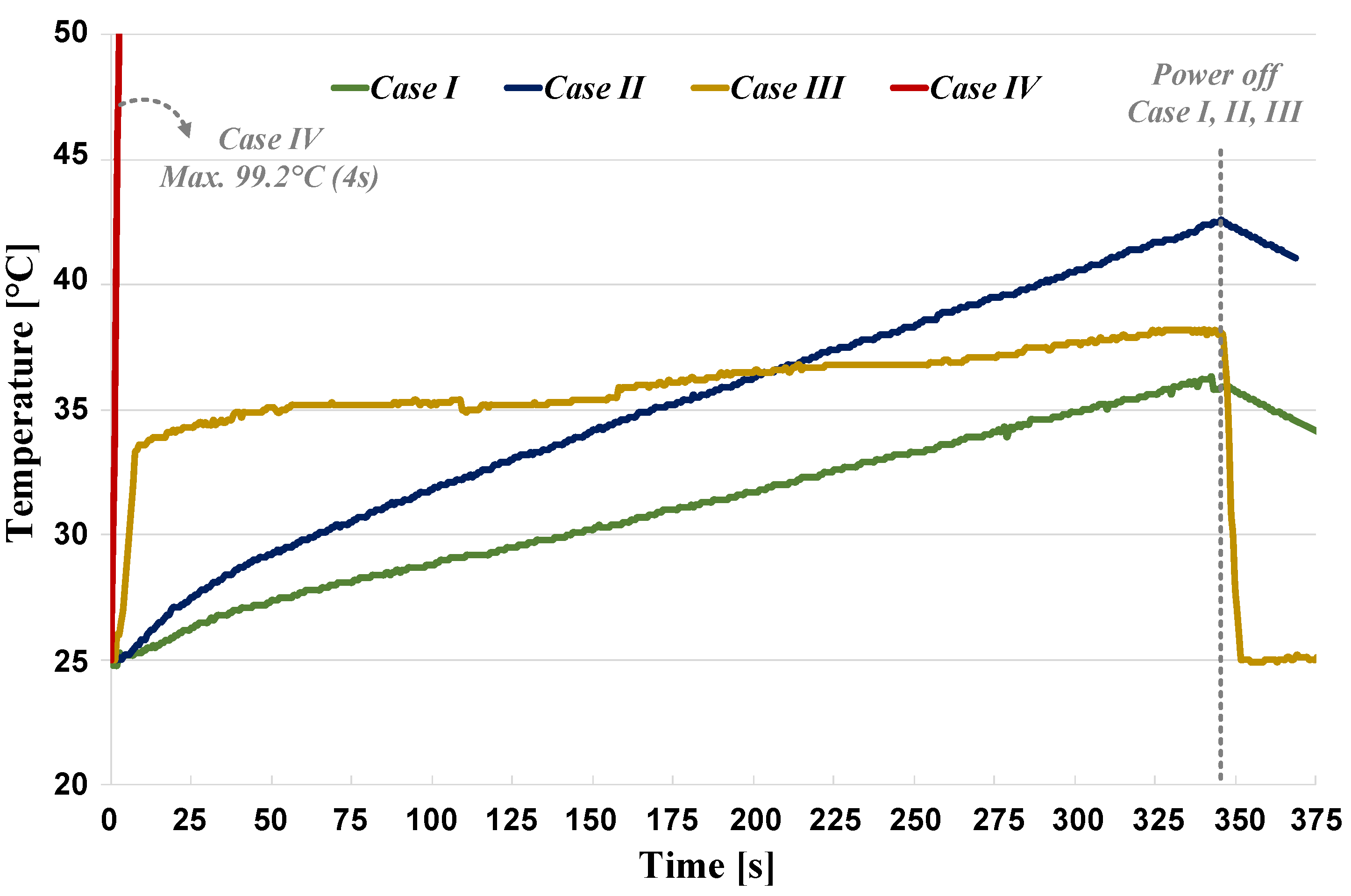

3.1. Preliminary Experiment Using a Water Chiller System

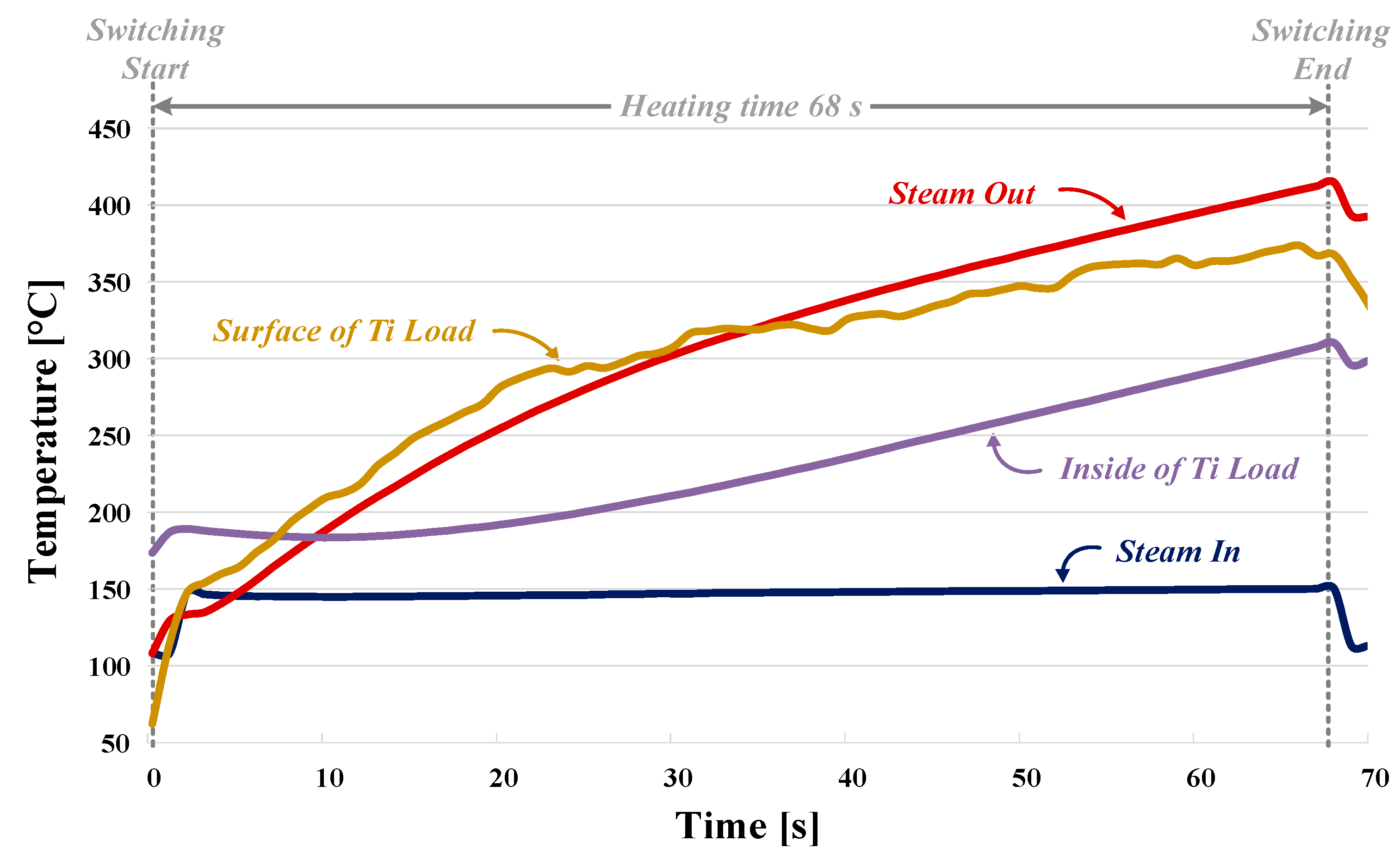

3.2. SHS Generation Heating Test Bed

- Saturated steam that was heated to generate SHS, supplied by preheating the water using a quartz heater.

- The instantaneous input and output steam temperatures of the Ti load were measured using a k-type thermocouple (TC).

- The copper tubing coil of the Ti load and inverter switch were water-cooled using the chiller system.

- The time at which the high-temperature pure SHS to be used in the wafer cleaning process was generated by IH was measured.

3.3. Experimental Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Samadi, H.; Pfeffer, M.; Altmann, R.; Leibold, A.; Gumprecht, T.; Bauer, A. Particle free handling of substrates. IEEE Trans. Semicond. Manuf. 2016, 29, 314–319. [Google Scholar] [CrossRef]

- Lee, J.S.; Jun, P.K.; Lim, H.B. Determination of Metal Contaminants Using Automated In-Situ Metrology in Semiconductor Cleaning Process. IEEE Sens. J. 2011, 11, 1120–1128. [Google Scholar] [CrossRef]

- Nagai, M. Substrate Cleaning Methods for Fabricating OLEDs and Its Effect on Current Leakage Defect Formation. J. Disp. Technol. 2009, 5, 126–132. [Google Scholar] [CrossRef]

- Cui, W.; Liu, W.; Wang, T.; Ma, C. The Application of Atmospheric Pressure Dielectric Barrier Discharge Plasma on the Cleaning of Photovoltaic Panels. IEEE Trans. Plasma Sci. 2017, 45, 328–335. [Google Scholar] [CrossRef]

- Mitsumori, K.; Nobuaki, H.; Takahashi, N.; Imaoka, T.; Ohmi, T. Advanced wet cleaning using novel nozzle and functional ultrapure water in next generation FPD/LSI manufacturing. In Proceedings of the ISSM2000. Ninth International Symposium on Semiconductor Manufacturing (IEEE Cat. No.00CH37130), Tokyo, Japan, 26 September 2000; pp. 329–332. [Google Scholar]

- Ward, P.P. Ultra-fast plasma cleaning as a waste minimization tool and some applications in environmentally conscious manufacturing. In Proceedings of the International Conference on Plasma Science (Papers in Summary from Only Received), Madison, WI, USA, 5–8 June 1995; p. 268. [Google Scholar]

- Sahari, S.K.; Fathi, N.A.F.N.Z.; Sutan, N.M.; Sapawi, R.; Hamzah, A.A.b.; Majlis, B.Y. Wet chemical cleaning effect on the formation of ultrathin interfacial layer between Germanium (Ge) and high-k dielectric. In Proceedings of the 2015 IEEE Regional Symposium on Micro and Nanoelectronics (RSM), Kuala, Terengganu, 19–21 August 2015; pp. 1–3. [Google Scholar]

- Hu, S.; Shiue, A.; Tseng, W.; Leggett, G. Perfluorocompound Emissions Control and Kinetic Characteristics in Point-of-Use Wet-Thermal-Wet Abatement of Plasma-Enhanced Chemical Vapor Deposition Chamber Cleaning. IEEE Trans. Semicond. Manuf. 2018, 31, 302–308. [Google Scholar] [CrossRef]

- Dragonas, F.A.; Neretti, G.; Sanjeevikumar, P.; Grandi, G. High-Voltage High-Frequency Arbitrary Waveform Multilevel Generator for DBD Plasma Actuators. IEEE Trans. Ind. Appl. 2015, 51, 3334–3342. [Google Scholar] [CrossRef]

- Liu, H.; Tang, Z.; Yang, K.; Zhang, Y.; Li, H.; Zhu, X. Optical Properties of Arc Spot Plasma for Cleaning Oxide on the Steel Surface. IEEE Trans. Plasma Sci. 2018, 46, 2916–2919. [Google Scholar] [CrossRef]

- Liu, C.; Nishida, Y.; Iwasaki, K.; Sung, W.; Wu, F. Characteristics of DC or Pulsed-Type High-Electric Field Plasma and its Application to Air Cleaning System. IEEE Trans. Plasma Sci. 2019, 47, 1121–1128. [Google Scholar] [CrossRef]

- Jun, Z.; Fei, Y.X.; Hailin, S. A highly reliable cleaning process. In Proceedings of the International Conference on Electronic Packaging Technology (ICEPT), Shanghai, China, 8–11 August 2018; pp. 834–839. [Google Scholar]

- Nakata, K.; Fukui, T.; Nagai, T. Particle Adsorption onto Si-Based Wafers in Ultrapure Water; Its Mechanism and Effect of Carbon Dioxide. IEEE Trans. Semicond. Manuf. 2017, 30, 371–376. [Google Scholar] [CrossRef]

- Ukai, Y. TFT-LCD manufacturing technology—Current status and future prospect. In Proceedings of the 2007 International Workshop on Physics of Semiconductor Devices, Mumbai, India, 16–20 December 2007; pp. 29–34. [Google Scholar]

- Liu, Y.; Zhou, C.; Xiang, W. DE Algorithm Fuzzy Control of Super-Heated Steam Temperature. In Proceedings of the 2016 9th International Symposium on Computational Intelligence and Design (ISCID), Hangzhou, China, 10–11 December 2016; pp. 282–285. [Google Scholar]

- Zhao, W.J.; Niu, Y.U.; Liu, J.Z. Multi-model adaptive control for the superheated steam temperature. In Proceedings of the International Conference on Machine Learning and Cybernetics, Beijing, China, 4–5 November 2002; Volume 1, pp. 269–272. [Google Scholar]

- Kazarinov, L.S.; Shnayder, D.A.; Kolesnikova, O.V. Heat load control in steam boilers. In Proceedings of the 2017 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), St. Petersburg, Russia, 16–19 May 2017; pp. 1–4. [Google Scholar]

- Liplavk, V.M.; Bikbulatov, R.K.; Zyryanov, V.P. Experience and trends in automation of the burning process in steam boilers of Ufa Thermal Power Plants. Electr. Pow. Plants 2011, 3, 16–23. [Google Scholar]

- Han, Z.; He, R.; Xu, Y. Effect of steam pressure fluctuation in turbine steam pipe on stability of power system. In Proceedings of the 2008 Third International Conference on Electric Utility Deregulation and Restructuring and Power Technologies, Nanjing, China, 6–9 April 2008; pp. 1127–1131. [Google Scholar]

- Wei, L.; Fang, F. A novel IMC cascade control structure of super-heated steam temperature system for super-critical coal-fired boilers. In Proceedings of the 2011 Chinese Control and Decision Conference (CCDC), Mianyang, China, 23–25 May 2011; pp. 641–645. [Google Scholar]

- Jin, X.; Sun, J.; Liu, J.; Zhang, L. Design of adaptive internal model for main steam temperature control system based on single neuron. In Proceedings of the Fifth World Congress on Intelligent Control and Automation (IEEE Cat. No. 04EX788), Hangzhou, China, 15–19 June 2004; Volume 4, pp. 3560–3564. [Google Scholar]

- Wang, Q.; Yao, J.; Wang, J. Genetic-Based Active Disturbance Rejection Controller for Super-Heated Steam Temperature Regulation. In Proceedings of the Second International Conference on Genetic and Evolutionary Computing, Jingzhou, China, 25–26 September 2008; pp. 101–104. [Google Scholar]

- Jeong, S.; Park, H.; Jung, J. Design Methodology of 3 kW Induction Heating System for both Low Resistance and High Resistance Containers in a Single Burner. In Proceedings of the 2018 International Power Electronics Conference (IPEC-Niigata 2018 -ECCE Asia), Niigata, Japan, 20–24 May 2018; pp. 289–295. [Google Scholar]

- Wesołowski, M. Induction heating of thin aluminum layers during depolymerization process. In Proceedings of the 2017 Progress in Applied Electrical Engineering (PAEE), Koscielisko, Poland, 25–30 June 2017; pp. 1–4. [Google Scholar]

- Phadungthin, R.; Haema, J. Full bridge resonant inverter for non-ferrous metal induction heating application. In Proceedings of the 2015 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Brisbane, QLD, Australia, 15–18 November 2015. [Google Scholar]

- Tomita, H.; Maruyama, T.; Yoshimura, S.; Takahashi, N. Superheated steam generator by induction heating. In Proceedings of the 2009 13th European Conference on Power Electronics and Applications, Barcelona, Spain, 8–10 September 2009; pp. 1–4. [Google Scholar]

- Makimura, Y.; Tomita, H.; Motegi, S. Improvement of superheated steam generator by induction heating. In Proceedings of the 2010 International Conference on Computer Applications and Industrial Electronics, Kuala Lumpur, Malaysia, 5–8 December 2010; pp. 615–618. [Google Scholar]

- Muhammad, Z.; Rahiman, M.H.F.; Taib, M.N. Characteristic of steam distillation pot with induction heating system based on step test response. In Proceedings of the 2011 IEEE Control and System Graduate Research Colloquium, Shah Alam, Malaysia, 27–28 June 2011; pp. 98–102. [Google Scholar]

- Makulov, I.A.; Alitdinov, A.E. The equipment and application features of induction heating in oil and gas industry. In Proceedings of the 2017 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), St. Petersburg, Russia, 16–19 May 2017; pp. 1–4. [Google Scholar]

- Zhu, T.; Feng, P.; Li, X.; Li, F.; Rong, Y. The Study of the Effect of Magnetic Flux Concentrator to the Induction Heating System Using Coupled Electromagnetic-Thermal Simulation Model. In Proceedings of the 2013 International Conference on Mechanical and Automation Engineering, Jiujang, China, 21–23 July 2013; pp. 123–127. [Google Scholar]

- Cho, K.H. Coupled electro-magneto-thermal model for induction heating process of a moving billet. Int. J. Therm. Sci. 2012, 60, 195–204. [Google Scholar] [CrossRef]

- Kim, D.; So, J.; Kim, D. Study on Heating Performance Improvement of Practical Induction Heating Rice Cooker with Magnetic Flux Concentrator. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- Han, W.; Chau, K.T.; Jiang, C.; Liu, W. All-Metal Domestic Induction Heating Using Single-Frequency Double-Layer Coils. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar]

- Han, W.; Chau, K.T.; Zhang, Z. Flexible induction heating using magnetic resonant coupling. IEEE Trans. Ind. Electron. 2017, 64, 1982–1992. [Google Scholar] [CrossRef]

- Mollov, S.V.; Theodoridis, M.; Forsyth, A.J. High frequency voltage-fed inverter with phase-shift control for induction heating. IEE Proc. Electr. Power Appl. 2004, 151, 12–18. [Google Scholar] [CrossRef]

- Park, T.J.; Kim, T.W.; Han, M.H. Load estimation and effective heating method of LCL-resonant inductive heater. In Proceedings of the 8th International Conference on Power Electronics ECCE Asia, Jeju, Korea, 30 May–3 June 2011; pp. 1576–1578. [Google Scholar]

- Yoo, H.; Shim, E.; Kang, J.; Choi, G.; Lee, C.; Bang, B. 100 kHz IGBT inverter use of LCL topology for high power induction heating. In Proceedings of the 8th International Conference on Power Electronics ECCE Asia, Jeju, Korea, 30 May–3 June 2011; pp. 1572–1575. [Google Scholar]

- Dzieniakowski, M.A. LCL topology variability in the VSI-LCL induction heating system. In Proceedings of the 2014 16th European Conference on Power Electronics and Applications, Lappeenranta, Finland, 26–28 August 2014; pp. 1–7. [Google Scholar]

- Dzieniakowski, M.A.; Fabianowski, J.; Ibach, R. LCL-load modular converter for induction heating. In Proceedings of the 2008 IEEE Power Electronics and Motion Control Conference. (EPE/PEMC), Poznan, Poland, 1–3 September 2008; pp. 2082–2086. [Google Scholar]

- Espi-Huerta, J.M.; Santamaria, E.J.D.G.; Gil, R.G.; Castello-Moreno, J. Design of the L-LC Resonant Inverter for Induction Heating Based on Its Equivalent SRI. IEEE Trans. Ind. Electron. 2007, 54, 3178–3187. [Google Scholar] [CrossRef]

- Deng, L.; Wang, P.; Li, X.; Xiao, H.; Peng, T. Investigation on the Parasitic Capacitance of High Frequency and High Voltage Transformers of Multi-Section Windings. IEEE Access 2020, 8, 14065–14073. [Google Scholar] [CrossRef]

- Borage, M.; Nagesh, K.V.; Bhatia, M.S.; Tiwari, S. Design of LCL-T Resonant Converter Including the Effect of Transformer Winding Capacitance. IEEE Trans. Ind. Electron. 2009, 56, 1420–1427. [Google Scholar] [CrossRef]

| Parameter | Grade 2 Ti | Stainless Steel (SUS304) |

|---|---|---|

| Resistivity [ρ(μΩcm)] | 55 | 72 |

| Relative Permeability [μs] | 1.00018 | 2.291 |

| Thermal Conductivity [Wm−1 K−1] | 0.041 | 0.039 |

| Wafer Cleaning Equipment Spec. | Resonant Network | ||

|---|---|---|---|

| Parameters | Value [Unit] | Parameters | Value [Unit] |

| DC-link Voltage | 280 [V] | Capacitance, Cp | 100 [nF] |

| Input Steam Temp. | 133.25 [°C] | Primary Inductance, Lmat. | 7.5 [μH] |

| Output Steam Temp. | >200 [°C] | Secondary Inductance, Leq | 1.556 [μH] |

| Active Power | 2.2 [kW] | Coil Resistance, Req | 209.1 [mΩ] |

| Coil Current | 100 [Arms] | Coil Conduit Size | 1/4 [inch] |

| Switching Frequency | 465 [kHz] | Coil Turns | 9 [turn] |

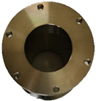

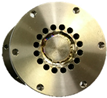

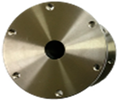

| Picture of Heating Object |  |  |  |  |

|---|---|---|---|---|

| Case | I | II | III | IV |

| Frequency | 435 [kHz] | 452 [kHz] | 480 [kHz] | 465 [kHz] |

| Current | 99.3 [Arms] | 99.2 [Arms] | 98.3 [Arms] | 99.9 [Arms] |

| Heating time | 343 [s] | 343 [s] | 343 [s] | 4 [s] |

| Max. temperature | 36.3 [°C] | 43.4 [°C] | 37.8 [°C] | 99.2 [°C] |

| ΔT/Δt | 0.03 [°C/s] | 0.05 [°C/s] | 0.04 [°C/s] | 18.55 [°C/s] |

| Case | Heating Time | |||||

|---|---|---|---|---|---|---|

| 10 [s] | 20 [s] | 30 [s] | 40 [s] | 50 [s] | 60 [s] | |

| Inside of Ti load | 183.6 [°C] | 191.9 [°C] | 211.1 [°C] | 235.3 [°C] | 262.2 [°C] | 288.9 [°C] |

| Surface of Ti load | 209.3 [°C] | 281.2 [°C] | 307.8 [°C] | 326.1 [°C] | 347.5 [°C] | 363.7 [°C] |

| Steam in | 144.8 [°C] | 145.6 [°C] | 146.9 [°C] | 147.9 [°C] | 148.7 [°C] | 149.5 [°C] |

| Steam out | 201.2 [°C] | 262.9 [°C] | 310.7 [°C] | 344.5 [°C] | 370.8 [°C] | 400.1 [°C] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.M.; Jang, E.; Park, J.S.; Kim, J.-H.; Choi, J.-H.; Lee, B.K. Optimal Design of High-Frequency Induction Heating Apparatus for Wafer Cleaning Equipment Using Superheated Steam. Energies 2020, 13, 6196. https://doi.org/10.3390/en13236196

Park SM, Jang E, Park JS, Kim J-H, Choi J-H, Lee BK. Optimal Design of High-Frequency Induction Heating Apparatus for Wafer Cleaning Equipment Using Superheated Steam. Energies. 2020; 13(23):6196. https://doi.org/10.3390/en13236196

Chicago/Turabian StylePark, Sang Min, Eunsu Jang, Joon Sung Park, Jin-Hong Kim, Jun-Hyuk Choi, and Byoung Kuk Lee. 2020. "Optimal Design of High-Frequency Induction Heating Apparatus for Wafer Cleaning Equipment Using Superheated Steam" Energies 13, no. 23: 6196. https://doi.org/10.3390/en13236196

APA StylePark, S. M., Jang, E., Park, J. S., Kim, J.-H., Choi, J.-H., & Lee, B. K. (2020). Optimal Design of High-Frequency Induction Heating Apparatus for Wafer Cleaning Equipment Using Superheated Steam. Energies, 13(23), 6196. https://doi.org/10.3390/en13236196