Abstract

The paper presents the results of the pelletization (agglomeration) tests of post-harvest tobacco waste as a feedstock for fuel pellet production. The experiment was conducted on a prototype pelleting–briquetting device with a flat matrix. The influence of the tobacco waste moisture content (17, 21 and 25wt.%) and the rotational speed of the agglomerating rolls (120, 170 and 220 rpm) on the power demand and on the pellet’s kinetic durability and density were determined. It was found that the moisture content has a significant impact on the pellet’s density but slightly affects its kinetic durability. The obtained pellets were characterized by a high density above 1000 kg·m−3 and kinetic durability above 97%. In order to examine the exhaust composition, the obtained pellets were combusted in a 25 kW fixed great boiler. High amounts of CO, SOx, NO and HCl were obtained, which suggests that the selection of a different technology for tobacco waste pellet combustion should be made.

1. Introduction

Today, the growing energy demand and the need for a significant reduction of greenhouse gas emissions are some of the main reasons for an intensive search for alternative, clean and cheap energy sources [1,2,3]. Increasingly, waste biomass is considered as an attractive solution for these requirements [3,4,5]. Popular research objects in this area are shells and husks [6,7], fruit stones [8,9], stovers [10], straw [11,12], pomace [13,14] etc. According to FAO (Food and Agriculture Organization of the United Nations) [15], in 2018, the worldwide production of tobacco reached over 6 million tonnes, of which 25% is considered as harvest and production waste [16,17]. Tobacco waste disposed in landfills may result in ground and water pollution, caused by several chemicals applied to the plant during its growth [18,19]. Therefore, the possibilities of its use as a substrate for thermal processes are being investigated. Tobacco stalks are one of the types of waste material obtained during the production of tobacco leaves [19]. Czerwińska et al. [20] reported that tobacco stalks are 40% cellulose; moreover, their mass constitutes up to 45% of the total plant dry mass over-ground. Cai et al. [21] investigated the carbonization behavior of tobacco stalks and hydrochar produced from tobacco stalks, by means of thermogravimetry, finding higher values of activation energy for hydrochars (caused by the higher contents of fixed carbons in hydrochars). Pyrolysis experiments with tobacco stalks conducted by Strezov et al. [22] showed that the biochars produced were particularly rich in potassium. According to Yang et al. [23], tobacco waste may contain more ash and nitrogen than other types of lignocellulosic biomass. During high-temperature processes, the nitrogen contained in fuels is emitted in the form of harmful NOx oxides [24]; a high ash content may contribute to slag deposition in the boiler, which hinders heat transfer and results in the accelerated wear of the metal elements of the installation due to corrosion [25]. This problem can be solved by using fuel mixtures of tobacco waste and higher-quality biomass or fossil fuels [26]. Cong et al. [27] confirmed that metal salts, which tobacco stalks are rich in, could work as catalysts in the co-combustion processes and improve the process efficiency. It should be emphasised that most of available research papers detail the problem of tobacco stalk thermal utilization with the use of instrumental methods, mainly thermogravimetry (TGA). The obtained results are important due to the valuable data received, which may become the design assumptions for combustion and pyrolysis installations [28]. In order to more precisely determine the suitability of a given fuel for its use in a particular installation, real-scale tests should also be carried out. The problem that arises during the energetic use of tobacco stalks is their low homogeneity, which primarily hinders the stability and automation of the thermal process. A solution enabling the use of agri-food production waste in prosumer and small-scale energetic installations is supplying them in the form of pellets [29]. The pelletization process, as a result of internal and external forces, allows obtaining a product in a solid geometric form. The material restrictions for the process are often a too-high [30] or too-low moisture content [6], high fat content [8] or large particle size [31]. In connection with the above, agri-food waste must be properly prepared before the pelletization process, e.g., by wetting, drying or adding binder materials. The operations preparing the material for pelletization must be optimized to obtain a high-quality product (pellet), with the possible reduction of the process energy consumption.

In reference to the above, Serrano et al. [32] assessed the mechanical strength, density, length and moisture of granules from barley straw and barley straw mixed with pine sawdust and reported that with the addition of pine sawdust, the pellet’s kinetic durability increased. Mediavilla and colleagues [33], by compacting various mixtures of vine shoots and cork, found that with an increase in the addition of industrial waste cork to vine shoots, the energy consumption of granulation decreased, and the ash content decreased during the combustion of the obtained pellets. Nasrin et al. [34] examined the physical properties of briquettes from oil palm waste and concluded that the fragmentation and mixing of seed nests, fibers and grains improves the quality properties of the obtained briquette and at the same time decreases the briquetting process energy consumption. Stahl and Berghel [35] produced fuel pellets composed of sawdust and turnip waste. The turnip waste was obtained in the production of turnip oil. In the investigation, it was found that with an increase in the content of turnip waste, the pellet’s mechanical durability and density decreased. Miranda et al. [36] characterized pellets made from grape pomace and found that up on the addition of Pyrenean oak, the durability and bulk density were improved. In other work, Miranda and colleagues [37] compacted olive pulp waste produced in the production of oil, and they found that the addition of Pyrenean oak waste to the olive pulp ensured a more effective granulating of the mixture and also improved the kinetic durability of the products. Obidziński et al. [38] claimed that tobacco waste most preferably should be pelletized at temperatures above 70 °C to obtain a high-density pellet with the optimal pelletizer’s energy consumption. Reducing the power demand of tobacco waste pelletization is also possible with the use of a binder in the form of potato pulp. The starch contained in the pulp, under the high temperature of the process, gelatinizes and thus binds together the particles of the material; moreover, the moisture contained in it, acting as a lubricant, reduces friction in the holes of the pelletizer’s matrix, directly affecting (decreasing) the energy consumption of the process.

The aim of the study was to determine the usefulness of post-harvest tobacco waste as a feedstock material for fuel pellet production. The scope of the work involved testing the influence of the material (moisture content) and process (rotational speed of compacting rolls) conditions on the density and kinetic durability of the obtained pellets and on the power demand of the pelletizing system. Moreover, the ultimate analysis, high heating value (HHV) and low heating value (LHV) of the obtained products were investigated. Subsequently, tobacco stalk pellets were combusted in a prosumer-scale installation, and the flue gas composition was determined.

2. Materials and Methods

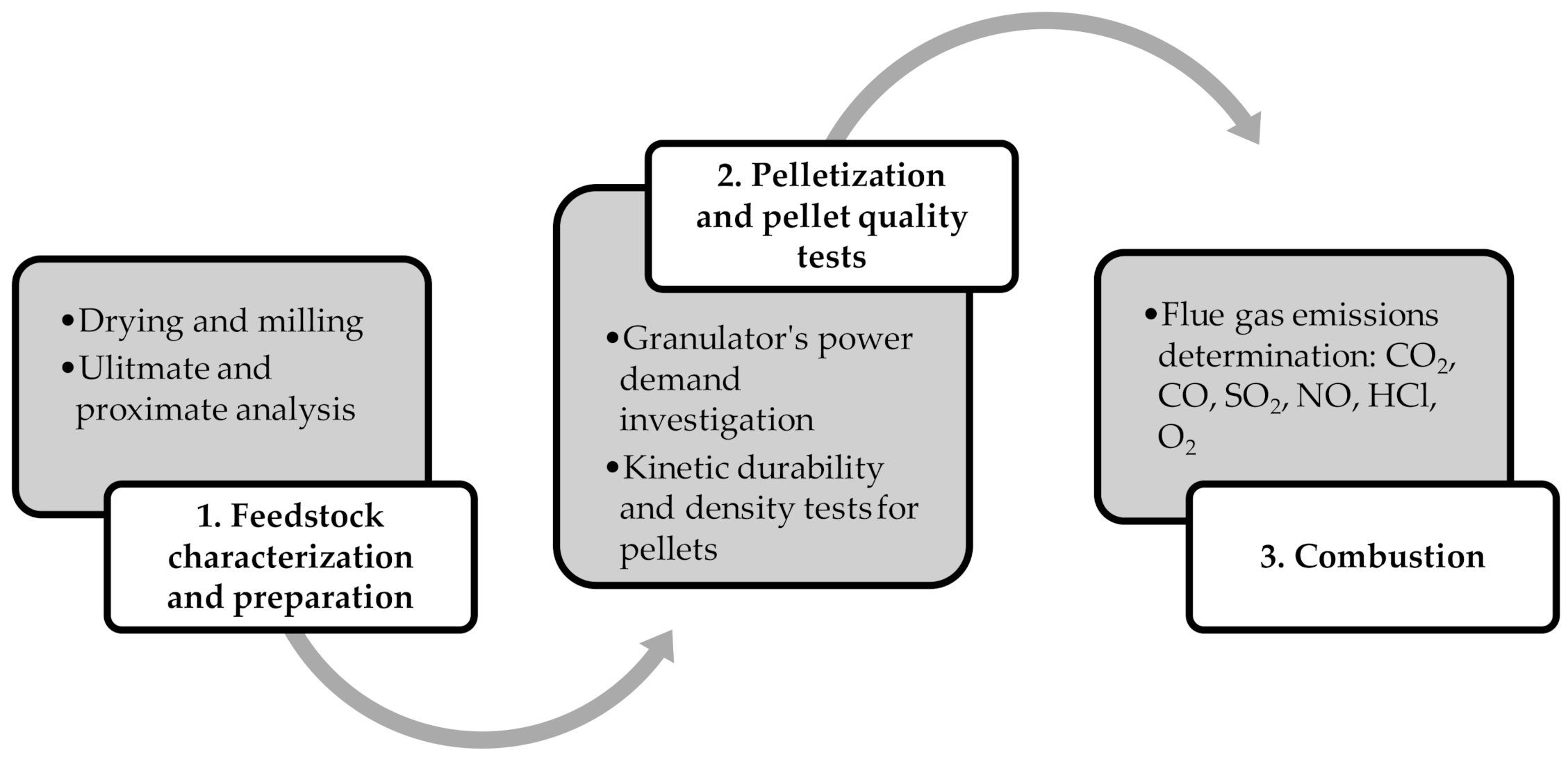

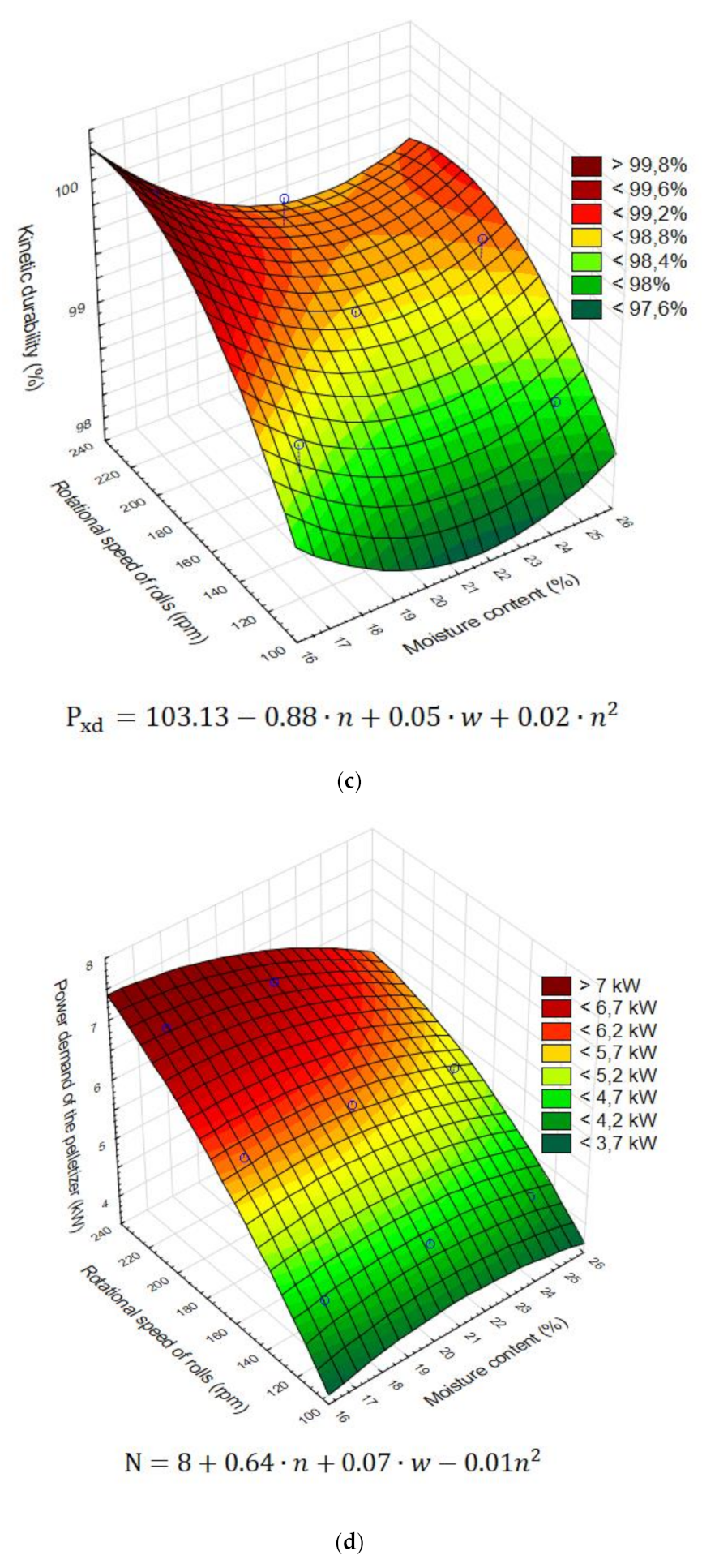

The research was performed according to the plan shown in Figure 1.

Figure 1.

Scheme of the research.

2.1. Feedstock

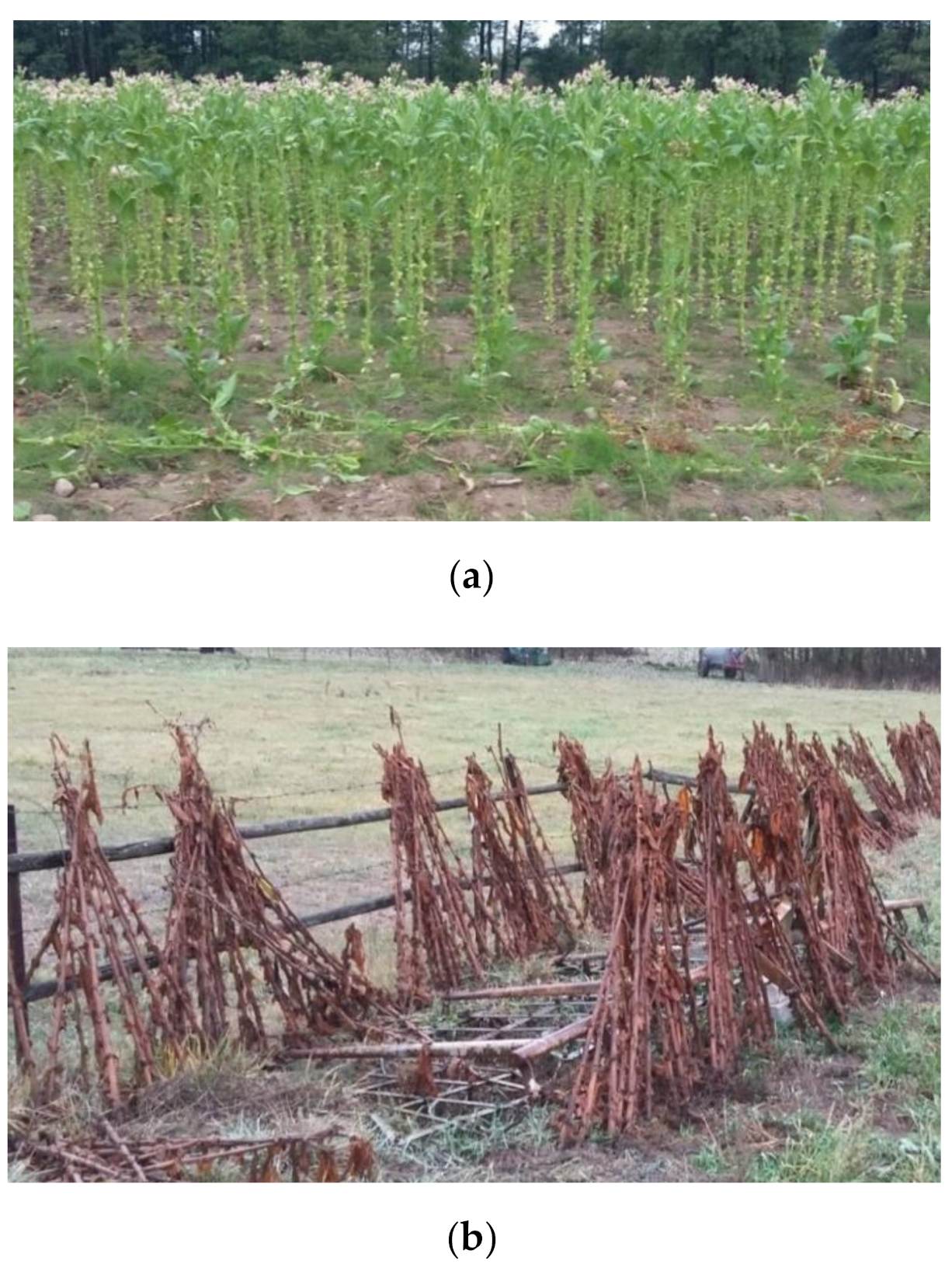

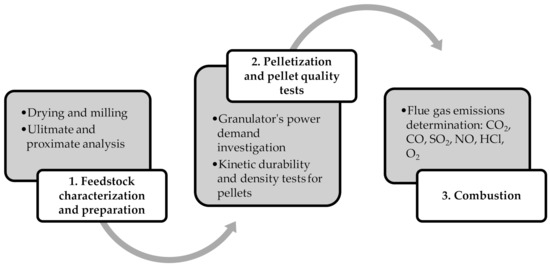

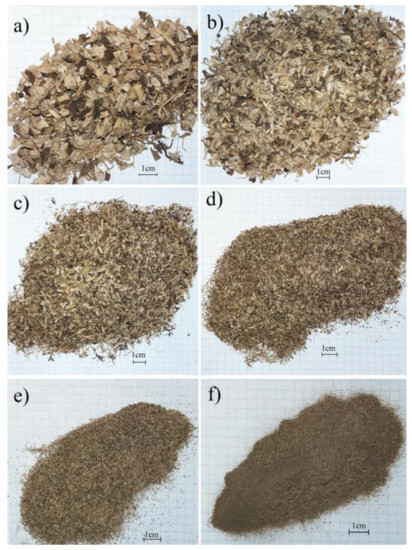

The post-harvest tobacco waste used for the pelletization tests was obtained from a tobacco plantation placed in Suchowola, Poland (Figure 2a), and contained plant stalks, shoots, flowers and the leaves of leaf blades. Before processing, the material was pre-dried under atmospheric conditions by convection (Figure 2b) and subsequently ground in the POM H115 mill using 5 mm mesh sieves (Figure 2c).

Figure 2.

Post-harvest tobacco waste (stalks): (a) after-harvesting tobacco, (b) during pre-drying and (c) milled and pre-dried (own source).

2.2. Methods

2.2.1. Feedstock Property Determination

The granulometric composition of the milled post-harvest tobacco waste was determined in accordance with PN-R-64798:2009 [39], with the use of a LPz-2e laboratory shaker (produced by MultiservMorek) and a set of sieves with mesh diameters of 6, 4, 2, 1, 0.5 and 0.25 mm, according to the methodology presented by Obidziński and Hejft [40]. A sample of 100 g was placed on the upper sieve. After 5 min, the residue on each of the sieves was weighed on a balance with an accuracy of 0.01 g. The analysis was repeated three times; as the final result, the arithmetic average was calculated.

Prior to the granulation process, the moisture content of the post-harvest tobacco waste was determined in accordance with PN-EN ISO 18134:2017 [41]. A WPE 300S moisture balance with an accuracy of 0.01% was used for the test. The analysis was repeated three times; as the final result, the arithmetic average was calculated.

The proximate analysis of the tobacco waste pellets (moisture [41], volatile matter [42], ash content [43] and fixed carbon by difference) was conducted by thermogravimetry using a Libra 209 F1 NETZSCH thermobalance. The ultimate analysis was performed on a CHN628 analyzer. The contents of carbon, hydrogen, nitrogen [44] and sulfur (dry basis (d.b.) %) [45] were determined by IR (infrared radiation) detection through high-temperature combustion; nitrogen (d.b.%) was analyzed by a catarometric method, which was also described in [46]. The chlorine content (d.b.%) was examined using the Mohr method [47], with the use of Eschka’s mixture.

The investigation of the HHV (high heating value) and LHV (low heating value) was performed in accordance with PN-ISO 1928:2002 [48], with the use of a Precyzja-Bit KL-12Mn calorimeter. The HHV and LHV of the fuel were calculated in an automatic manner (according to the internal software managing the calorimeter). Having specified values of the fuel HHV and LHV (d.b.%), it was possible to calculate the calorific value of the material at another known moisture content [48]:

where the terms are defined as follows: Qi (d.b.)—the HHV of the fuel (MJ·kg−1), γ—the heat of water vaporization at 20 °C equivalent to a 1% moisture content (γ = 24.55 kJ·kg−1), and w—water vapor content in combustion gases (%).

Basing on the abovementioned abovementioned properties, the so-called fuel value index (FVI), which describes the pro-energetic value of biomass, was calculated for the pellets according to the formula [49]:

The range of the FVI is given in the results as the effect of the differences in the bulk densities of the pellets obtained: the lowest value stands for the lowest density.

2.2.2. Pelletization Process and Pellets’ Quality Determination

In the present study, a prototype PROTECHNIKA (Poland) pelletizing–briquetting device [50,51] was used to perform the agglomeration tests. The pellet mill was provided with a 22 kW motor equipped with a recorder connected to a computer and a universal meter for taking the measurements of the power demand of the pelletizer in continuous mode. At 50 Hz, the rotational speed of the compacting rolls was 220 rpm, and a variable-frequency drive was provided to the device to vary the rotational speed of the rolls. The feedstock material was provided to the pelletizer’s chamber by a Hydrapress screw feeder (0.75 kW) continuously.

Studies on the process of post-harvest tobacco waste pelletization were carried out at a constant material feed rate of Q = 42 kg∙h−1, gap between the matrix and rolls of h = 0.4 mm, die hole diameter of 12 mm and die hole length of 28 mm. Feedstock at moisture contents (w) of 17, 21 and 25% was agglomerated at rotational speeds (n) of 120, 170 and 220 rpm for each.

Quality tests were performed 24 h after pelletization. The particle density of the produced pellets was determined by measuring the height and diameter of 10 randomly selected pellets with a caliper with an accuracy of ±0.02 mm. Next, their masses were determined by means of a WPS 360 analytic balance with an accuracy of ±0.001 g. The density was calculated as the ratio of the mass and volume of the obtained pellets. The pellets’ kinetic durability was determined in accordance with PN-EN ISO 17831-1:2016-02 [52] using a Holman tester, which cascades them in an air stream, causingthe pellets to collide with each other and the hard, perforated surfaces of the test chamber. The analysis was repeated three times for each sample type.

2.2.3. Combustion Tests and Flue Gas Analysis

The combustion of the produced pellets was carried out at the laboratory of Low Emission Combustion Technologies described in papers [8,53].

The stand includes a UnicaVentoEko boiler fabricated by Moderator and equipped with a retort grate (25 kW) and Dr. Födisch MCA10 flue gas analyzer. In the research, by a controlled automatic screw feeder, a sample of ca. 10 kg was fed into the boiler’s combustion chamber. The fuel mass flow and the combustion airflow were selected by the boiler controller in Fuzzy Logic mode. The fuel mass flow was ca. 3.6 kg·h−1, and the airflow was given as a percentage of the fan performance; therefore, due to highly inaccurate calculations, an exact value is not provided here. The hot exhaust gas was collected from ca. 1.5 m above the grate and continuously analyzed by the MCA10. The contents of CO2, CO, NO, SO2and HCl and loss of O2were determined. The results are expressed in terms of normal conditions (1013.25 hPa, 0 °C) and normalized to a 10% O2 content according to the formula:

where the terms are defined as follows: Zs1—the component content in the flue gas (%,mg·Nm−3), Zs2—the component content in the flue gas for a given oxygen content (%,mg·Nm−3), O2′—the set oxygen content in the flue gas (%), and O2″—the obtained oxygen content in the flue gas (%).

In order to investigate the fuel–air conditions in the combustion chamber, the excess air factor λ was calculated as follows:

3. Results and Discussion

3.1. Feedstock Properties

The ultimate analysis of the tobacco waste samples were presented in Table 1. According to Wandrasz and Wandrasz [54], biomass (including waste), compared to coal, is characterized by high contents of oxygen and hydrogen. The high speed of hydrogen oxidation affects the acceleration of combustion and thus the emission of combustion products: increasing the hydrogen content in the combustion chamber results in a decrease in the CO and SOx contents in the exhaust gas and an increase in the combustion temperature [55]. Comparing tobacco waste to wood biomass, it has to be noted that the content of carbon is ca. 10% lower for tobacco [56], which directly influences its calorific value. After milling, the bulk density of the material was 213.5 kg·m−3.

Table 1.

Physicochemical properties of tobacco waste pellets.

The current standard for the quality of non-wood pellets, ISO 17225-6 [58], does not reflect either recommended quality value for tobacco pellets. However, in the general requirements for so-called agropellets, the analyzed pellets slightly exceed the values for ash, Cu and Ni for the tested characteristics.

On the other hand, the HHV and LHV (Table 2) of the analyzed waste should allow its successful use in combustion processes for heat or electricity generation. It is interesting, and also observed by other science units [23], that tobacco waste contains high amounts of nitrogen, which in high-temperature conditions (above 800 °C) may decompose to its oxide form.

Table 2.

HHV and LHV of pellets from tobacco stalks.

The fuel value index, which takes into account the ash content, density, HHV and moisture content, describes the energy properties of a given fuel. In the case of tobacco stalk pellets, the FVI is similar to the FVIs calculated for similar types of agro-waste biomass such as cup plant fanpetals (0.08) or willow leaf sunflowers (0.11) [49]. Woody biomass is characterized by FVIs in the range of 0.6–1.29 [59]. The moisture content has a significant influence on the values of the heat of combustion and the calorific value of the tested pellets from tobacco waste (tobacco stalks). An increase in the moisture content from 0 to 30%results in a reduction of the HHV from 18.02 to 12.62 MJ·kg−1 and the LHV from 16.02 to 10.48 MJ·kg−1.

The influence of the tobacco waste moisture content w onthe heat of combustion Qs is described by the following equation:

while the influence of the moisture content w on the calorific value Qi of the tobacco waste is described as follows:

Qs = −0.18w + 18.017

Qi = −0.1845w + 16.016

The obtained values of the HHV and LHV (Table 2) show that the tobacco stalkswere characterized by high-energy qualities. Similar results for the heating values for tobacco waste briquettes (tobacco stalks) were obtained by Peševski and colleagues [60]. The values of the tobacco waste heat of combustion are similar to those obtained by Obidzinski [61] for buckwheat hulls, Niedziółka and Zuchniarz [62] for barley straw, Maj and Piekut [63] for walnut leaves or Szyszlak-Bargłowicz et al. [64] for Miscanthus giganteus.

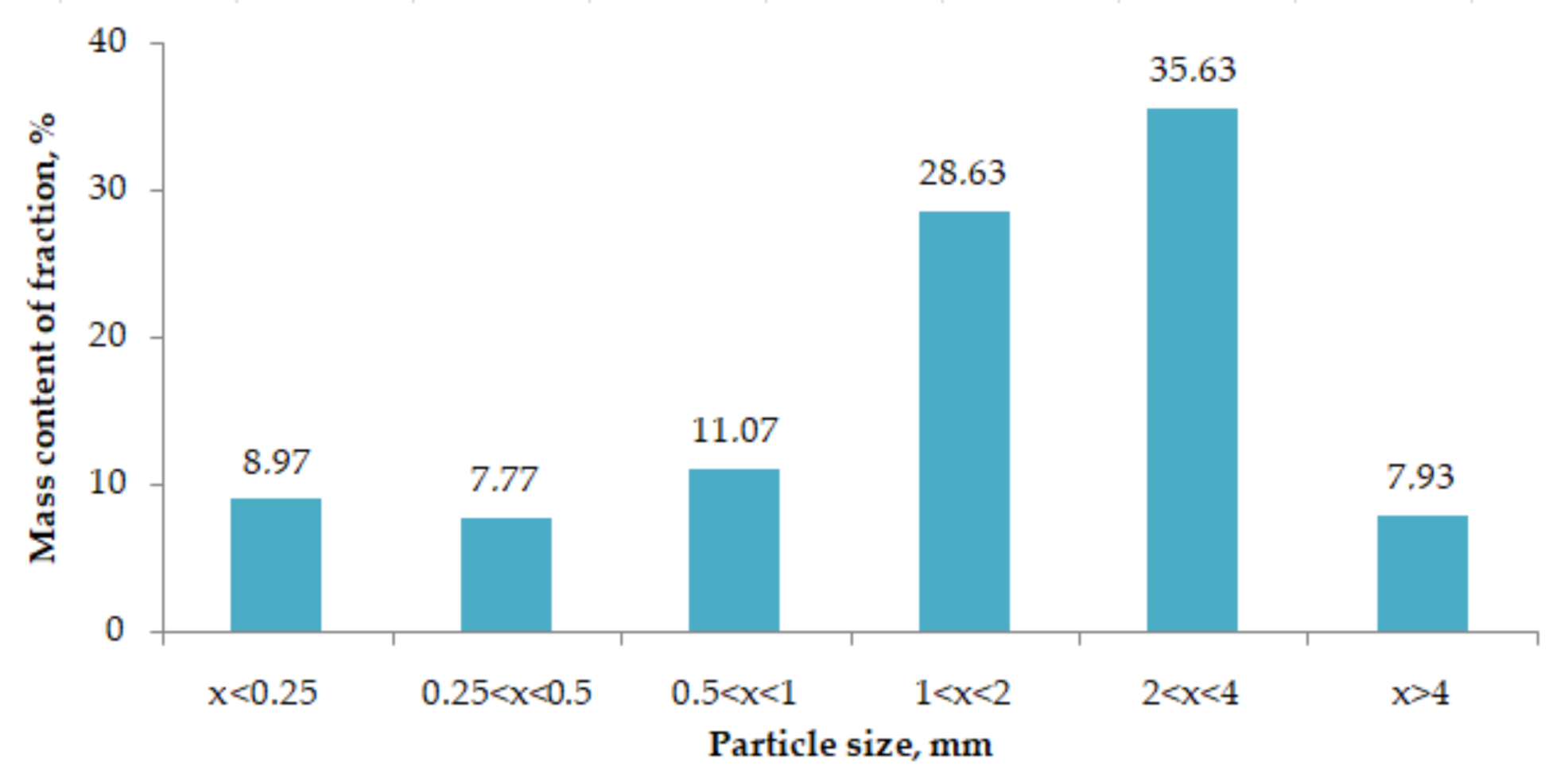

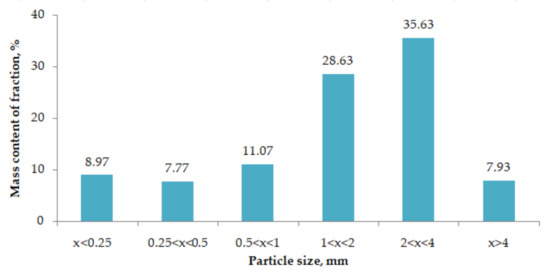

Plant-derived materials are highly heterogeneous in chemical structure and discontinuous in the distribution of mass concentrated in particles and grains. This, usually, determines the need to modify the material prior to the agglomeration process, i.e., give it an appropriate granulometric composition [34]. Figure 3 shows the results of tests on the granulometric distribution of the milled post-harvest tobacco stalks.

Figure 3.

Grain size distribution of shredded post-harvest tobacco waste.

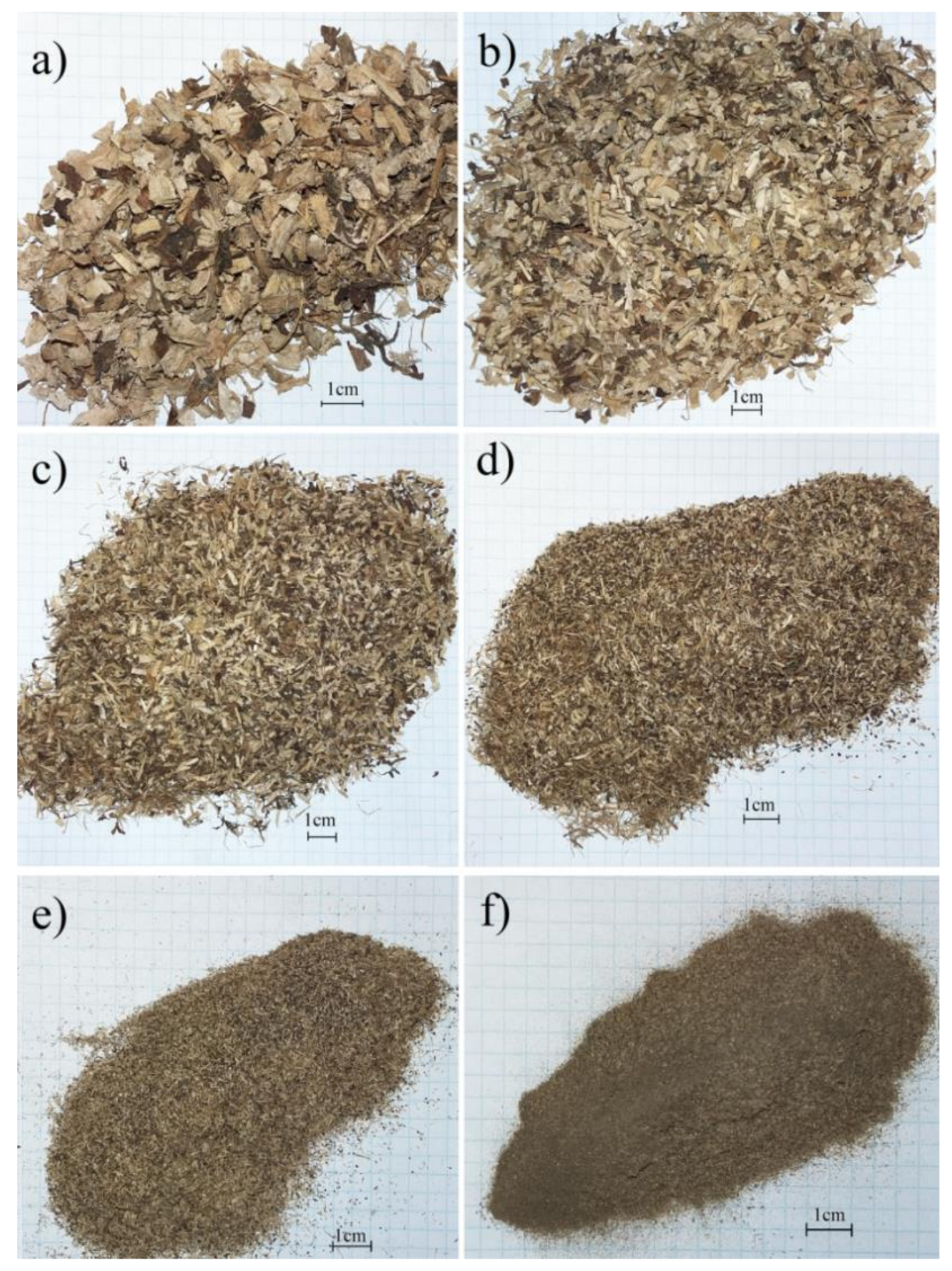

Based on the granulometric test, it was found that the largest share, i.e., 35.6%, in the milled material was the 2 mm fraction. The next positions were taken by the fractions from the sieves with mesh sizes of 1 and 0.5 mm, which were 28.6 and 11.07%, respectively. The fractions of 0.25 mm and smaller (7.77 and 8.97%) made up a relatively large percentage, which might have had a negative effect on the pelletization process. According to Zawiślak et al. [65], substances with medium and fine grinding, i.e., in the range of 0.4–2 mm, are the most suitable for compacting. The diversity of the tested material fractions means they are highly susceptible to fractional separation. This property is directly affected by the particle size, which depends on the parameters of the milling process. Figure 4 presents a view of the individual fractions obtained during one of the performed granulometric distribution tests.

Figure 4.

View of individual fractions of shredded post-harvest tobacco waste (own source): (a) 4 mm fraction, (b) 2 mm, (c) 1 mm, (d) 0.5 mm, (e) 0.25 mm and (f) <0.25 mm.

3.2. Pelletization Tests

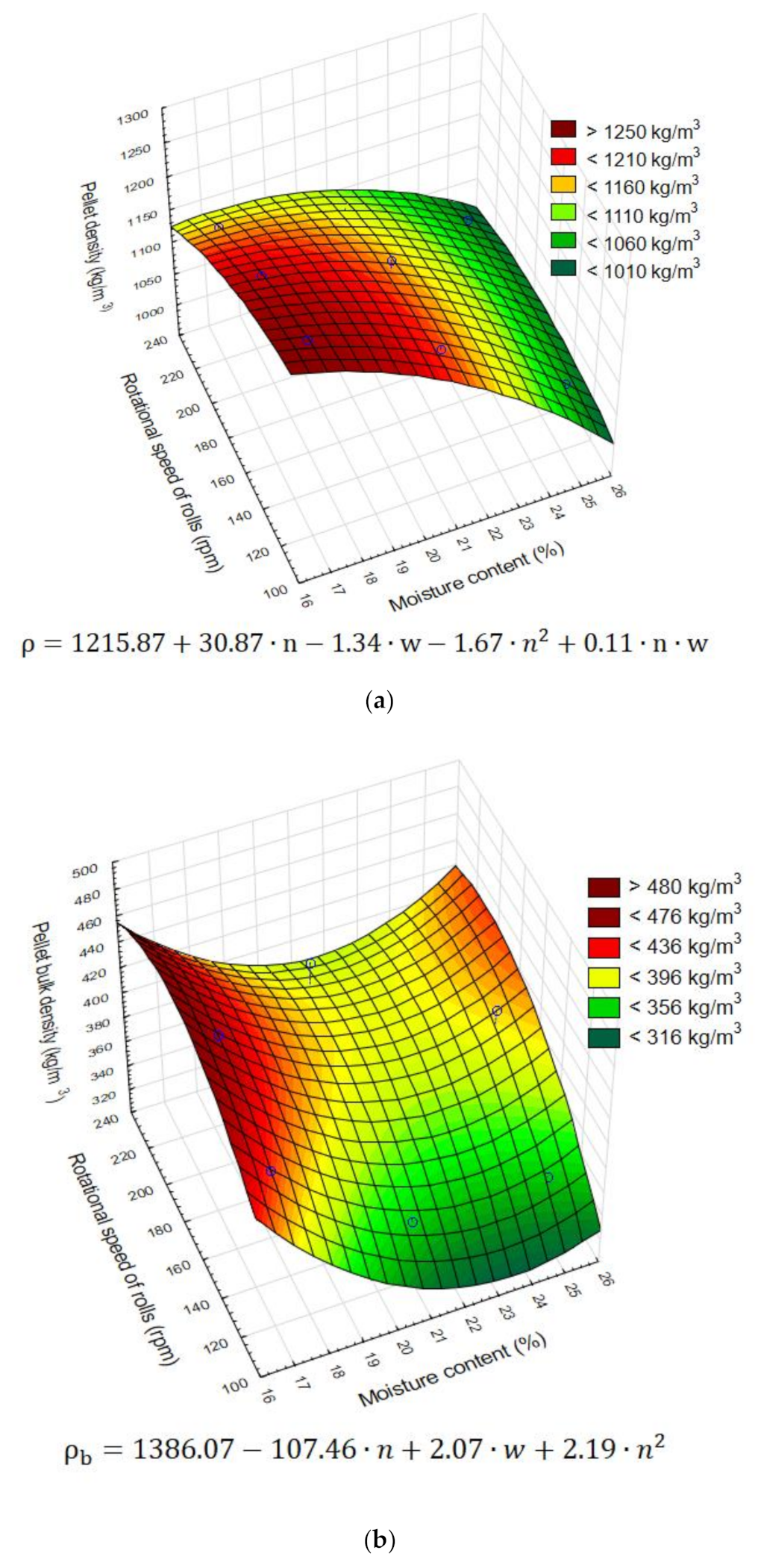

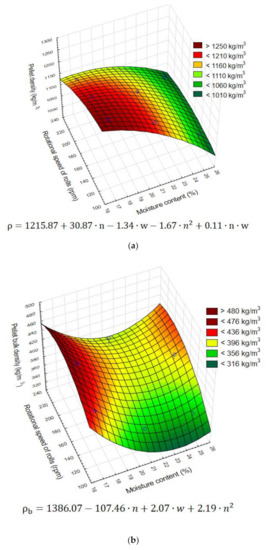

Table 3 and Figure 5 present the results of the tobacco stalk agglomeration tests, where the pellet’s density (ρ), bulk density (ρb) and kinetic durability (Pdx) were analyzed and the pelletizer’s demand for power (N) was investigated.

Table 3.

Results of densification tests fortobacco waste.

Figure 5.

Influence of material and process factors (moisture content of waste and the rotational speed of the compacting rolls) on the (a) pellet density, (b) pellet bulk density (c) pellet kinetic durability and (d) power demand of the granulating system.

From Table 3 and Figure 5a, it can be seen that as the moisture content of the tobacco waste increased from 17 to 25%, the values of the density decreased, which had an impact on the energy density of the fuel pellets. The highest decrease from 1260 to 1060 kg·m−3 was observed for the first case of tests, i.e., for the agglomeration speed of 120 rpm. When increasing the agglomeration speed, the observed density decrease was lower by ca. 90 kg·m−3 for the highest speed of 220 rpm.

On the basis of the performed tests (Figure 5a and Table 3), it was concluded that by increasing the speed of agglomeration, a decrease in the pellet’s density is observed, especially for the lowest analyzed moisture content of 17%, where the decrease was from 1260 to 1160 kg·m−3. Furthermore, at higher agglomeration speeds and higher moisture contents in the feedstock, the impact on density was slighter. A moisture content above 20% does not significantly increase the granulation rate of the expansion that takes place after exit from the working system. The conducted analysis showed that the density of the tobacco waste pellets depends largely on the material moisture, R2 = 0.81; no correlation was obtained between the pellet density and the pelletization speed. Mediavilla et al. [33] produced pellets from various mixtures of vine shoots and cork in a commercial pelletizer using a 20 mm flat matrix. The feedstock moisture content varied between 15 and 25%. They concluded that the addition of industrial cork residue lowered the process energy demanded, and during combustion, it lowered the ash content. The effects of the feedstock moisture content, its bulk density after a pre-agglomeration process, steam addition and the matrix temperature on the kinetic durability and bulk density of pellets from reed canary grass was reported by Larsson et al. [66]. They found that the moisture content was the factor most affecting the durability and bulk density of pellets. It was also confirmed for the tobacco stalk pellets from this study (Figure 5b and Table 3), where the bulk density was mostly correlated with the moisture content of the feedstock. As a result of the palletization process, the bulk density of the tobacco waste was increased from ca. 213.5 up to 460 kg·m−3 for pellets produced with a moisture content of 17% and a roll rotational speed of 170 rpm. However, the level of bulk density described by the norm ISO 17225-6 [57] (i.e., 600 kg·m−3) was not reached.

Increasing the moisture content from 17 to 25% did not significantly affect the kinetic durability of the produced pellets (Figure 5c and Table 3). The highest values of kinetic durability were observed for the lowest moisture content of 17%. Agglomeration speeds between 120 and 170 rpm did not significantly affect the Pdx value. However, at 220 rpm, the kinetic durability of the pellets decreased with an increase in the moisture content. Serrano et al. [32] evaluated the properties of pellets from barley straw: pellets were produced in an annular matrix pelletizer at a semi-industrial scale. They found that during pelletization, the optimum feedstock moisture contents were in the range of 19–23%. A kinetic durability value of 95.5% was obtained under these conditions, and was improved to 97–98%by the addition of 2–12wt.%pine sawdust. The conducted analysis showed that the kinetic durability of tobacco waste pellets has a slight correlation with the pelletization speed, R2 = 0.60.

On the basis of the performed tests (Figure 5d and Table 3), it was found that increasing the rotational speed of the agglomerating roller system results in an increase in the pelletizer’s power demand. For example, increasing the speed from 120 to 170 rpm (at 17% humidity) results in an increase in power demand by 1.33 kW (from 4.58 to 5.91 kW). Increasing the feedstock moisture content caused a slight decrease in the power consumption, only at a rotational speed of 220 rpm; a noticeable effect of the moisture content was noted—an increase from 17 to 25% resulted in a decrease in the power demand by 1.07 kW (from 7.04 to 5.94 kW). The lowest power demand (4.32 kW) was recorded at the lowest rotational speed (120 rpm) and the highest moisture content (25%). For the lowest value of moisture, there was an almost linear dependence of the power requirement on the engine speed. The power demand of the performed process mainly depended on the speed of the pelletizer working system, R2 = 0.88. The feedstock moisture content did not affect the power demand of the device.

Based on the test results presented above, it was concluded that high-quality pellets were obtained in all the tested cases: a density above 1000 kg·m−3and durability above 97%. However, changes in the process and material conditions particularly influenced the pelletizer’s power demand, which decreased with an increase in the material’s moisture and a decrease in the rotational speed of the rolls. Hence, it was concluded that with a constant process efficiency, the most favorable pelletization conditions were obtained using a roll rotational speed of 120 rpm and a material moisture content of 25%. According to [67], the process conditions for each material and device have to be validated to not reach a specific state where the pelletization efficiency is high but the product is characterized by small-sized particles and low durability values. In the case of tobacco stalks, there is an advantage of the possibility of drying them in the field (Figure 2) until they reachan adequate moisture content, which prevents the additional costs of pellet production [68].

3.3. Combustion Tests

Table 4 presents the averaged results for flue gas composition obtained during the combustion of the tobacco stalk pellets. The results were calculated to a 10% oxygen content in the flue gas, according to the requirements of the Ecodesign Directive [51]. For comparative purposes, Table 4 also shows the results of the flue gas emissions during the combustion of wood pellets at semi-constant heat and flow conditions for the boiler installation.

Table 4.

Flue gas composition and conditions of combustion of tobacco pellets.

During combustion, certain attention is given to the carbon monoxide emission, which is treated as a determinant of the presence of furans, dioxins, soot and hydrocarbons in the exhaust [51]. According to the Ecodesign Directive, the maximum CO content in the flue gas for boilers having a capacity below 0.5 MW cannot exceed 500 mg·Nm−3 [54]. The high value of CO emissions during the tobacco pellet combustion, reaching ca. 8243 mg·Nm−3, indicates problems in the CO to CO2oxidation and poor stability of the combustion process [62]. The obtained low combustion temperature (Table 4) causes high emissions of both nitrogen oxides and hydrogen chloride. Nitrogen oxides are mainly formed from the oxidation reactions of chemical compounds containing nitrogen in the fuel. Naturally, the NOx emissions tend to increase as the nitrogen content in the fuel increases [24,56]. Moreover, the decrease in the combustion temperature causes an increase in NO emissions, which according to researchers is the result of changes in the course of NO synthesis under these conditions [24]. It should be noted that the Ecodesign [51] standard provides a maximum value of NO emissions at a level not exceeding 200 mg·Nm−3. Currently, European emission regulations do not limit emissions of HCl and SOx. Certified wood pellets combusted in the same installation generated SOx emissions at the level of ca. 23 mg·m−3. Another tested combustion parameter is the excess air factor λ, which describes the contact area of the oxidizing agent and the fuel particle; the lower the value obtained, the closer the process parameters are to stoichiometric combustion (where λ = 1 stands for stoichiometric combustion). Agri-food waste is often characterized by high λ values due to the higher ash content, which impedes effective combustion. The above-described studies indicate that pellets produced from tobacco stalks require further research for an appropriate method for their thermal utilization.

4. Conclusions

This work outlines the (i) physical and chemical properties of tobacco stalks and tobacco stalk pellets, (ii) pelletization process for post-harvest tobacco waste in the form of stalks, and (ii) combustion properties of the obtained fuel pellets. The ultimate analysis of the post-harvest tobacco waste showed that it is similar to the wood biomass used in industrial pellet production. The differences are clearly notable in the results of proximate analysis, where tobacco stalks were characterized by a high ash content, which during the combustion processes, may decrease its effectiveness. Detailed studies about the calorific value, and the effect of moisture on the HHV and LHV were conducted. It was confirmed that increasing the moisture content from 0 to 30% causes a 30% reduction in the high heating value and the low heating value. During the pelletization process, increasing the moisture content of the raw material caused a decrease in the pellet density. The biggest decrease in density was observed in pellets produced at the lowest analyzed agglomeration speed of 120 rpm. As the roll speed was increased, the differences in density were lower. Moreover, increasing the moisture content and the agglomeration speed slightly affected the kinetic durability of the obtained pellets and decreased the power demand of the pelletizer. The results for tobacco waste pellet combustion, where high emissions of CO and NO were obtained, indicate a need for additional analyses of their suitability as a solid fuel and the selection of other combustion technologies or conditions than those used in this paper.

Author Contributions

Conceptualization, S.O. and M.P.; methodology, S.O.; software, S.O.; validation, S.O., M.P. and M.D.; formal analysis, S.O.; investigation, M.P.; resources, M.P.; data curation, S.O.; writing—original draft preparation, S.O. and M.D.; writing—review and editing, M.D.; visualization, M.D.; supervision, S.O. and M.D.; project administration, S.O.; funding acquisition, S.O. All authors have read and agreed to the published version of the manuscript.

Funding

The work was carried out as part of a team project no. WZ/WB-IIŚ/2020 and financed by the Polish Ministry of Science and Higher Education.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses or interpretation of data; in the writing of the manuscript; or in the decision to publish the results. All authors have read and agreed to the published version of the manuscript.

Nomenclature

| Symbol | Description |

| LHV | lower heating value (MJ·kg−1) |

| HHV | higher heating value (MJ·kg−1) |

| w | moisture content (wt.%) |

| n | pelletizer’s matrix rotational speed (rpm) |

| Zs1 | the actual chemical content in the exhaust gas (%,mg·Nm−3) |

| Zs2 | content of the chemical compounds in the exhaust gas for a given oxygen content (%, mg·Nm−3) |

| O2′ | set value of the oxygen content in the exhaust (%) |

| O2″ | actual oxygen content in the exhaust gas (%) |

| FVI | fuel value index |

| λ | excess air factor (-) |

| ρ | pellet’s density (kg·m−3) |

| Px | pellet’s kinetic durability (%) |

| N | granulator’s power demand (kW) |

| wt.% | weight percent |

| a.r. | as received |

| d.b. | dry basis |

References

- Liu, Z.; Quek, A.; Balasubramanian, R. Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl. Energy 2014, 113, 1315–1322. [Google Scholar] [CrossRef]

- Ugwua, S.N.; Enweremadu, C.C. Effects of pre-treatments and co-digestion on biogas production from Okra waste. J. Renew. Sustain. Energy 2019, 11, 013101. [Google Scholar] [CrossRef]

- Łochyńska, M.; Frankowski, J. The biogas production potential from silkworm waste. J. Waste Manag. 2018, 79, 564–570. [Google Scholar] [CrossRef] [PubMed]

- Oniszczuk, T.; Pilawka, R. Effect of cellulose fibers on thermal strength of thermoplastic starch. Przem. Chem. 2013, 2, 265–269. [Google Scholar]

- Czekała, W.; Bartnikowska, S.; Lewicka, A.; Bugała, A.; Zbytek, Z.; Lewicki, A. Economic and energy efficiency of the solid biofuels produced from digested pulp. MATEC Web Conf. 2016, 60, 04005. [Google Scholar] [CrossRef]

- Obidziński, S.; Dołżyńska, M.; Kowczyk-Sadowy, M.; Jadwisieńczak, K.; Sobczak, P. Densification and Fuel Properties of Onion Husks. Energies 2019, 12, 4687. [Google Scholar] [CrossRef]

- Abedi, A.; Dalai, A.K. Study on the quality of oat hull fuel pellets using bio-additives. Biomass Bioenergy 2017, 106, 166–175. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M. Densification and Combustion of Cherry Stones. Energies 2019, 12, 3042. [Google Scholar] [CrossRef]

- Braadbaart, F.; Marinova, E.; Sarpaki, A. Charred olive stones: Experimental and archaeological evidence for recognizing olive processing residues used as fuel. Veg. Hist. Archaeobotany 2016, 25, 415–430. [Google Scholar] [CrossRef]

- Gong, C.; Lu, D.; Wang, G.; Tabil, L.G.; Wang, D. Compression Characteristics and Energy Requirement of Briquettes Made from a Mixture of Corn Stover and Peanut Shells. BioResources 2015, 10, 5515–5531. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Bańda, M.; Wiącek, J.; Parafiniuk, P.; Gondek, E. Mechanical and combustion properties of sawdust—Straw pellets blended in different proportions. Fuel Process. Technol. 2017, 156, 366–375. [Google Scholar] [CrossRef]

- Ishii, K. Influence of moisture content, particle size and forming temperature on productivity and quality of rice straw pellets. Waste Manag. 2014, 34, 2621–2626. [Google Scholar] [CrossRef]

- Husain, Z.; Zainac, Z.; Abdullah, Z. Briquetting of palm bre and shell from the processing of palm nuts to palm oil. Biomass Bioenergy 2002, 22, 505–509. [Google Scholar] [CrossRef]

- Barbanera, M.; Lascaro, E.; Stanzione, V.; Esposito, A.; Altieri, R.; Bufacchi, M. Characterization of pellets from mixing olive pomace and olive tree pruning. Renew. Energy 2016, 185–191. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: http://www.fao.org/faostat/en/ (accessed on 3 January 2020).

- Wang, J.; Lu, D.; Zhao, H.; Ling, X.; Jiang, B.; Ouyang, P. Application of response surface methodology optimization for the production of caffeic acid from tobacco waste. South Afr. J. Enol. Vitic. 2009, 8, 1416–1424. [Google Scholar] [CrossRef]

- Mumba, P.P.; Phiri, R. Environmental impact assessment of tobacco waste disposal. Int. J. Environ. Res. 2008, 2, 225–230. [Google Scholar]

- Qin, Z.; Sun, M.; Luo, X.; Zhang, H.; Xie, J.; Chen, H.; Yang, L.; Shi, L. Life-cycle assessment of tobacco stalk utilization. Bioresour. Technol. 2018, 265, 119–127. [Google Scholar] [CrossRef]

- Chen, H.; Guo, Y.; Wang, F.; Wang, G.; Qi, P.; Guo, X.; Dai, B.; Yu, F. An activated carbon derived from tobacco waste for use as a supercapacitor electrode material. New Carbon Mater. 2016, 32, 592–599. [Google Scholar] [CrossRef]

- Czerwińska, E.; Koronowski, A.; Stankiewicz, D. The Tobacco Industry and the Issue of a State Monopoly; Report No. 61; Chancellery of the Polish Parliament, The Research Office: Warsaw, Poland, 1994. [Google Scholar]

- Cai, J.; Li, B.; Chen, C.; Wang, J.; Zhao, M.; Zhang, K. Hydrothermal carbonization of tobacco stalk for fuel application. Bioresour. Technol. 2016, 220, 305–311. [Google Scholar] [CrossRef]

- Strezov, V.; Popovic, E.; Filkoski, R.V.; Shah, P.; Evans, T. Assessment of the Thermal Processing Behavior of Tobacco Waste. Energy Fuels 2012, 26, 5930–5935. [Google Scholar] [CrossRef]

- Yang, Y.; Li, T.; Jin, S.; Lin, Y.; Yang, H. Catalytic pyrolysis of tobacco rob: Kinetic study and fuel gas produced. Bioresour. Technol. 2011, 102, 11027–11033. [Google Scholar] [CrossRef] [PubMed]

- Glarborg, P.; Miller, J.A.; Ruscic, B.; Klippenstein, S.J. Modeling nitrogen chemistry in combustion. Prog. Energy Combust. Sci. 2018, 67, 31–68. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef]

- Obidziński, S.; Joka, M.; Luto, E.; Bieńczak, A. Research of the densification process of post-harvest tobacco waste. J. Res. Appl. Agric. Eng. 2017, 62, 149–154. [Google Scholar]

- Cong, K.; Han, F.; Zhang, Y.; Li, Q. The investigation of co-combustion characteristics of tobacco stalk and low rank coal using a macro-TGA. Fuel 2019, 237, 126–132. [Google Scholar] [CrossRef]

- Cai, J.; Xu, D.; Dong, Z.; Yu, X.; Yang, Y.; Banks, S.W.; Bridgwater, A.V. Processing thermogravimetric analysis data for isoconversional kinetic analysis of lignocellulosic biomass pyrolysis: Case study of corn stalk. Renew. Sustain. Energy Rev. 2018, 82, 2705–2715. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S.; Simiński, P. Evaluation of granulates from hemp sowing waste as a biofuel. Przem. Chem. 2018, 97, 686–688. [Google Scholar] [CrossRef]

- Obidzinski, S. Pelletisation of biomass waste with potato pulp content. Int. Agrophys. 2014, 28, 85–91. [Google Scholar] [CrossRef][Green Version]

- Tumuluru, J.S.; Fillerup, E. Briquetting characteristics of woody and herbaceous biomass blends: Impact on physical properties, chemical composition, and calorific value. Biofuel Bioprod. Biorefin 2020, 14, 1105–1124. [Google Scholar] [CrossRef]

- Serrano, C.; Monedero, E.; Lapuerta, M.; Portero, H. Effect of moisture content, particle size and pine addition on quality parameters of barley straw pellets. Fuel Process. Technol. 2011, 92, 699–706. [Google Scholar] [CrossRef]

- Mediavilla, I.; Fernández, M.J.; Esteban, L.S. Optimization of pelletisation and combustion in a boiler of 17.5 kWth for vine shoots and industrial cork residue. Fuel Process. Technol. 2009, 90, 621–628. [Google Scholar] [CrossRef]

- Nasrin, A.B.; Ma, A.N.; Mohammad, S.; Rohaya, M.H.; Azali, A.; Zainal, Z. Oil palm biomass as potential substitution raw materials for commercial biomass briquettes production. Am. J. Appl. Sci. 2008, 5, 179–183. [Google Scholar] [CrossRef]

- Stahl, M.; Berghel, J. Energy efficient pilot-scale production of wood fuel pellets made from a raw material mix including sawdust and rapeseed cake. Biomass Bioenergy 2011, 35, 4849–4854. [Google Scholar] [CrossRef]

- Miranda, M.T.; Arranz, J.I.; Rojas, S.; Montero, I. Energetic characterization of densified residues from Pyrenean oak forest. Fuel 2009, 88, 2106–2112. [Google Scholar] [CrossRef]

- Miranda, T.; Arranz, J.I.; Montero, I.; Román, S.; Rojas, C.V.; Nogales, S. Characterization and combustion of olive pomace and forest residue pellets. Fuel Process. Technol. 2012, 103, 91–96. [Google Scholar] [CrossRef]

- Obidziński, S.; Dołżyńska, M.; Bobowik, G.; Bieńczak, A. Agglomeration process of post-production tobacco waste. J. Res. Appl. Agric. Eng. 2018, 63, 40–45. [Google Scholar]

- PN-R-64798:2009. Feeds—Determination of Grinding; Polski Komitet Normalizacyjny = Polish Committee for Standardization: Warsaw, Poland, 2009. [Google Scholar]

- Obidziński, S.; Hejft, R. Granulowanie odpadów pochodzenia roślinnego w układzie roboczym granulatora. J. Res. Appl. Agric. Eng. 2013, 58, 133–138. [Google Scholar]

- PN-EN ISO 18134:2017. Solid Biofuels—Determination of Moisture Content—Drying Method—Part 2: Total Moisture—Simplified Method; ISO: Geneve, Switzerland, 2017. [Google Scholar]

- PN-EN ISO 18123:2016. Solid Biofuels—Determination of Volatile Matter; ISO: Geneve, Switzerland, 2016. [Google Scholar]

- PN-EN ISO 18122:2016. Solid Biofuels—Determination of Ash Content; ISO: Geneve, Switzerland, 2016. [Google Scholar]

- PN-EN ISO 16948:2016. Solid Biofuels—Determination of Total Carbon, Hydrogen and Nitrogen Content; ISO: Geneve, Switzerland, 2016. [Google Scholar]

- PN-EN ISO 16994:2016. Solid Biofuels—Determination of Total Sulfur and Chlorine Content; ISO: Geneve, Switzerland, 2016. [Google Scholar]

- Dołżyńska, M.; Obidziński, S.; Piekut, J.; Yildiz, G. The Utilization of Plum Stones for Pellet Production and Investigation of Post-Combustion Flue Gas Emissions. Energies 2020, 13, 5107. [Google Scholar] [CrossRef]

- PN-ISO 587:2000. Solid Fuels—Determination of the Chlorine Content Using the Eschki Mixture; ISO: Geneve, Switzerland, 2000. [Google Scholar]

- PN-ISO 1928:2002. Solid Fuels—Determination of Heat of Combustion by Calorimetric Bomb Method Andcalorific Value Calculation; ISO: Geneve, Switzerland, 2002. [Google Scholar]

- Wróbel, M.; Mudryk, K.; Jewiarz, M.; Głowacki, S.; Tulej, W. Characterization of Selected Plant Species in Terms of Energetic Use. Renew. Energy SourcesEng. Technol. Innov. 2018, 671–681. [Google Scholar] [CrossRef]

- Obidziński, S.; Hejft, R. Briquetting waste material in a prototype pelletizing and briquetting arrangement. Agric. Eng. 2015, 1, 107–116. [Google Scholar] [CrossRef]

- Obidziński, S.; Dołżyńska, M.; Stasiełuk, W. Production of fuel pellets from a mixture of sawdust and rye bran. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019. [Google Scholar] [CrossRef]

- PN-EN ISO 17831-1:2016-02. Solid Biofuels—Determination of the Mechanical Strength of Pellets and Briquettes—Part 1: Pellets; ISO: Geneve, Switzerland, 2016. [Google Scholar]

- Dołżyńska, M.; Obidziński, S. Wpływ dodatku zużytego oleju spożywczego na efekty spalania osadów ściekowych. Przem. Chem. 2017, 96, 1848–1851. [Google Scholar] [CrossRef]

- Wandrasz, J.W.; Wandrasz, A.J. Paliwa Formowane Biopaliwa i Paliwa z Odpadów w Procesach Termicznych; Wydawnictwo Seidel-Przywecki: Warszawa, Poland, 2006. [Google Scholar]

- Lazaroiu, G.; Pop, E.; Negreanu, G.; Pisa, I.; Mihaescu, L.; Bondrea, A.; Berbece, V. Biomass combustion with hydrogen injection for energy applications. Energy 2017, 127, 351–357. [Google Scholar] [CrossRef]

- Yahya, M.A.; Al-Qodah, Z.; ZanariahNgah, C.W. Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: A review. Renew. Sustain. Energy Rev. 2015, 46, 218–235. [Google Scholar] [CrossRef]

- Phyllis2. Available online: https://phyllis.nl/Home/Help (accessed on 20 July 2020).

- ISO 17225-6:2014. Solid Biofuels—Fuel Specifications and Classes—Part 6: Graded Non-Woody Pellets; ISO: Geneve, Switzerland, 2014. [Google Scholar]

- Karbowniczak, A.; Hamerska, J.; Wróbel, M.; Jewiarz, M.; Nęcka, K. Evaluation of Selected Species of Woody Plants in Terms of Suitability for Energy Production. Renew. Energy Sources Eng. Technol. Innov. 2018, 735–742. [Google Scholar] [CrossRef]

- Peševski, M.D.; Iliev, B.M.; Živković, D.L.; Jakimovska-Popovska, V.T.; Srbinoska, M.A.; Filiposki, B.K. Possibilities for utilisation of tobacco stems for production of energetic briquettes. J. Agric. Sci. Technol. 2010, 55, 45–54. [Google Scholar] [CrossRef]

- Obidziński, S. Utilization of post-production waste of potato pulp and buckwheat hulls in the form of pellets. Pol. J. Environ. Stud. 2014, 23, 1391–1395. [Google Scholar]

- Niedziółka, I.; Zuchniarz, A. Analiza energetyczna wybranych rodzajów biomasy pochodzenia roślinnego. Motrol 2006, 8A, 232–237. [Google Scholar]

- Maj, G.; Piekut, J. Comparing emission factors and physicochemical properties of waste-biomass leaves of selected species of trees. Pol. J. Environ. Stud. 2018, 27, 2155–2162. [Google Scholar] [CrossRef]

- Szyszlak-Bargłowicz, J.; Zając, G.; Piekarski, W. Energy biomass characteristics of chosen plants. Int. Agrophys. 2012, 26, 175–179. [Google Scholar] [CrossRef]

- Zwiślak, K.; Sobczak, P.; Panasiewicz, M.; Mazur, J.; Nadulski, R.; Starek, A. Wpływ wielkości frakcji otrąb pszennych na jakość granulatu. InżynieriaPrzetwórstwa Spożywczego 2014, 3, 25–28. [Google Scholar]

- Larsson, S.H.; Thyrel, M.; Geladi, P.; Lestander, T.A. High quality biofuel pellet production from pre-compacted low density raw material. Bioresour. Technol. 2008, 99, 7176–7182. [Google Scholar] [CrossRef] [PubMed]

- Miranda, M.T.; Sepúlveda, F.J.; Arranz, J.I.; Montero, I.; Rojas, C.V. Analysis of pelletizing from corn cob waste. J. Environ. Manag. 2018, 228, 303–311. [Google Scholar] [CrossRef] [PubMed]

- Sepúlveda, F.J.; Arranz, J.I.; Miranda, M.T.; Montero, I.; Rojas, C.V. Drying and Pelletizing Analysis of Waste from Cork Granulated Industry. Energies 2018, 11, 109. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).