Carbon Monoxide Formation during Aerobic Biostabilization of the Organic Fraction of Municipal Solid Waste: The Influence of Technical Parameters in a Full-Scale Treatment System

Abstract

1. Introduction

2. Materials and Methods

2.1. Waste Biostabilization Technology

2.2. Methodology

2.2.1. Monitoring the Treatment Piles

- Piles A1 and A2 represented the variant with lower waste mass load ranging from 391 to 465 Mg, and higher aeration rate between 6.6, and 10.7 m3·Mg−1·h−1;

- Piles B1, B2, C1, and C2 represented the variant with higher waste mass load from 611 to 702 Mg, and lower aeration rate between 4.4, and 6.5 m3·Mg−1·h−1;

- Piles C1 and C2 differed from A1, A2, B1 and B2 by being confined by brick sidewalls running the length of the pile, over which the membrane was stretched. In piles A1, A2, B1 and B2, the semipermeable membrane covering the piles was attached to the ground by means of firehoses filled with sand. In other respects, piles C1 and C2 were similar to B1 and B2, having similar waste mass load from 626 to 672 Mg, and aeration rate between 4.6, and 6.1 m3·Mg−1·h−1;

- The duration of the full cycle of AB lasted nine weeks in piles (A1, A2 and B1) and six weeks in the remaining piles (B2, C1 and C2).

2.2.2. Material and Course of Experiment

2.2.3. Measurements of Waste Properties

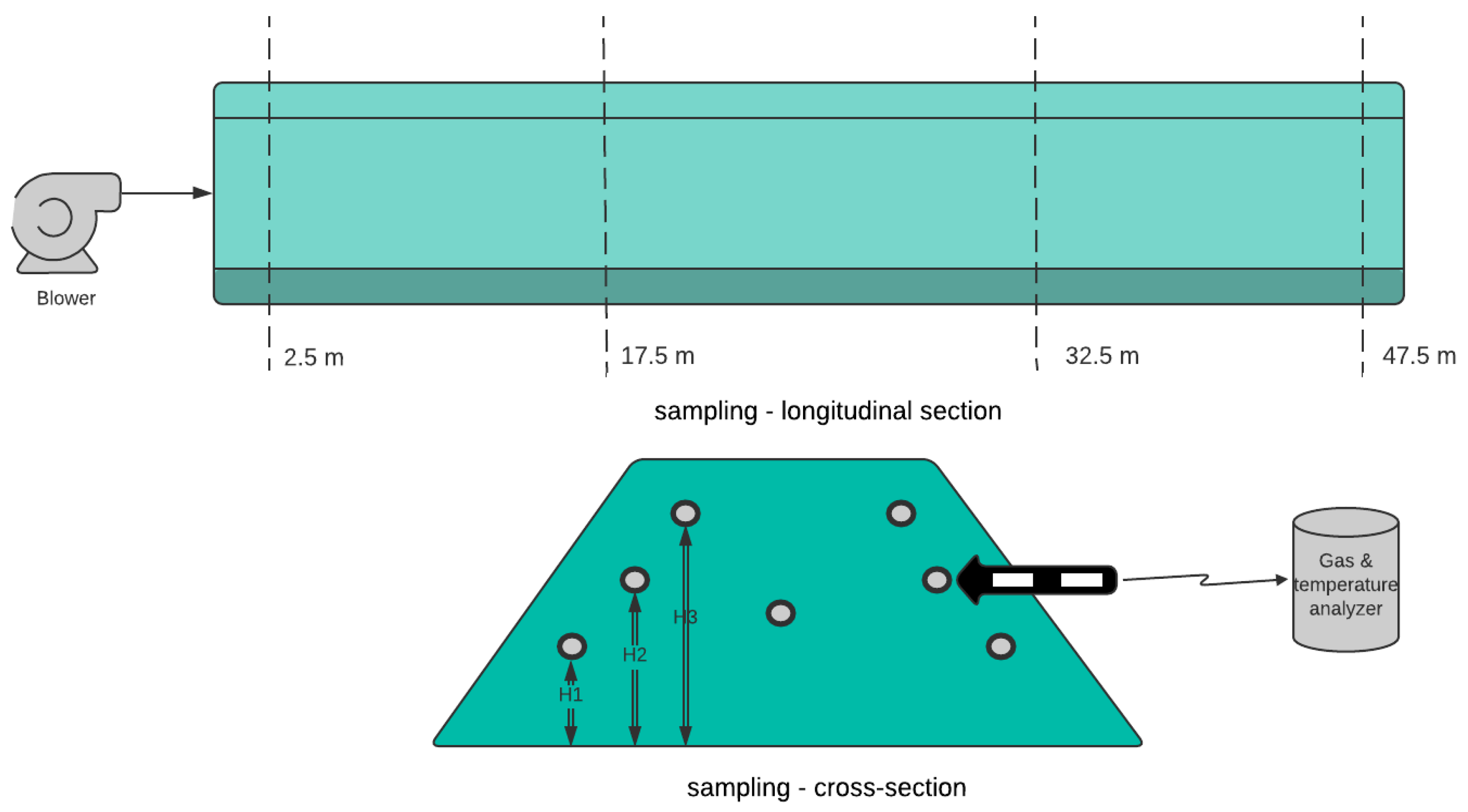

2.2.4. Measurements of Temperature and Gas Distribution in the Piles

2.3. Statistical Data Analysis

3. Results and Discussion

3.1. Process Effectiveness

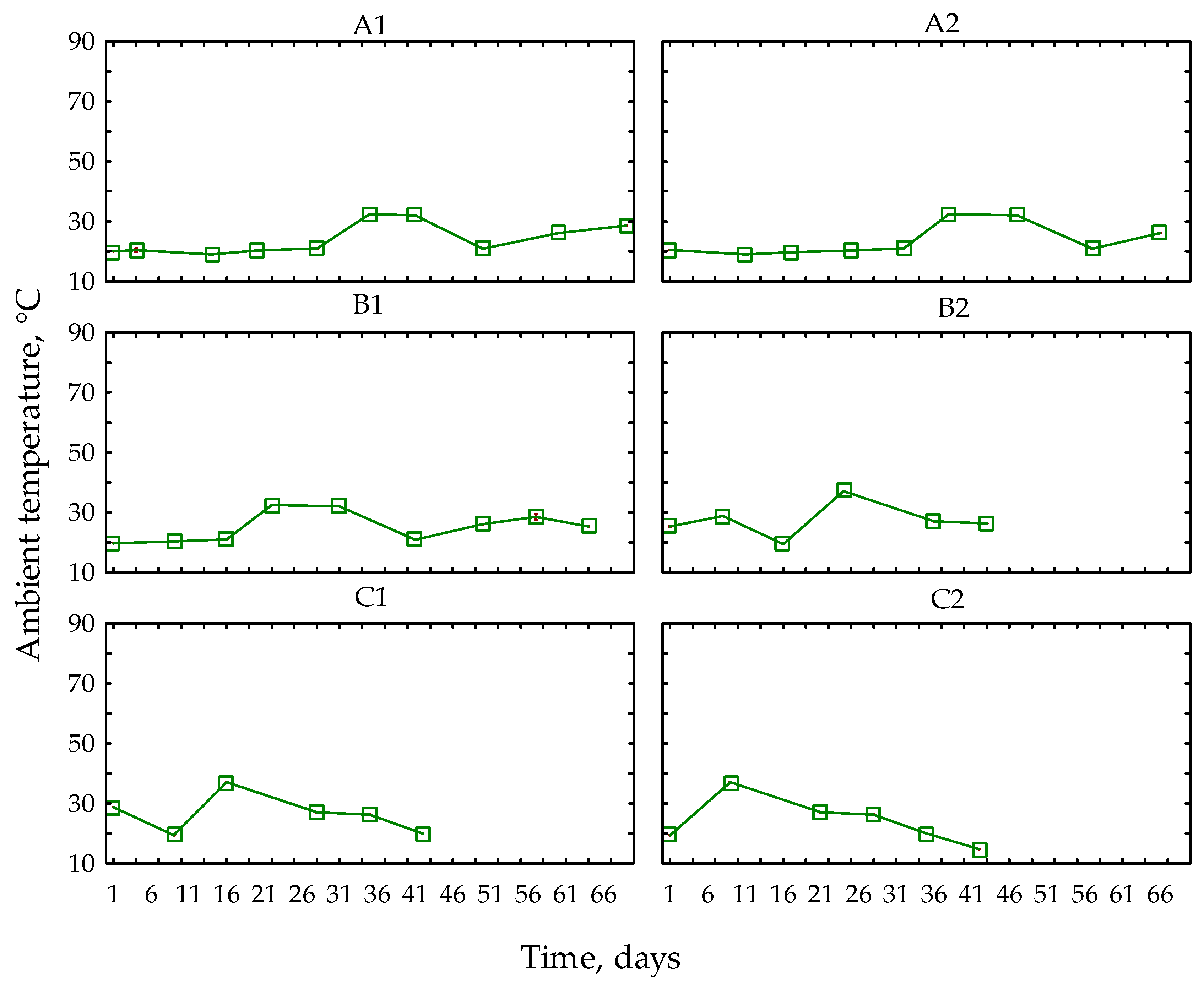

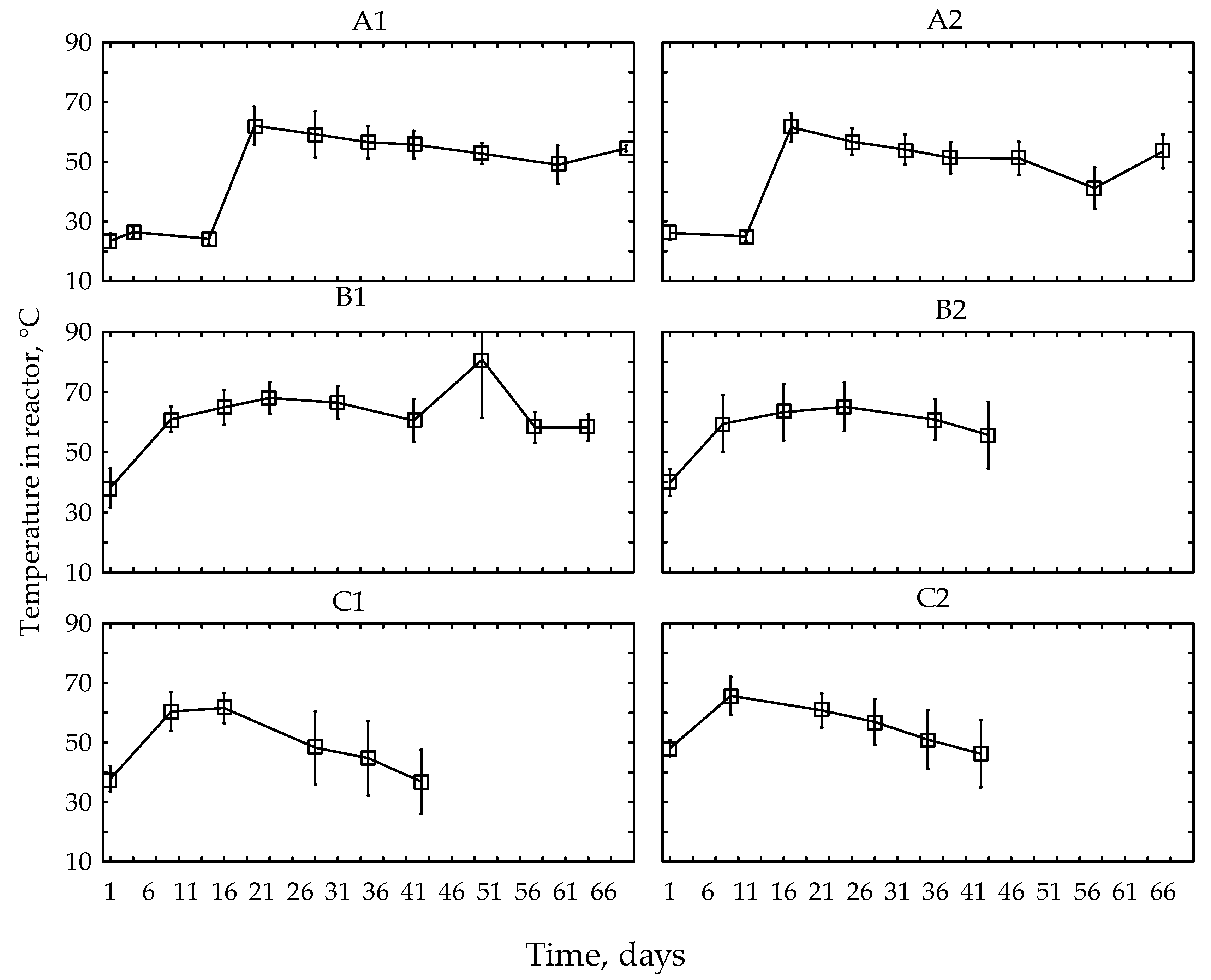

3.2. Thermal Conditions of the Process

3.3. Changes in Gas Concentrations during Waste Aerobic Biostabilization

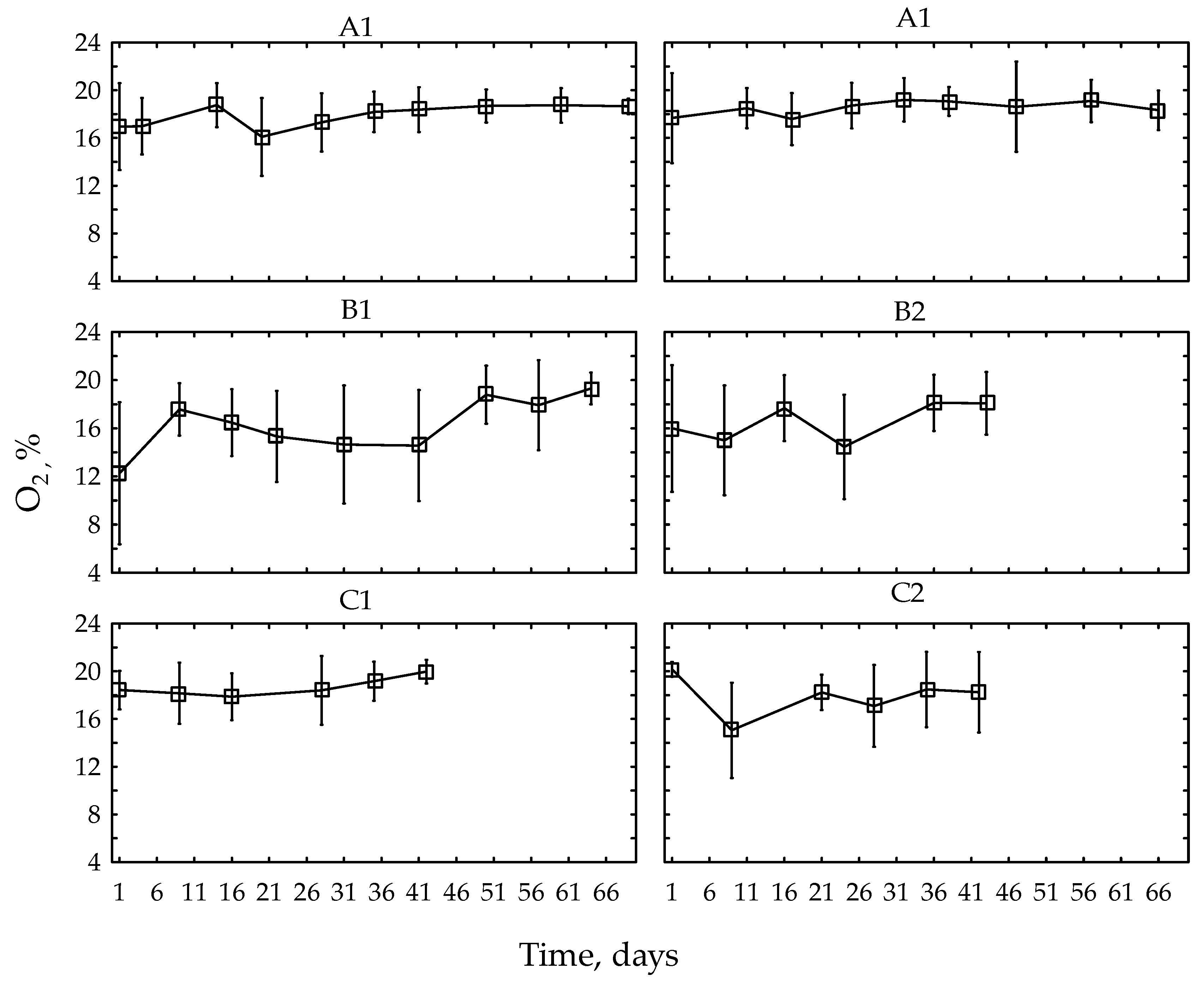

3.3.1. O2 Concentrations in Waste Piles

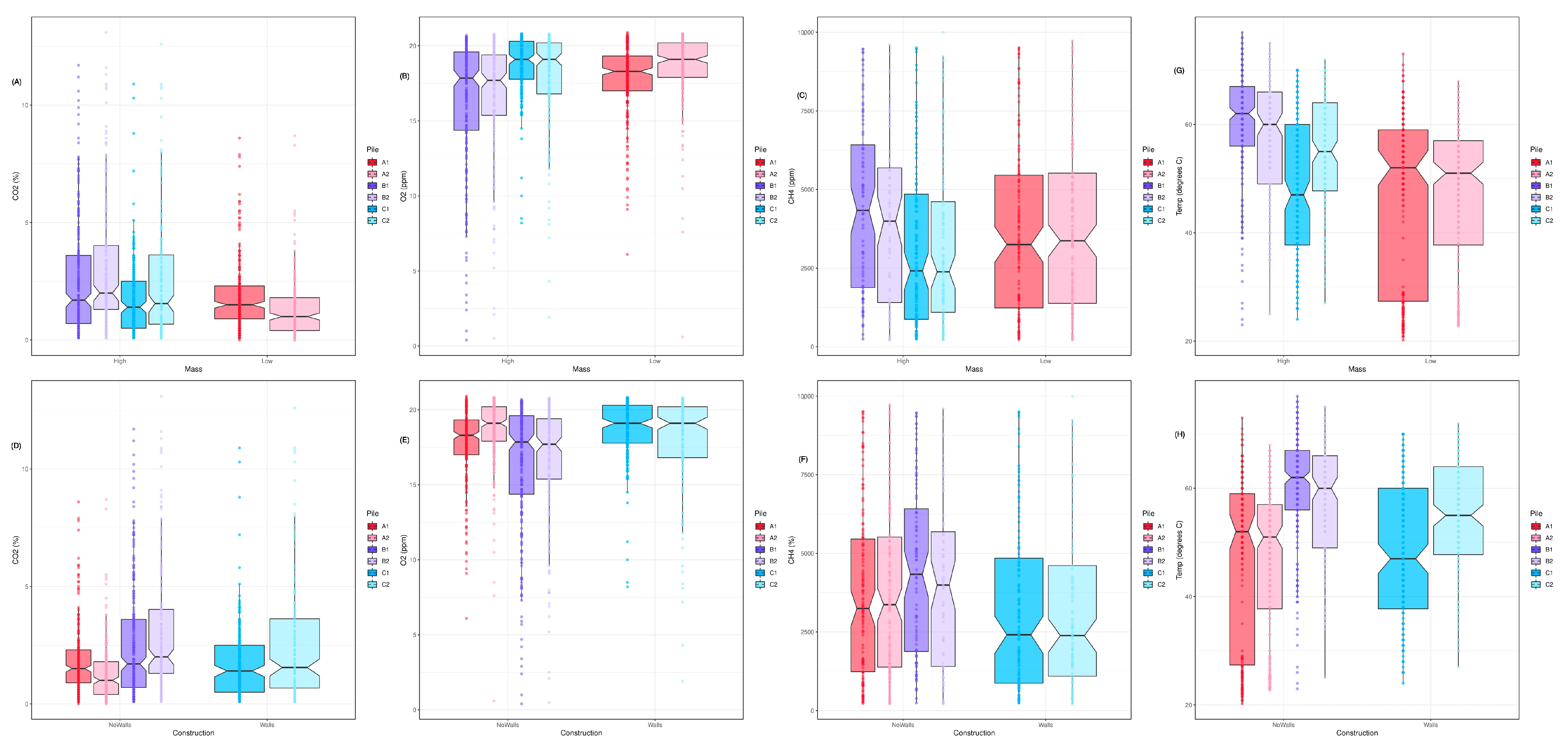

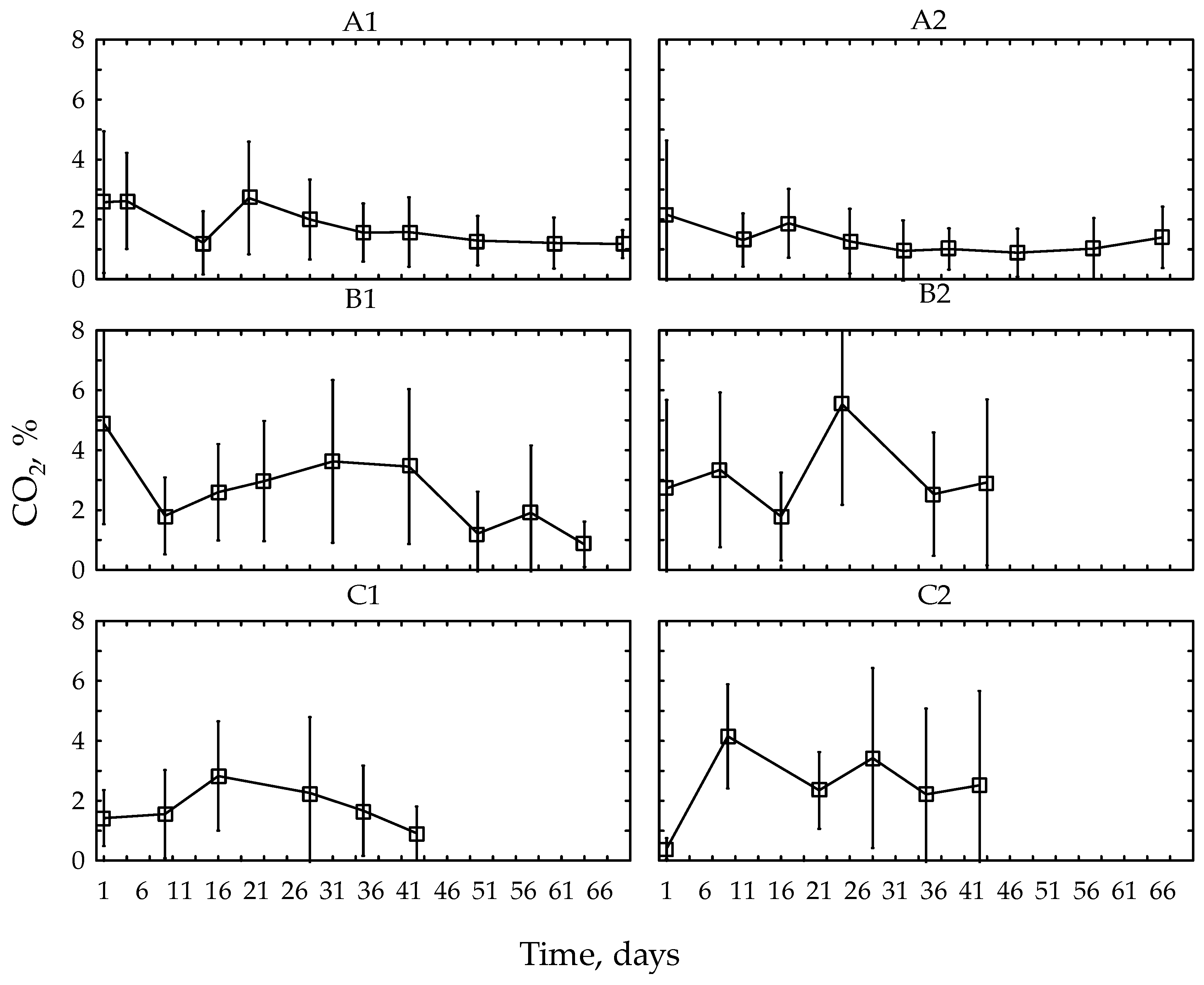

3.3.2. CO2 Concentration in Waste Piles

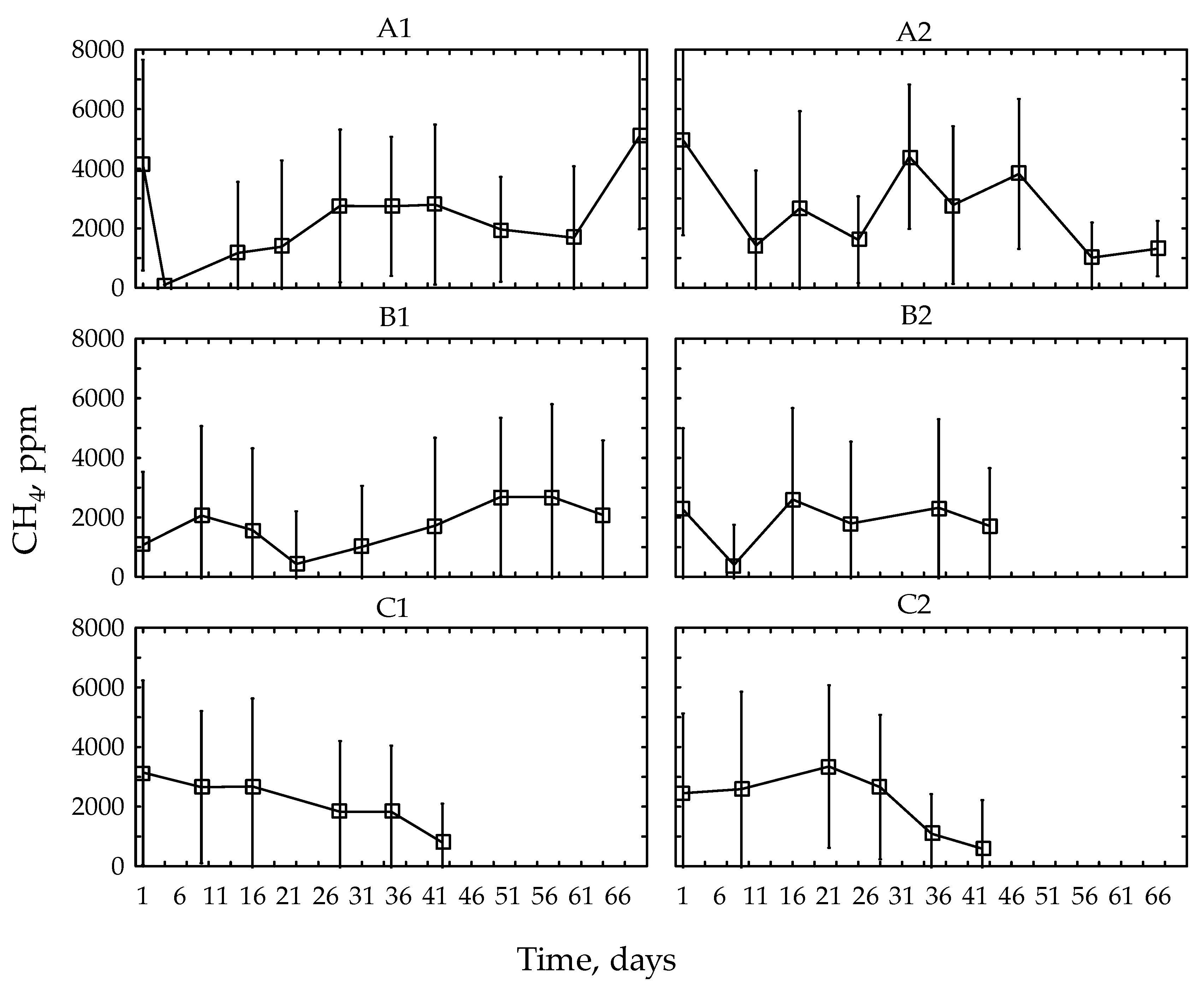

3.3.3. CH4 Concentration in Waste Piles

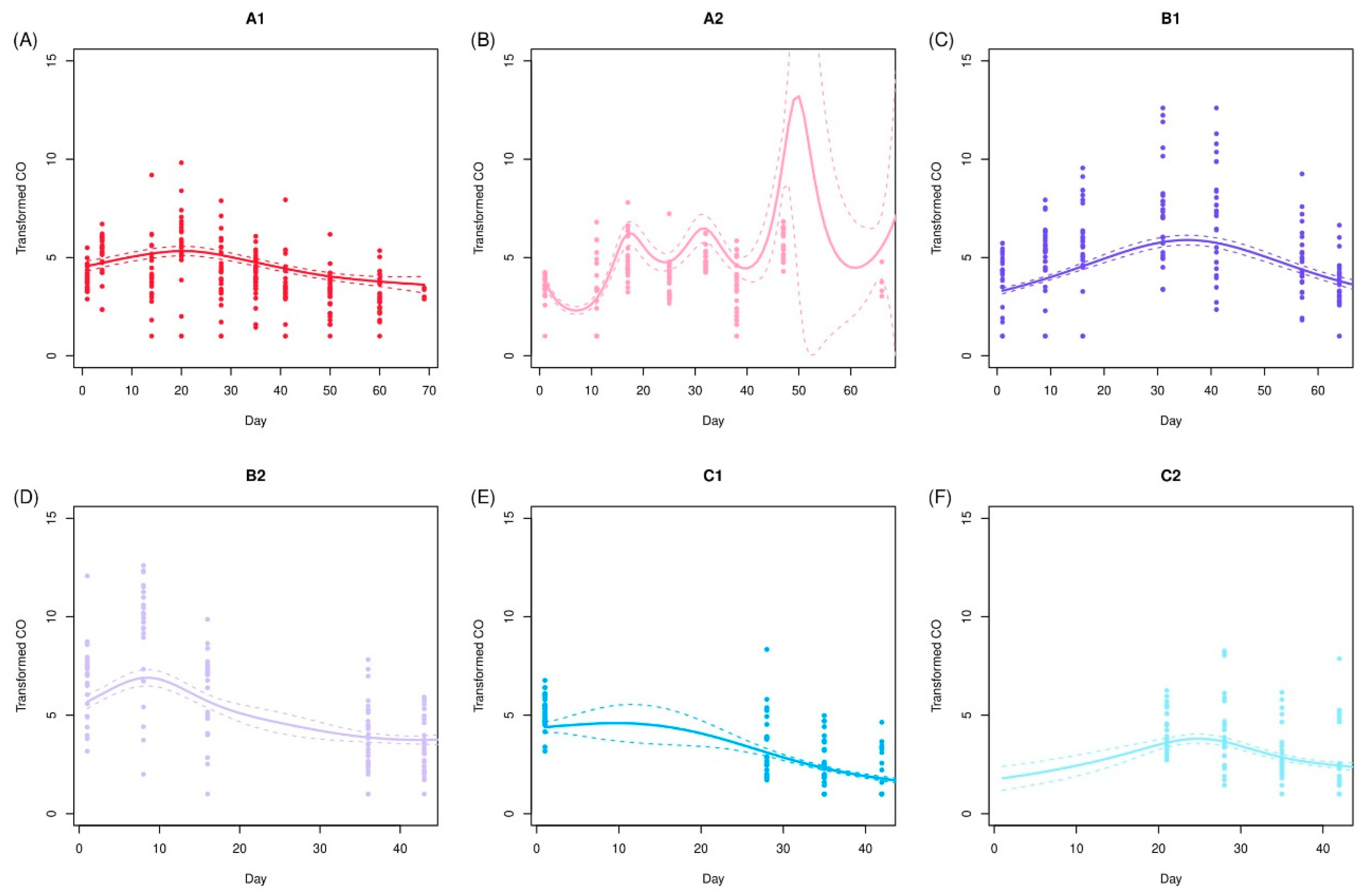

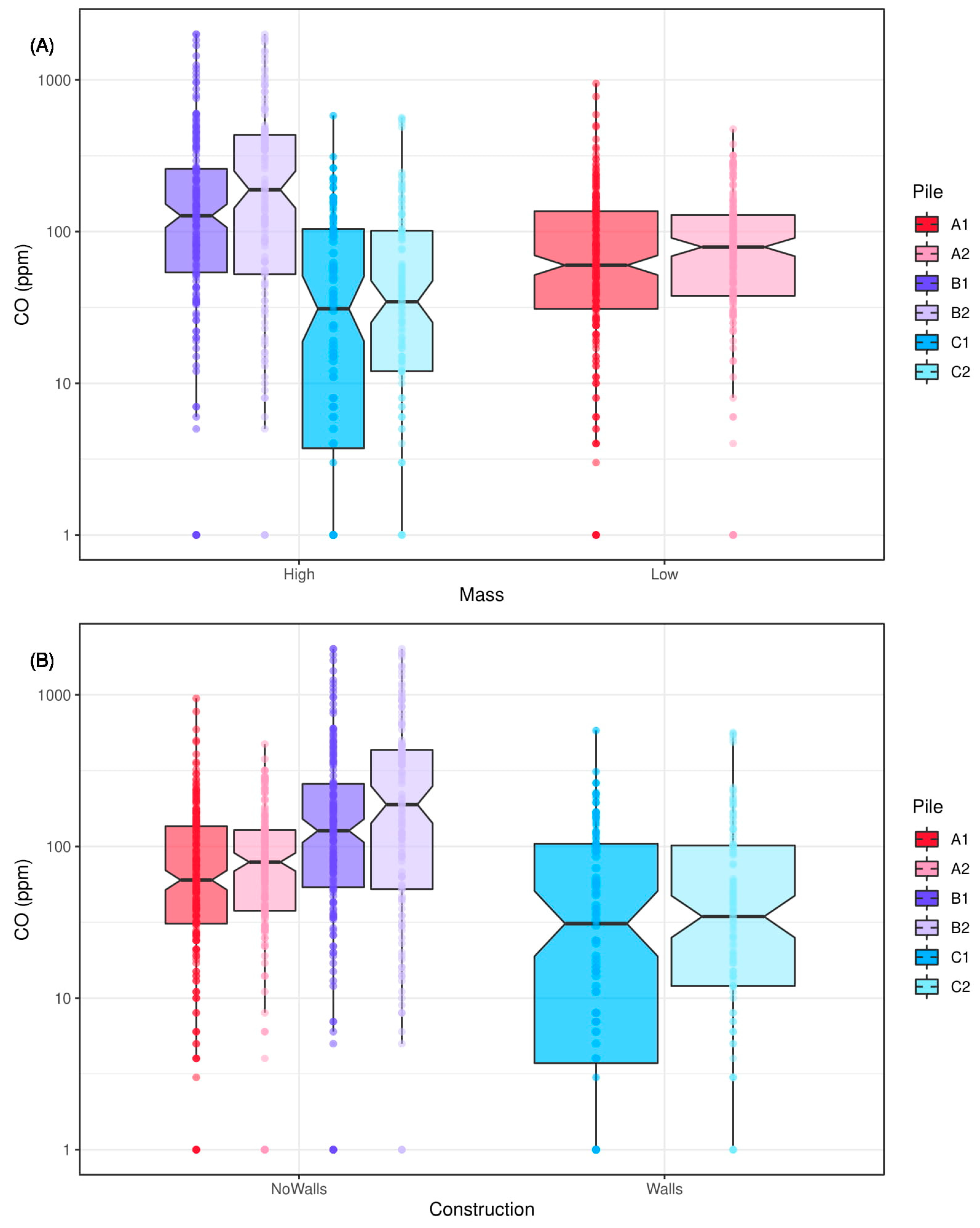

3.3.4. CO Concentration in Waste Piles

3.4. The Influence of Technical Parameters of OFMSW Aerobic Biostabilization

3.4.1. Generalized Additive Model

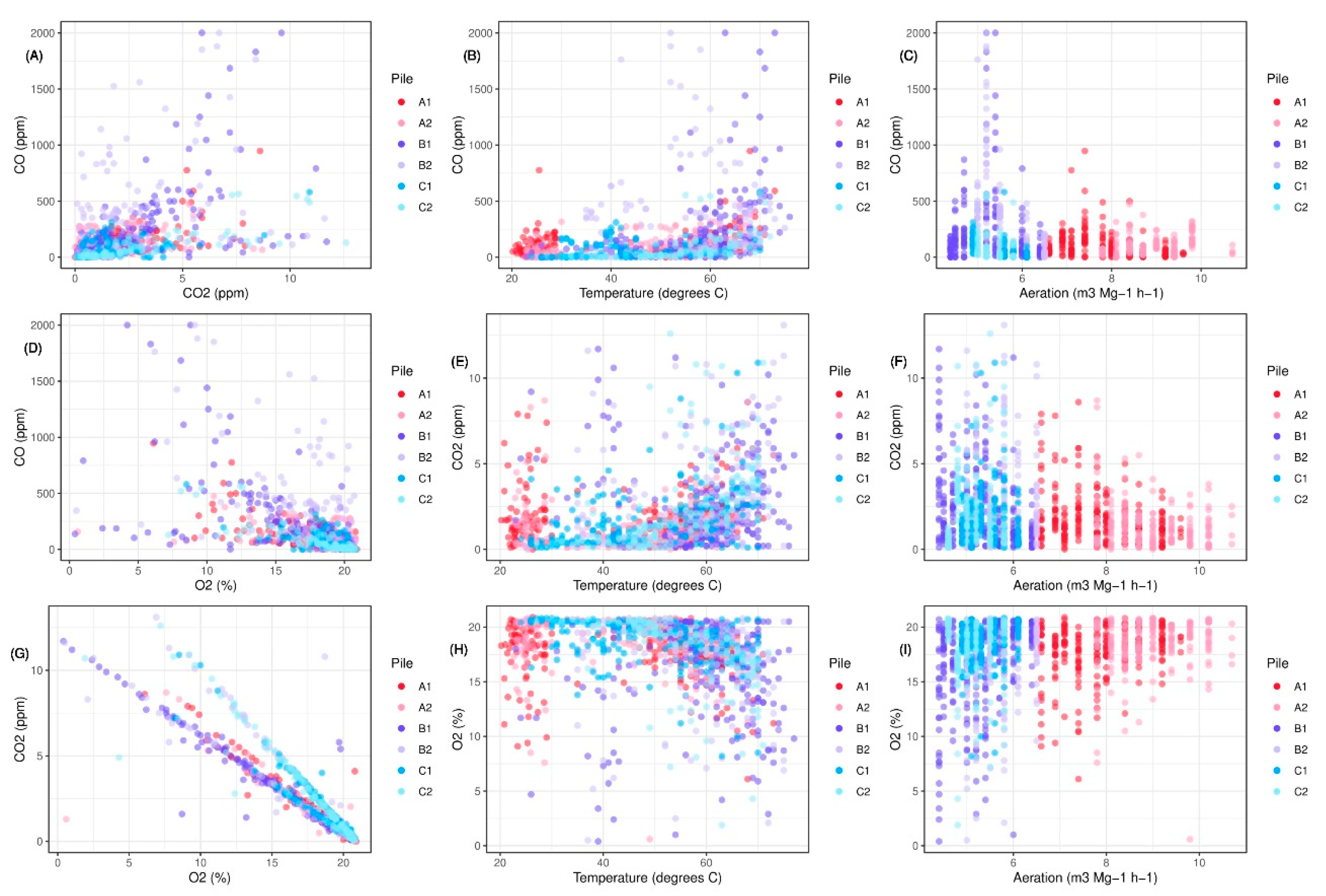

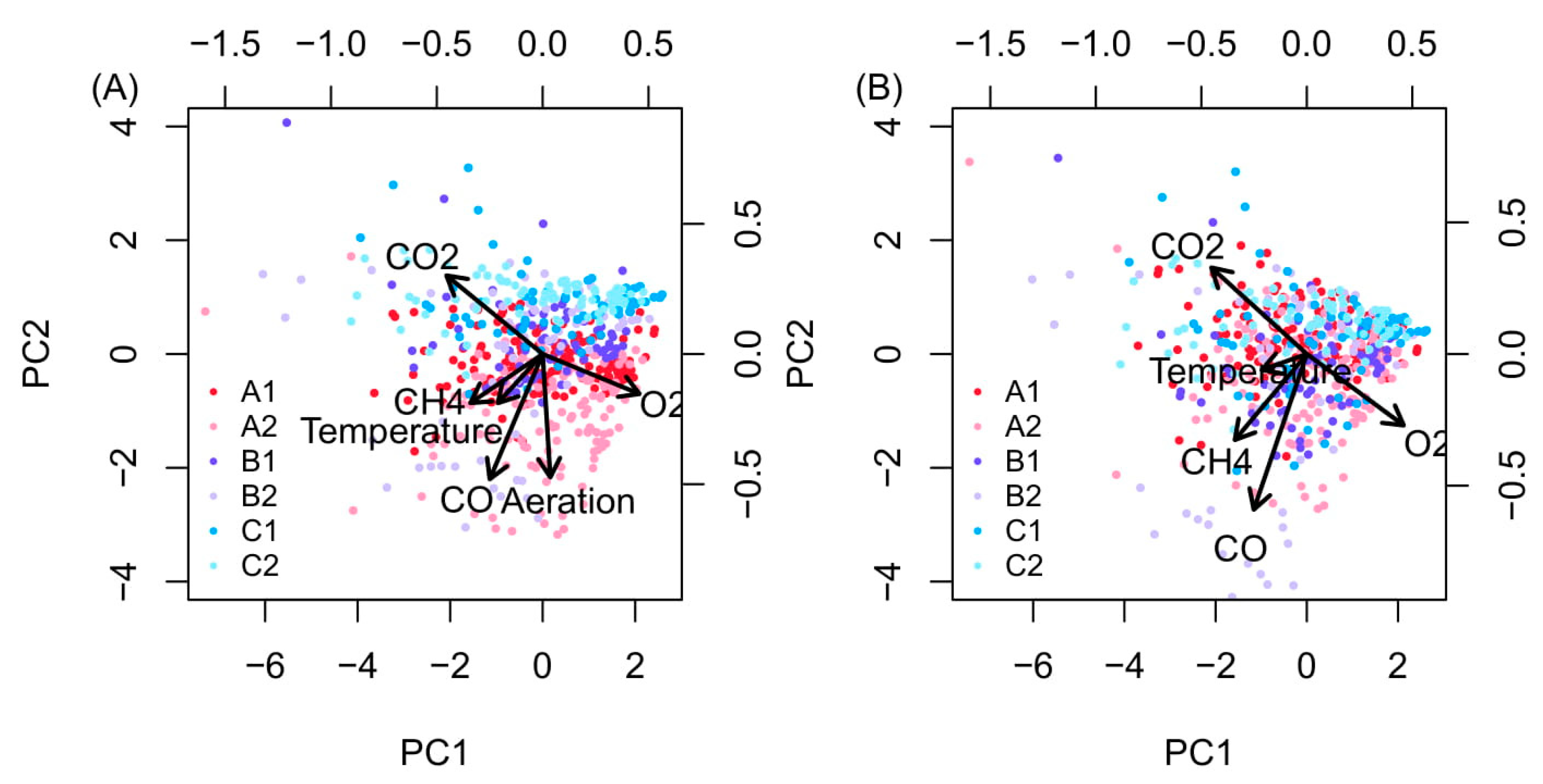

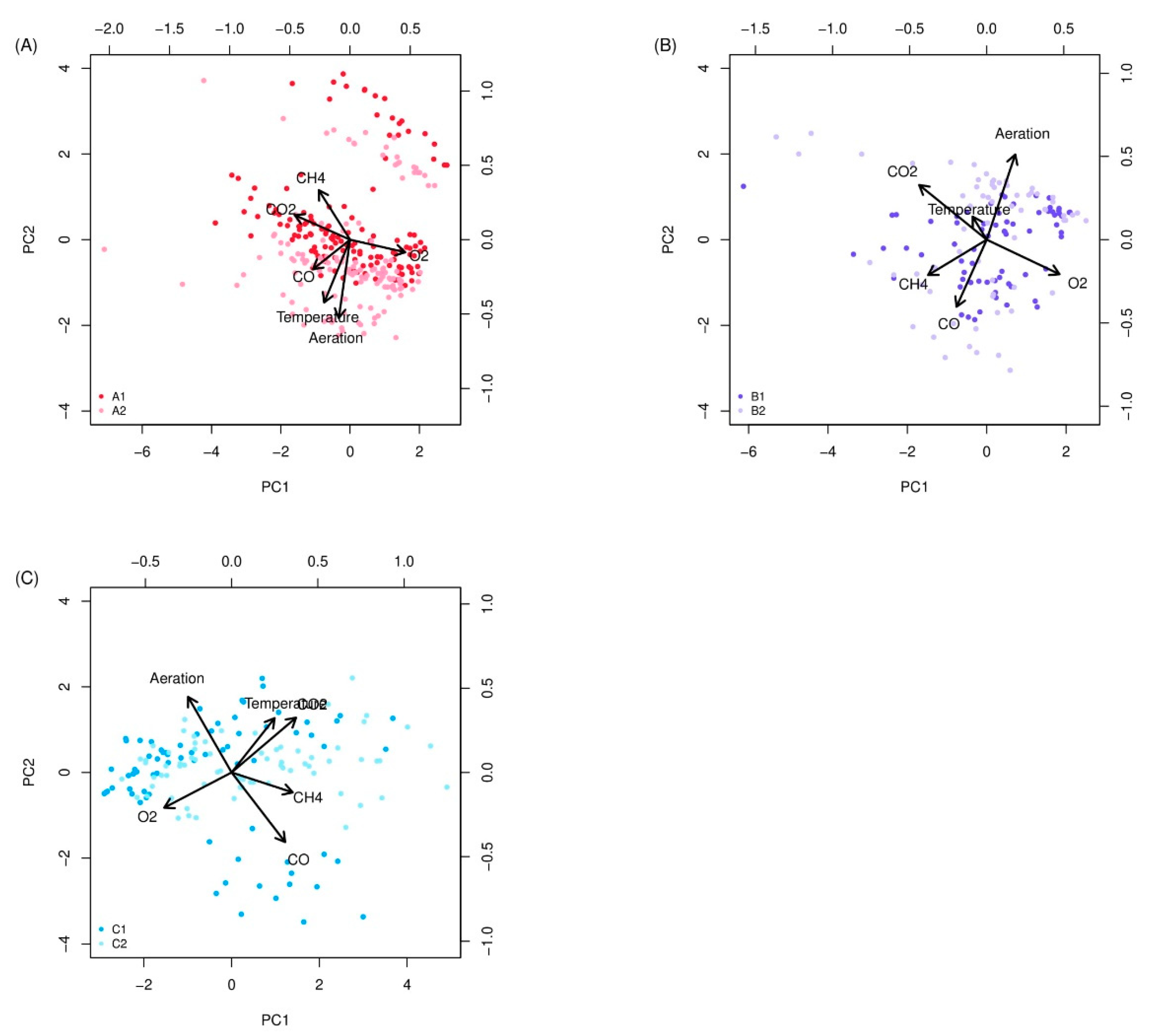

3.4.2. Relationships between CO, Gases and Other Variables in the Biostabilization Process

4. Conclusions

- All examined piles were well aerated and had stable thermal conditions (O2 > 15%, Temperature > 50 °C), yet the presence of CO and CO2 and CH4 was observed, which suggests that ensuring apparently optimum conditions for the process does not eliminate CO;

- Increase in waste mass load promotes conditions for CO accumulation;

- The use of side walls influenced pile cooling. A decrease in the temperature reduced the possibility of thermo-chemical CO generation;

- Oxygen concentration (R2 = 0.55) and temperature (R2 = 0.44) had moderate effects on the CO concentration in the waste piles;

- Aeration rate influenced CO concentration in the waste piles when its value did not exceed 6 m3·Mg−1·h−1;

- The most preferable aeration rate for CO formation was about 5.3 m3·Mg−1·h−1.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| OFMSW | organic fraction of municipal solid waste |

| AB | Aerobic biostabilization |

| MSW | Municipal solid waste |

| GHG | Greenhouses gases |

| MCP | membrane-covered pile |

| SW | with side walls |

Appendix A

References

- Hellebrand, H.J. Emission of nitrous oxide and other trace gases during composting of grass and green waste. J. Agric. Eng. Res. 1998, 69, 365–375. [Google Scholar] [CrossRef]

- Haarstad, K.; Bergersen, O.; Sorheim, R. Occurrence of carbon monoxide during organic waste degradation. J. Air Waste Manag. Assoc. 2006, 56, 575–580. [Google Scholar] [CrossRef]

- Phillip, E.A.; Clark, O.G.; Londry, K.; Yu, S.; Leonard, J. Emission of carbon monoxide during composting of municipal solid waste. Compost Sci. Util. 2011, 19, 170–177. [Google Scholar] [CrossRef]

- Stegenta, S.; Dębowski, M.; Bukowski, P.; Randerson, P.F.; Białowiec, A. The influence of perforation of foil reactors on greenhouse gas emission rates during aerobic biostabilization of the undersize fraction of municipal wastes. J. Environ. Manag. 2018, 207, 355. [Google Scholar] [CrossRef] [PubMed]

- Ritzkowski, M.; Heerenklage, J.; Stegmann, R. An overview on techniques and regulations of mechanical-biological pre-treatment of municipal solid waste. Environ. Biotechnol. 2006, 2, 57–68. [Google Scholar]

- Jędrczak, A. Properties of the Organic Fraction Directed to Biostabilization in MBT Installations During the Heating Season. Civ. Environ. Eng. Rep. 2018, 28, 65–78. [Google Scholar] [CrossRef]

- Döing, M. The Market for Mechanical Biological Waste Treatment Plants in Europe. Available online: https://www.wtert.net/paper/3765/The-Market-for-Mechanical-Biological-Waste-Treatment-Plants-in-Europe.html (accessed on 3 September 2020).

- Andersen, J.K.; Boldrin, A.; Christensen, T.H.; Scheutz, C. Home composting as an alternative treatment option for organic household waste in Denmark: An environmental assessment using life cycle assessment-modelling. Waste Manag. 2012, 32, 31–40. [Google Scholar] [CrossRef] [PubMed]

- Manfredi, S.; Tonini, D.; Christensen, T.H. Environmental assessment of different management options for individual waste fractions by means of life-cycle assessment modelling. Resour. Conserv. Recycl. 2011, 55, 995–1004. [Google Scholar] [CrossRef]

- Lee, S.H.; Choi, K.I.; Osako, M.; Dong, J.I. Evaluation of environmental burdens caused by changes of food waste management systems in Seoul, Korea. Sci. Total Environ. 2007, 387, 42–53. [Google Scholar] [CrossRef]

- Hellebrand, H.J.; Schade, G.W. Carbon monoxide from composting due to thermal oxidation of biomass. J. Environ. Qual. 2008, 37, 592. [Google Scholar] [CrossRef]

- Schade, G.W.; Hoffman, R.M.; Crutzen, P.J. CO emissions from degrading plant matter. I. Measurements. Tellus B Chem. Phys. Meteorol. 1999, 51, 889–908. [Google Scholar] [CrossRef][Green Version]

- Hellebrand, H.J.; Kalk, W.D. Emission of carbon monoxide during composting of dung and green waste. Nutr. Cycl. Agroecosyst. 2001, 60, 79–82. [Google Scholar] [CrossRef]

- Rich, J.J.; King, G.M. Carbon monoxide consumption and production by wetland peats. FEMS Microbiol. Ecol. 1999, 28, 215–224. [Google Scholar] [CrossRef]

- Voordouw, G. Carbon monoxide cycling by Desulfovibrio vulgaris Hildenborough. J. Bacteriol. 2002, 184, 5903–5911. [Google Scholar] [CrossRef] [PubMed]

- Ljungdahl, L.G. The Acetyl-CoA Pathway and the Chemiosmotic Generation of ATP during Acetogenesis. In Acetogenesis; Springer: Boston, MA, USA, 1994; pp. 63–87. [Google Scholar] [CrossRef]

- Hogan, J.A.; Miller, F.C.; Finstein, M.S. Physical modeling of the composting ecosystem. Appl. Environ. Microbiol. 1989, 55, 1082–1092. [Google Scholar] [CrossRef]

- Favoino, E.; Hogg, D. The potential role of compost in reducing greenhouse gases. Waste Manag. Res. 2008, 26, 61–69. [Google Scholar] [CrossRef]

- Chadwick, D.; Sommer, S.G.; Thorman, R.; Fangueiro, D.; Cardenas, L.; Amon, B.; Misselbrook, T. Manure management: Implications for greenhouse gas emissions. Anim. Feed Sci. Technol. 2011, 166–167, 514–531. [Google Scholar] [CrossRef]

- Amlinger, F.; Peyr, S.; Cuhls, C. Green house gas emissions from composting and mechanical biological treatment. Waste Manag. Res. 2008, 26, 47–60. [Google Scholar] [CrossRef]

- Su, J.J.; Liu, B.Y.; Chang, Y.C. Emission of greenhouse gas from livestock waste and wastewater treatment in Taiwan. Agric. Ecosyst. Environ. 2003, 95, 253–263. [Google Scholar] [CrossRef]

- Neuwahl, F.; Cusano, G.; Gómez Benavides, J.; Holbrook, S.; Roudier, S. Best Available Techniques (BAT) Reference Document for Waste Incineration: Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control), EUR 29971 EN; Publications Office of the European Union: Luxembourg, 2019; ISBN 9789276129936. [Google Scholar]

- Stegenta-Dąbrowska, S.; Rogosz, J.; Bukowski, P.; Dębowski, M.; Randerson, P.F.; Bieniek, J.; Białowiec, A. The fluctuation of process gasses especially of carbon monoxide during aerobic biostabilization of an organic fraction of municipal solid waste under different technological regimes. Data 2020, 5, 40. [Google Scholar] [CrossRef]

- RStudio Team. RStudio: Integrated Development for R. RStudio, PBC, Boston. 2016. Available online: https://rstudio.com/ (accessed on 23 August 2020).

- R Core Team. R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. 2019. Available online: https://www.r-project.org/ (accessed on 23 August 2020).

- Wood, S.N. Fast stable restricted maximum likelihood and marginal likelihood estimation of semiparametric generalized linear models. J. R. Stat. Soc. Ser. B (Stat. Methodol.) 2011, 73, 3–36. [Google Scholar] [CrossRef]

- Liang, C.; Das, K.C.; McClendon, R.W. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour. Technol. 2003, 86, 131–137. [Google Scholar] [CrossRef]

- Velis, C.A.; Longhurst, P.J.; Drew, G.H.; Smith, R.; Pollard, S.J.T. Biodrying for mechanical-biological treatment of wastes: A review of process science and engineering. Bioresour. Technol. 2009, 100, 2747–2761. [Google Scholar] [CrossRef]

- Ermolaev, E.; Pell, M.; Smårs, S.; Sundberg, C.; Jönsson, H.; Smars, S.; Sundberg, C.; Jonsson, H. Greenhouse gas emission from covered windrow composting with controlled ventilation. Waste Manag. Res. 2012, 30, 155–160. [Google Scholar] [CrossRef]

- Mulbry, W.; Ahn, H. Greenhouse gas emissions during composting of dairy manure: Influence of the timing of pile mixing on total emissions. Biosyst. Eng. 2014, 126, 117–122. [Google Scholar] [CrossRef]

- Evangelou, A.; Gerassimidou, S.; Mavrakis, N.; Komilis, D. Monitoring the performances of a real scale municipal solid waste composting and a biodrying facility using respiration activity indices. Environ. Monit. Assess. 2016, 188, 302. [Google Scholar] [CrossRef]

- Komilis, D.; Evangelou, A.; Giannakis, G.; Lymperis, C. Revisiting the elemental composition and the calorific value of the organic fraction of municipal solid wastes. Waste Manag. 2012, 32, 372–381. [Google Scholar] [CrossRef] [PubMed]

- Jędrczak, A.; DenBoer, E. The Final Report of the Third Stage of the Expertize Aiming to Conducting the Waste Research in 20 Mechanical, and Biological Treatment Plants in Poland In Polish: Raport Końcowy III Etapu Ekspertyzy Mającej na Celu Przeprowadzenie Badań Odpadów w 20 Inst. 2015. Available online: https://sdr.gdos.gov.pl/Documents/GO/Ekspertyzy/Ekspertyza%20MBP_III%20etap_%2022-06-2015%20+%20za%C5%82aczniki.pdf (accessed on 3 September 2020).

- Jiang, T.; Li, G.; Tang, Q.; Ma, X.; Wang, G.; Schuchardt, F. Effects of aeration method and aeration rate on greenhouse gas emissions during composting of pig feces in pilot scale. J. Environ. Sci. 2015, 31, 124–132. [Google Scholar] [CrossRef]

- Shen, Y.J.; Ren, L.M.; Li, G.X.; Chen, T.B.; Guo, R. Influence of aeration on CH4, N2O and NH3 emissions during aerobic composting of a chicken manure and high C/N waste mixture. Waste Manag. 2011, 31, 33–38. [Google Scholar] [CrossRef]

- Adani, F.; Tambone, F.; Gotti, A. Biostabilization of municipal solid waste. Waste Manag. 2004, 24, 775–783. [Google Scholar] [CrossRef] [PubMed]

- Andersen, J.K.; Boldrin, A.; Samuelsson, J.; Christensen, T.H.; Scheutz, C. Quantification of greenhouse gas emissions from windrow composting of garden waste. J. Environ. Qual. 2010, 39, 713. [Google Scholar] [CrossRef] [PubMed]

- Beck-Friis, B.; Pell, M.; Sonesson, U.; Jonsson, H.; Kirchmann, H. Formation and emission of N2O and CH4 from compost heaps of organic household waster. Environ. Monit. Assess. 2000, 62, 317–331. [Google Scholar] [CrossRef]

- Wang, J.Z.; Hu, Z.Y.; Xu, X.K.; Jiang, X.; Zheng, B.H.; Liu, X.N.; Pan, X.B.; Kardol, P. Emissions of ammonia and greenhouse gases during combined pre-composting and vermicomposting of duck manure. Waste Manag. 2014, 34, 1546–1552. [Google Scholar] [CrossRef]

- Mason, I.G. Mathematical modelling of the composting process: A review. Waste Manag. 2006, 26, 3–21. [Google Scholar] [CrossRef] [PubMed]

- Luangwilai, T.; Sidhu, H.S.; Nelson, M.I.; Chen, X.D. Modelling air flow and ambient temperature effects on the biological self-heating of compost piles. Asia Pac. J. Chem. Eng. 2010, 5, 609–618. [Google Scholar] [CrossRef]

- Clemens, J.; Cuhls, C. Greenhouse gas emissions from mechanical and biological waste treatment of municipal waste. Environ. Technol. 2003, 24, 745–754. [Google Scholar] [CrossRef] [PubMed]

- Stegenta, S.; Sobieraj, K.; Pilarski, G.; Koziel, J.A.; Białowiec, A. Analysis of the spatial and temporal distribution of process gases within municipal biowaste compost. Sustainability 2019, 11, 2340. [Google Scholar] [CrossRef]

- Adhikari, B.K.; Tremier, A.; Barrington, S.; Martinez, J.; Daumoin, M. Gas emissions as influenced by home composting system configuration. J. Environ. Manag. 2013, 116, 163–171. [Google Scholar] [CrossRef]

- Colon, J.; Cadena, E.; Pognani, M.; Barrena, R.; Sanchez, A.; Font, X.; Artola, A. Determination of the energy and environmental burdens associated with the biological treatment of source-separated Municipal Solid Wastes. Energy Environ. Sci. 2012, 5, 5731–5741. [Google Scholar] [CrossRef]

- Fukumoto, Y.; Osada, T.; Hanajima, D.; Haga, K. Patterns and quantities of NH3, N2O and CH4 emissions during swine manure composting without forced aeration—Effect of compost pile scale. Bioresour. Technol. 2003, 89, 109–114. [Google Scholar] [CrossRef]

- He, Y.W.; Inamori, Y.; Mizuochi, M.; Kong, H.N.; Iwami, N.; Sun, T.H. Measurements of N2O and CH4 from the aerated composting of food waste. Sci. Total Environ. 2000, 254, 65–74. [Google Scholar] [CrossRef]

- Sommer, S.G.; Moller, H.B. Emission of greenhouse gases during composting of deep litter from pig production—Effect of straw content. J. Agric. Sci. 2000, 134, 327–335. [Google Scholar] [CrossRef]

- Thompson, A.G.; Wagner-Riddle, C.; Fleming, R. Emissions of N2O and CH4 during the composting of liquid swine manure. Environ. Monit. Assess. 2004, 91, 87–104. [Google Scholar] [CrossRef] [PubMed]

- Zeman, C.; Depken, D.; Rich, M. Research on how the composting process impacts greenhouse gas emissions and global warming. Compost Sci. Util. 2002, 10, 72–86. [Google Scholar] [CrossRef]

- Ragsdale, S.W. Life with carbon monoxide. Crit. Rev. Biochem. Mol. Biol. 2004, 39, 165–195. [Google Scholar] [CrossRef]

- Boldrin, A.; Andersen, J.K.; Moller, J.; Christensen, T.H.; Favoino, E. Composting and compost utilization: Accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 2009, 27, 800–812. [Google Scholar] [CrossRef]

- Andersen, J.K.; Boldrin, A.; Christensen, T.H.; Scheutz, C. Greenhouse gas emissions from home composting of organic household waste. Waste Manag. 2010, 30, 2475–2482. [Google Scholar] [CrossRef]

- Techtmann, S.M.; Colman, A.S.; Robb, F.T. ‘That which does not kill us only makes us stronger’: The role of carbon monoxide in thermophilic microbial consortia. Environ. Microbiol. 2009, 11, 1027–1037. [Google Scholar] [CrossRef]

- Stegenta-Dąbrowska, S.; Drabczyński, G.; Sobieraj, K.; Koziel, J.A.; Białowiec, A. The biotic and abiotic carbon monoxide formation during aerobic co-digestion of dairy cattle manure with green waste and sawdust. Front. Bioeng. Biotechnol. 2019, 7, 283. [Google Scholar] [CrossRef]

- Hsu, T.; Lux, M.F.; Drake, H.L. Expression of an aromatic-dependent decarboxylase which provides growth-essential CO2 equivalents for the acetogenic (wood) pathway of Clostridium thermoaceticum. J. Bacteriol. 1990, 172, 5901–5907. [Google Scholar] [CrossRef]

- Hsu, T.; Daniel, S.L.; Lux, M.F.; Drake, H.L. Biotransformations of carboxylated aromatic compounds by the acetogen Clostridium thermoaceticum: Generation of growth-supportive CO2 equivalents under CO2-limited conditions. J. Bacteriol. 1990, 172, 212–217. [Google Scholar] [CrossRef] [PubMed]

| Parameter | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pile | Moisture | Loss on Ignition | Total Organic Carbon | Waste Mass | Total Aeration Intensity | Waste Mass Load | Reactor Design | Duration of Cycle |

| % | % | % | % | m3·Mg−1 | Mg | - | Days | |

| A1 | 61.1 | 26.1 | 27.3 | 35.2 | 12,744 | 465.38 | MCP | 69 |

| A2 | 71.4 | 31.0 | 34.5 | 33.6 | 12,681 | 391.02 | MCP | 66 |

| B1 | 22.8 | 18.0 | 8.2 | 35.8 | 5205 | 702.38 | MCP | 64 |

| B2 | 30.8 | 12.0 | 9.6 | 27.4 | 5690 | 611.36 | MCP | 43 |

| C1 | 26.0 | - | - | 24.4 | 5461 | 626.14 | SW | 42 |

| C2 | 26.7 | 4.2 | 3.9 | 25.9 | 3365 | 671.84 | SW | 42 |

| Rank | Whole Dataset | Piles A1, B1 and C1 | Piles A2, B2 and C2 |

|---|---|---|---|

| 1 | Aeration + construction | Construction + mass | Aeration + construction + mass |

| 2 | Construction + mass | Aeration + construction | Aeration + construction |

| 3 | Aeration + construction + mass | Aeration + construction + mass | Construction + mass |

| 4 | Aeration | Mass | Aeration |

| 5 | Mass | Aeration | Mass |

| 6 | Aeration + mass | Aeration + mass | Aeration + mass |

| 7 | Construction | Construction | Smoothed-term only |

| 8 | Smoothed-term only | Smoothed-term only | Construction |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stegenta-Dąbrowska, S.; Randerson, P.F.; Christofides, S.R.; Białowiec, A. Carbon Monoxide Formation during Aerobic Biostabilization of the Organic Fraction of Municipal Solid Waste: The Influence of Technical Parameters in a Full-Scale Treatment System. Energies 2020, 13, 5624. https://doi.org/10.3390/en13215624

Stegenta-Dąbrowska S, Randerson PF, Christofides SR, Białowiec A. Carbon Monoxide Formation during Aerobic Biostabilization of the Organic Fraction of Municipal Solid Waste: The Influence of Technical Parameters in a Full-Scale Treatment System. Energies. 2020; 13(21):5624. https://doi.org/10.3390/en13215624

Chicago/Turabian StyleStegenta-Dąbrowska, Sylwia, Peter F. Randerson, Sarah R. Christofides, and Andrzej Białowiec. 2020. "Carbon Monoxide Formation during Aerobic Biostabilization of the Organic Fraction of Municipal Solid Waste: The Influence of Technical Parameters in a Full-Scale Treatment System" Energies 13, no. 21: 5624. https://doi.org/10.3390/en13215624

APA StyleStegenta-Dąbrowska, S., Randerson, P. F., Christofides, S. R., & Białowiec, A. (2020). Carbon Monoxide Formation during Aerobic Biostabilization of the Organic Fraction of Municipal Solid Waste: The Influence of Technical Parameters in a Full-Scale Treatment System. Energies, 13(21), 5624. https://doi.org/10.3390/en13215624