Analysis of the Characteristics of External Walls of Wooden Prefab Cross Laminated Timber

Abstract

1. Introduction

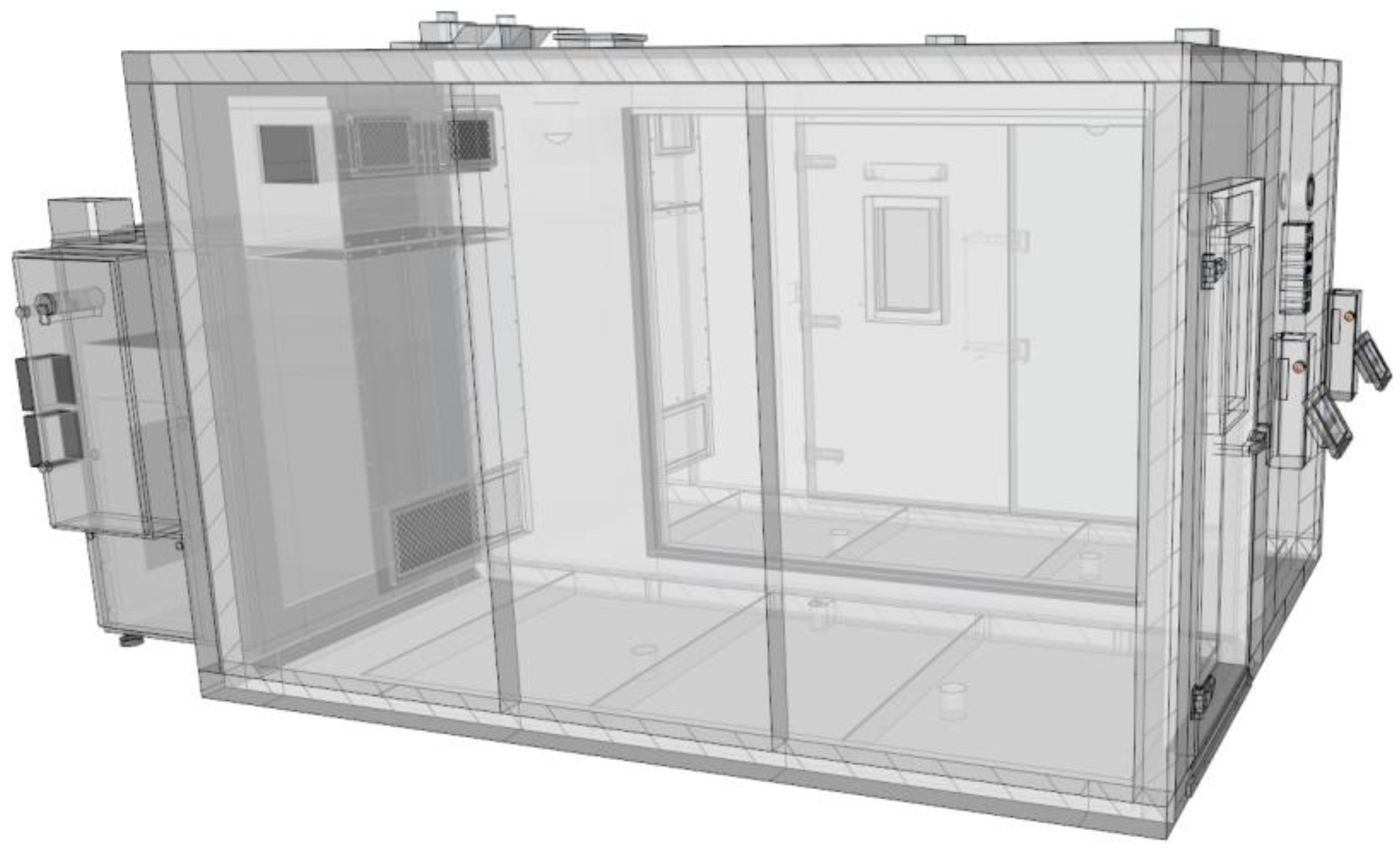

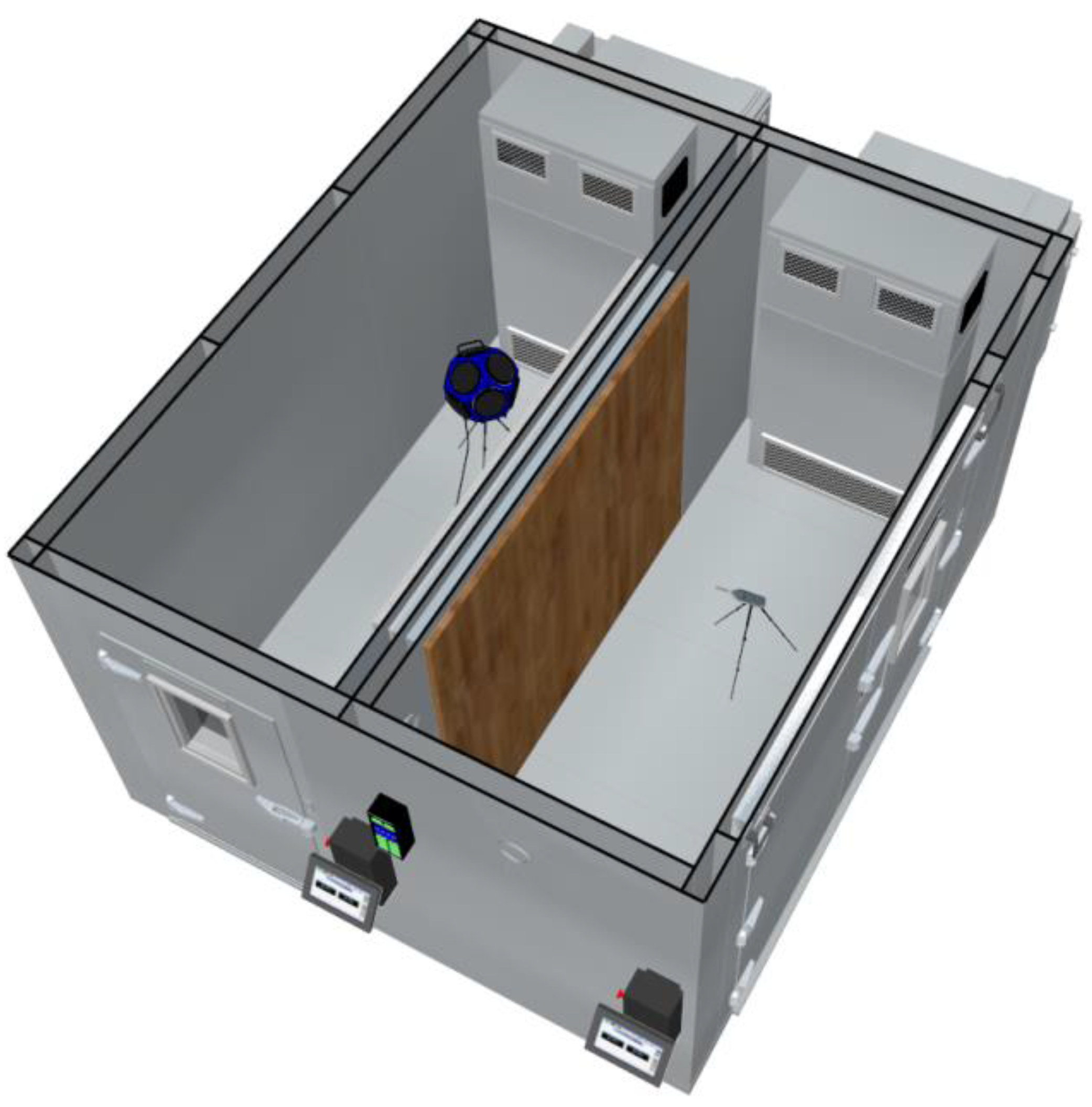

2. Materials and Methods

2.1. Description of Investigated Structures

2.2. Methods of Assessment of Selected Thermal-Technical Parameters

2.3. Methods of Measuring and Evaluating Acoustic Parameters

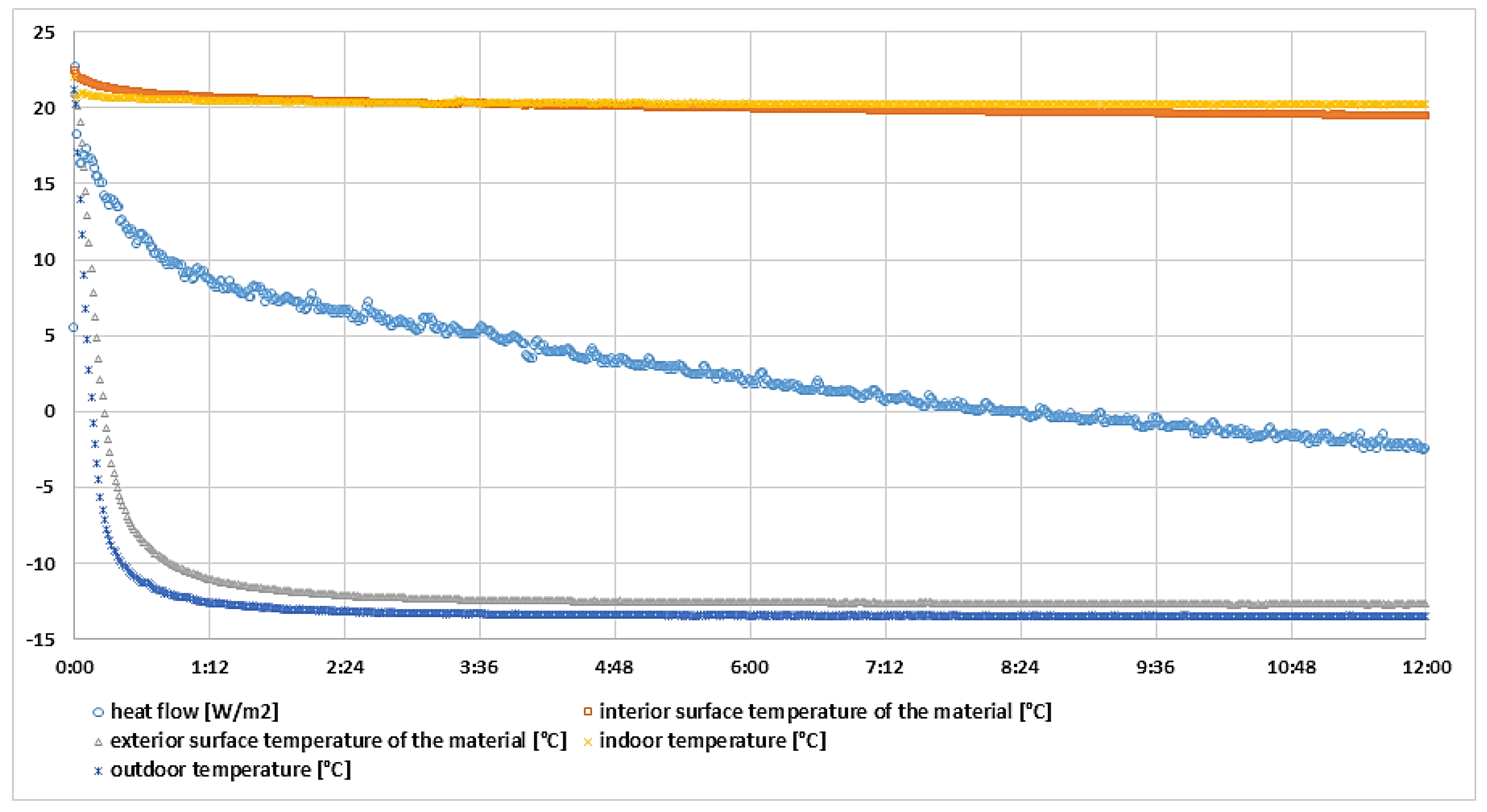

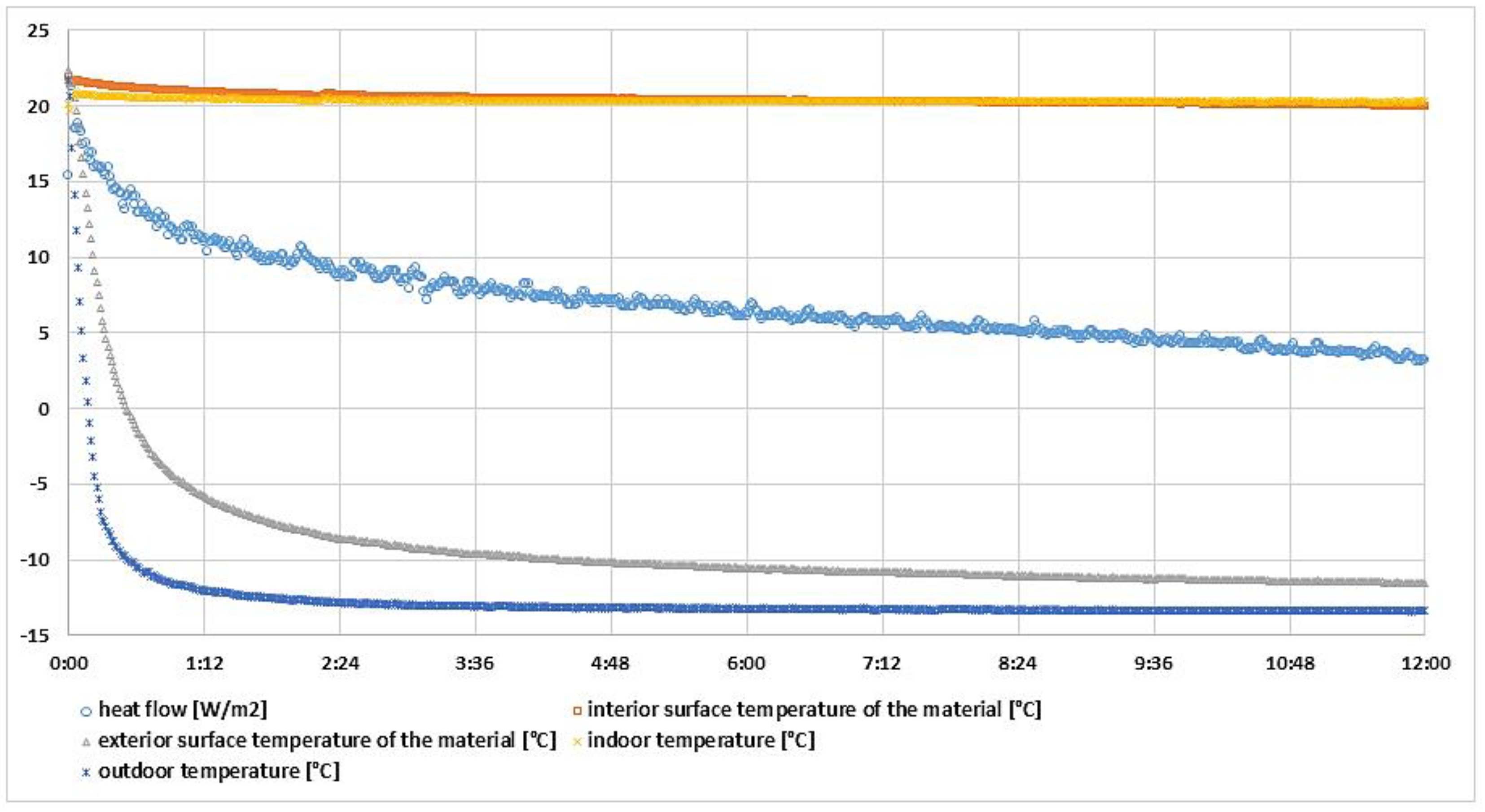

3. Results and Discussion

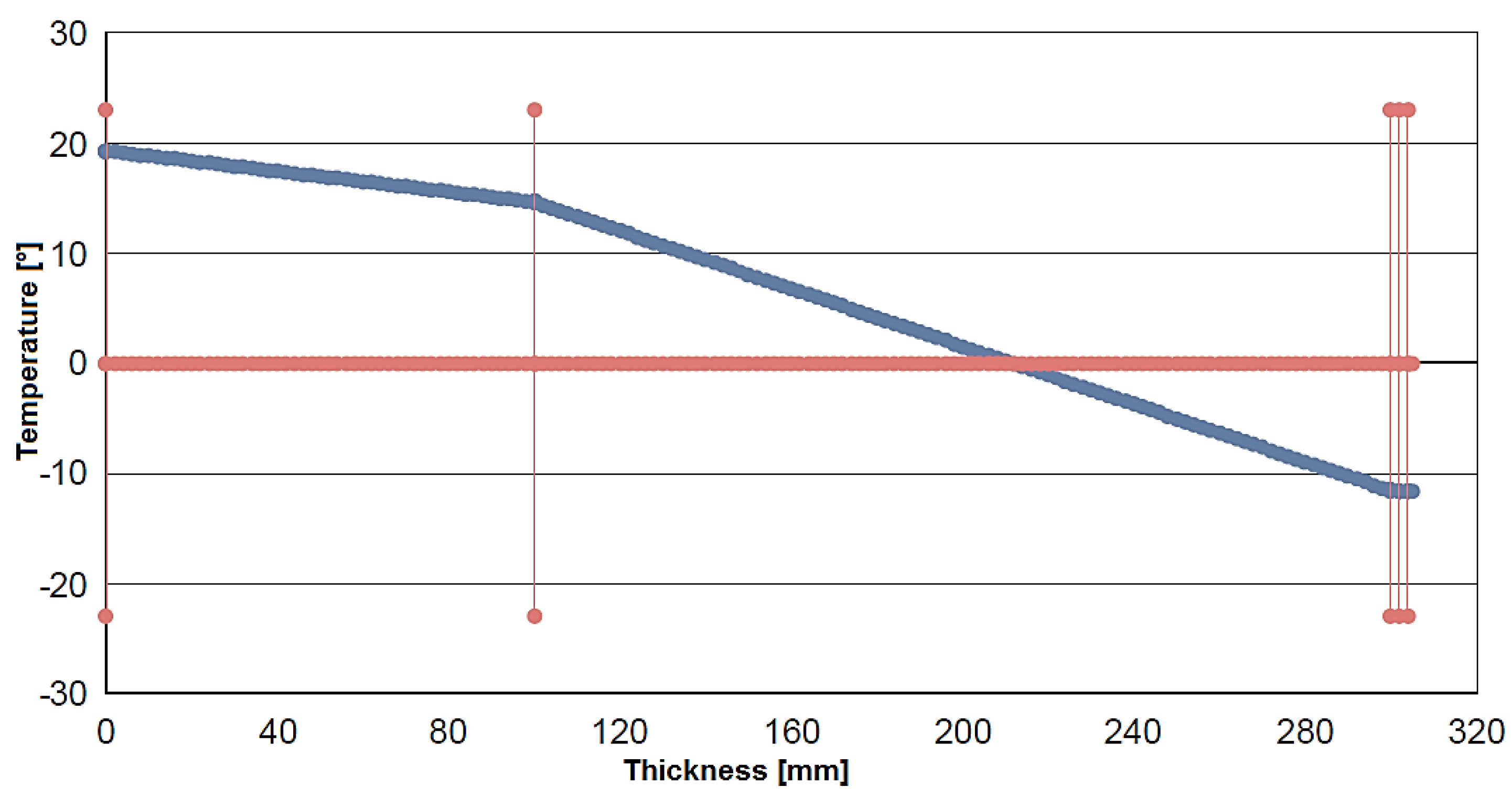

3.1. Analysis of Selected Thermal-Technical Parameters of the Examined Design Variants

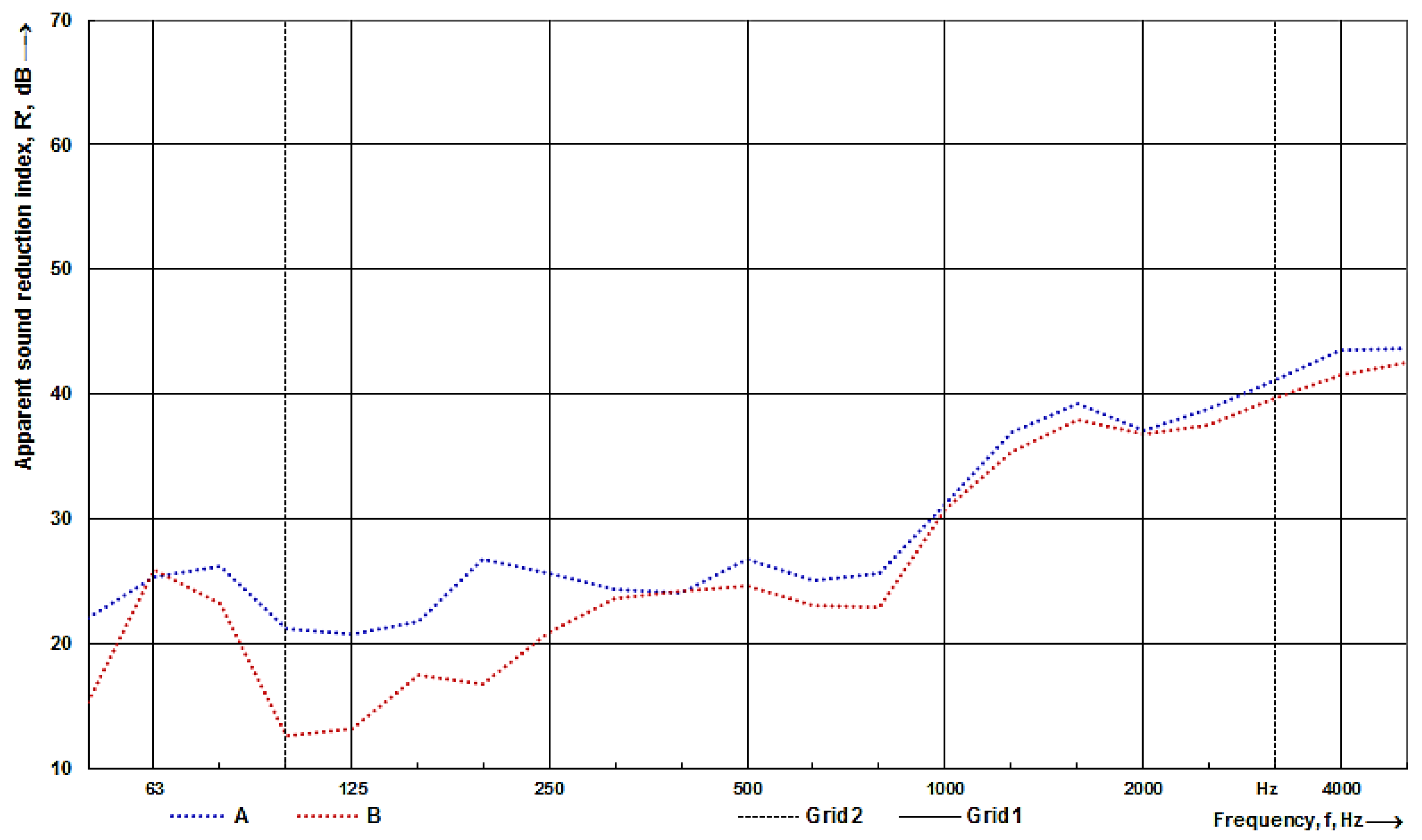

3.2. Analysis of Acoustic Parameters of the Examined Design Variants

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wimmers, G. Wood: A construction material for tall buildings. Nat. Rev. Mater. 2017, 2, 17051. [Google Scholar] [CrossRef]

- Hemström, K.; Mahapatra, K.; Gustavsson, L. Perceptions, attitudes and interest of Swedish architects towards the use of wood frames in multi-storey buildings. Resour. Conserv. Recycl. 2011, 55, 1013–1021. [Google Scholar] [CrossRef]

- Ohashi, H.; Igarashi, S.; Nagaoka, T. Development of wood structural elements for fire resistant buildings. J. Struct. Fire Eng. 2018, 9, 126–137. [Google Scholar] [CrossRef]

- Kuzman, M.K.; Sandberg, D. Development of multi-storey buildings and future trends. In Proceedings of the CLEM-CIMAD 2017, II Latin American Congress on Timber Structures, II Ibero-American Congress on Construction Timber, Junin, Argentina, 17–19 May 2017. [Google Scholar]

- Lindblad, F. A Comparative Study of the Environmental Impact from Transportation of Prefabricated Building Elements Using Wood or Concrete. Int. J. Eng. Technol. 2019, 11, 154–161. [Google Scholar] [CrossRef]

- Loss, C.; Piazza, M.; Zandonini, R. Connections for steel–timber hybrid prefabricated buildings. Part I: Experimental tests. Constr. Build. Mater. 2016, 122, 781–795. [Google Scholar] [CrossRef]

- Zhou, L.; Ni, C.; Chui, Y.-H. Testing and Modeling of Wood–Masonry Hybrid Wall Assembly. J. Struct. Eng. 2017, 143, 04016167. [Google Scholar] [CrossRef]

- Matová, H.; Kaputa, V. Attitudes of active and upcoming architects towards wood: The case study in Slovakia. Acta Fac. Xylologiae 2018, 60, 199–210. [Google Scholar]

- Tomás, H.; Korytarova, J. Procurement management in construction: Study of Czech municipalities. Open Eng. 2019, 9, 151–158. [Google Scholar] [CrossRef]

- Gašparík, J.; Szalayová, S.; Alamro, B.; Gašparík, M. Optimization method of elevator selection for the realization of construction processes. In Advances and Trends in Engineering Sciences and Technologies III, Proceedings of the 3rd International Conference on Engineering Sciences and Technologies (ESaT 2018), Tatranské Matliare, Slovak Republic, 12–14 September 2018; CRC Press: Boca Raton, FL, USA, 2019; p. 369. [Google Scholar]

- Gao, P.; Gao, W. Wooden Wall Construction of Traditional Miao Stilted Buildings: A Case Study of Xijiang Miao Village in Guizhou. J. Landsc. Res. 2019, 11, 68–70. [Google Scholar]

- Goverse, T.; Hekkert, M.P.; Groenewegen, P.; Worrell, E.; Smits, R.E. Wood innovation in the residential construction sector; opportunities and constraints. Resour. Conserv. Recycl. 2001, 34, 53–74. [Google Scholar] [CrossRef]

- Silva, C.V.; Branco, J.M.; Lourenço, P.B. A Project Contribution to the Development of Sustainable Multi-Storey Timber Buildings; Universidade do Minho: Braga, Portugal, 2013. [Google Scholar]

- Jalilzadehazhari, E.; Johansson, J. Material properties of wooden surfaces used in interiors and sensory stimulation. Wood Mater. Sci. Eng. 2019, 14, 192–200. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustainable Materials and Technologies 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Motuzienė, V.; Rogoža, A.; Lapinskienė, V.; Vilutienė, T. Construction solutions for energy efficient single-family house based on its life cycle multi-criteria analysis: A case study. J. Clean. Prod. 2016, 112, 532–541. [Google Scholar] [CrossRef]

- De Araujo, V.A.; Cortez-Barbosa, J.; Gava, M.; Garcia, J.N.; De Souza, A.J.D.; Savi, A.F.; Morales, E.A.M.; Molina, J.C.; Vasconcelos, J.S.; Christoforo, A.L.; et al. Classification of Wooden Housing Building Systems. Bioresources 2016, 11, 7889–7901. [Google Scholar] [CrossRef]

- Chwieduk, D.A. Towards modern options of energy conservation in buildings. Renew. Energy 2017, 101, 1194–1202. [Google Scholar] [CrossRef]

- Evin, D.; Ucar, A. Energy impact and eco-efficiency of the envelope insulation in residential buildings in Turkey. Appl. Therm. Eng. 2019, 154, 573–584. [Google Scholar] [CrossRef]

- Kralikova, R.; Sokolova, H.; Wessely, E. Thermal Environment Evaluation According to Indices in Industrial Workplaces. Procedia Eng. 2014, 69, 158–167. [Google Scholar] [CrossRef]

- KrálikovÁ, R.; Beneová, A. Measuring thermal comfort in working environment. In International Joint Conference on Environmental and Light Industry Technologies: 18.19.11.2010; Óbuda University: Budapest, Hungary, 2010; pp. 45–51. [Google Scholar]

- Holleran, C.L.; Curry, A.; O’connor, D.; Tim, A.S.K.E.; Ogden, G.; Sansom, B.U.S. Patent No. 10,338, 2019. Available online: https://patents.google.com/patent/US20190235459A1/en (accessed on 13 November 2020).

- Hrdlicka, T.; Cupal, M. Brick versus wood construction in residential. In Proceedings of the 19th International Multidisciplinary Scientific GeoConference: Surveying Geology and Mining Ecology Management (SGEM), Albena, Bulgaria, 28 June–7 July 2019; p. 395. [Google Scholar]

- Kaputa, V.; Olšiaková, M.; Maťová, H.; Drličková, E. Do preferences for wood-framed houses’ attributes change over time? Digitalisation and Circular Economy: Forestry and Forestry Based Industry Implications. Digit. Circ. Econ. 2019, 161. Available online: http://www.woodema.org/proceedings/WoodEMA_2019_Proceedings.pdf#page=163 (accessed on 13 November 2020).

- Králiková, R.; Andrejiová, M. Thermal comfort in the working environment-assessment through objective and subjective approaches. In Proceedings of the 5th ICEEE-2014 International Conference: Global Environmental Change and Population Health: Progress and Challenges, Budapest, Hungary, 19–21 November 2014; pp. 352–356. [Google Scholar]

- Gou, S.; Nik, V.M.; Scartezzini, J.-L.; Zhao, Q.; Li, Z. Passive design optimization of newly-built residential buildings in Shanghai for improving indoor thermal comfort while reducing building energy demand. Energy Build. 2018, 169, 484–506. [Google Scholar] [CrossRef]

- Korytárová, J.; Hanák, T.; Kozik, R.; Zielina, E.R. Exploring the Contractors’ Qualification Process in Public Works Contracts. Procedia Eng. 2015, 123, 276–283. [Google Scholar] [CrossRef][Green Version]

- Zgútová, K.; Decký, M.; Šrámek, J.; Drevený, I. Using of Alternative Methods at Earthworks Quality Control. Procedia Earth Planet. Sci. 2015, 15, 263–270. [Google Scholar] [CrossRef]

- Wang, R.; Lu, S.; Feng, W. A three-stage optimization methodology for envelope design of passive house considering energy demand, thermal comfort and cost. Energy 2020, 192, 116723. [Google Scholar] [CrossRef]

- Antošová, N.; Belániová, B.; Chamulová, B.; Janušová, K.; Takács, J. The protection of environment during cleaning ETICS with biocides. In The Advances and Trends in Engineering Sciences and Technologies III; Informa UK Limited: Colchester, UK, 2019; pp. 281–286. [Google Scholar]

- Vilches, A.; Barrios-Padura, Á.; Molina-Huelva, M. Retrofitting of homes for people in fuel poverty: Approach based on household thermal comfort. Energy Policy 2017, 100, 283–291. [Google Scholar] [CrossRef]

- Park, J.Y.; Nagy, Z. Comprehensive analysis of the relationship between thermal comfort and building control research—A data-driven literature review. Renew. Sustain. Energy Rev. 2018, 82, 2664–2679. [Google Scholar] [CrossRef]

- Pearce, L. Translating across Disciplines: On Coding Interior Architecture Theory to Advance Complex Indoor Environment Quality. Buildings 2018, 8, 82. [Google Scholar] [CrossRef]

- Linhares, T.B.; Pereira, A.F. Sustainable Buildings and Interior Design. In SBDS + ISSD 2017; Editora Edgard Blucher, Ltda: São Paulo, Brazil, 2017; Volume 3, pp. 82–87. Available online: http://pdf.blucher.com.br.s3-sa-east-1.amazonaws.com/designproceedings/sbds-issd-2017/014.pdf (accessed on 13 November 2020).

- Gallo, P.; Romano, R. Adaptive Facades, Developed with Innovative Nanomaterials, for a Sustainable Architecture in the Mediterranean Area. Procedia Eng. 2017, 180, 1274–1283. [Google Scholar] [CrossRef]

- Cai, M.; Lan, Z.; Zhang, Z.; Wang, H. Evaluation of road traffic noise exposure based on high-resolution population distribution and grid-level noise data. Build. Environ. 2019, 147, 211–220. [Google Scholar] [CrossRef]

- Argalasova, L.; Mihalcik, L.; Filova, A.; Vondrova, D.; Babjakova, J.; Samohyl, M.; Jurkovicova, J. Exposure to road traffic noise in new residential buildings. Euronoise Heraklion 2018, 27–31. Available online: http://www.euronoise2018.eu/docs/papers/73_Euronoise2018.pdf (accessed on 13 November 2020).

- Nang, E.E.K.; Abuduxike, G.; Posadzki, P.P.; Divakar, U.; Visvalingam, N.; Nazeha, N.; Dunleavy, G.; Christopoulos, G.I.; Soh, C.-K.; Jarbrink, K.; et al. Review of the potential health effects of light and environmental exposures in underground workplaces. Tunn. Undergr. Space Technol. 2019, 84, 201–209. [Google Scholar] [CrossRef]

- Schiavoni, S.; D׳Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Duggal, S. Building Materials; Informa UK Limited: Colchester, UK, 2017. [Google Scholar]

- Thomas, D.; Ding, G. Comparing the performance of brick and timber in residential buildings–The case of Australia. Energy Build. 2018, 159, 136–147. [Google Scholar] [CrossRef]

- Schiavi, A.; Prato, A.; Vallée, J.C. Building components and materials for low frequency airborne and structure-borne sound insulation. In Proceedings of the 24th International Congress of Sound and Vibration (ICSV), London, UK, 23–27 July 2017; pp. 5362–5369. [Google Scholar]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Holz Roh Werkst. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Espinoza, O.; Trujillo, V.R.; Mallo, M.F.L.; Buehlmann, U. Cross-Laminated Timber: Status and Research Needs in Europe. BioResources 2015, 11, 281–295. [Google Scholar] [CrossRef]

- Lukacs, I.; Björnfot, A.; Tomasi, R. Strength and stiffness of cross-laminated timber (CLT) shear walls: State-of-the-art of analytical approaches. Eng. Struct. 2019, 178, 136–147. [Google Scholar] [CrossRef]

- Popovski, M.; Gavric, I. Performance of a 2-Story CLT House Subjected to Lateral Loads. J. Struct. Eng. 2016, 142, 4015006. [Google Scholar] [CrossRef]

- Ruxton, G.D. The unequal variance t-test is an underused alternative to Student’s t-test and the Mann–Whitney U test. Behav. Ecol. 2006, 17, 688–690. [Google Scholar] [CrossRef]

- STN 73 0540. Thermal performance of buildings and components. Thermal Protection of Buildings. 2002. Available online: https://www.sutn.sk/eshop/public/standard_detail.aspx?id=128945 (accessed on 13 November 2020).

- EN ISO 10456. Building Materials and Products-Hygrothermal Properties-Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; ICS: 91.120.10; EN ISO: Geneva, Switzerland, 2007; Available online: https://www.iso.org/standard/40966.html (accessed on 13 November 2020).

- ISO 16283-1. Acoustics—Field Measurement of Sound Insulation in Buildings and of Building Elements—Part 1: Airborne sound Insulation; ISO: Geneva, Switzerland, 2014.

- ISO 3382-2. Acoustics—Measurement of Room Acoustic Parameters—Part 2: Reverberation Time in Ordinary Rooms; ISO: Geneva, Switzerland, 2008. [Google Scholar]

- STN EN ISO 717-1. Acoustics—Rating of Sound Insulation in Buildings and of Building Elements–Part 1: Airborne Sound Insulation; ISO: Geneva, Switzerland, 2013.

- STN EN ISO 717-2. Acoustics—Rating of Sound Insulation in Buildings and of Building Elements—Part 2: Impact Sound Insulation; ISO: Geneva, Switzerland, 2013.

- Stürzenbecher, R.; Hofstetter, K.; Eberhardsteiner, J.; De Borst, K. Structural design of Cross Laminated Timber (CLT) by advanced plate theories. Compos. Sci. Technol. 2010, 70, 1368–1379. [Google Scholar] [CrossRef]

- Leijten, A.J. Europe Goes Green. Procedia Eng. 2017, 171, 104–112. [Google Scholar] [CrossRef]

- Shahnewaz, M.; Tannert, T.; Alam, M.S.; Popovski, M. Capacity-Based Design for Platform-Framed Cross-Laminated Timber Buildings. In Structures Congress; ASCE: Denver, CO, USA, 2017. [Google Scholar]

- Ehrhart, T.; Brandner, R.; Schickhofer, G.; Frangi, A. Rolling Shear Properties of some European Timber Species with Focus on Cross Laminated Timber (CLT): Test Configuration and Parameter Study. In International Network on Timber Engineering Research: Proceedings of Meeting; Timber Scientific Publishing, KIT Holzbau und Baukonstruktionen: Karlsruhe, Germany, 2015; pp. 61–76. [Google Scholar] [CrossRef]

- Jing, L.; Hongpeng, X.; Xiabin, G.; Di, Y. Technical advantages and limitations of cross-laminated timber high-rise buildings. Urban Archit. 2017, 14, 7. [Google Scholar]

- Frangi, A.; Fontana, M.; Hugi, E.; Jübstl, R. Experimental analysis of cross-laminated timber panels in fire. Fire Saf. J. 2009, 44, 1078–1087. [Google Scholar] [CrossRef]

- Schmid, J.; König, J.; Köhler, J. Fire-exposed cross-laminated timber–modelling and tests. In Proceedings of the World Conference on Timber Engineering, Trento, Italy, 20–24 June 2010. [Google Scholar]

- Klippel, M.; Schmid, J. Design of Cross-Laminated Timber in Fire. Struct. Eng. Int. 2017, 27, 224–230. [Google Scholar] [CrossRef]

- Chang, S.J.; Wi, S.; Kim, S. Thermal bridging analysis of connections in cross-laminated timber buildings based on ISO. Constr. Build. Mater. 2019, 213, 709–722. [Google Scholar] [CrossRef]

- Dong, Q.; Xing, K.; Zhang, H. Artificial Neural Network for Assessment of Energy Consumption and Cost for Cross Laminated Timber Office Building in Severe Cold Regions. Sustainability 2017, 10, 84. [Google Scholar] [CrossRef]

- Khavari, A.M.; Pei, S.; Tabares-Velasco, P.C. Energy Consumption Analysis of Multistory Cross-Laminated Timber Residential Buildings: A Comparative Study. J. Arch. Eng. 2016, 22, 04016002. [Google Scholar] [CrossRef]

- Jowett, O. The thermal behaviour of cross-laminated timber construction and its resilience to summertime overheating. In Proceedings of the PLEA 2011—The 27th Conference on Passive and Low Energy Architecture, Louvain-la-Neuve, Belgium, 15 July 2011; pp. 339–344. [Google Scholar]

- Adekunle, T.O. Thermal comfort and heat stress in cross-laminated timber (CLT) school buildings during occupied and unoccupied periods in Summer. In Proceedings of the 10th Windsor Conference, London, UK, 12–15 April 2018. [Google Scholar]

- Schoenwald, S.; Zeitler, B.; Sabourin, I.; King, F. Sound insulation performance of cross laminated timber building systems. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings; Institute of Noise Control Engineering: Washington, DC, USA, 2013; Volume 247, pp. 4337–4346. Available online: https://www.researchgate.net/profile/Berndt_Zeitler/publication/258987891_Sound_insulation_performance_of_Cross_Laminated_Timber_Building_Systems/links/0deec5298a7a261856000000.pdf (accessed on 13 November 2020).

- Pérez, M. Acoustic design through predictive methods in Cross Laminated Timber (CLT) panel structures in buildings. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings; Institute of Noise Control Engineering: Washington, DC, USA, 2013; Volume 247, pp. 5539–5547. Available online: https://www.researchgate.net/profile/Marta_Fuente_Gonzalez/publication/260904195_Acoustic_design_through_predictive_methods_in_Cross_Laminated_Timber_CLT_panel_structures_for_buildings/links/0f3175329e6ab0f144000000.pdf (accessed on 13 November 2020).

- Di Bella, A.; Granzotto, N.; Barbaresi, L. Analysis of acoustic behavior of bare CLT floors for the evaluation of impact sound insulation improvement. In Proceedings of the 172nd Meeting of the Acoustical Society of America, Honolulu, HI, USA, 28 November–2 December 2016; Volume 28, p. 015016. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, M.C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Pagnoncelli, L.; Morales, F. Cross-laminated timber system (CLT): Laboratory and in situ measurements of airborne and impact sound insulation. In Proceedings of the EuroRegio Conference, Porto, Portugal, 13–15 June 2016; pp. 3–15. Available online: http://mail.sea-acustica.es/fileadmin/publicaciones/80_01.pdf (accessed on 13 November 2020).

| Layer Name | Volumetric Weight ρ (kg.m3) | Layer Thickness d (mm) | Thermal Resistance Rd (m2.K/W) | Thermal Conductivity Coefficient λd (W/(.m.K)) | Diffusion Resistance Factor μ (-) |

|---|---|---|---|---|---|

| CLT | 470 | 100 | 0.909 | 0.11 | 40–70 |

| Material for gluing insulation panels | 15–25 | - | - | 0.035 | 28 |

| Thermal insulation—EPS | 13.5–18 | 200 | 5.25 | 0.038 | 20–40 |

| Construction glue | 1400 | 2.5 | - | 0.45 | 25 |

| Plastering | 1200 | 2.5 | - | 0.5 | 25 |

| Additional anchoring material | |||||

| Layer Name | Volumetric Weight ρ (kg.m3) | Layer Thickness d (mm) | Thermal Resistance Rd (m2.K/W) | Thermal Conductivity Coefficient λd (W/(.m.K)) | Diffusion Resistance Factor μ (-) |

|---|---|---|---|---|---|

| CLT | 470 | 100 | 0.909 | 0.11 | 40–70 |

| Material for gluing insulation panels | 15–25 | - | - | 0.035 | 28 |

| Thermal insulation—wood fiber | 230 | 200 | 4.34 | 0.046 | 5 |

| Construction adhesive | 1400 | 2.5 | - | 0.45 | 25 |

| Plastering | 1200 | 2.5 | - | 0.5 | 25 |

| Additional anchoring material | |||||

| U Value (W/m2K) | U Value (W/m2K) | |

|---|---|---|

| Variant A | Variant B | |

| Average | 0.064 | 0.114 |

| ± std | 0.009 | 0.009 |

| Min | 0.046 | 0.098 |

| Max | 0.081 | 0.137 |

| Median | 0.062 | 0.114 |

| 25th perc | 0.056 | 0.108 |

| 75th perc | 0.068 | 0.117 |

| t-test * | p < 0.0001 *** | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Švajlenka, J.; Kozlovská, M.; Badida, M.; Moravec, M.; Dzuro, T.; Vranay, F. Analysis of the Characteristics of External Walls of Wooden Prefab Cross Laminated Timber. Energies 2020, 13, 5974. https://doi.org/10.3390/en13225974

Švajlenka J, Kozlovská M, Badida M, Moravec M, Dzuro T, Vranay F. Analysis of the Characteristics of External Walls of Wooden Prefab Cross Laminated Timber. Energies. 2020; 13(22):5974. https://doi.org/10.3390/en13225974

Chicago/Turabian StyleŠvajlenka, Jozef, Mária Kozlovská, Miroslav Badida, Marek Moravec, Tibor Dzuro, and František Vranay. 2020. "Analysis of the Characteristics of External Walls of Wooden Prefab Cross Laminated Timber" Energies 13, no. 22: 5974. https://doi.org/10.3390/en13225974

APA StyleŠvajlenka, J., Kozlovská, M., Badida, M., Moravec, M., Dzuro, T., & Vranay, F. (2020). Analysis of the Characteristics of External Walls of Wooden Prefab Cross Laminated Timber. Energies, 13(22), 5974. https://doi.org/10.3390/en13225974