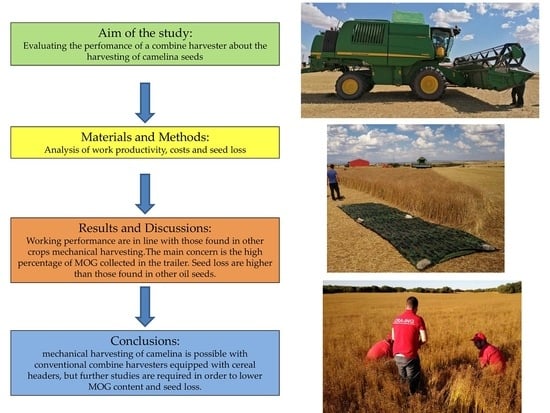

Mechanical Harvesting of Camelina: Work Productivity, Costs and Seed Loss Evaluation

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Site

2.2. Pre-Harvest Tests: Theoretical Biomass Assessment

2.3. Combine Harvester

2.4. Harvesting Performance

2.5. Costs Analysis

2.6. Post-Harvesting Test: Seed Losses

2.7. Statistical Analysis

3. Results

3.1. Biomass Characterization

3.2. Work Performance and Costs Analysis

3.3. Seed Loss and Presence of MOG

4. Discussion

4.1. Biomass Characterization

4.2. Work Performance and Cost Analysis

4.3. Seed Loss and Presence of MOG

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Union (EU). Renewable Energy Directive II (EU) 2018/2001 11th December 2018. Available online: https://eur-lex.europa.eu/legal-content/IT/TXT/PDF/?uri=CELEX:32018L2001&from=IT (accessed on 10 July 2020).

- Maity, S.K. Opportunities, recent trends and challenges of integrated biorefinery: Part II. Renew. Sustain. Energy Rev. 2015, 43, 1446–1466. [Google Scholar] [CrossRef]

- Silvestre, W.P.; Pauletti, G.F.; Baldasso, C. Fodder radish (Raphanus sativus L.) seed cake as a feedstock for pyrolysis. Ind. Crops Prod. 2020, 154, 112689. [Google Scholar] [CrossRef]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Karampinis, E.; Kougioumtzis, M.A.; Grammelis, P.; Pari, L. Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields. Energies 2020, 13, 1713. [Google Scholar] [CrossRef]

- Suardi, A.; Stefanoni, W.; Bergonzoli, S.; Latterini, F.; Jonsson, N.; Pari, L. Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis. Sustainability 2020, 12, 4936. [Google Scholar] [CrossRef]

- Cocco, D.; Deligios, P.A.; Ledda, L.; Sulas, L.; Virdis, A.; Carboni, G. LCA study of oleaginous bioenergy chains in a Mediterranean environment. Energies 2014, 7, 6258–6281. [Google Scholar] [CrossRef]

- Dangol, N.; Shrestha, D.S.; Duffield, J.A. Life-cycle energy, GHG and cost comparison of camelina-based biodiesel and biojet fuel. Biofuels 2017, 11, 1–9. [Google Scholar] [CrossRef]

- Carlsson, A.S. Plant oils as feedstock alternatives to petroleum–A short survey of potential oil crop platforms. Biochimie 2009, 91, 665–670. [Google Scholar] [CrossRef]

- Bessou, C.; Ferchaud, F.; Gabrielle, B.; Mary, B. Biofuels, greenhouse gases and climate change. A review. Agron. Sustain. Dev. 2011, 31, 1–79. [Google Scholar] [CrossRef]

- Pari, L.; Suardi, A.; Stefanoni, W.; Latterini, F.; Palmieri, N. Environmental and Economic Assessment of Castor Oil Supply Chain: A Case Study. Sustainability 2020, 12, 6339. [Google Scholar] [CrossRef]

- Paulsen, H.M.; Wichmann, V.; Schuemann, U.; Richter, B. Use of straight vegetable oil mixtures of rape and camelina as on farm fuels in agriculture. Biomass Bioenergy 2011, 35, 4015–4024. [Google Scholar] [CrossRef]

- Esteban, B.; Riba, J.-R.; Baquero, G.; Rius, A.; Puig, R. Temperature dependence of density and viscosity of vegetable oils. Biomass Bioenergy 2012, 42, 164–171. [Google Scholar] [CrossRef]

- Haas, M.J.; McAloon, A.J.; Yee, W.C.; Foglia, T.A. A process model to estimate biodiesel production costs. Bioresour. Technol. 2006, 97, 671–678. [Google Scholar] [CrossRef] [PubMed]

- Amigun, B.; Sigamoney, R.; von Blottnitz, H. Commercialisation of biofuel industry in Africa: A review. Renew. Sustain. Energy Rev. 2008, 12, 690–711. [Google Scholar] [CrossRef]

- Keske, C.M.H.; Hoag, D.L.; Brandess, A.; Johnson, J.J. Is it economically feasible for farmers to grow their own fuel? A study of Camelina sativa produced in the western United States as an on-farm biofuel. Biomass Bioenergy 2013, 54, 89–99. [Google Scholar] [CrossRef]

- Yang, J.; Caldwell, C.; Corscadden, K.; He, Q.S.; Li, J. An evaluation of biodiesel production from Camelina sativa grown in Nova Scotia. Ind. Crops Prod. 2016, 81, 162–168. [Google Scholar] [CrossRef]

- Tepelus, A.; Rosca, P.; Dragomir, R. Biojet from hydroconversion of camelina oil mixed with straight run gas oil. Rev. Chim. 2019, 70, 3284–3291. [Google Scholar] [CrossRef]

- Mohammad, B.T.; Al-Shannag, M.; Alnaief, M.; Singh, L.; Singsaas, E.; Alkasrawi, M. Production of multiple biofuels from Whole Camelina Material: A renewable energy crop. BioResources 2019, 13, 4870–4883. [Google Scholar]

- Natelson, R.H.; Wang, W.C.; Roberts, W.L.; Zering, K.D. Technoeconomic analysis of jet fuel production from hydrolysis, decarboxylation, and reforming of camelina oil. Biomass Bioenergy 2015, 75, 23–34. [Google Scholar] [CrossRef]

- Pietras, M.P.; Orczewska-Dudek, S. The effect of dietary camelina sativa oil on quality of broiler chicken meat. Ann. Anim. Sci. 2013, 13, 869–882. [Google Scholar] [CrossRef]

- Orczewska-Dudek, S.; Pietras, M. The effect of dietary Camelina sativa oil or cake in the diets of broiler chickens on growth performance, fatty acid profile, and sensory quality of meat. Animals 2019, 9, 734. [Google Scholar] [CrossRef]

- Halmemies-Beauchet-Filleau, A.; Shingfield, K.J.; Simpura, I.; Kokkonen, T.; Jaakkola, S.; Toivonen, V.; Vanhatalo, A. Effect of incremental amounts of camelina oil on milk fatty acid composition in lactating cows fed diets based on a mixture of grass and red clover silage and concentrates containing camelina expeller. J. Dairy Sci. 2017, 100, 305–324. [Google Scholar] [CrossRef] [PubMed]

- Hixson, S.M.; Parrish, C.C.; Anderson, D.M. Use of camelina oil to replace fish oil in diets for farmed salmonids and atlantic cod. Aquaculture 2014, 431, 44–52. [Google Scholar] [CrossRef]

- Toyes-Vargas, E.A.; Parrish, C.C.; Viana, M.T.; Carreón-Palau, L.; Magallón-Servín, P.; Magallón-Barajas, F.J. Replacement of fish oil with camelina (Camelina sativa) oil in diets for juvenile tilapia (var. GIFT Oreochromis niloticus) and its effect on growth, feed utilization and muscle lipid composition. Aquaculture 2020, 523, 735177. [Google Scholar] [CrossRef]

- Pernak, J.; Łęgosz, B.; Klejdysz, T.; Marcinkowska, K.; Rogowski, J.; Kurasiak-Popowska, D.; Stuper-Szablewska, K. Ammonium bio-ionic liquids based on camelina oil as potential novel agrochemicals. RSC Adv. 2018, 8, 28676–28683. [Google Scholar] [CrossRef]

- Pawlowska-Olszewska, M.; Puzio, I.; Harrison, A.P.; Borkowski, L.; Tymicki, G.; Grabos, D. Supplementation with camelina oil prevents negative changes in the artery in orchidectomized rats. J. Physiol. Pharmacol. 2018, 69, 109–116. [Google Scholar] [PubMed]

- Omonov, T.S.; Kharraz, E.; Curtis, J.M. Camelina (Camelina Sativa) oil polyols as an alternative to Castor oil. Ind. Crops Prod. 2017, 107, 378–385. [Google Scholar] [CrossRef]

- Cherian, G.; Campbell, A.; Parker, T. Egg quality and lipid composition of eggs from hens fed Camelina sativa. J. Appl. Poult. Res. 2009, 18, 143–150. [Google Scholar] [CrossRef]

- Giuliano, A.; Cerulli, R.; Poletto, M.; Raiconi, G.; Barletta, D. Optimization of a Multiproduct Lignocellulosic Biorefinery using a MILP Approximation. In 24 European Symposium on Computer Aided Process Engineering; Klemeš, J.J., Varbanov, P.S., Liew, P.Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; Volume 33, pp. 1423–1428. ISBN 1570-7946. [Google Scholar]

- Murphy, E.J. Camelina (Camelina sativa). In Industrial Oil Crops; McKeon, T.A., Hayes, D.G., Hildebrand, D.F., Weselake, R.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 207–230. ISBN 978-1-893997-98-1. [Google Scholar]

- Gesch, R.W.; Archer, D.W. Double-cropping with winter camelina in the northern Corn Belt to produce fuel and food. Ind. Crops Prod. 2013, 44, 718–725. [Google Scholar] [CrossRef]

- Zanetti, F.; Gesch, R.W.; Walia, M.K.; Johnson, J.M.F.; Monti, A. Winter camelina root characteristics and yield performance under contrasting environmental conditions. Field Crops Res. 2020, 252, 107794. [Google Scholar] [CrossRef]

- Gesch, R.W.; Archer, D.W.; Berti, M.T. Dual cropping winter camelina with soybean in the northern corn belt. Agron. J. 2014, 106, 1735–1745. [Google Scholar] [CrossRef]

- Chen, C.; Bekkerman, A.; Afshar, R.K.; Neill, K. Intensification of dryland cropping systems for bio-feedstock production: Evaluation of agronomic and economic benefits of Camelina sativa. Ind. Crops Prod. 2015, 71, 114–121. [Google Scholar] [CrossRef]

- Berti, M.; Samarappuli, D.; Johnson, B.L.; Gesch, R.W. Integrating winter camelina into maize and soybean cropping systems. Ind. Crops Prod. 2017, 107, 595–601. [Google Scholar] [CrossRef]

- Royo-Esnal, A.; Valencia-Gredilla, F. Camelina as a Rotation Crop for Weed Control in Organic Farming in a Semiarid Mediterranean Climate. Agriculture 2018, 8, 156. [Google Scholar] [CrossRef]

- Peterson, A.T.; Berti, M.T.; Samarappuli, D. Intersowing cover crops into standing soybean in the US upper midwest. Agronomy 2019, 9, 264. [Google Scholar] [CrossRef]

- Zanetti, F.; Christou, M.; Alexopoulou, E.; Berti, M.T.; Vecchi, A.; Borghesi, A.; Monti, A. Innovative double cropping systems including camelina [camelina sativa (L.) crantz] a valuable oilseed crop for bio-based applications. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Lisbon, Portugal, 27–30 May 2019; pp. 127–130. [Google Scholar]

- Li, X.; Mupondwa, E. Life cycle assessment of camelina oil derived biodiesel and jet fuel in the Canadian Prairies. Sci. Total Environ. 2014, 481, 17–26. [Google Scholar] [CrossRef]

- Lohaus, R.H.; Neupane, D.; Mengistu, M.A.; Solomon, J.K.Q.; Cushman, J.C. Five-Year Field Trial of Eight Camelina sativa Cultivars for Biomass to be Used in Biofuel under Irrigated Conditions in a Semi-Arid Climate. Agronomy 2020, 10, 562. [Google Scholar] [CrossRef]

- Christopher, L.P.; Kumar, H.; Zambare, V.P. Enzymatic biodiesel: Challenges and opportunities. Appl. Energy 2014, 119, 497–520. [Google Scholar] [CrossRef]

- FAO. FAO Global agriculture towards 2050. In How to Feed World; FAO: Rome, Italy, 2009. [Google Scholar]

- Gui, M.M.; Lee, K.T.; Bhatia, S. Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 2008, 33, 1646–1653. [Google Scholar] [CrossRef]

- Bušić, A.; Kundas, S.; Morzak, G.; Belskaya, H.; Mardetko, N.; Šantek, M.I.; Komes, D.; Novak, S.; Šantek, B. Recent trends in biodiesel and biogas production. Food Technol. Biotechnol. 2018, 56, 152–173. [Google Scholar] [CrossRef]

- Latterini, F.; Stefanoni, W.; Suardi, A.; Alfano, V.; Bergonzoli, S.; Palmieri, N.; Pari, L. A GIS Approach to Locate a Small Size Biomass Plant Powered by Olive Pruning and to Estimate Supply Chain Costs. Energies 2020, 13, 3385. [Google Scholar] [CrossRef]

- Pari, L.; Latterini, F.; Stefanoni, W. Herbaceous Oil Crops, a Review on Mechanical Harvesting State of the Art. Agriculture 2020, 10, 309. [Google Scholar] [CrossRef]

- Zubr, J. Qualitative variation of Camelina sativa seed from different locations. Ind. Crops Prod. 2003, 17, 161–169. [Google Scholar] [CrossRef]

- Vollmann, J.; Moritz, T.; Kargl, C.; Baumgartner, S.; Wagentristl, H. Agronomic evaluation of camelina genotypes selected for seed quality characteristics. Ind. Crops Prod. 2007, 26, 270–277. [Google Scholar] [CrossRef]

- Obour, K.A. Oilseed Camelina (Camelina sativa L Crantz): Production Systems, Prospects and Challenges in the USA Great Plains. Adv. Plants Agric. Res. 2015, 2, 1–10. [Google Scholar] [CrossRef]

- Leclère, M.; Jeuffroy, M.-H.; Butier, A.; Chatain, C.; Loyce, C. Controlling weeds in camelina with innovative herbicide-free crop management routes across various environments. Ind. Crops Prod. 2019, 140, 111605. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Zheljazkov, V.D.; Obour, A.K.; Garcia y Garcia, A. Managing harvest time to control pod shattering in oilseed camelina. Agron. J. 2016, 108, 656–661. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Tworkowski, J.; Załuski, D.; Kwiatkowski, J.; Szczukowski, S. Camelina and crambe production—Energy efficiency indices depending on nitrogen fertilizer application. Ind. Crops Prod. 2019, 137, 386–395. [Google Scholar] [CrossRef]

- NSAI ISO 18134-2:2017 Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. Available online: https://www.iso.org/standard/71536.html (accessed on 6 July 2020).

- ISO 17828:2015 ISO 17828:2015 Solid Biofuels—Determination of Bulk Density. Available online: https://www.iso.org/obp/ui/#iso:std:iso:17828:ed-1:v1:en (accessed on 23 July 2020).

- Assirelli, A.; Croce, S.; Acampora, A.; Civitarese, V.; Suardi, A.; Santangelo, E.; Pari, L. An Innovative System for Conditioning Biomass [Sorghum bicolo (L.) Moench.]. Am. Soc. Agric. Biol. Eng. 2013, 56, 829–837. [Google Scholar]

- Assirelli, A.; Pignedoli, S. Costo di esercizio delle macchine agricole. Cent. Ric. e Prod. Anim. 2005, 5, 1–10. [Google Scholar]

- Banca d’Italia Banca d’Italia Lending Rate. Available online: https://www.bancaditalia.it/ (accessed on 11 July 2020).

- Statsoft Website. Available online: https://www.statsoft.de/en/home (accessed on 5 July 2020).

- Mauri, P.V.; Mostaza, D.; Plaza, A.; Ruiz-Fernandez, J.; Prieto, J.; Capuano, A. Variability of camelina production in the center of Spain in two years of cultivation, a new profitable and alternative crop. In Proceedings of the 27th European Biomass Conference and Exhibition, Lisbon, Portugal, 27–30 May 2019; pp. 196–200. [Google Scholar]

- Schillinger, W.F. Camelina: Long-term cropping systems research in a dry Mediterranean climate. Field Crops Res. 2019, 235, 87–94. [Google Scholar] [CrossRef]

- Imbrea, F.; Jurcoane, S.; Hǎlmǎjan, H.V.; Duda, M.; Botoş, L. Camelina sativa: A new source of vegetal oils. Rom. Biotechnol. Lett. 2011, 16, 6263–6270. [Google Scholar]

- FAO FAOSTAT Agriculture Data. Available online: http://www.fao.org/faostat/en/#data (accessed on 30 August 2020).

- Hernando, H.; Fermoso, J.; Moreno, I.; Coronado, J.M.; Serrano, D.P.; Pizarro, P. Thermochemical valorization of camelina straw waste via fast pyrolysis. Biomass Convers. Biorefinery 2017, 7, 277–287. [Google Scholar] [CrossRef]

- Olughu, O.O.; Tabil, L.G.; Dumonceaux, T. Effect of Ultrasonic Pretreatment on the Chemical Composition and Pellet Quality of Camelina Straw. In Proceedings of the 2019 ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA; p. 1. [Google Scholar]

- Krzyżaniak, M.; Stolarski, M.J.; Graban, Ł.; Lajszner, W.; Kuriata, T. Camelina and Crambe Oil Crops for Bioeconomy—Straw Utilisation for Energy. Energies 2020, 13, 1503. [Google Scholar] [CrossRef]

- Suardi, A.; Stefanoni, W.; Alfano, V.; Bergonzoli, S.; Pari, L. Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff. Energies 2020, 13, 1572. [Google Scholar] [CrossRef]

- Suardi, A.; Saia, S.; Stefanoni, W.; Gunnarsson, C.; Sundberg, M.; Pari, L. Admixing Chaff with Straw Increased the Residues Collected without Compromising Machinery Efficiencies. Energies 2020, 13, 1766. [Google Scholar] [CrossRef]

- Chaplygin, M.; Bespalova, O.; Podzorova, M. Results of tests of devices for sunflower harvesting in economic conditions. E3S Web Conf. 2019, 126, 1–7. [Google Scholar] [CrossRef]

- Pari, L.; Fedrizzi, M.; Gallucci, F. Cynara cardunculus exploitation for energy applications: Development of a combine head for thesing and concurrent residues collecting and utilization. In Proceedings of the 16th European Biomass Conference & Exhibition, Valencia, Spain, 2–6 June 2008. [Google Scholar]

- Pari, L.; Alfano, V.; Acampora, A.; Del Giudice, A.; Scarfone, A.; Sanzone, E. Harvesting and Separation of Different Plant Fractions in Cynara cardunculus L. In Perennial Biomass Crops for a Resource-Constrained World; Barth, S., Murphy-Bokern, D., Kalinina, O., Taylor, G., Jones, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 261–271. ISBN 978-3-319-44529-8. [Google Scholar]

- Semerci, A.; Kaya, Y. The Components of Production Cost in Sunflower and its Relationships with Input Prices. Int. Rev. Appl. Econ. 2010, 5, 139–146. [Google Scholar]

- Semerci, A. Cost analysis of oily sunflower production: The case of Tekirdag province, Turkey. Custos e Agronegocio 2019, 15, 167–191. [Google Scholar]

- Bergonzoli, S.; Suardi, A.; Rezaie, N.; Alfano, V.; Pari, L. An innovative system for Maize Cob and wheat chaff harvesting: Simultaneous grain and residues collection. Energies 2020, 13, 1265. [Google Scholar] [CrossRef]

- Wiwart, M.; Kurasiak-Popowska, D.; Suchowilska, E.; Wachowska, U.; Stuper-Szablewska, K. Variation in the morphometric parameters of seeds of spring and winter genotypes of Camelina sativa (L.) Crantz. Ind. Crops Prod. 2019, 139, 111571. [Google Scholar] [CrossRef]

- Startsev, A.S.; Demin, E.E.; Danilin, A.V.; Vasilyev, O.A.; Terentyev, A.G. Results of the production test of sunflower harvesting attachment with an auger reel. IOP Conf. Ser. Earth Environ. Sci. 2020, 433, 012006. [Google Scholar] [CrossRef]

- Shaforostov, V.D.; Makarov, S.S. The header for a breeding plot combine for sunflower harvesting. Acta Technol. Agric. 2019, 22, 60–63. [Google Scholar] [CrossRef]

- Asoodar, A.M.; Izadinia, Y.; Desbiolles, J. Benefits of harvester front extension in reducing canola harvest losses. Int. Agric. Eng. J. 2012, 21, 32–37. [Google Scholar]

- Pari, L.; Assirelli, A.; Suardi, A. Evaluation of Brassica napus and Brassica carinata losses during harvesting: Three years of experience. In Proceedings of the 18th European Biomass Conference and Exhibition Proceedings, Lyon, France, 3–7 May 2010; pp. 1790–1793. [Google Scholar]

- Pari, L.; Assirelli, A.; Suardi, A.; Civitarese, V.; Del Giudice, A.; Costa, C.; Santangelo, E. The harvest of oilseed rape (Brassica napus L.): The effective yield losses at on-farm scale in the Italian area. Biomass Bioenergy 2012, 46, 453–458. [Google Scholar] [CrossRef]

- Reginato, P. Colheita Mecanizada de Sementes de Crambe (Crambe abyssinica L.) no Cerrado Sul Mato Grossense. Ph.D. Thesis, Universidade Federal da Grande Dourados, Dourados, Brazil, 2014. [Google Scholar]

- Grady, K.; Nleya, T. Camelina Production. Ext. Extra, South Dakota State Univ. 2010, 8167, 1–3. [Google Scholar]

- Ma, S.; Eckhoff, S.R. Economy of scale for biomass refineries: Bulk densities, transportation cost, and producer incentives. Trans. ASABE 2014, 57, 85–91. [Google Scholar]

- Eisenbies, M.H.; Volk, T.A.; Therasme, O.; Hallen, K. Three bulk density measurement methods provide different results for commercial scale harvests of willow biomass chips. Biomass Bioenergy 2019, 124, 64–73. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

| Parameter | Setting |

|---|---|

| Rotor speed (rpm) | 800 |

| Cleaning Fan Speed (rpm) | 700 |

| Openings of Upper Sieve (mm) | closed |

| Openings of Lower Sieve (mm) | 5 |

| Straw treatment | threshed |

| Parameter | Measure Unit | Value | |

|---|---|---|---|

| Machine | Power | kW | 240 |

| Financial costs | Investment | € | 380,000.00 |

| Service life | year | 10 | |

| Service life | H | 3000 | |

| Resale | % | 19.00 | |

| Resale | € | 72,200.00 | |

| Depreciation | € | 307,800.00 | |

| Annual usage | h year−1 | 312 | |

| Interest rate | % | 3 | |

| Fixed costs | Ownership costs | € year−1 | 30,780.00 |

| Interests | € year−1 | 6783.00 | |

| Machine shelter | m2 | 30.82 | |

| Value of the shelter | € m−2 | 100.00 | |

| Value of the shelter | € year−1 | 61.64 | |

| Insurance | € year−1 | 950.00 | |

| Variable costs | Repair factor | % | 40 |

| Repairs and maintenance | € h−1 | 52.69 | |

| Fuel cost | € L−1 | 0.57 | |

| Fuel consumption | L h−1 | 37.37 | |

| Fuel cost | € h−1 | 21.30 | |

| Lubricant cost | € L−1 | 3.03 | |

| Lubricant consumption | L h−1 | 0.36 | |

| Lubricant cost | € h−1 | 1.08 | |

| Worker salary | € h−1 | 11.5 |

| Parameter | Measure Unit | Average | St.Dev. |

|---|---|---|---|

| Harvested surface | ha | 3.82 | - |

| Number of plants | N m−2 | 311 | 43 |

| Plant height | cm | 70.53 | 6.27 |

| Straw weight | Mg ha−1 FM | 3.31 | 0.25 |

| Straw moisture content | % | 10.46 | 0.14 |

| Siliques weight | Mg ha−1 FM | 1.20 | 0.05 |

| Siliques moisture content | % | 7.27 | 0.59 |

| Potential seed yield | Mg ha−1 FM | 1.03 | 0.01 |

| Harvest Index (HI) | - | 0.186 | 0.013 |

| Seed moisture content | % | 5.18 | 0.58 |

| Parameter | Measure Unit | Average | St.Dev. |

|---|---|---|---|

| Seed yield | Mg ha−1 FM | 0.95 | - |

| Working speed | km h−1 | 5.05 | 0.35 |

| Theoretical Field Capacity (TFC) | ha h−1 | 3.38 | 0.24 |

| Effective Field Capacity (EFC) | ha h−1 | 3.17 | 0.20 |

| Field Efficiency (FE) | % | 93.7 | 0.83 |

| Material Capacity (MC) | Mg h−1 FM | 3.01 | 0.19 |

| Parameter | Measure Unit | Value |

|---|---|---|

| Costs per time unit | € h−1 | 210.21 |

| Costs per surface unit | € ha−1 | 65.97 |

| Costs per biomass unit | € Mg−1 FM | 69.42 |

| Parameter | Measure Unit | Average | St.Dev. |

|---|---|---|---|

| Total Seed loss (TLS) | Mg ha−1 | 0.0806 | - |

| Total Seed loss (TLS) | % w/w | 7.82 | - |

| Combine Seed Loss (CSL) | Mg ha−1 | 0.0598 | - |

| Combine Seed Loss (CSL) | % w/w | 5.80 | - |

| Impact Seed Loss (ILS) | Mg ha−1 | 0.0208 | - |

| Impact Seed Loss (ILS) | % w/w | 2.02 | - |

| Bulk density of collected material | kg m−3 | 439.947 | 43.064 |

| Bulk density of cleaned seed | kg m−3 | 642.332 | 7.435 |

| Material Other than Grain (MOG) | % w/w | 31.77 | 3.10 |

| Moisture content of harvested seeds | % | 15.71 | 0.53 |

| 1000 seed-weight of harvested seeds | g | 1.1925 | 0.0168 |

| 1000 seed-weight of not-harvested seeds | g | 1.2074 | 0.0113 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stefanoni, W.; Latterini, F.; Ruiz, J.P.; Bergonzoli, S.; Attolico, C.; Pari, L. Mechanical Harvesting of Camelina: Work Productivity, Costs and Seed Loss Evaluation. Energies 2020, 13, 5329. https://doi.org/10.3390/en13205329

Stefanoni W, Latterini F, Ruiz JP, Bergonzoli S, Attolico C, Pari L. Mechanical Harvesting of Camelina: Work Productivity, Costs and Seed Loss Evaluation. Energies. 2020; 13(20):5329. https://doi.org/10.3390/en13205329

Chicago/Turabian StyleStefanoni, Walter, Francesco Latterini, Javier Prieto Ruiz, Simone Bergonzoli, Consuelo Attolico, and Luigi Pari. 2020. "Mechanical Harvesting of Camelina: Work Productivity, Costs and Seed Loss Evaluation" Energies 13, no. 20: 5329. https://doi.org/10.3390/en13205329

APA StyleStefanoni, W., Latterini, F., Ruiz, J. P., Bergonzoli, S., Attolico, C., & Pari, L. (2020). Mechanical Harvesting of Camelina: Work Productivity, Costs and Seed Loss Evaluation. Energies, 13(20), 5329. https://doi.org/10.3390/en13205329