Turbocompound Power Unit Modelling for a Supercapacitor-Based Series Hybrid Vehicle Application

Abstract

1. Introduction

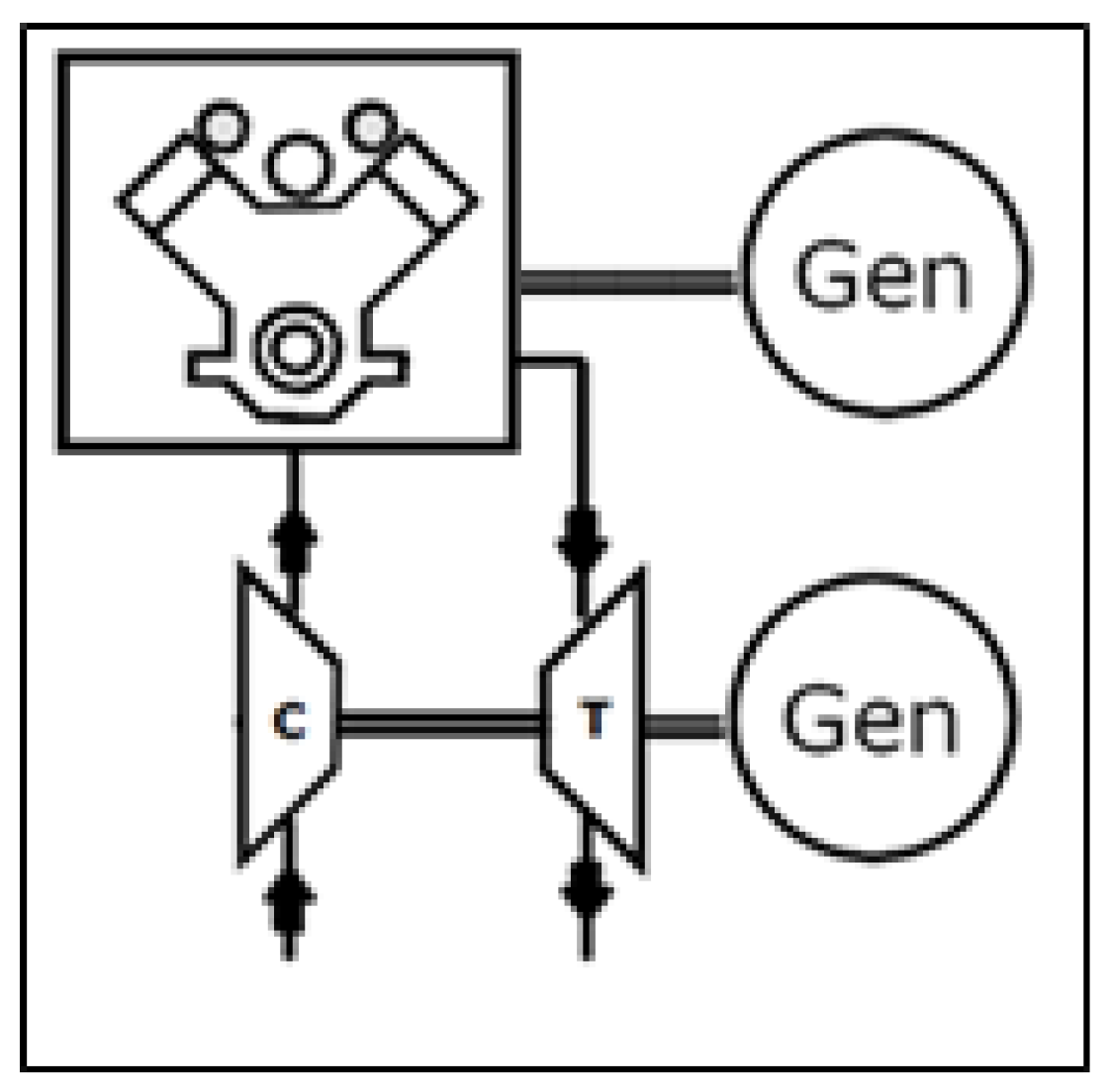

2. Turbocompound Efficiency Evaluation

2.1. Turbocompound Overview

- Thermal losses;

- Mechanical efficiency;

- Effects of outflow cyclic variation (pulsating factor).

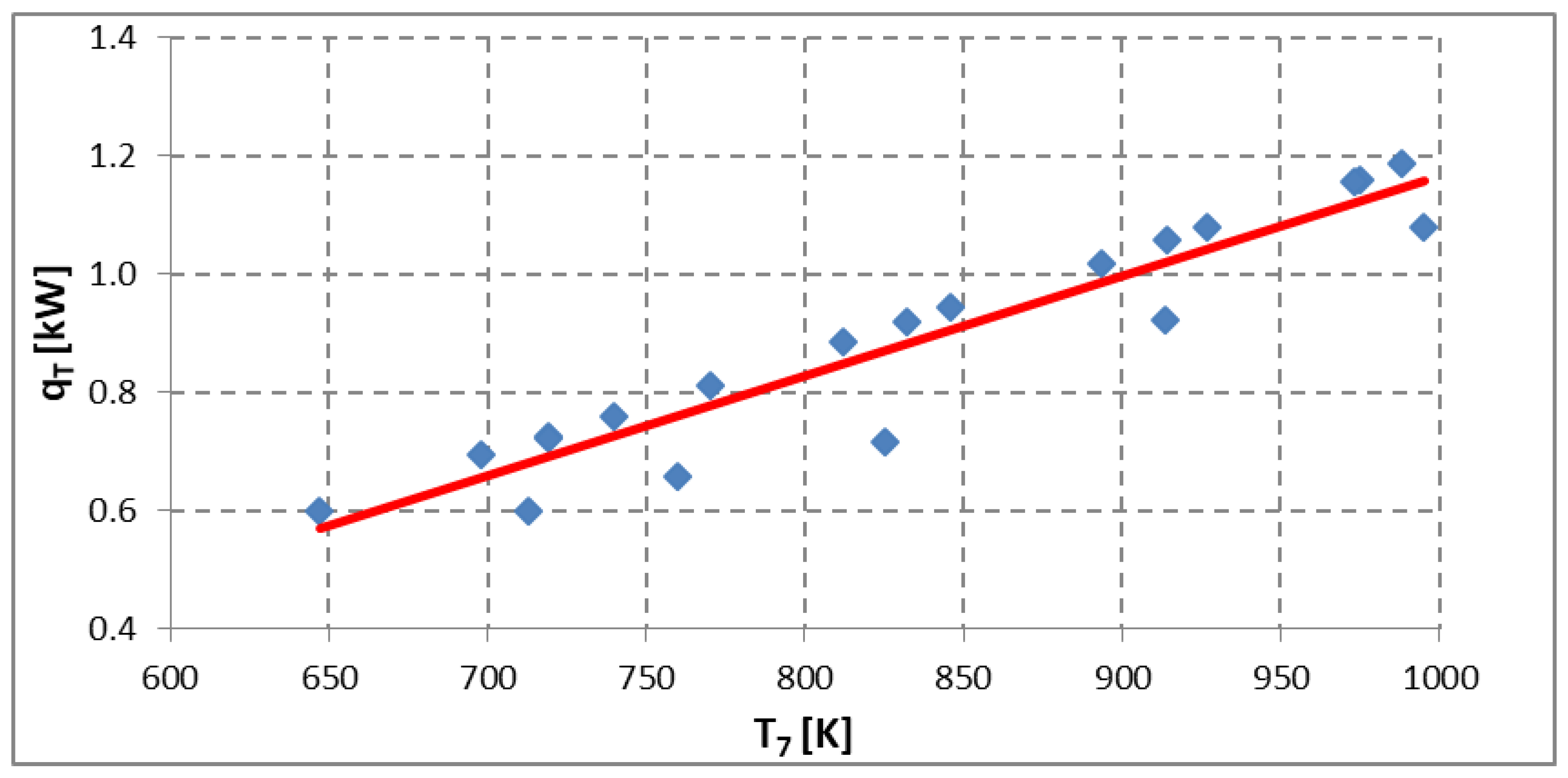

2.2. Analytical Model of a Turbocharger via Experimental Measurements

- Air and fuel mass flow rate ();

- Temperature before and after compressor and turbine (T1, T2, T7, and T8);

- Pressure before and after compressor and turbine (p1, p2, p7, and p8);

- Torque to ICE shaft;

- Speed of ICE (rpm).

- ICE power;

- Mean effective pressure (pme).

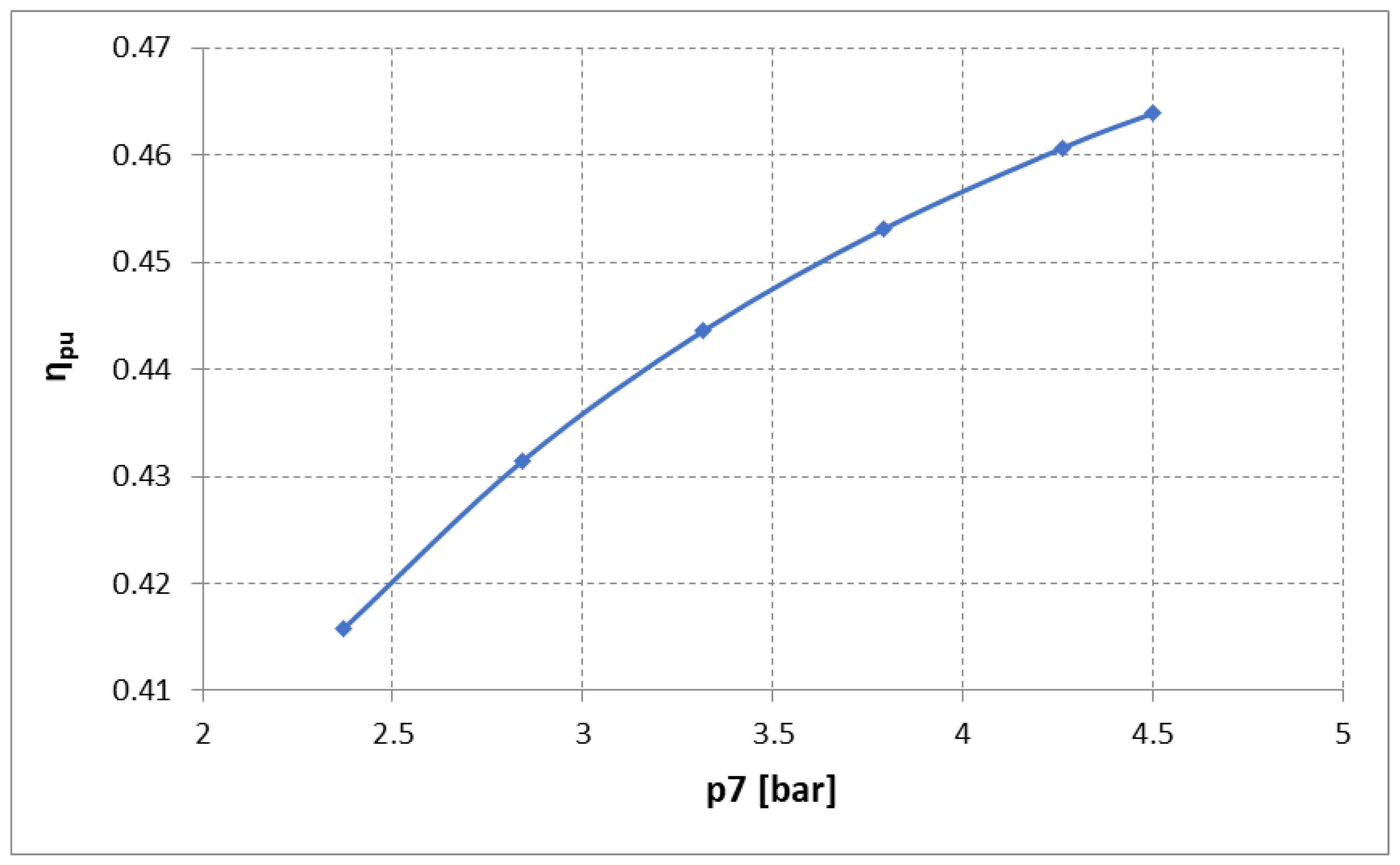

2.3. Turbocompound Modelling: An Extrapolation of Turbocharger Analytical Model

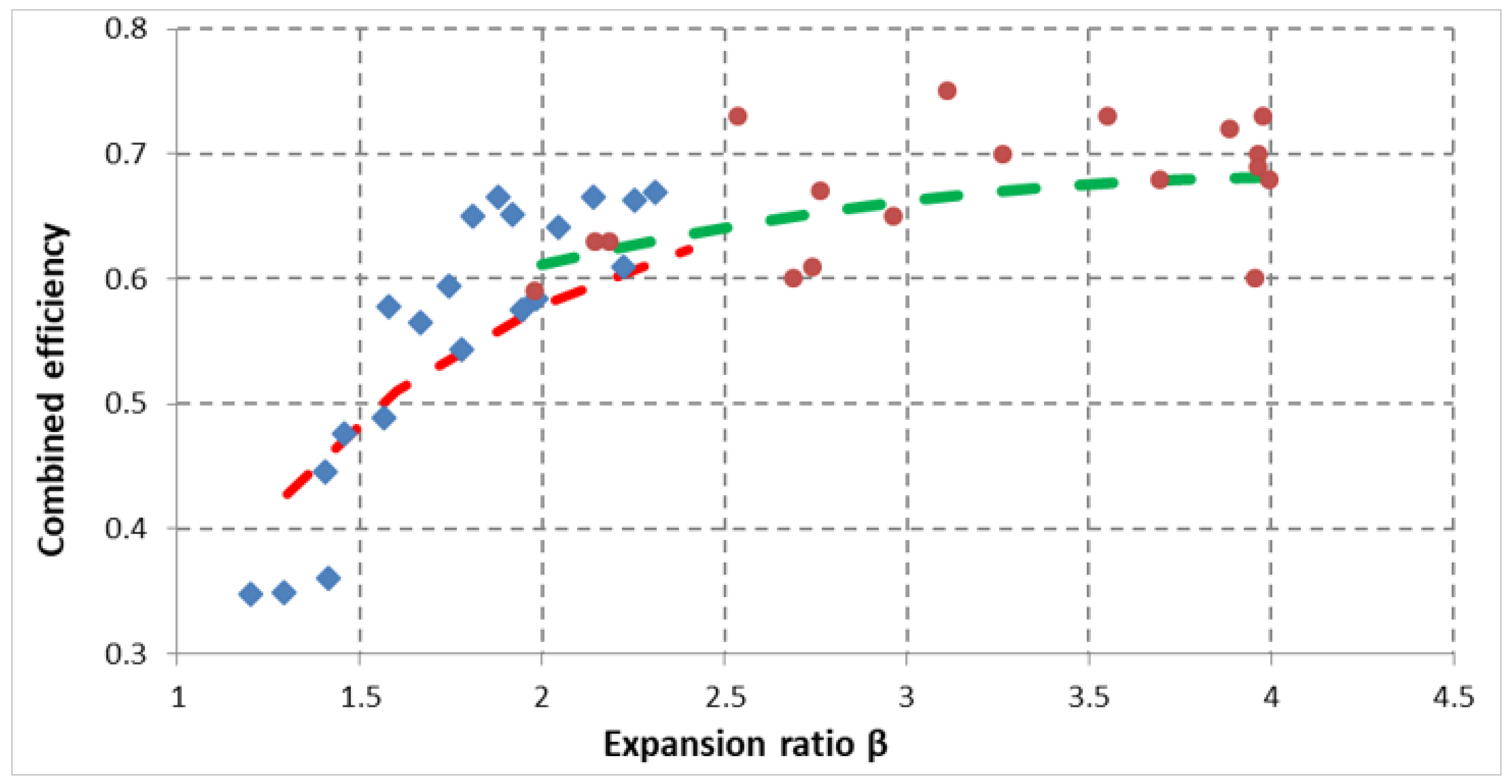

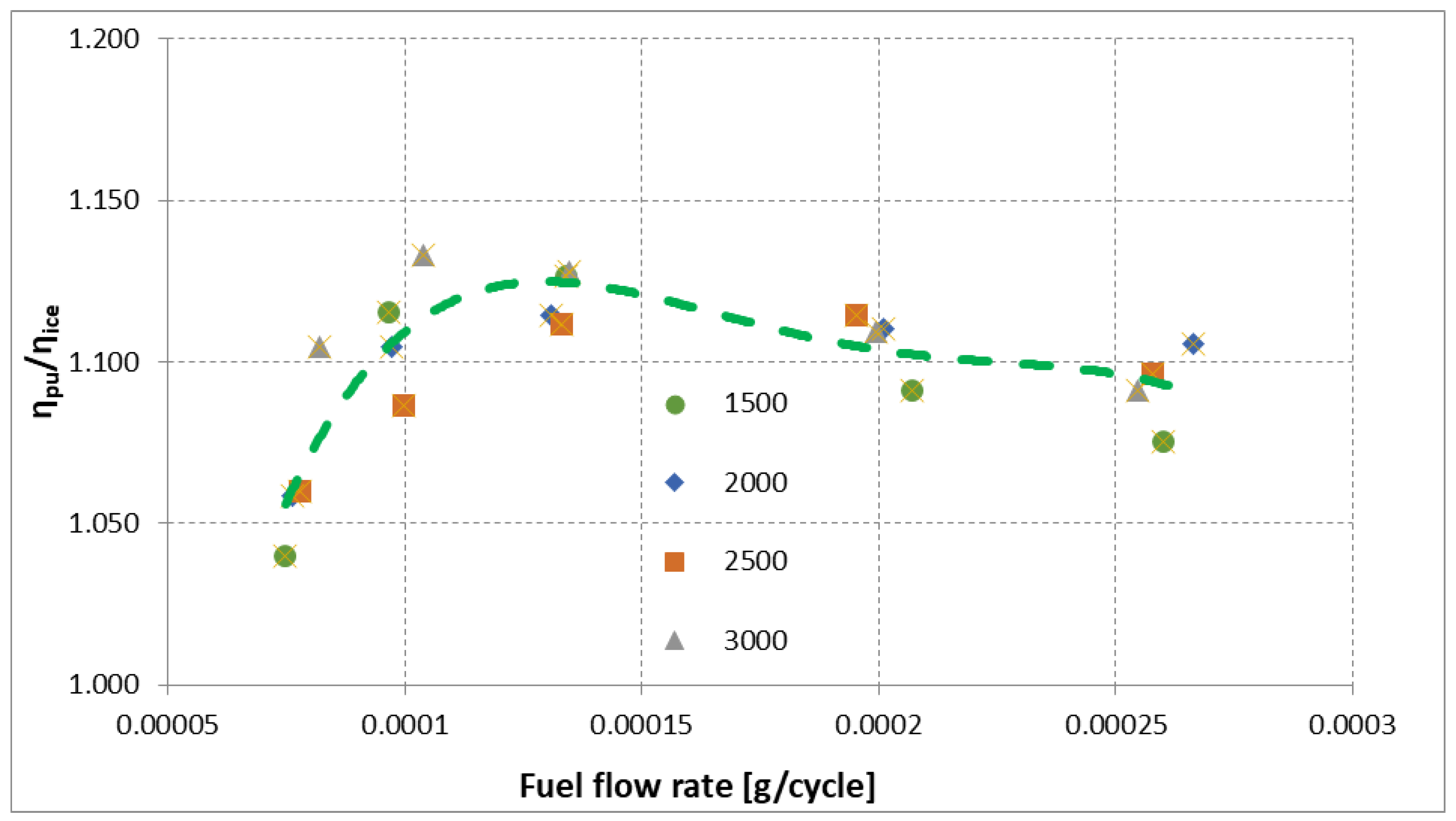

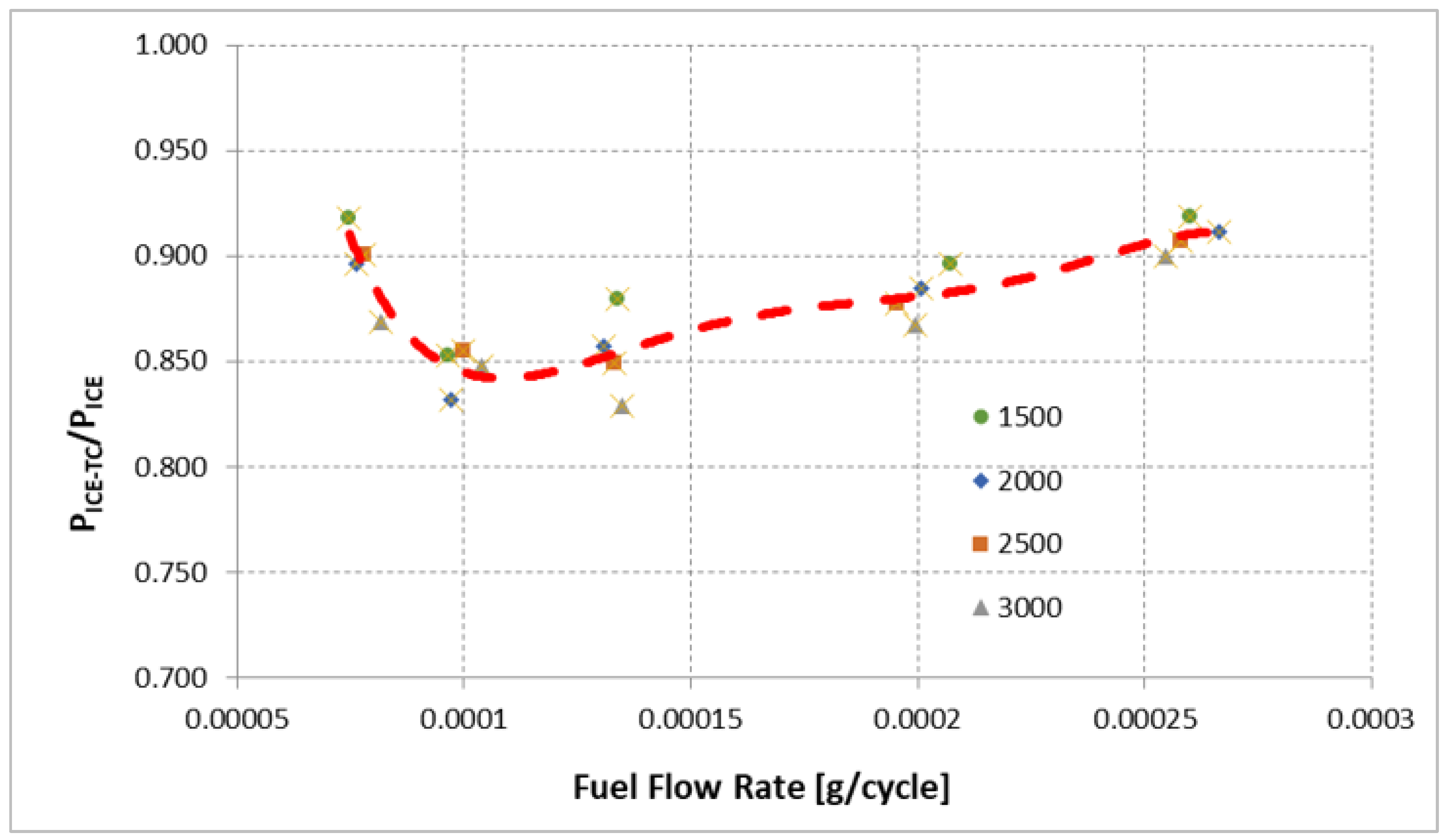

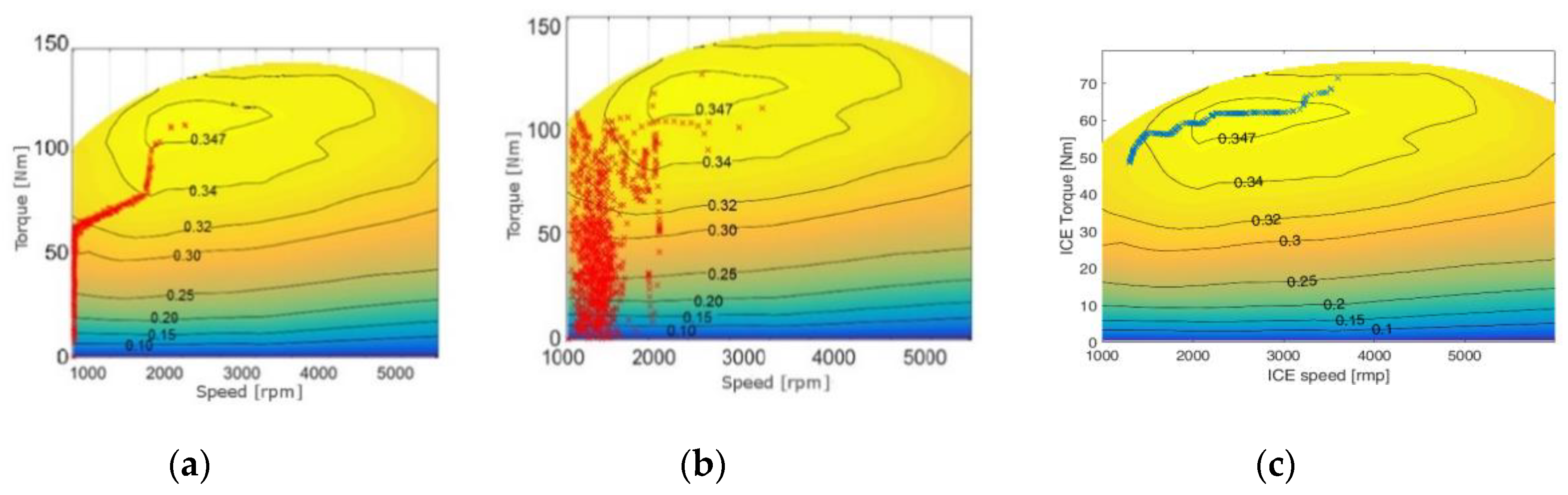

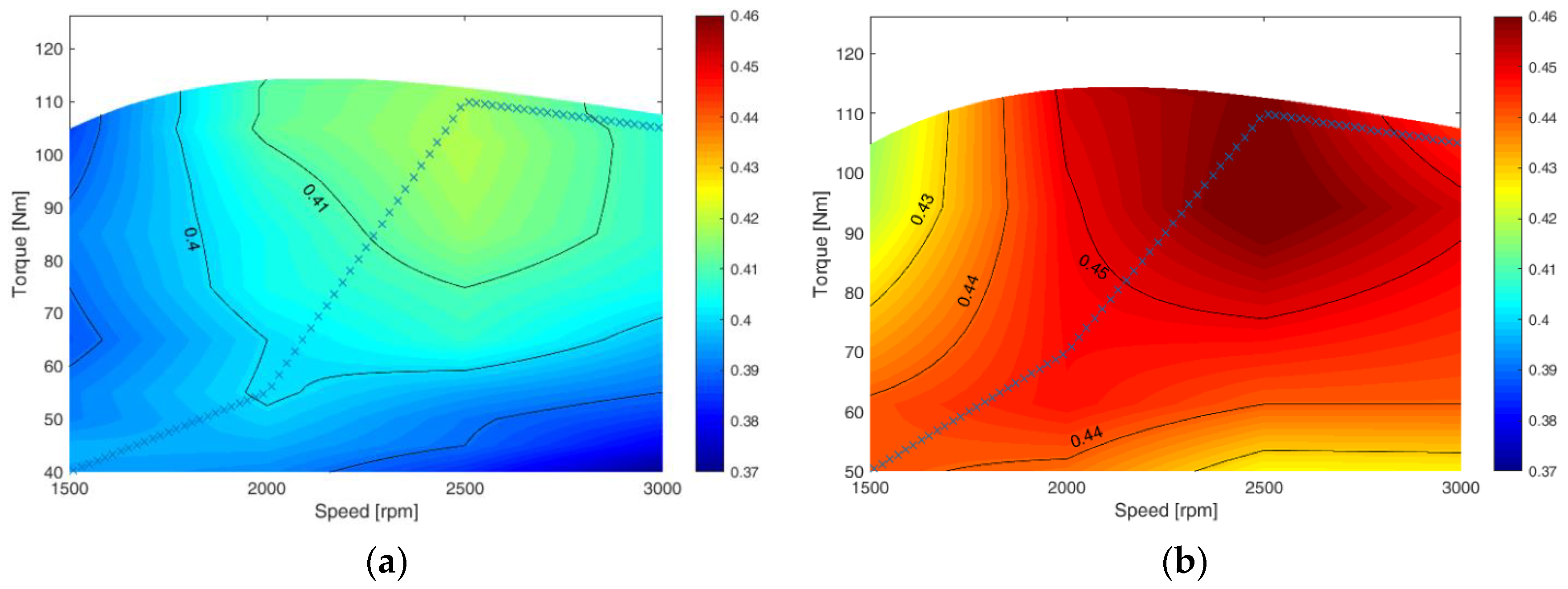

2.4. Turbine Limits and Turbocompound Efficiency

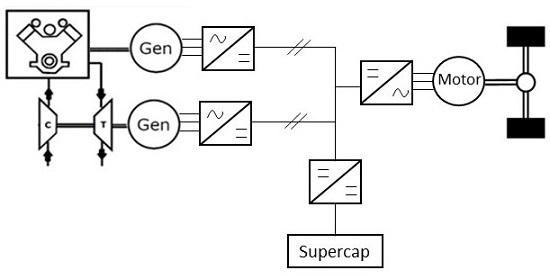

3. Turbocompound Application on Series Hybrid Vehicles

3.1. Simulated Road Missions

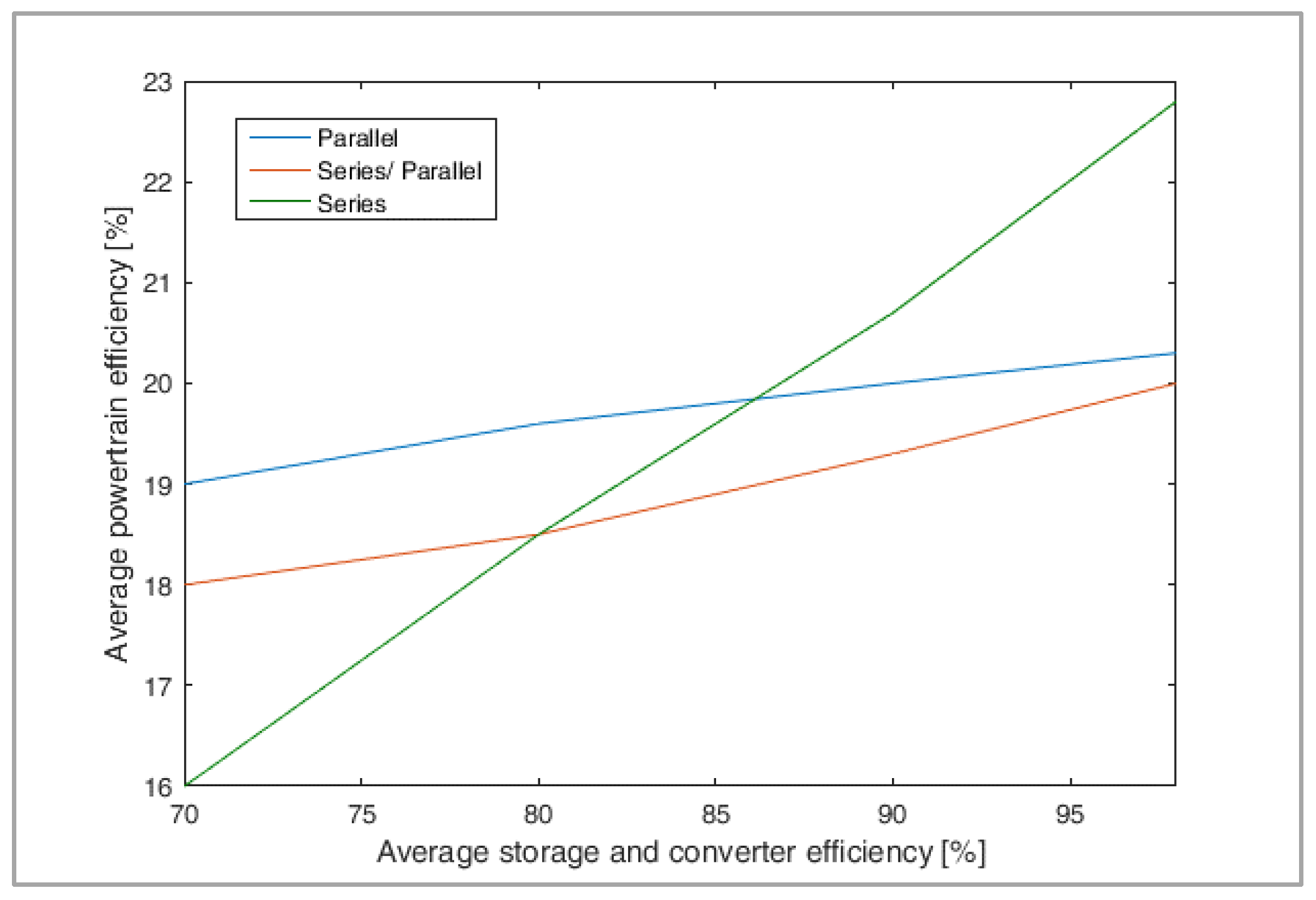

3.2. Overview on Series Hybrid Vehicles

3.3. Vehicle Modelling

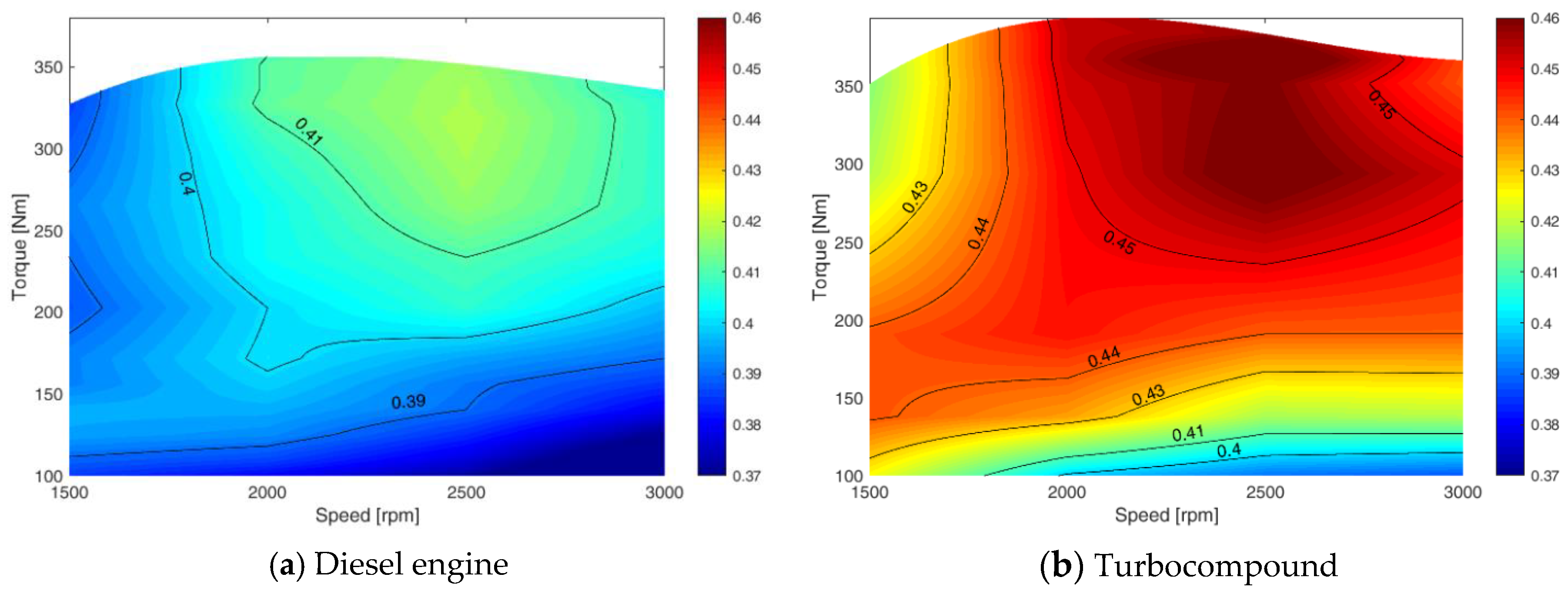

3.4. Simulation Results

- Regular vehicle (RV): spark ignition engine, automatic transmission optimized for consumption minimization.

- Spark Ignition Series Hybrid Vehicle (SI SHV): spark ignition engine, series architecture, supercapacitor module, SiC power converters.

- Diesel Series Hybrid Vehicle (D SHV): diesel engine, series architecture, supercapacitor module, SiC power converters.

- Turbocompound Diesel Series Hybrid Vehicle (TCD SHV): diesel engine combined with the turbocompound technology, series architecture, supercapacitor module, SiC power converters.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Definition |

| h | Enthalpy for mass unit (kJ/kg) |

| W | Work for mass unit (kJ/kg) |

| Q | Exchanged heat for mass unit (kJ/kg) |

| p | Pressure (Pa) |

| T | Temperature (K) |

| c | Speed (m/s) |

| m | Mass (kg) |

| η | Efficiency |

| β | Expansion ratio |

| ε | Pulsating factor |

| A | Pulsation amplitude |

| λ | (k-1)/k where k is the exponent of Poisson adiabatic equation |

| P | Power (kW) |

| ICE | Internal Combustion Engine |

| TC | Turbocharger |

| PU | Power Unit (ICE + TC) |

| v | Specific volume (m3/kg) |

| pme | Mean effective pressure (Pa) |

| Cp | Constant pressure specific heat capacity (kJ/K) |

| F | Fuel power (kW) |

| q | Exchanged heat per time unit (kW) |

| Pipe section (m2) | |

| Density (kg/m3) | |

| Ψ | Efficiency increase |

| α | Exchanged heat equation slope |

| φ | Exchanged heat equation intercept |

| Subscript | |

| e | External |

| t | Total |

| m | Mechanical |

| T | Turbine |

| max | Maximum |

| min | Minimum |

| a | Friction |

| c | Compressor |

| A | Air |

| F | Fuel |

| Superscript | |

| _ | Stationary conditions |

| . | Time derivative |

| Apparent | |

| Thermodynamic Cycle Points | |

| 1 | Ambient condition |

| 2 | Compressor output |

| 3 | Intercooler output |

| 4 | ICE end of compression |

| 5 | ICE End of combustion |

| 6 | ICE end of expansion |

| 7 | Turbine input |

| 8 | Turbine output |

References

- Salmasi, F.R. Control strategies for hybrid electric vehicles: Evolution, classification, comparison, and future trends. IEEE Trans. Veh. Technol. 2007, 56, 2393–2404. [Google Scholar] [CrossRef]

- Uebel, S.; Murgovski, N.; Tempelhahn, C.; Bäker, B. Optimal energy management and velocity control of hybrid electric vehicles. IEEE Trans. Veh. Technol. 2017, 67, 327–337. [Google Scholar] [CrossRef]

- Awadallah, M.; Tawadros, P.; Walker, P.; Zhang, N.; Tawadros, J. A system analysis and modeling of a HEV based on ultracapacitor battery. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 2–5 August 2017; pp. 792–798. [Google Scholar]

- Millo, F.; Cubito, C.; Rolando, L.; Pautasso, E.; Servetto, E. Design and development of an hybrid light commercial vehicle. Energy 2017, 136, 90–99. [Google Scholar] [CrossRef]

- Cheng, Y.-H.; Lai, C.-M. Control strategy optimization for parallel hybrid electric vehicles using a memetic algorithm. Energies 2017, 10, 305. [Google Scholar] [CrossRef]

- Lanzarotto, D.; Passalacqua, M.; Repetto, M. Energy comparison between different parallel hybrid vehicles architectures. Int. J. Energy Prod. Manag. 2017, 2, 370–380. [Google Scholar] [CrossRef][Green Version]

- Burress, T.A.; Campbell, S.L.; Coomer, C.; Ayers, C.W.; Wereszczak, A.A.; Cunningham, J.P.; Lin, H.T. Evaluation of the 2010 Toyota Prius hybrid synergy drive system. In Power Electronics and Electric Machinery Research Facility; Technical Report ORNL/TM2010/253; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2010. [Google Scholar]

- Kim, N.; Cha, S.; Peng, H. Optimal control of hybrid electric vehicles based on Pontryagin’s minimum principle. IEEE Trans. Control Syst. Technol. 2011, 19, 1279–1287. [Google Scholar]

- Chung, C.-T.; Wu, C.-H.; Hung, Y.-H. Effects of electric circulation on the energy efficiency of the power split e-CVT hybrid systems. Energies 2018, 11, 2342. [Google Scholar] [CrossRef]

- Bonfiglio, A.; Lanzarotto, D.; Marchesoni, M.; Passalacqua, M.; Procopio, R.; Repetto, M. Electrical-loss analysis of power-split hybrid electric vehicles. Energies 2017, 10, 2142. [Google Scholar] [CrossRef]

- Kim, H.; Wi, J.; Yoo, J.; Son, H.; Park, C.; Kim, H. A Study on the fuel economy potential of parallel and power split type hybrid electric vehicles. Energies 2018, 11, 2103. [Google Scholar] [CrossRef]

- Pei, H.; Hu, X.; Yang, Y.; Tang, X.; Hou, C.; Cao, D. Configuration optimization for improving fuel efficiency of power split hybrid powertrains with a single planetary gear. Appl. Energy 2018, 214, 103–116. [Google Scholar] [CrossRef]

- Xiang, C.; Ding, F.; Wang, W.; He, W. Energy management of a dual-mode power-split hybrid electric vehicle based on velocity prediction and nonlinear model predictive control. Appl. Energy 2017, 189, 640–653. [Google Scholar] [CrossRef]

- Yang, Y.; Pei, H.; Hu, X.; Liu, Y.; Hou, C.; Cao, D. Fuel economy optimization of power split hybrid vehicles: A rapid dynamic programming approach. Energy 2019, 166, 929–938. [Google Scholar] [CrossRef]

- Chen, J.; Du, J.; Wu, X. Fuel economy analysis of series hybrid electric bus with idling stop strategy. In Proceedings of the 2014 9th International Forum on Strategic Technology (IFOST), Cox’s Bazar, Bangladesh, 21–23 October 2014; pp. 359–362. [Google Scholar]

- Kim, M.; Jung, D.; Min, K. Hybrid Thermostat strategy for enhancing fuel economy of series hybrid intracity bus. IEEE Trans. Veh. Technol. 2014, 63, 3569–3579. [Google Scholar] [CrossRef]

- Zhao, Y.; Yao, J.; Zhong, Z.M.; Sun, Z.C. The research of powertrain for supercapacitor-based series hybrid Bus. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–4. [Google Scholar]

- Passalacqua, M.; Lanzarotto, D.; Repetto, M.; Marchesoni, M. Advantages of Using Supercapacitors and Silicon Carbide on Hybrid Vehicle Series Architecture. Energies 2017, 10, 920. [Google Scholar] [CrossRef]

- Xie, S.; Hu, X.; Liu, T.; Qi, S.; Lang, K.; Li, H. Predictive vehicle-following power management for plug-in hybrid electric vehicles. Energy 2019, 166, 701–714. [Google Scholar] [CrossRef]

- Liu, T.; Wang, B.; Yang, C. Online Markov Chain-based energy management for a hybrid tracked vehicle with speedy Q-learning. Energy 2018, 160, 544–555. [Google Scholar] [CrossRef]

- Passalacqua, M.; Lanzarotto, D.; Repetto, M.; Marchesoni, M. Conceptual design upgrade on hybrid pow ertrains resulting from electric improv ements. Int. J. Transp. Dev. Integr. 2018, 2, 146–154. [Google Scholar] [CrossRef]

- Passalacqua, M.; Lanzarotto, D.; Repetto, M.; Vaccaro, L.; Bonfiglio, A.; Marchesoni, M. Fuel Economy and ems for a series hybrid vehicle based on supercapacitor storage. IEEE Trans. Power Electron. 2019, 34, 9966–9977. [Google Scholar] [CrossRef]

- Jain, A.; Nueesch, T.; Naegele, C.; Lassus, P.M.; Onder, C.H. Modeling and control of a hybrid electric vehicle with an electrically assisted turbocharger. IEEE Trans. Veh. Technol. 2016, 65, 4344–4358. [Google Scholar] [CrossRef]

- Mamat, A.M.I.B.; Martinez-Botas, R.F.; Rajoo, S.; Romagnoli, A.; Petrovic, S. Waste heat recovery using a novel high performance low pressure turbine for electric turbocompounding in downsized gasoline engines: Experimental and computational analysis. Energy 2015, 90, 218–234. [Google Scholar] [CrossRef]

- Dimitriou, P.; Burke, R.; Zhang, Q.; Copeland, C.; Stoffels, H. Electric turbocharging for energy regeneration and increased efficiency at real driving conditions. Appl. Sci. 2017, 7, 350. [Google Scholar] [CrossRef]

- Jye, A.T.S.; Pesiridis, A.; Rajoo, S. Effects of Mechanical Turbo Compounding on a Turbocharged Diesel Engine; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Katsanos, C.; Hountalas, D.; Zannis, T. Simulation of a heavy-duty diesel engine with electrical turbocompounding system using operating charts for turbocharger components and power turbine. Energy Convers. Manag. 2013, 76, 712–724. [Google Scholar] [CrossRef]

- Kant, M.; Romagnoli, A.; Mamat, A.M.; Martinez-Botas, R.F. Heavy-duty engine electric turbocompounding. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015, 229, 457–472. [Google Scholar] [CrossRef]

- Zhao, R.; Zhuge, W.; Zhang, Y.; Yang, M.; Martinez-Botas, R.; Yin, Y. Study of two-stage turbine characteristic and its influence on turbo-compound engine performance. Energy Convers. Manag. 2015, 95, 414–423. [Google Scholar] [CrossRef]

- Zhao, R.; Zhuge, W.; Zhang, Y.; Yin, Y.; Zhao, Y.; Chen, Z. Parametric study of a turbocompound diesel engine based on an analytical model. Energy 2016, 115, 435–445. [Google Scholar] [CrossRef]

- Marelli, S.; Carraro, C.; Marmorato, G.; Zamboni, G.; Capobianco, M. Experimental analysis on the performance of a turbocharger compressor in the unstable operating region and close to the surge limit. Exp. Therm. Fluid Sci. 2014, 53, 154–160. [Google Scholar] [CrossRef]

- Bozza, F.; de Bellis, V.; Marelli, S.; Capobianco, M. 1D simulation and experimental analysis of a turbocharger compressor for automotive engines under unsteady flow conditions. SAE Int. J. Engines 2011, 4, 1365–1384. [Google Scholar] [CrossRef]

- Pasini, G.; Lutzemberger, G.; Frigo, S.; Marelli, S.; Ceraolo, M.; Gentili, R.; Capobianco, M. Evaluation of an electric turbo compound system for SI engines: A numerical approach. Appl. Energy 2016, 162, 527–540. [Google Scholar] [CrossRef]

- Zinner, K.A. Supercharging of Internal Combustion Engines: Additional; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Marelli, S.; Capobianco, M.; Zamboni, G. Pulsating flow performance of a turbocharger compressor for automotive application. Int. J. Heat Fluid Flow 2014, 45, 158–165. [Google Scholar] [CrossRef]

- Confidential data related to test performed by the Department of Mechanical Engineering (DIME) of the University of Genova in collaboration with Centro Ricerche Fiat (CRF).

- Deligant, M.; Podevin, P.; Descombes, G. Experimental identification of turbocharger mechanical friction losses. Energy 2012, 39, 388–394. [Google Scholar] [CrossRef]

- Confidential data of the Department of Mechanical Engineering (DIME), regarding studies on turbocharged power unit for car racing application.

- United States Environmental Protection Agency (EPA). Vehicle and Fuel Emissions Testing Dynamometer Drive Schedules. Available online: https://www.epa.gov/vehicle-and-fuel-emissions-testing/dynamometer-drive-schedules (accessed on 14 January 2020).

- Passalacqua, M.; Carpita, M.; Gavin, S.; Marchesoni, M.; Repetto, M.; Vaccaro, L.; Wasterlain, S. Supercapacitor storage sizing analysis for a series hybrid vehicle. Energies 2019, 12, 1759. [Google Scholar] [CrossRef]

- Lanzarotto, D.; Marchesoni, M.; Passalacqua, M.; Prato, A.P.; Repetto, M. Overview of different hybrid vehicle architectures. IFAC PapersOnLine 2018, 51, 218–222. [Google Scholar] [CrossRef]

- Zhao, R.; Zhuge, W.; Zhang, Y.; Yin, Y.; Chen, Z.; Li, Z. Parametric study of power turbine for diesel engine waste heat recovery. Appl. Therm. Eng. 2014, 67, 308–319. [Google Scholar] [CrossRef]

- Königstein, A.; Grebe, U.D.; Wu, K.-J.; Larsson, P.-I. Differentiated analysis of downsizing concepts. MTZ Worldwide 2008, 69, 4–11. [Google Scholar] [CrossRef]

| PME | 1500 rpm | 2000 rpm | 2500 rpm | 3000 rpm |

|---|---|---|---|---|

| 6 bar | 16.3 kW | 20.7 kW | 26.0 kW | 33.5 kW |

| 8 bar | 21.8 kW | 28.8 kW | 35.6 kW | 44.6 kW |

| 11 bar | 30.3 kW | 40.0 kW | 50.0 kW | 60.8 kW |

| 17 bar | 44.5 kW | 61.6 kW | 77.3 kW | 92.4 kW |

| Maximum load | 55.3 kW (21.1 bar) | 82.6 kW (22.9 bar) | 101 kW (22.6 bar) | 115 kW (21.6 bar) |

| RPM | 6 bar | 8 bar | 11 bar | 17 bar | 22 bar |

|---|---|---|---|---|---|

| 1500 | 1.67 | 1.70 | 1.67 | 1.45 | 1.36 |

| 2000 | 1.28 | 1.35 | 1.34 | 1.25 | 1.20 |

| 2500 | 1.15 | 1.18 | 1.19 | 1.15 | 1.12 |

| 3000 | 1.07 | 1.08 | 1.11 | 1.09 | 1.08 |

| RPM | 6 bar | 8 bar | 11 bar | 17 bar | 22 bar |

|---|---|---|---|---|---|

| 1500 | 0.35 | 0.35 | 0.36 | 0.54 | 0.58 |

| 2000 | 0.45 | 0.48 | 0.49 | 0.56 | 0.61 |

| 2500 | 0.58 | 0.57 | 0.59 | 0.64 | 0.66 |

| 3000 | 0.65 | 0.67 | 0.65 | 0.67 | 0.67 |

| Road Mission | Average Speed (km/h) | Maximum Speed (km/h) | Length (km) | Change of Altitude | Maximum Road Slope (%) |

|---|---|---|---|---|---|

| US06 | 78 | 130 | 13 | - | - |

| UDDS | 31 | 90 | 12 | - | - |

| HWFET | 78 | 97 | 16.5 | - | - |

| Urban | 24 | 57 | 11.4 | 20 | Negligible |

| Fast-urban | 27 | 68 | 22 | 62 | 6 |

| Extra-urban | 45 | 80 | 36 | 300 | 9 |

| Parameters | Value |

|---|---|

| Mass 1 (kg) | 1450 |

| Rolling coefficient | 0.01 |

| Aerodynamic drag coefficient | 0.25 |

| Front section (m2) | 2.3 |

| Wheel radius (m) | 0.3 |

| Final gear ratio | 8 |

| Differential gear efficiency Gearbox efficiency (parallel) Power-split gear efficiency (series/parallel) | 0.97 0.95 0.95 |

| Air density (kg/m3) ICE maximum power (parallel) (kW) | 1.22 72 |

| ICE maximum power 2 (series) (kW) | 40 |

| Mass 1 (kg) | 1450 |

| Rolling coefficient | 0.01 |

| Aerodynamic drag coefficient | 0.25 |

| Features | Value |

|---|---|

| Elementary module employed | BMOD0165 P048 C01 |

| Series module number | 4 |

| Total mass (kg) | 56 |

| Rated capacitance, C (F) | 41.2 |

| Rated voltage, Vmax (V) | 192 |

| Equivalent series resistance (ESR) (mΩ) | 24 |

| Rated power 1 (kW) | 365 |

| Usable energy 2 (Wh) | 162 |

| Road Mission | RV | SI SHV | D SHV | TCD SHV |

|---|---|---|---|---|

| US06 | 16.1 | 20.7 | 27.5 | 29.1 |

| UDDS | 19.1 | 34.7 | 45.4 | 49.5 |

| HWFET | 23.2 | 27.6 | 36.2 | 38.9 |

| Urban | 19.5 | 35 | 45.2 | 50.2 |

| Fast-urban | 20 | 35.3 | 46 | 50 |

| Extra-urban | 25.2 | 36 | 46.9 | 50.6 |

| Road Mission | Turbocompound Fuel Saving |

|---|---|

| US06 | 10.2% |

| UDDS | 11.6% |

| HWFET | 11.0% |

| Urban | 12.5% |

| Fast-urban | 11.5% |

| Extra-urban | 11.1% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Repetto, M.; Passalacqua, M.; Vaccaro, L.; Marchesoni, M.; Pini Prato, A. Turbocompound Power Unit Modelling for a Supercapacitor-Based Series Hybrid Vehicle Application. Energies 2020, 13, 447. https://doi.org/10.3390/en13020447

Repetto M, Passalacqua M, Vaccaro L, Marchesoni M, Pini Prato A. Turbocompound Power Unit Modelling for a Supercapacitor-Based Series Hybrid Vehicle Application. Energies. 2020; 13(2):447. https://doi.org/10.3390/en13020447

Chicago/Turabian StyleRepetto, Matteo, Massimiliano Passalacqua, Luis Vaccaro, Mario Marchesoni, and Alessandro Pini Prato. 2020. "Turbocompound Power Unit Modelling for a Supercapacitor-Based Series Hybrid Vehicle Application" Energies 13, no. 2: 447. https://doi.org/10.3390/en13020447

APA StyleRepetto, M., Passalacqua, M., Vaccaro, L., Marchesoni, M., & Pini Prato, A. (2020). Turbocompound Power Unit Modelling for a Supercapacitor-Based Series Hybrid Vehicle Application. Energies, 13(2), 447. https://doi.org/10.3390/en13020447