Analysis and Design of Innovative Magnetic Wedges for High Efficiency Permanent Magnet Synchronous Machines †

Abstract

1. Introduction

- Greater efficiency, essentially due to the reduction of Joule losses (at the expense of an increase in iron and magnet losses);

- Greater power density, thanks to the reduced size of the machine;

- Higher field weakening capability;

- Fault tolerance.

- Increase in the Carter factor and the equivalent length of the airgap, with a consequently greater reluctance of the magnetic path;

- Worsening of the harmonic content of the magnetic field, with particular negative consequences in surface-mounted permanent magnet (SPM) machines;

- Possible increasing in the cogging torque, due to the considerable discontinuity of the magnetic permeability of the stator core.

1.1. State of the Art of the FSCW Machines

1.2. State of the Art of the Magnetic Wedges Employed in Rotating Electrical Machines

1.3. Novelties of the Paper

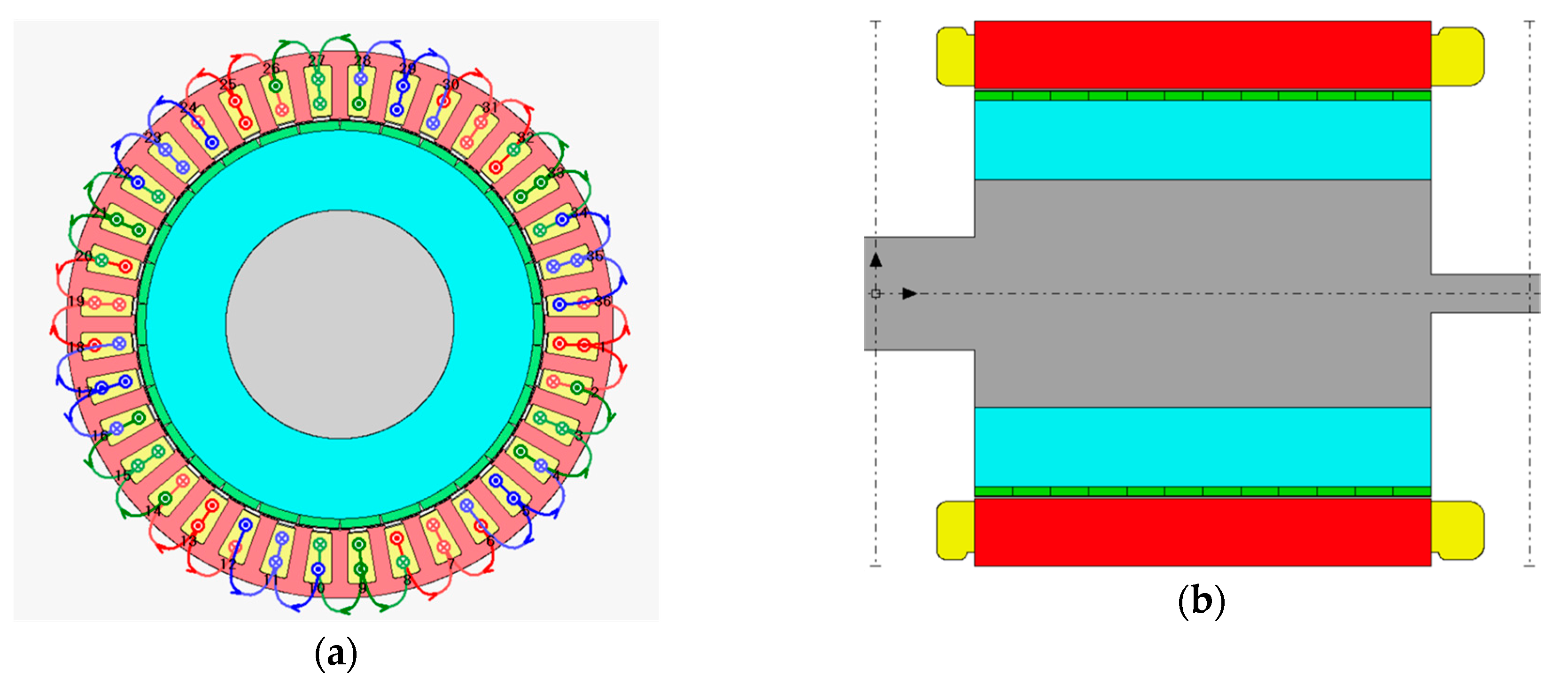

2. Design of a FSCW-SPM Synchronous Machine

- High winding factor for the fundamental component of the magnetomotive force (m.m.f.), which maximizes the torque;

- Low winding factor for the other harmonics of the m.m.f., which reduces the torque ripple;

- Reduced cogging torque;

- Null unbalance in the electromagnetic force.

3. Power Losses in FSCW SPM Synchronous Machines

3.1. Joule Losses

3.2. Iron Losses

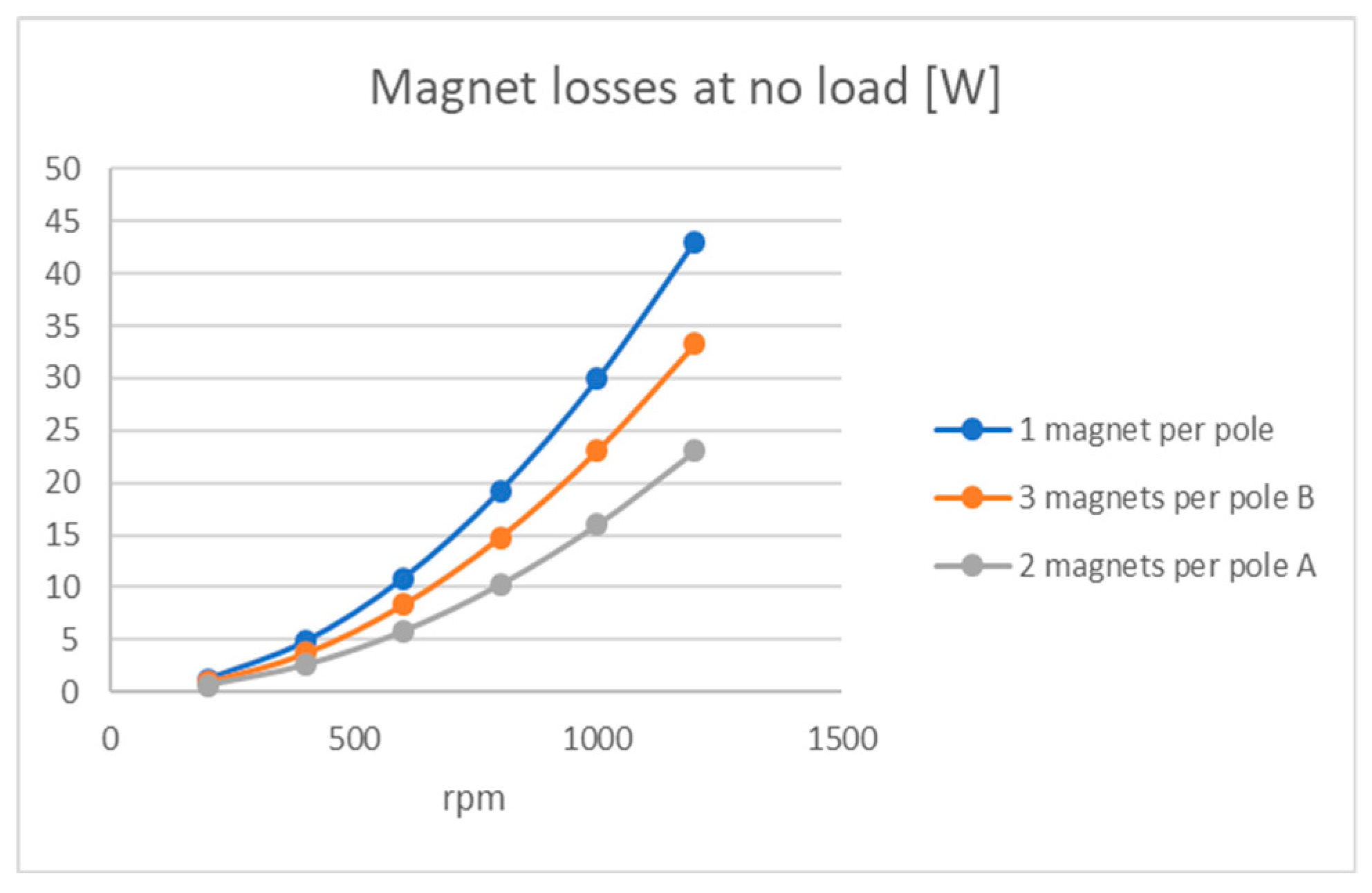

3.3. Losses in the Magnets

4. Application of Magnetic Wedges in SPM Synchronous Machines

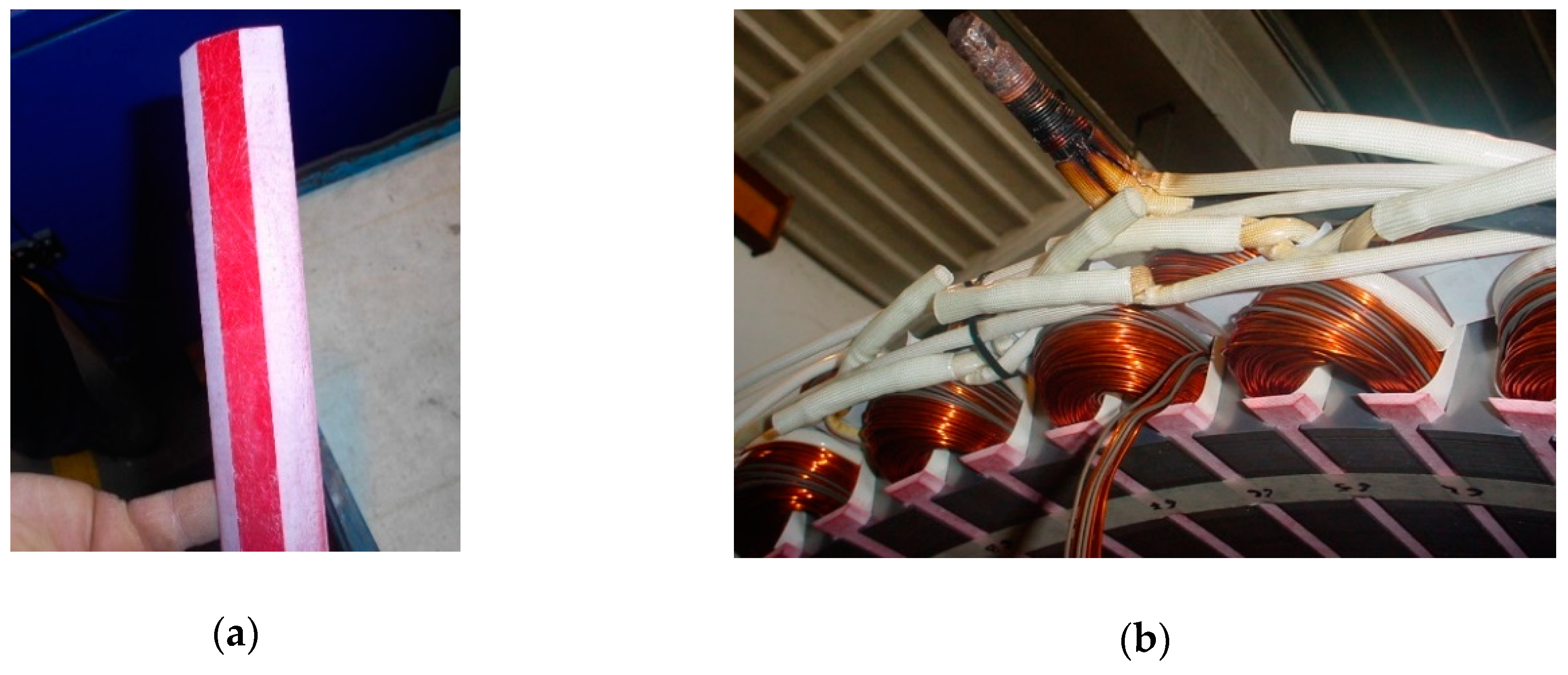

4.1. Characteristics of Magnetic Wedges

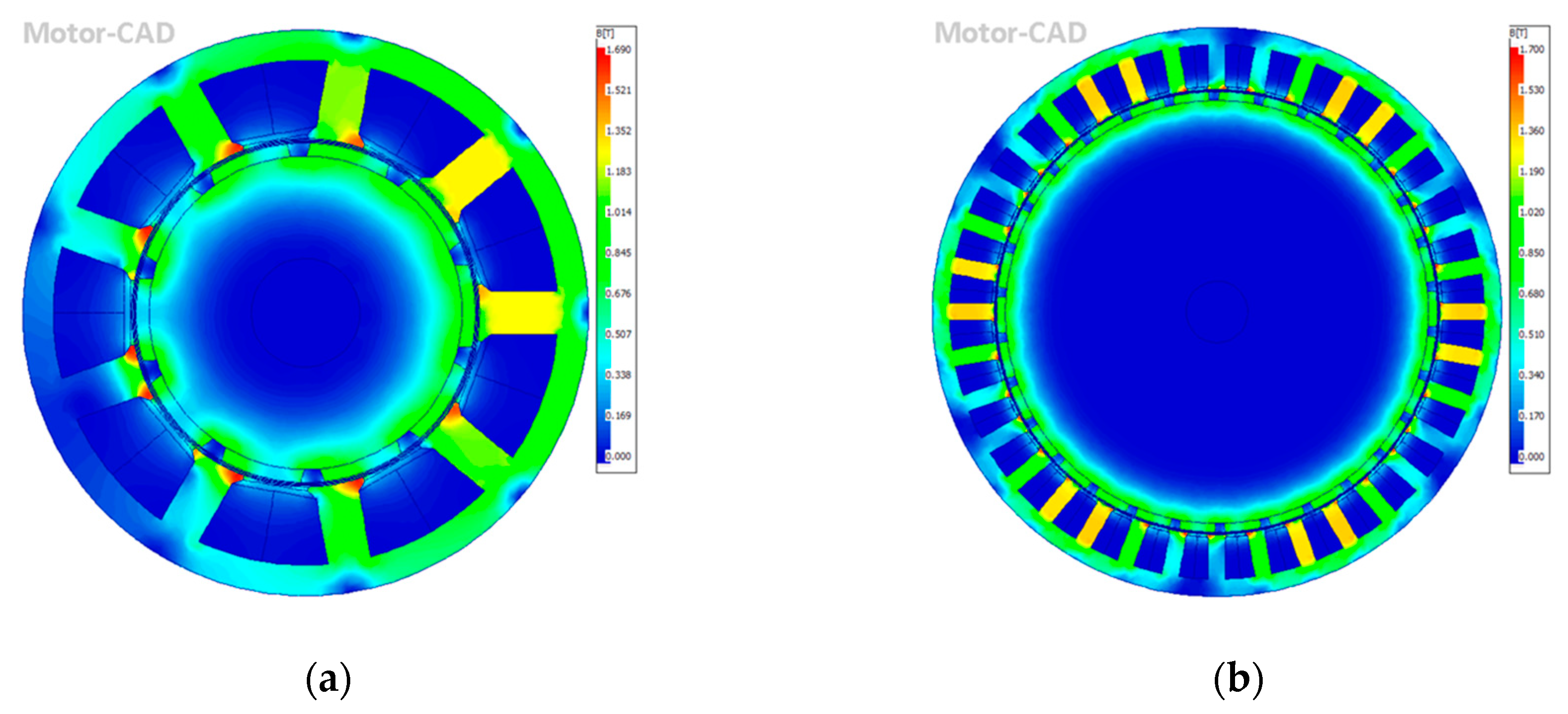

4.2. Effects of the Magnetic Wedges on the Flux Density and BEMF

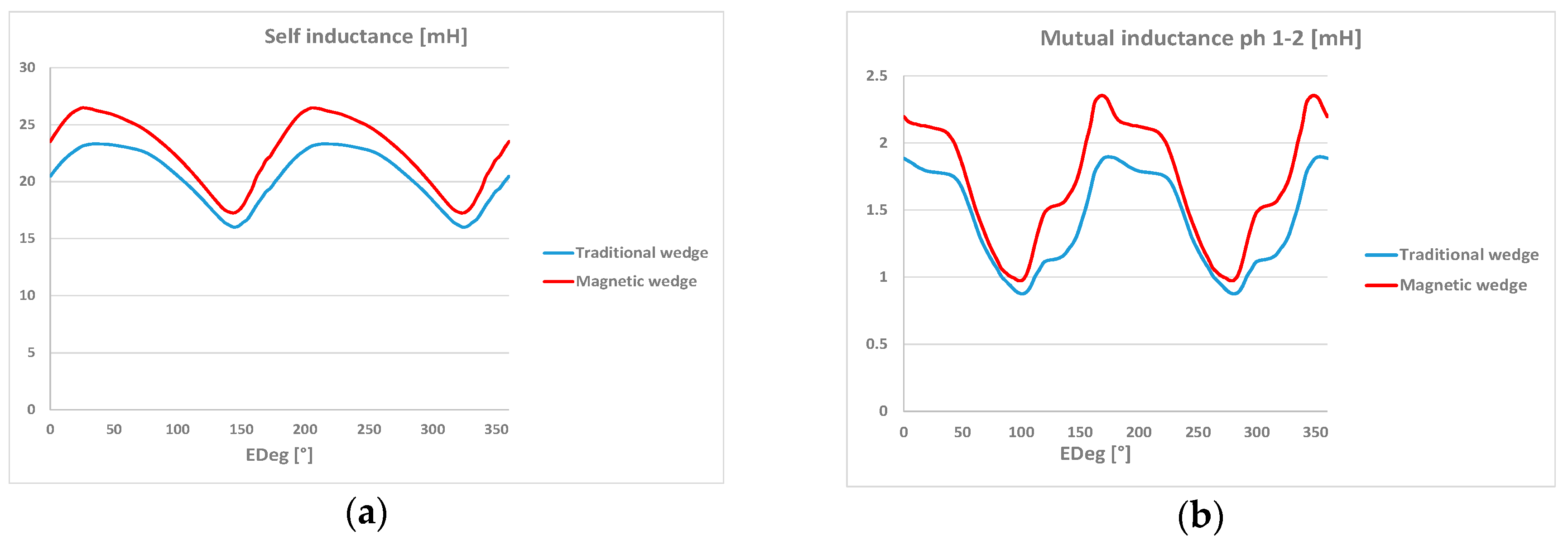

4.3. Effects of the Magnetic Wedges on the Inductances

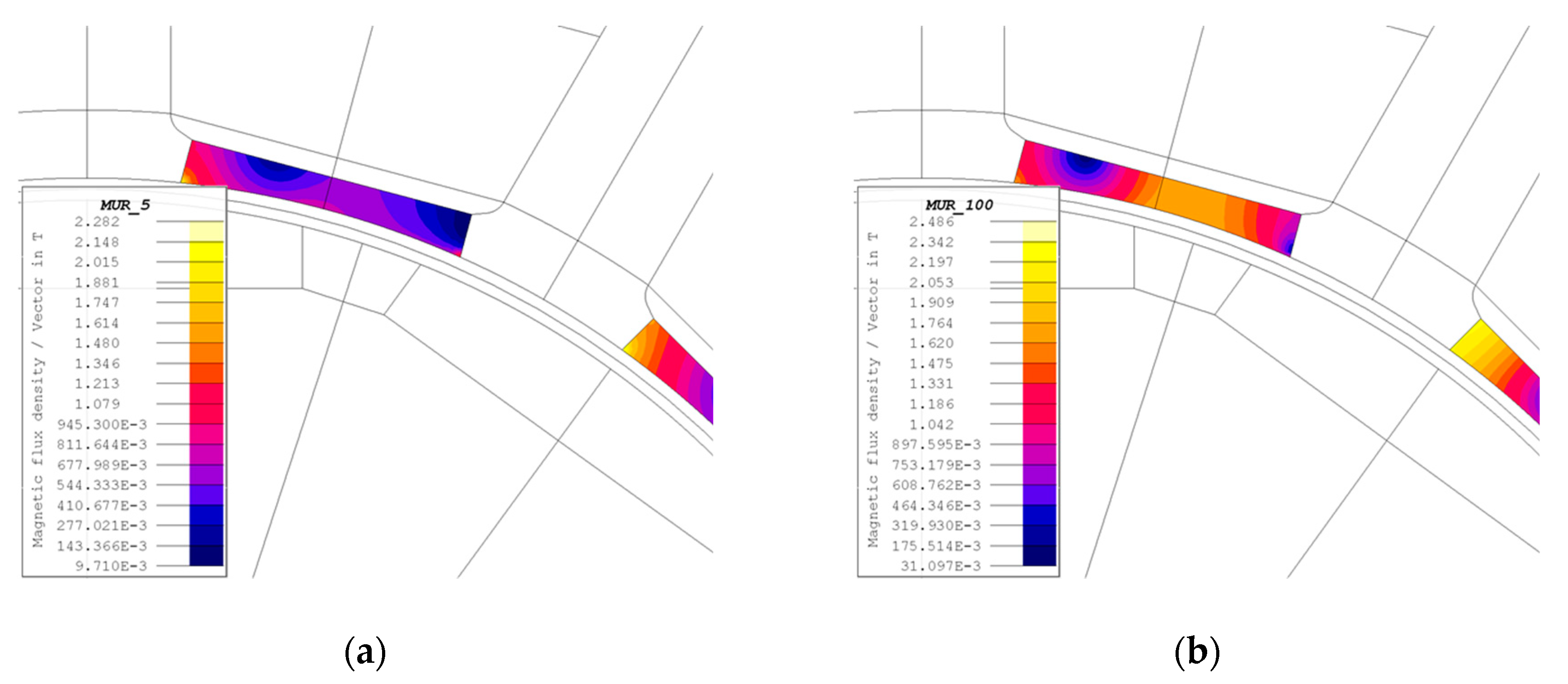

4.4. Effects of the Saturation on the Magnetic Wedges

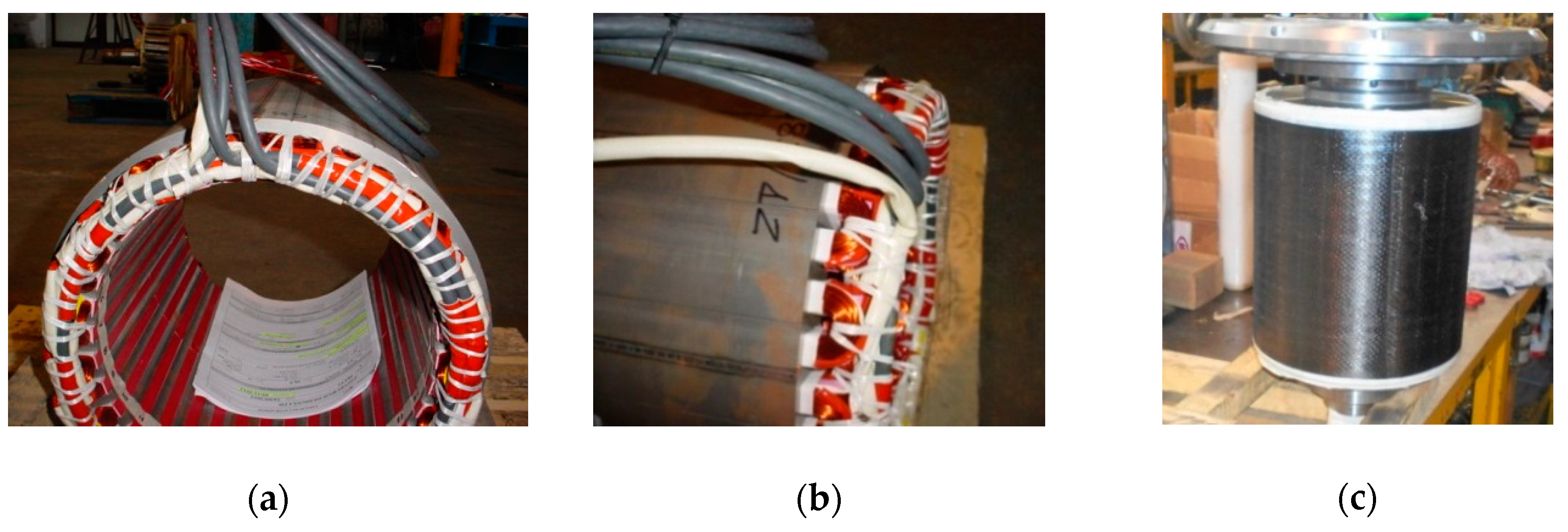

5. Case Study

6. Behavior of SPM Synchronous Machines with Uniform Magnetic Wedges

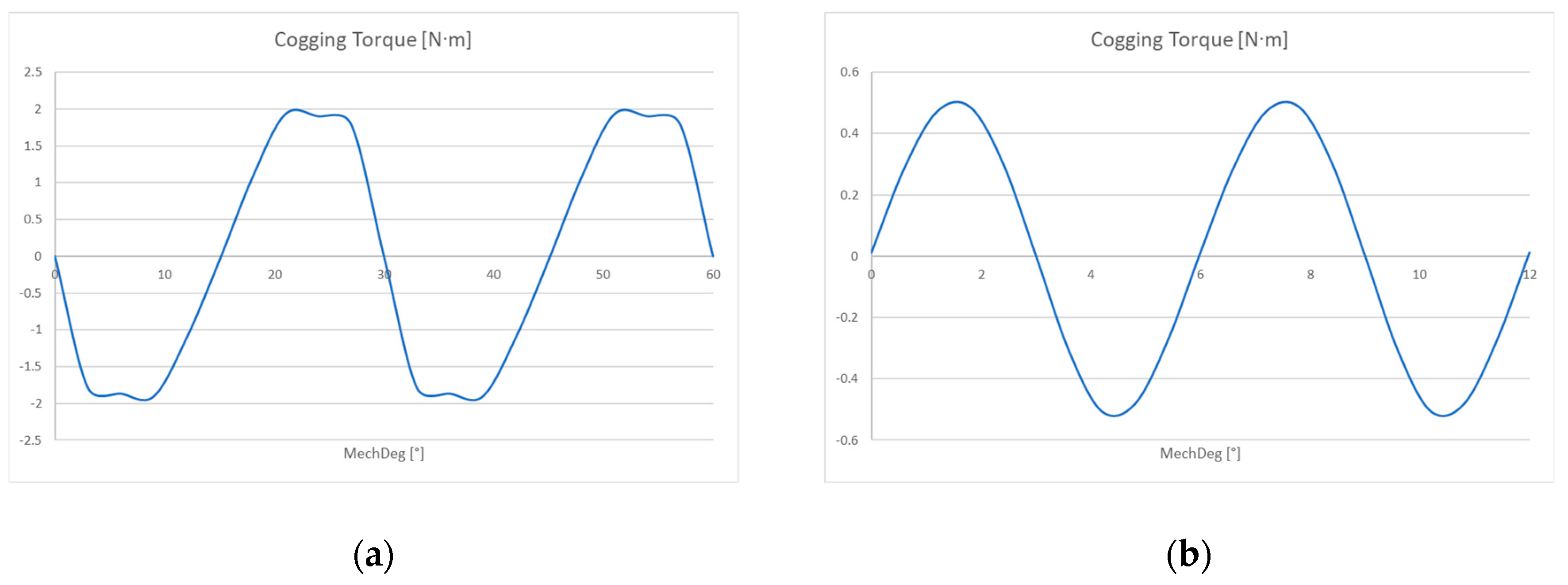

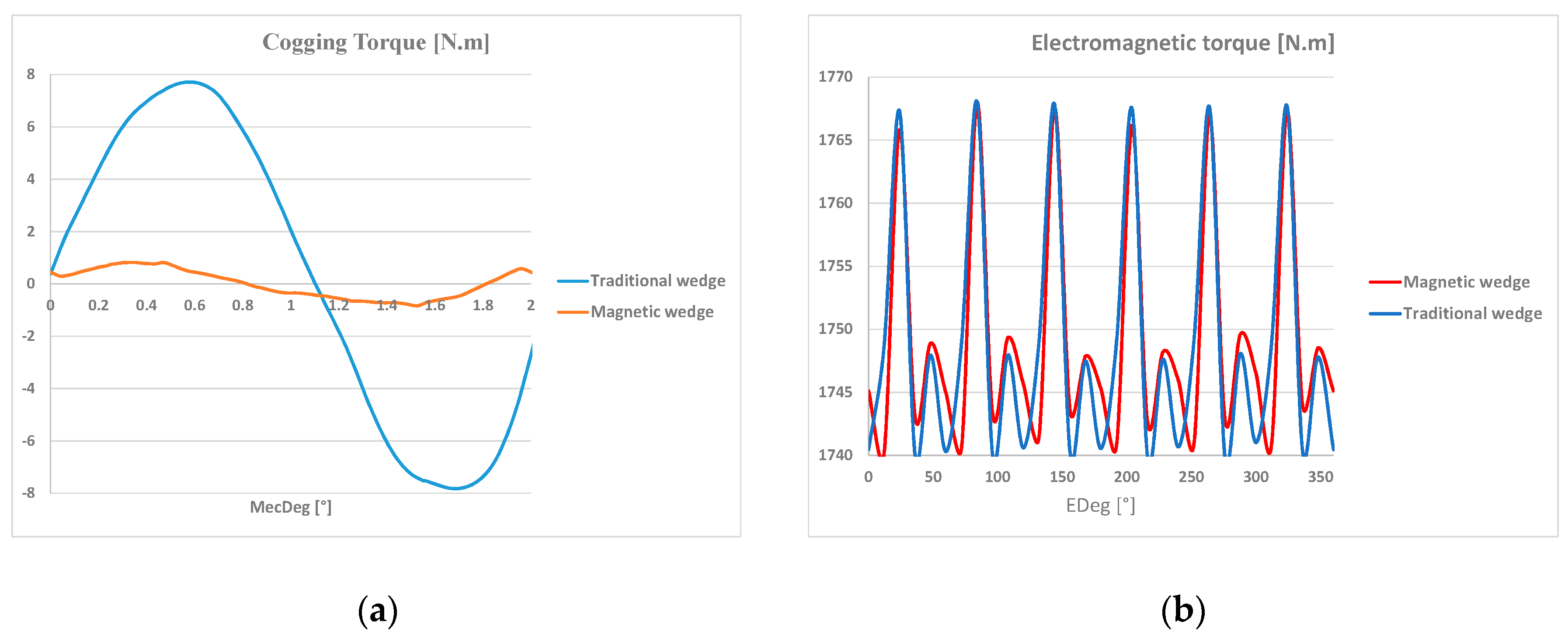

6.1. Effect of Uniform Magnetic Wedges under No Load

6.2. Effect of Uniform Magnetic Wedges at Full Load

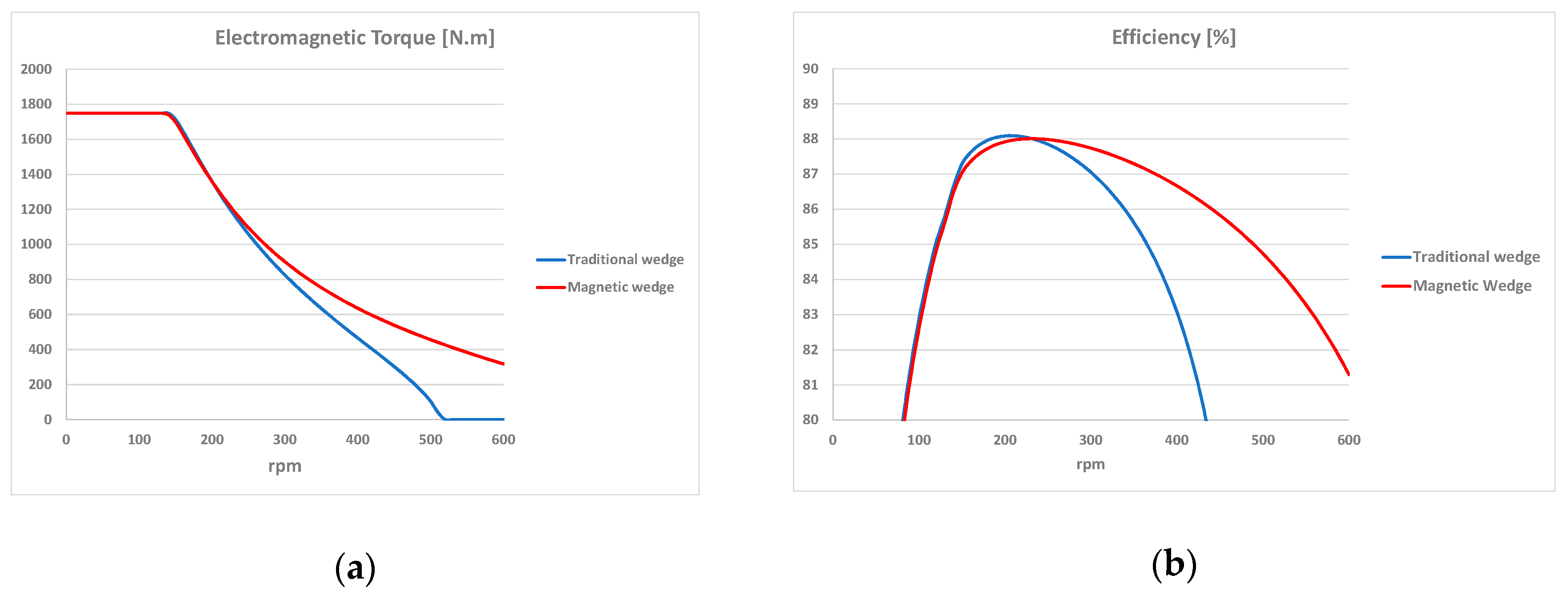

6.3. Effect of Uniform Magnetic Wedges at Intermediate Load and in Field Weakening Operation

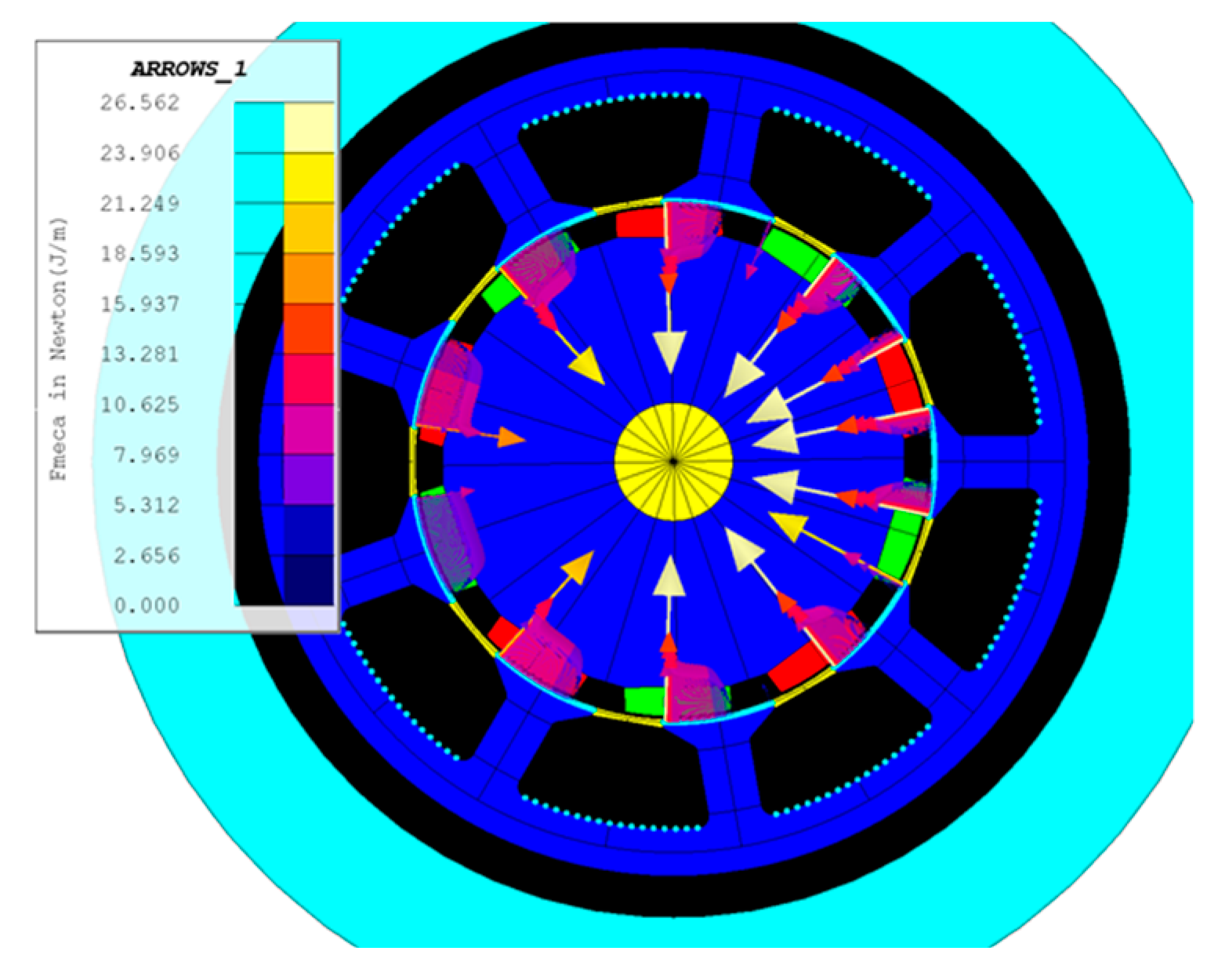

6.4. Effect of Uniform Magnetic Wedges on the Radial Forces

7. Optimization of a Non-Conventional Magnetic Wedge

7.1. Effect of Non-Conventional Magnetic Wedges at Full Load

7.2. Effect of Non-Conventional Magnetic Wedges in Field Weakening Operation

7.3. Effect of Non-Conventional Magnetic Wedges at Low Load

8. Discussion

9. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EL-Refaie, A.M. Fractional-slot concentrated-windings synchronous permanent magnet machines: Opportunities and challenges. IEEE Trans. Ind. Electron. 2010, 57, 107–121. [Google Scholar] [CrossRef]

- Meyer, F. Permanent Magnet Synchronous Machines with Non-Overlapping Concentrated Windings for Low-Speed Direct-Drive Applications. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2008. [Google Scholar]

- Martinez, D. Design of a Permanent-Magnet Synchronous Machine with Non-Overlapping Concentrated Windings for the Shell Eco Marathon Urban Prototype. Master’s Thesis, Royal Institute of Technology, Stockholm, Sweden, 2012. [Google Scholar]

- Salminen, P. Fractional Slot Permanent Magnet Synchronous Motors for Low Speed Applications. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2004. [Google Scholar]

- Alberti, L.; Bianchi, N. Theory and design of fractional-slot multilayer windings. IEEE Trans. Ind. Appl. 2013, 49, 841–849. [Google Scholar] [CrossRef]

- Chen, Q.; Liang, D.; Jia, S.; Ze, Q.; Liu, Y. Loss analysis and experiment of fractional-slot concentrated-winding axial flux PMSM for EV applications. In Proceedings of the 2018 IEEE ECCE, Portland, OR, USA, 23–27 September 2018. [Google Scholar]

- Abdel-Khalik, A.S.; Massoud, A.; Ahmed, S. Nine-phase six-terminal pole-amplitude modulated induction motor for electric vehicle applications. IET Electric Power Appl. 2019, 13, 1696–1707. [Google Scholar] [CrossRef]

- Sun, A.; Li, J.; Qu, R.; Li, D. Effect of multilayer windings on rotor losses of interior permanent magnet generator with fractional-slot concentrated-windings. IEEE Trans. Magn. 2014, 50. [Google Scholar] [CrossRef]

- Islam, M.S.; Kabir, M.A.; Mikail, R.; Husain, I. Method to minimize space harmonics of fractional slot concentrated windings in AC machines. In Proceedings of the 2018 IEEE ECCE, Portland, OR, USA, 23–27 September 2018. [Google Scholar]

- Tessarolo, A.; Ciriani, C.; Bortolozzi, M.; Mezzarobba, M.; Barbini, N. Investigation into multi-layer fractional-slot concentrated windings with unconventional slot-pole combinations. IEEE Trans. Energy Convers. 2019, 34, 1985–1996. [Google Scholar] [CrossRef]

- Liu, G.; Zhai, F.; Chen, Q.; Xu, G. Torque pulsation reduction in fractional-slot concentrated-windings IPM motors by lowering sub-harmonics. IEEE Trans. Energy Convers. 2019, 34, 2084–2095. [Google Scholar] [CrossRef]

- Asef, P.; Bargalló Perpiñà, R.; Lapthorn, A.C. Optimal pole number for magnetic noise reduction in variable-speed permanent magnet synchronous machines with fractional-slot concentrated windings. IEEE Trans Transport. Electrific. 2019, 5, 126–134. [Google Scholar] [CrossRef]

- Chalmers, B.J.; Richardson, J. Performance of some magnetic slot wedges in an open-slot induction motor. Proc. IEEE 1967, 114, 258–260. [Google Scholar] [CrossRef]

- Anazawa, Y.; Kaga, A.; Akagami, H.; Watabe, S.; Makino, M. Prevention of harmonic torques in squirrel cage induction motors by means of soft ferrite magnetic wedges. IEEE Trans. Magn. 1982, 18, 1550–1552. [Google Scholar] [CrossRef]

- Takeda, Y.; Yagisawa, T.; Suyama, A.; Yamamoto, M. Application of magnetic wedges to large motors. IEEE Trans. Magn. 1984, 20, 1780–1782. [Google Scholar] [CrossRef]

- Mikami, H.; Ide, K.; Arai, K.; Takahashi, M.; Kajiwara, K. Dynamic harmonic field analysis of a cage type induction motor when magnetic slot wedges are applied. IEEE Trans. Energy Convers. 1997, 12, 337–343. [Google Scholar] [CrossRef]

- Gaerke, T.R.; Hernandez, D.C. The temperature impact of magnetic wedges on TEFC induction motors. In Proceedings of the 2012 Annual IEEE Pulp and Paper Industry Technical Conference, Portland, OR, USA, 17–21 June 2012. [Google Scholar]

- Gyftakis, K.N.; Panagiotou, P.A.; Kappatou, J. The influence of semi-magnetic wedges on the electromagnetic variables and the harmonic content in induction motors. In Proceedings of the 2012 XXth ICEM, Marseille, France, 2–5 September 2012. [Google Scholar]

- Lavanya, M.; Selvakumar, P.; Vijayshankar, S.; Easwarlal, C. Performance analysis of three phase induction motor using different magnetic slot wedges. In Proceedings of the 2014 IEEE 2nd ICEES, Chennai, India, 7–9 January 2014. [Google Scholar]

- Madescu, G.; Moţ, M.; Greconici, M.; Biriescu, M.; Vesa, D. Performances analysis of an induction motor with stator slot magnetic wedges. In Proceedings of the 2016 International Conference on Applied and Theoretical Electricity, Craiova, Romania, 6–8 October 2016. [Google Scholar]

- Abdi, S.; Abdi, E.; McMahon, R. Numerical analysis of stator magnetic wedge effects on equivalent circuit parameters of brushless doubly fed machines. In Proceedings of the 2018 XIII ICEM, Alexandroupoli, Greece, 3–6 September 2018. [Google Scholar]

- Donaghy-Spargo, C.; Spargo, A. Use of fractional-conductor windings and semi-magnetic slot wedges in synchronous machines. J. Eng. 2019, 2019, 4396–4400. [Google Scholar] [CrossRef]

- Di Napoli, A.; Honorati, O.; Santini, E.; Solero, L. The use of soft magnetic materials for improving flux weakening capabilities of axial flux PM machines. In Proceedings of the 2000 IEEE Industry Applications Conference, Rome, Italy, 8–12 October 2000. [Google Scholar]

- De Donato, G.; Giulii Capponi, F.; Caricchi, F. Influence of magnetic wedges on the no-load performance of axial flux permanent magnet machines. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010. [Google Scholar]

- De Donato, G.; Giulii Capponi, F.; Caricchi, F. Influence of magnetic wedges on the load performance of axial flux permanent magnet machines. In Proceedings of the IECON 2010, Glendale, AZ, USA, 7–10 November 2010. [Google Scholar]

- Tessarolo, A.; Luise, F.; Bortolozzi, M.; Mezzarobba, M. A new magnetic wedge design for enhancing the performance of open-slot electric machines. In Proceedings of the 2012 Electrical Systems for Aircraft, Railway and Ship Propulsion, Bologna, Italy, 16–18 October 2012. [Google Scholar]

- Tessarolo, A.; Luise, F.; Mezzarobba, M.; Bortolozzi, M.; Branz, L. Special magnetic wedge design optimization with genetic algorithms for cogging torque reduction in permanent-magnet synchronous machines. In Proceedings of the 2012 Electrical Systems for Aircraft, Railway and Ship Propulsion, Bologna, Italy, 16–18 October 2012. [Google Scholar]

- Tessarolo, A.; Branz, L.; Mezzarobba, M. Optimization of a SPM machine using a non-isotropic magnetic wedge with an analytical method for cogging torque estimation. In Proceedings of the 2016 XXII ICEM, Lausanne, Switzerland, 4–7 September 2016. [Google Scholar]

- Lindh, P.M.; Pyrhönen, J.J.; Ponomarev, P.; Vinnikov, D. Influence of wedge material on losses of a traction motor with tooth-coil windings. In Proceedings of the IECON 2013, Vienna, Austria, 10–13 November 2013. [Google Scholar]

- Belhadi, M.; Krebs, G.; Marchand, C.; Hannoun, H.; Mininger, X. Evaluation of a switched reluctance motor with magnetic slot wedges. In Proceedings of the 2014 ICEM, Berlin, Germany, 2–5 September 2014. [Google Scholar]

- Frosini, L.; Pastura, M.; Pacinotti, G. Performance improvement of SPM synchronous machines with non-conventional stator slot magnetic wedges. In Proceedings of the EPE’19 ECCE Europe, Genova, Italy, 2–6 September 2019. [Google Scholar]

- Wang Lee, K.; Hong, J.; Hyun, D.; Bin Lee, S.; Wiedenbrug, E.J.; Teska, M.; Lim, C. Detection of stator-slot magnetic wedge failures for induction motors without disassembly. IEEE Trans. Ind. Appl. 2014, 50, 2410–2419. [Google Scholar]

- Chu, K.H.; Anand Prabhu, M.; Pou, J.; Ramakrishna, S.; Gupta, A.K. Analysis of local forces acting on stator teeth and magnetic wedges in large synchronous machines. In Proceedings of the 2018 ACEPT, Singapore, Singapore, 30 October–2 November 2018. [Google Scholar]

| THD BEMF [%] | Tripple [%] | kw1 | |

|---|---|---|---|

| Single layer | 9.16 | 10.54 | 0.966 |

| Double layer | 6.45 | 8.87 | 0.933 |

| μr = 1 | μr = 5 | μr = 20 | μr = 100 | Unit | |

|---|---|---|---|---|---|

| BEMFrms | 57.89 | 60 | 58.93 | 55.87 | V |

| BEMFpeak | 87.71 | 88.35 | 84 | 78.85 | V |

| ψrms | 91 | 95 | 94 | 89 | mWb |

| THDBEMF | 9.66 | 6.64 | 4.13 | 3.78 | % |

| Parameter | Value | Unit of Measurement |

|---|---|---|

| Rated power | 23.1 | kW |

| Rated torque | 1700 | N·m |

| Rated speed | 130 | rpm |

| Rated frequency | 32.5 | Hz |

| Rated current | 46.5 | A |

| Rated voltage | 381 | V |

| Rated efficiency | 87 | % |

| Number of poles | 30 | - |

| Number of slots | 36 | - |

| Stator core length | 300 | mm |

| External stator diameter | 359 | mm |

| Internal stator diameter | 270 | mm |

| Shaft diameter | 150 | mm |

| Magnet length | 25 | mm |

| Magnet width | 6 | mm |

| Parameter | Traditional Wedge | Magnetic Wedge | ∆ (%) |

|---|---|---|---|

| Ld | 10.38 mH | 11.82 mH | 13.87 |

| L | 20.65 mH | 22.86 mH | 10.7 |

| |M| | 1.42 mH | 1.70 mH | 19.7 |

| ψd | 1131 mWb | 1094 mWb | −3.3 |

| ψq | 785 mWb | 876 mWb | 11.6 |

| Parameter | Uniform Wedge | Mixed Wedge | ∆ (%) |

|---|---|---|---|

| PCu | 3512 W | 3286 W | −6.4 |

| Pmag | 56.62 W | 55.7 W | −1.6 |

| PFestat | 354.2 W | 361.1 W | 1.9 |

| PFerot | 1.86 W | 1.87 W | 0.5 |

| Ptot | 3924.68 W | 3704.67 W | −5.6 |

| Efficiency | 85.63% | 86.32% | 0.8% |

| Airgap flux density | 1.18 T | 1.13 T | 4.4% |

| Flux density in the tooth (no polar shoe) | 1.75 T | 1.77 T | −1.1% |

| Flux density in the polar shoe of the tooth | 2.45 T | 2.43 T | 0.8% |

| Flux density in the stator yoke | 1.25 T | 1.23 T | 1.6% |

| Parameter | Uniform Wedge | Mixed Wedge | ∆ (%) |

|---|---|---|---|

| Efficiency @ Pn/2 | 91.18% | 91.04% | −0.2% |

| Efficiency @ Pn/4 | 91.77% | 92.02% | 0.3% |

| Stator Joule losses @ Pn/2 | 855.2 W | 817.3 W | −4.4 |

| Stator Joule losses @ Pn/4 | 212.5 W | 203.4 W | −4.3 |

| Total iron losses @ Pn/2 | 296.55 W | 314.18 W | 5.9 |

| Total iron losses @ Pn/4 | 281.07 W | 304.52 W | 8.3 |

| Magnets losses @ Pn/2 | 24.88 W | 25.15 W | 1.1 |

| Magnets losses @ Pn/4 | 16.82 W | 17.44 W | 3.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frosini, L.; Pastura, M. Analysis and Design of Innovative Magnetic Wedges for High Efficiency Permanent Magnet Synchronous Machines. Energies 2020, 13, 255. https://doi.org/10.3390/en13010255

Frosini L, Pastura M. Analysis and Design of Innovative Magnetic Wedges for High Efficiency Permanent Magnet Synchronous Machines. Energies. 2020; 13(1):255. https://doi.org/10.3390/en13010255

Chicago/Turabian StyleFrosini, Lucia, and Marco Pastura. 2020. "Analysis and Design of Innovative Magnetic Wedges for High Efficiency Permanent Magnet Synchronous Machines" Energies 13, no. 1: 255. https://doi.org/10.3390/en13010255

APA StyleFrosini, L., & Pastura, M. (2020). Analysis and Design of Innovative Magnetic Wedges for High Efficiency Permanent Magnet Synchronous Machines. Energies, 13(1), 255. https://doi.org/10.3390/en13010255