Shaping High Efficiency, High Temperature Cavity Tubular Solar Central Receivers

Abstract

1. Introduction

1.1. Context

1.2. Background

1.3. Objective

- The acceptable length of the absorber tubes limits the maximum power of the solar receiver. Based on a previous study [29] and further unpublished experimental results, the length of the tubes is fixed at 7 m. Accounting for this limited length of the tubes, the nominal power of a single solar receiver is approximately 50 MW [31].

- The wall-to-fluidized bed heat transfer coefficient is chosen in agreement with previous experimental data [26].

- The tubes are vertical. Vertical position of the absorber tubes is mandatory because tilting will result in a strong channeling and particle segregation. Indeed, this would cause a very non-homogeneous bed, with a dense bed (without bubbles) near the solar-irradiated part of the tube and all the bubbles in the opposite region [34]. This will cause a dramatic decrease of wall-to-bed heat transfer.

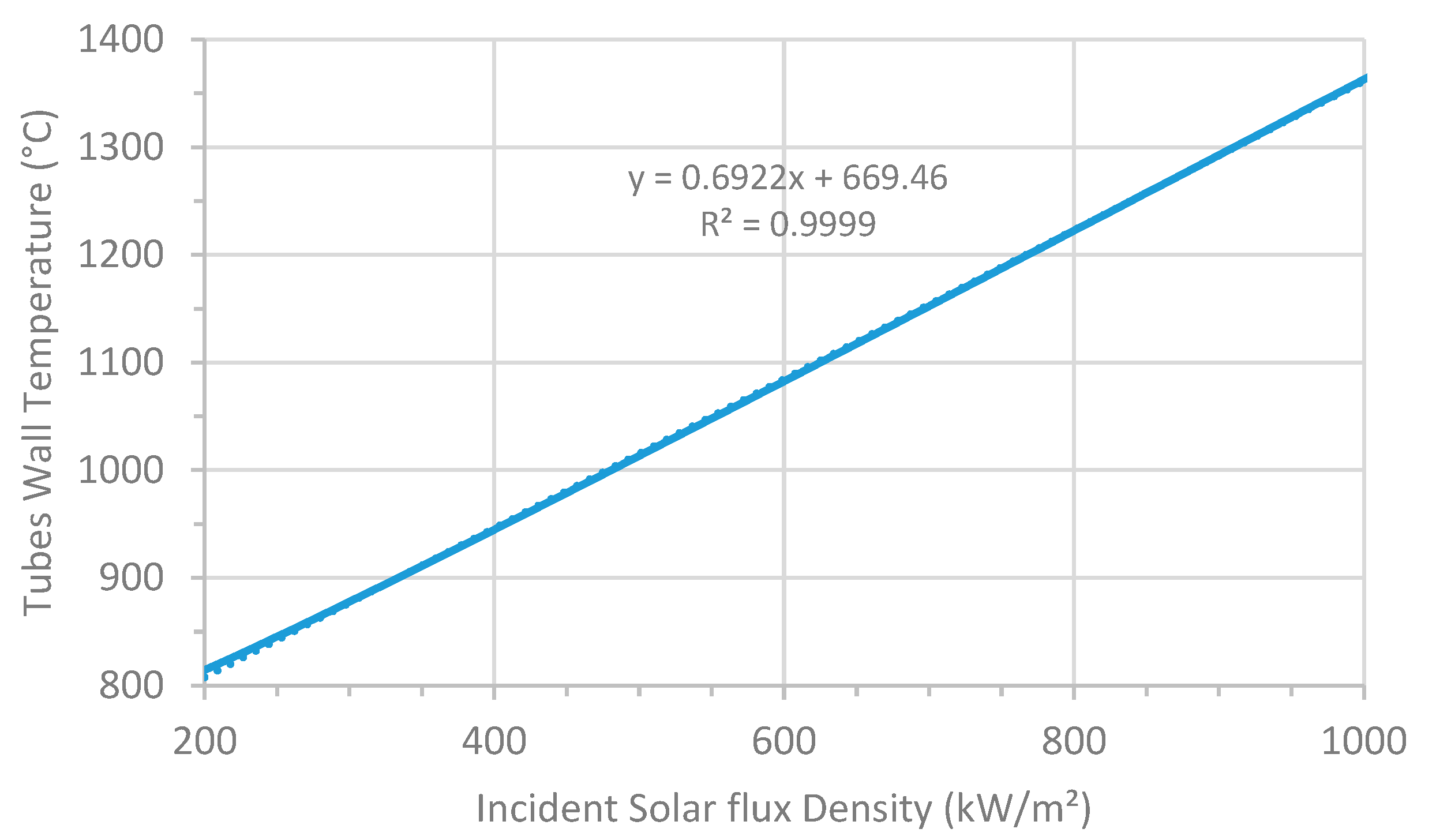

- The solar radiation acceptable flux density is another constraint related to the working temperature limit of the tube wall. This value is discussed in the next section.

2. Receiver’s Geometry and Preliminary Considerations

2.1. General Description and Material Properties

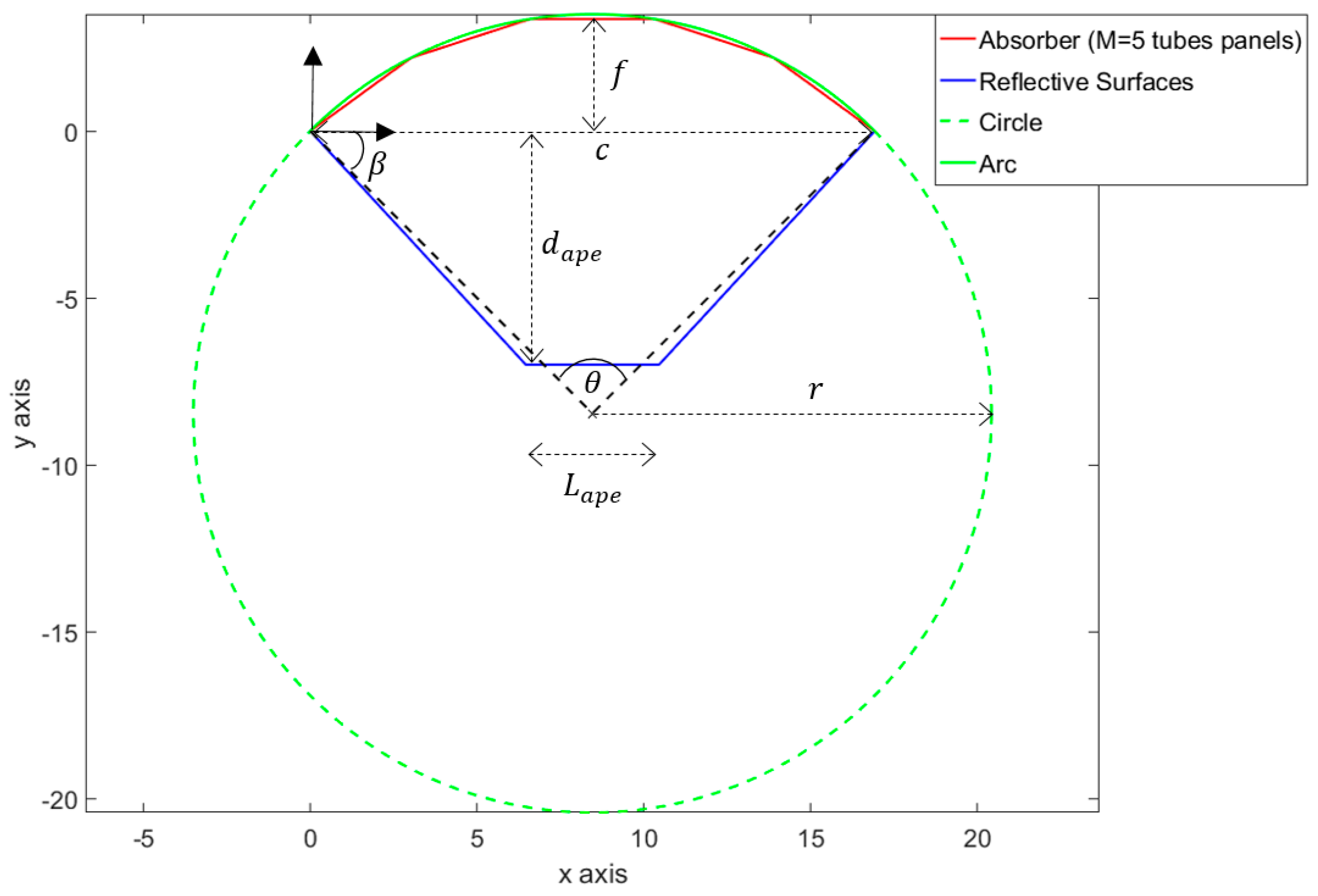

2.2. Geometry Parametrization

2.2.1. The Absorber

2.2.2. The Aperture

2.3. Tubes Number Calculation

2.4. Incident Concentrated Solar Flux

3. Numerical Modelling

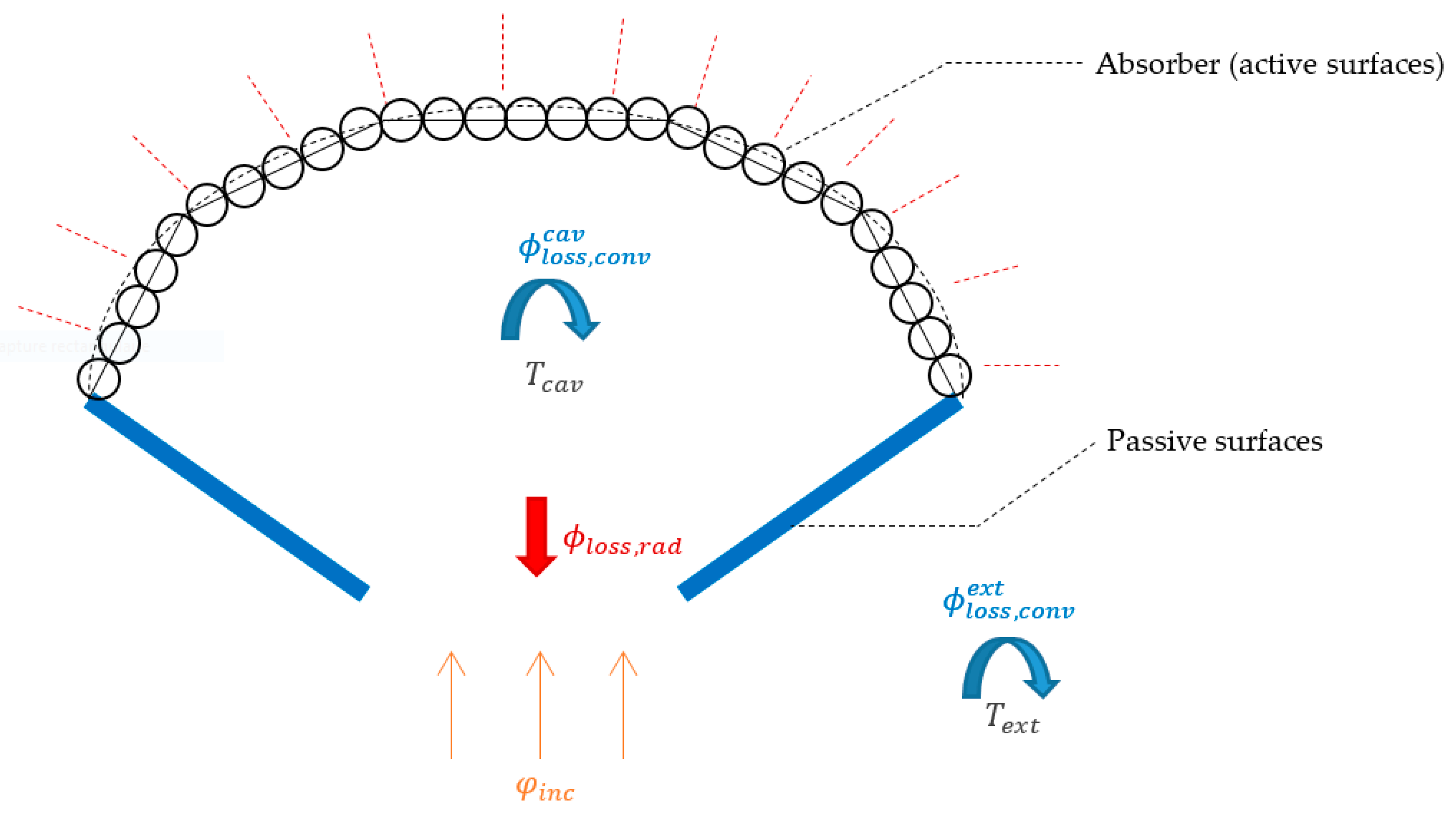

3.1. Radiative Balance

3.2. Losses and Efficiency

3.2.1. Absorbed Power

3.2.2. Radiative Losses

3.2.3. Convective Losses

3.2.4. Receiver Power and Efficiency

4. Results

- The incident flux on the absorber tubes is 400 kW/m2 and the active and passive surfaces wall temperatures are homogenous and equal to 950 °C (see preliminary calculations).

- The ambient air temperature is set at 15 °C while the air temperature inside the cavity is set to 500 °C.

- The total number of tubes Nt is set at 360 but is rounded to have a ratio Nt/M as an integer.

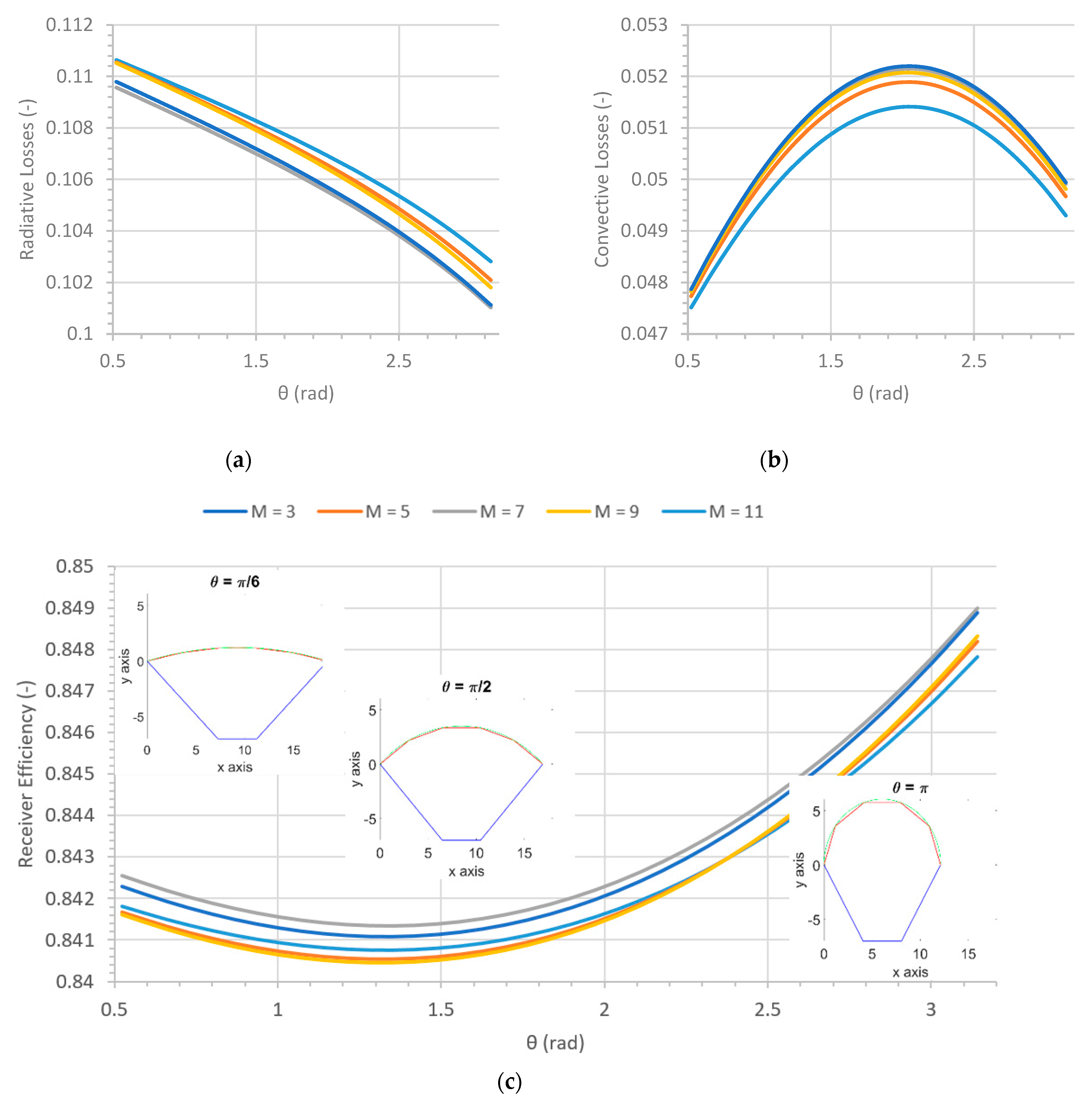

4.1. Influence of the Absorber Geometry

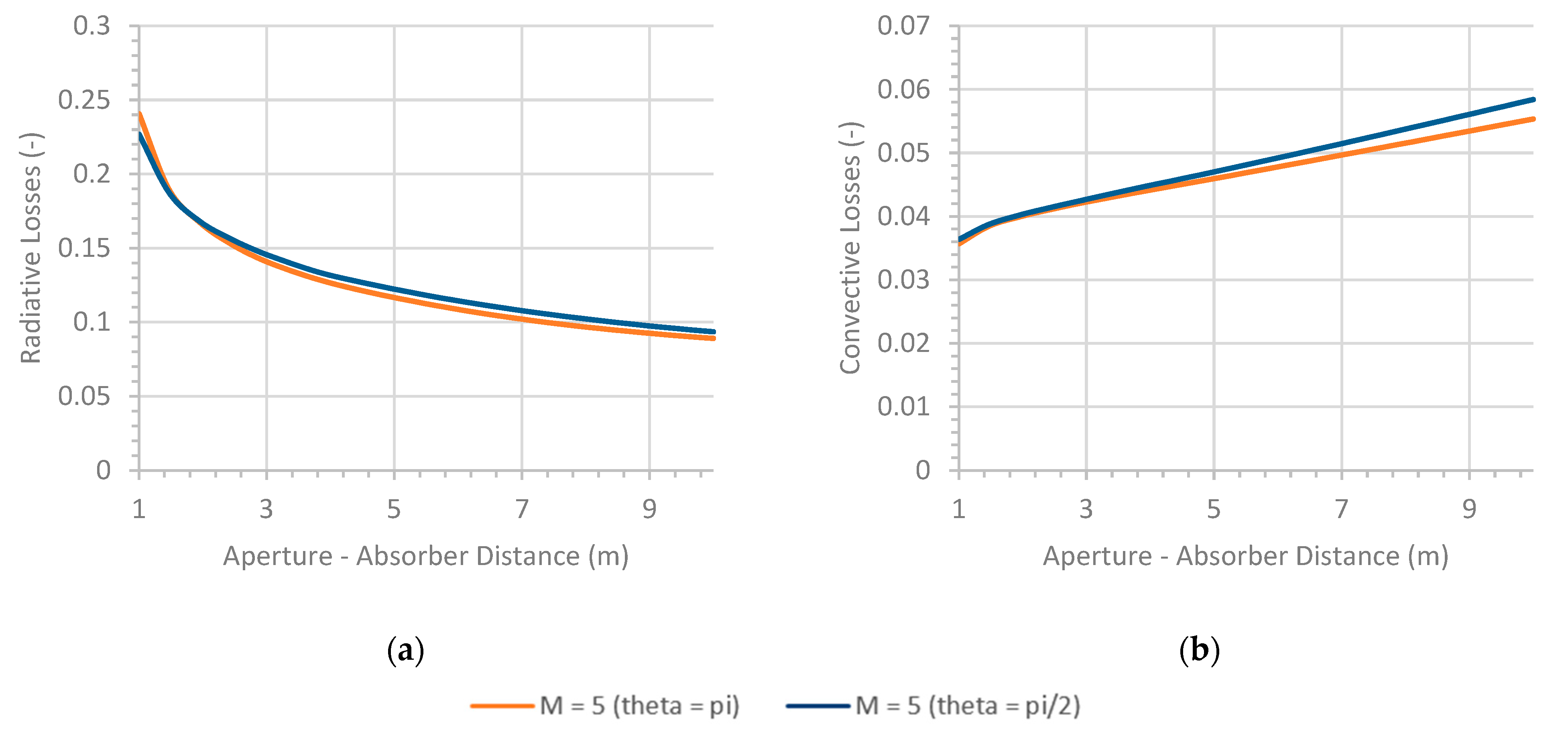

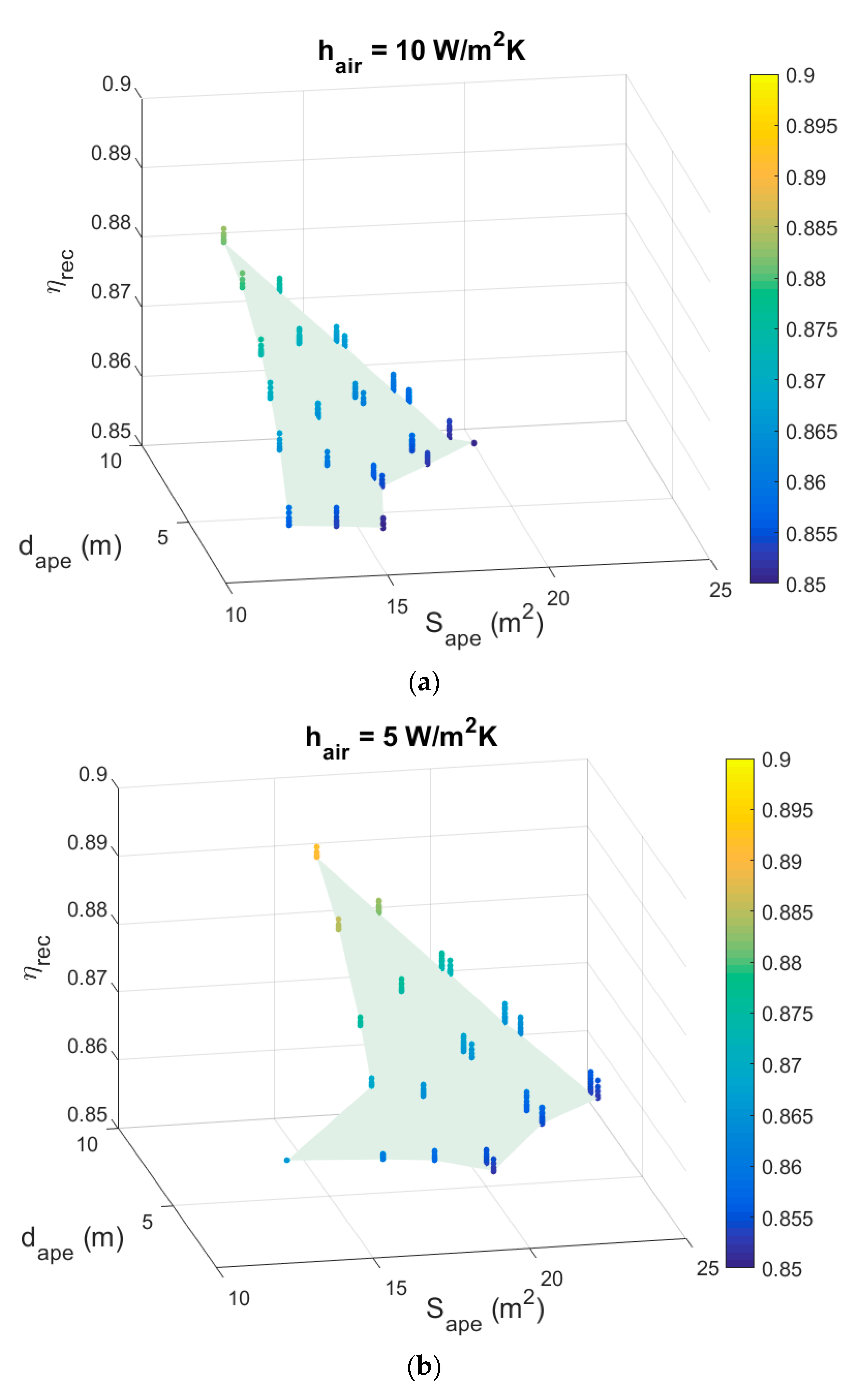

4.2. Influence of the Aperture’s Distance

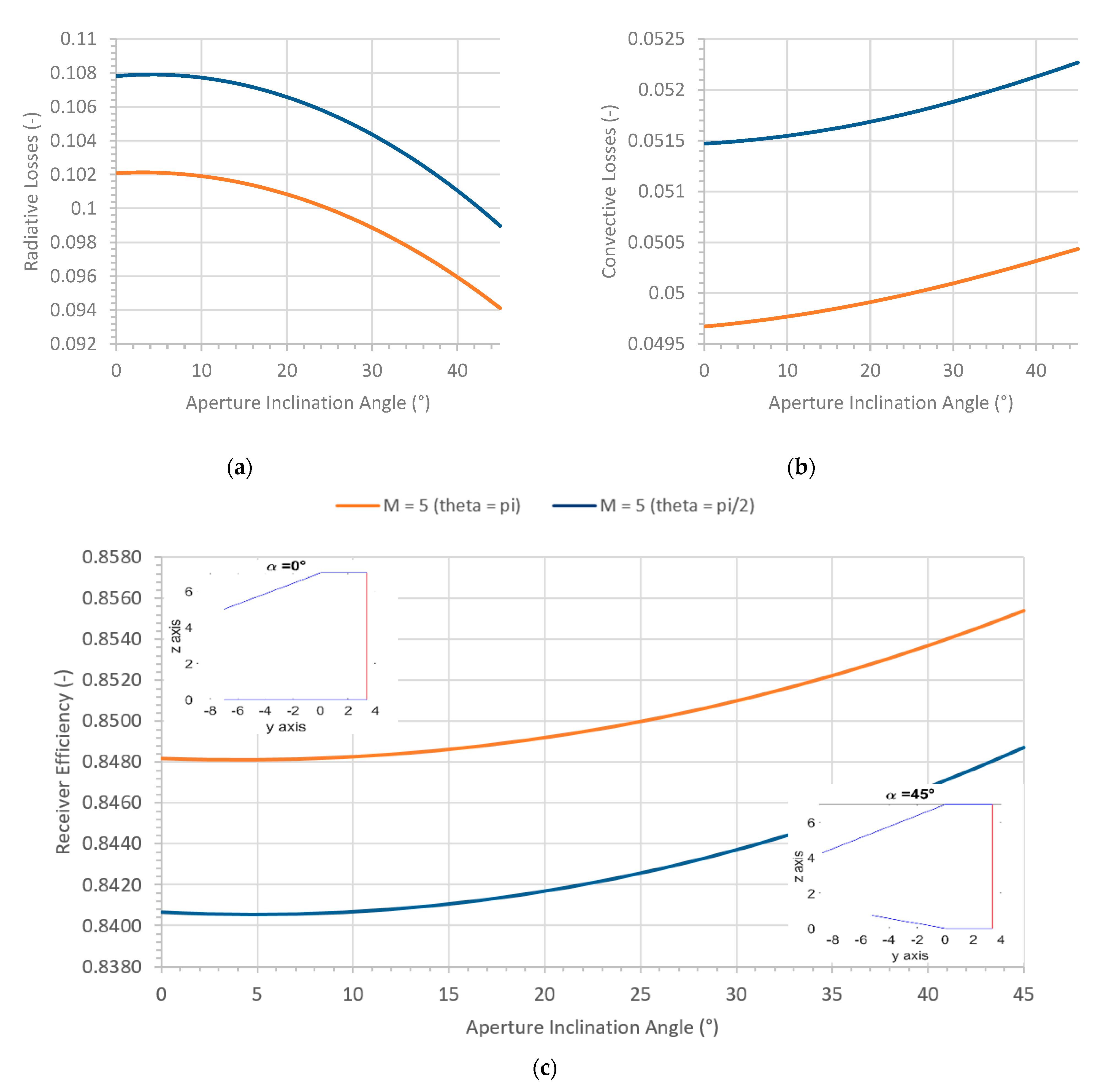

4.3. Influence of the Aperture Inclination

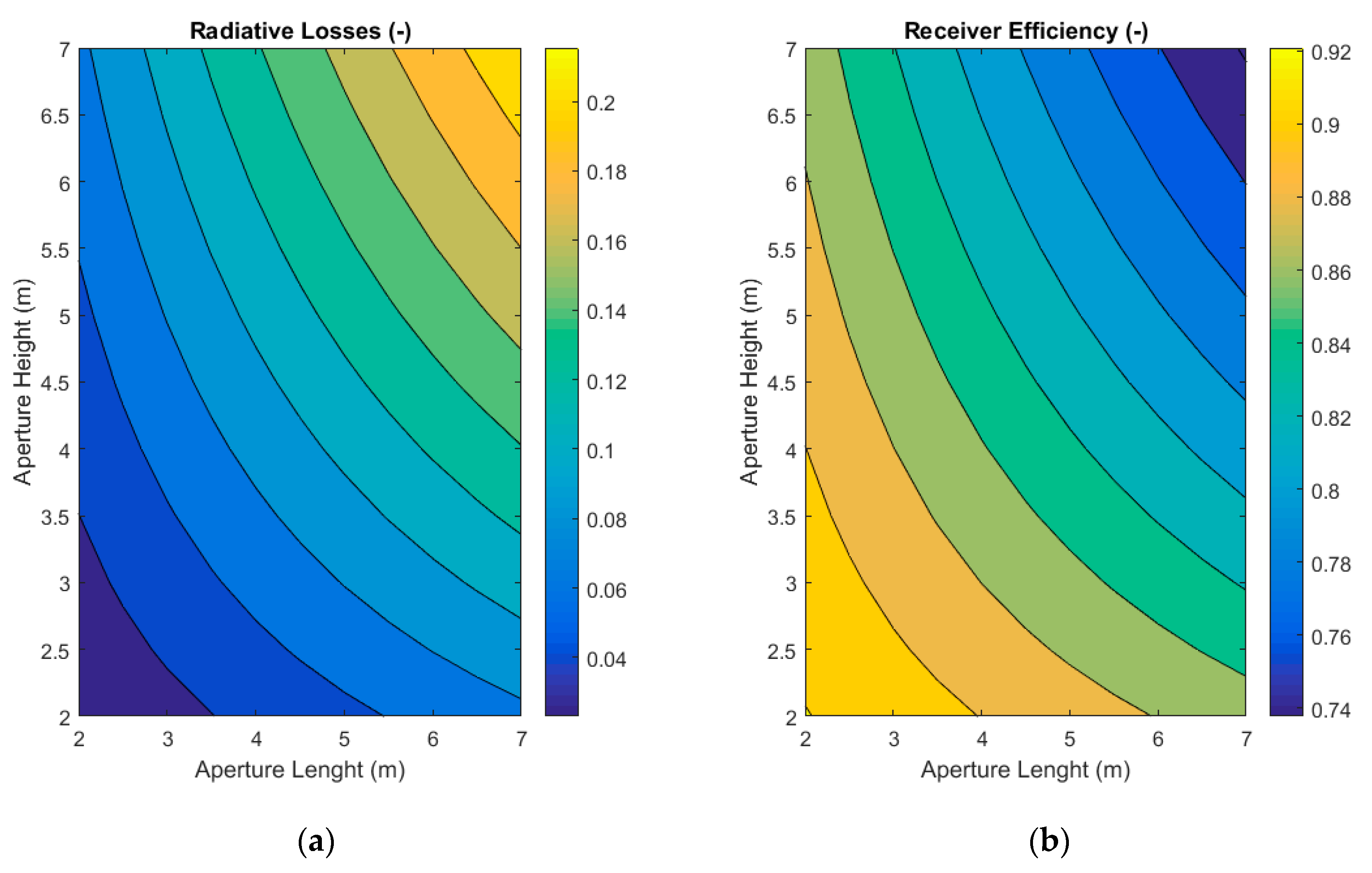

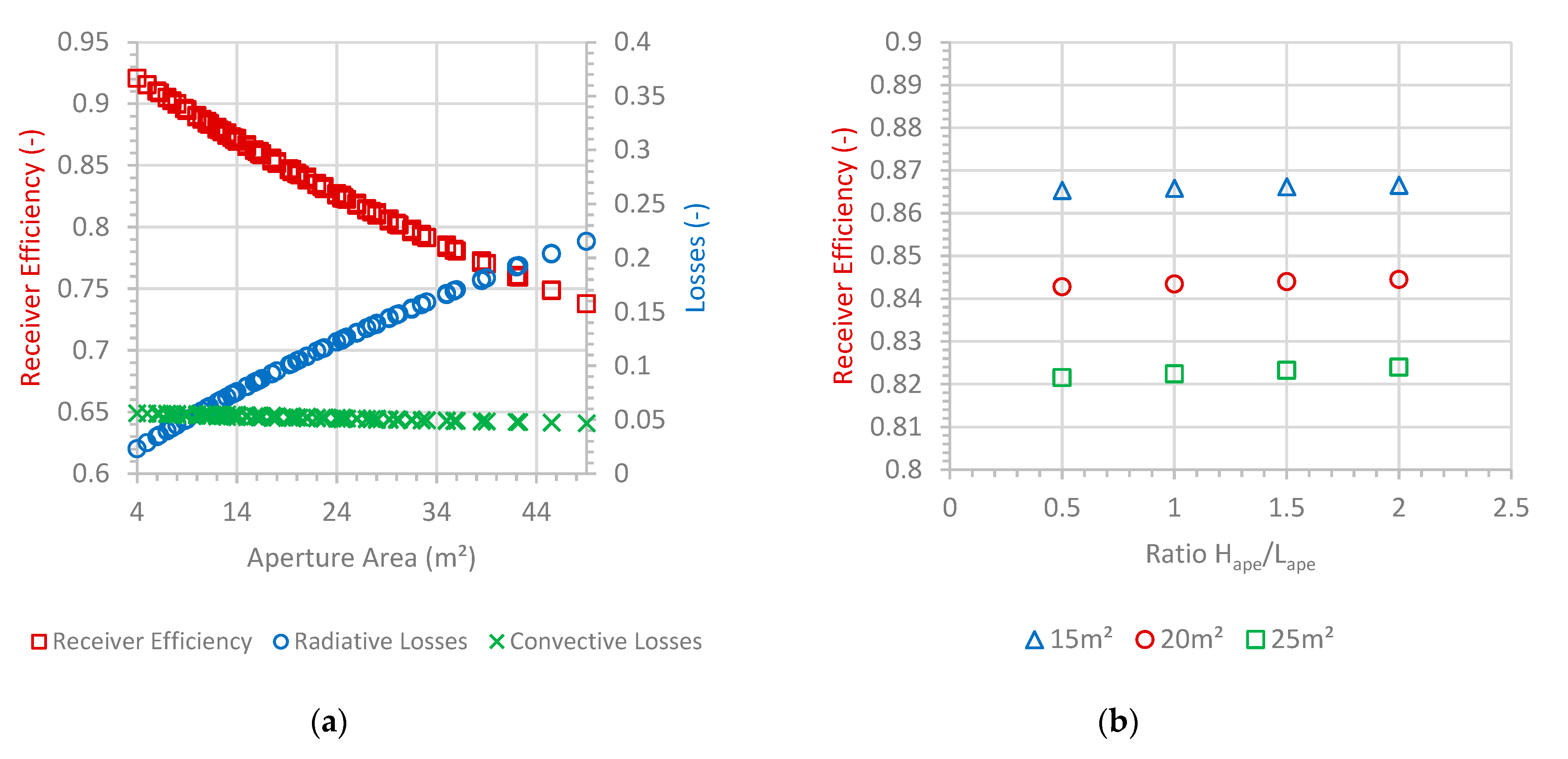

4.4. Influence of the Aperture Dimensions

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Irradiated area of a tube (m2) | |

| Chord of the circle arc (m) | |

| Specific heat (J/kgK) | |

| Aperture—absorber distance (m) | |

| Shift of the aperture coordinates in the y axis due to its inclination (m) | |

| Internal diameter of a tube (m) | |

| Thickness of a tube (m) | |

| Arrow of the arc circle (m) | |

| View factor between the i and j surfaces (-) | |

| Mass flux of particles (kg/m2s) | |

| Heat transfer coefficient between wall tubes and fluidized particles (W/m2K) | |

| Convective heat transfer coefficient with the air (W/m2K) | |

| Aperture height (m) | |

| Shift of the aperture coordinates in the z axis due to its inclination (m) | |

| Radiosity of the i surface (W/m2) | |

| Aperture length (m) | |

| Mass flow rate of particles per tube (kg/s) | |

| Number of tubes panels in the absorber | |

| Number of tubes in each panel | |

| Total number of tubes in the absorber | |

| Receiver power input (W) | |

| Radius of curvature of the arc circle (m) | |

| Reflectivity in the infrared spectral band (-) | |

| Reflectivity in the solar spectral band (-) | |

| Aperture area (m2) | |

| Area of the i surface (m2) | |

| Internal section of a tube (m2) | |

| Temperature of the air inside the cavity (K) | |

| Temperature of the air outside the cavity (K) | |

| Wall temperature (inside the cavity) (K) | |

| Wall temperature outside the cavity (K) | |

| Inlet temperature of the particles in a tube (K) | |

| Outlet temperature of the particles in a tube (K) | |

| Inclination angle of the aperture relative to the vertical plane (rad) | |

| Absorptivity in the infrared spectral band (-) | |

| Absorptivity in the solar spectral band (-) | |

| Angle between the vertical absorber plane and the passive vertical surfaces (rad) | |

| Angle between the absorber plane and the top passive surface (rad) | |

| Angle between the absorber plane and the bottom passive surface (rad) | |

| Mean logarithmic temperature of a tube (K) | |

| Emissivity in the infrared spectral band (-) | |

| Receiver efficiency (-) | |

| Angle of the arc circle (rad) | |

| Absorbed power by the particles (W) | |

| Convective losses of the receiver (W) | |

| Radiative losses of the receiver (W) | |

| Thermal conductivity (W/mK) | |

| Density (kg/m3) | |

| Boltzman constant (W/m2K4) | |

| Incident solar flux density (W/m2) |

Appendix A. Convective Losses Studies in Cavity Receivers

| Reference | Topic of the Paper | Main Parameters | Results | Correlation |

|---|---|---|---|---|

| R.D. Jilte et al. [7] | Numerical 3D study of the combined natural convection and radiation losses associated to dish concentrators | T° = [250–650] °C. Cavity inclination: 0 to 90°. Cavity shapes: cylindrical, conical, etc and spherical | Convection losses decrease strongly with the inclination angle of the cavity for all the receiver shapes. | For Rayleigh number between 2 × 108 and 6 × 108. Standard deviation of 16%. |

| C. Zou et al. [9] | 3D numerical simulation of cylindrical cavity receiver | Cavity inclination: 45° | The receiver efficiency varied sharply with the aperture size. The ratio of radiation to convection losses ranges from approximately 2 to 4 at low DNI and high DNI, respectively. | Ø |

| J. Kim et al. [12] | Model of heat losses of Solar Power Tower receivers | External and cavity receiver with a 9 m2 absorber T° = [600–900] °C. = [1,2,3,4,5,6,7,8,9,10] m/s, head-on and side-on. | For low wind velocity, calculated efficiency of Solar Two external receiver was 88%. For cavity receivers at 900 °C, the ratio of radiation to convection losses ranged generally between 2 and 7, except with head-on high wind condition (10 m/s) that result in a ratio around 1. | Standard deviation of 11.4%. |

| A.M. Clausing [16] | Analytical approach of convective losses in cavity central receivers | = 1 and 39 MW T° = 920 and 1020 °C = 5.6 and 0.93 m | The influence of the wind on the convective losses at normal operating conditions are small. The inclination of the aperture is critical since it strongly influences the height of the convective zone within the cavity. | Ø |

| A.M. Clausing [17] | = 45 and 180° with the vertical Gr = [–]. | The wind and buoyancy driven bulk flow both appear to have secondary influences for the cubic cavity orientations. There is a strong evidence for the existence of the stagnation zone and the proposed low convective energy flux across the boundary of this zone. The comparison with experimental data resulted in a convective heat transfer coefficient of 7.2 and 9.7 W/m2K for the inactive and the absorber surfaces respectively. | Factor z added to account for all orientation. Without it, previous authors found absolute deviation of 1%. | |

| J. Samanes et al. [18] | Comparison of correlations for convective losses | Ps-10 like cavity receiver (300 tubes in a 7 m radius and 12 m height, and = 56.7 MW) Five models are compared and validated | Clausing’s model provides the heat losses on each surface of the cavity receiver, and its method is considered as the best choice. | Ø |

| R. Flesch et al. [19] | Numerical analysis of convective losses | Head-on and side-on wind = [0–90]° | Clausing’s model is a good approach for natural convection. When no wind is present, the losses decrease considerably with increasing the inclination angle of the receiver. | Ø |

Appendix B. Calculation of Radiosities

References

- Ho, C.K.; Iverson, B.D. Review of high-temperature central receiver designs for concentrating solar power. Renew. Sustain. Energy Rev. 2014, 29, 835–846. [Google Scholar] [CrossRef]

- Rao, Z.; Xue, T.; Huang, K.; Liao, S. Multi-objective optimization of supercritical carbon dioxide recompression Brayton cycle considering printed circuit recuperator design. Energy Convers. Manag. 2019, 201, 112094. [Google Scholar] [CrossRef]

- Valentin, B.; Siros, F.; Brau, J.-F. Optimization of a Decoupled Combined Cycle Gas Turbine Integrated in a Particle Receiver Solar Power Plant. AIP Conf. Proc. 2019, 2126, 140007. [Google Scholar] [CrossRef]

- Fletcher, E.A.; Moen, R.L. Hydrogen and oxygen from water. Science 1977, 197, 1050–1056. [Google Scholar] [CrossRef]

- Benoit, H.; Spreafico, L.; Gauthier, D.; Flamant, G. Review of heat transfer fluids in tube-receivers used in concentrating solar thermal systems: Properties and heat transfer coefficients. Renew. Sustain. Energy Rev. 2016, 55, 298–315. [Google Scholar] [CrossRef]

- Steinfeld, A.; Schubnell, M. Optimum aperture size and operating temperature of a solar cavity-receiver. Sol. Energy 1993, 50, 19–25. [Google Scholar] [CrossRef]

- Jilte, R.D.; Kedare, S.B.; Nayak, J.K. Natural Convection and Radiation Heat Loss from Open Cavities of Different Shapes and Sizes Used with Dish Concentrator. Mech. Eng. Res. 2013, 3, 25–43. [Google Scholar] [CrossRef]

- Le Roux, W.G.; Bello-Ochende, T.; Meyer, J.P. The efficiency of an open-cavity tubular solar receiver for a small-scale solar thermal Brayton cycle. Energy Convers. Manag. 2014, 84, 457–470. [Google Scholar] [CrossRef]

- Zou, C.; Feng, H.; Zhang, Y.; Falcoz, Q.; Zhang, C.; Gao, W. Geometric optimization model for the solar cavity receiver with helical pipe at different solar radiation. Front. Energy 2019, 13, 284–295. [Google Scholar] [CrossRef]

- Grange, B.; Ferrière, A.; Bellard, D.; Vrinat, M.; Couturier, R.; Pra, F.; Fan, Y. Thermal Performances of a High Temperature Air Solar Absorber Based on Compact Heat Exchange Technology. J. Sol. Energy Eng. 2011, 133, 031004. [Google Scholar] [CrossRef]

- Rodriguez-Sanchez, M.R.; Sanchez-Gonzalez, A.; Santana, D. Revised receiver efficiency of molten-salt power towers. Renew. Sustain. Energy Rev. 2015, 52, 1331–1339. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.-S.; Stein, W. Simplified heat loss model for central tower solar receiver. Sol. Energy 2015, 116, 314–322. [Google Scholar] [CrossRef]

- Schöttl, P.; Bern, G.; van Rooyen, D.W.; Heimsath, A.; Fluri, T.; Nitz, P. Solar tower cavity receiver aperture optimization based on transient optical and thermo-hydraulic modeling. AIP Conf. Proc. 2017, 1850, 030046. [Google Scholar] [CrossRef]

- Qiu, Y.; Ling He, Y.; Li, P.; Du, B.C. A comprehensive model for analysis of real time optical performance of a solar power tower with a multi tube cavity receiver. Appl. Energy 2017, 185, 589–603. [Google Scholar] [CrossRef]

- Larrouturou, F.; Caliot, C.; Flamant, G. Effect of directional dependency of wall reflectivity and incident concentrated solar flux on the efficiency of a cavity solar receiver. Sol. Energy 2014, 109, 153–164. [Google Scholar] [CrossRef]

- Clausing, A.M. An analysis of convective losses from cavity solar central receivers. Sol. Energy 1981, 77, 295–300. [Google Scholar] [CrossRef]

- Clausing, A.M. Convective losses from cavity solar receivers—Comparisons between analytical predictions and experimental results. J. Sol. Energy Eng. 1983, 105, 29–33. [Google Scholar] [CrossRef]

- Samanes, J.; Garcia-Barberena, J.; Zaversky, F. Modeling solar cavity receivers: A review and comparison of natural convection heat loss correlations. Energy Procedia 2015, 69, 543–552. [Google Scholar] [CrossRef]

- Flesch, R.; Stadler, H.; Uhlig, R.; Pitz-Paal, R. Numerical analysis of the influence of inclination angle and wind on the heat losses of cavity receivers for solar thermal power towers. Sol. Energy 2014, 110, 427–437. [Google Scholar] [CrossRef]

- Mehos, M.; Turchi, C.; Vidal, J.; Wagner, M.; Ma, Z.; Ho, C.; Kolb, W.; Andraka, C.; Kruizenga, A. Concentrating Solar Power Gen3 Demonstration Roadmap; NREL/TP-5500-67464; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2017.

- Ho, C.K.; Christian, J.; Yellowhair, J.; Jeter, S.; Golob, M.; Nguyen, C.; Repole, K.; Abdel-Khalik, S.; Siegel, N.; Al-Ansary, H.; et al. Highlights of the high-temperature falling particle receiver project: 2012–2016. AIP Conf. Proc. 2017, 1850, 030027. [Google Scholar] [CrossRef]

- Wu, W.; Amsbeck, L.; Buck, R.; Uhlig, R.; Ritz-Paal, R. Proof of concept test of a centrifugal particle receiver. Energy Procedia 2014, 49, 560–568. [Google Scholar] [CrossRef]

- Flamant, G.; Gauthier, D.; Benoit, H.; Sans, J.L.; Garcia, R.; Boissière, B.; Ansart, R.; Hemati, M. Dense suspension of solid particles as a new heat transfer fluid for concentrated solar thermal plants: On-sun proof of concept. Chem. Eng. Sci. 2013, 102, 567–576. [Google Scholar] [CrossRef]

- Benoit, H.; Perez Lopez, I.; Gauthier, D.; Sans, J.-L.; Flamant, G. On-sun demonstration of a 750 °C heat transfer fluid for concentrating solar systems: Dense particle suspension in tube. Sol. Energy 2015, 118, 622–633. [Google Scholar] [CrossRef]

- Next-CSP. High Temperature Concentrated Solar Thermal Power Plant with Particle Receiver and Direct Thermal Storage. 2020. Available online: http://next-csp.eu/ (accessed on 11 September 2020).

- Le Gal, A.; Grange, B.; Tessonneaud, M.; Perez, A.; Escape, C.; Sans, J.-L.; Flamant, G. Thermal analysis of fluidized particle flows in a finned tube solar receiver. Sol. Energy 2019, 191, 19–33. [Google Scholar] [CrossRef]

- Flamant, G.; Hemati, H. Dispositif Collecteur D’énergie Solaire (Device for Collecting Solar Energy). French Patent FR 1058565, 20 October 2010. [Google Scholar]

- Bi, H.T.; Grace, J.R.; Zhu, J.-X. Types of choking in vertical pneumatic systems. Int. J. Multiph. Flow 1993, 19, 1077–1092. [Google Scholar] [CrossRef]

- Kong, W.; Tan, T.; Baeyens, J.; Flamant, G.; Zhang, H. Bubbling and slugging of Geldart group A powders in small diameters columns. Ind. Eng. Chem. Res. 2017, 56, 4136–4144. [Google Scholar] [CrossRef]

- Perez-Lopez, I.; Benoit, H.; Gauthier, D.; Sans, J.L.; Guillot, E.; Mazza, G.; Flamant, G. On-sun operation of a 150 kWth pilot solar receiver using dense particle suspension as heat transfer fluid. Sol. Energy 2016, 137, 463–476. [Google Scholar] [CrossRef]

- Behar, O.; Grange, B.; Flamant, G. Design and performance of a modular combined cycle solar power plant using the fluidized particle solar receiver technology. Energy Convers. Manag. 2020, 220, 113108. [Google Scholar] [CrossRef]

- Zhang, H.; Benoit, H.; Gauthier, D.; Degrève, J.; Baeyens, J.; López, I.P.; Hemati, M.; Flamant, G. Particle circulation loops in solar energy capture and storage: Gas-solid flow and heat transfer considerations. Appl. Energy 2016, 161, 206–224. [Google Scholar] [CrossRef]

- Bi, H.T.; Ellis, N.; Abba, I.A.; Grace, J.R. A state-of-the-art review of gas-solid turbulent fluidization. Chem. Eng. Sci. 2000, 55, 4789–4825. [Google Scholar] [CrossRef]

- Gilbertson, A.M.; Yates, J.G. The tilting fluidized bed: A re-examination. Powder Technol. 1996, 89, 29–36. [Google Scholar] [CrossRef]

- Special Metals, High Performance Alloys Literature. Available online: https://www.specialmetals.com/assets/smc/documents/alloys/inconel/inconel-alloy-601.pdf (accessed on 11 September 2020).

- Alloy Wire International, Inconel 601. Available online: www.alloywire.fr/products/inconel-601 (accessed on 11 September 2020).

- Ho, C.K.; Mahoney, A.R.; Ambrosini, A.; Bencomo, M.; Hall, A.; Lambert, T.N. Characterization of Pyromark 2500 paint for high-temperature solar receivers. J. Sol. Energy Eng. 2014, 136, 014502. [Google Scholar] [CrossRef]

- Coventry, J.; Burge, P. Optical properties of Pyromark 2500 coatings of variable thicknesses on a range of materials for concentrating solar thermal applications. AIP Conf. Proc. 2017, 1850, 030012. [Google Scholar] [CrossRef]

- Refractaris R, Properties of Scuttherm. Available online: www.refractaris.com (accessed on 11 September 2020).

- Promat, Properties of Promaform. Available online: https://www.promat-hpi.com/en/products/microporous/promaform-products (accessed on 11 September 2020).

- MCI Technologies, Properties of Insulfrax. Available online: https://www.mci-tech.com/produits/nappes-et-feutres-ht/insulfrax (accessed on 11 September 2020).

- Geldart, D. Types of gas fluidization. Powder Technol. 1973, 7, 285–292. [Google Scholar] [CrossRef]

- Kang, Q.; Flamant, G.; Dewil, R.; Baeyens, J.; Zhang, H.L.; Deng, Y.M. Particles in a circulation loop for solar energy capture and storage. Particuology 2019, 43, 149–156. [Google Scholar] [CrossRef]

- Iverson, B.D.; Conboy, T.M.; Pasch, J.J.; Kruizenga, A.M. Supercritical CO2 Brayton cycles for solar-thermal energy. Appl. Energy 2013, 111, 957–970. [Google Scholar] [CrossRef]

- Mathworks, View-Factor Function. Available online: www.mathworks.com/matlabcentral/fileexchange/5664-view-factors (accessed on 11 September 2020).

| (kg/m3) | (W/mK) | ||||||

|---|---|---|---|---|---|---|---|

| Absorbent Surfaces | 0.9 | 0.1 | 0.85 | 0.15 | 0.85 | 8110 | 26.1 |

| Reflective Surfaces | 0.22 | 0.78 | 0.95 | 0.05 | 0.95 | 315 | 0.1 |

| 20 m2 | 25 m2 | |||||||

|---|---|---|---|---|---|---|---|---|

| 800 | 10 | 90.6 | 5 | 92.9 | 10 | 89.6 | 5 | 91.9 |

| 850 | 10 | 89.4 | 5 | 92.0 | 10 | 88.3 | 5 | 90.9 |

| 900 | 10 | 88.2 | 5 | 91.0 | 10 | 87.0 | 5 | 89.8 |

| 950 | 10 | 86.9 | 5 | 90.0 | 10 | 85.6 | 5 | 88.5 |

| 1000 | 10 | 85.6 | 5 | 88.9 | 10 | 84.1 | 5 | 87.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gueguen, R.; Grange, B.; Bataille, F.; Mer, S.; Flamant, G. Shaping High Efficiency, High Temperature Cavity Tubular Solar Central Receivers. Energies 2020, 13, 4803. https://doi.org/10.3390/en13184803

Gueguen R, Grange B, Bataille F, Mer S, Flamant G. Shaping High Efficiency, High Temperature Cavity Tubular Solar Central Receivers. Energies. 2020; 13(18):4803. https://doi.org/10.3390/en13184803

Chicago/Turabian StyleGueguen, Ronny, Benjamin Grange, Françoise Bataille, Samuel Mer, and Gilles Flamant. 2020. "Shaping High Efficiency, High Temperature Cavity Tubular Solar Central Receivers" Energies 13, no. 18: 4803. https://doi.org/10.3390/en13184803

APA StyleGueguen, R., Grange, B., Bataille, F., Mer, S., & Flamant, G. (2020). Shaping High Efficiency, High Temperature Cavity Tubular Solar Central Receivers. Energies, 13(18), 4803. https://doi.org/10.3390/en13184803