Application of Microemulsion Systems in the Formulation of Biodegradable Pre-Flush Fluid for Primary Cementing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microemulsion Systems

2.2. Removal Test

2.3. Wettability and Contact Angle Measurement

2.4. Fluid Compatibility Test

2.5. Influence of Cleanup Fluid on the Performance of Cement Slurries

2.6. Analysis of Cement Slurries Contamination Using X-ray Diffractometry (XRD)

3. Results

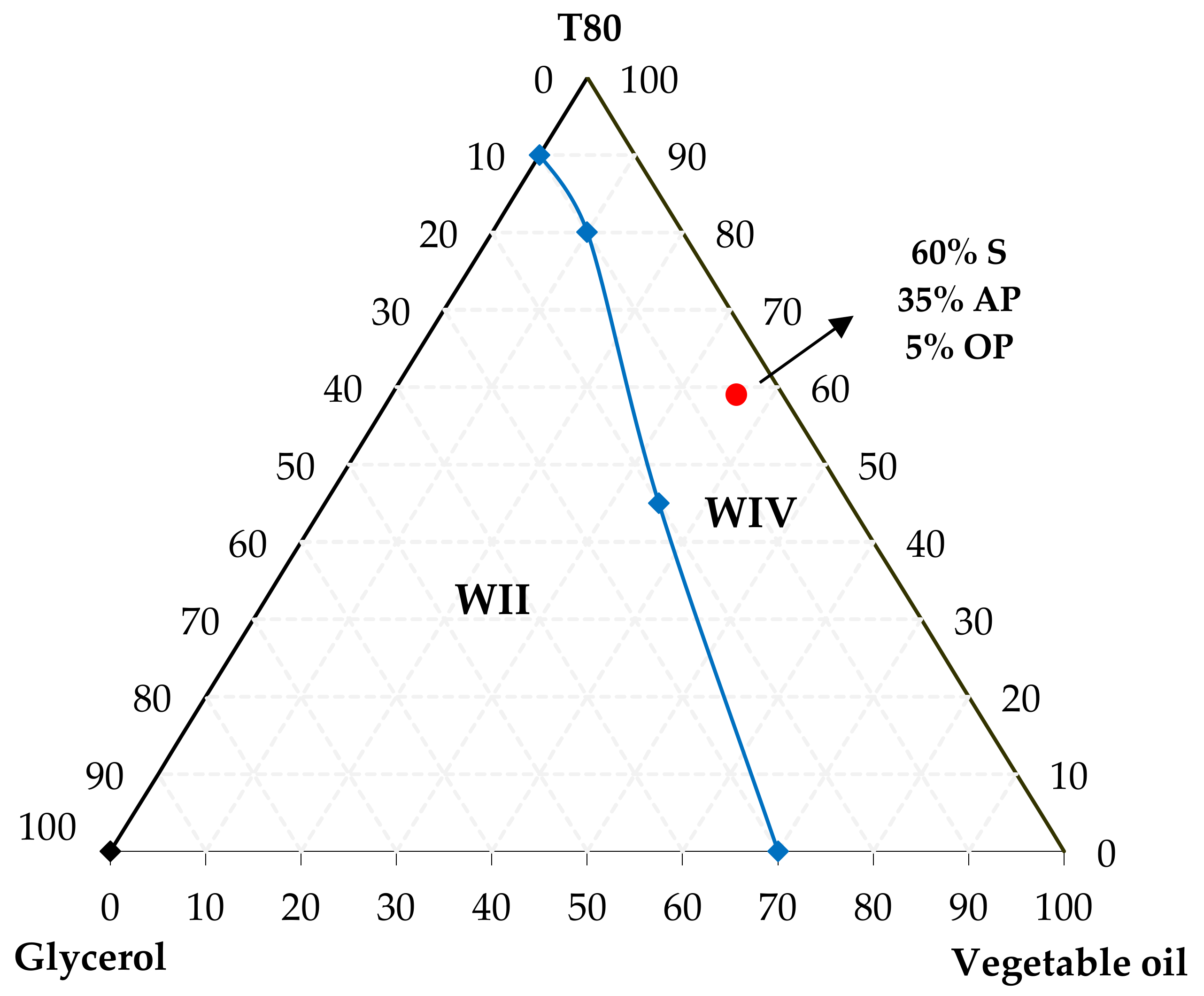

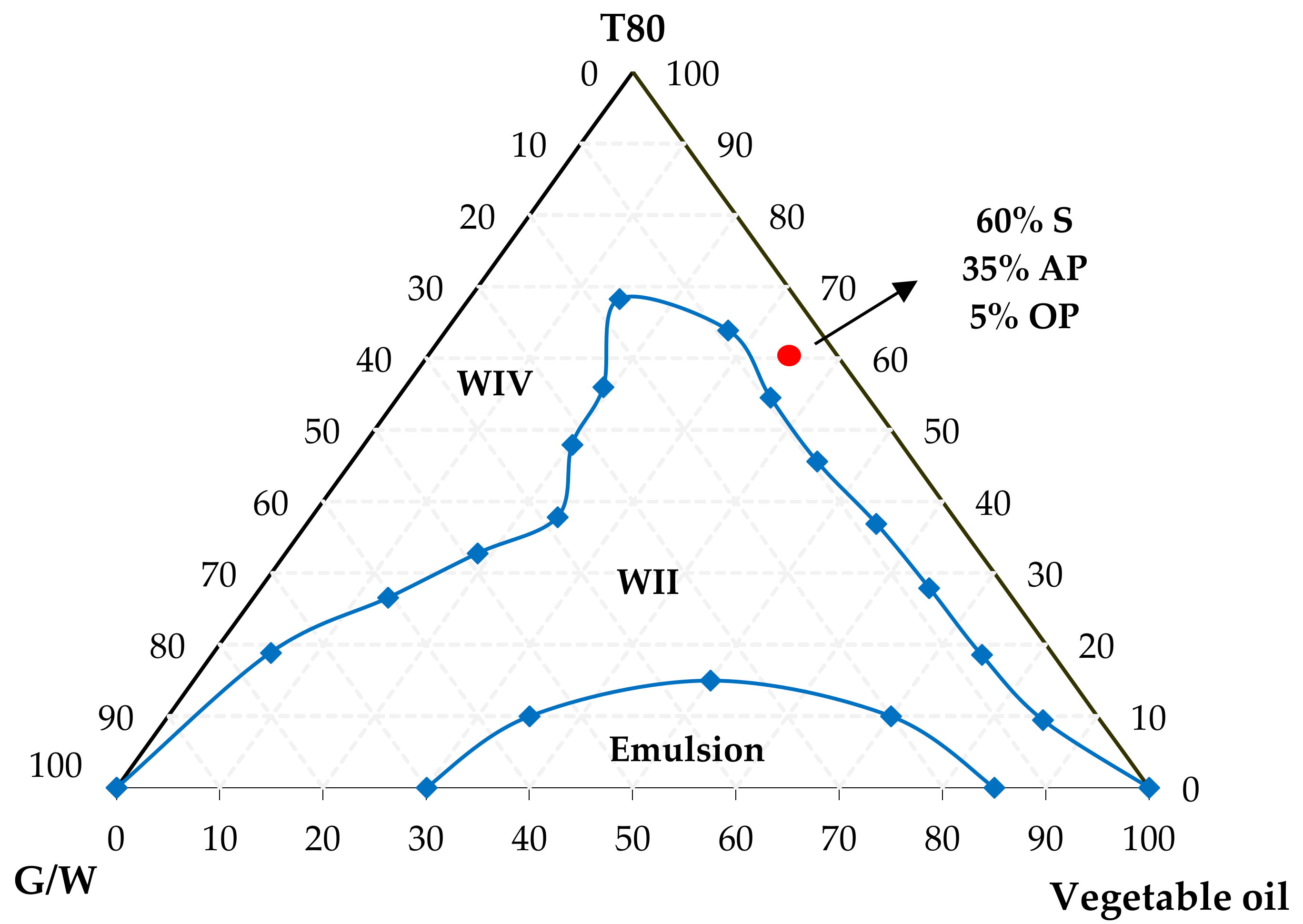

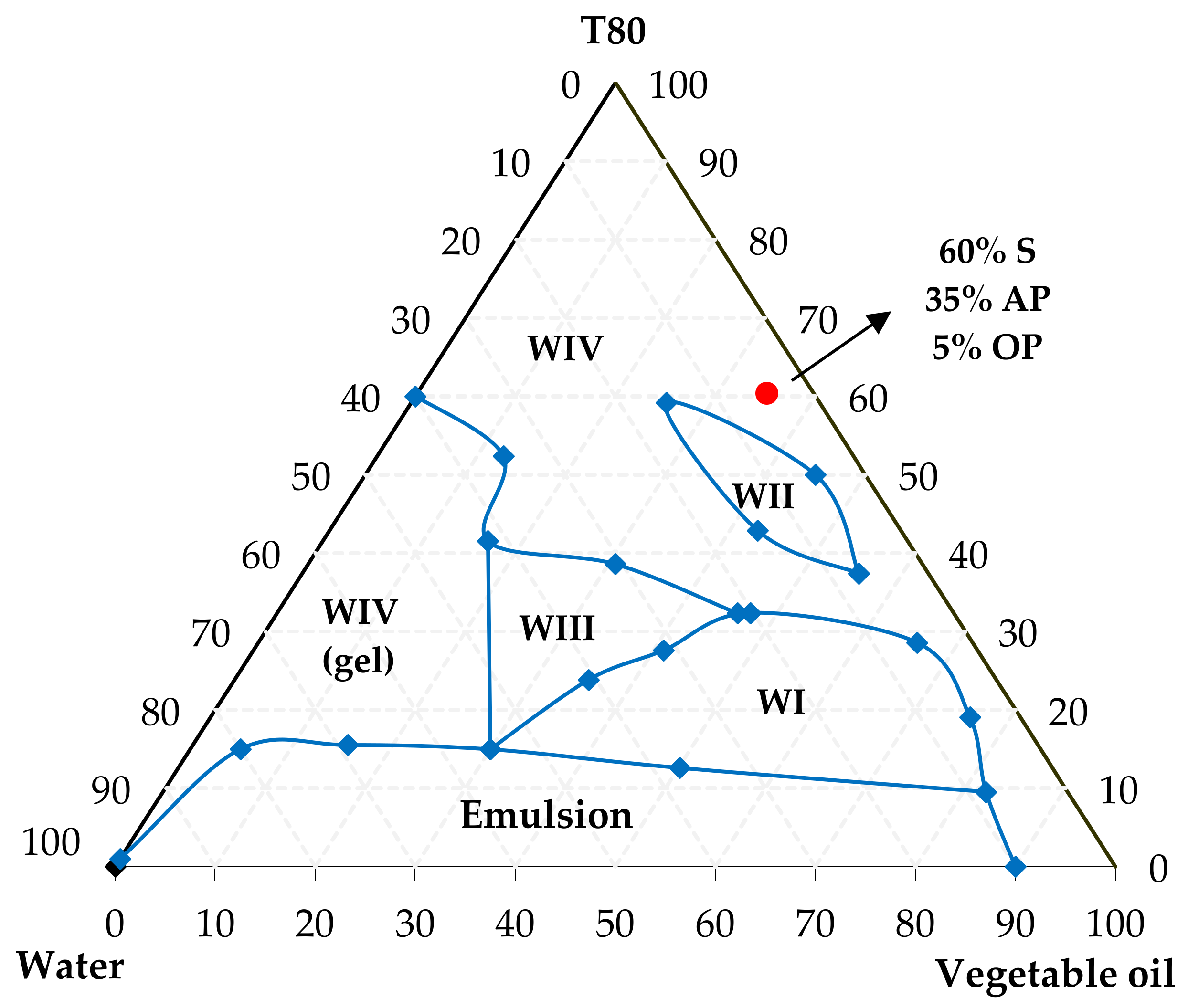

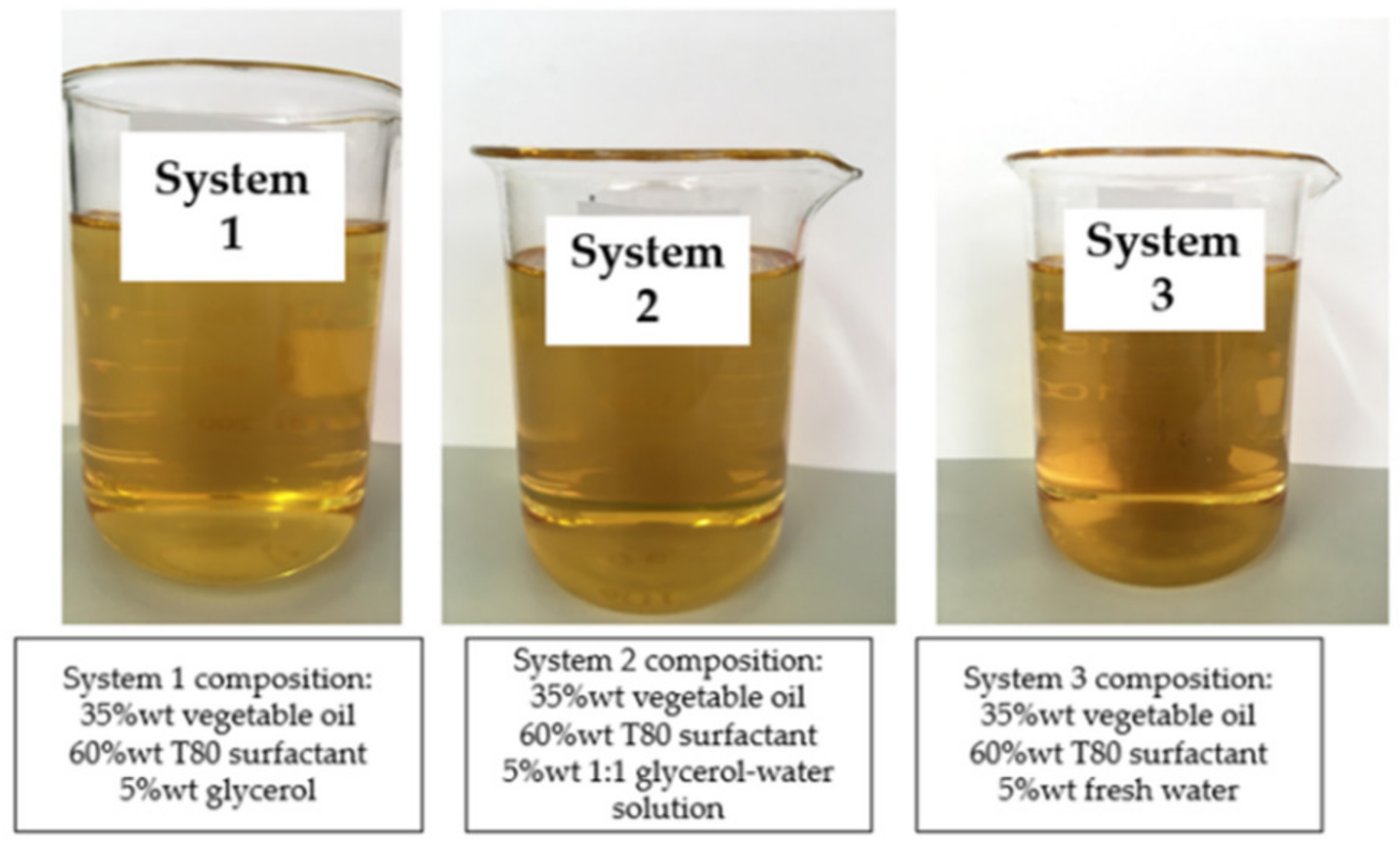

3.1. Microemulsion Systems: Ternary Phase Diagrams

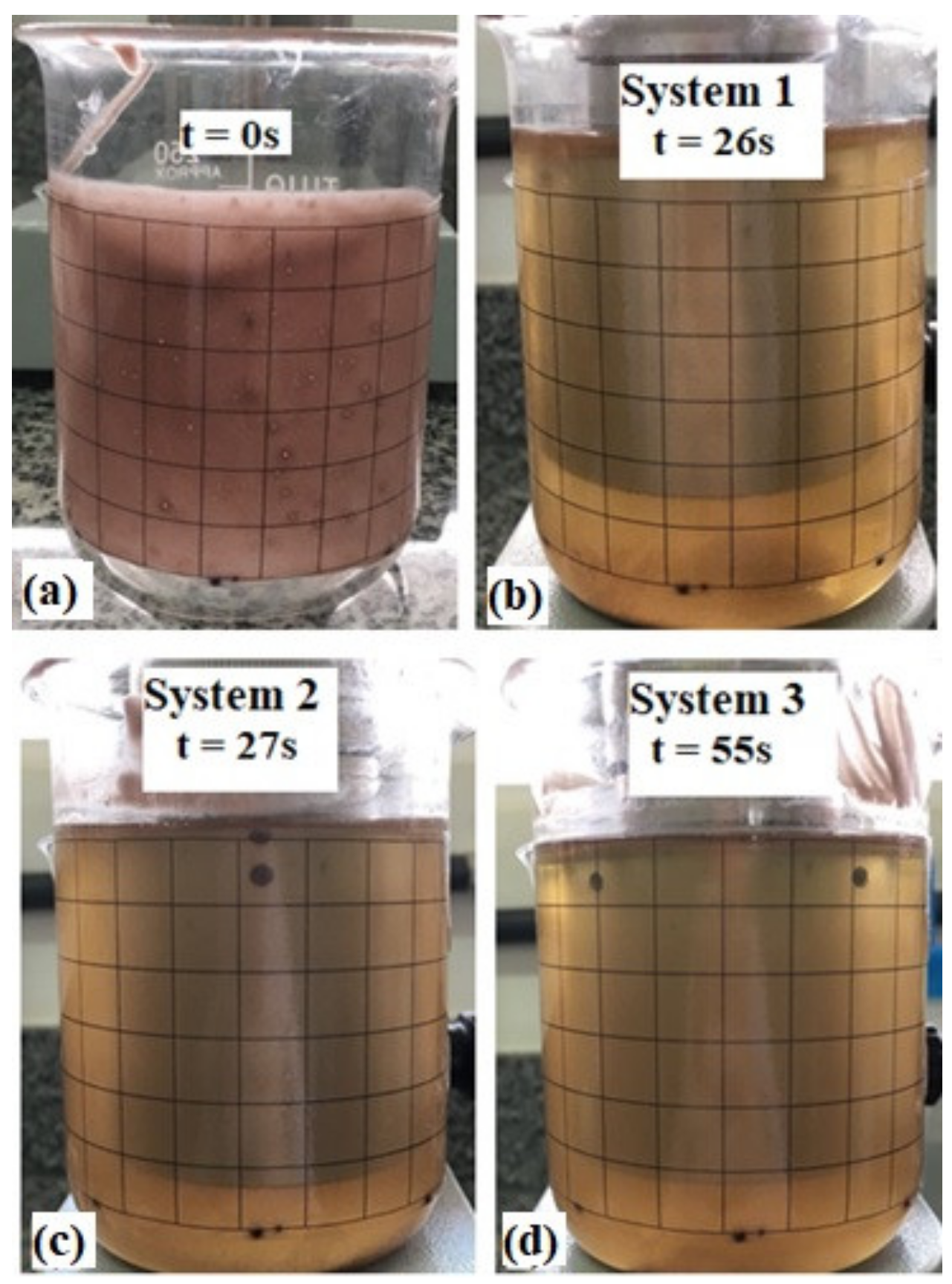

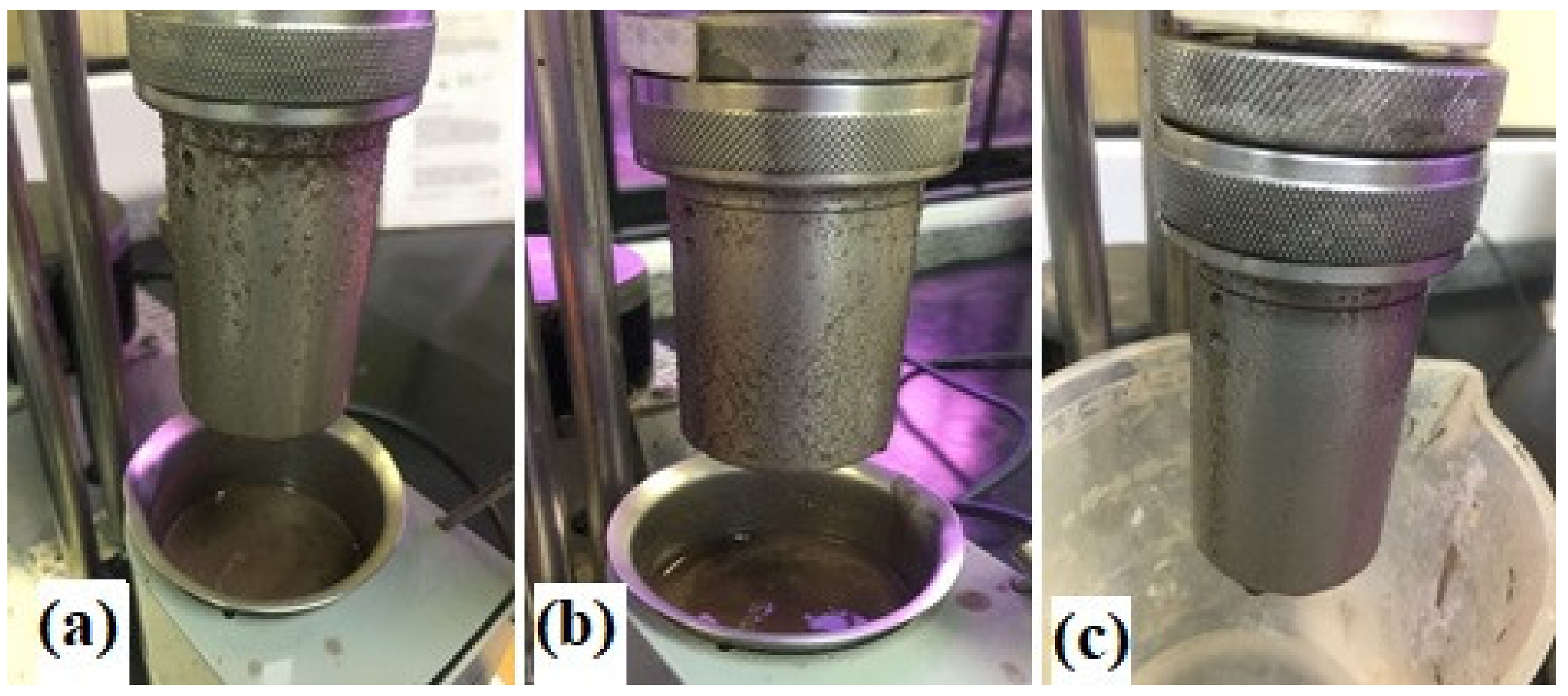

3.2. Filter Cake Removal Test

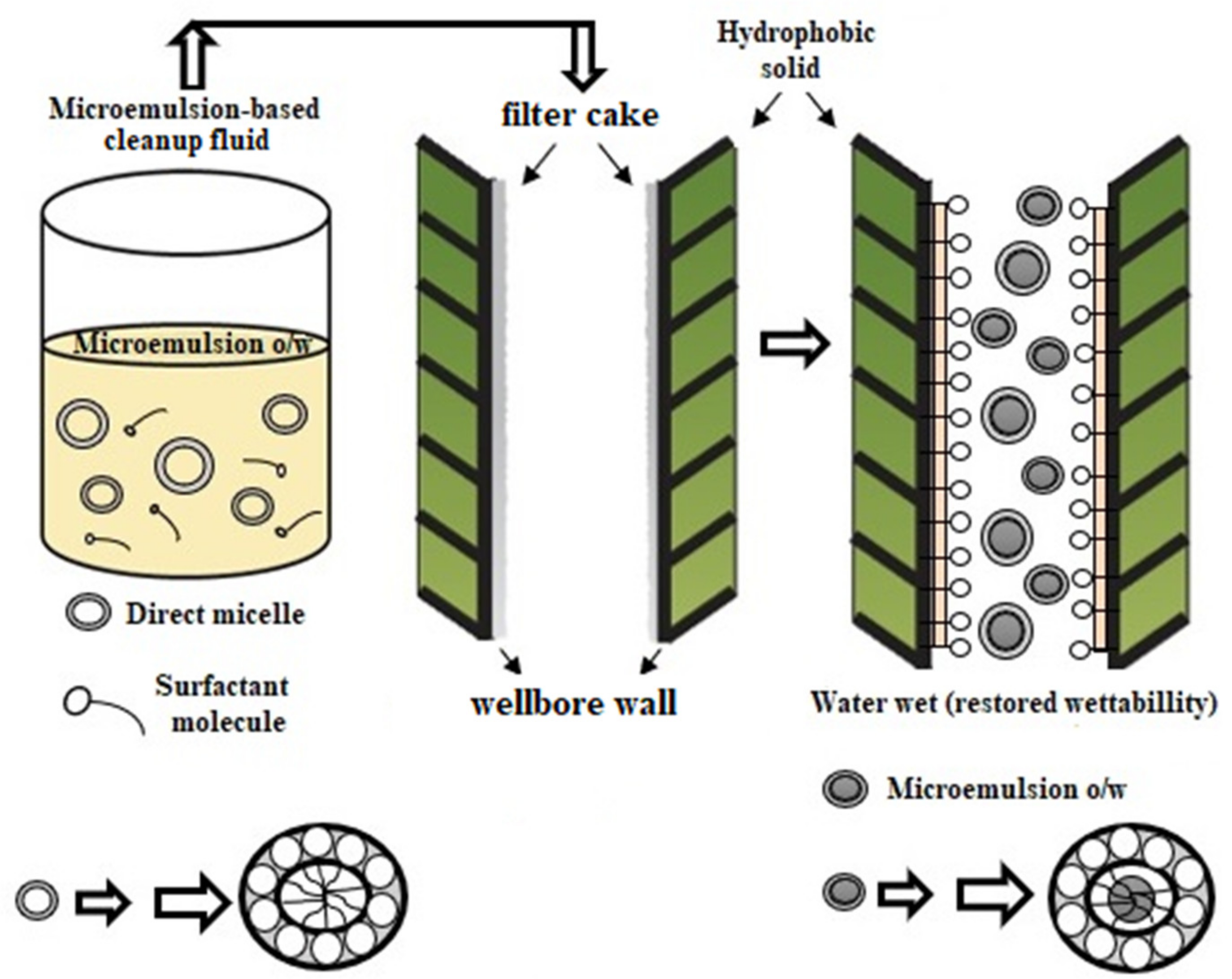

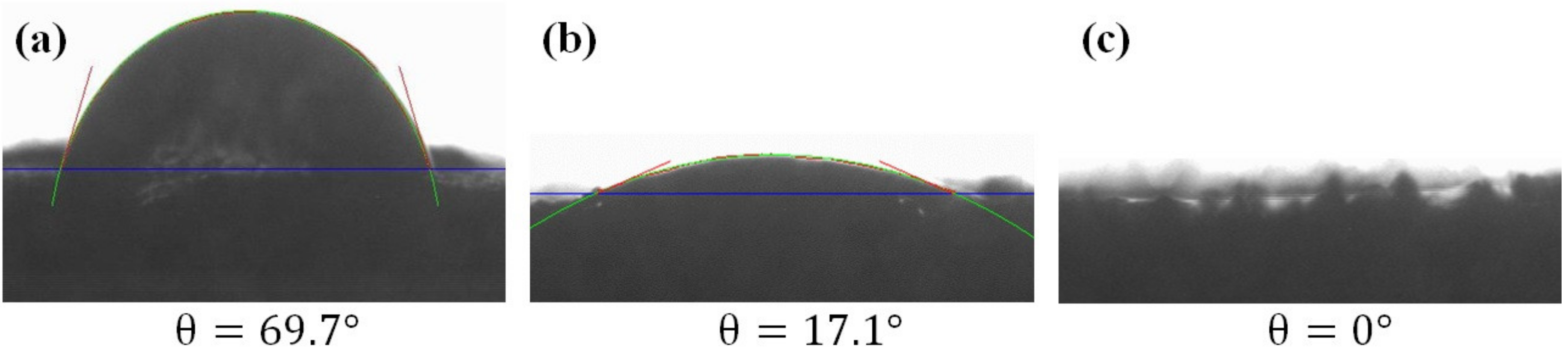

3.3. Wettability Test

3.4. Compatibility Test

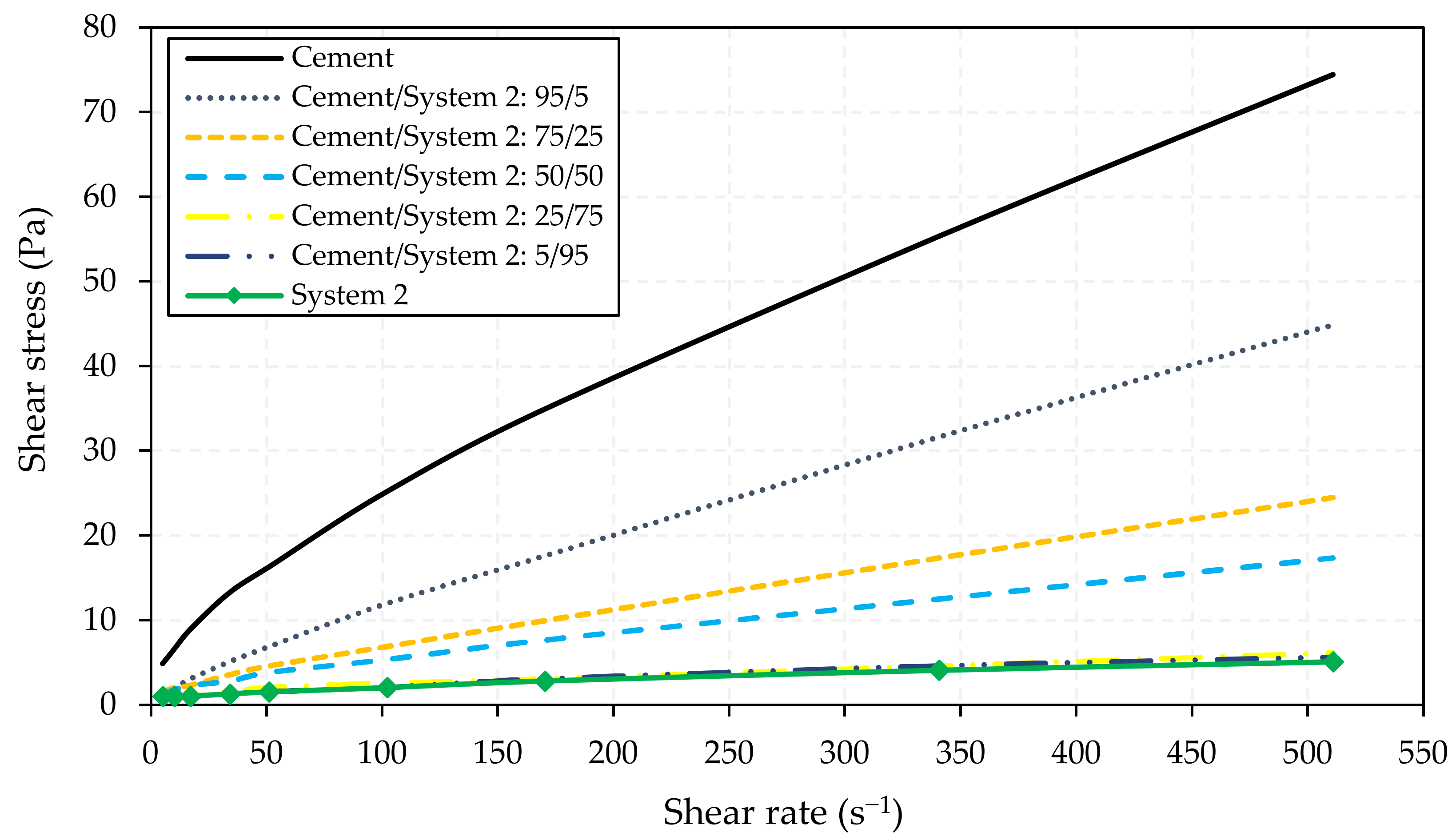

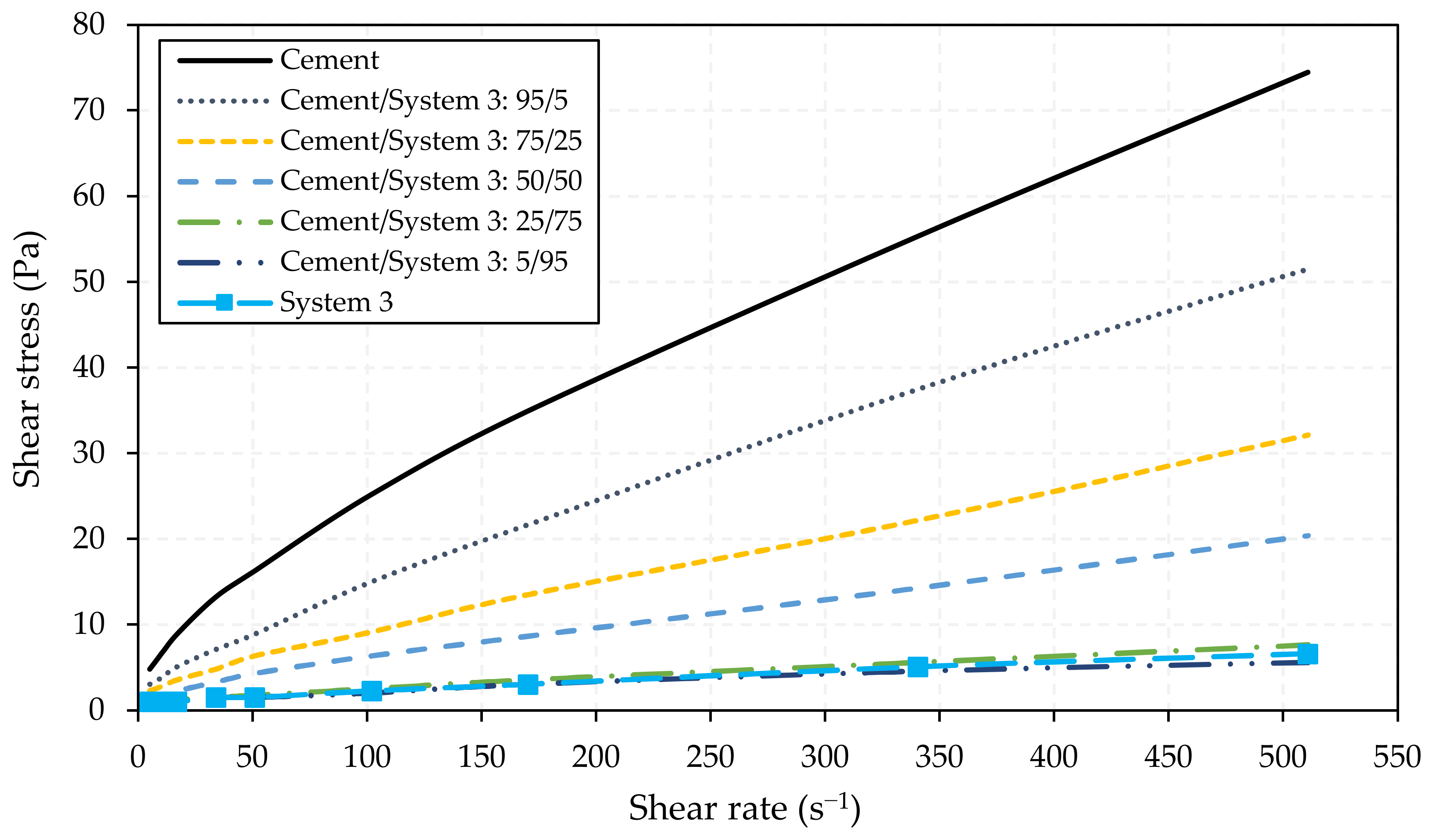

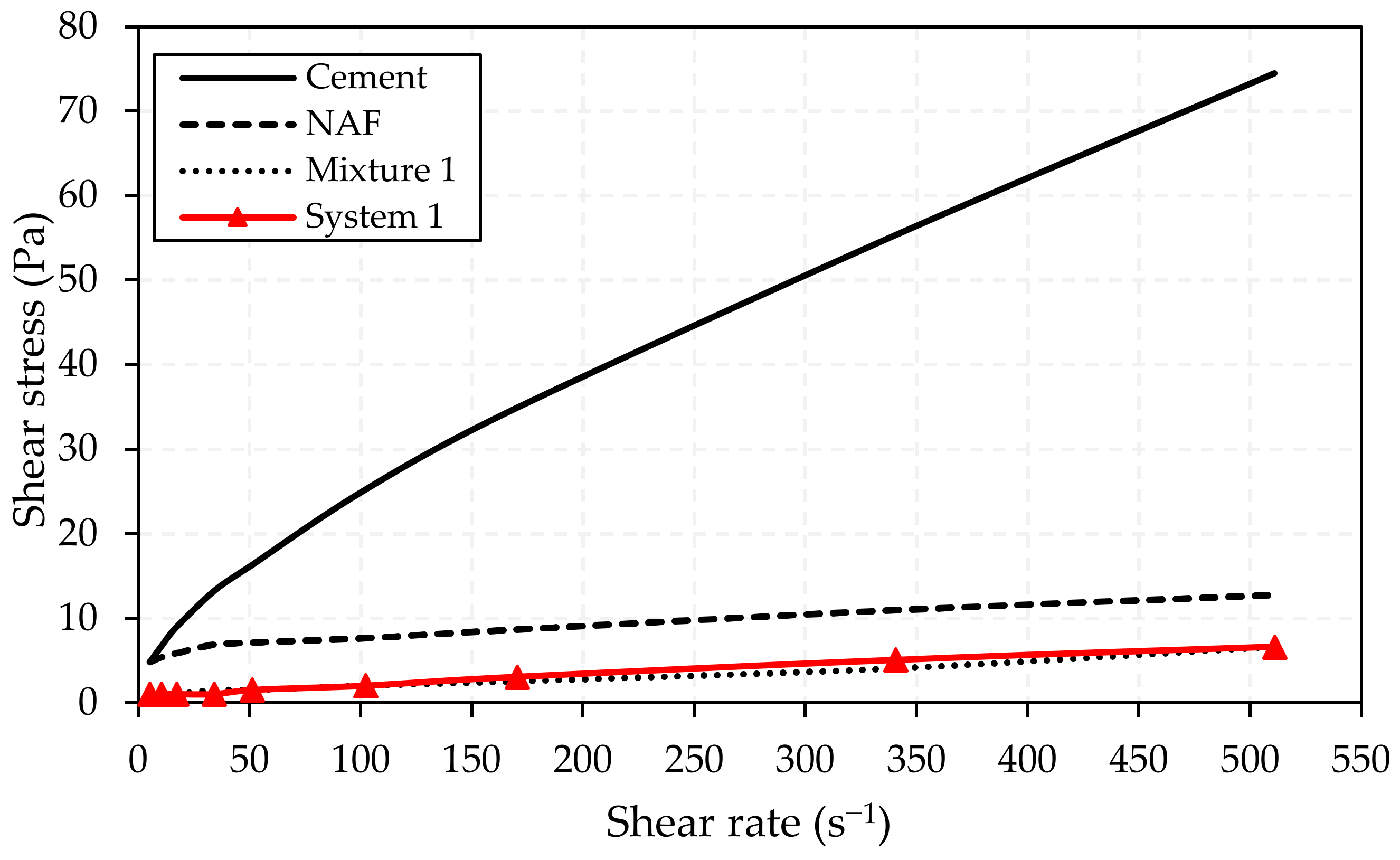

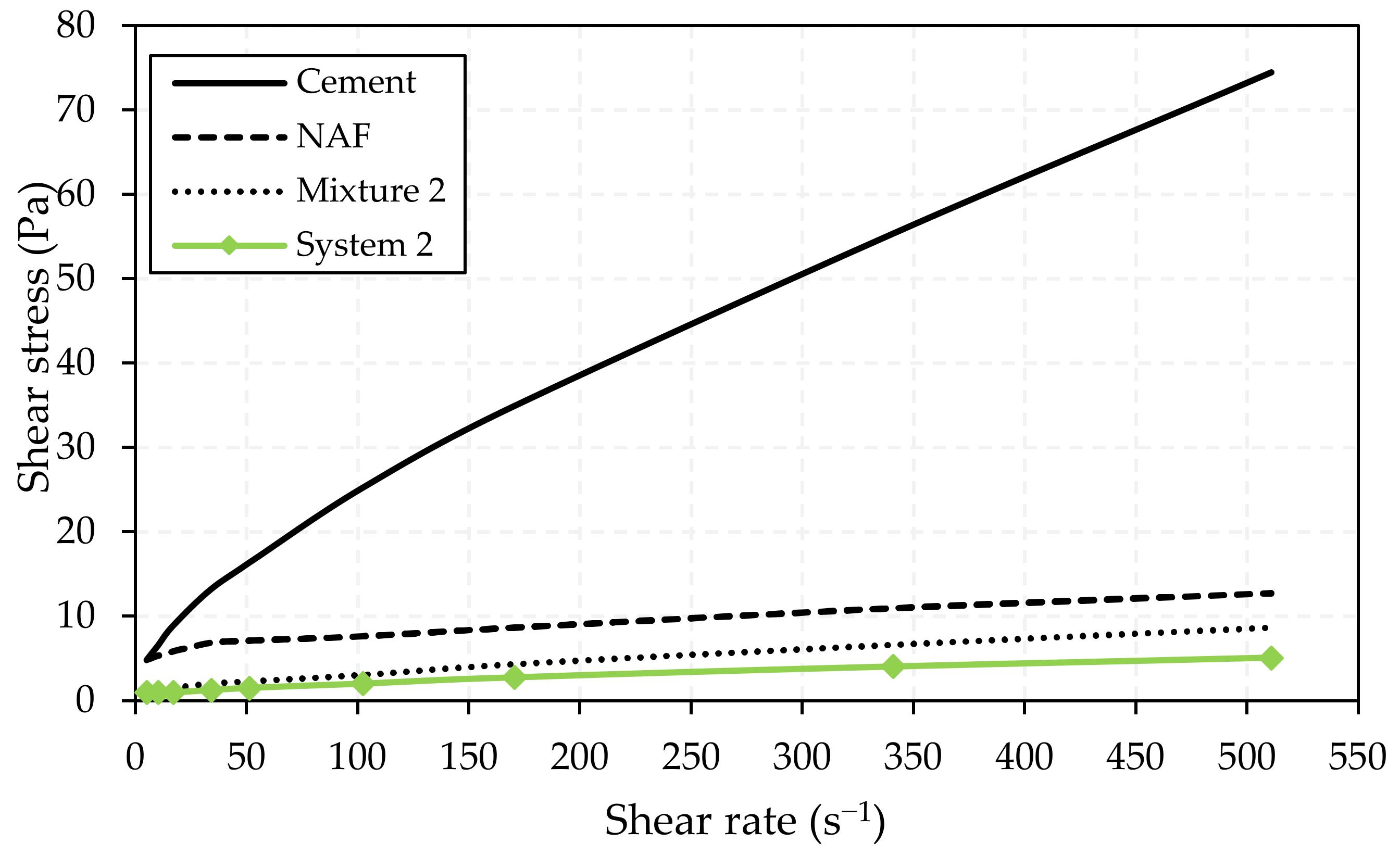

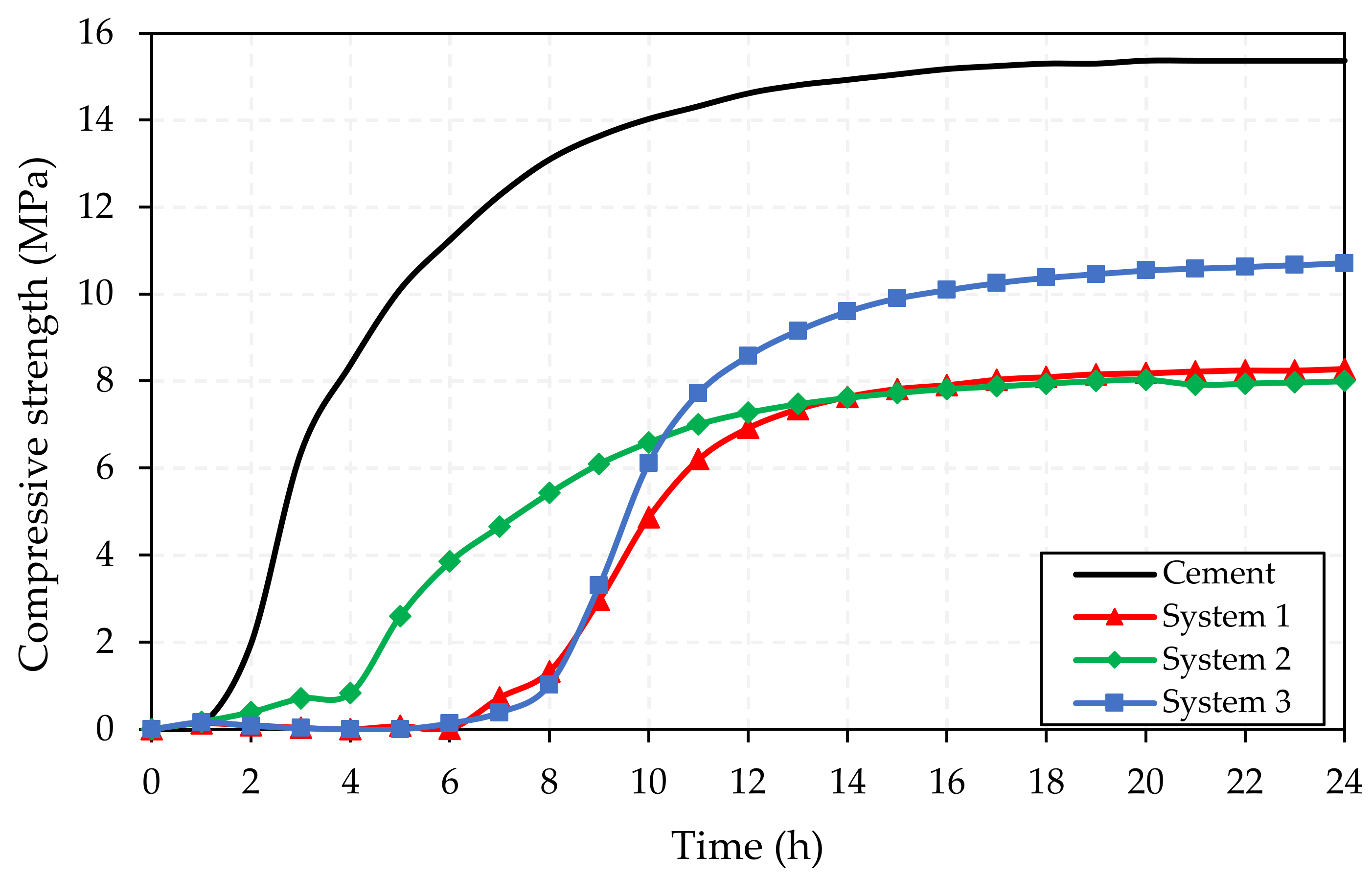

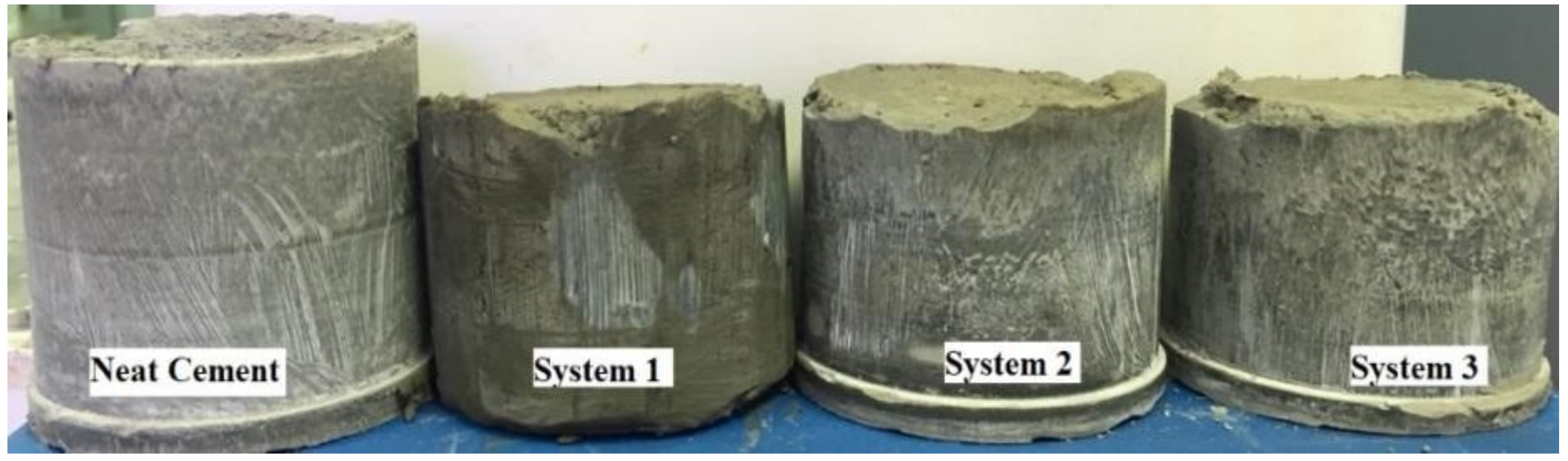

3.5. Influence of Cleanup Fluid on the Performance of Cement Slurries

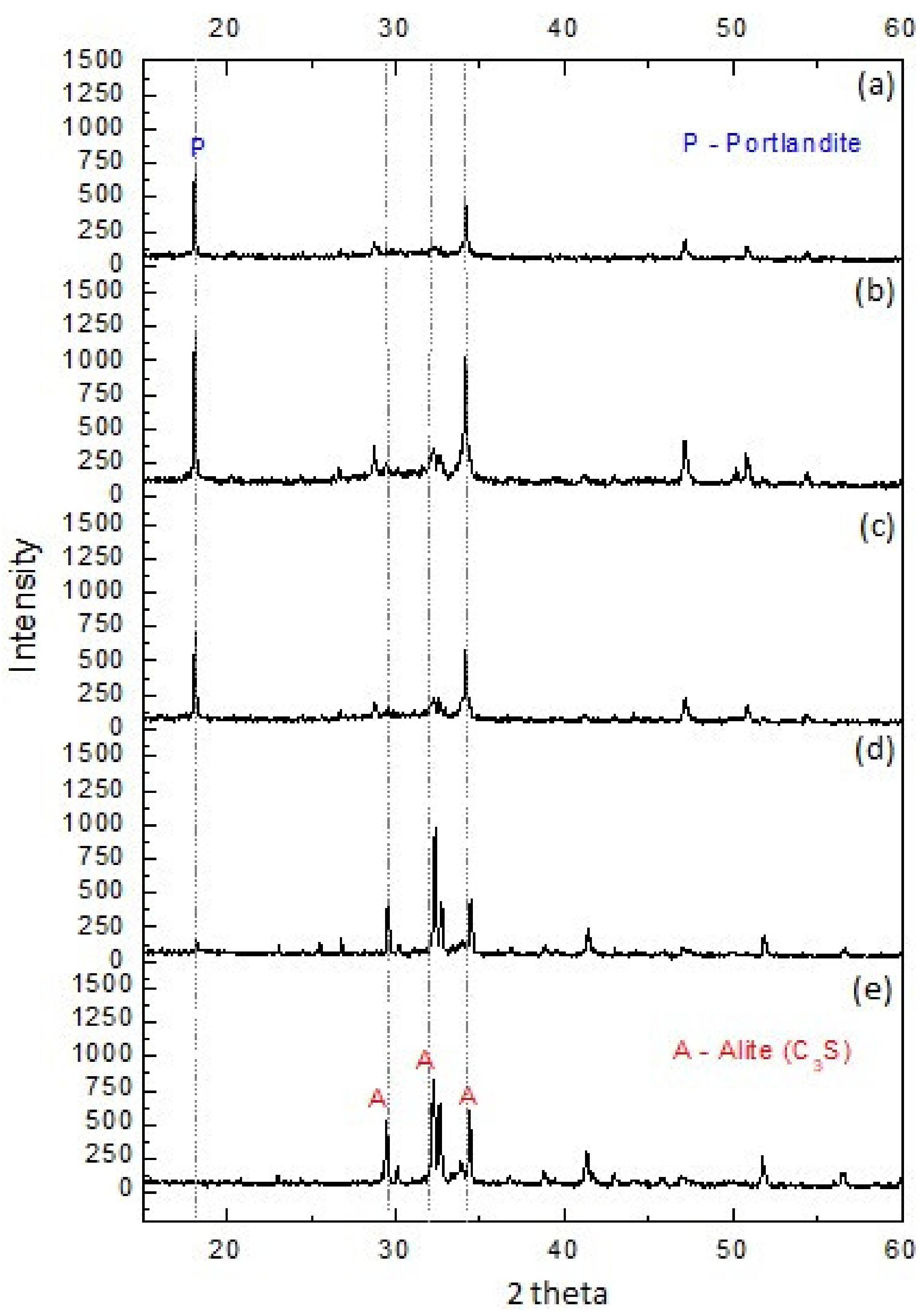

3.6. X-Ray Diffractometry (XRD)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bishop, M.; Moran, L.; Stephens, M.; Reneau, W. A robust, field friendly, cement spacer system. In Proceedings of the AADE Fluids Conference and Exhibition, Houston, TX, USA, 8–9 April 2008. [Google Scholar]

- Zhang, Z.; Scherer, G.W.; Prud’Homme, R.K. Adhesion and bonding between steel pipe and cement/spacer/mud system. In Proceedings of the 9th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Berkeley, CA, USA, 22–25 May 2016. [Google Scholar] [CrossRef]

- Zhang, Z.; Scherer, G.W.; Prud’Homme, R.K.; Choi, M. Effect of casing surface roughness on the removal efficiency of non-aqueous drilling fluids. J. Nat. Gas Sci. Eng. 2018, 51, 155–165. [Google Scholar] [CrossRef]

- Mcclure, J.; Khalfallah, I.; Taoutaou, S.; Bermea, J.A.V.; Kefi, S. New cement spacer chemistry enhances removal of nonaqueous drilling fluid. J. Petrol. Technol. 2014, 15–32. [Google Scholar] [CrossRef]

- Nelson, E.B.; Guillot, D. Well Cementing; Schlumberger: Houston, TX, USA, 2006; p. 773. [Google Scholar]

- Pietrangeli, G.; Quintero, L. Enhanced oil solubilization using microemulsion with linkers. In Proceedings of the SPE International Simposium on Oilfield Chemistry, The Woodlands, TX, USA, 8–10 April 2013. [Google Scholar] [CrossRef]

- Pernites, R.; Khammar, M.; Santra, A. Robust spacer system for water and oil based mud. In Proceedings of the SPE Western Regional Meeting, California, CA, USA, 27–30 April 2015. [Google Scholar] [CrossRef]

- Wang, C.; Meng, R.; Xiao, F.; Wang, R. Use of nanoemulsion for effective removal of both oil-based drilling fluid and filter cake. J. Nat. Gas Sci. Eng. 2016, 36, 328–338. [Google Scholar] [CrossRef]

- Curbelo, F.D.S.; Garnica, A.I.C.; Araujo, E.A.; Paiva, E.M.; Cabral, A.G.; Araujo, E.A.; Freitas, J.C.O. Vegetable oil-based preflush fluid in well cementing. J. Petrol. Sci. Eng. 2018, 170, 392–399. [Google Scholar] [CrossRef]

- Curbelo, F.D.S.; Caminha, T.T.; Garnica, A.I.C.; Melo, G.N.A.; Araújo, E.A.; Freitas, J.C.O. Microemulsion-based flushing fluid for effective removal of filter cake in wells cementation. Bra. J. Petrol. Gas 2019, 13, 119–127. [Google Scholar] [CrossRef]

- Wanderley Neto, A.O.; Silva, V.L.; Rodrigues, D.V.; Ribeiro, L.S.; Silva, D.N.N.; Freitas, J.C.O. A novel oil-in-water microemulsion as a cementation flushing fluid for removing nonaqueous filter cake. J. Petrol. Sci. Eng. 2019, 184. [Google Scholar] [CrossRef]

- Silva, D.C.; Araújo, C.R.B.; Freitas, J.C.O.; Rodrigues, M.A.F.; Wanderley Neto, A.O. Formulation of new microemulsion systems containing produced water for removal of filter cake from olefin-based drilling fluid. J. Petrol. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Brege, J.; Sherbeny, W.E.; Quintero, L.; Jones, T. Using microemulsion technology to remove oil-based mud in wellbore displacement and remediation applications. In Proceedings of the North Africa Technical Conference and Exhibition, Cairo, Egypt, 20–22 February 2012. [Google Scholar] [CrossRef]

- Zanten, R.V.; Lawrence, B.; Henzler, S. Using surfactant nanotechnology to engineer displacement packages for cementing operations. In Proceedings of the IADC/SPE Drilling Conference and Exhibition, New Orleans, LA, USA, 2–4 February 2000. [Google Scholar] [CrossRef]

- Schulman, J.H.; Stoeckenius, W.; Prince, L.M. Mechanism of formation and structure of micro emulsions by electron microscopy. J. Phys. Chem. 1959, 63, 1677–1680. [Google Scholar] [CrossRef]

- Danielsson, I.; Lindman, B. The definition of microemulsion. Colloids Surf. 1981, 3, 391–392. [Google Scholar] [CrossRef]

- Quintero, L.; Christian, C.; Halliday, W.; White, C.; Dean, D.; Courtney, G. New spacer technology for cleaning and water wetting of casing and riser. In Proceedings of the AADE-08- DF-HO-01, Houston, TX, USA, 8–9 April 2008. [Google Scholar]

- Pietrangeli, G.; Quintero, L.; Gonzalez, Y. In-situ microemulsions enhance removal of non-aqueous drilling fluid in gulf of Guinea Wells. In Proceedings of the SPE European Formation Damage Conference and Exhibition, Budapest, Hungary, 3–5 June 2015. [Google Scholar] [CrossRef]

- Darugar, Q.; Quintero, L.; Christian, C.F.; Ellis, D.R. Fluorescence microscopy: A technique to study and evaluate spacer fluids for wettability inversion. In Proceedings of the AADE Fluids Conference and Exhibition, Houston, TX, USA, 6–7 April 2010. [Google Scholar]

- Maserati, G.; Daturi, E.; Gaudio, L.D.; Belloni, A.; Bolzoni, S.; Lazzari, W.; Leo, G. Nano-emulsions as cement spacer improve the cleaning of casing bore during cementing operations. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010. [Google Scholar] [CrossRef]

- American Petroleum Institute (API). Recommended Practice for Testing Well Cements; API RP 10B-2; American Petroleum Institute (API): Washington, DC, USA, 2013. [Google Scholar]

- Campos, G. PROCELAB—Procedimentos e métodos de laboratório destinados à cimentação de poços de Petróleo (Procedures and methods laboratory for cementing of oil wells). Rio de Janeiro. 2014, 12, 1–3. [Google Scholar]

- Alotaibi, M.B.; Nasralla, R.A.; Nasr-El-Din, H.A. Wettability challenges in carbonate reservoirs. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. [Google Scholar] [CrossRef]

- Dantas, T.N.C.; Soares A, P.J.; Wanderley Neto, A.O.; Dantas Neto, A.A.; Barros Neto, E.L. Implementing new microemulsion systems in wettability inversion and oil recovery from carbonate reservoirs. Energy Fuels 2014, 28, 6749–6759. [Google Scholar] [CrossRef]

- Winsor, P.A. Solvent Properties of Amphiphilic Compounds; Butterworth: London, UK, 1954. [Google Scholar]

- Heathman, J.; Wilson, J.M.; Cantrell, J.H.; Gardner, C. Removing subjective judgment from wettability analysis aids displacement. In Proceedings of the IADC/SPE Drilling Conference, New Orleans, LA, USA, 23–25 February 2000. [Google Scholar] [CrossRef]

- Brege, J.J.; Pietrangeli, G.; McKellar, A.J.; Quintero, L.; Forgiarini, A.; Salager, J. Fluid formulations for cleaning oil-based or synthetic oil-based mud filter cakes. U.S. Patent US20150087563 A1, 26 March 2015. [Google Scholar]

- Quintero, L.; Passanha, W.D.; Aubry, E.; Poitrenaud, H. Advanced microemulsion cleaner fluid applications in deepwater wells. In Proceedings of the OTC Brasil, Rio de Janeiro, Brazil, 27–29 October 2015. [Google Scholar] [CrossRef]

- Shadravan, A.; Narvaez, G.; Alegria, A.; Carman, P.; Perez, C.; Erger, R. Engineering the mud-spacer-cement rheological hierarchy improves wellbore integrity. In Proceedings of the SPE E&P Health, Safety, Security and Environmental Conference-Americas, Denver, CO, USA, 16–18 March 2015. [Google Scholar] [CrossRef]

- Li, M.; Ou, H.; Li, Z.; Gu, T.; Liu, H.; Guo, X. Contamination of cement slurries with diesel based drilling fluids in a shale gas well. J. Nat. Gas Sci. Eng. 2015, 27, 1312–1320. [Google Scholar] [CrossRef]

| Formulation | Concentration | Units |

|---|---|---|

| Olefin | 0.57 | L/L |

| Hydrated calcium oxide | 10.00 | 2.85 × 10−3 kg/L |

| Primary emulsifier (NEW MUL) | 10.00 | 2.85 × 10−3 kg/L |

| NaCl brine | 0.39 | L/L |

| Organophilic Clay | 4.00 | 2.85 × 10−3 kg/L |

| Filtrate Control (ECOTROL) | 1.00 | 2.85 × 10−3 kg/L |

| Rheological modifier (HRP) | 1.00 | 2.85 × 10−3 kg/L |

| Baritine | 80.00 | 2.85 × 10−3 kg/L |

| Formulation | Weight (kg) | Aspect |

|---|---|---|

| Class A Cement | 0.540 | Powder |

| Silica | 0.216 | Solid |

| Water | 0.285 | Liquid |

| Antifoam | 0.00031 | Liquid |

| Filtrate controller 1 | 0.045 | Liquid |

| Filtrate controller 2 | 0.024 | Liquid |

| Retarder | 0.0077 | Liquid |

| System | Volume of Cleanup Fluid Used (L) |

|---|---|

| 1 | 0.033 |

| 2 | 0.053 |

| 3 | 0.037 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Araújo, E.A.; Caminha, T.T.; Paiva, E.M.; Silva, R.R.; Freitas, J.C.O.; Garnica, A.I.C.; Curbelo, F.D.S. Application of Microemulsion Systems in the Formulation of Biodegradable Pre-Flush Fluid for Primary Cementing. Energies 2020, 13, 4683. https://doi.org/10.3390/en13184683

Araújo EA, Caminha TT, Paiva EM, Silva RR, Freitas JCO, Garnica AIC, Curbelo FDS. Application of Microemulsion Systems in the Formulation of Biodegradable Pre-Flush Fluid for Primary Cementing. Energies. 2020; 13(18):4683. https://doi.org/10.3390/en13184683

Chicago/Turabian StyleAraújo, Elayne A., Thaine T. Caminha, Evanice M. Paiva, Raphael R. Silva, Júlio Cézar O. Freitas, Alfredo Ismael C. Garnica, and Fabíola D. S. Curbelo. 2020. "Application of Microemulsion Systems in the Formulation of Biodegradable Pre-Flush Fluid for Primary Cementing" Energies 13, no. 18: 4683. https://doi.org/10.3390/en13184683

APA StyleAraújo, E. A., Caminha, T. T., Paiva, E. M., Silva, R. R., Freitas, J. C. O., Garnica, A. I. C., & Curbelo, F. D. S. (2020). Application of Microemulsion Systems in the Formulation of Biodegradable Pre-Flush Fluid for Primary Cementing. Energies, 13(18), 4683. https://doi.org/10.3390/en13184683