Sizing of Lithium-Ion Battery/Supercapacitor Hybrid Energy Storage System for Forklift Vehicle †

Abstract

1. Introduction

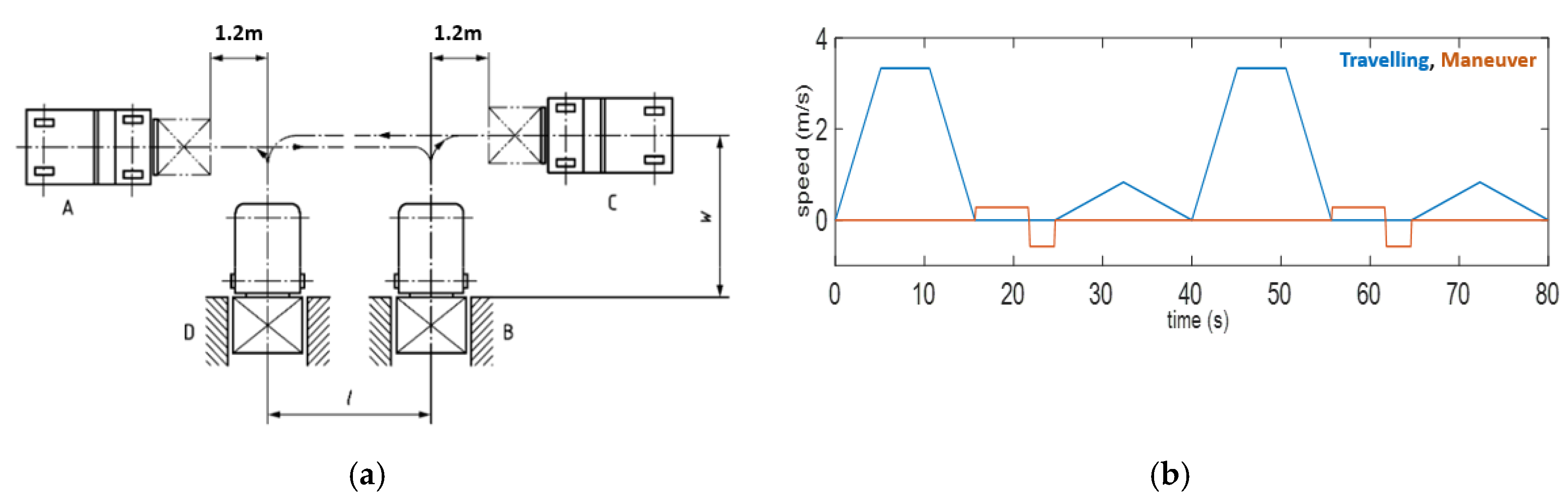

2. Driving Cycles

- -

- Start at position A, the forklift holds the load

- -

- Forward travel from A to B—lift the load up to 2 m

- -

- Lower the load and backward travel from B to C

- -

- Forward travel from C to D—lift the load up to 2 m

- -

- Lower the load and backward travel from D to A

- -

- End of the cycle

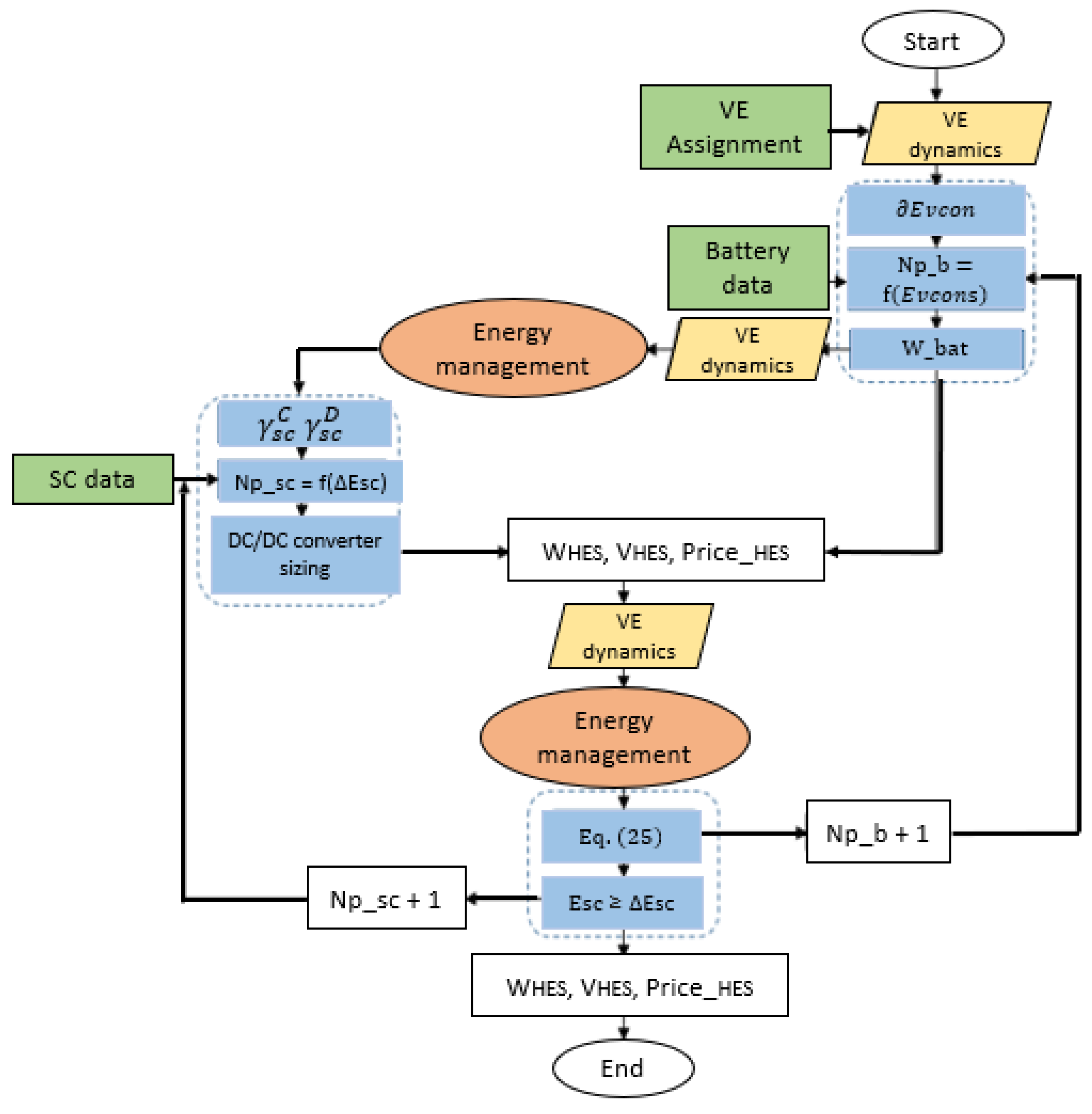

3. Methodology for Sizing Lithium-Ion Battery/Supercapacitor Hybrid Energy Storage System

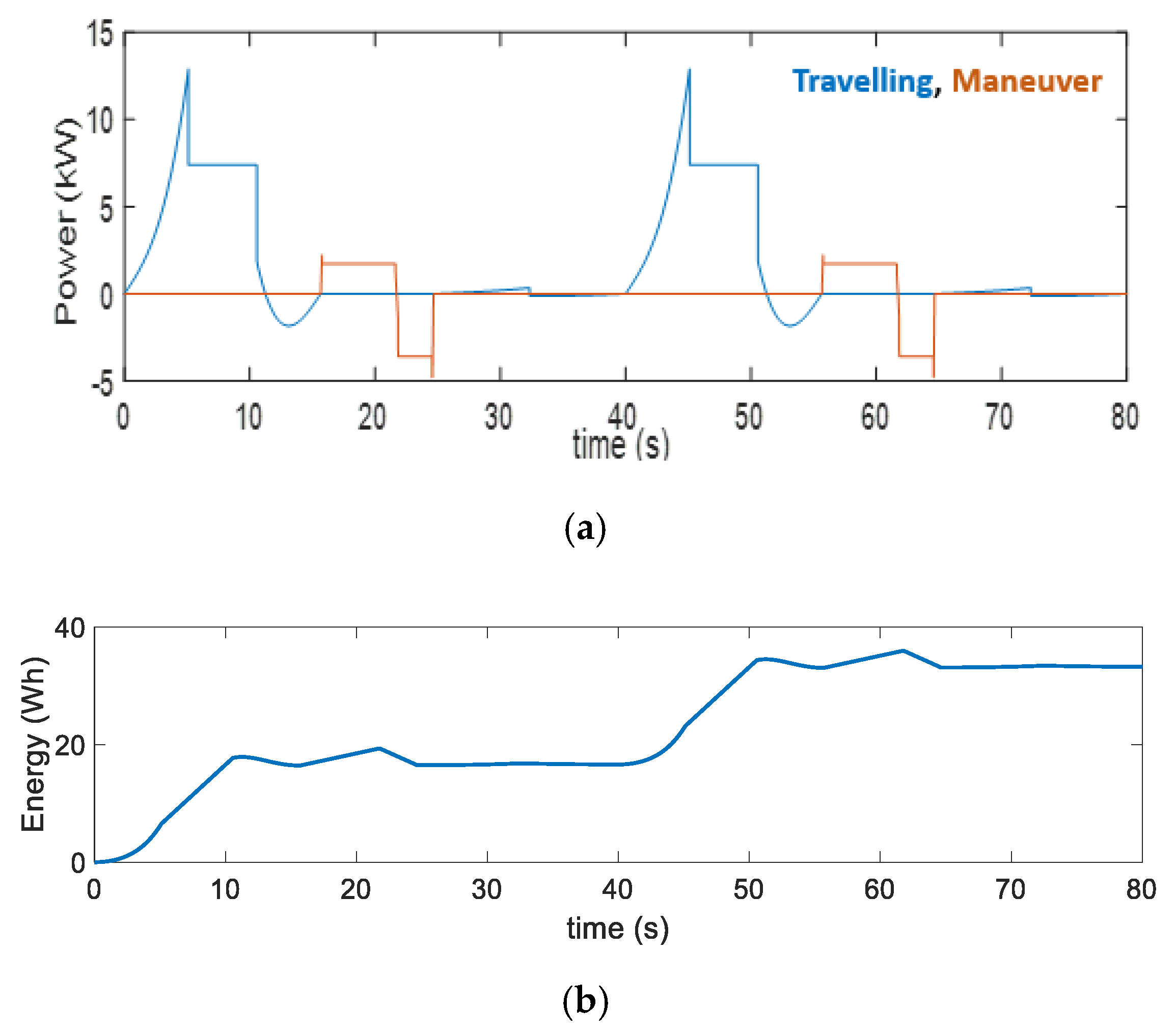

3.1. Conversion from a Driving Cycle to a Power Cycle

3.2. Sizing of the Battery

- Ensure the maximal consuming power (using maximal power requested)

- Ensure the maximal braking power (using minimal power requested)

- Ensure only the vehicle range (using final value of the energy)

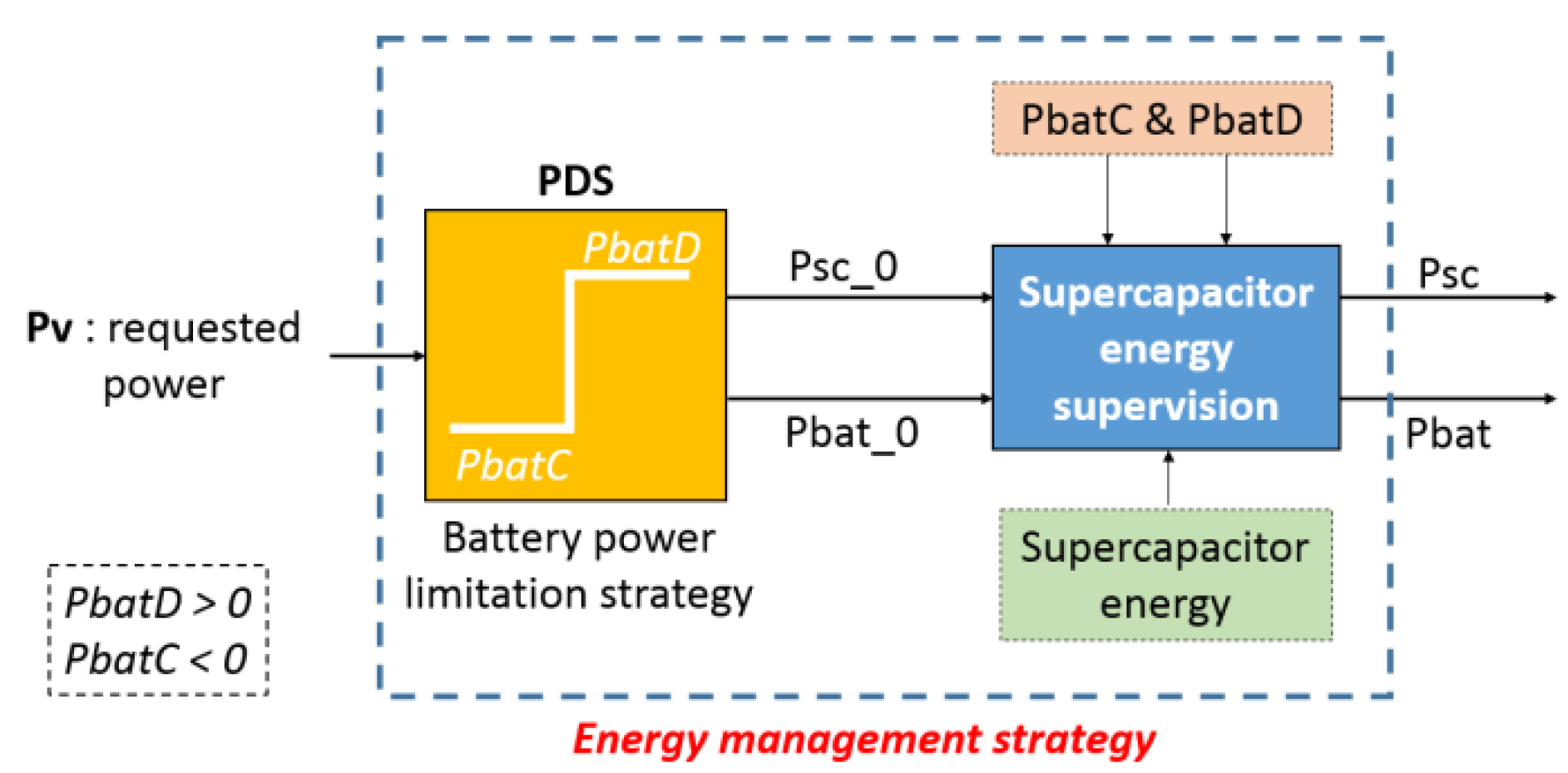

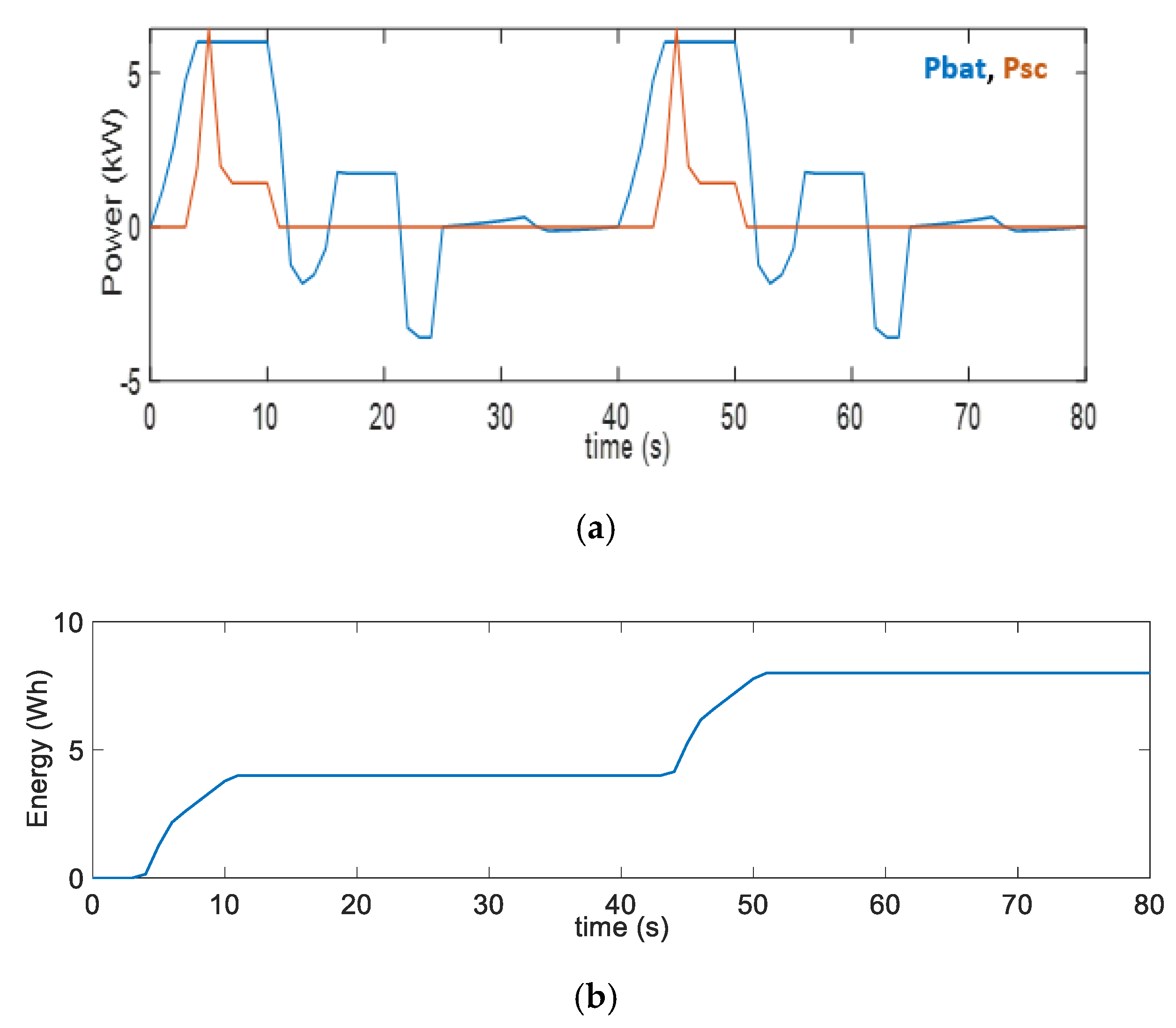

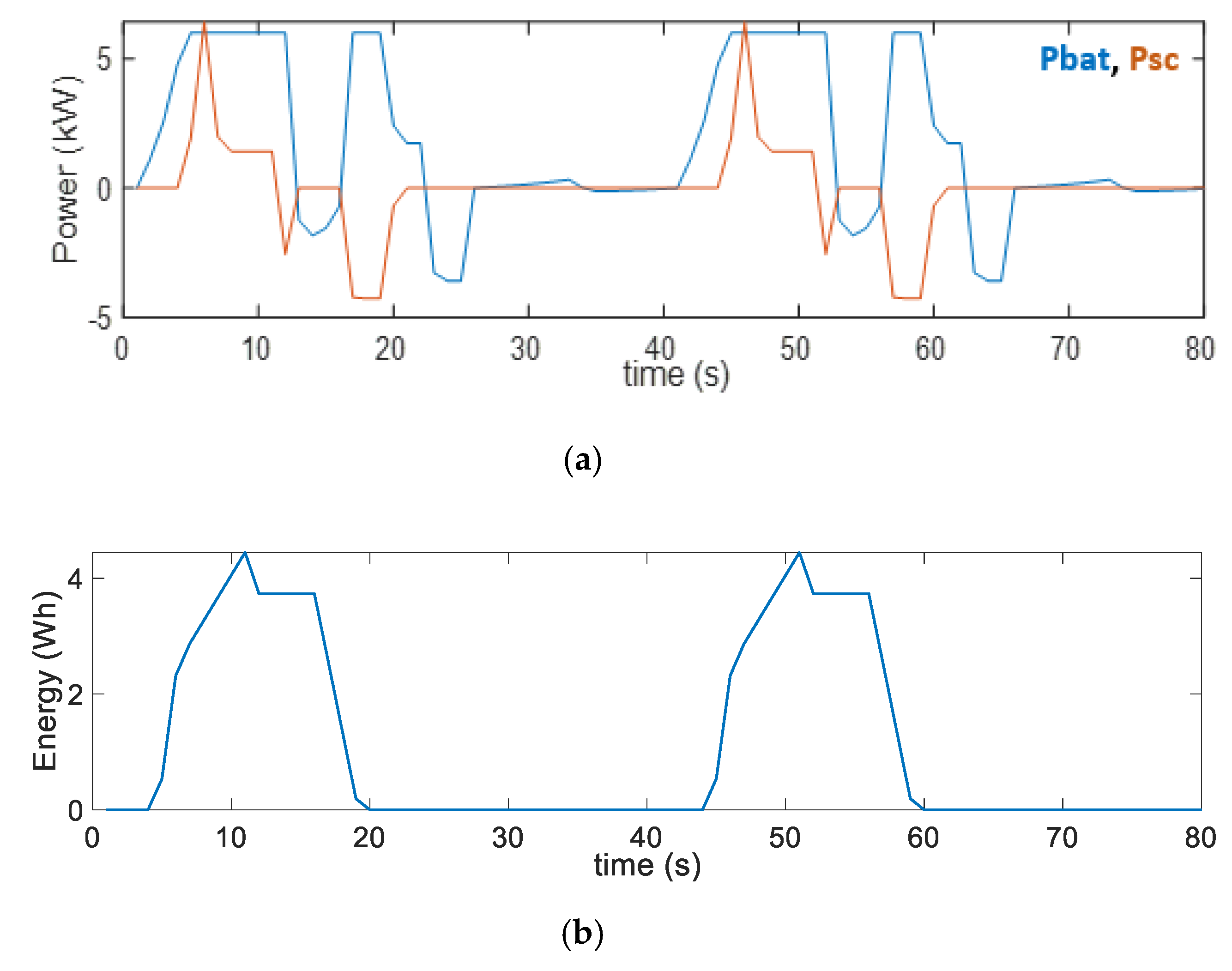

3.3. Energy Management Strategy

3.4. Sizing of the Supercapacitor

3.5. DC/DC Converter Sizing

3.6. Adjusting the Number of Cells

- The energy of the battery, taking into account the DOD, is higher than the total energy requested by the vehicle range:

- The supercapacitor energy, taking into account a yield of 85%, is higher than the difference between the two extrema of supercapacitor energy after energy management Esc ≥ ∆Esc.

4. Results

4.1. Requested Power and Energy

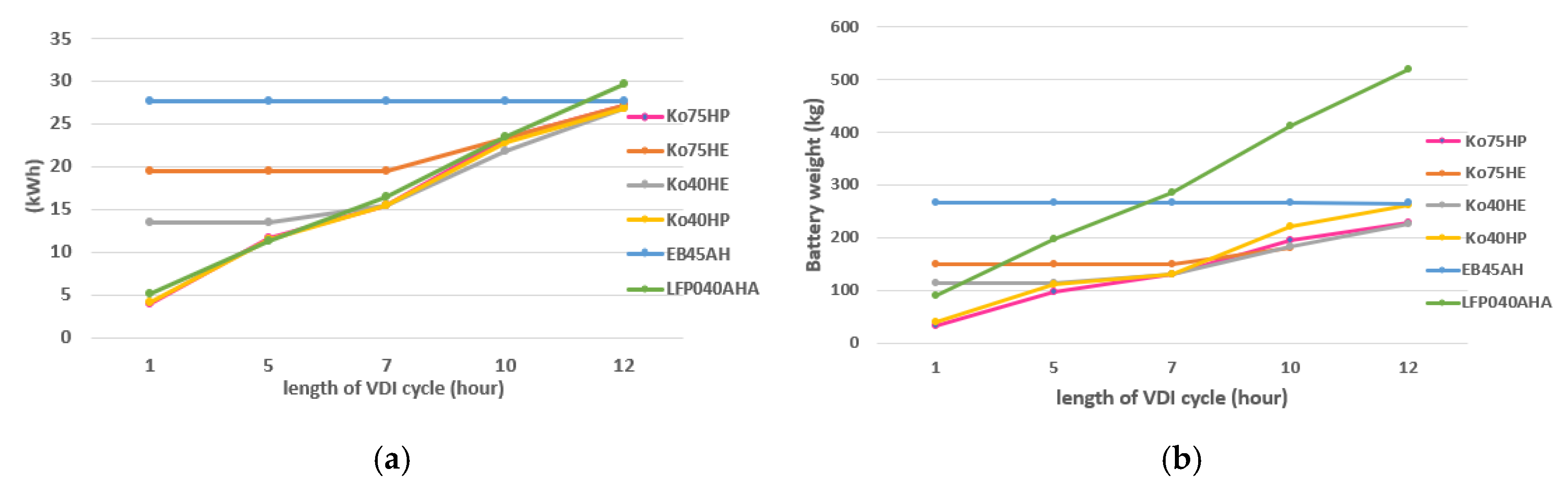

4.2. Comparison of Single Source Sizing

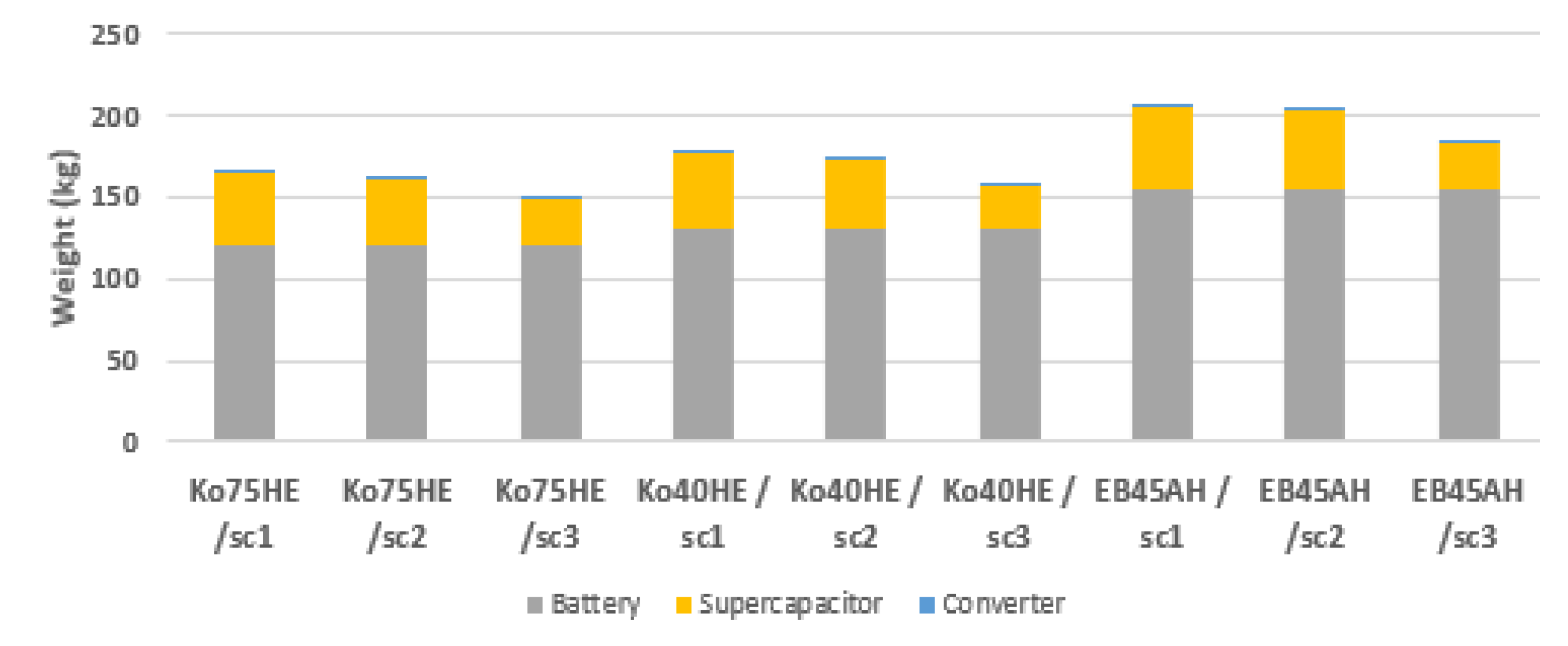

4.3. Comparison of Hybrid Source

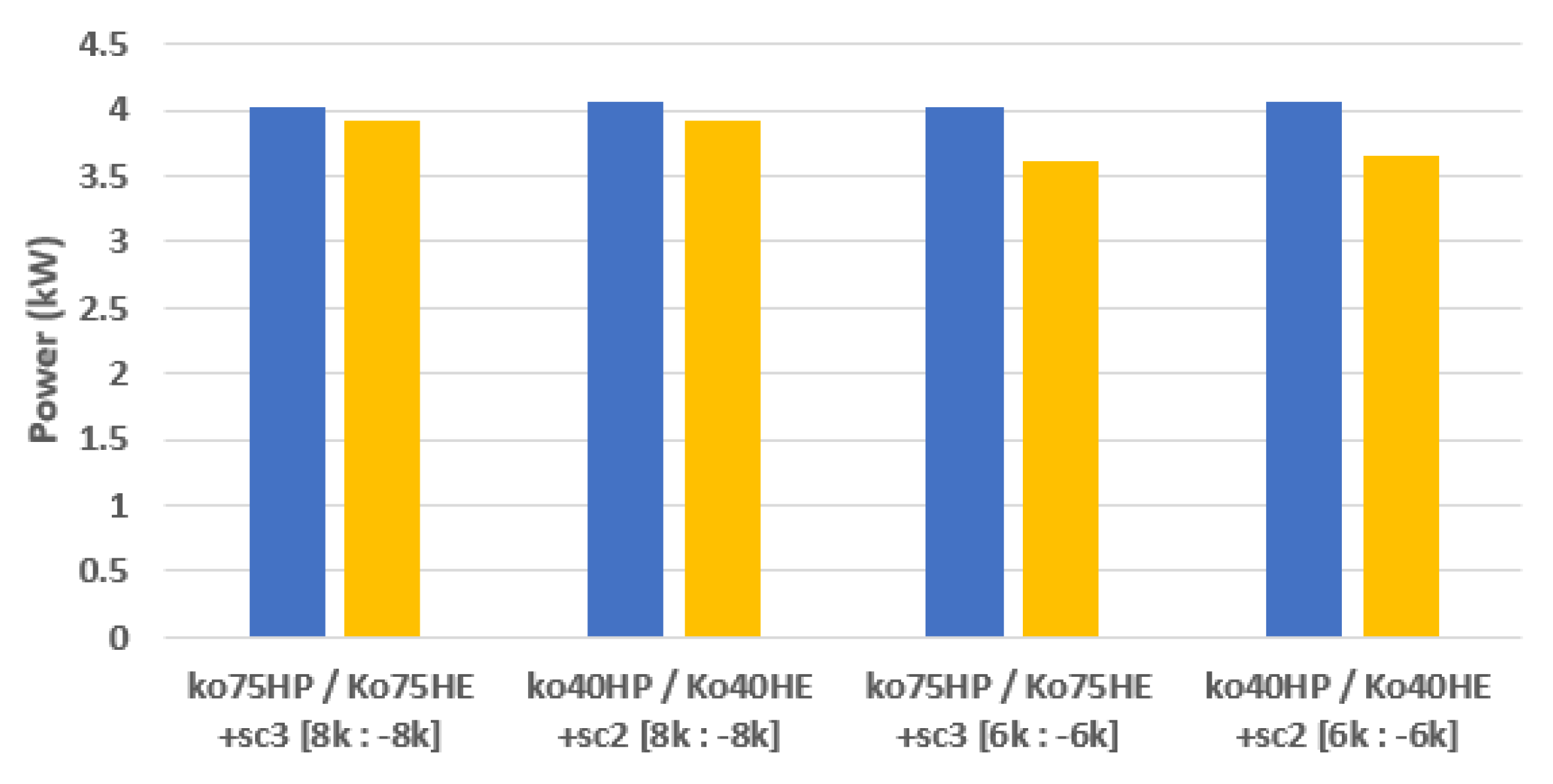

4.4. Energy Management Influence

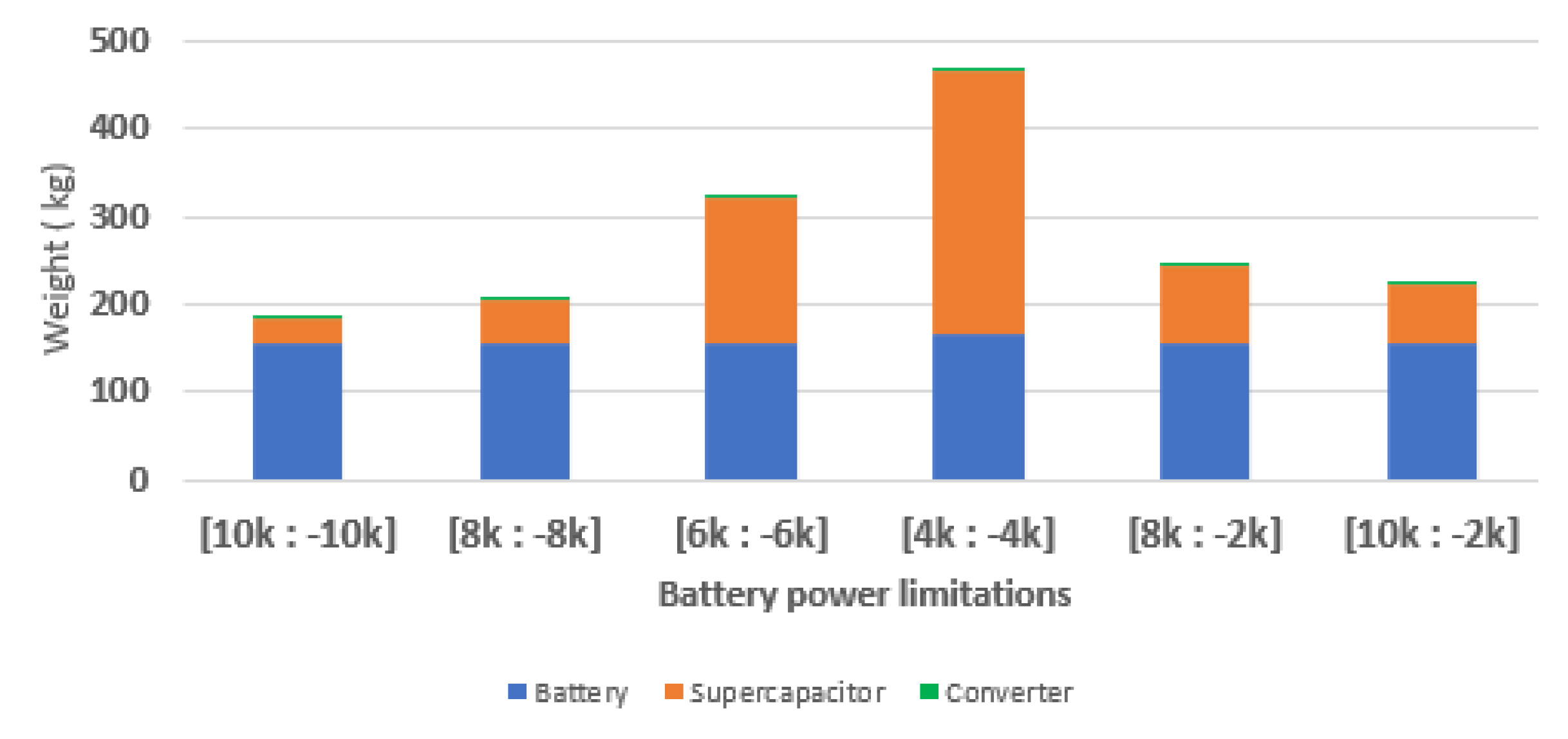

4.5. Price Constraint

4.6. Ageing Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Variable | Description |

| Resistive force due to aerodynamic | |

| Resistive force due to wheels | |

| Resistive forces due to gravity | |

| Traction force | |

| Lifting (and lowering) force due to the fork | |

| Longitudinal vehicle velocity | |

| Longitudinal fork velocity | |

| Forklift mass | |

| Load mass | |

| Power from travelling operation | |

| Power from lifting operation | |

| Bus voltage | |

| Number of battery cells in series | |

| Number of battery cells in parallel | |

| Nominal voltage of one battery cell | |

| Energy requested by the vehicle ( | |

| Energy of one battery cell | |

| Mass of one battery cell | |

| Internal resistance of the battery | |

| Depth of discharge | |

| Gradient of energy requested over mass | |

| Number of supercapacitor cells in series | |

| Number of supercapacitor cells in parallel | |

| Nominal voltage of one supercapacitor cell | |

| Mass of one supercapacitor cell | |

| Capacity of one supercapacitor cell | |

| Maximum variation of supercapacitor energy | |

| Gradient of maximum supercapacitor energy requested over mass | |

| Gradient of minimum supercapacitor energy requested over mass |

References

- Brettel, M.; Friederichsen, N.; Keller, M.; Rosenberg, M. How Virtualization, Decentralization and Network Building Change the Manufacturing Landscape: An Industry 4.0 Perspective. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2014, 8, 37–44. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Lasi, H.; Kemper, H.-G.; Fettke, P.; Thomas, F.; Hoffman, M. Industry 4.0; no. Business & Information Systems Engineering; Springer Fachmedien Wiesbad: Wiesbaden, Germany, 2014; Volume 2014. [Google Scholar]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnish, M. Industry 4.0 The Future of Productivity and Growth in Manufacturing Industries; The Boston Consulting Group: Boston, MA, USA, 2015. [Google Scholar]

- Lom, M.; Pribyl, O.; Svitek, M. Industry 4.0 as a part of smart cities. In Proceedings of the 2016 Smart Cities Symposium Prague, SCSP 2016, Prague, Czech Republic, 26–27 May 2016. [Google Scholar]

- Cao, L.; Depner, T.; Borstell, H.; Richter, K. Discussions on sensor-based assistance systems for forklifts. In Proceedings of the Smart SysTech 2019—European Conference on Smart Objects, Systems and Technologies, Magdeburg, Germany, 4–5 June 2019; pp. 35–42. [Google Scholar]

- Mohammadi, A.; Mareels, I.; Oetomo, D. Model predictive motion control of autonomous forklift vehicles with dynamics balance constraint. In Proceedings of the 2016 14th International Conference on Control, Automation, Robotics and Vision, ICARCV 2016, Phuket, Thailand, 13–15 November 2016; Volume 2016, pp. 13–15. [Google Scholar]

- Kim, S.; Choi, S.; Lee, J.; Hong, S.; Yoon, J. A study of hybrid propulsion system on forklift trucks. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition, EVS 2014, Barcelona, Spain, 17–20 November 2013; pp. 1–8. [Google Scholar]

- Fuc, P.; Kurczewski, P.; Lewandowska, A.; Nowak, E.; Selech, J.; Ziolkowski, A. An environmental life cycle assessment of forklift operation: A well-to-wheel analysis. Int. J. Life Cycle Assess. 2016, 21, 1438–1451. [Google Scholar] [CrossRef]

- Li, J.; Lutzemberger, G.; Poli, D.; Scarpelli, C.; Piazza, T. Simulation and experimental validation of a hybrid forklift truck. In Proceedings of the 2019 AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Torino, Italy, 2–4 July 2019. [Google Scholar]

- Dezza, F.C.; Musolino, V.; Piegari, L.; Rizzo, R. Hybrid battery-supercapacitor system for full electric forklifts. IET Electr. Syst. Transp. 2019, 9, 16–23. [Google Scholar] [CrossRef]

- Lototskyy, M.V.; Tolj, I.; Parsons, A.; Smith, F.; Sita, C.; Linkov, V. Performance of electric forklift with low-temperature polymer exchange membrane fuel cell power module and metal hydride hydrogen storage extension tank. J. Power Sources 2016, 316, 239–250. [Google Scholar] [CrossRef]

- Schaltz, E.; Khaligh, A.; Rasmussen, P.O. Influence of battery/ultracapacitor energy-storage sizing on battery lifetime in a fuel cell hybrid electric vehicle. IEEE Trans. Veh. Technol. 2009, 58, 3882–3891. [Google Scholar] [CrossRef]

- Kim, T.H.; Lee, S.J.; Choi, W. Design and control of the phase shift full bridge converter for the on-board battery charger of the electric forklift. In Proceedings of the 8th International Conference of Power Electronics—ECCE Asia “Green World with Power Electronics ICPE 2011-ECCE Asia, Jeju, Korea, 30 May–3 June 2011; pp. 2709–2716. [Google Scholar]

- Khaligh, A.; Li, Z. Battery, ultracapacitor, fuel cell, and hybrid energy storage systems for electric, hybrid electric, fuel cell, and plug-in hybrid electric vehicles: State of the art. IEEE Trans. Veh. Technol. 2010, 59, 2806–2814. [Google Scholar] [CrossRef]

- Battery Reality: There’s Nothing Better Than Lithium-Ion Coming Soon—Bloomberg. Available online: https://www.bloomberg.com/news/articles/2019-04-03/battery-reality-there-s-nothing-better-than-lithium-ion-coming-soon (accessed on 15 January 2020).

- Hannan, M.A.; Member, S. State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications: Issues and Recommendations. IEEE Access 2018, 6, 19362–19378. [Google Scholar] [CrossRef]

- Amrouche, S.O.; Rekioua, D.; Rekioua, T.; Bacha, S. Overview of energy storage in renewable energy systems. Int. J. Hydrog. Energy 2016, 41, 20914–20927. [Google Scholar] [CrossRef]

- Babin, A.; Rizoug, N.; Mesbahi, T.; Boscher, D.; Hamdoun, Z. Total Cost of Ownership Improvement of Commercial Electric Vehicles Using Battery Sizing and Intelligent Charge Method. IEEE Trans. Ind. Appl. 2018, 54, 1691–1700. [Google Scholar] [CrossRef]

- Kuperman, A.; Aharon, I. Battery-ultracapacitor hybrids for pulsed current loads: A review. Renew. Sustain. Energy Rev. 2011, 15, 981–992. [Google Scholar] [CrossRef]

- Fleischhammer, M.; Waldmann, T.; Bisle, G.; Hogg, B.I.; Wohlfahrt-Mehrens, M. Interaction of cyclic ageing at high-rate and low temperatures and safety in lithium-ion batteries. J. Power Sources 2015, 274, 432–439. [Google Scholar] [CrossRef]

- Cao, J.; Emadi, A. A New Battery/Ultra-Capacitor Hybrid Energy Storage System for Electric, Hybrid and Plug-in Hybrid Electric Vehicles. In Proceedings of the 2009 IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–9 September 2009; pp. 941–946. [Google Scholar]

- Sadoun, R.; Rizoug, N.; Bartholomeus, P.; Le Moigne, P. Optimal architecture of the hybrid source (battery/supercapacitor) supplying an electric vehicle according to the required autonomy. In Proceedings of the 2013 15th Europe Conference on Power Electronics and Applications EPE 2013, Lille, France, 2–6 September 2013. [Google Scholar]

- Mesbahi, T.; Rizoug, N.; Bartholomeüs, P.; Sadoun, R.; Khenfri, F.; le Moigne, P. Optimal Energy Management for a Li-Ion Battery/Supercapacitor Hybrid Energy Storage System Based on a Particle Swarm Optimization Incorporating Nelder Mead Simplex Approach. IEEE Trans. Intell. Veh. 2017, 2, 99–110. [Google Scholar] [CrossRef]

- Herrera, V.; Milo, A.; Gaztañaga, H.; Etxeberria-otadui, I.; Villarreal, I. Adaptive energy management strategy and optimal sizing applied on a battery-supercapacitor based tramway. Appl. Energy 2016, 169, 831–845. [Google Scholar] [CrossRef]

- Joshi, M.C.; Samanta, S.; Srungavarapu, G. Frequency Sharing Based Control of Battery/Ultracapacitor Hybrid Energy System in the Presence of Delay. IEEE Trans. Veh. Technol. 2019, 68, 10571–10584. [Google Scholar] [CrossRef]

- Khalid, M. A Review on the Selected Applications of Battery-Supercapacitor Hybrid Energy Storage Systems for Microgrids. Energies 2019, 12, 4559. [Google Scholar] [CrossRef]

- Douglas, H.; Pillay, P. Sizing ultracapacitors for hybrid electric vehicles. In Proceedings of the IECON Proc. (Industrial Electronics Conference 2005), Raleigh, NC, USA, 6–10 November 2005; Volume 2005, pp. 1599–1604. [Google Scholar]

- Vadlamudi, S.D.V.R.; Kumtepeli, V.; Ozcira, S.; Tripathi, A. Hybrid energy storage power allocation and motor control for electric forklifts. In Proceedings of the 2016 Asian Conference Energy, Power and Transportation Electrification (ACEPT) 2016, Singapore, 25–27 October 2016; pp. 1–5. [Google Scholar]

- Ostadi, A.; Kazerani, M. A Comparative Analysis of Optimal Sizing of Battery-Only, Ultracapacitor-Only, and Battery-Ultracapacitor Hybrid Energy Storage Systems for a City Bus. IEEE Trans. Veh. Technol. 2015, 64, 4449–4460. [Google Scholar] [CrossRef]

- Meyer, R.T.; Decarlo, R.A.; Pekarek, S. Hybrid model predictive power management of a battery-supercapacitor electric vehicle. Asian J. Control 2016, 18, 150–165. [Google Scholar] [CrossRef]

- Stroe, D.; Swierczynski, M. Accelerated Aging of Lithium-Ion Batteries based on Electric Vehicle Mission Profile. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 5631–5637. [Google Scholar]

- Feroldi, D.; Zumoffen, D. Sizing methodology for hybrid systems based on multiple renewable power sources integrated to the energy management strategy. Int. J. Hydrog. Energy 2014, 39, 8609–8620. [Google Scholar] [CrossRef]

- Araújo, R.E.; de Castro, R.; Pinto, C.; Melo, P.; Freitas, D. Combined sizing and energy management in EVs with batteries and supercapacitors. IEEE Trans. Veh. Technol. 2014, 63, 3062–3076. [Google Scholar] [CrossRef]

- Sampietro, J.L.; Puig, V.; Costa-Castelló, R. Optimal Sizing of Storage Elements for a Vehicle Based on Fuel Cells, Supercapacitors, and Batteries. Energies 2019, 12, 925. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Z.; Li, F.; An, X.; Lin, F. Optimization of Energy Management Strategy and Sizing in Hybrid Storage System for Tram. Energies 2018, 11, 752. [Google Scholar] [CrossRef]

- Paul, T.; Mesbahi, T.; Durand, S.; Flieller, D.; Uhring, W. Study and Influence of Standardized Driving Cycles on the Sizing of Li-Ion Battery/Supercapacitor Hybrid Energy Storage. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Dearborn, MI, USA, 7–9 September 2019; pp. 1–6. [Google Scholar]

- Hammani, A.; Sadoun, R.; Rizoug, N.; Bartholomeüs, P.; Barbedette, B.; le Moigne, P. Influence of the management strategies on the sizing of hybrid supply composed with battery and supercapacitor. In Proceedings of the 2012 1st International Conference on Renewable Energies and Vehicular Technology (REVET 2012), Nabeul, Tunisia, 26–28 March 2012; pp. 1–7. [Google Scholar]

- Sadoun, R.; Rizoug, N.; Bartholumeüs, P.; Barbedette, B.; Lemoigne, P. Sizing of hybrid supply (battery-supercapacitor) for electric vehicle taking into account the weight of the additional Buck-Boost chopper. In Proceedings of the 2012 1st International Conference on Renewable Energies and Vehicular Technology (REVET 2012), Nabeul, Tunisia, 26–28 March 2012; pp. 8–14. [Google Scholar]

- Mahayadin, A.R.; Ibrahim, I. Development of Driving Cycle Construction Methodology in Malaysia’s Urban Road System. In Proceedings of the 2018 International Conference Computational Approach in Smart Systems Design and Applications (ICASSDA), Kuching, Malaysia, 15–17 August 2018; pp. 1–5. [Google Scholar]

- Hosseinzadeh, E.; Rokni, M.; Advani, S.G.; Prasad, A.K. Performance simulation and analysis of a fuel cell/battery hybrid forklift truck. Int. J. Hydrog. Energy 2013, 38, 4241–4249. [Google Scholar] [CrossRef]

- Omar, N.; Monem, M.A.; Firouz, Y.; Salminen, J.; Smekens, J.; Hegazy, O.; Gaulous, H.; Mulder, G.; Bossche, P.V.D.; Coosemans, T.; et al. Lithium iron phosphate based battery—Assessment of the aging parameters and development of cycle life model. Appl. Energy 2014, 113, 1575–1585. [Google Scholar] [CrossRef]

- Sadoun, R.; Rizoug, N.; Bartholomeüs, P.; Barbedette, B.; le Moigne, P. Optimal sizing of hybrid supply for electric vehicle using Li-ion battery and supercapacitor. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, VPPC 2011, Chicago, IL, USA, 5–8 September 2011. [Google Scholar]

- Song, Z.; Hofmann, H.; Li, J.; Hou, J.; Han, X.; Ouyang, M. Energy management strategies comparison for electric vehicles with hybrid energy storage system. Appl. Energy 2014, 134, 321–331. [Google Scholar] [CrossRef]

- Zheng, C.; Li, W.; Liang, Q. An Energy Management Strategy of Hybrid Energy Storage Systems for Electric Vehicle Applications. IEEE Trans. Sustain. Energy 2018, 9, 1880–1888. [Google Scholar] [CrossRef]

- Castaings, A.; Lhomme, W.; Trigui, R.; Bouscayrol, A. Comparison of energy management strategies of a battery/supercapacitors system for electric vehicle under real-time constraints. Appl. Energy 2016, 163, 190–200. [Google Scholar] [CrossRef]

- Wirasingha, S.G.; Emadi, A. Classification and review of control strategies for plug-in hybrid electric vehicles. IEEE Trans. Veh. Technol. 2011, 60, 111–122. [Google Scholar] [CrossRef]

- Sun, L.; Feng, K.; Chapman, C.; Zhang, N. An adaptive power-split strategy for battery-supercapacitor powertrain-design, simulation, and experiment. IEEE Trans. Power Electron. 2017, 32, 9364–9375. [Google Scholar] [CrossRef]

- Long, B.; Lim, S.T.; Bai, Z.F.; Ryu, J.H.; Chong, K.T. Energy Management and Control of Electric Vehicles, Using Hybrid Power Source in Regenerative Braking Operation. Energies 2014, 7, 4300–4315. [Google Scholar] [CrossRef]

- Paul, T.; Mesbahi, T.; Durand, S.; Flieller, D.; Uhring, W. Smart Energy management of Li-ion battery/Supercapacitor Hybrid Energy Storage System for Electric Vehicle Application. In Proceedings of the PCIM EUROPE, Nuremberg, Germany, 7–9 May 2019; pp. 7–9. [Google Scholar]

- Mesbahi, T.; Khenfri, F.; Rizoug, N.; Bartholome, P.; le Moigne, P. Combined Optimal Sizing and Control of Li-Ion Battery/Supercapacitor Embedded Power Supply Using Hybrid Particle Swarm—Nelder—Mead Algorithm. IEEE Trans. Sustain. Energy 2017, 8, 59–73. [Google Scholar] [CrossRef]

- González, A.; Goikolea, E.; Barrena, J.A.; Mysyk, R. Review on supercapacitors: Technologies and materials. Renew. Sustain. Energy Rev. 2016, 58, 1189–1206. [Google Scholar] [CrossRef]

- Rizoug, N.; Sadoun, R.; Mesbahi, T.; Bartholumeus, P.; Lemoigne, P. Aging of high power Li-ion cells during real use of electric vehicles. IET Electr. Syst. Transp. 2017, 7, 14–22. [Google Scholar] [CrossRef]

- A Behind the Scenes Take on Lithium-ion Battery Prices. BloombergNEF. Available online: https://about.bnef.com/blog/behind-scenes-take-lithium-ion-battery-prices/ (accessed on 17 January 2020).

- Lead-Acid Batteries Are on a Path to Extinction. Available online: https://www.forbes.com/sites/rrapier/2019/10/13/lead-acid-batteries-are-on-a-path-to-extinction/ (accessed on 17 January 2020).

- Rajani, S.V.; Pandya, V.J. Ultracapacitor-battery hybrid energy storage for pulsed, cyclic and intermittent loads. In Proceedings of the 2016 IEEE 6th International Conference on Power Systems ICPS 2016, New Delhi, India, 4–6 March 2016; pp. 1–6. [Google Scholar]

- Li, W.; Joós, G. A power electronic interface for a battery supercapacitor hybrid energy storage system for wind applications. In Proceedings of the PESC Rec.—IEEE Annual Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008; pp. 1762–1768. [Google Scholar]

| Variable | Description | Value | SI |

|---|---|---|---|

| Drag coefficient | 0.9 | / | |

| Forklift front surface | 1.676 | ||

| Air density | 1.25 | ||

| Static rolling resistance coefficient | 1.6 × | ||

| Dynamic rolling resistance coefficient | 0.008 | / | |

| Forklift weight without battery and load | 2110 | ||

| 70% of maximal load weight | 700 | ||

| Gravity | 9.81 | ||

| Angle of inclination | 0 | ||

| / | Travelling speed with/without load | 12/12.5 | |

| / | Load lifting speed with/without | 0.28/0.5 | |

| / | Load lowering speed with/without | 0.58/0.6 |

| Variable | Description | Value |

|---|---|---|

| Maximal induction | 0.4 T | |

| J | Current density | |

| Winding ratio | 0.4 | |

| Proportionality AeSb/weight | ||

| Proportionality weight/volume | ||

| d | Duty cycle | 0.5 |

| F | Converter frequency | 15 kHz |

| Isc ripple tolerance | 10% |

| VDI Cycle (1 h) | VDI Cycle (5 h) | VDI Cycle (7 h) | VDI Cycle (10 h) | VDI Cycle (12 h) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nsb | Npb | Ah | Nsb | Npb | Ah | Nsb | Npb | Ah | Nsb | Npb | Ah | Nsb | Npb | Ah | |

| Ko75HP | 7 | 2 | 150 | 7 | 6 | 450 | 7 | 8 | 600 | 7 | 12 | 900 | 7 | 14 | 1050 |

| Ko75HE | 7 | 10 | 750 | 7 | 10 | 750 | 7 | 10 | 750 | 7 | 12 | 900 | 7 | 14 | 1050 |

| Ko40HE | 7 | 13 | 520 | 7 | 13 | 520 | 7 | 15 | 600 | 7 | 21 | 840 | 7 | 26 | 1040 |

| Ko40HP | 7 | 4 | 160 | 7 | 11 | 440 | 7 | 15 | 600 | 7 | 22 | 880 | 7 | 26 | 1040 |

| EB45AH | 8 | 24 | 1080 | 8 | 24 | 1080 | 8 | 24 | 1080 | 8 | 24 | 1080 | 8 | 24 | 1080 |

| LFP040AHA | 8 | 5 | 200 | 8 | 11 | 640 | 8 | 16 | 640 | 8 | 23 | 920 | 8 | 29 | 1160 |

| VDI Cycle (7 h) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Battery | Supercapacitor | Converter | ||||||||

| Nsb | Npb | Ah | kWh | Vol | Ns_sc | Np_sc | kWh | Vol | Vol | |

| Ko75HE/sc1 | 7 | 8 | 600 | 15.5 | 65.7 | 9 | 57 | 0.1 | 38 | 0.18 |

| Ko75HE/sc2 | 7 | 8 | 600 | 15.5 | 65.7 | 9 | 44 | 0.1 | 33.8 | 0.18 |

| Ko75HE/sc3 | 7 | 8 | 600 | 15.5 | 65.7 | 8 | 5 | 0.1 | 27.7 | 0.18 |

| Ko40HE/sc1 | 7 | 15 | 600 | 15.5 | 64.8 | 9 | 58 | 0.1 | 3.87 | 0.19 |

| Ko40HE/sc2 | 7 | 15 | 600 | 15.5 | 64.8 | 9 | 45 | 0.1 | 34.6 | 0.19 |

| Ko40HE/sc3 | 7 | 15 | 600 | 15.5 | 64.8 | 8 | 5 | 0.1 | 27.7 | 0.18 |

| EB45AH/sc1 | 8 | 14 | 630 | 16.1 | 92.5 | 9 | 64 | 0.1 | 42.7 | 0.19 |

| EB45AH/sc2 | 8 | 14 | 630 | 16.1 | 92.5 | 9 | 50 | 0.1 | 38.5 | 0.19 |

| EB45AH/sc3 | 8 | 14 | 630 | 16.1 | 92.5 | 8 | 5 | 0.1 | 27.7 | 0.18 |

| EB45AH/BCAP0350—VDI Cycle (7 h) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Battery | Supercapacitor | Converter | ||||||||

| Nsb | Npb | Ah | kWh | Vol | Ns_sc | Np_sc | kWh | Vol | Vol | |

| [10 k:−10 k] | 8 | 14 | 630 | 16.13 | 92.49 | 9 | 34 | 0.069 | 22.7 | 0.1 |

| [8 k:−8 k] | 8 | 14 | 630 | 16.13 | 92.49 | 9 | 64 | 0.13 | 42.73 | 0.19 |

| [6 k:−6 k] | 8 | 14 | 630 | 16.13 | 92.49 | 9 | 209 | 0.425 | 139.5 | 0.36 |

| [4 k:−4 k] | 8 | 14 | 675 | 17.28 | 99.1 | 9 | 376 | 0.764 | 251.1 | 0.53 |

| [8 k:−2 k] | 8 | 14 | 630 | 16.13 | 92.49 | 9 | 113 | 0.23 | 75.46 | 0.25 |

| [10 k: −2 k] | 8 | 14 | 630 | 16.13 | 92.19 | 9 | 83 | 0.169 | 55.42 | 0.15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul, T.; Mesbahi, T.; Durand, S.; Flieller, D.; Uhring, W. Sizing of Lithium-Ion Battery/Supercapacitor Hybrid Energy Storage System for Forklift Vehicle. Energies 2020, 13, 4518. https://doi.org/10.3390/en13174518

Paul T, Mesbahi T, Durand S, Flieller D, Uhring W. Sizing of Lithium-Ion Battery/Supercapacitor Hybrid Energy Storage System for Forklift Vehicle. Energies. 2020; 13(17):4518. https://doi.org/10.3390/en13174518

Chicago/Turabian StylePaul, Théophile, Tedjani Mesbahi, Sylvain Durand, Damien Flieller, and Wilfried Uhring. 2020. "Sizing of Lithium-Ion Battery/Supercapacitor Hybrid Energy Storage System for Forklift Vehicle" Energies 13, no. 17: 4518. https://doi.org/10.3390/en13174518

APA StylePaul, T., Mesbahi, T., Durand, S., Flieller, D., & Uhring, W. (2020). Sizing of Lithium-Ion Battery/Supercapacitor Hybrid Energy Storage System for Forklift Vehicle. Energies, 13(17), 4518. https://doi.org/10.3390/en13174518