Biorefinery of the Olive Tree—Production of Sugars from Enzymatic Hydrolysis of Olive Stone Pretreated by Alkaline Extrusion

Abstract

1. Introduction

2. Materials and Methods

2.1. Biomass

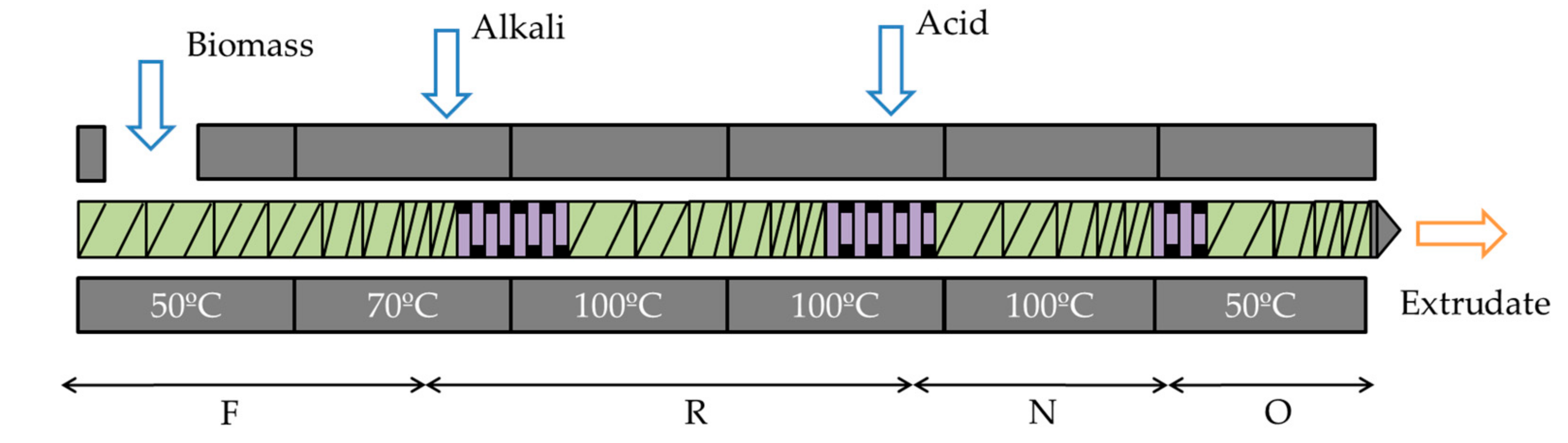

2.2. Alkaline Extrusion

2.3. Material Characterization

2.4. Enzymatic Hydrolysis

2.5. Analytical Methods

2.6. Statistical Analysis

3. Results and Discussion

3.1. Characterization of OS Biomass

3.2. Alkaline Extrusion Pretreatment of OS Biomass

3.2.1. Extrusion Configuration and Performance

3.2.2. Characterization of Extrudates and Liquid Fractions

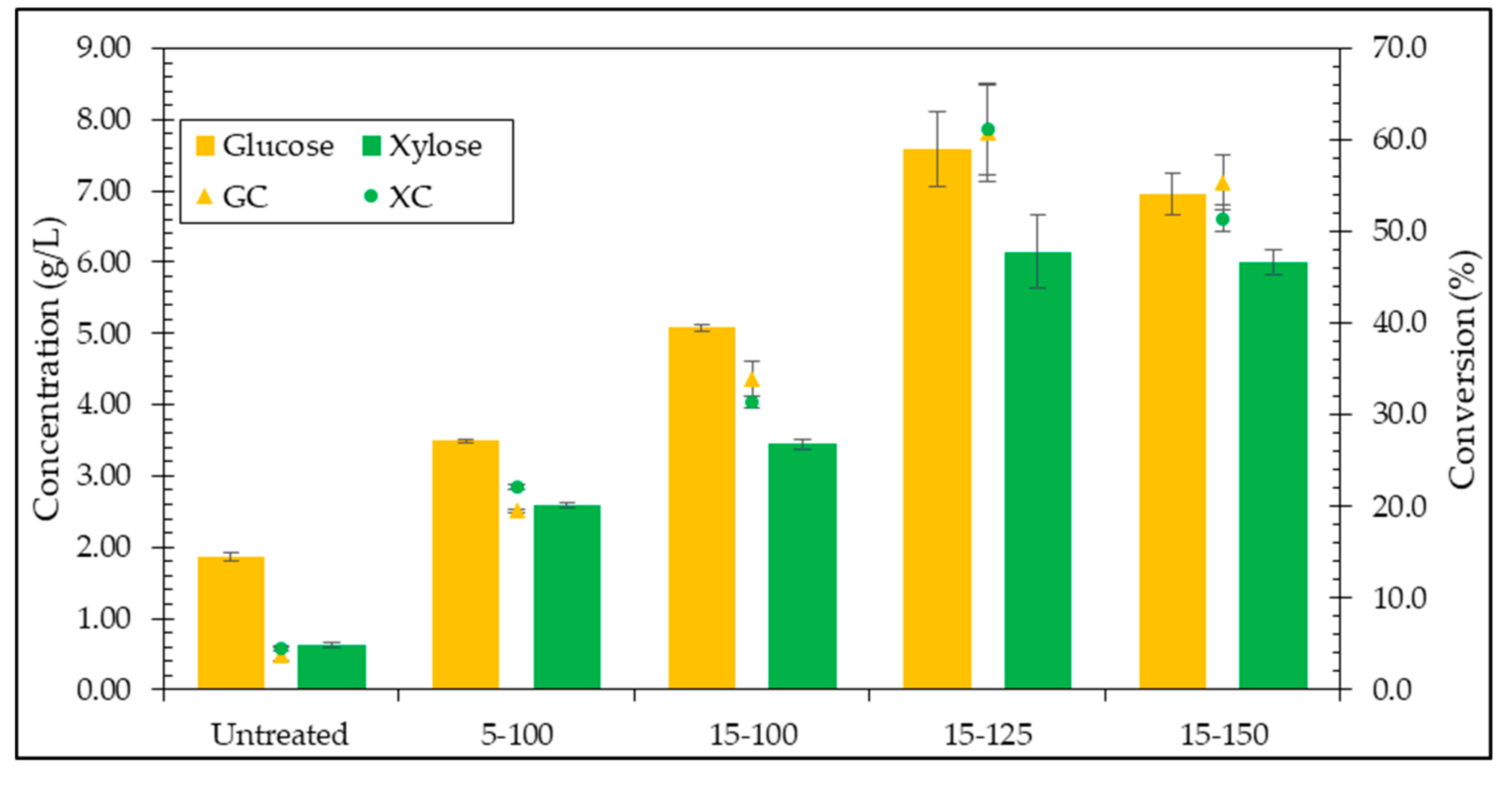

3.3. Evaluation of the Enzymatic Digestibility of the Extrudates

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment; Publications Office of the European Union: Luxembourg, 2018; ISBN 9789279941450. [Google Scholar]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef]

- Manzanares, P.; Ruiz, E.; Ballesteros, M.; Negro, M.J.; Gallego, F.J.; López-Linares, J.C.; Castro, E. Residual biomass potential in olive tree cultivation and olive oil industry in Spain: Valorization proposal in a biorefinery context. Span. J. Agric. Res. 2017, 15, 1–12. [Google Scholar] [CrossRef]

- Romero-García, J.M.; Niño, L.; Martínez-Patiño, C.; Álvarez, C.; Castro, E.; Negro, M.J. Biorefinery based on olive biomass. State of the art and future trends. Bioresour. Technol. 2014, 159, 421–432. [Google Scholar] [CrossRef] [PubMed]

- Solarte-Toro, J.C.; Romero-García, J.M.; Susmozas, A.; Ruiz, E.; Castro, E.; Cardona-Alzate, C.A. Techno-economic feasibility of bioethanol production via biorefinery of olive tree prunings (OTP): Optimization of the pretreatment stage. Holzforschung 2019, 73, 3–13. [Google Scholar] [CrossRef]

- Negro, M.J.; Alvarez, C.; Ballesteros, I.; Romero, I.; Ballesteros, M.; Castro, E.; Manzanares, P.; Moya, M.; Oliva, J.M. Ethanol production from glucose and xylose obtained from steam exploded water-extracted olive tree pruning using phosphoric acid as catalyst. Bioresour. Technol. 2014, 153, 101–107. [Google Scholar] [CrossRef]

- Gullón, B.; Gullón, P.; Eibes, G.; Cara, C.; De Torres, A.; López-Linares, J.C.; Ruiz, E.; Castro, E. Valorisation of olive agro-industrial by-products as a source of bioactive compounds. Sci. Total Environ. 2018, 645, 533–542. [Google Scholar] [CrossRef]

- Manzanares, P.; Ballesteros, I.; Negro, M.J.; González, A.; Oliva, J.M.; Ballesteros, M. Processing of extracted olive oil pomace residue by hydrothermal or dilute acid pretreatment and enzymatic hydrolysis in a biorefinery context. Renew. Energy 2020, 145, 1235–1245. [Google Scholar] [CrossRef]

- Romero-García, J.M.; Lama-Muñoz, A.; Rodríguez-Gutiérrez, G.; Moya, M.; Ruiz, E.; Fernández-Bolaños, J.; Castro, E. Obtaining sugars and natural antioxidants from olive leaves by steam-explosion. Food Chem. 2016, 210, 457–465. [Google Scholar] [CrossRef]

- Zhang, Y.; Oates, L.G.; Serate, J.; Xie, D.; Pohlmann, E.; Bukhman, Y.V.; Karlen, S.D.; Young, M.K.; Higbee, A.; Eilert, D.; et al. Diverse lignocellulosic feedstocks can achieve high field-scale ethanol yields while providing flexibility for the biorefinery and landscape-level environmental benefits. GCB Bioenergy 2018, 10, 825–840. [Google Scholar] [CrossRef]

- Ruiz, E.; Romero-García, J.M.; Romero, I.; Manzanares, P.; Negro, M.J.; Castro, E. Olive-derived biomass as a source of energy and chemicals. Biofuels Bioprod. Biorefining 2017, 11, 1077–1094. [Google Scholar] [CrossRef]

- Spanish Ministry of Agriculture Fisheries and Food. Superficies y Producciones Anuales de Cultivo de Acuerdo con el Reglamento (CE) 543/2009. Available online: https://www.mapa.gob.es/es/estadistica/temas/estadisticas-agrarias/agricultura/superficies-producciones-anuales-cultivos/ (accessed on 5 May 2020).

- Álvarez, A.; Pizarro, C.; García, R.; Bueno, J.L. Spanish biofuels heating value estimation based on structural analysis. Ind. Crops Prod. 2015, 77, 983–991. [Google Scholar] [CrossRef]

- Baruah, J.; Nath, B.K.; Sharma, R.; Kumar, S.; Deka, R.C.; Baruah, D.C.; Kalita, E. Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front. Energy Res. 2018, 6, 1–19. [Google Scholar] [CrossRef]

- Martínez-Patiño, J.C.; Ruiz, E.; Romero, I.; Cara, C.; López-Linares, J.C.; Castro, E. Combined acid/alkaline-peroxide pretreatment of olive tree biomass for bioethanol production. Bioresour. Technol. 2017, 239, 326–335. [Google Scholar] [CrossRef] [PubMed]

- Ballesteros, I.; Ballesteros, M.; Cara, C.; Sáez, F.; Castro, E.; Manzanares, P.; Negro, M.J.; Oliva, J.M. Effect of water extraction on sugars recovery from steam exploded olive tree pruning. Bioresour. Technol. 2011, 102, 6611–6616. [Google Scholar] [CrossRef] [PubMed]

- Duque, A.; Manzanares, P.; Ballesteros, I.; Negro, M.J.; Oliva, J.M.; Saez, F.; Ballesteros, M. Optimization of integrated alkaline-extrusion pretreatment of barley straw for sugar production by enzymatic hydrolysis. Process Biochem. 2013, 48, 775–781. [Google Scholar] [CrossRef]

- Duque, A.; Manzanares, P.; Ballesteros, M. Extrusion as a pretreatment for lignocellulosic biomass: Fundamentals and applications. Renew. Energy 2017, 114, 1427–1441. [Google Scholar] [CrossRef]

- Zheng, J.; Rehmann, L. Extrusion pretreatment of lignocellulosic biomass: A review. Int. J. Mol. Sci. 2014, 15, 18967–18984. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K. Thermo-Mechanical Pretreatment of Feedstocks. In Green Biomass Pretreatment for Biofuels Production; Gu, T., Ed.; Springer: Netherlands, 2013; pp. 31–65. ISBN 978-94-007-6051-6. [Google Scholar]

- Oliva, J.M.; Negro, M.J.; Manzanares, P.; Ballesteros, I.; Chamorro, M.Á.; Sáez, F.; Ballesteros, M.; Moreno, A.D. A sequential steam explosion and reactive extrusion pretreatment for lignocellulosic biomass conversion within a fermentation-based biorefinery perspective. Fermentation 2017, 3, 15. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K.; Gibbons, W.R. Sequential extrusion-microwave pretreatment of switchgrass and big bluestem. Bioresour. Technol. 2014, 153, 393–398. [Google Scholar] [CrossRef]

- Choi-Il, W.; Oh, K.K.; Park, J.Y.; Lee, J.S. Continuous sodium hydroxide-catalyzed pretreatment of empty fruit bunches (EFB) by continuous twin-screw-driven reactor (CTSR). J. Chem. Technol. Biotechnol. 2014, 89, 290–296. [Google Scholar] [CrossRef]

- Zhang, S.; Keshwani, D.R.; Xu, Y.; Hanna, M.A. Alkali combined extrusion pretreatment of corn stover to enhance enzyme saccharification. Ind. Crops Prod. 2012, 37, 352–357. [Google Scholar] [CrossRef]

- Vandenbossche, V.; Doumeng, C.; Rigal, L. Thermomechanical and Thermo-mechano-chemical Pretreatment of Wheat Straw using a Twin-screw Extruder. BioResources 2014, 9, 1519–1538. [Google Scholar] [CrossRef]

- Duque, A.; Manzanares, P.; Ballesteros, I.; Negro, M.J.; Oliva, J.M.; González, A.; Ballesteros, M. Sugar production from barley straw biomass pretreated by combined alkali and enzymatic extrusion. Bioresour. Technol. 2014, 158, 262–268. [Google Scholar] [CrossRef] [PubMed]

- Duque, A.; Manzanares, P.; González, A.; Ballesteros, M. Study of the Application of Alkaline Extrusion to the Pretreatment of Eucalyptus Biomass as First Step in a Bioethanol Production Process. Energies 2018, 11, 2961. [Google Scholar] [CrossRef]

- Negro, M.J.; Duque, A.; Manzanares, P.; Sáez, F.; Oliva, J.M.; Ballesteros, I.; Ballesteros, M. Alkaline twin-screw extrusion fractionation of olive-tree pruning biomass. Ind. Crops Prod. 2015, 74, 336–341. [Google Scholar] [CrossRef]

- Duque, A.; Manzanares, P.; Ballesteros, I.; Negro, M.J.; Oliva, J.M.; Saez, F.; Ballesteros, M. Study of process configuration and catalyst concentration in integrated alkaline extrusion of barley straw for bioethanol production. Fuel 2014, 134, 448–454. [Google Scholar] [CrossRef]

- Sluiter, J.B.; Ruiz, R.O.; Scarlata, C.J.; Sluiter, A.D.; Templeton, D.W. Compositional analysis of lignocellulosic feedstocks. 1. Review and description of methods. J. Agric. Food Chem. 2010, 58, 9043–9053. [Google Scholar] [CrossRef]

- Tayyab, M.; Noman, A.; Islam, W.; Waheed, S.; Arafat, Y.; Ali, F.; Zaynab, M.; Lin, S.; Zhang, H.; Lin, W. Bioethanol production from lignocellulosic biomass by environment-friendly pretreatment methods: A review. Appl. Ecol. Environ. Res. 2018, 16, 225–249. [Google Scholar] [CrossRef]

- Çetinkol, Ö.P.; Smith-Moritz, A.M.; Cheng, G.; Lao, J.; George, A.; Hong, K.; Henry, R.; Simmons, B.A.; Heazlewood, J.L.; Holmes, B.M. Structural and Chemical Characterization of Hardwood from Tree Species with Applications as Bioenergy Feedstocks. PLoS ONE 2012, 7. [Google Scholar] [CrossRef]

- Castro, E.; Conde, E.; Moure, A.; Falqué, E.; Cara, C.; Ruiz, E.; Domínguez, H. Antioxidant activity of liquors from steam explosion of Olea europea wood. Wood Sci. Technol. 2008, 42, 579–592. [Google Scholar] [CrossRef]

- Berbel, J.; Posadillo, A. Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 2018, 10, 237. [Google Scholar] [CrossRef]

- Xu, H.; Li, B.; Mu, X. Review of Alkali-Based Pretreatment to Enhance Enzymatic Saccharification for Lignocellulosic Biomass Conversion. Ind. Eng. Chem. Res. 2016, 55, 8691–8705. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Saleh, M.; Cuevas, M.; García, J.F.; Sánchez, S. Valorization of olive stones for xylitol and ethanol production from dilute acid pretreatment via enzymatic hydrolysis and fermentation by Pachysolen tannophilus. Biochem. Eng. J. 2014, 90, 286–293. [Google Scholar] [CrossRef]

- Cuevas, M.; Sánchez, S.; García, J.F.; Baeza, J.; Parra, C.; Freer, J. Enhanced ethanol production by simultaneous saccharification and fermentation of pretreated olive stones. Renew. Energy 2015, 74, 839–847. [Google Scholar] [CrossRef]

- Cuevas, M.; Saleh, M.; García-Martín, J.F.; Sánchez, S. Acid and enzymatic fractionation of olive stones for ethanol production using Pachysolen tannophilus. Processes 2020, 8, 195. [Google Scholar] [CrossRef]

- Padilla-Rascón, C.; Ruiz, E.; Romero, I.; Castro, E.; Oliva, J.M.; Ballesteros, I.; Manzanares, P. Valorisation of olive stone by-product for sugar production using a sequential acid/steam explosion pretreatment. Ind. Crops Prod. 2020, 148, 112279. [Google Scholar] [CrossRef]

| Component | Composition (%) |

|---|---|

| Cellulose | 20.8 ± 0.2 |

| Hemicellulose | 25.9 ± 0.1 |

| Xylan | 23.4 ± 0.1 |

| Galactan | 1.2 ± 0.0 |

| Arabinan | 1.2 ± 0.0 |

| Mannan | 0.1 ± 0.0 |

| Acetyl groups | 5.9 ± 0.1 |

| Acid insoluble lignin | 33.8 ± 0.6 |

| Acid soluble lignin | 1.7 ± 0.1 |

| Ash | 0.6 ± 0.0 |

| Extractives | 6.4 ± 0.5 |

| Others | 5.0 |

| 5–100 | 15–100 | 15–125 | 15–150 | |

|---|---|---|---|---|

| Inputs | ||||

| Ss (rpm) | 150 | 120 | 150 | 150 |

| T (°C) | 100 | 100 | 125 | 150 |

| QB (kg/h) | 1.3 | 2.0 | 1.0 | 1.0 |

| QNaOH (kg/h) | 0.6 | 1.8 | 0.92 | 0.92 |

| cNaOH(% w/v) | 10 | 15 | 15 | 15 |

| RNaOH (% w/w) | 5 | 15 | 15 | 15 |

| L/S1 | 0.5 | 1 | 1 | 1 |

| QH2SO4 (kg/h) | 1.5 | 0 | 0 | 0 |

| cH2SO4(% w/v) | 5 | - | - | - |

| RH2SO4 (% w/w) | 6.2 | 0 | 0 | 0 |

| L/S2 | 1.8 | 1 | 1 | 1 |

| Outputs | ||||

| SME (Wh/kg) | 134.8 | 67.7 | 226.8 | 226.8 |

| QE (kg/h) | 1.5 | 2.2 | 1.3 | 1.1 |

| DME (%) | 56.0 | 59.0 | 83.1 | 86.5 |

| Component | 5–100 | 15–100 | 15–125 | 15–150 |

|---|---|---|---|---|

| Cellulose (%dwb) | 18.3 ± 2.8 | 18.3 ± 0.4 | 18.1 ± 0.3 | 17.8 ± 0.3 |

| Hemicellulose (%dwb) | 22.4 ± 0.4 | 21.1 ± 0.4 | 19.5 ± 1.3 | 22.4 ± 0.6 |

| Xylan (%dwb) | 20.8 ± 0.0 | 19.2 ± 0.3 | 18.9 ± 0.2 | 20.6 ± 0.5 |

| Lignin (%dwb) | 39.0 ± 0.2 | 41.9 ± 0.3 | 34.3 ± 0.2 | 36.5 ± 0.3 |

| Acetyl groups (%dwb) | 3.2 ± 0.05 | 0.6 ± 0.02 | 1.9 ± 0.02 | 2.1 ± 0.1 |

| Component | 5–100 | 15–100 | 15–125 | 15–150 |

|---|---|---|---|---|

| IS (%dwb) | n.d. 2 | 0.50 | 9.80 | 11.83 |

| Glucose (%dmi) | 0.09 | 0.03 | 0.07 | 0.10 |

| Xylose (%dmi) | 0.62 | 1.35 | 1.89 | 1.79 |

| Other 1 (%dmi) | 0.35 | 0.18 | 0.40 | 0.46 |

| Acetic acid (%dmi) | 0.20 | 1.24 | 3.39 | 4.50 |

| Experiment | Glucose Production (g/100 g Raw OS) | Xylose Production (g/100 g Raw OS) | Total Sugars (g/100 g Raw OS) |

|---|---|---|---|

| 5–100 | 7.76 ± 0.07 | 5.75 ± 0.12 | 13.51 ± 0.19 |

| 15–100 | 11.69 ± 0.16 | 7.92 ± 0.22 | 19.61 ± 0.38 |

| 15–125 | 17.43 ± 1.07 | 14.14 ± 1.62 | 31.57 ± 3.35 |

| 15–150 | 15.97 ± 0.95 | 13.80 ± 0.55 | 29.77 ± 1.50 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doménech, P.; Duque, A.; Higueras, I.; Iglesias, R.; Manzanares, P. Biorefinery of the Olive Tree—Production of Sugars from Enzymatic Hydrolysis of Olive Stone Pretreated by Alkaline Extrusion. Energies 2020, 13, 4517. https://doi.org/10.3390/en13174517

Doménech P, Duque A, Higueras I, Iglesias R, Manzanares P. Biorefinery of the Olive Tree—Production of Sugars from Enzymatic Hydrolysis of Olive Stone Pretreated by Alkaline Extrusion. Energies. 2020; 13(17):4517. https://doi.org/10.3390/en13174517

Chicago/Turabian StyleDoménech, Pablo, Aleta Duque, Isabel Higueras, Raquel Iglesias, and Paloma Manzanares. 2020. "Biorefinery of the Olive Tree—Production of Sugars from Enzymatic Hydrolysis of Olive Stone Pretreated by Alkaline Extrusion" Energies 13, no. 17: 4517. https://doi.org/10.3390/en13174517

APA StyleDoménech, P., Duque, A., Higueras, I., Iglesias, R., & Manzanares, P. (2020). Biorefinery of the Olive Tree—Production of Sugars from Enzymatic Hydrolysis of Olive Stone Pretreated by Alkaline Extrusion. Energies, 13(17), 4517. https://doi.org/10.3390/en13174517