Abstract

At most of the installations for the mechanical and biological treatment of waste operated in Poland, the 0–80 mm fraction, separated from the municipal waste stream, are completely stored after biostabilization. Such an action does not fit into the EU strategy focused on circular waste management. The purpose of this study was to assess the technical feasibility of recovering the mineral fractions contained in the compost-like-output (CLO) on a technological line designed for glass recovery. The research started in January 2019, lasted for the next 12 months, and covered 29 measurement series. The following two high-energy fractions were separated from the CLO: 10–35 mm light fraction after separation in the air separator (M-1) and 35–80 mm light fraction after separation in the air separator (M-2). The stabilization processing on the glass recovery line allowed for the recovery of two high energy fractions in the total amount of 24.5% of the processed, and it stabilized the product’s mass. In terms of materials, the M-1 and M-2 wastes were a mixture of organic, paper, and plastic materials. Under the Refuse Derived Fuel (RDF) classification, according to the European Committee for Standardization, the tested waste fell within the following classes: waste M-1: 4NCV2Cl4Hg and M-2: 4NCV1Cl4Hg.

1. Introduction

EU law on municipal waste and packaging waste explicitly requires its selective collection as the primary route to waste recycling, which aims to create a circular economic model for Europe.

The implementation of this model limits the importance of mechanical-biological waste treatment (MBT) technologies on the waste market, resulting in a decrease in the amount of mixed waste (municipal solid waste (MSW)) fed to MBT installations. However, these installations are and will be necessary for many years in order to ensure that biodegradable waste is reduced, and to supplement recycling levels in areas where the total cost of the systems and the various local implementation aspects generally give unsatisfactory results for selective collection [1,2,3,4,5,6].

MBT installations are a bridge between the current state of the solid municipal waste management (MSW) in Europe and the need to meet current needs, and the necessary intensive development of recycling. This is confirmed by the operation of approximately 570 MBT installations with a processing capacity of over 55 million tonnes in Europe at the beginning of 2017. At that time, it was planned to commission another 120 facilities with a capacity of nearly 10 million tons per year by 2025 [7].

Installations using the biostabilization process of mixed municipal waste dominated the sector. For example, in Poland at the end of 2016, there were 192 MBP installations with a capacity of about 11 million Mg of waste per year. The total throughput of methane fermentation installations did not exceed 200.000 tpy, although this method has a number of benefits compared with composting [8].

In these installations, the mechanical part separates organic waste from municipal waste, which is biologically stabilized under aerobic or anaerobic conditions. Waste treatment allows secondary raw materials to be recovered, as well as the high-calorie fraction, from which refuse derived fuels (RDF)/solid recovered fuels (SRF) type fuels are composed directly in the MBT installation or in the plant producing fuels from waste [9,10,11]. These fuels are used as an energy source in combustion or co-combustion processes. Biologically stabilized organic fraction below 80 mm, extracted from MSW called compost-like-output (CLO) in the article and ballast from sorting processes are removed to landfills [12,13].

For example, in Poland, 61% of MSW (municipal solid waste) manufactured in 2018 was directed to MBT installations. Almost half of this waste was disposed of in landfills (45.9%) [14]. In Spain, 48% of mixed waste was processed at MBT plants. The percentage of the fraction rejected in relation to the mass of waste delivered to MBT plants was 63%, of which 95% was stored and the remaining 5% went to energy recovery [15].

Generally, the production of CLO at MBT plants usually accounts for about a quarter of the mass of the input waste stream, regardless of the MSW biostabilization method used [16]. This means that in the EU, more than 15 million tonnes of CLO irretrievably goes to landfills every year.

There are no data in the professional literature on the morphological composition of CLO. Jędrczak and Den Boer [14], conducting tests in 20 installations as part of the third stage of the MBT expertise in Poland, determined that the share of limiting substances in the mass of stabilized products, expressed as ignition loss, occured at a level of 24.4 up to 38.6% DM, with an average value of 29.6 ± 4.0% dm. The organic carbon content ranged from 14.0 to 19.9% dm (average 16.0 ± 1.7).

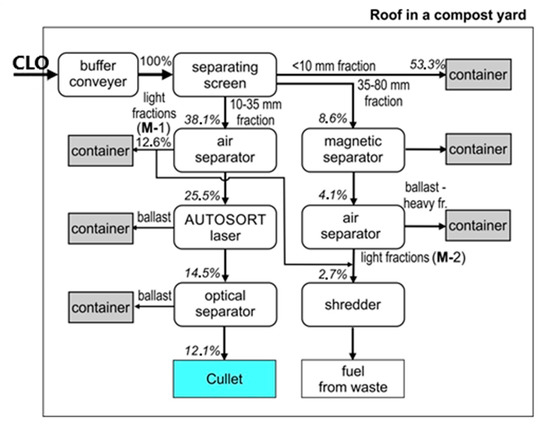

At the end of 2018 at the Waste Management Plant in Marszów in the Lubuskie voivodeship, the first installation in Poland for CLO processing was commissioned (Figure 1). Its creation was associated with attempts to extract packaging glass from the CLO product and to achieve such parameters of recovered glass that would allow for it to be sent directly for recycling [17].

Figure 1.

Technological scheme of the compost-like-output (CLO) processing line (material balance for Marszów waste).

The purpose of this study was to assess the technical feasibility of recovering combustible fractions contained in the CLO on a technological line designed for glass recovery, using processes commonly used in MBT installations. To this end, the types and amounts of high-energy fractions that could be separated from the CLO were determined, and their morphological composition, selected properties, and results of the tests of their use were examined.

Refuse derived fuels (RDF) are defined as fuels from municipal waste. The term solid recovered fuels (SRF) means, in accordance with EN-15359:2005 and PN-EN 15357:2015 standards, a solid fuel with standardized quality characteristics, not generated from hazardous waste, used as an energy source in the waste incineration or co-incineration processes. The most important types of waste used as components for the production of SRF are paper, used tires, plastic waste, wood, and textiles—the share of which in the thick fraction of MBP ranges from 45 to 70%.

SRF classification according to the European Committee for Standardization (PN-EN 15359:2015) is based on three key parameters: calorific value, chlorine content, and mercury content.

The physico-chemical properties of SRF-type fuels produced depend mainly on the type of waste from which they are made. The range of literature physico-chemical properties of SRF fuels is shown in Table 1.

Table 1.

Properties of solid recovered fuels (SRF) fuels [18].

It should be stressed that SRF fuels are legally waste. So far, the procedure for converting this waste into a product has not been developed. Directive 2008/89/EC does not, in principle, provide this possibility for waste fuels—the fuel production process is not considered a recycling process, and fuel cannot therefore be considered a product.

2. Materials and Methods

Here, the research on the content of combustible fractions in the CLO focused on two types of waste generated on the CLO processing line: light fraction after using the Zig-Zag air separator with a granulation of 10–35 mm (waste M-1), and light fraction with granulation of 35–80 mm after using the NIHOT air separator (waste M-2). The morphological composition of the MSW waste processed in the MBT Marszów installation is shown in Table 2. The morphological composition of waste from other installations cannot be reported because ZZO Marszów utilized CLO.

Table 2.

Morphological composition of waste.

The tests were carried during in the period of 15 January 2019 to 21 January 2020. A total of 29 measurement series were carried out. The CLO produced in the MBT installation in Marszów was processed in 23 series, and the CLO supplied from other MBTs located in various regions of Poland was processed in six series.

The MBT plant in Marszów processes waste from 22 municipalities, with over 200.000 collective inhabitants. A detailed description of the MBT system in Marszów are presented in the publication “Efficiency of waste processing in the MBT system” [8]. In the mechanical part of the MSW installation, after removing the terracing waste and after passing through the bag discruptor, the waste stream was separated in an 80/280 mm drum screen into three fractions. The fractions > 280 mm and 80–280 mm were subjected to treatment for the production of fuel from waste. The 0–80 mm sieve fraction was administered by biological stabilization under aerobic conditions. The process was carried out in two stages. Stage I was an intensive waste stabilization in reinforced concrete bioreactors with full automatic control of its course, for a duration of 3 weeks. Stage II was the maturation of waste in piles in the open air for a period of 10–12 weeks, using a waste shovel [8].

Detailed descriptions of the processing line of the CLO and devices used are presented in the publication “Recovery of Stabilizer Glass in Innovative MBT Installation: An Analysis of a New Technological Procedure” [17]. Waste after intensive stabilization was directed to the tests. In the last week of this stage of the process, the waste treatment parameters were set at such a level that intensive drying of the collected materials took place.

Waste supplied from other MBT plants also constituted a <80 mm fraction after the process of intensive oxygen stabilization. For these plants, the collection areas of the MSW were different, as well as the devices used and the parameters of conducting the biological stabilization process, as a result of which the characteristics of the samples tested were also different (Table 3).

Table 3.

Characteristics mass and material composition of intermediate products obtained in subsequent stages of the processing of CLO from Marszów and material entrusted from other mechanical-biological waste treatment (MBT) installations.

3. Results and Discussion

The masses of CLOs from Marszów and entrusted from other MBT installations processed on the processing line, as well as the sieve fractions and light fractions (M-1 and M-2) obtained during the process, are presented in Table 3. The table also presents the material composition of the treated CLOs and separated fractions.

The mass of the tested CLO samples from ZZO Marszów ranged from 28.4 to 154.5 tonnes and averaged 47.5 ± 26.9 tonnes. This waste was very well dried. Its humidity ranged from 6.0 to 15.5 (average 10.0 ± 2.6%). The CLO from ZZO Marszów contained 51.4 ± 6.7% fraction < 10 mm, 9.1 ± 1.7% debris and stones, and 17.4 ± 2.1% glass.

The weight of the entrusted CLO samples ranged from 10.3 to 22.0 tonnes and averaged 17.5 ± 5.0 tonnes. The humidity of the entrusted samples was more diverse and ranged from 9.6 to 32.0% (average 20.9 ± 9.6%). These CLOs contained 52.5 ± 13.3% of the fraction < 10 mm and 11.9 ± 5.8% of debris and stones. The share of glass in the entrusted material was 11.4% 4 ± 2.4% of glass, and was almost 1.5 times lower than for the waste from Marszów (17.4% 4 ± 2.1%).

Using the double-deck VARIOMAT sifter, the CLO stream was divided into three fractions of <10 mm, 10–35 mm, and >35 mm.

The fraction <10 mm constituted 50.9 ± 6.4 of the mass of CLOs from Marszów and 53.0 ± 13.5% of the entrusted CLO mass. It was a mixture of ash and sand in large quantities of organic fraction, which was dried and largely fragmented during the unloading of chambers, transport of CLO to the screen, and grain screening operations (<10 mm). The high content of ignition loss (from 27.1 to 45.8% dm, on average 36.8% dm) confirmed the high content of organic matter in this fraction. Air separation of this fraction on Trenso separation tables led to a mineral fraction of −40.7% (including fraction < v5 mm, 32.9%; stones > 5 mm, 5.2%; and glass > 5 mm, 2.6%), a light fraction of 50.6%, and a dust fraction of 8.7%.

The 10–35 mm fraction directed to the production of glass concentrate constituted 39.1 ± 5.6% of the mass of the CLOs from Marszów and 34.5 ± 6.7% of the mass of the entrusted CLOs. The basic component of this fractions was glass 42.7 ± 4.7% and 30.9 ± 7.4, respectively. In quantities greater than 10%, the fraction contained debris and stones, as well as paper. The total share of paper, plastics, and organics was 32.6 ± 4.6% and 32.2 ± 4.4%, respectively.

The fraction share > 35 mm in the mass of CLOs was small: an average of 9.2 ± 2.1% of the sample from Marszów and 12.5 ± 9.9% of the sample entrusted. The basic components of this fraction were plastics 42.7 ± 4.7% and 42.9 ± 3.5, respectively. In quantities greater than 10%, the fraction contained paper, cardboard, and rubble stones. The total share of paper, plastics, and organic matter was 69.4 ± 4.5% and 65.3 ± 5.4%.

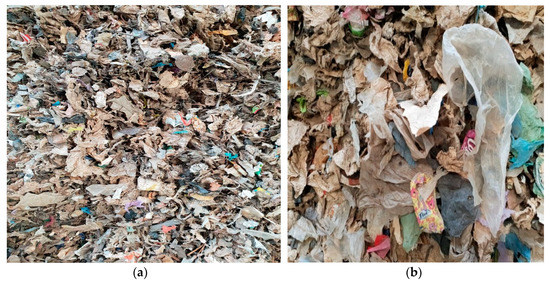

The first combustible fraction was the light fraction after the Zig-Zag separator (M-1). In the case of ZZO in Marszów, this waste constituted 12.6 ± 3.7% of the weight of the CLO. The waste was dominated by paper and cardboard (53.9 ± 19.9%). Plastic (12.9 ± 4.6%) and organics (11.7 ± 2.6%) were also found in large quantities (Figure 2). The impurities were primarily stones and debris (inert; 10.3 ± 3.1%) and glass (9.0 ± 1.2%; Table 3). This waste showed low moisture (12.2 ± 5.6%) and relatively high ignition loss (56.9 ± 8.2%; laboratory analysis). In the case of the entrusted CLOs, M-1 waste constituted 11.3 ± 4.1% of the CLO’s weight. Compared to the waste from Marszów, 2.8% less paper and cardboard and 1.1% less plastics contained in the CLO product passed into it. The organic content was the same at 11.7 ± 3.6%. The waste contained slightly more debris and stones (13.0 ± 3.4%) and glass (9.8 ± 1.3%; Table 3).

Figure 2.

High-energy fractions separated from the CLO: (a) after the Zig-Zag separator (M-1); (b) after the NIHOT (M-2) separator.

RDF separated from the 35–80 mm (M-2) fraction accounted for 6.6 ± 1.9% of the mass of processed CLO from ZZO in Marszów—30.5% of organic matter, paper, cardboard, and plastics contained in the CLO passed into it (Figure 2), and their share in waste was 95.8 ± 1.7%. This waste did not contain any glass or inert materials, but the proportion of metals was 3.2 ± 0.1 (Table 3). The waste had a moisture content of 19.1 ± 11.6% and high ignition loss of 80.9 ± 6.1% (laboratory analysis). In the case of the entrusted M-2 ballasts after the NIHOT separator, they constituted 11.9 ± 9.7% of the CLOs—35.0% of all organic matter, paper and cardboard, and plastics passed into them. The share of these components in waste was 95.7 ± 3.6%. Out of the impurities, metals were the most prominent, at 3.2 ± 0.8% (Table 3). The analyses were carried out in the factory laboratory of ZZO Marszów and periodically, for control purposes, in the Laboratory of the Institute of Environmental Engineering at University of Zielona Góra, which is accredited for taking and analyzing waste samples. Waste analyses were performed according to the standards and procedures in force in the accredited laboratory [19,20].

The work of the CLO processing line was evaluated in terms of the content and level of material recovery (η) in the product (combustible ingredients). Material recovery is the quotient of its quantity in the product in relation to its content in the input material (CLO). The results were presented and discussed for the intermediates after each device in order to show the effect of each stage of the process.

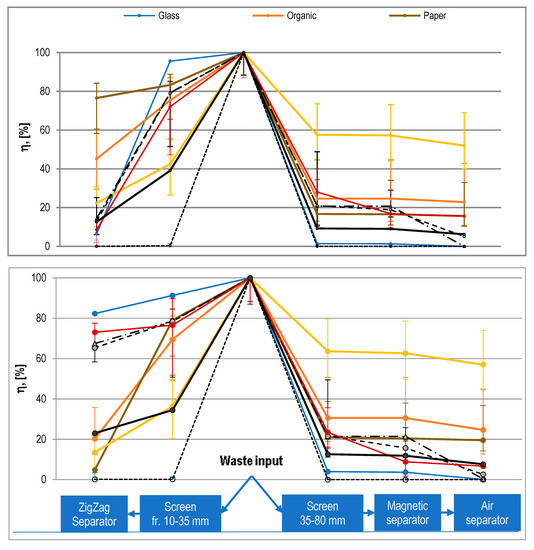

Figure 3 presents the average levels of recovery of components from CLO’s in the subsequent stages of the CLO process (A—waste from Marszów; B—entrusted waste).

Figure 3.

Recovery (η) of material components in subsequent stages of the CLO processing (average values: waste from Marszów 13 series, entrusted waste 6 series).

The Zig-Zag type air separator was quite effective in separating paper, organics, and plastics from the remaining stream of fractions, with a grain size of 10–35 mm. Paper recovery was 76.5% and 74.1% of the mass in the feed for samples from Marszów and the entrusted samples, respectively. Organisms were 45.2% and 49.2%, and plastics were 22.3% and 22.8%, respectively (Figure 3). The efficiency of paper, organic, and plastic recovery from the 10–35 mm fraction on an air separator was on average 76.1 ± 8.4% (samples from Marszów) and 80.5 ± 14.4% (entrusted samples).

The purification of the 35–80 mm fraction on an electromagnetic separator was quite efficient in the range of metals (16.8 and 8.9%) in relation to their content in the charge. The metal removal efficiency was low, at 63.0 ± 9.5% and 34.4 ± 12.8%, respectively. The M-2 waste contained practically no glass, stones, or debris. Debris occurred in one sample derived from the entrusted 2.8% CLO. Pollutants were 3.5% (Marszów) and 3.2% (entrusted CLO’s), and other components were 0.7 and 0.5%, respectively (Table 3).

In the CLO, 52.0% and 57.1% of plastics were present. After using the NIHOT air separator, 15.7% and 19.5% of paper, and 22.9% and 24.7% of organic matter were recovered in the stream.

The efficiency of paper, organic, and plastic recovery from the electromagnet fraction on the NIHOT air separator was on average 90.3 ± 1.9% (samples from Marszów) and 90.8 ± 2.0% (entrusted samples).

The CLO processing on the Marszów line allowed for the recovery of two high-energy fractions in a total of 19.2% of the processed CLO. The total recovery of three components (organic, paper, and plastics) ranged from 70.2% to 95% (average 83.4 ± 9.1%) in the case of CLOs from Marszów, and from 76.5% to 94.5% (average 85.1 ± 7.1%) in the case of entrusted CLOs.

The levels of recovery of these components on the stabilization processing line, in the cases of samples from Marszów and other MBT installations, were as follows:

- organics from 51.7% to 87.5% (on average 71.1 ± 9.2%) and from 39.3% to 94.5% (on average 73.8 ± 19.8%), respectively;

- paper from 86.8% to 98.7% (93.4 ± 4.6% on average) and 88.1% to 98.4% (93.7 ± 3.7% on average), respectively;

- plastics from 53.3% to 94.7% (on average 76.7 ± 14.7%) and from 68.1% to 87.9% (on average 79.6 ± 7.3%), respectively.

The cement and energy industries are interested in only obtaining fuels with strictly defined utility features, supplied continuously in large quantities, meeting the requirements for SRF (solid recovered fuels) [21]. The elected properties of the M-1 and M-2 waste are shown in Table 4. The moisture of the tested waste meets the expectations of the recipients (<20%). The fraction requires fragmentation to grain <30 mm; therefore, it goes to the RDF production line, which is located in the sorting hall at MBT Marszów. It is equipped with a magnetic separator, which effectively removes the metals contained in the M-2 waste. There is no technical possibility to remove glass and inert fractions from M-1 waste. However, this does not affect the deterioration of the parameters of the RDF produced. In MBT Marszów, the annual production of alternative fuel from MSW sorting residues, selectively collected waste (plastics and paper waste), is about 12,000 tonnes. Only about 10% of the mass is waste from M-1 CLO, which contains about 270 tonnes of glass and inert waste, and about 5% of the mass of RDF produced is M-2. The introduction of effective methods for cleaning M-1 and M-2 waste from non-combustible fractions will result in an improvement in the caloric value of the SRF produced.

Table 4.

Selected properties of M-1 and M-2 waste and RDF produced in MBT installation in Marszów.

Under the SRF classification, according to the European Committee for Standardization (PN-EN 15359: 2015), which is based on three key parameters (caloric value, chlorine content, and mercury content [18]), the tested waste can be assigned to the following classes:

- M-1 waste: 4NCV2Cl4Hg;

- M-2 waste: 4NCV1Cl4Hg;

- RDF: 3NCV3Cl3Hg.

4. Conclusions

The ban on landfilling in 2030 of no more than 10%, introduced by an EU Directive, and the ban on burning not more than 30% of the mass of municipal waste generated will necessitate a change in the current management of the MSW in EU member states, where it is based on MBT installations. The development of selective collection to achieve the required levels of recycling, and the reconstruction of MBT installations in packaging waste sorting plants and biowaste composting, takes time. It is possible, during this transitional period, to significantly reduce the mass of CLOs disposed of in landfills by recovering and even recycling a large proportion of the mass of the components contained therein. The research conducted on the CLOs in Marszów confirms and proves that from this type of waste, in addition to recyclable glass [17], RDF can be recovered, which can successfully be used, e.g., in cement plants.

On the CLO processing line, the following was recovered: the combustible fraction after the Zig-Zag M-1 separator and the combustible fraction M-2 after the NIHOT air separator. In the case of the CLO from ZZO Marszów, M-1 waste constituted 12.6 ± 3.7% of the mass of the CLO, and in the case of entrusted CLOs, M-1 waste constituted 11.3 ± 4.1% of the mass of the CLO. RDF separated from the 35–80 mm (M-2) fraction accounted for 6.6 ± 1.9% of the mass of the processed CLO from ZZO in Marszów. In the case of the entrusted waste, M-2 waste after the NIHOT separator accounted for 11.9 ± 9.7% of the weight of the CLO.

The processing of the CLO on the Marszów line allowed for the recovery of two high-energy fractions from the CLOs, in the total amount of 19.2% of their mass and a calorific value of 13.3 MJ/kg t.q., which is directed to the waste fuel production line. The positive effects of the experiments on a semi-commercial scale resulted in the implementation of the technology into production on a technological scale. Work is currently underway to optimize the performance of the equipment and to recover mineral materials from CLO.

Author Contributions

Conceptualization, J.P. and A.J.; methodology, A.J. and J.P.; validation, A.J.; formal analysis, J.P.; resources, J.P. and A.J.; writing (original draft preparation), J.P.; writing (review and editing), A.J.; visualization, J.P.; supervision A.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Trulli, E.; Ferronato, N.; Torretta, V.; Piscitelli, M.; Masi, S.; Mancini, I. Sustainable mechanical biological treatment of solid waste in urbanized areas with low recycling rates. Waste Manag. 2018, 71, 556–564. [Google Scholar] [CrossRef] [PubMed]

- Hornsby, K.; Benesova, L.; Zimová, M. A long-term challenge-Enabling the uptake of advanced MBT technologies in eastern european countries. J. Environ. Account. Manag. 2016, 4, 59–71. [Google Scholar] [CrossRef]

- Rada, E.C.; Ragazzi, M.; Badea, A. MSW Bio-drying: Design criteria from A 10 years research. UPB Sci. Bull. Ser. D Mech. Eng. 2012, 74, 209–216. [Google Scholar]

- Di Lonardo, M.C.; Lombardi, F.; Gavasci, R. Characterization of MBT plants input and outputs: A review. Rev. Environ. Sci. Biotechnol. 2012, 11, 353–363. [Google Scholar] [CrossRef]

- Ragazzi, M.; Rada, E.C. RDF/SRF evolution and MSW bio-drying. Wit Trans. Ecol. Environ. 2012, 163, 199–208. [Google Scholar]

- Bayard, R.; de Araújo Morais, J.; Ducom, G.; Achour, F.; Rouez, M.; Gourdon, R. Assessment of the effectiveness of an industrial unit of mechanical-biological treatment of municipal solid waste. J. Hazard. Mater. 2010, 175, 23–32. [Google Scholar] [CrossRef]

- The Market for Mechanical Biological Waste Treatment in Europe, 2nd ed.; Mai Ecoprog GmbH: Cologne, Germany, 2017; Available online: https://www.ecoprog.com/index.html (accessed on 14 October 2019).

- Połomka, J.; Jędrczak, A. Efficiency of waste processing in the MBT system. Waste Manag. 2019, 96, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Sarc, R.; Lorber, K.E.; Pomberger, R.; Rogetzer, M.; Sipple, E.M. Design, quality, and quality assurance of solid recovered fuels for the substitution of fossil feedstock in the cement industry. Waste Manag. Res. 2014, 32, 565–585. [Google Scholar] [CrossRef] [PubMed]

- Rada, E.C.; Squazardo, L.; Ionescu, G.; Badea, A. Economic viability of srf co-combustion in cement factory. UPB Sci. Bull. Ser. D Mech. Eng. 2014, 76, 199–206. [Google Scholar]

- Vesanto, P.; Hiltunen, M.; Moilanen, A.; Laine-Ylijoki, J.; Kaartinen, T.; Sipilä, K.; Wilén, C. Solid recovered fuels, quality analyses and combustion experiences. Vtt Tied. -Valt. Tek. Tutk. 2007, 2416, 3–55. [Google Scholar]

- De Araújo Morais, J.; Ducom, G.; Achour, F.; Rouez, M.; Bayard, R. Mass balance to assess the efficiency of a mechanical-biological treatment. Waste Manag. 2008, 28, 1791–1800. [Google Scholar] [CrossRef] [PubMed]

- Gug, J.; Cacciola, D.; Sobkowicz, M.J. Processing and properties of a solid energy fuel from municipal solid waste (MSW) and recycled plastics. Waste Manag. 2015, 35, 283–292. [Google Scholar] [CrossRef] [PubMed]

- Jędrczak, A.; Den Boer, E. Final Report of the 3rd Stage of the Study to Carry out Waste Tests in 20 Plants for Mechanical and Biological Waste Treatment; University of Zielona Góra: Zielona Góra, Poland, 2015. Available online: http://sdr.gdos.gov.pl/Documents/GO/Ekspertyzy/Ekspertyza%20MBP_III%20etap_%2022-06-2015%20+%20za%C5%82aczniki.pdf (accessed on 2 May 2015).

- Edo-Alcón, N.; Gallardo, A.; Colomer-Mendoza, F.J. Characterization of SRF from MBT plants: Influence of the input waste and of the processing technologies. Fuel Process. Technol. 2016, 153, 19–27. [Google Scholar] [CrossRef]

- Guinan, B.; Milton, D.; Kirkman, R.; Kristiansen, T.; O’Sullivan, D. Critical Analysis of the Potential of Mechanical Biological Treatment for Irish Waste Management (2005-WRM-MS-35); Synthesis Report; Environmental Protection Agency: Washington, DC, USA, 2015. Available online: http://erc.epa.ie/safer/iso19115/displayISO19115.jsp?isoID=98 (accessed on 14 November 2018).

- Połomka, J.; Jędrczak, A.; Myszograj, S. Recovery of Stabilizer Glass in Innovative MBT Installation—An Analysis of New Technological Procedure. Materials 2020, 13, 1356. [Google Scholar] [CrossRef] [PubMed]

- Pawłowski, P.; Bałazińska, M.; Ignasiak, K.; Robak, J. Przygotowanie odpadów komunalnych do ich energetycznego wykorzystania-paliwo typu SRF. Piece Przemysłowe Kotły 2016, 4, 20–26. [Google Scholar]

- PN-EN 14346: 2011. Characterization of Waste-Calculation of Dry Matter by Determination of Dry Residue or Water Content, Characterization of Waste-Determination of Loss on Ignition in Waste, Sludge and Sediment; PKN: Warsaw, Poland, 2011.

- PN-Z-15006: 1993. Material Analysis of a Sample of Mixed Municipal Waste Sent to a Mechanical-Biological Processing Installation; PKN: Warsaw, Poland, 1993.

- Wasilewski, R. Conditions for the Use of Waste Fuels in the Power and Heating Plants. Logistyka Odzysku 2017, 3, 51–56. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).