A Comparative Economic Feasibility Study of Photovoltaic Heat Pump Systems for Industrial Space Heating and Cooling

Abstract

1. Introduction

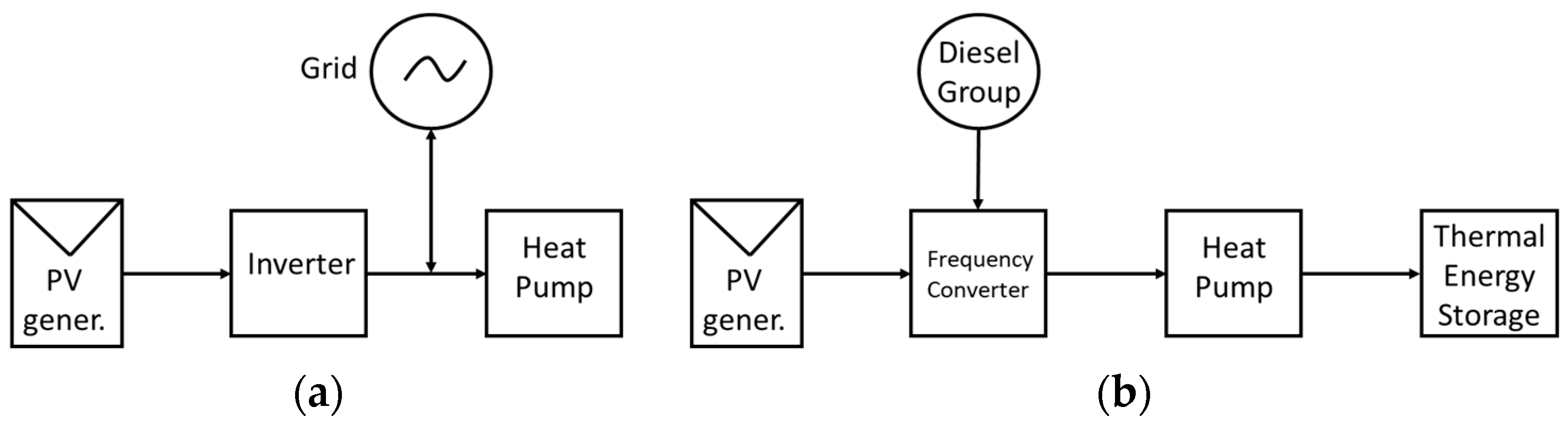

- The profitability of the Initial Investment Cost (IIC) required to install a PV system, as well as the water tank for the AU solution (the diesel generator is assumed to be pre-existent, as they are usually installed in this type of installation for back-up purposes). This profitability is quantified by the Profitability Index (PI), the Internal Rate of Return (IRR) and the Payback Period (PBP).

- The savings in terms of the Levelized Cost of Energy (LCOE) throughout the lifetime of the system (typically 25 years for PV systems), comparing the two PV-HP solutions (SC and AU) to the Only Grid-Powered system only.

2. Nomenclature

| AM | Amortization Cost |

| AU | Autonomous |

| CF | Cash Flow |

| DFC | Diesel Fuel Cost [€] |

| eff | Efficiency of the heat exchanger of the Thermal Storage System [-] |

| Enight | Daily nightly consumption of the Heat Pump system [Wh] |

| Eth | Thermal energy stored in the Thermal Storage System [Wh] |

| EC | Energy Cost [€/Wh] |

| EES | Electricity Energy Storage |

| EP | Electricity Production [Wh] |

| GEC | Grid Expansion Cost [€/W] |

| HP | Heat Pump |

| i | Interest rate [%] |

| IIC | Initial Investment Cost [€] |

| IRR | Internal Rate of Return [%] |

| LCOE | Levelized Cost of Energy [€/Wh] |

| NOCT | Nominal Operating Cell Temperature [°C] |

| OGP | Only grid powered |

| OM | Operation and Maintenance Cost [€] |

| PBP | Payback Period [years] |

| PC | Power Cost [€] |

| PI | Profitability Index [€/€] |

| PO | Poultry farm |

| PV | Photovoltaic |

| RA | Rabbit farm |

| RC | Replacement Cost [€] |

| S | Savings [€] |

| SC | Self-Consumption |

| SPF | Seasonal Performance Factor [Wh/Wh] |

| St | Static PV structure |

| SuC | PV surplus cost [€] |

| t | Corporate tax rate [%] |

| te | Tax rate on electricity costs [%] |

| TES | Thermal Energy Storage |

| Tr | Tracking PV structure |

3. Materials and Methods

3.1. System Sizing

3.2. Economic Viability Analysis

3.3. Levelized Cost of Energy (LCOE)

4. Results and Discussion

4.1. System Sizing and Energy Yield

4.2. Economic Viability Analysis

4.3. Levelized Cost of Energy (LCOE)

4.4. General Discussion

5. Sensitivity Analysis

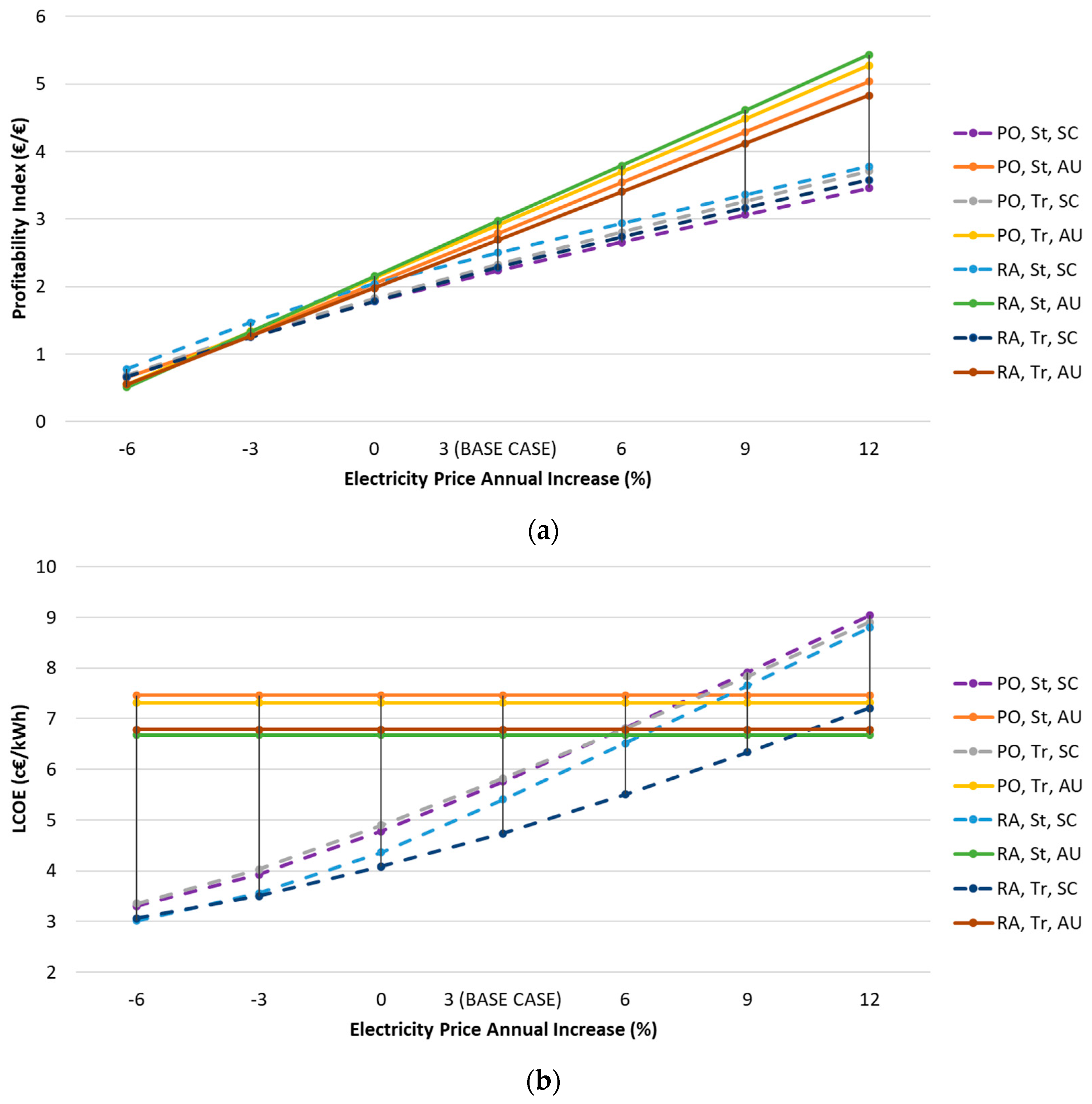

5.1. Annual Variation of Electricity Costs (PC and EC)

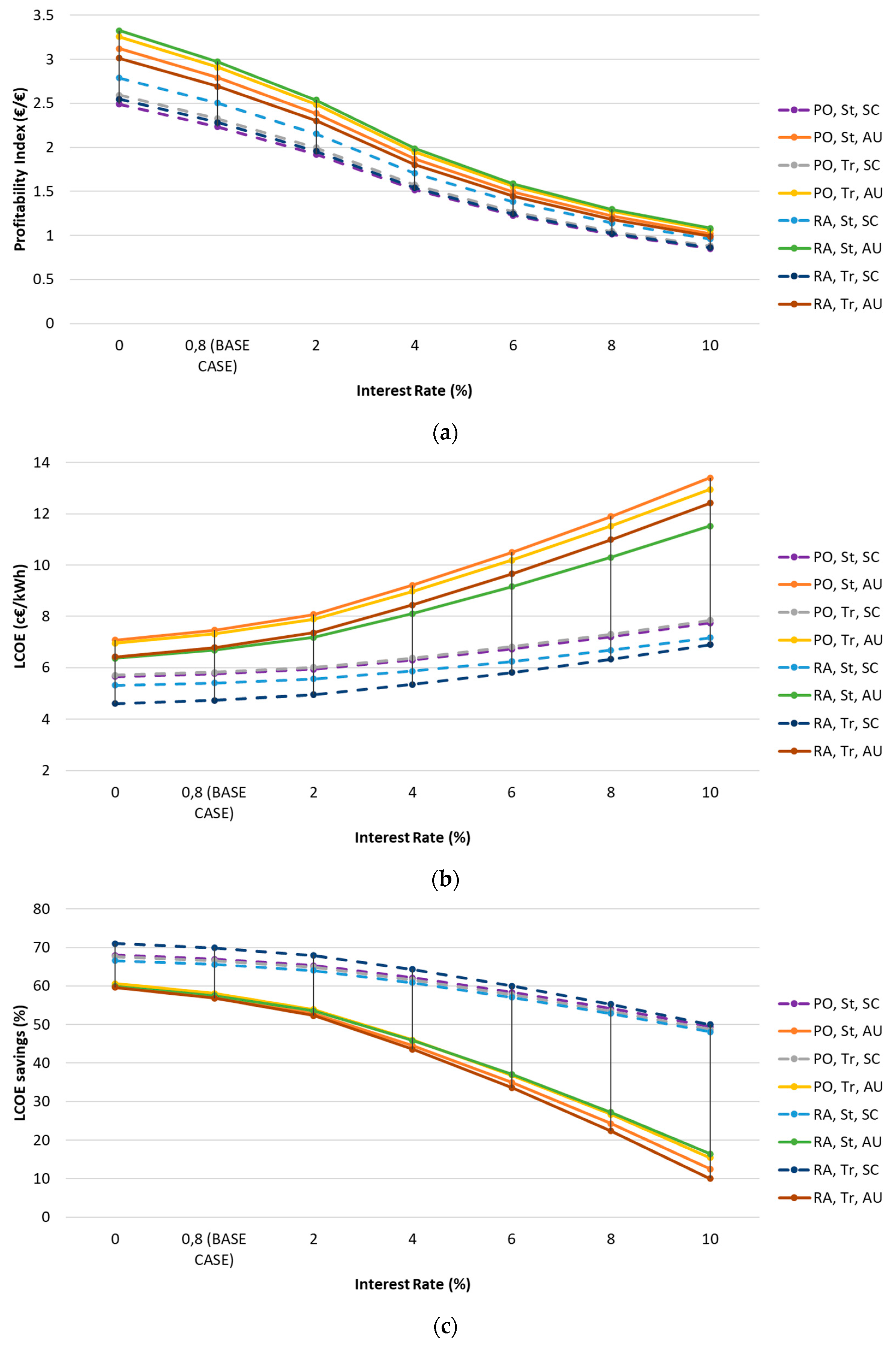

5.2. Interest Rate (i)

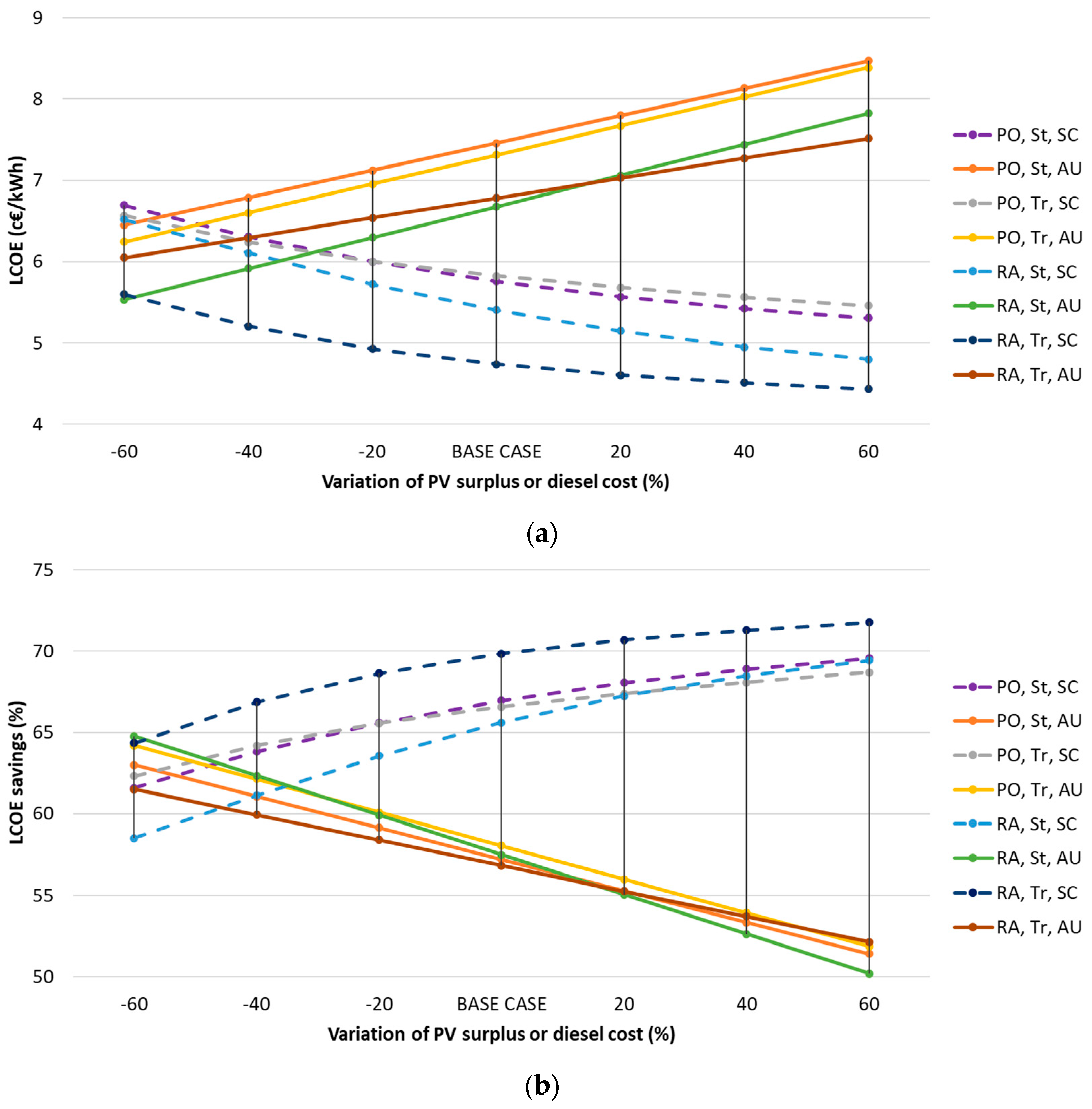

5.3. PV Surplus and Diesel Costs (SuC and DFC)

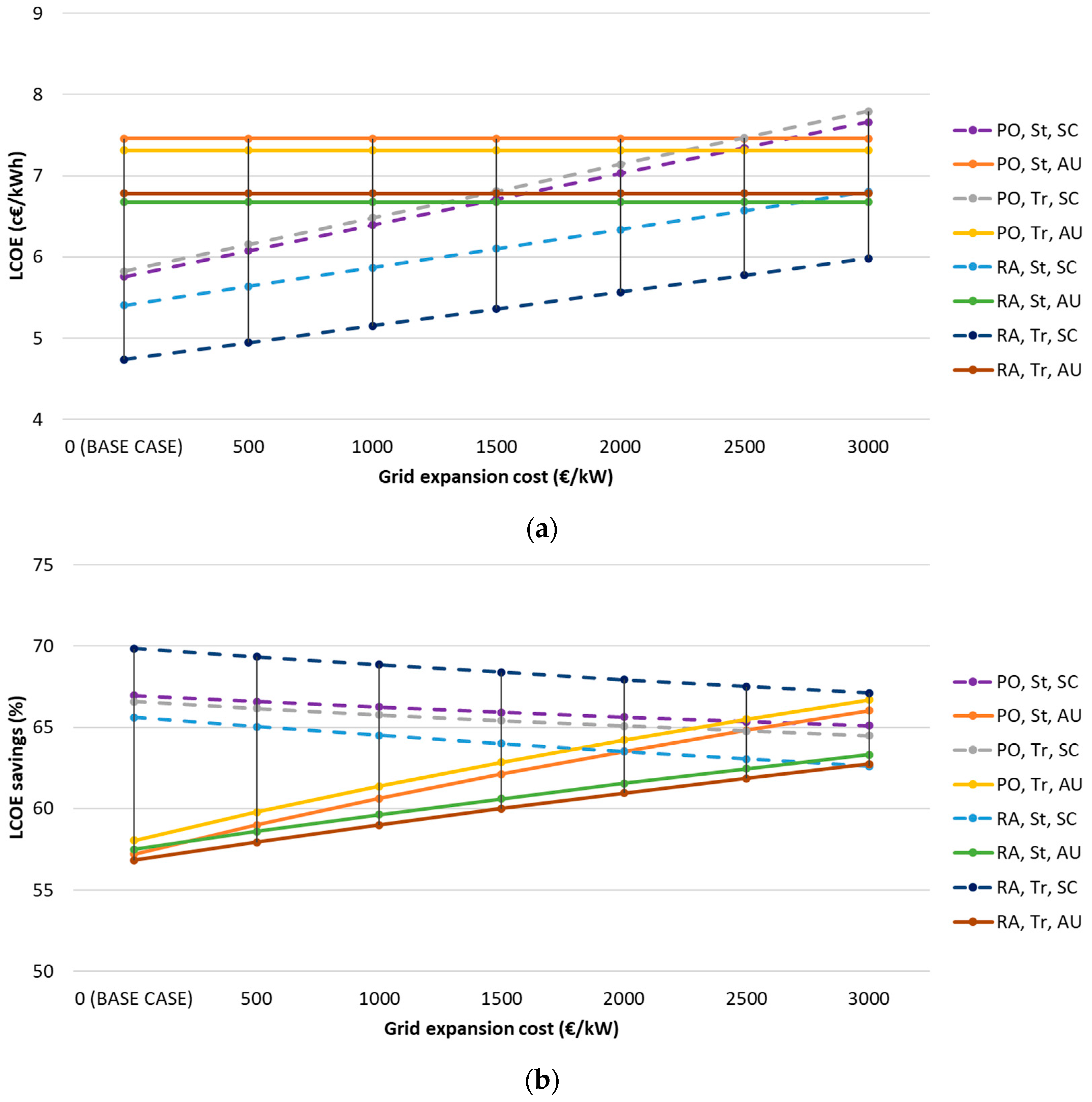

5.4. Grid Expansion Costs (GEC)

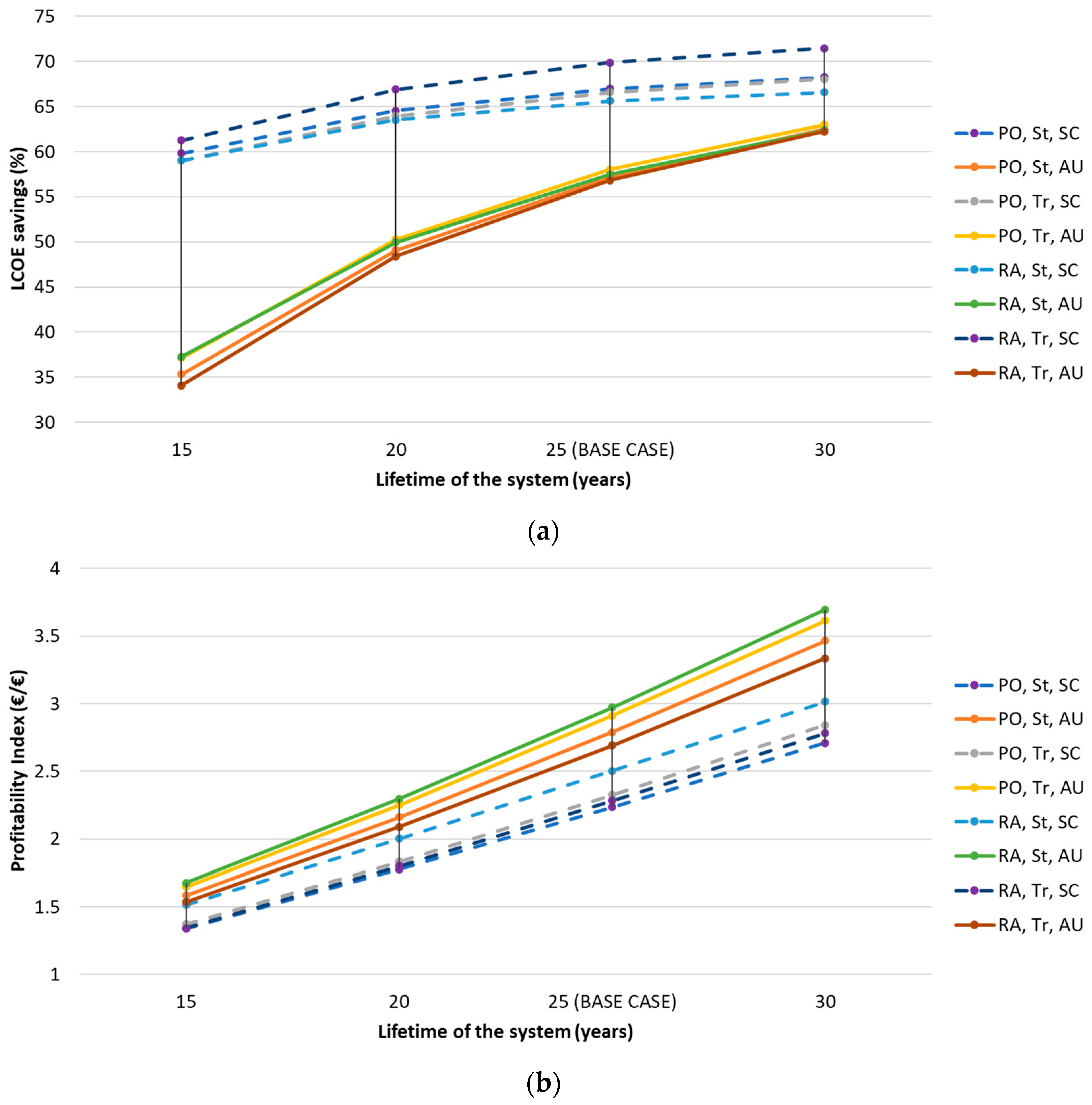

5.5. Lifetime of the System

6. Conclusions

- SC solutions achieve bigger PV energy yields than AU solutions, because the PV surplus can be sold to the grid even when there is no consumption. Tracking structures obtain higher PV productions than static ones, hence requiring smaller PV systems for covering a certain demand.

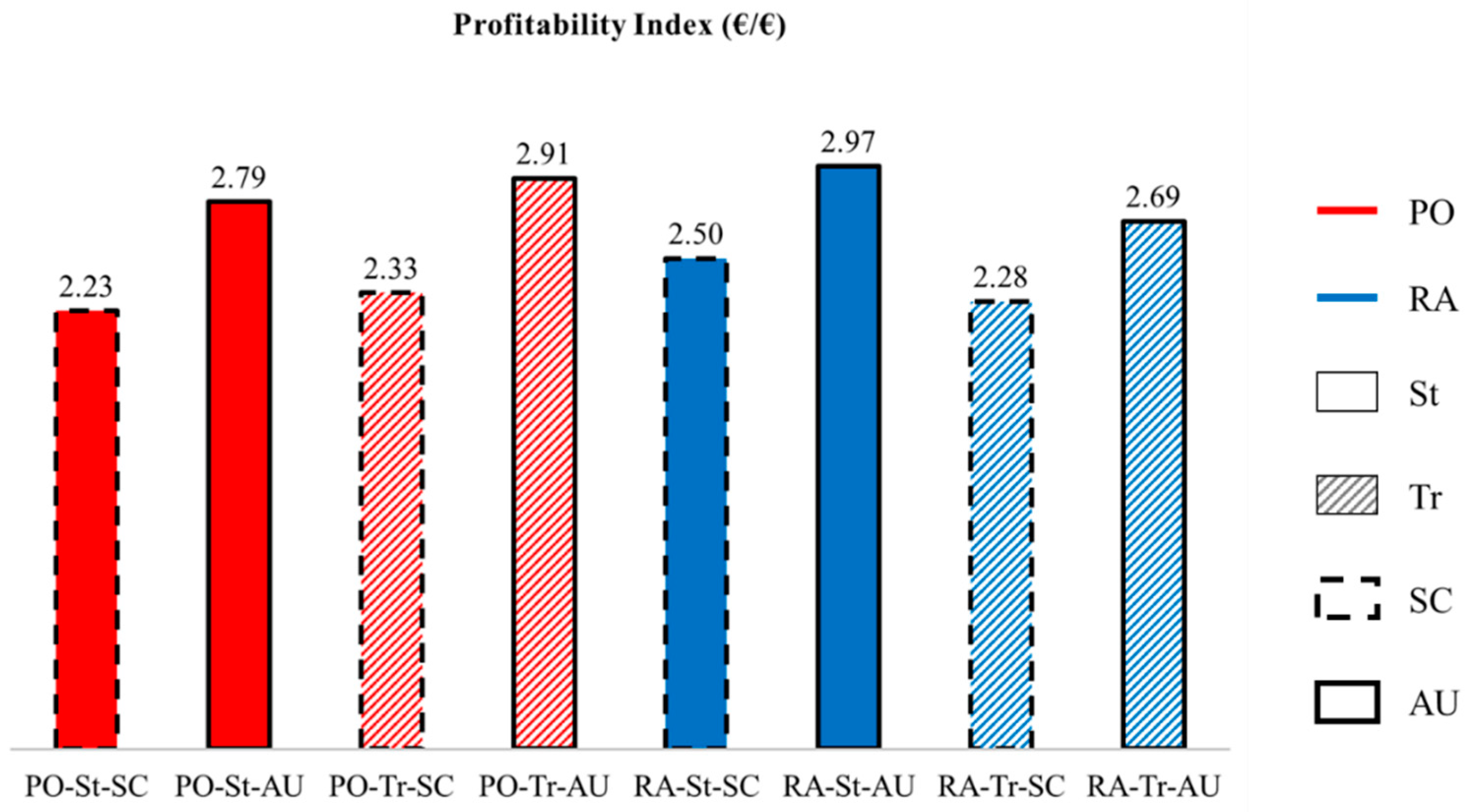

- The PI values obtained are all positive and in the 2.23–2.97 €/€ range, all bigger than 1. AU solutions offer higher PIs than SC solutions (because they imply big savings in electricity costs).

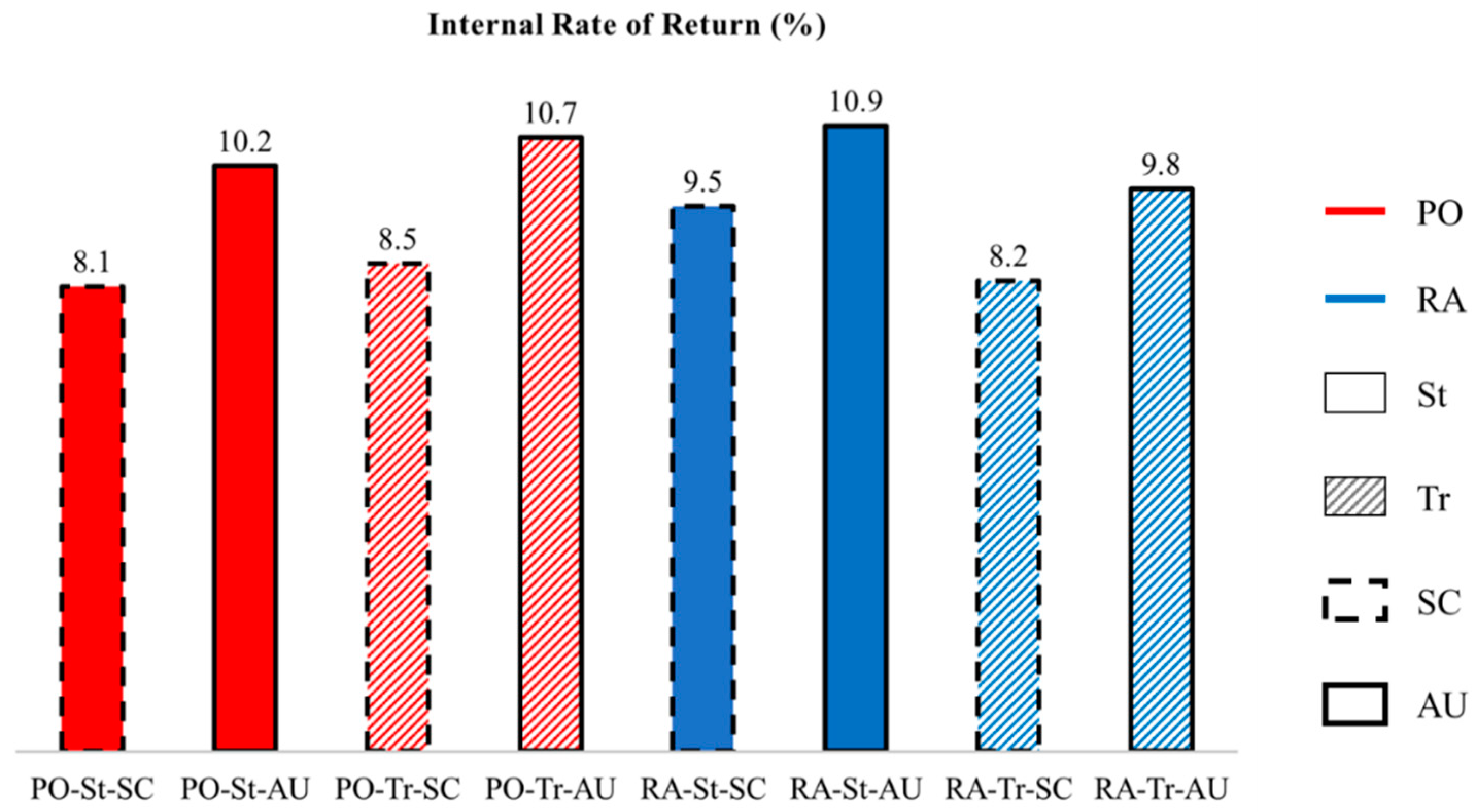

- The IRR values are in the 8.1–10.9% range, all higher than the interest rate (0.8%). AU solutions offer better profitability in term of IRR than SC solutions.

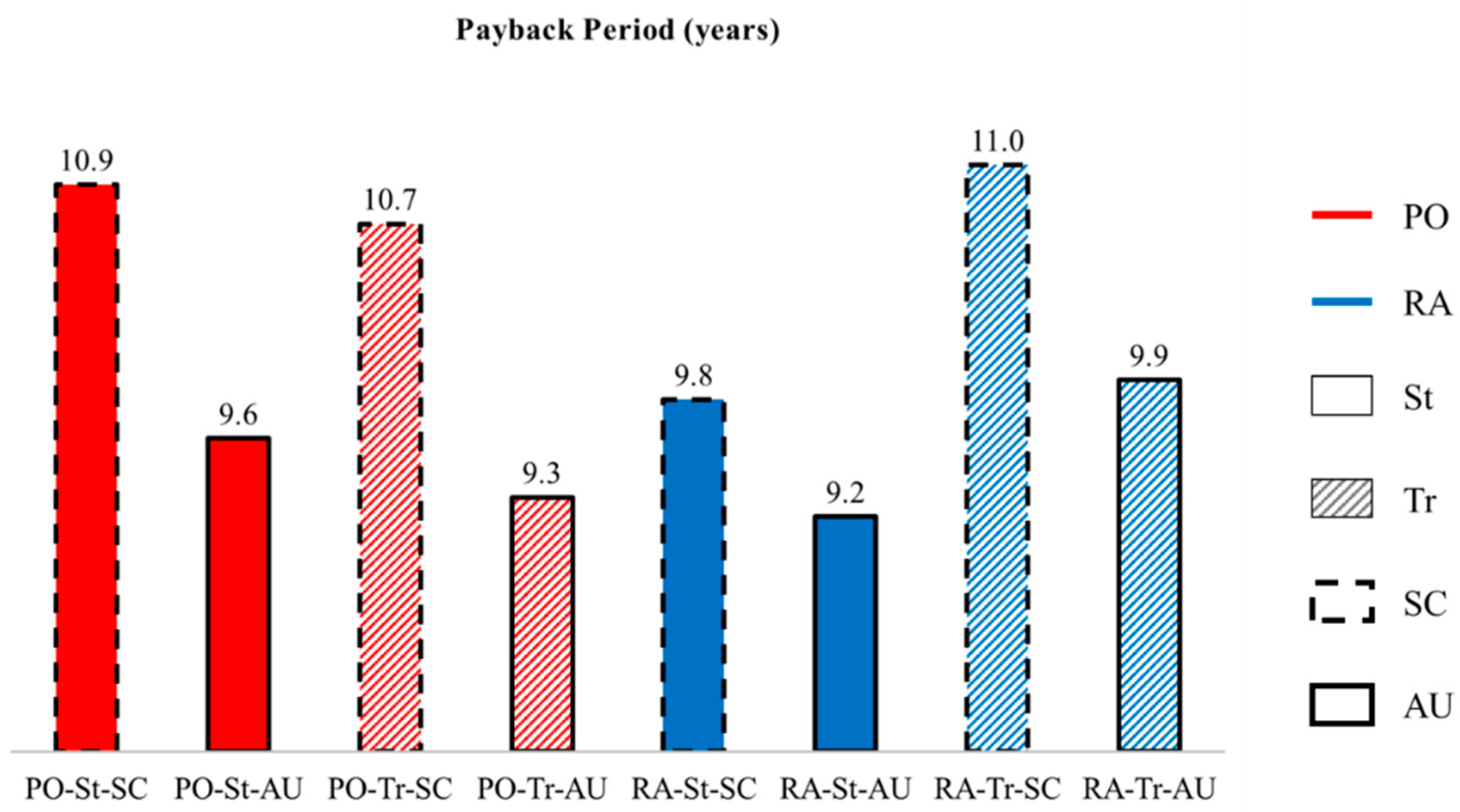

- The PBP values are in the 9.2–11 years range, all less than half the lifetime of the PV system (25 years). The bigger the IRR, the lower the PBP, so AU solutions permit to recover the economic investment sooner than the SC solutions.

- The LCOE values are in the 4.74–7.46 c€/kWh range, representing LCOE savings compared to the Only Grid-Powered system between 57% and 70%. Lower LCOEs (or higher LCOE savings) correspond to the SC solutions because of their higher energy yields.

- The PI, IRR and PBP express the economic profitability of a project and are the relevant selection criteria for an investor. The most significant factor for determining which solution is better are the economic savings in the electricity bill. The LCOE, on the other hand, expresses the energetic profitability of a project, helping to determine which option generates the maximum energy at the minimum cost. The most relevant factor in this case is the annual electricity production.

- The results are significantly sensitive to: the annual variation of electricity prices (the installation of a PV-HP system would be profitable unless these prices decreased by more than −3% annually, which is unlikely), the interest rate (PV-HP systems would be profitable unless it was more than 10%), the PV surplus cost -in the case of SC solutions- or the diesel cost -in the case of the AU solutions- (if both decreased by more than −60%, LCOEAU could be lower than LCOESC), the grid expansion cost (if it was more than 2500 €/kW, LCOEAU could be lower than LCOESC) and the lifetime of the system (although even for a lifetime of 15 years, PV-HP systems would still be profitable and generate LCOE savings of more than 30%).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lorenzo, C.; Narvarte, L. Performance indicators of photovoltaic heat-pumps. Heliyon 2019, 5, e02691. [Google Scholar] [CrossRef] [PubMed]

- European Heat Pump Association. European Heat Pump Online Assoaciation Stats Tool. Available online: http://www.stats.ehpa.org/hp_sales/story_sales (accessed on 6 April 2020).

- European Heat Pump Association. The European Heat Pump Market and Statistics Report 2019—Executive Summary. 2019. Available online: https://www.ehpa.org/fileadmin/red/07._Market_Data/2019/2019_Executive_Summary.pdf (accessed on 2 June 2020).

- Photovoltaics Report; Fraunhofer Institute for Solar Energy Systems: Freiburg, Germany, 2019.

- Lorenzo, C.; Narvarte, L.; Almeida, R.H.; Cristóbal, A.B. Technical evaluation of a stand-alone photovoltaic heat pump system without batteries for cooling applications. Sol. Energy 2020, 206, 92–105. [Google Scholar] [CrossRef]

- Aguilar, F.J.; Aledo, S.; Quiles, P.V. Experimental analysis of an air conditioner powered by photovoltaic energy and supported by the grid. Appl. Therm. Eng. 2017, 123, 486–497. [Google Scholar] [CrossRef]

- Romaní, J.; Belusko, M.; Alemu, A.; Cabeza, L.F.; de Gracia, A.; Bruno, F. Control concepts of a radiant wall working as thermal energy storage for peak load shifting of a heat pump coupled to a PV array. Renew. Energy 2018, 118, 489–501. [Google Scholar] [CrossRef]

- Opoku, R.; Mensah-Darkwa, K.; Muntaka, A.S. Techno-economic analysis of a hybrid solar PV-grid powered air-conditioner for daytime office use in hot humid climates–A case study in Kumasi city, Ghana. Sol. Energy 2018, 165, 65–74. [Google Scholar] [CrossRef]

- Aguilar, F.; Crespí-Llorens, D.; Quiles, P.V. Techno-economic analysis of an air conditioning heat pump powered by photovoltaic panels and the grid. Sol. Energy 2019, 180, 169–179. [Google Scholar] [CrossRef]

- Roselli, C.; Sasso, M.; Tariello, F. Dynamic Simulation of a Solar Electric Driven Heat Pump for an Office Building Located in Southern Italy. Int. J. Heat Technol. 2016, 34, S496–S504. [Google Scholar] [CrossRef]

- Gantenbein, L.O.P.; Notter, D.; Snegirjovs, A. Combined PV solar compression cooling and free cooling system. In Proceedings of the 32nd European Photovoltaic Solar Energy Conference and Exhibition, Munich, Germany, 20–24 June 2016. [Google Scholar]

- Li, Y.; Zhao, B.Y.; Zhao, Z.G.; Taylor, R.A.; Wang, R.Z. Performance study of a grid-connected photovoltaic powered central air conditioner in the South China climate. Renew. Energy 2018, 126, 1113–1125. [Google Scholar] [CrossRef]

- Rudischer, R.; Waschull, J.; Hernschier, W.; Friebe, C. Available solar cooling applications for different purposes. In Proceedings of the 1st International Conference of Solar Air-Conditioning, Bad Staffelstein, Germany, 6–7 October 2005. [Google Scholar]

- Daut, I.; Adzrie, M.; Irwanto, M.; Ibrahim, P.; Fitra, M. Solar Powered Air Conditioning System. Energy Procedia 2013, 36, 444–453. [Google Scholar] [CrossRef][Green Version]

- SISIFO Simulation Tool. Available online: https://www.sisifo.info/es/default (accessed on 3 June 2020).

- International Energy Agency (IEA). Average CO2 Emissions Intensity of Hourly Electricity Supply in the European Union, 2018 and 2040 by Scenario and Average Electricity Demand in 2018. Available online: https://www.iea.org/data-and-statistics/charts/average-co2-emissions-intensity-of-hourly-electricity-supply-in-the-european-union-2018-and-2040-by-scenario-and-average-electricity-demand-in-2018 (accessed on 22 July 2020).

- Product Catalogue 2018–2019. Available online: https://www.keyter.com/downloads/ (accessed on 5 June 2020).

- Hauer, A. Thermal energy storage. Energy Technology System Analysis Programme (ETSAP) and International Renewable Energy Agency (IRENA). Technology Policy Brief E17. January 2013. Available online: https://iea-etsap.org/E-TechDS/HIGHLIGHTS%20PDF/E17IR%20ThEnergy%20Stor_AH_Jan2013_final_GSOK%201.pdf (accessed on 2 June 2020).

- PVGIS Database. Available online: https://ec.europa.eu/jrc/en/pvgis (accessed on 3 June 2020).

- Erbs, D.G.; Klein, S.A.; Duffie, J.A. Estimation of the diffuse radiation fraction for hourly, daily and monthly-average global radiation. Sol. Energy 1982, 28, 293–302. [Google Scholar] [CrossRef]

- Collares-Pereira, M.; Rabl, A. The average distribution of solar radiation-correlations between diffuse and hemispherical and between daily and hourly insolation values. Sol. Energy 1979, 22, 155–164. [Google Scholar] [CrossRef]

- Perez, R.; Seals, R.; Ineichen, P.; Stewart, R.; Menicucci, D. A new simplified version of the perez diffuse irradiance model for tilted surfaces. Sol. Energy 1987, 39, 221–231. [Google Scholar] [CrossRef]

- Martínez-Moreno, F.; Muñoz, J.; Lorenzo, E. Experimental model to estimate shading losses on PV arrays. Sol. Energy Mater. Sol. Cells 2010, 94, 2298–2303. [Google Scholar] [CrossRef]

- Crundwell, F.K. Finance for Engineers, Evaluation and Funding of Capital Projects; Springer: London, UK, 2008. [Google Scholar]

- Vartiainen, E.; Masson, G. PV LCOE in Europe 2015–2050. In Proceedings of the 31st European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 14–18 September 2015. [Google Scholar]

- Lorenzo, C.; Almeida, R.H.; Martínez-Núñez, M.; Narvarte, L.; Carrasco, L.M. Economic assessment of large power photovoltaic irrigation systems in the ECOWAS region. Energy 2018, 155, 992–1003. [Google Scholar] [CrossRef]

- Jefatura de Estado, D.L. M-1/1958-ISSN: 0212-033X, Ley 27/2014, del 27 de noviembre, del Impuesto sobre Sociedades. 2014. Available online: https://www.boe.es/boe/dias/2015/03/13/pdfs/BOE-A-2015-2668.pdf (accessed on 4 June 2020).

- Trending Economics, Spain Indicators. Available online: https://tradingeconomics.com/spain/indicators (accessed on 7 April 2020).

- Ministerio de Economía. Real decreto 1164/2001, de 26 de octubre, por el que se establecen tarifas de acceso a las redes de transporte y distribución de energía eléctrica. 2001. Available online: https://www.boe.es/eli/es/rd/2001/10/26/1164 (accessed on 4 June 2020).

- Operador del Mercado Ibérico de Energía (OMIE). Componentes Precio Final Medio de la Demanda Nacional. Available online: https://www.omie.es/es/market-results/interannual/average-final-prices/components-spanish-demand?scope=interannual (accessed on 3 June 2020).

- Agencia Tributaria. Impuestos Especiales, Capítulo 6 (Impuesto Especial Sobre la Electricidad). 2015. Available online: https://www.agenciatributaria.es/static_files/AEAT/Aduanas/Contenidos_Privados/Impuestos_especiales/Estudio_relativo_2009/06elec.pdf (accessed on 4 June 2020).

- Expansion Datosmacro. Precios de los Derivados del Petróleo en España. Available online: https://datosmacro.expansion.com/energia/precios-gasolina-diesel-calefaccion/espana?anio=2019 (accessed on 3 June 2020).

- European Central Bank. Inflation Rate. Available online: http://sdw.ecb.europa.eu/ (accessed on 3 June 2020).

- Carrêlo, I.B.; Almeida, R.H.; Narvarte, L.; Martinez-Moreno, F.; Carrasco, L.M. Comparative analysis of the economic feasibility of five large-power photovoltaic irrigation systems in the Mediterranean region. Renew. Energy 2020, 145, 2671–2682. [Google Scholar] [CrossRef]

- Range, A.d.S.; Santos, J.C.d.S.; Savoia, J.R.F. Modified Profitability Index and Internal Rate of Return. J. Int. Bus. Econ. 2016, 4. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. Levelized Cost and Levelized Avoided Cost of New Generation Resources in the Annual Energy Outlook 2020; February 2020. Available online: https://www.eia.gov/aeo (accessed on 5 June 2020).

- Coady, D.; Parry, I.; Sears, L.; Shang, B. How large are global energy subsidies? World Dev. 2017, 91, 11–27. [Google Scholar] [CrossRef]

- Todde, G.; Murgia, L.; Carrelo, I.; Hogan, R.; Pazzona, A.; Ledda, L.; Narvarte, L. Embodied Energy and Environmental Impact of Large-Power Stand-Alone Photovoltaic Irrigation Systems. Energies 2018, 11, 2110. [Google Scholar] [CrossRef]

- Jordan, D.C.; Silverman, T.J.; Sekulic, B.; Kurtz, S.R. PV degradation curves: Non-linearities and failure modes. Prog. Photovolt. Res. Appl. 2017, 25, 583–591. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Generator inclination [°] | 30 |

| Generator orientation [°] | 0 |

| Separation between structure rows in N-S direction | 1.5 |

| Parameter | Value |

|---|---|

| Separation between trackers in E-W direction | 3 |

| Maximum rotation angle [°] | 45 |

| Axis orientation [°] | 0 |

| Axis inclination [°] | 0 |

| Module inclination [°] | 0 |

| Backtracking option | Yes |

| PV Power (kWp)/Surface (m2) | PV Energy Yield (kWh/kWp) | CO2 Savings (kgCO2/kWp) | TES Capacity (kWhth/kWp)/Volume (m3) | |||

|---|---|---|---|---|---|---|

| PO | St | SC | 90/675 | 1530.5 | 351.2 | NA |

| AU | 972.4 | 223.2 | 11.6/20.9 | |||

| Tr | SC | 70/1050 | 1951.3 | 447.8 | NA | |

| AU | 1250.2 | 286.9 | 12.0/16,8 | |||

| RA | St | SC | 250/1875 | 1571.9 | 360.8 | NA |

| AU | 1165.6 | 267.5 | 10.3/51.5 | |||

| Tr | SC | 240/3600 | 2006.9 | 460.6 | NA | |

| AU | 1214.2 | 278.7 | 8.3/39.8 |

| PI (€/€) | IRR (%) | PBP (years) | |||

|---|---|---|---|---|---|

| PO | St | SC | 2.23 | 8.1 | 10.9 |

| AU | 2.79 | 10.2 | 9.6 | ||

| Tr | SC | 2.33 | 8.5 | 10.7 | |

| AU | 2.91 | 10.7 | 9.3 | ||

| RA | St | SC | 2.50 | 9.5 | 9.8 |

| AU | 2.97 | 10.9 | 9.2 | ||

| Tr | SC | 2.28 | 8.2 | 11.0 | |

| AU | 2.69 | 9.8 | 9.9 |

| LCOEOGP (c€/kWh) | LCOEPV-HP (c€/kWh) | LCOE Savings (%) | |||

|---|---|---|---|---|---|

| PO | St | SC | 17.43 | 5.76 | 67 |

| AU | 7.46 | 57 | |||

| Tr | SC | 5.83 | 67 | ||

| AU | 7.31 | 58 | |||

| RA | St | SC | 15.71 | 5.40 | 66 |

| AU | 6.68 | 57 | |||

| Tr | SC | 4.74 | 70 | ||

| AU | 6.78 | 57 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lorenzo, C.; Narvarte, L.; Cristóbal, A.B. A Comparative Economic Feasibility Study of Photovoltaic Heat Pump Systems for Industrial Space Heating and Cooling. Energies 2020, 13, 4114. https://doi.org/10.3390/en13164114

Lorenzo C, Narvarte L, Cristóbal AB. A Comparative Economic Feasibility Study of Photovoltaic Heat Pump Systems for Industrial Space Heating and Cooling. Energies. 2020; 13(16):4114. https://doi.org/10.3390/en13164114

Chicago/Turabian StyleLorenzo, Celena, Luis Narvarte, and Ana Belén Cristóbal. 2020. "A Comparative Economic Feasibility Study of Photovoltaic Heat Pump Systems for Industrial Space Heating and Cooling" Energies 13, no. 16: 4114. https://doi.org/10.3390/en13164114

APA StyleLorenzo, C., Narvarte, L., & Cristóbal, A. B. (2020). A Comparative Economic Feasibility Study of Photovoltaic Heat Pump Systems for Industrial Space Heating and Cooling. Energies, 13(16), 4114. https://doi.org/10.3390/en13164114