Abstract

The growing interest in the use of unconventional energy sources is a stimulus for the development of dedicated devices and technologies. Drain water heat recovery (DWHR) units can be an example of such devices. They allow the recovery of part of the heat energy deposited in grey water. This paper describes the results of research on the assessment of the financial profitability of the use of two horizontal heat exchanger solutions, taking into account the actual distribution of cold water temperature during the operating year in the plumbing and two operating regimes of the premises as the residential and service facilities. The analysis showed that the use of a horizontal heat exchanger with increased efficiency in a dwelling in a 15-year life cycle allowed for achieving more than twice as much savings (reaching up to EUR 1427) compared to a classic horizontal heat exchanger. At the same time, it was shown that the installation of this type of equipment was more profitable the greater the water consumption of the premises. The article also notes the impact of cold water temperature in the installation on the results of the analysis. It was featured that taking temperature on the basis of installation design recommendations led to significant distortions in the financial analysis. On the other hand, comparing the method of averaging the cold water temperature (daily, monthly and yearly), it was determined that averaging the temperature over the annual cycle was an acceptable simplification of the model. The research results presented in the paper have a practical aspect and may constitute guidelines for designers and potential investors. In addition, they can be an incentive to continue research on heat exchangers by other scientific centers, which on a global scale will increase the universality of their use.

1. Introduction

Human activity is currently accompanied by a gradual worsening of the natural environment [1,2]. The bad condition of the atmospheric air, which is a consequence of excessive greenhouse gas emissions [3,4], the worrying quantitative and qualitative condition of rivers [5,6] or an increase in the amount of waste [7], are just some examples of problems. They are additionally compounded by climate change [8], which poses a threat to health and even people’s lives [9]. In response to the above, governments and organizations in many countries have decided to take action to prevent environmental degradation [10,11]. Such actions include an improvement of law regulations [12] and the intensification of efforts to reduce greenhouse gas emissions [13] and water protection [14]. Some improvement of the effects can also be achieved due to the involvement of individual energy users in the environmental protection process [15,16]. Therefore, public education [17] remains an extremely important issue, especially since the lack of environmental awareness is one of the main barriers to the implementation of sustainable solutions [18].

Complete elimination of the negative impact of human activities on the environment is barely possible. However, the involvement of the public in actions aimed at reducing the consumption of fossil fuels and the emission of their combustion products can clearly limit this impact. To enable full public participation in the environmental protection process, it is necessary to develop and implement relatively cheap solutions whose application will achieve significant energy savings. Financial issues are one of the most important factors that determine the society’s approach to pro-ecological investments [19].

Possibilities of saving natural energy resources should be seen both while running advanced industrial processes [20] as well as individual energy consumers [21]. In the latter case, special attention should be paid to issues related to hot water heating. Binks et al. [22] and Meggers and Leibundgut [23] indicated that the share of energy used for this purpose in the total energy consumption balance in buildings is systematically growing and, in some cases, can reach up to 50% and more.

By far the easiest way to save energy used for water heating is to use water-saving taps. The implementation of such a solution allows one not only to significantly reduce the amount of water consumed, but also to reduce the consumption of energy used for heating it. In addition, this is done with minimal embodied energy [24] compared to other water-saving strategies, such as grey water recycling or the economic use of rainwater harvesting [25,26].

Instead, a more advanced way to reduce energy consumption for this purpose is to replace traditional fuels with unconventional energy sources, which include renewable energy. Solar energy is the most popular and its use is possible thanks to the application of solar collectors and photovoltaic panels [27,28]. The installation of this type of equipment allows a significant reduction in the consumption of fossil fuels and greenhouse gas emissions. Similar effects can also be achieved by using third-generation renewable energy sources, including wastewater [29].

2. Review of Waste Heat Recovery from Drain Water

Thermal energy contained in wastewater can be recovered at various stages of their production, transport and utilization [30,31]. For example, Zhu et al. [32] analyzed the possibilities of heat recovery from wastewater collection system. However, the dominant way of managing the energy carried by wastewater is using drain water heat recovery (DWHR) units [33,34]. These devices are mounted on the grey water outflow from the shower or at the outlet of the wastewater from the building to the wastewater network. They include, among others: vertical spiral heat exchangers, vertical heat exchangers of the pipe-in-pipe type, horizontal heat exchangers, heat exchangers mounted in linear shower drains and wastewater retention devices. A number of the solutions are commercially available. The research on the possibilities of heat recovery from wastewater within buildings has also been also undertaken by many scientific centers, as shown in Table 1.

Table 1.

The examples of research in the field of heat recovery from sewage.

The examples presented above prove that the use of heat recovery systems with drain water for water heating is technically justified. However, in many cases this solution turns out to be financially unviable. The reasons for the unexpected extension of the payback period should be seen in the low efficiency of equipment, variable quantity and temperature of water and wastewater, as well as too high investment costs that should be incurred for the implementation of the DWHR system. This causes the need to improve the systems currently used in order to achieve high efficiency in all operating conditions of the installation. An analysis of the impact of variability of shower installation parameters on the financial effectiveness of investments remains an unsolved issue.

The research conducted so far to determine the financial efficiency of the investment involving the implementation of the DWHR unit assumed a constant temperature of cold water, usually equal to 10 °C [34], and sometimes even less [9]. The preliminary studies [40] carried out in this area indicate, however, that the water temperature in the water supply system may reach, in polish conditions, much higher values. This calls into question the results of studies that have been published in other articles. In addition, the previous analyses concerned commercially available heat exchangers, the application of which requires significant investment outlays, and the data on their efficiency come from device manufacturers. Therefore, they are clearly limited. This, in turn, prevents an in-depth analysis of the possible heat exchanger configurations.

In response to the above, the paper analyzes the impact of changes in tap water temperature over the year on the financial efficiency of the investment consisting of the installation of a DWHR unit on the grey water outflow from the shower. The subject of the research was the highly effective horizontal drain water heat recovery unit developed by the authors [45]. The research used the results presented in the previous authors publication [40]. The previous article, however, focused on the assessment of the effectiveness of the heat exchangers at different operating parameters. The subject of this paper is the assessment of the financial efficiency of the investment. As part of the research, the profitability of the implementation of a single heat exchanger was assessed, as well as the use of a set of devices characterized by greater efficiency. The analysis was carried out on the example of a premises located in a residential and service facility assuming two different regimes of using the shower installation. The results were then compared with those obtained for a simple horizontal tube exchanger.

3. Methodology

3.1. A Description of Tested Heat Exchangers

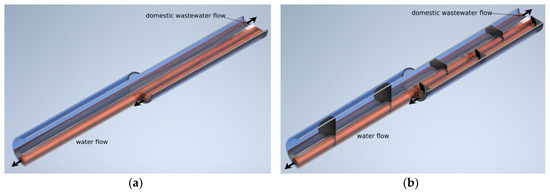

The tests were carried out on the example of two horizontal exchangers. One of them was a highly efficient horizontal heat exchanger (hereinafter referred to as HE_1), described in patent document [45], while the other was a simple horizontal heat exchanger (hereinafter referred to as HE_0). Both solutions are shown in Figure 1.

Figure 1.

The heat exchangers analyzed: (a) HE_0; (b) HE_1.

The purpose of the heat exchangers is to recover the energy deposited in the drain water, which is usually irretrievably wasted. Both solutions can be used in existing and newly designed buildings. They are made of a plastic body and a conduit that transports heated water inside. The conduit is made of a material with high thermal conductivity, e.g., copper. In the case of the HE_1 heat exchanger, additional partitions were used to extend the flow path and intensify the turbulent flow of wastewater, as a result of which a significant increase in its efficiency was obtained [40].

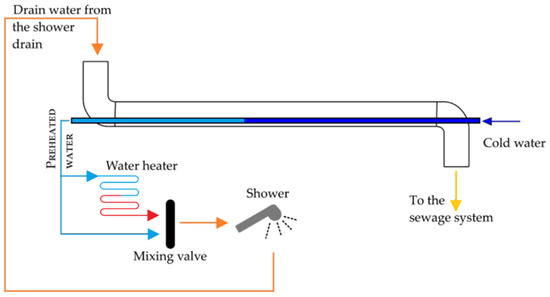

The implementation of the DWHR unit requires modification of the plumbing installation in the building. In the case of shower heat exchangers, the water preheated in the heat exchanger can be fed to the hot water heater, shower mixing valve or both devices simultaneously (instead of cold water). The research [46] shows, however, that the greatest financial benefits can be achieved when the preheated water is supplied both to the shower mixing valve and to the hot water heater. Therefore, such a solution was adopted in the analysis (Figure 2). In this case, flow rates of water and drain water through the heat exchanger are equal.

Figure 2.

The connection diagram for the heat exchanger with the shower installation.

3.2. Description of the Research Method

Financial efficiency is one of the main determinants of the implementation of the solution. At the investment planning stage, it can be determined by means of both static and dynamic methods [47], and the rationality of using a particular method depends mainly on the scale and type of the project. In the case of the dynamic methods, the cash flows projected in subsequent years of system operation are discounted, which allows for taking into account the change in the time value of money. The dynamic methods are usually applied to evaluate investment projects based on the use of unconventional energy sources, whose examples can be found in [48,49].

In the research described in the paper, we decided to use the net present value (NPV). This rate is the difference between the discounted proceeds from the implementation of the project and the necessary expenses [50]. It is determined for the assumed system lifetime based on the formula (1).

where:

- NPV—Net Present Value of the project, €;

- CFt—cash flows determined for the given year t, €;

- r—discount rate, -;

- t—system year of operation;

- n—number of years of system operation, years.

The NPV can have the following values:

- NPV > 0—discounted proceeds from the project are greater than investment outlays, so undertaking the project is profitable,

- NPV = 0—revenues from a potential project offset investments,

- NPV < 0—capital expenditure on a potential project is higher than the discounted proceeds from its implementation, therefore the project is not profitable.

The value of cash flows (CFt) was determined as the difference between the projected savings (St) and the outlays (INVt) necessary to be incurred in a given year (t). The savings (St) were calculated based on the energy price of the year (Cet) and the annual energy saving resulting from the installation of the heat exchanger (ΔCrt). The latter value was determined based on the installation usage characteristics (duration of showering, water temperature) and the heat exchanger efficiency from Equation (2).

where:

- M—number of calculation periods during the year;

- DMi—number of days within one calculation period, days;

- p—daily duration of showering, s;

- q0hi—flow rate of water heated in a water heater in a case without a heat exchanger, m3/s;

- q1hi—flow rate of water heated in a water heater in a case with a heat exchanger, m3/s;

- ρw0i, ρw1i—density of water heated in a water heater (dependent on water temperature), kg/m3;

- cp0i, cp1i—specific heat of water heated in a water heater (dependent on water temperature), J/(kg·K);

- Twh—hot water temperature, °C;

- Twci—average cold water temperature (in a given calculation period), °C;

- Twpi—preheated water temperature, °C.

- η—efficiency of hot water heater.

The flow rate of water heated in a water heater in a case without a heat exchanger (q0h) was calculated based on Equation (3). According to this heat balance equation, the amount of heat given out by the hot water is equal to the amount of heat taken by the cold water. The value of q1h was determined analogously.

where:

- qwm—flow rate of mixed water, m3/s;

- q0i—flow rate of cold water, m3/s;

- Twm—mixed water temperature, °C;

- ρ0h, ρ0i—density of water (dependent on water temperature), kg/m3;

- cp0h, cp0i—specific heat of water (dependent on water temperature), J/(kg·K).

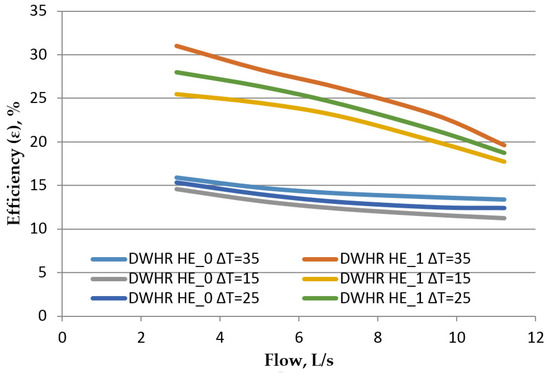

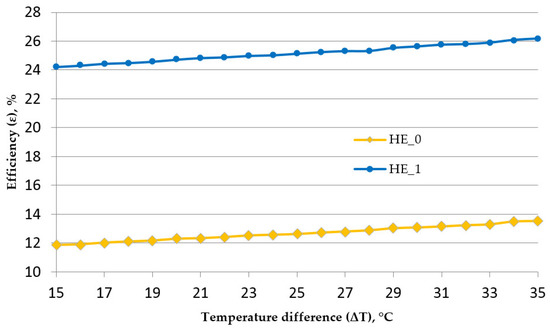

The temperature to which the tap water will be preheated thanks to the use of the DWHR unit (Twpi) can be determined on the basis of the efficiency (ε) that the device achieves in given conditions of the installation use. Research on the efficiency (ε) of HE_1 and HE_0 heat exchangers for various parameters of their operation was described by the authors in paper [40]. Based on the results presented in this article, the most favorable parameters of the exchanger’s operation in terms of slope and flow ratio were selected. The dependence of the HE_0 and HE_1 heat exchangers’ efficiency on the water and drain water flow through the device for such working conditions is shown in Figure 3. The graph relates to a 1:1 flow ratio, a 3% heat exchanger slope and three different ΔT (temperature difference between heated water and greywater) values.

Figure 3.

Efficiency of HE_0 and HE_1 (based on [40]).

3.3. Case Study

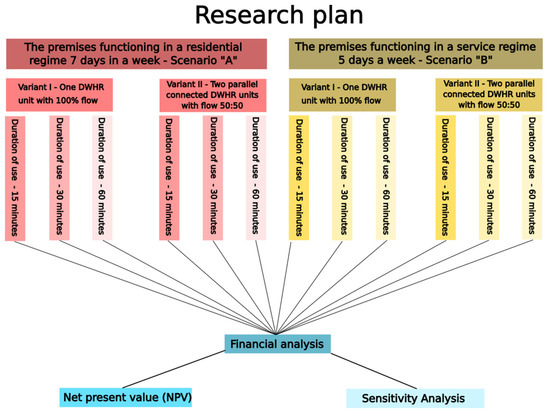

The aim of the research was to analyze the financial efficiency of using the innovative HE_1 heat exchanger in the premises which, according to the building’s purpose, can function as a residential or commercial facility. The study analyzed two scenarios, “A” and “B”, of its use and for both, parallel studies were conducted. In scenario “A”, the premises operated in a residential regime 7 days a week (365 days a year). However, in scenario “B”, the premises operated in a service regime 5 days a week (261 days a year). The research included real (variable) water temperature from the water supply network. The test results were compared with those obtained for the simple HE_0 exchanger. The research was carried out on the example of a building located in south-eastern Poland, where domestic hot water is prepared by means of an electric heater.

The following preliminary assumptions were made in the research:

- the same water and drain water flow rate through the heat exchanger, equal to the mixed water flow rate (qwm),

- water outflow from the shower head qwm = 7.0 L/min,

- fifteen years of operation of the heat recovery system and the same period of financial analysis (n),

- three variants of the total daily shower length (p): 15, 30 and 60 min (e.g., 6 × 10 min = 60 min),

- maximum 6 people using the shower,

- 3% exchanger slope.

In addition, in both scenarios for the premises operation, two variants of DWHR unit assembly were analyzed. Variant “I” assumes the installation of a single device, and Variant “II” assumes the installation of two devices connected in parallel with a split stream of both media in the proportion of 50:50.

At a specified grey water supply temperature to the DWHR unit, a change in the cold water temperature during the year affects the value of the ΔT parameter, and thus the heat exchanger efficiency (ε). Therefore, the NPV values were determined, taking into account the changes in cold water temperature that were adopted on the basis of real measurements carried out from 01/07/2018 to 30/06/2019. The results were compared with those obtained assuming a constant cold water temperature of 10 °C.

The analysis was carried out for 15 years of DWHR system operation (n) and four methods of averaging the cold water temperature, i.e.,

- average daily cold water temperature,

- average weekly cold water temperature,

- average monthly cold water temperature,

- average annual cold water temperature (14.33 °C).

Calculations of the financial effectiveness of the investment were carried out for the input data, whose values are presented in Table 2.

Table 2.

Values of input parameters of the calculation model.

The amount of necessary investment outlays (INV0) was estimated for Polish conditions. The costs of materials needed to make the heat exchangers, the costs of their construction and installation, and a margin were taken into account. Due to the simple design, HE_1 and HE_0 heat exchangers are characterized by a competitive price compared to the solutions currently available on the Polish market. The electricity prices (Cet) were determined on the basis of data provided by PGE [51]. The density and specific heat of water were assumed on the basis of tables of physical properties of water [52] depending on water temperature.

The research plan for financial analysis based on energy efficiency of solutions was tested in the scenarios presented in Figure 4.

Figure 4.

Research plan for HE_0 and HE_1.

4. Results and Discussion

4.1. Impact of Cold Water Temperature Averaging on the NPV Value

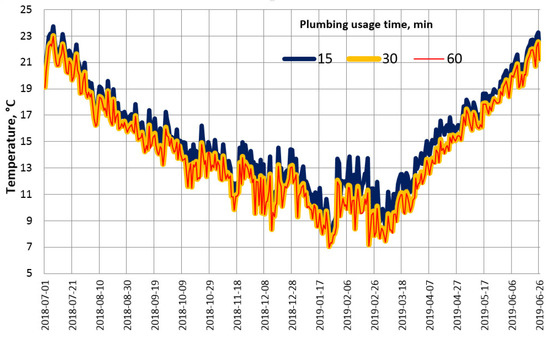

According to the objective of the research, the financial analysis was based on the actual temperature distribution of cold water supplying the draw-off points. In the first stage, water temperature measurements were taken for the draw-off point from which water was supplied to the DWHR units tested. On the basis of the measurement results, the average daily cold water temperatures were determined for three times of the system usage—15, 30 and 60 min, respectively. They are shown in Figure 5.

Figure 5.

Average daily cold water temperature distribution for the draw-off point.

The basis for further considerations were the results of the studies presented in [40], which showed that the efficiency of HE_0 and HE_1 heat exchangers changed with the change in the temperature difference between heated water and grey water (ΔT). This is shown in Figure 6.

Figure 6.

The dependence of the exchanger efficiency on the temperature difference at a 3% slope and the flow rate of both media 7.0 L/min.

In the case of averaging the daily cold water temperatures, the calculation of the NPV value was possible thanks to summing up the daily energy savings obtained in the consecutive days of the year, according to the Equation (3). The same procedure was followed for the remaining time periods, except that the mean values of the ΔT from the period of the week, month and year were taken consecutively.

Table 3 presents the results of the NPV analysis for the option of using the bathroom 7 days a week, 365 days a year (Scenario A). The calculations are presented in accordance with the test plan (Figure 4) for the flow of 7 (Variant I) and 3.5 L/s (Variant II) and three option of times of using the shower per day (15, 30 and 60 min). Similar results are presented in Table 4 for the option of using the bathroom 5 days a week, 251 days a year (Scenario B), illustrating the service operation of the premises.

Table 3.

Results of net present value (NPV) analysis for Scenario A.

Table 4.

Results of NPV analysis for Scenario B.

The obtained NPV results for the analyzed methods of averaging the cold water temperature (daily, daily, monthly and annual) do not differ significantly from each other.

The largest difference noted is EUR 17. This value was noticed between the daily and yearly temperature averaging period for year-round operation of the installation and the following configuration: Scenario A (Table 3), 60 min of daily shower time and division of the waste water stream into two HE_1 heat exchangers—Variant II.

Taking into account such small differences between the results obtained in the fifteen-year calculation period, it can be concluded that the consideration of the temperature of cold water averaged annually is an acceptable simplification of analyses. Therefore, in the further part of the article, the NPV was analyzed for the average annual cold water temperature.

4.2. Impact of Cold Water Temperature on the NPV Value

The effects of financial analysis in the aspect of investment profitability depend on the temperature of cold water supplying the DWHR unit. This was verified by comparing the results of analyzes when supplying the device with cold water at different temperatures.

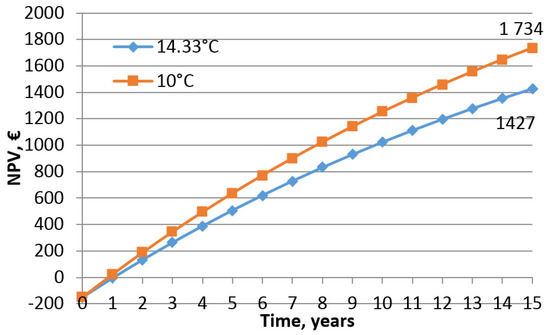

In the first case, a cold water temperature of 10 °C was assumed for analysis. This value is the temperature most commonly adopted in Poland in the process of designing plumbing installations whose source is the water supply network. In the second case, the results of actual annual measurements in the form of average annual temperature were used as the cold water temperature. These tests were carried out for different times of using the shower and HE_0 and HE_1 devices. Figure 7 presents selected NPV results for Scenario A assuming the use of a shower 60 min a day and energy recovery by the HE_1 heat exchanger according to Variant II.

Figure 7.

The impact of cold water temperature on the value of the NPV rate when using a HE_1 heat exchanger.

Based on the research conducted, it was found that in each analyzed case, taking a cold water temperature of 10 °C was inappropriate. The results presented in Figure 7 clearly indicate that the NPV rate has more favorable values with the simplified assumption that the temperature of cold water is 10 °C. This approach, therefore, leads to some distortions in financial analysis at the decision-making stage.

When assuming a cold water temperature of 10 °C, NPV is set at EUR 1734, while with average annual temperature obtained from real measurements (14.33 °C), the NPV is only EUR 1427. On this basis, it can be concluded that excessive simplification of input data for the analysis in the scope of cold water temperature might result in overly favorable results. This approach in the long term may discourage investors from using this type of solution due to the significant discrepancies between initial analyzes and actual effects.

Therefore, the average annual temperature determined on the basis of the measurements carried out should always be used. However, in the absence of such data, an increase in cold water temperature from the water supply network due to heat gains in the installation or seasonal changes in ground temperature should be taken into account.

4.3. Impact of the Applied Solution on the Payback Period

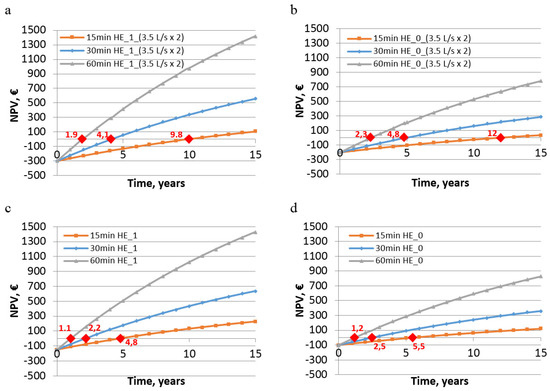

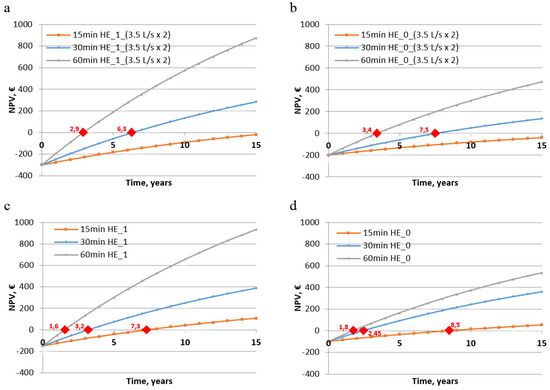

The test results are shown in Figure 8 and Figure 9, which reflect the NPV value in subsequent years of using the system. The investment payback period for each case is marked in red.

Figure 8.

NPV values for Scenario A (365 days): (a) HE_1, Variant II; (b) HE_0, Variant II; (c) HE_1, Variant I; (d) HE_0, Variant I.

Figure 9.

NPV values for Scenario B (261 days): (a) HE_1, Variant II; (b) HE_0, Variant II; (c) HE_1, Variant I; (d) HE_0, Variant I.

In the case of Scenario A (Figure 8), it was noted that the use of the DWHR HE_1 device was financially more advantageous than the use of the simple HE_0 device. This was verified for both Variant I and Variant II.

The most favorable NPV result after 15 years of operation for the HE_0 device was EUR 828, and for the HE_1 exchanger EUR 1427, which is nearly 72% more.

At the same time, it is noted that in each of the cases the greatest financial benefits were obtained with a daily shower time of 60 min. In the most critical case, the difference in NPV between 60 and 15 min of shower length was EUR 1201 after 15 years. Thus, it can be concluded that this system is financially more effective the greater the water consumption in the building. On the other hand, with a shorter daily time of using the shower, the use of the proposed solutions is unfounded.

In the case of Scenario B and Variant I, the investments are returned after the first year. In the cases studied, savings of EUR 133 for HE_1 and EUR 66 for HE_0 are already achieved in the second year. In turn, in Variant II, in spite of greater heat exchange efficiency, the return on investment takes place between the second and third year of use. It is caused by bigger investments for the purchase of devices.

Comparing the NPV values obtained after 15 years of using the system, it can be concluded that it is not cost-effective to use the division of the drain water stream into two devices for both HE_0 and HE_1.

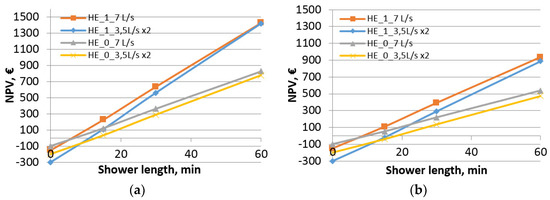

The test results for Scenario B (assuming the premises operate in a service regime 5 days a week, 261 days a year) are shown in Figure 9.

Similar dependencies are noticed in this scenario, but each time this scenario is less favorable than Scenario A. At the same time, the data presented for this scenario similarly indicate that the use of the HE_1 device is financially more favorable than HE_0, and the extension of the daily shower length increases the profitability of such a project.

However, it is not profitable to make the investment in every variant examined. The highest NPV, equal to EUR 936, was obtained for Variant I, HE_1 and a shower time of 60 min a day. Not all cases of Variant II in the 15-year cycle are characterized by the positive value of NPV. In the most unfavorable cases, providing for a shower time of 15 min, the NPV for HE_1 was EUR −18, and for HE_0, EUR −40€. For these cases, the payback period is longer than the DWHR system’s lifetime (n = 15 years).

In the most favorable case for Variant I, with a shower length of 60 min a day and using the HE_1 device, the return on investment occurred between the first and the second year of operation (profit in the second year was EUR 45; NPV = EUR 936), and for the HE_0 device, also between the first and the second year of operation (profit in the second year it was EUR 14; NPV = EUR 536). As in Scenario A, it is less cost-effective to use Variant II (HE_1—NPV = EUR 875; HE_0—NPV = EUR 474).

The impact of shower duration on the NPV value over a 15-year life cycle in both scenarios was also analyzed, and its results are shown in Figure 10.

Figure 10.

Dependence of NPV on shower length: (a) Scenario A (365 days); (b) Scenario B (261 days).

The detailed analysis of the results showed that in the case of both tested DWHR units (HE_0 and HE_1), the value of financial benefits obtained also increased along with the extension of the shower length. This trend is independent of the device used and the characteristics of its use.

The results indicate that the most advantageous solution is to use a single HE_1 device (Variant I). However, in the case of a very short time of using the installation (below 15 min), it may turn out that due to lower investments, it will be more advantageous to use a single HE_0 exchanger than a double HE_1 exchanger with much higher efficiency.

In turn, in scenario B (assuming that the premises are used for 261 days a year) and a short time of use of less than 15 min, only the HE_0 and HE_1 heat exchanger solutions in Variant I showed a positive NPV result.

The obtained results of the tests confirm, therefore, that the profitability of heat recovery from the drain water discharged from the shower grows with an increase in the use of the shower and the efficiency of the heat exchanger.

Considering that the profitability of the investment is influenced by an increase in water consumption, DWHR devices should be applied primarily in facilities where significant amounts of domestic hot water are used. For this reason, it can be considered appropriate to install them in buildings with a larger number of showers or in those where these facilities are used a greater number of times per day.

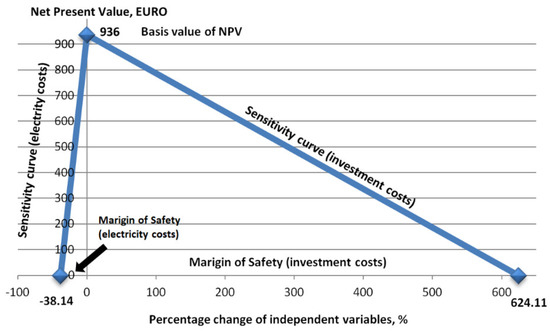

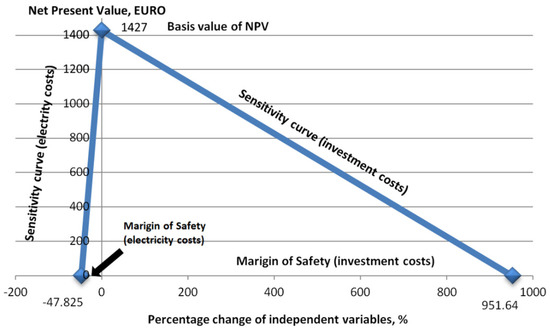

4.4. Sensitivity Analysis

For both scenarios, one financially most favorable case was selected (heat exchanger HE_1 in Variant I and a 60 min daily shower length) and a sensitivity analysis was performed. For this purpose, the NPV values for various levels of percentage changes of independent variables (electricity prices, investment costs) were determined. The results were plotted on the charts presented in Figure 11 and Figure 12, thus obtaining sensitivity curves. Their intersection with the horizontal axis indicates the values of the relative safety margins. These are the permissible deviation of the electricity costs and investment costs from the base values, where the project remains profitable.

Figure 11.

Graphic form of sensitivity analysis for variables that linearly change the profitability of HE_1 heat exchanger investments in Scenario A, Variant I and a 60 min shower time.

Figure 12.

Graphic form of sensitivity analysis for variables that linearly change the profitability of HE_1 exchanger investments in Scenario B, Variant I and a 60-min shower time.

Figure 11 presents the results of the analysis for Scenario A. The safety margin for electricity prices in this case is −47.825%, while for capital expenditure, it is 951.64%. The risk of investment failure is therefore negligible. Electricity prices in Poland and in the world are unlikely to decrease, which is associated with the need to purchase greenhouse gas emission permits. In addition, an increase in investments necessary to incur the purchase of the HE_1 heat exchanger by as much as almost 952% is also virtually impossible. It can be concluded that the application of the solution in question in the conditions considered is beneficial and financially secure.

A relatively low investment risk also occurs in the case of the functioning of the premises in a service regime (Scenario B). In such a situation, the relative safety margins are equal to −38.14% and 624.11%, respectively (Figure 12). Although the financial risk of the investment increases with decreasing water use for showering, in this case it is negligible.

5. Conclusions

The analysis of the financial efficiency of the application of the heat recovery system from drain water discharged from the shower enabled drawing the following conclusions:

- Adoption of the temperature of cold water on the basis of actual measurements at the draw-off point enables obtaining more real and reliable results of the financial analysis.

- Averaging the cold water temperature in any way—daily, weekly, annually—does not significantly affect the results of the financial analysis. It is an acceptable simplification of the model.

- There is a correlation between daily shower time and possible financial savings. Financial efficiency increases with increasing shower length and water consumption. Hence, it is beneficial to use the DWHR system for large families, sports, service and industrial facilities, where showers are often used.

- In each of the cases analyzed, using HE_1 allows greater financial savings than in the case of HE_0. In both cases, dividing the drain water stream into two devices, although the efficiency of the devices is higher in this case, it is not financially advantageous.

- An assessment of the sensitivity of the model to changes in independent variables, such as electricity prices and capital expenditure, showed that in the case of installations with high water consumption and a significant duration of showering, the risk of investment failure is small. However, this risk increases if water consumption is significantly reduced.

To sum up, the research conducted indicates that before making a decision on the use of the DWHR unit, it is necessary to carry out a detailed analysis of the financial indicators of the investment. Only such calculations allow for limiting the risk of making wrong decisions from the investor’s point of view. The research results presented do not fully cover the issue of using DWHR horizontal units. The next stage of research should be an analysis of the functioning of highly effective horizontal heat exchangers at various hydraulic conditions of their operation using CFD modeling.

The research results have a significant impact on the development of branches of engineering sciences dealing with heat recovery from wastewater, especially in the scope of the need to search for new solutions and equipment design, with higher heat exchange efficiency, the implementation of which allows for achieving clear social, financial and environmental profits.

Author Contributions

Conceptualization, K.P. and M.S.; data curation, M.S.; formal analysis, K.P. and S.K.-O.; investigation, M.S.; methodology, S.K.-O.; project administration, S.K.-O. and B.P.; software, K.P.; supervision, K.P. and S.K.-O.; validation, K.P.; writing—review and editing, B.P., M.S., S.K.-O., and K.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The author would like to thank the reviewers for their feedback, which has helped improve the quality of the manuscript. We would also like to thank the Energies’ staff and Editors for handling the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Caruso, G.; Colantonio, E.; Gattone, S.A. Relationships between Renewable Energy Consumption, Social Factors, and Health: A Panel Vector Auto Regression Analysis of a Cluster of 12 EU Countries. Sustainability 2020, 12, 2915. [Google Scholar] [CrossRef]

- Zamil, G.M.S.; Hassan, Z. Impact of Environmental Reporting on Financial Performance: Study of Global Fortune 500 Companies. Indones. J. Sustain. Account. Manag. 2019, 3, 109–118. [Google Scholar] [CrossRef]

- Shahmohammadi, S.; Steinmann, Z.J.; King, H.; Hendrickx, H.; Huijbregts, M.A. The influence of consumer behavior on energy, greenhouse gas, and water footprints of showering. J. Ind. Ecol. 2019, 23, 1186–1195. [Google Scholar] [CrossRef]

- Simionescu, M.; Bilan, Y.; Gędek, S.; Streimikiene, D. The Effects of Greenhouse Gas Emissions on Cereal Production in the European Union. Sustainability 2019, 11, 3433. [Google Scholar] [CrossRef]

- Starzec, M.; Dziopak, J.; Słyś, D. An Analysis of Stormwater Management Variants in Urban Catchments. Resources 2020, 9, 19. [Google Scholar] [CrossRef]

- Pochwat, K.; Kida, M.; Ziembowicz, S.; Koszelnik, P. Odours in Sewerage—A Description of Emissions and of Technical Abatement Measures. Environments 2019, 6, 89. [Google Scholar] [CrossRef]

- Taušová, M.; Mihalikova, E.; Čulková, K.; Stehlíková, B.; Tauš, P.; Kudelas, D.; Štrba, L. Recycling of Communal Waste: Current State and Future Potential for Sustainable Development in the EU. Sustainability 2019, 11, 2904. [Google Scholar] [CrossRef]

- Stagrum, A.E.; Andenæs, E.; Kvande, T.; Lohne, J. Climate Change Adaptation Measures for Buildings—A Scoping Review. Sustainability 2020, 12, 1721. [Google Scholar] [CrossRef]

- Stec, A.; Mazur, A. An Analysis of Eco-Technology Allowing Water and Energy Saving in an Environmentally Friendly House—A Case Study from Poland. Buildings 2019, 9, 180. [Google Scholar] [CrossRef]

- Maund, K.; Gajendran, T.; Brewer, G. Key Issues for Implementation of Environmental Planning Policy: Construction Management Practice. Sustainability 2018, 10, 2156. [Google Scholar] [CrossRef]

- Zhou, Q.; Yabar, H.; Mizunoya, T.; Higano, Y. Evaluation of Integrated Air Pollution and Climate Change Policies: Case Study in the Thermal Power Sector in Chongqing City, China. Sustainability 2017, 9, 1741. [Google Scholar] [CrossRef]

- Listiyani, N.; Said, M.Y. Political Law on the Environment: The Authority of the Government and Local Government to File Litigation in Law Number 32 Year 2009 on Environmental Protection and Management. Resources 2018, 7, 77. [Google Scholar] [CrossRef]

- Mikhailov, V.; Kiseleva, T.; Bugrova, S.; Muromtseva, A.; Mikhailova, Y. Research of Environmental and Economic Interactions of Coke And By-Product Process. E3S Web Conf. 2017, 21, 2004. [Google Scholar] [CrossRef]

- Kida, M.; Ziembowicz, S.; Koszelnik, P. Study on the suitability of using low-frequency ultrasonic field for removing di(2-ethylhexyl) phthalate from bottom sediments. Sep. Purif. Technol. 2020, 233, 116010. [Google Scholar] [CrossRef]

- Ma, X.; Wang, M.; Li, C. A Summary on Research of Household Energy Consumption: A Bibliometric Analysis. Sustainability 2019, 12, 316. [Google Scholar] [CrossRef]

- Vranay, F.; Vranayova, Z. Influence of Heat Source Choice on Building Energy Certification Process and CO2 Emissions. In Proceedings of CEE 2019. Lecture Notes in Civil Engineering; Blikharskyy, Z., Koszelnik, P., Mesaros, P., Eds.; Springer: Cham, Swizerland, 2020; Volume 47, pp. 541–548. [Google Scholar] [CrossRef]

- Kretschmer, F.; Neugebauer, G.; Stoeglehner, G.; Ertl, T. Participation as a Key Aspect for Establishing Wastewater as a Source of Renewable Energy. Energies 2018, 11, 3232. [Google Scholar] [CrossRef]

- Yaqoot, M.; Diwan, P.; Kandpal, T.C. Review of barriers to the dissemination of decentralized renewable energy systems. Renew. Sustain. Energy Rev. 2016, 58, 477–490. [Google Scholar] [CrossRef]

- Kordana, S. SWOT analysis of wastewater heat recovery systems application. E3S Web Conf. 2017, 17, 42. [Google Scholar] [CrossRef]

- De La Casa, J.A.; Castro, E. Fuel savings and carbon dioxide emission reduction in a fired clay bricks production plant using olive oil wastes: A simulation study. J. Clean. Prod. 2018, 185, 230–238. [Google Scholar] [CrossRef]

- Gaglia, A.G.; Tsikaloudaki, K.; Laskos, C.M.; Dialynas, E.N.; Argiriou, A.A. The impact of the energy performance regulations’ updated on the construction technology, economics and energy aspects of new residential buildings: The case of Greece. Energy Build. 2017, 155, 225–237. [Google Scholar] [CrossRef]

- Binks, A.; Kenway, S.; Lant, P.; Head, B. Understanding Australian household water-related energy use and identifying physical and human characteristics of major end uses. J. Clean. Prod. 2016, 135, 892–906. [Google Scholar] [CrossRef]

- Meggers, F.; Leibundgut, H. The potential of wastewater heat and exergy: Decentralized high-temperature recovery with a heat pump. Energy Build. 2011, 43, 879–886. [Google Scholar] [CrossRef]

- Marinoski, A.K.; Rupp, R.; Ghisi, E. Environmental benefit analysis of strategies for potable water savings in residential buildings. J. Environ. Manag. 2018, 206, 28–39. [Google Scholar] [CrossRef] [PubMed]

- Zelenakova, M.; Alkhalaf, I.; Harbulakova, V.O. Applying of dimensional analysis in rainwater management systems design. In Advances and Trends in Engineering Sciences and Technologies—Proceedings of the International Conference on Engineering Sciences and Technologies; CRC Press: Boca Raton, FL, USA, 2016; pp. 443–448. [Google Scholar]

- Wanjiru, E.M.N.; Xia, X. Sustainable energy-water management for residential houses with optimal integrated grey and rain water recycling. J. Clean. Prod. 2018, 170, 1151–1166. [Google Scholar] [CrossRef]

- Fertahi, S.E.-D.; Jamil, A.; Kousksou, T.; Benbassou, A. Energy performance enhancement of a collective hot water production process equipped with a centralized storage tank. J. Energy Storage 2019, 25, 100849. [Google Scholar] [CrossRef]

- Mostafa, A.A.A.; Youssef, K.; Abdelrahman, M. Analysis of Photovoltaics in Egypt using SWOT and PESTLE. In Proceedings of the 5th International Conference on Energy Engineering, Aswan, Egypt, 24–26 December 2019; pp. 11–14. [Google Scholar]

- Mazhar, A.R.; Liu, S.; Shukla, A. A Key Review of Non-Industrial Greywater Heat Harnessing. Energies 2018, 11, 386. [Google Scholar] [CrossRef]

- Sitzenfrei, R.; Hillebrand, S.; Rauch, W. Investigating the interactions of decentralized and centralized wastewater heat recovery systems. Water Sci. Technol. 2016, 75, 1243–1250. [Google Scholar] [CrossRef]

- Spriet, J.; McNabola, A.; Neugebauer, G.; Stoeglehner, G.; Ertl, T.; Kretschmer, F. Spatial and temporal considerations in the performance of wastewater heat recovery systems. J. Clean. Prod. 2020, 247, 119583. [Google Scholar] [CrossRef]

- Zhu, J.-J.; Wang, X.; Anderson, P.R. Modeling and spatial optimization of wastewater-source heat pump implementation in a wastewater collection system. Urban Water J. 2019, 16, 698–708. [Google Scholar] [CrossRef]

- Akbarzadeh, P.; Nejad, A.A.; Movahed, F.; Zolfaghari, S. A new approach to numerical investigation of gfx and power-pipe drain water heat recovery (dwhr) systems in buildings. Heat Transf. Res. 2018, 49, 1339–1352. [Google Scholar] [CrossRef]

- Kordana, S.; Słyś, D. Analysis of profitability of using a heat recovery system from grey water discharged from the shower (case study of Poland). E3S Web Conf. 2017, 22, 85. [Google Scholar] [CrossRef]

- Gabor, T.; Dan, V.; Tiuc, A.E.; Sur, I.M.; Badila, I.N. Experimental setup for analysis of drain water heat recovery system in civil buildings. J. Environ. Prot. Ecol. 2019, 20, 1960–1969. [Google Scholar]

- Ip, K.; She, K.; Adeyeye, K. Life-cycle impacts of shower water waste heat recovery: Case study of an installation at a university sport facility in the UK. Environ. Sci. Pollut. Res. 2017, 25, 19247–19258. [Google Scholar] [CrossRef] [PubMed]

- Kordana-Obuch, S.; Pochwat, K.; Słyś, D.; Starzec, M. Opportunities and Threats of Implementing Drain Water Heat Recovery Units in Poland. Resources 2019, 8, 88. [Google Scholar] [CrossRef]

- Li, X.; Gul, M.; Sharmin, T.; Nikolaidis, I.; Al-Hussein, M. A framework to monitor the integrated multi-source space heating systems to improve the design of the control system. Energy Build. 2014, 72, 398–410. [Google Scholar] [CrossRef]

- Paduchowska, J.; Żabnieńska-Góra, A.; Polarczyk, I. Energy-saving analysis of grey water heat recovery systems for student dormitory. E3S Web Conf. 2019, 116, 00056. [Google Scholar] [CrossRef]

- Pochwat, K.; Kordana, S.; Starzec, M.; Słyś, D. Comparison of two-prototype near-horizontal Drain Water Heat Recovery units on the basis of effectiveness. Energy 2019, 173, 1196–1207. [Google Scholar] [CrossRef]

- Selimli, S.; Karabas, T.; Taskin, Y.; Karatas, M.B. Experimental study of the performance of heat recovery by a fin and tube heat exchange tank attached to the dishwasher greywater line. Sustain. Energy Technol. Assess. 2019, 36, 100552. [Google Scholar] [CrossRef]

- Słyś, D.; Pochwat, K.; Czarniecki, D. An Analysis of Waste Heat Recovery from Wastewater on Livestock and Agriculture Farms. Resources 2020, 9, 3. [Google Scholar] [CrossRef]

- Spriet, J.; McNabola, A. Decentralized drain water heat recovery from commercial kitchens in the hospitality sector. Energy Build. 2019, 194, 247–259. [Google Scholar] [CrossRef]

- Torras, S.; Oliet, C.; Rigola, J.; Oliva, A. Drain water heat recovery storage-type unit for residential housing. Appl. Therm. Eng. 2016, 103, 670–683. [Google Scholar] [CrossRef]

- Kordana, S.; Pochwat, K.; Starzec, M.; Słyś, D. Poziomy Wymiennik Ciepła (Horizontal Heat Exchanger). Patent Office of the Republic of Poland Patent Number 234929, 18 May 2020. [Google Scholar]

- Kimmels, A. Shower Water Heat Recovery: Overview of Commercially Available DWHR Systems. Meander Heat Recovery. 2011. Available online: http://www.meanderhr.com/report/meanderhr_com_shower_dwhr_overview.pdf (accessed on 10 April 2020).

- Tworek, P. Relationships and Dependencies between Discount Methods Used in Capital Budgeting Process in Enterprises. Univers. J. Account. Financ. 2015, 3, 175–184. [Google Scholar] [CrossRef][Green Version]

- Lin, W.-M.; Chang, K.-C.; Chung, K.-M. Economic aspects for solar thermal application in Taiwan. Sustain. Cities Soc. 2016, 26, 354–363. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, J.; Adkins, D.; Yang, T.; Tang, L.; Zhao, X.; He, W.; Xu, P.; Liu, C.; Luo, H. The early design stage for building renovation with a novel loop-heat-pipe based solar thermal facade (LHP-STF) heat pump water heating system: Techno-economic analysis in three European climates. Energy Convers. Manag. 2015, 106, 964–986. [Google Scholar] [CrossRef]

- Rout, A.; Sahoo, S.S.; Thomas, S.; Varghese, S.M. Development of Customized Formulae for Feasibility and Break-Even Analysis of Domestic Solar Water Heater. Int. J. Renew. Energy Res. 2017, 7, 386–398. [Google Scholar]

- Tariff for Electricity Distribution Services of PGE Dystrybucja S.A. Available online: https://pgedystrybucja.pl/strefa-klienta/informacje-dla-konsumenta/taryfy-i-cenniki (accessed on 1 January 2020).

- Wiśniewski, S.; Wiśniewski, T.S. Wymiana Ciepła (Heat Exchange), 6th ed.; WNT: Warszaw, Poland, 2009. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).