Analysis on the Fire Growth Rate Index Considering of Scale Factor, Volume Fraction, and Ignition Heat Source for Polyethylene Foam Pipe Insulation

Abstract

1. Introduction

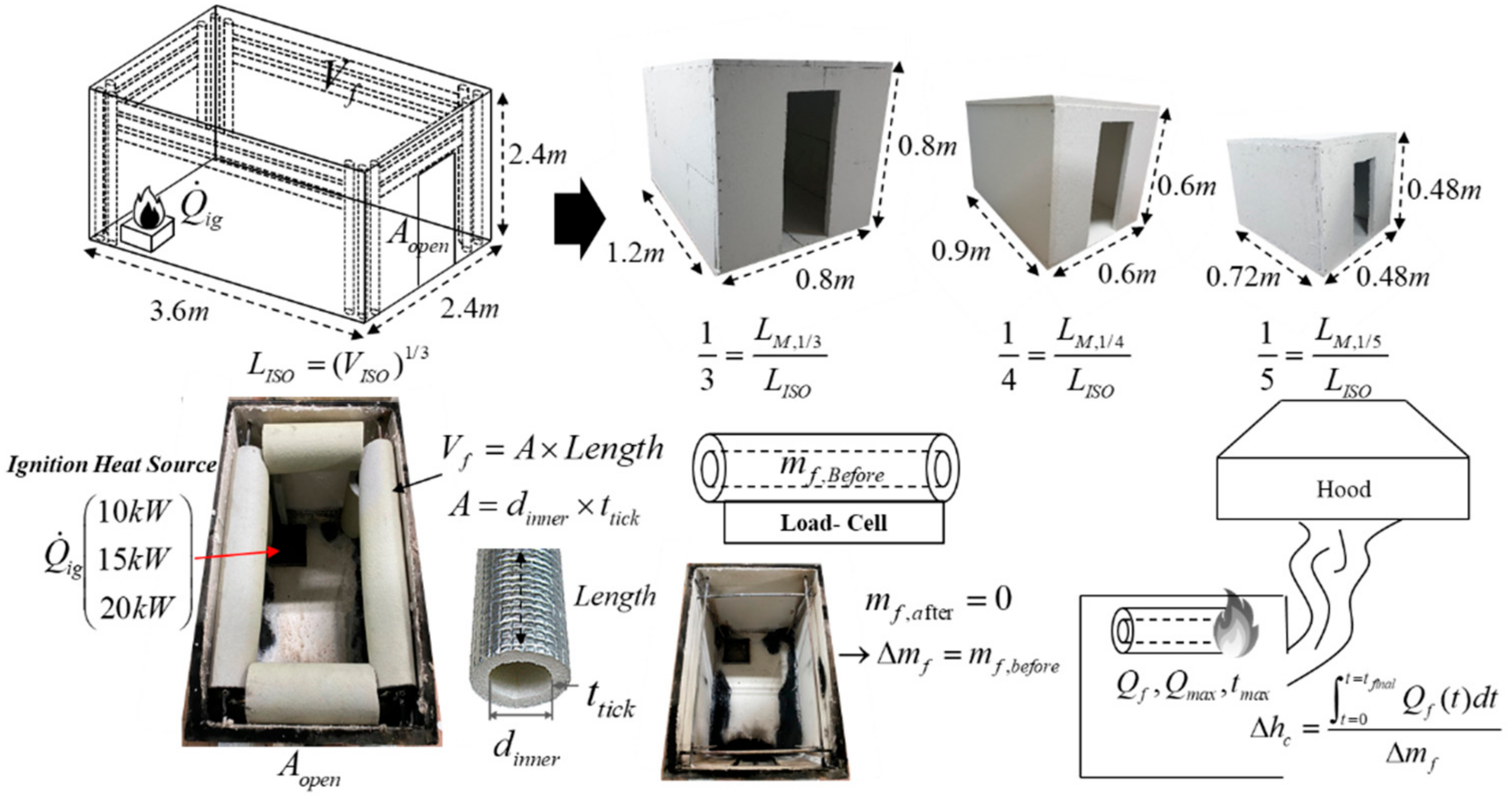

2. Materials and Methods

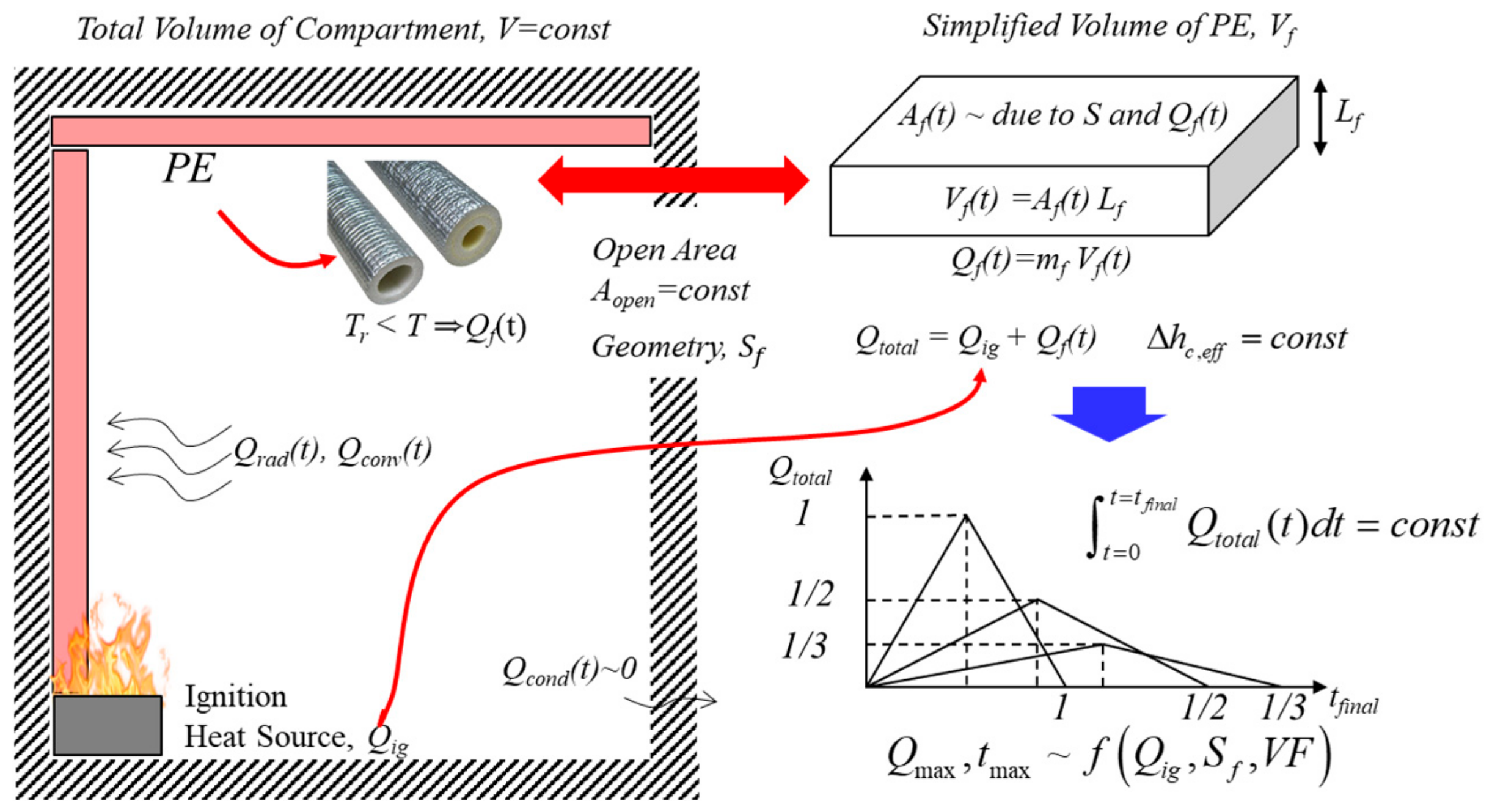

2.1. Heat Transfer Phenomenon

2.2. Heat Transfer Phenomenon

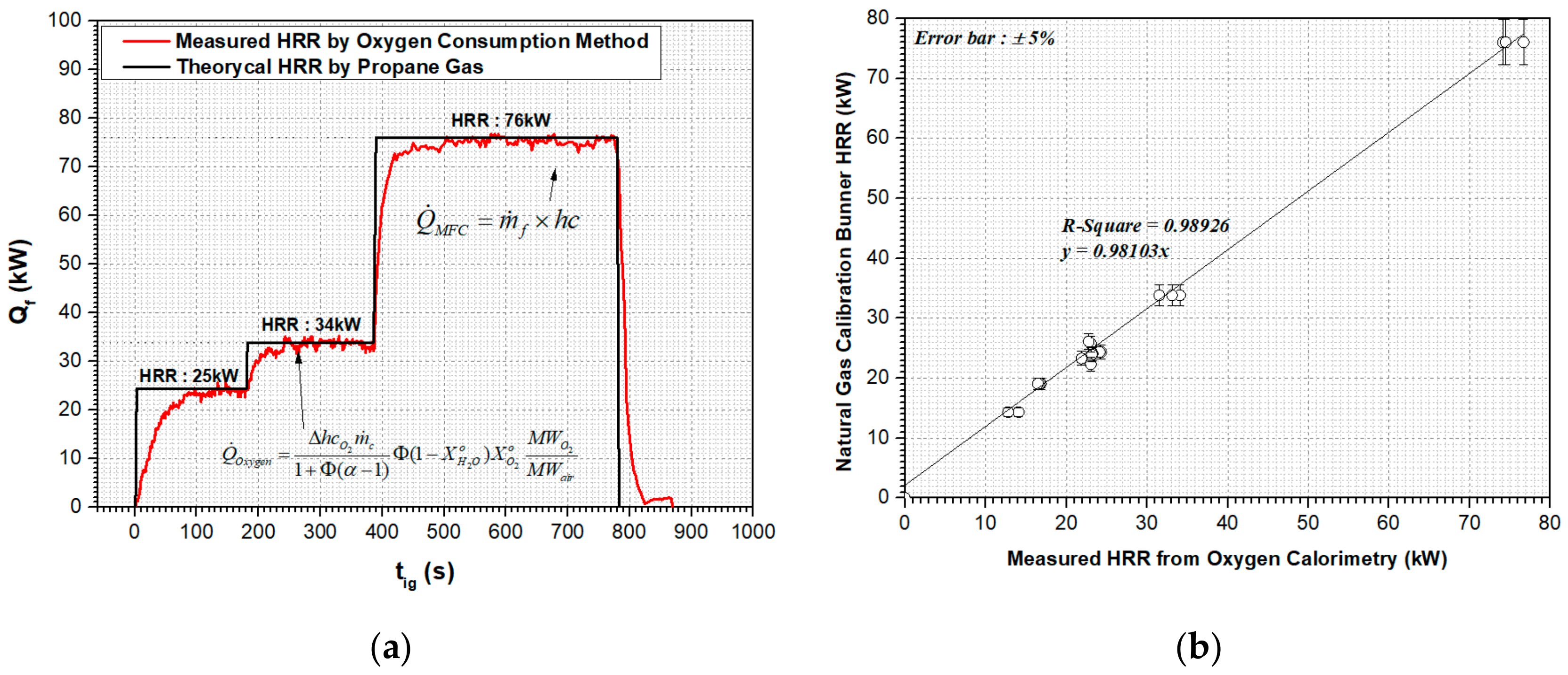

2.3. Calibration of the Heat Release Rate

2.4. Material Properties of the Test Sample

3. Results and Discussion

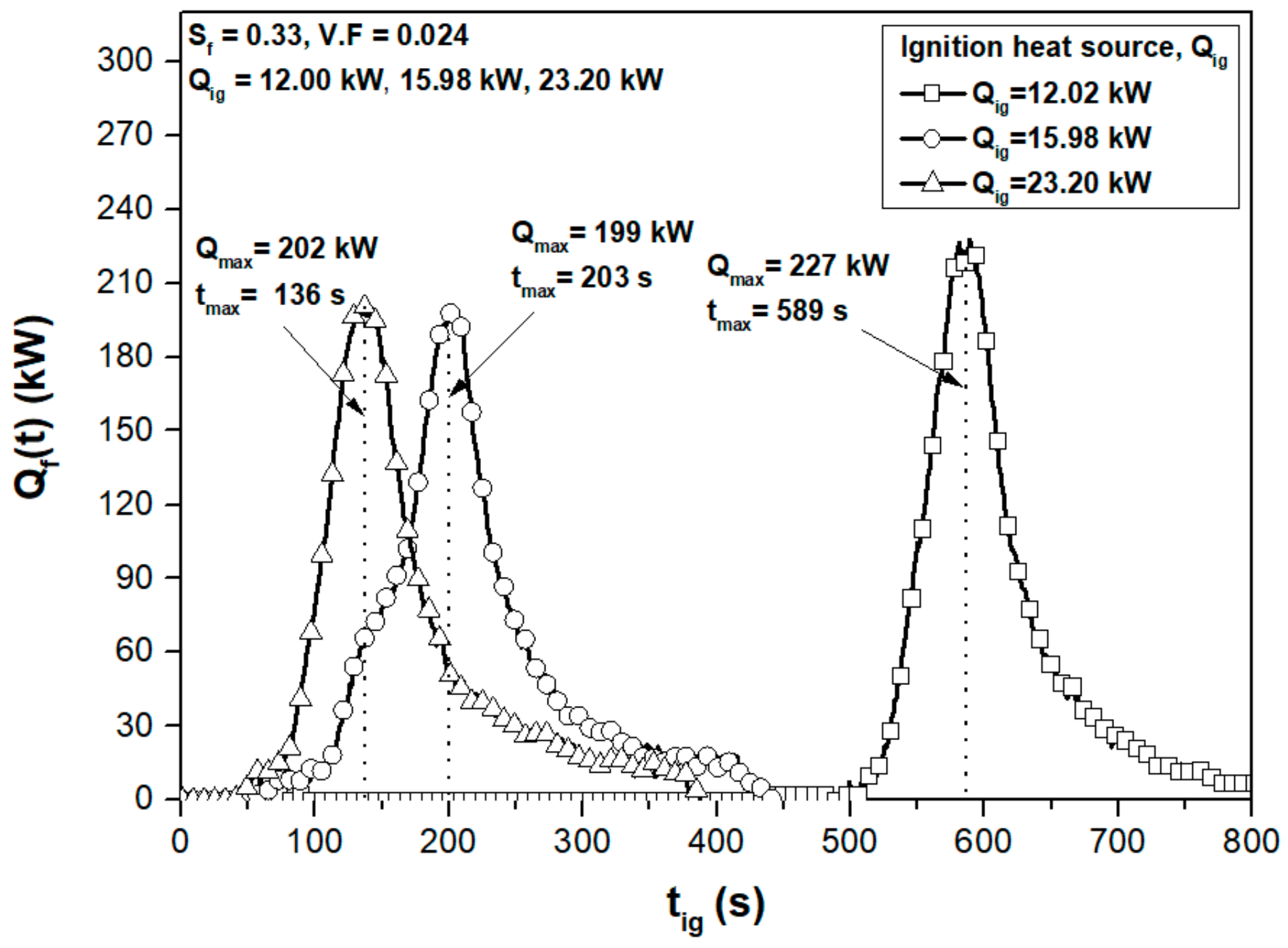

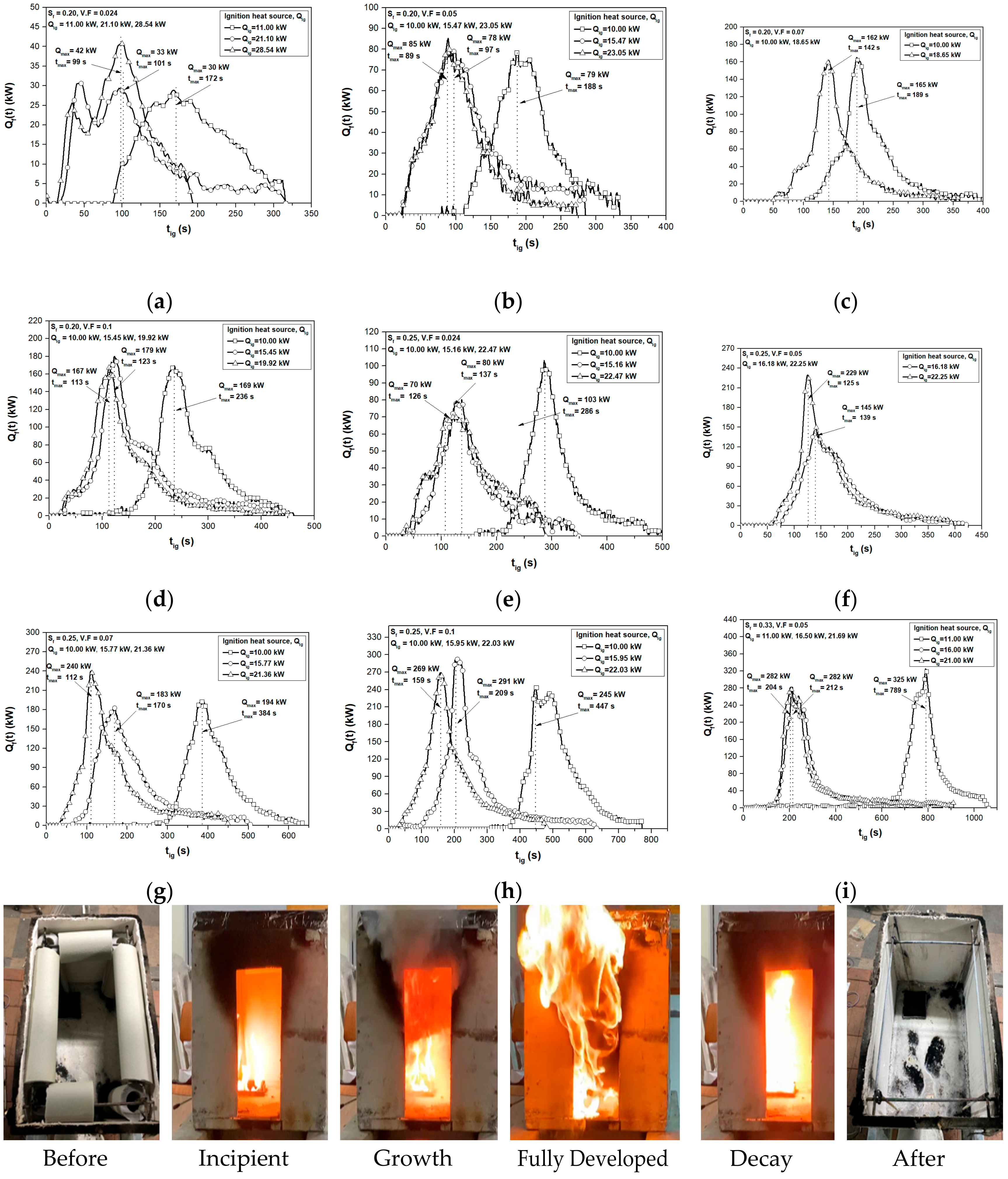

3.1. Experiment of Heat Release Rate

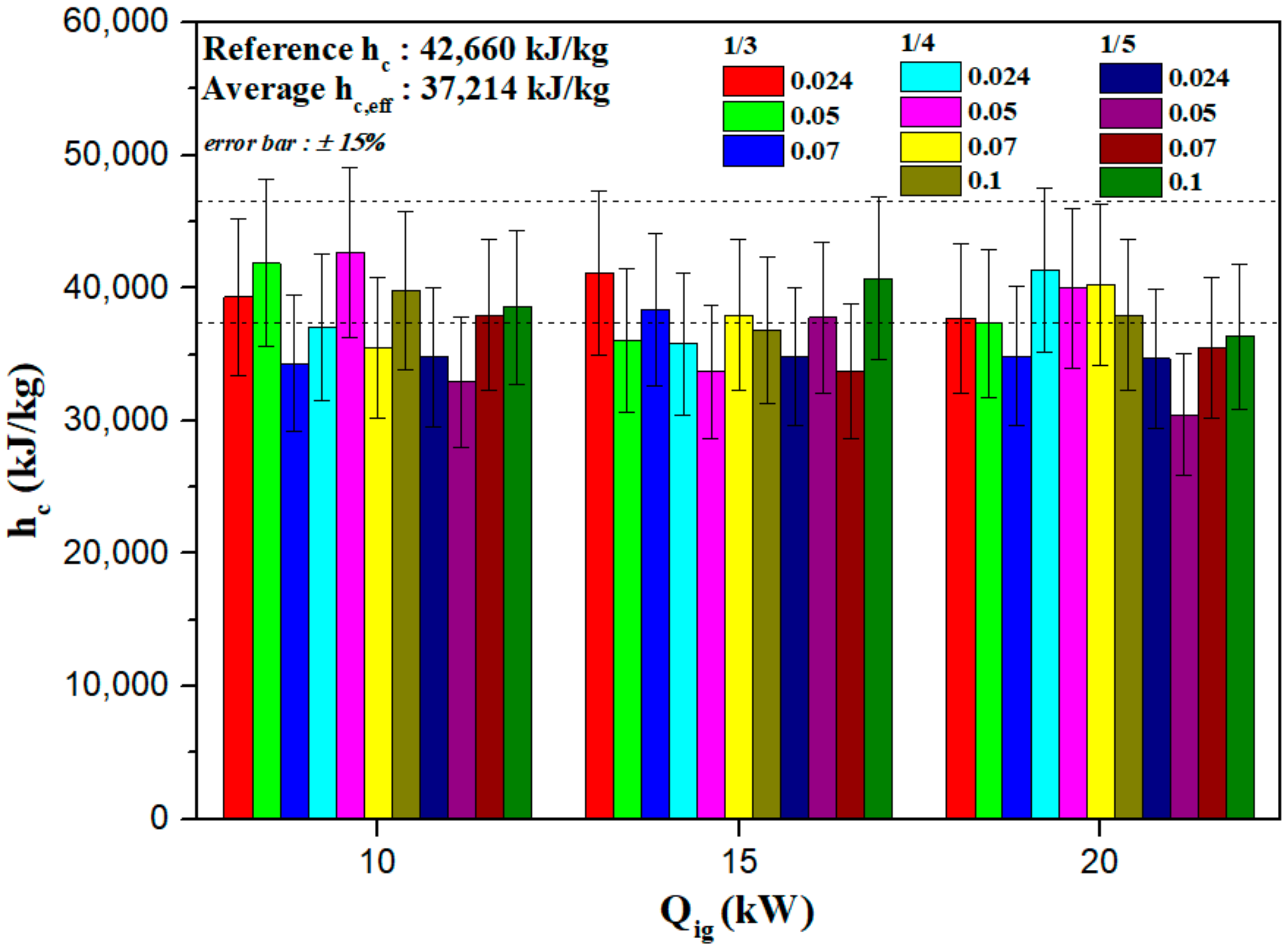

3.2. Comparison of the Effective Heat of Combustion, Δhc,eff

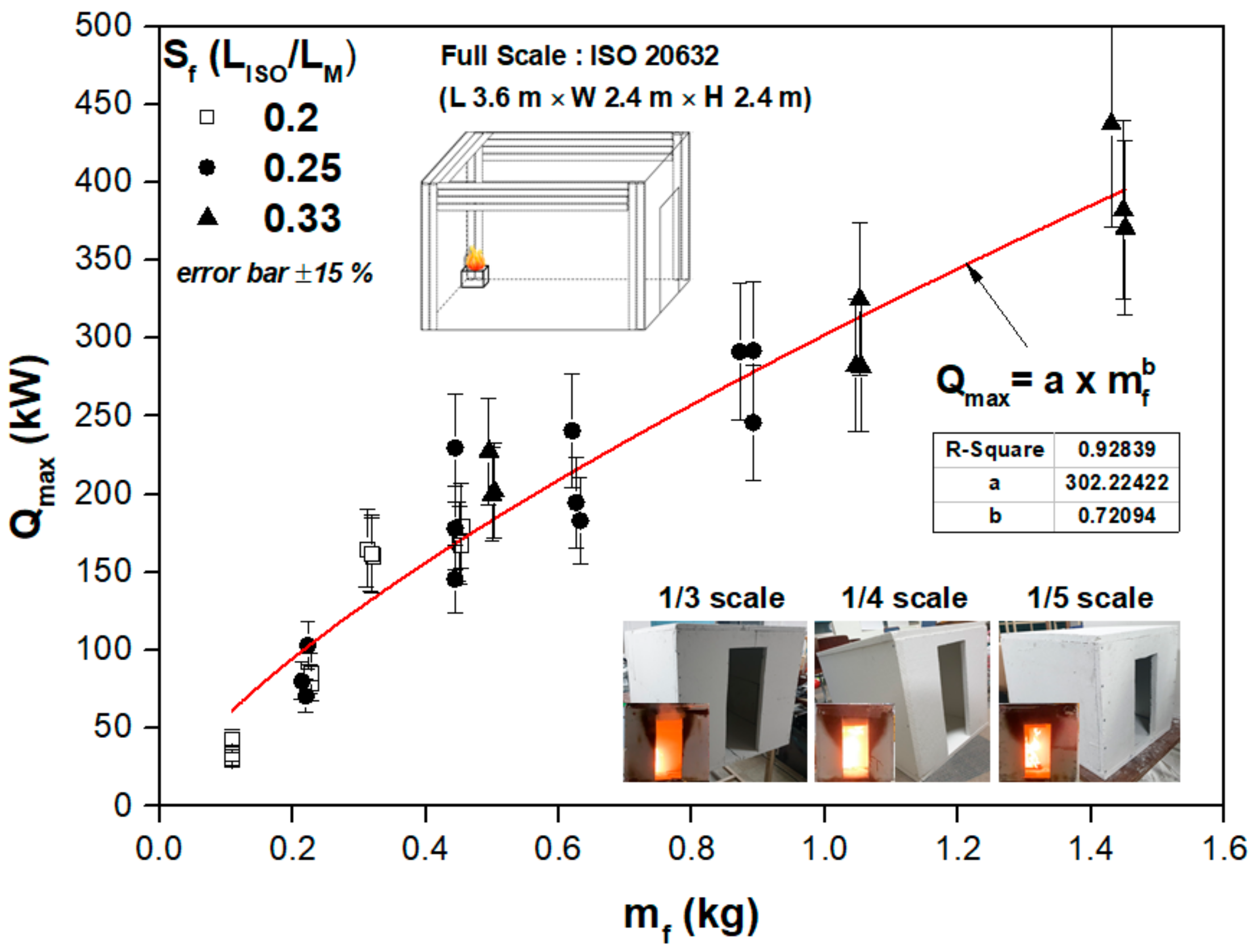

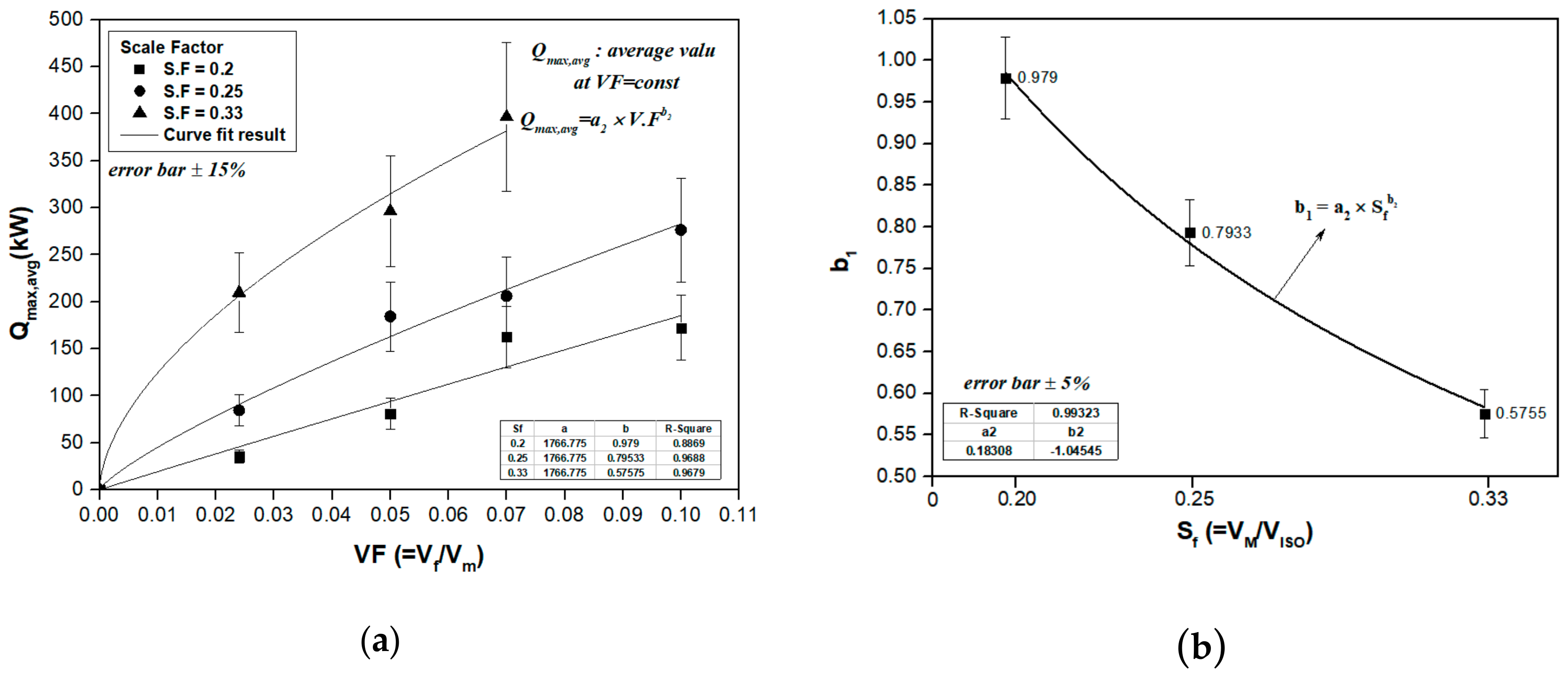

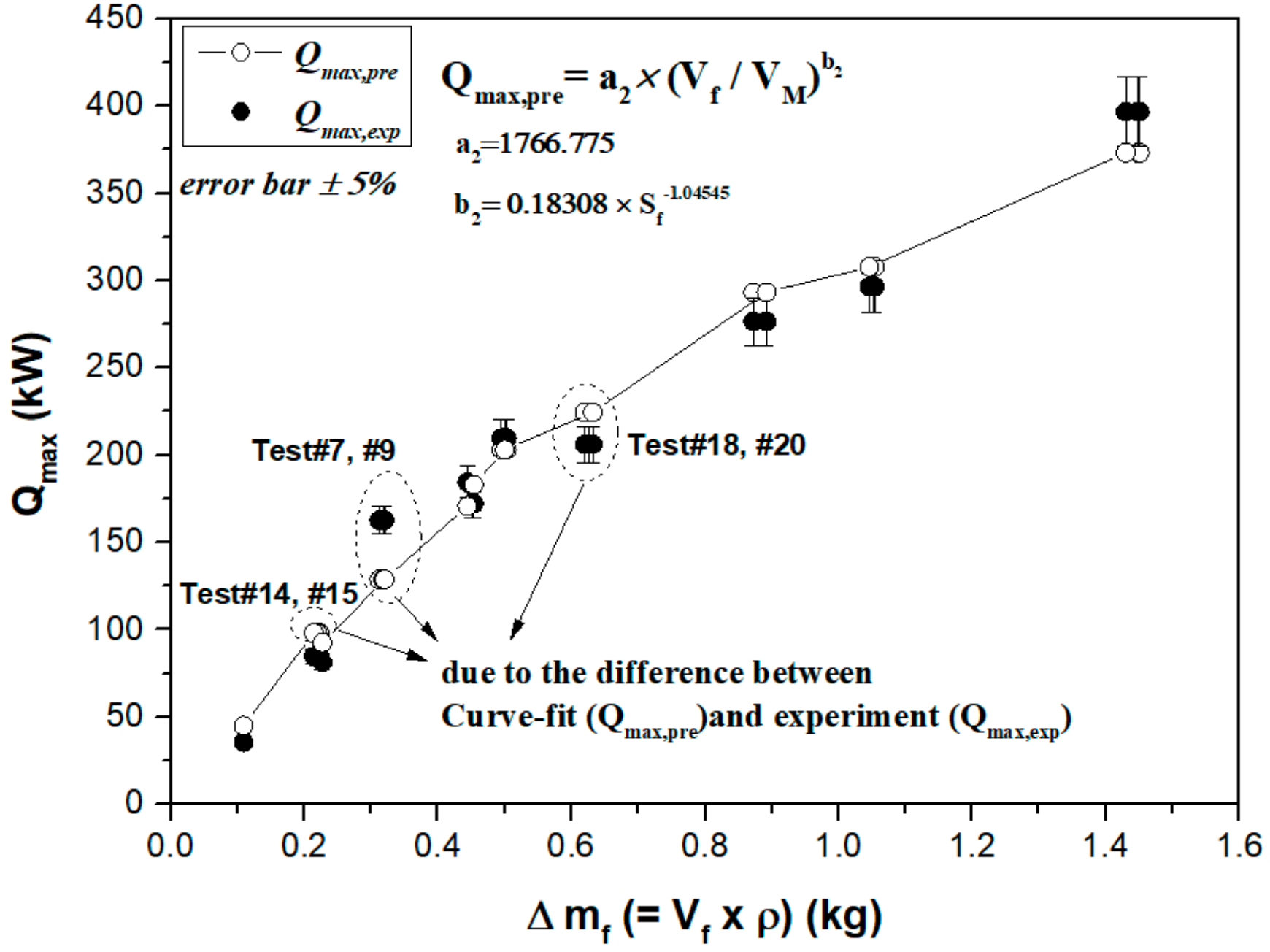

3.3. Analysis of the Maximum Heat Release Rate, Qmax

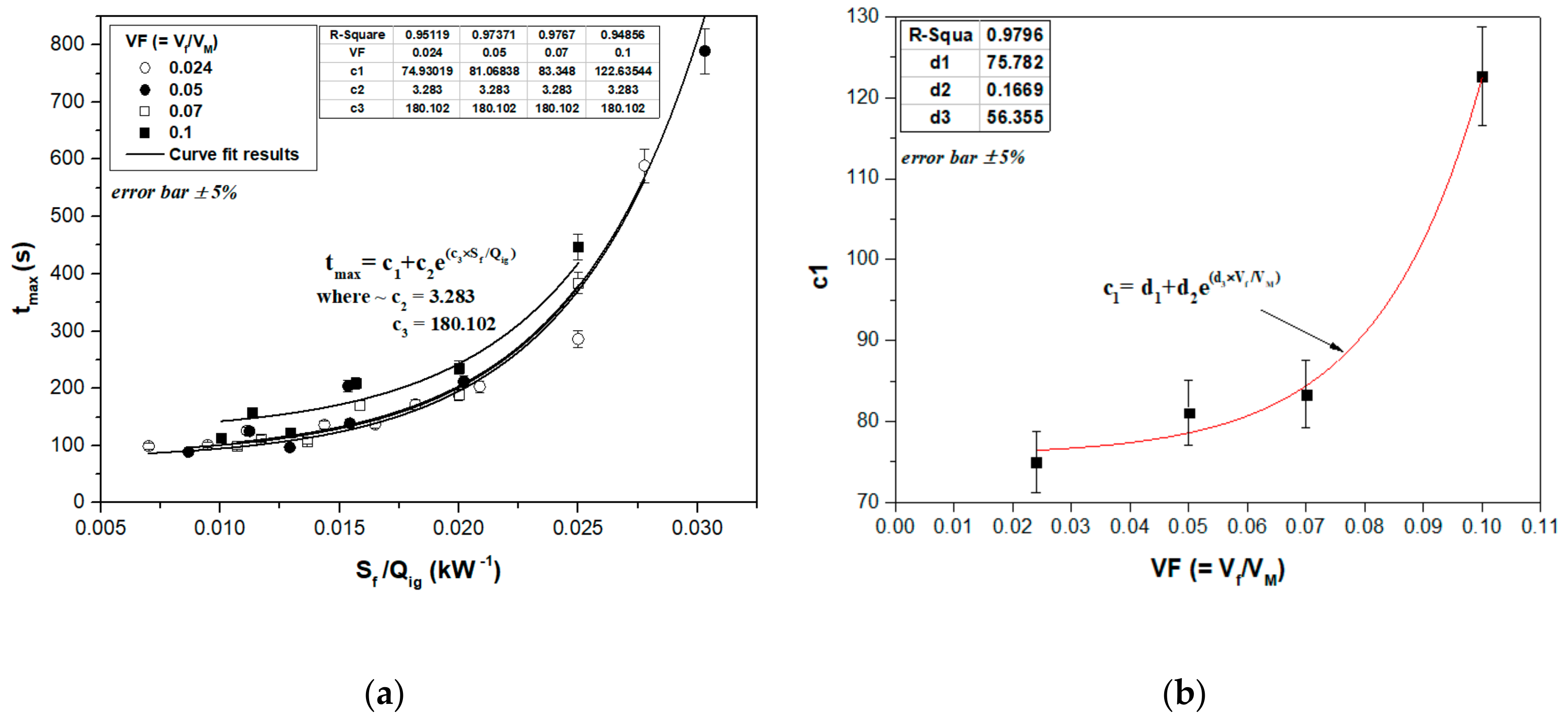

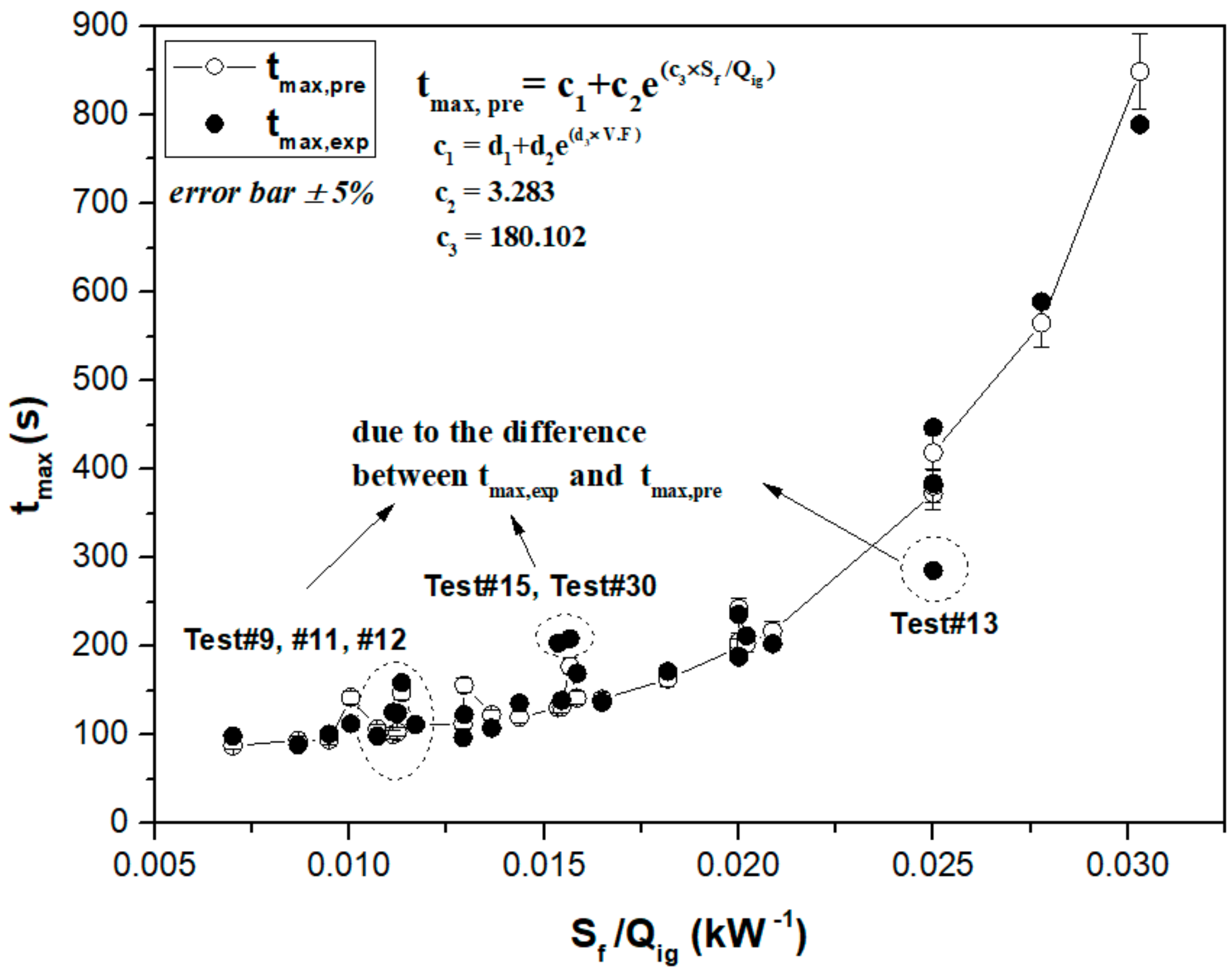

3.4. Analysis of the Time to Reach the Maximum Heat Release Rate, tmax

3.5. Estimation of the Fire Growth Rate Index, FIGRA

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kecebas, A. Determination of insulation thickness by means of exergy analysis in pipe insulation. Energy Convers. Manag. 2012, 58, 76–83. [Google Scholar] [CrossRef]

- Kayfeci, M.; Yabanova, I.; Kecebas, A. The use of artificial neural network to evaluate insulation thickness and life cycle costs: Pipe insulation application. Appl. Therm. Eng. 2014, 63, 370–378. [Google Scholar] [CrossRef]

- Kecebas, A.; Alkan, M.A.; Bayhan, M. Thermo-economic analysis of pipe insulation for district heating piping systems. Appl. Therm. Eng. 2011, 31, 17–18. [Google Scholar] [CrossRef]

- Mangs, S. Insulation Materials in District Heating Pipes: Environmental and Thermal Performance of Polyethylene Terephthalae and Polyurethane Foam; Chalmers University of technology: Göteborg, Sweden, 2005; pp. 1–2. [Google Scholar]

- Vega, A.; Yarahmadi, N.; Jakubowicz, I. Determination of the long-term performance of district heating pipes through accelerated ageing. Polym. Degrad. Stab. 2018, 153, 15–22. [Google Scholar] [CrossRef]

- Winkler-Skalna, A.; Łoboda, B. Determination of the thermal insulation properties of cylindrical PUR foam products throughout the entire life cycle using accelerated aging procedures. J. Build. Eng. 2020, 31, 101348. [Google Scholar] [CrossRef]

- Hilado, C.J.; Cumming, H.J. Fire Safety Aspects of Thermal Insulation. J. Therm. Insul. 1977, 1, 116–128. [Google Scholar] [CrossRef]

- Goldfarb, I.; Zinoviev, A. A study of delayed spontaneous insulation fires. Phys. Lett. A 2003, 311, 491–500. [Google Scholar] [CrossRef]

- Hidalgo, J.P.; Welch, S.; Torero, J.L. Performance criteria for the fire safe use of thermal insulation in buildings. Constr. Build. Mater. 2015, 100, 285–297. [Google Scholar] [CrossRef]

- Ye, L.; Meng, X.Y.; Ji, X.; Li, Z.M.; Tang, J.H. Synthesis and characterization of expandable graphite–poly (methyl methacrylate) composite particles and their application to flame retardation of rigid polyurethane foams. Polym. Degrad. Stab. 2009, 94, 971–979. [Google Scholar] [CrossRef]

- Xu, W.; Chen, R.; Du, Y.; Wang, G. Design water-soluble phenolic/zeolitic imidazolate framework-67 flame retardant coating via layer-by-layer assembly technology: Enhanced flame retardancy and smoke suppression of flexible polyurethane foam. Polym. Degrad. Stab. 2020, 176, 109152. [Google Scholar] [CrossRef]

- D’Alessandro, F.; Baldinelli, G.; Sambuco, S.; Rufini, A. Experimental assessment of the water content influence on thermo-acoustic performance of building insulation materials. Constr. Build. Mater. 2018, 158, 264–274. [Google Scholar] [CrossRef]

- Sundström, B. The Development of a European Fire Classification System for Building Products; Department of Fire Safety Engineering, Lund University: Lund, Sweden, 2007. [Google Scholar]

- European Committee for Standardization. EN ISO 11925-2 Reaction to Fire Tests—Ignitability of Building Products Subjected to Direct Impingement of Flame—Part 2: Single-Flame Source Test; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization. EN ISO 13823 Reaction to Fire Tests—Building Products-building Products Excluding Floorings Exposed to the Thermal Attack by a Single Burning Item; European Committee for Standardization: Brussels, Belgium, 2002. [Google Scholar]

- European Committee for Standardization. EN ISO 13501-1 Reaction to Fire Tests—Fire Classification of Construction Products and Building Elements-Part 1: Classification using Test Data; European Committee for Standardization: Brussels, Belgium, 2002. [Google Scholar]

- NFPA. NFPA Standard 274: Standard Test Method to Evaluate Fire Performance Characteristics of Pipe Insulation; Technical Report; National Fire Protection Association: Quincy, MA, USA, 2013. [Google Scholar]

- European Committee for Standardization. EN ISO 13501-1 Reaction to Fire Tests—Small Room Test for Pipe Insulation Products or Systems; European Committee for Standardization: Brussels, Belgium, 2008. [Google Scholar]

- Janssens, M.L.; Huczek, J.; Sauceda, A. Development of a model of the ASTM E 84 Steiner tunnel test. Fire Saf. Sci. 2008, 9, 279–289. [Google Scholar] [CrossRef]

- Pretrel, H.; Bouaza, L.; Suard, S. Multi-scale analysis of the under-ventilated combustion regime for the case of a fire event in a confined and mechanically ventilated compartment. Fire Saf. J. 2020, 5, 103069. [Google Scholar] [CrossRef]

- Hernández, N.; Fuentes, A.; Reszka, P.; Fernández-Pello, A.C. Piloted ignition delay times on optically thin PMMA cylinders. Proc. Combust. Inst. 2019, 37, 3993–4000. [Google Scholar] [CrossRef]

- Leisted, R.R.; Sørensen, M.X.; Jomaas, G. Experimental study on the influence of different thermal insulation materials on the fire dynamics in a reduced-scale enclosure. Fire Saf. J. 2017, 93, 114–125. [Google Scholar] [CrossRef]

- You, W.J.; Park, J.W.; Sin, J.Y.; Park, H.G.; Ohk, K.L. Analysis of the Maximum Heat Release Rate in Accordance with the Test Method of the Flame Retardant Performance for Pipe Insulation. Fire Sci. Eng. 2020, 34, 18–25. [Google Scholar] [CrossRef]

- Ohk, K.L.; Nam, D.G.; Jang, H.Y. Evaluation of the Reaction-to-fire Performance of Pipe Insulation Material using Small Room Test. Fire Sci. Eng. 2019, 33, 1–8. [Google Scholar]

- McGrattan, K.; Klein, B.; Hostikka, S.; Floyd, J. Fire Dynamics Simulator (Version 5), User’s Guide; NIST Special Publication; NIST: Gaithersburg, MD, USA, 2010; pp. 56–57. [Google Scholar]

- Quintiere, J.G. Fundamentals of Fire Phenomena; John Wiley & Sons: West Sussex, UK, 2006; pp. 96–133. [Google Scholar]

- Tewarson, A.; Jiang, F.H.; Morikawa, T. Ventilation controlled combustion of polymers. Combust. Flame 1993, 95, 151–169. [Google Scholar] [CrossRef]

- Madrigal, J.; Guijarro, M.; Hernando, C.; Diez, C.; Marino, E. Effective heat of combustion for flaming combustion of Mediterranean forest fuels. Fire Technol. 2011, 47, 461–474. [Google Scholar] [CrossRef]

- Al-Ghouti, M.; Al-Degs, Y.; Mustafa, F. Determination of hydrogen content, gross heat of combustion, and net heat of combustion of diesel fuel using FTIR spectroscopy and multivariate calibration. Fuel 2010, 89, 193–201. [Google Scholar] [CrossRef]

- Lyon, R.E.; Walters, R.N. Pyrolysis combustion flow calorimetry. Anal. Appl. Pyrolysis 2004, 71, 27–46. [Google Scholar] [CrossRef]

- Minakshi, M.; Visbal, H.; Mitchell, D.R.; Fichtner, M. Bio-waste chicken eggshells to store energy. Dalton Trans. 2018, 47, 16828–16834. [Google Scholar] [CrossRef] [PubMed]

- Minakshi, M.; Barmi, M.; Mitchell, D.R.; Barlow, A.J.; Fichtner, M. Effect of oxidizer in the synthesis of NiO anchored nanostructure nickel molybdate for sodium-ion battery. Mater. Today Energy 2018, 10, 1–14. [Google Scholar] [CrossRef]

- Lyon, R.E. An integral method of nonisothermal kinetic analysis. Thermochim. Acta 1997, 297, 117–124. [Google Scholar] [CrossRef]

- Walters, R.N.; Hackett, S.M.; Lyon, R.E. Heats of combustion of high temperature polymers. Fire Mater. 2000, 24, 245–252. [Google Scholar] [CrossRef]

- Bundy, M.F.; Hamins, A.P.; Johnsson, E.L.; Kim, S.C.; Ko, G.; Lenhert, D.B. Measurements of Heat and Combustion Products in Reduced-Scale Ventilation-Limited Compartment Fires; Technical Note (NIST TN) -1483; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2007; pp. 114–116. [Google Scholar]

- Van Krevelen, D.W. Some basic aspects of flame resistance of polymeric materials. Polymer 1975, 16, 615–620. [Google Scholar] [CrossRef]

- Filipczak, R.; Crowley, S.; Lyon, R.E. Heat release rate measurements of thin samples in the OSU apparatus and the cone calorimeter. Fire Saf. J. 2005, 40, 628–645. [Google Scholar] [CrossRef]

| Contents | ISO 20632 | NFPA 274 | Test Conditions |

|---|---|---|---|

| Volume of Compartment (m3) | VISO = 20.76 m3 | VM,NFPA = 0.78 m3 | VM,1/3 = 0.768 m3 |

| VM,1/4 = 0.324 m3 | |||

| VM,1/5 = 0.165 m3 | |||

| Scale Factor (-) | 1 | 1/3 ( = 0.33) | 1/3 ( = 0.33), ¼ ( = 0.25), 1/5 ( = 0.20) |

| Volume of Insulation (m3) | Vf,iso = 0.51 m3 | Vf,NFPA = 0.055 m3 | Vf,1/5 = 0.004 m3, 0.008 m3, 0.019 m3, 0.008 m3 |

| Vf,1/4 = 0.016 m3, 0.038 m3, 0.012 m3, 0.023 m3 | |||

| Vf,1/3 = 0.053 m3, 0.017 m3, 0.032 m3 | |||

| Volume Fraction (-) | VF = 0.024 | VF = 0.07 | VF = 0.024, 0.05, 0.07, 0.1 |

| Ignition (kW) and Time (s) | Qig,1 = 100 kW for 600 s | Qig,1 = 20 kW for 180 s | Qig = 10 kW, 15 kW, 20 kW for tfinal = 600 s |

| Qig,2 = 300 kW for 600 s | Qig,2 = 70 kW for 420 s |

| Measurement | Specification |

|---|---|

| Duct Temperature | K-Type Wire, Range: −200–1000 °C |

| DAQ | Voltage: 20 mV to 100 V, 1–5 V F.S., 20 channels, Accuracy: ±0.1% |

| Duct Size & Blower | Length: 5 m, Diameter: 0.2 m, Fan capacity: 3 hp |

| O2 Analyzer | Output: 4–20 mA, Range: 0.7–1.2 bar, Model: OXYMAT 61 |

| Pressure Sensor | Output: 0–10 V, Range: 1250 Pa, Model: MS-311 |

| Mass Flow Controller | Fuel: CH4, C3H8, Output: 0–5 VDC, Range: 200 LPM, Model: TSC-145 |

| Pressure Transmitter | Output: 0–20 mA, Range: 0–20 bar, Model: PSC-E-B-A-P-G |

| Properties | Values | Properties | Values |

|---|---|---|---|

| Reference Temperature, (K) | 744 | Heat of Combustion, (kJ/kg) | 42,660 |

| Activation Energy (kJ/kmole) | 1.19 × 10−5 | Density (kg/m3) | 26 |

| Pre-exponential Factor (1/s) | 1.05 × 10−6 | Specific Heat (kJ/kg-°C) | 2.31 |

| Test Num. | Test Conditions | Results of Experiment | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (-) | (m3) | (m3) | (-) | (kg) | (kW) | (kJ) | (kJ/kg) | (kW) | (s) | |

| #1 | 0.2 | 0.165 | 0.004 | 0.024 | 0.109 | 11.00 | 3795 | 34,817 | 30.23 | 172 |

| #2 | 0.2 | 0.165 | 0.004 | 0.024 | 0.109 | 21.10 | 3797 | 34,833 | 33.47 | 101 |

| #3 | 0.2 | 0.165 | 0.004 | 0.024 | 0.109 | 28.54 | 3779 | 34,672 | 42.63 | 99 |

| #4 | 0.2 | 0.165 | 0.008 | 0.050 | 0.227 | 10.00 | 7477 | 32,938 | 79.09 | 188 |

| #5 | 0.2 | 0.165 | 0.008 | 0.050 | 0.227 | 15.47 | 8576 | 37,778 | 78.96 | 97 |

| #6 | 0.2 | 0.165 | 0.008 | 0.050 | 0.227 | 23.05 | 6913 | 30,455 | 85.23 | 89 |

| #7 | 0.2 | 0.165 | 0.012 | 0.070 | 0.312 | 10.00 | 11,847 | 37,972 | 165.25 | 189 |

| #8 | 0.2 | 0.165 | 0.012 | 0.070 | 0.320 | 14.64 | 10,785 | 33,702 | 160.78 | N/A |

| #9 | 0.2 | 0.165 | 0.012 | 0.070 | 0.318 | 18.65 | 11,282 | 35,479 | 162.03 | 142 |

| #10 | 0.2 | 0.165 | 0.0165 | 0.1 | 0.450 | 10.00 | 17,344 | 38,541 | 169.34 | 236 |

| #11 | 0.2 | 0.165 | 0.0165 | 0.1 | 0.454 | 15.45 | 18,482 | 40,708 | 179.98 | 123 |

| #12 | 0.2 | 0.165 | 0.0165 | 0.1 | 0.452 | 19.92 | 16,436 | 36,362 | 167.22 | 113 |

| #13 | 0.25 | 0.324 | 0.008 | 0.024 | 0.223 | 10.00 | 8260 | 37,042 | 103.18 | 286 |

| #14 | 0.25 | 0.324 | 0.008 | 0.024 | 0.214 | 15.16 | 7660 | 35,797 | 80.16 | 137 |

| #15 | 0.25 | 0.324 | 0.008 | 0.024 | 0.220 | 22.47 | 9101 | 41,366 | 70.60 | 126 |

| #16 | 0.25 | 0.324 | 0.016 | 0.050 | 0.444 | 10.00 | 18,959 | 42,699 | 178.05 | N/A |

| #17 | 0.25 | 0.324 | 0.016 | 0.050 | 0.444 | 16.18 | 14,961 | 33,696 | 145.56 | 139 |

| #18 | 0.25 | 0.324 | 0.016 | 0.050 | 0.444 | 22.25 | 17,763 | 40,006 | 229.68 | 125 |

| #19 | 0.25 | 0.324 | 0.023 | 0.070 | 0.626 | 10.00 | 22,223 | 35,500 | 194.57 | 384 |

| #20 | 0.25 | 0.324 | 0.023 | 0.070 | 0.632 | 15.77 | 23,994 | 37,964 | 183.09 | 170 |

| #21 | 0.25 | 0.324 | 0.023 | 0.070 | 0.620 | 21.36 | 24,962 | 40,261 | 240.65 | 112 |

| #22 | 0.25 | 0.324 | 0.032 | 0.1 | 0.892 | 10.00 | 35,515 | 39,815 | 245.92 | 447 |

| #23 | 0.25 | 0.324 | 0.032 | 0.1 | 0.892 | 15.95 | 32,812 | 36,785 | 291.99 | 209 |

| #24 | 0.25 | 0.324 | 0.032 | 0.1 | 0.872 | 22.03 | 33,095 | 37,953 | 269.13 | 159 |

| #25 | 0.33 | 0.768 | 0.019 | 0.024 | 0.495 | 12.00 | 19,455 | 39,303 | 227.52 | 589 |

| #26 | 0.33 | 0.768 | 0.019 | 0.024 | 0.500 | 15.98 | 20,547 | 41,095 | 199.78 | 203 |

| #27 | 0.33 | 0.768 | 0.019 | 0.024 | 0.503 | 23.20 | 18,974 | 37,722 | 202.00 | 136 |

| #28 | 0.33 | 0.768 | 0.038 | 0.050 | 1.052 | 11.00 | 44,035 | 41,859 | 325.05 | 789 |

| #29 | 0.33 | 0.768 | 0.038 | 0.050 | 1.046 | 16.50 | 37,700 | 36,042 | 282.23 | 212 |

| #30 | 0.33 | 0.768 | 0.038 | 0.050 | 1.054 | 21.69 | 39,344 | 37,328 | 282.02 | 204 |

| #31 | 0.33 | 0.768 | 0.053 | 0.070 | 1.448 | 13.57 | 49,677 | 34,307 | 382.10 | N/A |

| #32 | 0.33 | 0.768 | 0.053 | 0.070 | 1.430 | 17.69 | 54,897 | 38,389 | 437.19 | N/A |

| #33 | 0.33 | 0.768 | 0.053 | 0.070 | 1.451 | 21.83 | 50,609 | 34,878 | 370.69 | N/A |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.W.; Lim, O.K.; You, W.J. Analysis on the Fire Growth Rate Index Considering of Scale Factor, Volume Fraction, and Ignition Heat Source for Polyethylene Foam Pipe Insulation. Energies 2020, 13, 3644. https://doi.org/10.3390/en13143644

Park JW, Lim OK, You WJ. Analysis on the Fire Growth Rate Index Considering of Scale Factor, Volume Fraction, and Ignition Heat Source for Polyethylene Foam Pipe Insulation. Energies. 2020; 13(14):3644. https://doi.org/10.3390/en13143644

Chicago/Turabian StylePark, Jung Wook, Ohk Kun Lim, and Woo Jun You. 2020. "Analysis on the Fire Growth Rate Index Considering of Scale Factor, Volume Fraction, and Ignition Heat Source for Polyethylene Foam Pipe Insulation" Energies 13, no. 14: 3644. https://doi.org/10.3390/en13143644

APA StylePark, J. W., Lim, O. K., & You, W. J. (2020). Analysis on the Fire Growth Rate Index Considering of Scale Factor, Volume Fraction, and Ignition Heat Source for Polyethylene Foam Pipe Insulation. Energies, 13(14), 3644. https://doi.org/10.3390/en13143644