Optimal Sizing of Fuel Cell Hybrid Power Sources with Reliability Consideration

Abstract

:1. Introduction

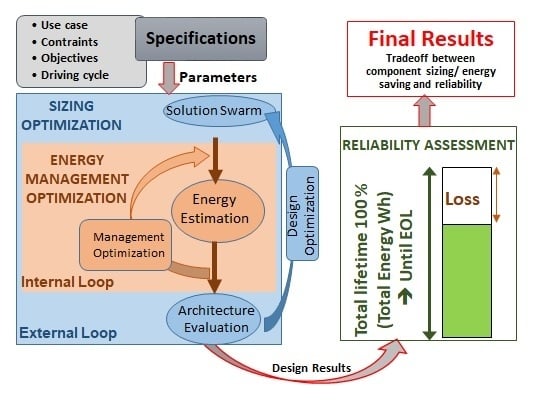

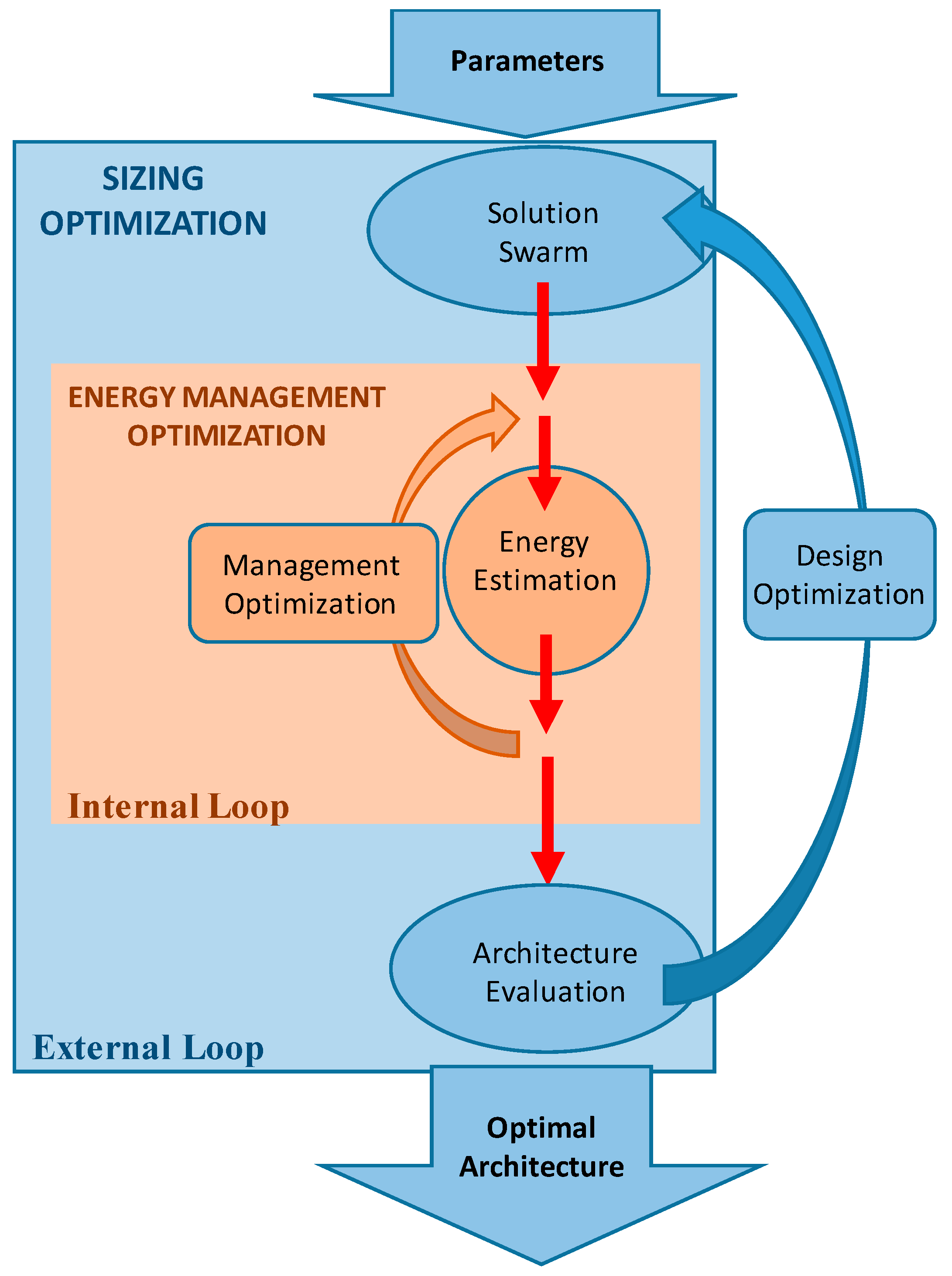

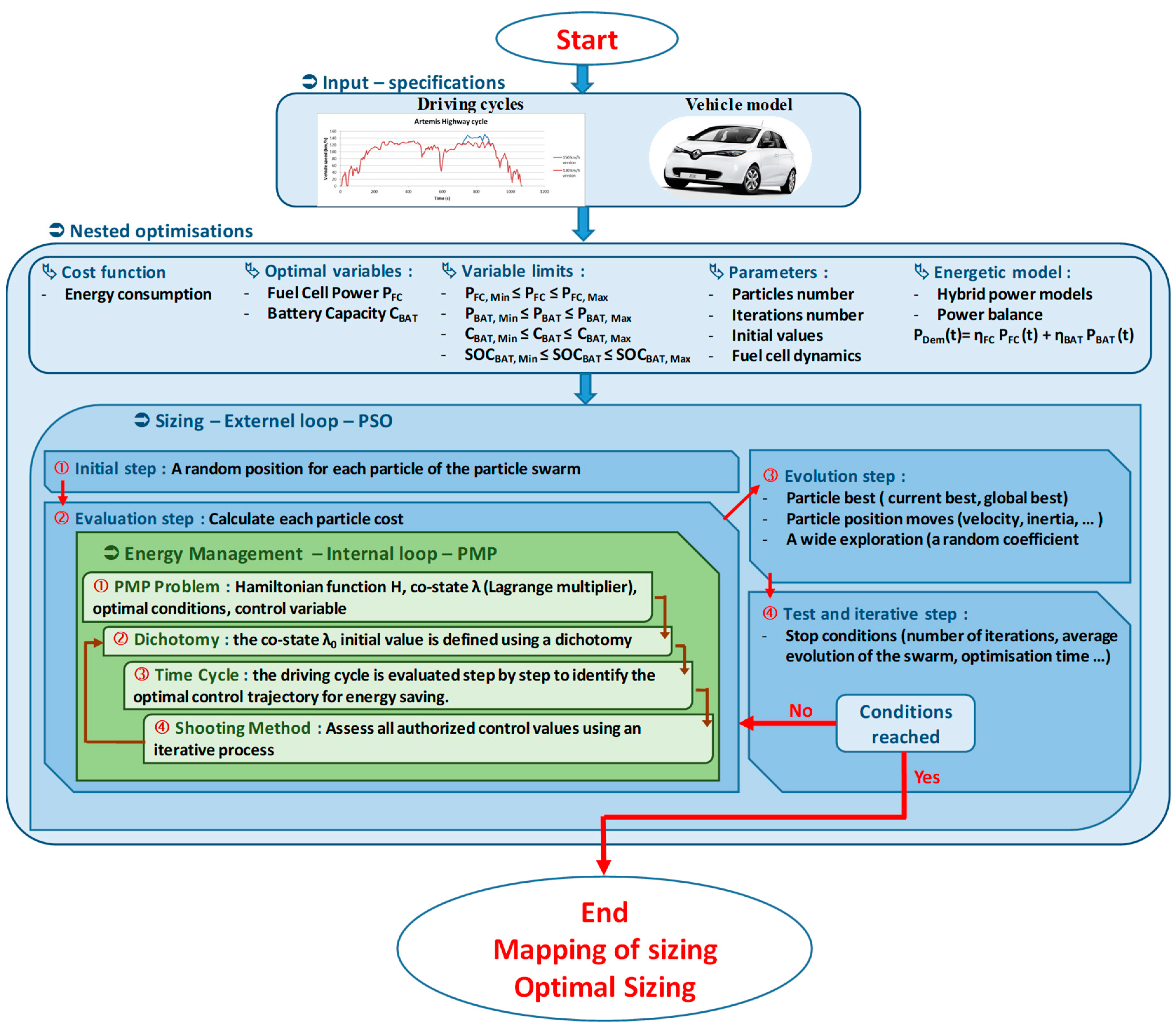

2. Optimization Sizing Approach

2.1. Principle of Sizing Approach

2.2. Use Case

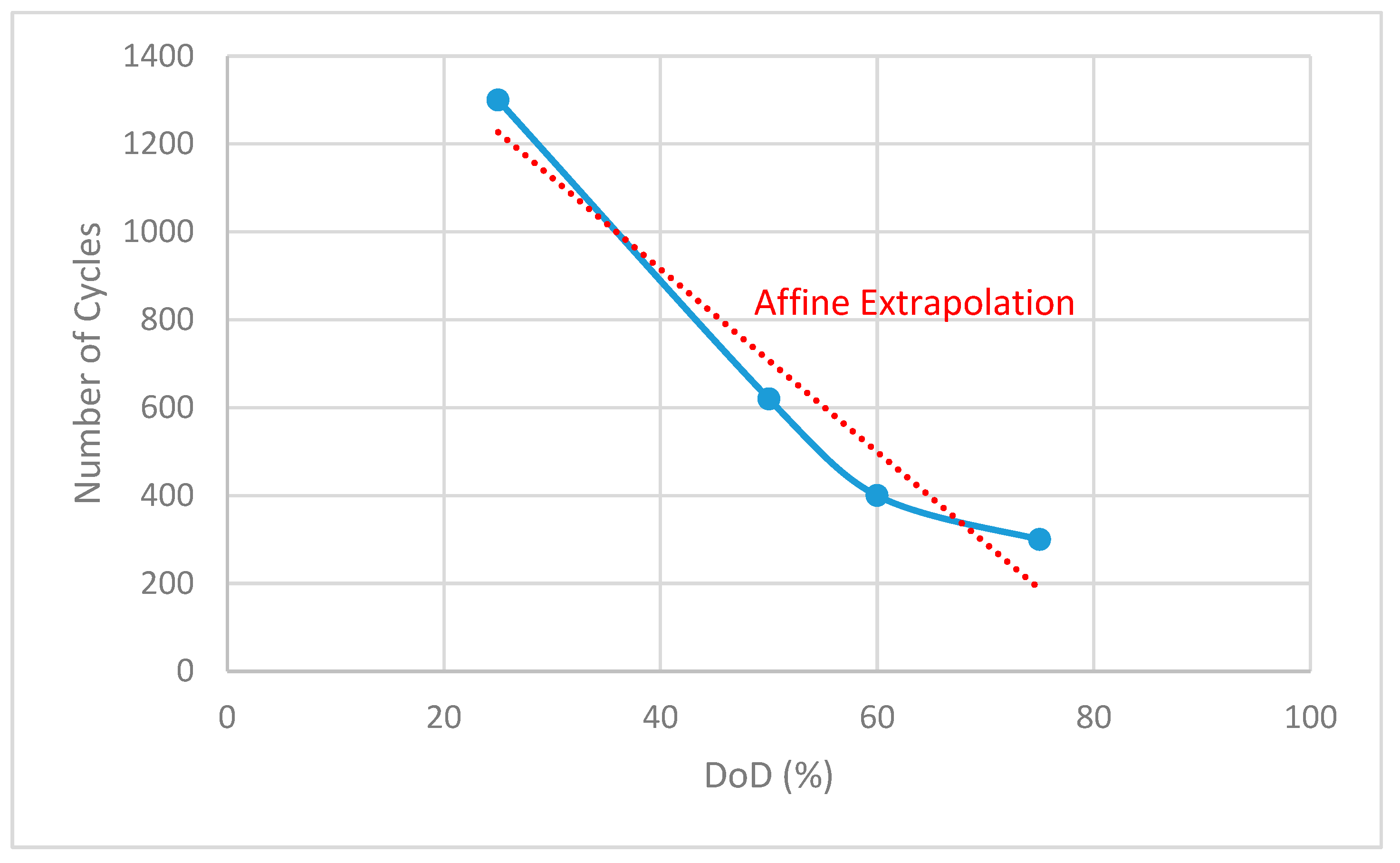

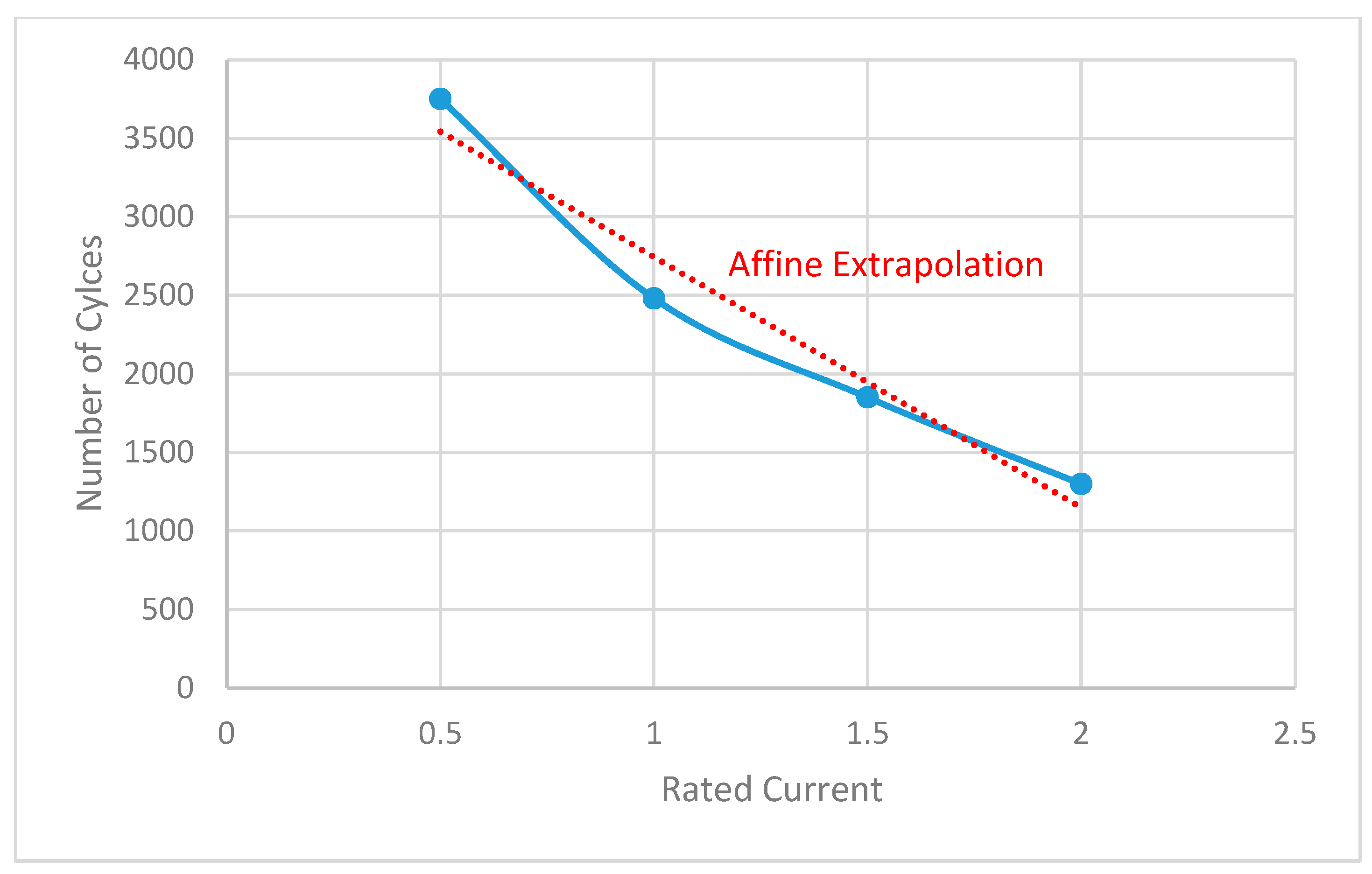

3. System Reliability Approach

- -

- -

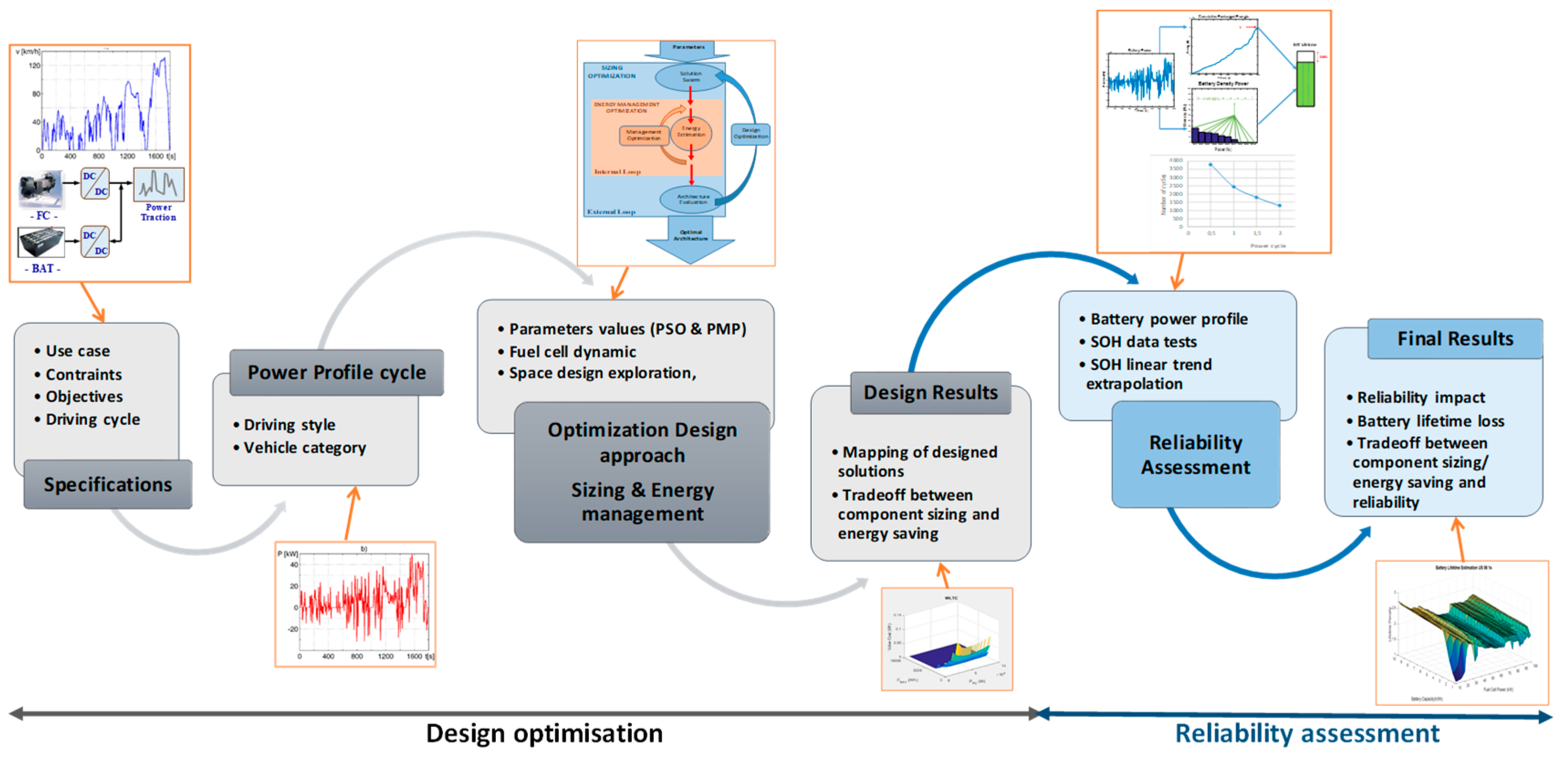

4. Reliability Process Integration

- -

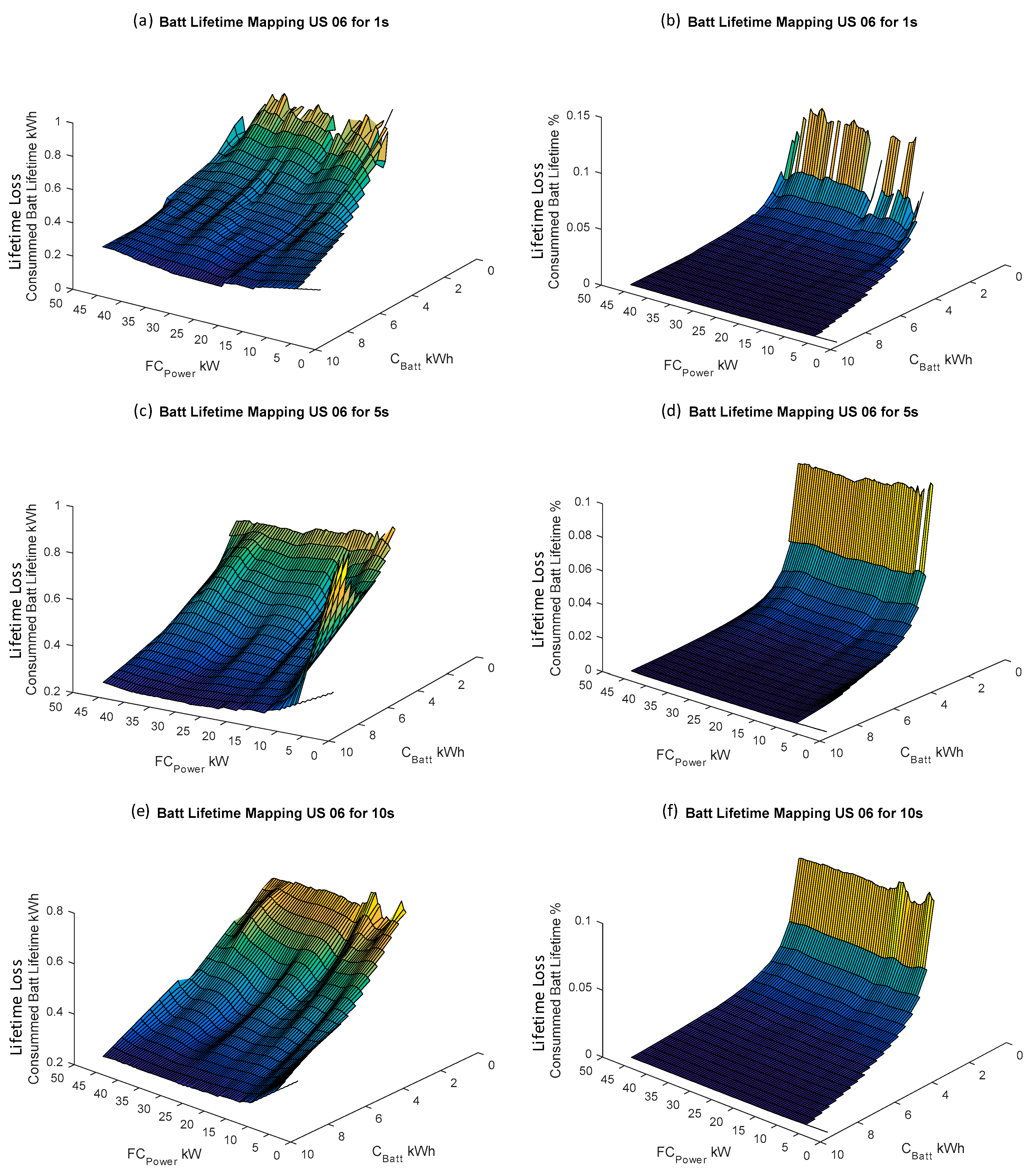

- Design optimization step: the proposed combined design approach gives a consistent set of solutions whatever the driving cycle. The mapping of designed solutions is depicted by a bowl shape surface. It shows clearly a trade-off between component sizing and energy saving. The hybrid system design is mainly affected by the load average power and the load power dynamics.

- -

- Reliability assessment step: For each driving cycle, the set of design solutions is assessed for reliability using lifetime loss rate. To this end, the linear trend extrapolation of battery SOH is considered, as explained before.

5. Results and Analysis

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| HEV | Hybrid Electric Vehicle |

| PSO | Particle Swarm Optimization |

| PMP | Pontryagin’s Minimum Principle |

| EV | Electrical Vehicle |

| FCHV | Fuel Cell Hybrid Vehicle |

| PEMFC | Proton Exchange Membrane Fuel Cell |

| SOH | State Of Health |

| WLTC | Worldwide Harmonized Light Vehicles Test Cycles |

| US Highway | Highway United States Test Cycle |

| US06 | Supplemental United States Test Cycle |

| VPD | Vector of Power Distribution |

| WV | Weighting Vector |

| D | Degradation degree |

| LLoss | Lifetime loss |

| SOE | State of Energy |

| DOD | Depth of Discharge |

| CCCV | Constant Current Constant Voltage |

| CC | Constant Current |

| EOL | End-of-Life |

| PFC/Max/Min | Fuel cell power, Maximum, Minimum, (W) |

| PBAT/Max/Min | Battery power, Maximum, Minimum, (W) |

| CBAT/Max/Min | Battery capacity, Maximum, Minimum, (Ah) |

| SOCBAT/Max/Min | Battery state of charge, Maximum, Minimum, (%) |

| ηFC ηBAT | Fuel cell and Battery efficiency, (%) |

| H | Hamiltonian function |

| λ | Co-state, Lagrange multiplier |

| PDem | Power demand, (W) |

| Cr, Cx | Friction and aerodynamic coefficients |

| ρ | Air density, (kg.m−3) |

| S | Front surface area, (m2) |

| M | Vehicle mass, (kg) |

| g | Gravity acceleration, (m.s−2) |

| α | Slope of the road, (deg) |

| CBAT,C, CBAT,Init | Current and initial battery capacity, (Wh) |

| SOC, SOC0 | Current and initial State Of Charge, (%) |

| iBAT | Battery current, (A) |

| SOHDOD | State of health as a function of DOD |

| SOHIc | State of health as a function of rated current. |

| NCycle,DOD | Number of cycles according to a DOD level |

| NCycle,Ic | Number of cycles according to a ratted current. |

| Crate is | Charging/discharge current, (A) |

| α, β, γ, δ, ρ, σ | Fitting parameters. |

| EBAT | Battery cumulated energy, (J or Wh) |

| EBAT,Tot,Init, NCycle,Init | Total initial battery energy and number of cycle. |

| TS | Simple time, (s) |

References

- Muneer, T.; Kolhe, M.; Doyle, A. Electric Vehicles: Prospects and Challenges; Elsevier: New York, NY, USA, 2017; ISBN 978-0-12-803021-9. [Google Scholar]

- Kaya, K.; Hames, Y. Two new control strategies: For hydrogen fuel saving and extend the life cycle in the hydrogen fuel cell vehicles. Int. J. Hydrog. Energy 2019, 44, 18967–18980. [Google Scholar] [CrossRef]

- Yue, M.; Jemei, S.; Gouriveau, R.; Zerhouni, N. Review on health-conscious energy management strategies for fuel cell hybrid electric vehicles: Degradation models and strategies. Int. J. Hydrog. Energy 2019, 44, 6844–6861. [Google Scholar] [CrossRef]

- Yao, G.; Du, C.; Ge, Q.; Jiang, H.; Wang, Y.; Ait-Ahmed, M.; Moreau, L. Traffic-Condition-Prediction-Based HMA-FIS Energy-Management Strategy for Fuel-Cell Electric Vehicles. Energies 2019, 12, 4426. [Google Scholar] [CrossRef] [Green Version]

- Fu, Z.; Li, Z.; Si, P.; Tao, F. A hierarchical energy management strategy for fuel cell/battery/supercapacitor hybrid electric vehicles. Int. J. Hydrog. Energy 2019, 44, 22146–22159. [Google Scholar] [CrossRef]

- Egan, P.; Cagan, J. Human and Computational Approaches for Design Problem-Solving. In Experimental Design Research; Cash, P., Stanković, T., Štorga, M., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 187–205. ISBN 978-3-319-33779-1. [Google Scholar]

- Serpi, A.; Porru, M. Modelling and Design of Real-Time Energy Management Systems for Fuel Cell/Battery Electric Vehicles. Energies 2019, 12, 4260. [Google Scholar] [CrossRef] [Green Version]

- Silvas, E.; Hofman, T.; Murgovski, N.; Etman, L.F.P.; Steinbuch, M. Review of Optimization Strategies for System-Level Design in Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2017, 66, 57–70. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Shang, Z.; Chen, Y.; Chen, Y. Multi-Objective Particle Swarm Optimization Algorithm for Multi-Step Electric Load Forecasting. Energies 2020, 13, 532. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Martinez, C.M.; Egardt, B.; Cao, D. Multi-objective optimal sizing and control of fuel cell systems for hybrid vehicle applications. In Proceedings of the 2015 European Control Conference (ECC), Linz, Austria, 15–17 July 2015; pp. 2559–2564. [Google Scholar]

- Zhou, X.; Qin, D.; Hu, J. Multi-objective optimization design and performance evaluation for plug-in hybrid electric vehicle powertrains. Appl. Energy 2017, 208, 1608–1625. [Google Scholar] [CrossRef]

- Nandi, A.K.; Chakraborty, D.; Vaz, W. Design of a comfortable optimal driving strategy for electric vehicles using multi-objective optimization. J. Power Sources 2015, 283, 1–18. [Google Scholar] [CrossRef]

- Gharibi, M.; Askarzadeh, A. Size and power exchange optimization of a grid-connected diesel generator-photovoltaic-fuel cell hybrid energy system considering reliability, cost and renewability. Int. J. Hydrog. Energy 2019, 44, 25428–25441. [Google Scholar] [CrossRef]

- Chen, H.; Yang, C.; Deng, K.; Zhou, N.; Wu, H. Multi-objective optimization of the hybrid wind/solar/fuel cell distributed generation system using Hammersley Sequence Sampling. Int. J. Hydrog. Energy 2017, 42, 7836–7846. [Google Scholar] [CrossRef]

- Faddel, S.; Elsayed, A.T.; Mohammed, O.A. Bilayer Multi-Objective Optimal Allocation and Sizing of Electric Vehicle Parking Garage. IEEE Trans. Ind. Appl. 2018, 54, 1992–2001. [Google Scholar] [CrossRef]

- Song, X.; Lin, H.; De, G.; Li, H.; Fu, X.; Tan, Z. An Energy Optimal Dispatching Model of an Integrated Energy System Based on Uncertain Bilevel Programming. Energies 2020, 13, 477. [Google Scholar] [CrossRef] [Green Version]

- Ceschia, A.; Azib, T.; Bethoux, O.; Alves, F. Sensitivity Analysis of an Optimal Design Methodology for Hybrid Power System. In Proceedings of the 2019 6th International Conference on Control, Decision and Information Technologies (CoDIT), Paris, France, 23–26 April 2019; pp. 1277–1282. [Google Scholar]

- Tran, D.-D.; Vafaeipour, M.; El Baghdadi, M.; Barrero, R.; Van Mierlo, J.; Hegazy, O. Thorough state-of-the-art analysis of electric and hybrid vehicle powertrains: Topologies and integrated energy management strategies. Renew. Sustain. Energy Rev. 2020, 119, 109596. [Google Scholar] [CrossRef]

- Biegler, L.T. An overview of simultaneous strategies for dynamic optimization. Chem. Eng. Process. Process Intensif. 2007, 46, 1043–1053. [Google Scholar] [CrossRef]

- Herber, D.R.; Allison, J.T. Nested and Simultaneous Solution Strategies for General Combined Plant and Control Design Problems. J. Mech. Des. 2019, 141, 11402–11413. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, R.; Wang, K.; Jiao, B. Optimal Energy Management Strategy of a Plug-in Hybrid Electric Vehicle Based on a Particle Swarm Optimization Algorithm. Energies 2015, 8, 3661–3678. [Google Scholar] [CrossRef] [Green Version]

- Yang, R.; Yuan, Y.; Ying, R.; Shen, B.; Long, T. A Novel Energy Management Strategy for a Ship’s Hybrid Solar Energy Generation System Using a Particle Swarm Optimization Algorithm. Energies 2020, 13, 1380. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Z.; Teng, L.; Fengchun, S.; Peng, H. Comparative Study of Dynamic Programming and Pontryagin’s Minimum Principle on Energy Management for a Parallel Hybrid Electric Vehicle. Energies 2013, 6, 2305–2318. [Google Scholar] [CrossRef]

- Liu, J.; Feng, L.; Li, Z. The Optimal Road Grade Design for Minimizing Ground Vehicle Energy Consumption. Energies 2017, 10, 700. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Liu, L. Optimal power source sizing of fuel cell hybrid vehicles based on Pontryagin’s minimum principle. Int. J. Hydrog. Energy 2015, 40, 8454–8464. [Google Scholar] [CrossRef]

- Wang, Y.; Moura, S.J.; Advani, S.G.; Prasad, A.K. Optimization of powerplant component size on board a fuel cell/battery hybrid bus for fuel economy and system durability. Int. J. Hydrog. Energy 2019, 44, 18283–18292. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, X.; Li, J.; Hofmann, H.; Ouyang, M.; Du, J. Component sizing optimization of plug-in hybrid electric vehicles with the hybrid energy storage system. Energy 2018, 144, 393–403. [Google Scholar] [CrossRef]

- Moura, S.J.; Stein, J.L.; Fathy, H.K. Battery-Health Conscious Power Management in Plug-In Hybrid Electric Vehicles via Electrochemical Modeling and Stochastic Control. IEEE Trans. Control Syst. Technol. 2013, 21, 679–694. [Google Scholar] [CrossRef]

- Maghami, M.R.; Hassani, R.; Gomes, C.; Hizam, H.; Othman, M.L.; Behmanesh, M. Hybrid energy management with respect to a hydrogen energy system and demand response. Int. J. Hydrog. Energy 2020, 45, 1499–1509. [Google Scholar] [CrossRef]

- Li, H.; Ravey, A.; N’Diaye, A.; Djerdir, A. A novel equivalent consumption minimization strategy for hybrid electric vehicle powered by fuel cell, battery and supercapacitor. J. Power Sources 2018, 395, 262–270. [Google Scholar] [CrossRef]

- Benmouna, A.; Becherif, M.; Chen, J.; Chen, H.; Depernet, D. Interconnection and damping assignment passivity based control for fuel cell and battery vehicle: Simulation and experimentation. Int. J. Hydrog. Energy 2019, 44, 22467–22477. [Google Scholar] [CrossRef]

- Tao, L.; Ma, J.; Cheng, Y.; Noktehdan, A.; Chong, J.; Lu, C. A review of stochastic battery models and health management. Renew. Sustain. Energy Rev. 2017, 80, 716–732. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.-I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Azib, T.; Bethoux, O.; Remy, G.; Marchand, C.; Berthelot, E. An Innovative Control Strategy of a Single Converter for Hybrid Fuel Cell/Supercapacitor Power Source. IEEE Trans. Ind. Electron. 2010, 57, 4024–4031. [Google Scholar] [CrossRef]

- Wilberforce, T.; Khatib, F.N.; Ijaodola, O.S.; Ogungbemi, E.; El-Hassan, Z.; Durrant, A.; Thompson, J.; Olabi, A.G. Numerical modelling and CFD simulation of a polymer electrolyte membrane (PEM) fuel cell flow channel using an open pore cellular foam material. Sci. Total Environ. 2019, 678, 728–740. [Google Scholar] [CrossRef] [PubMed]

- Thompson, A.W. Economic implications of lithium ion battery degradation for Vehicle-to-Grid (V2X) services. J. Power Sources 2018, 396, 691–709. [Google Scholar] [CrossRef]

- Babin, A.; Rizoug, N.; Mesbahi, T.; Boscher, D.; Hamdoun, Z.; Larouci, C. Total Cost of Ownership Improvement of Commercial Electric Vehicles Using Battery Sizing and Intelligent Charge Method. IEEE Trans. Ind. Appl. 2018, 54, 1691–1700. [Google Scholar] [CrossRef]

- Maher, K.; Yazami, R. A study of lithium ion batteries cycle aging by thermodynamics techniques. J. Power Sources 2014, 247, 527–533. [Google Scholar] [CrossRef]

- Maheshwari, A.; Heck, M.; Santarelli, M. Cycle aging studies of lithium nickel manganese cobalt oxide-based batteries using electrochemical impedance spectroscopy. Electrochim. Acta 2018, 273, 335–348. [Google Scholar] [CrossRef]

- Tang, X.; Zou, C.; Yao, K.; Chen, G.; Liu, B.; He, Z.; Gao, F. A fast estimation algorithm for lithium-ion battery state of health. J. Power Sources 2018, 396, 453–458. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [Google Scholar] [CrossRef]

- Pelletier, S.; Jabali, O.; Laporte, G.; Veneroni, M. Battery degradation and behaviour for electric vehicles: Review and numerical analyses of several models. Transp. Res. Part B Methodol. 2017, 103, 158–187. [Google Scholar] [CrossRef]

- Han, X.; Ouyang, M.; Lu, L.; Li, J. A comparative study of commercial lithium ion battery cycle life in electric vehicle: Capacity loss estimation. J. Power Sources 2014, 268, 658–669. [Google Scholar] [CrossRef]

- Martel, F.; Dubé, Y.; Kelouwani, S.; Jaguemont, J.; Agbossou, K. Long-term assessment of economic plug-in hybrid electric vehicle battery lifetime degradation management through near optimal fuel cell load sharing. J. Power Sources 2016, 318, 270–282. [Google Scholar] [CrossRef]

- Leng, F.; Tan, C.M.; Pecht, M. Effect of Temperature on the Aging rate of Li Ion Battery Operating above Room Temperature. Sci. Rep. 2015, 5, 12967. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zou, Y.; Hu, X.; Ma, H.; Li, S.E. Combined State of Charge and State of Health estimation over lithium-ion battery cell cycle lifespan for electric vehicles. J. Power Sources 2015, 273, 793–803. [Google Scholar] [CrossRef]

- Ecker, M.; Nieto, N.; Käbitz, S.; Schmalstieg, J.; Blanke, H.; Warnecke, A.; Sauer, D.U. Calendar and cycle life study of Li(NiMnCo)O2-based 18650 lithium-ion batteries. J. Power Sources 2014, 248, 839–851. [Google Scholar] [CrossRef]

- Quinard, H.; Redondo-Iglesias, E.; Pelissier, S.; Venet, P. Fast Electrical Characterizations of High-Energy Second Life Lithium-Ion Batteries for Embedded and Stationary Applications. Batteries 2019, 5, 33. [Google Scholar] [CrossRef] [Green Version]

- Martel, F.; Kelouwani, S.; Dubé, Y.; Agbossou, K. Optimal economy-based battery degradation management dynamics for fuel-cell plug-in hybrid electric vehicles. J. Power Sources 2015, 274, 367–381. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Particles number and Iteration | 30, 100 | Vehicle mass (kg) | 1428 |

| Values to design | PFC, CBAT | Air density (kg·m−3) | 1.2 |

| Search field: PFC, CBAT | 1–50 kW and 1–10 kWh | Friction coefficient | 0.012 |

| Fuel cell, battery models | PEMFC static, Li-Ion model | Aerodynamic coefficient | 0.29 |

| SOCMin, SOCMax | 15%, 90% | Front surface area (m2) | 2.69 |

| γ, α, β | 1400, −20, 1700 | δ, ρ, σ | 125, −1600, 4400 |

| Variable | Value |

|---|---|

| Fuel cell power | 30 kW |

| Battery power | 19.5 kW |

| Battery capacity | 6.5 kWh |

| Hydrogen consumption | 0.72 kg/100 km |

| Computation Time | 900 s |

| Battery lifetime—Number of cycles WLTC | 10,000 |

| Battery lifetime—Total exchanged energy | 4500 kWh |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceschia, A.; Azib, T.; Bethoux, O.; Alves, F. Optimal Sizing of Fuel Cell Hybrid Power Sources with Reliability Consideration. Energies 2020, 13, 3510. https://doi.org/10.3390/en13133510

Ceschia A, Azib T, Bethoux O, Alves F. Optimal Sizing of Fuel Cell Hybrid Power Sources with Reliability Consideration. Energies. 2020; 13(13):3510. https://doi.org/10.3390/en13133510

Chicago/Turabian StyleCeschia, Adriano, Toufik Azib, Olivier Bethoux, and Francisco Alves. 2020. "Optimal Sizing of Fuel Cell Hybrid Power Sources with Reliability Consideration" Energies 13, no. 13: 3510. https://doi.org/10.3390/en13133510

APA StyleCeschia, A., Azib, T., Bethoux, O., & Alves, F. (2020). Optimal Sizing of Fuel Cell Hybrid Power Sources with Reliability Consideration. Energies, 13(13), 3510. https://doi.org/10.3390/en13133510