Generalized Energy and Ecological Characteristics of the Process of Co-Firing Coal with Biomass in a Steam Boiler

Abstract

1. Introduction

- Difficulties with the delivery of large amounts of biomass to individual co-firing installations (the need to transport biomass over long distances, including even its import);

- Environmental costs of biomass transport over considerable distances;

- Lack of raw material for other biomass recipients, because the financial possibilities and obtained margin on sold energy from the co-firing process often allows operators of these installations to purchase biomass at much higher prices than the competition;

- Competition between energy crops and food crops.

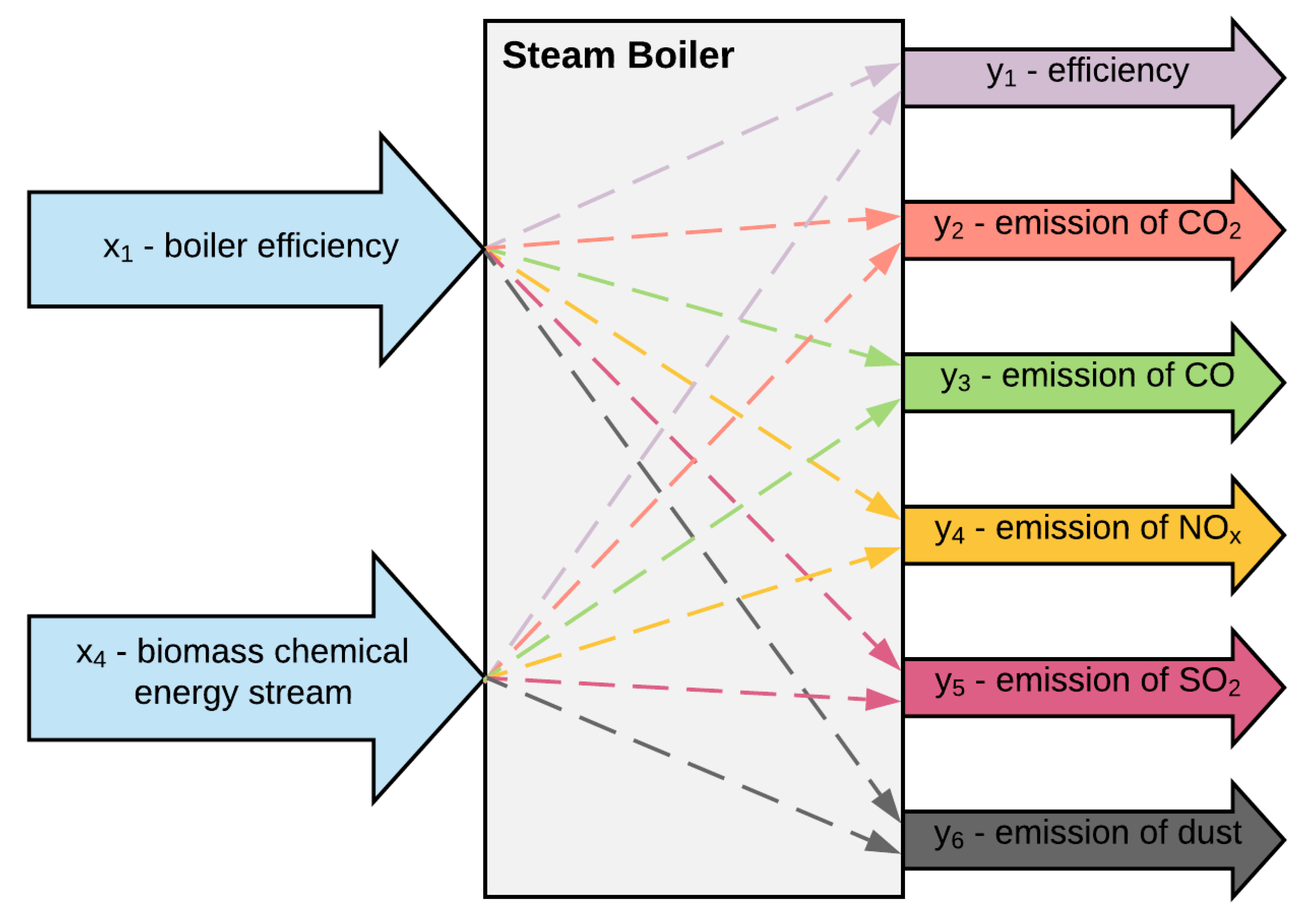

2. Materials and Methods

2.1. Method for Determining the Characteristics

- Its use is a compromise which, on the one hand, takes non-linearity of real test objects into account, and on the other hand, incorporates the tendency to reduce the number of measurements (an increase in the degree of polynomial significantly increases the number of tests necessary to carry out);

- It is characterized by high universality, as it allows adequate approximation of both simple linear and non-linear relationships;

- A polynomial is a particularly convenient form of a mathematical model in a case when only types of test factors and trends of their influence on the resulting factor are known.

2.2. Test Objects and Co-Firing Conditions

3. Results

3.1. Obtained Characteristics

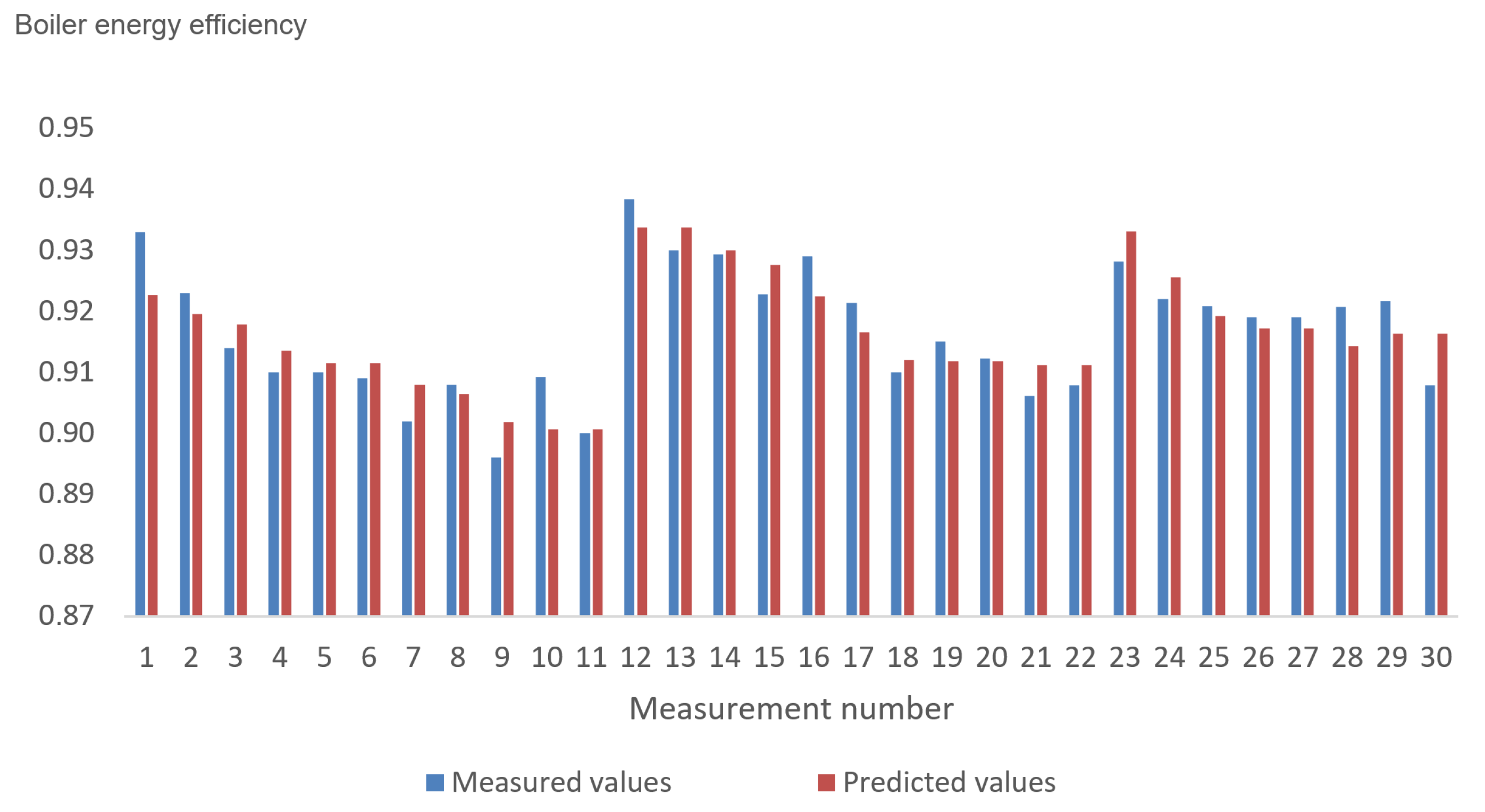

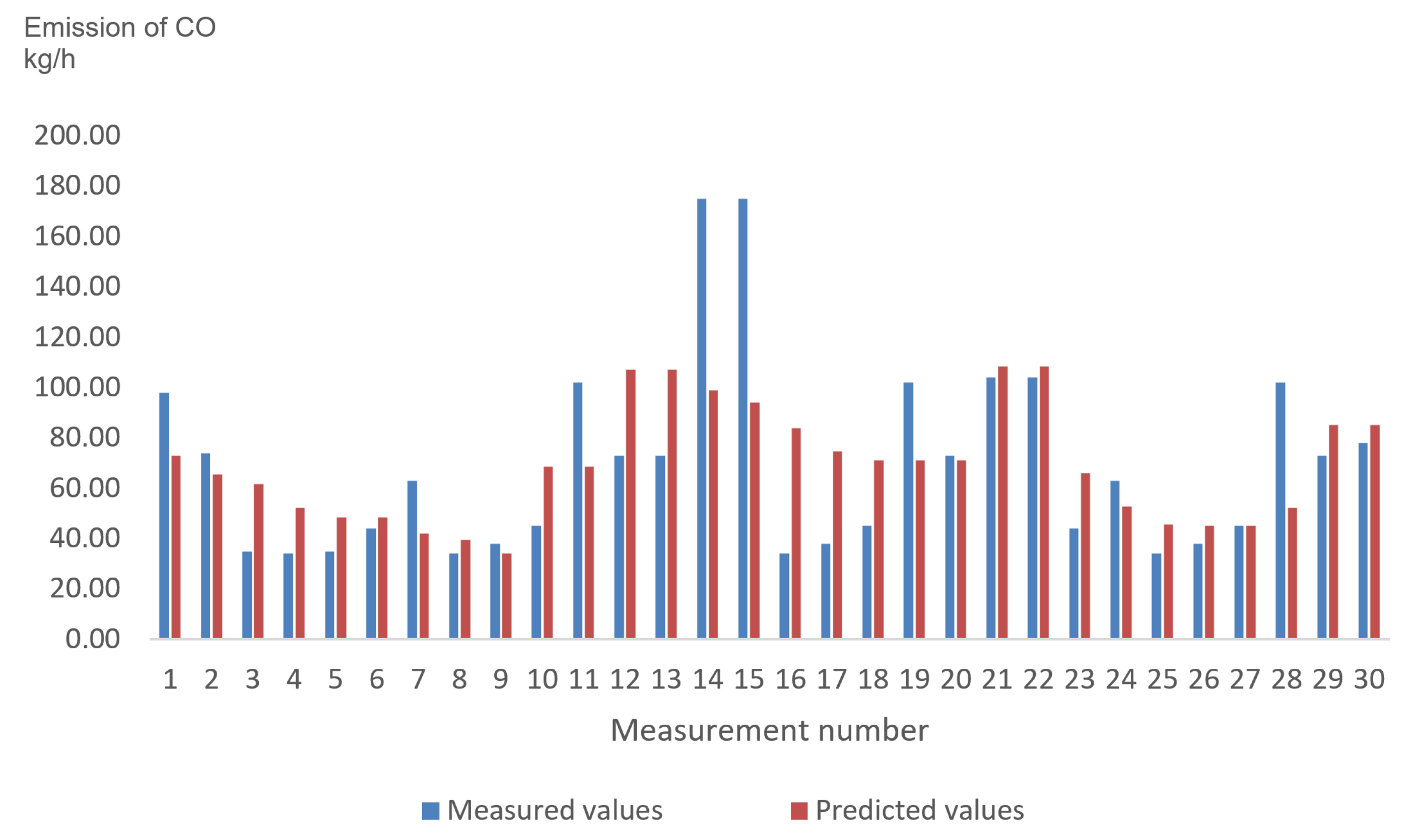

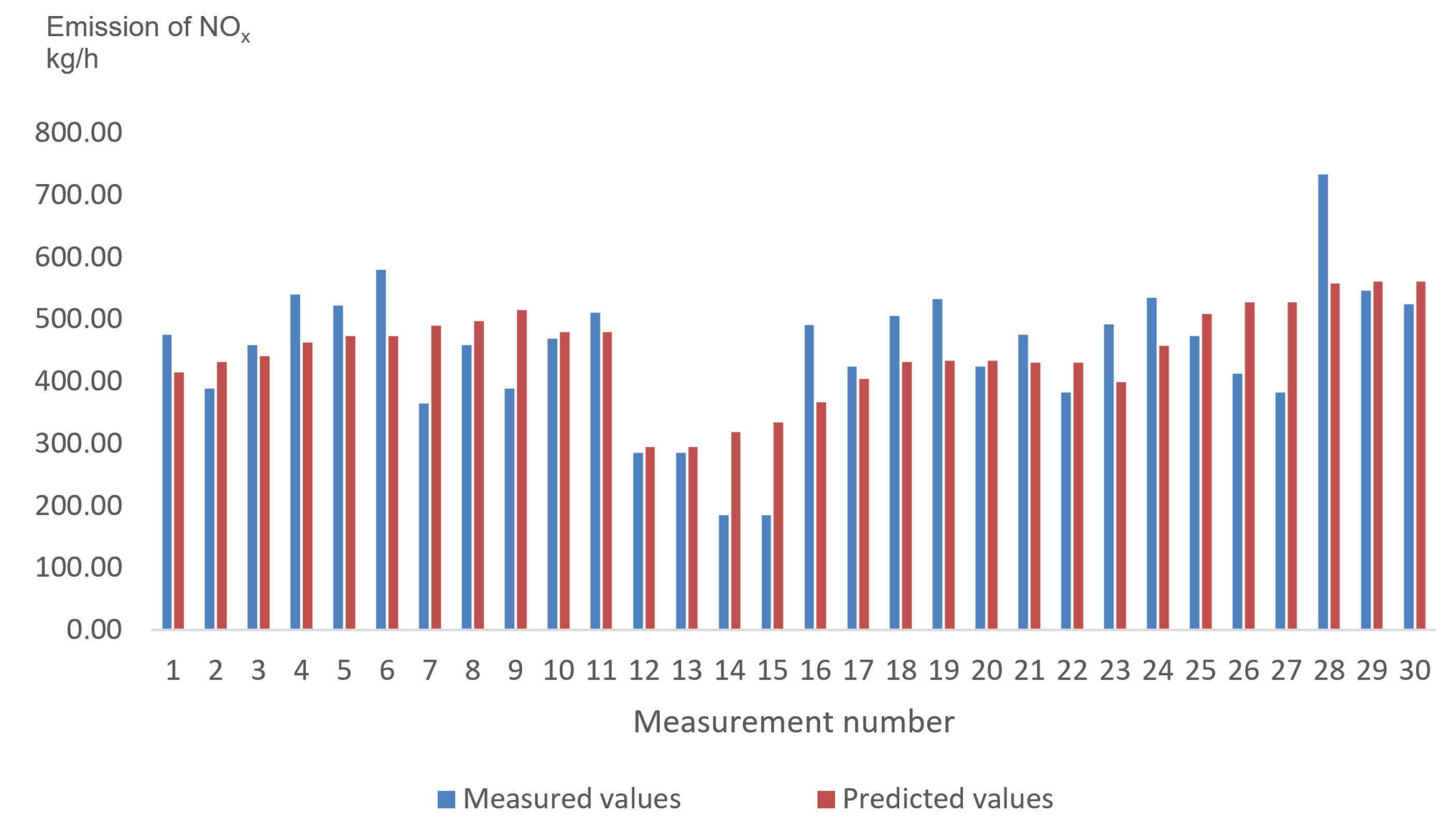

3.2. Verification of Characteristics

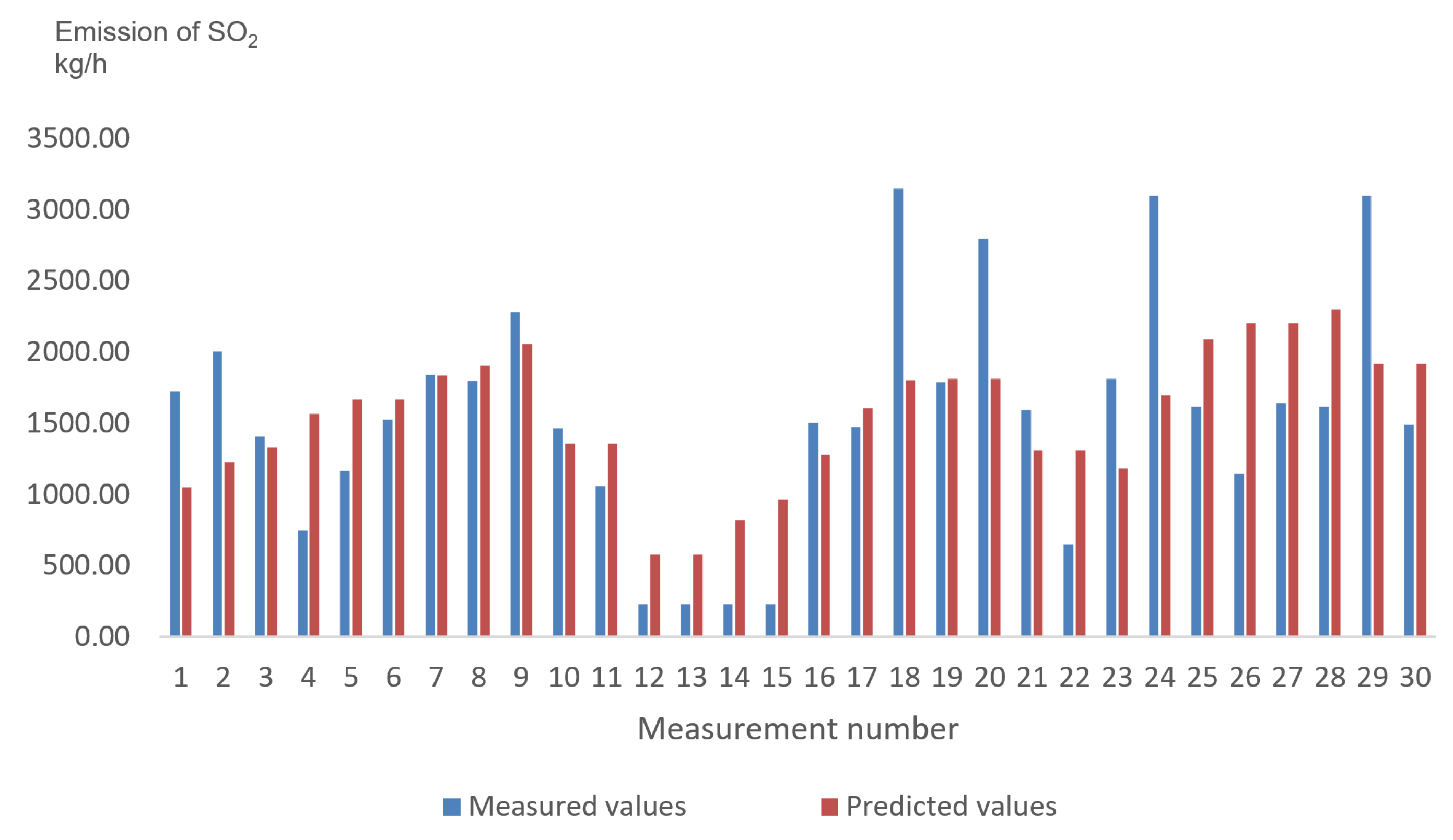

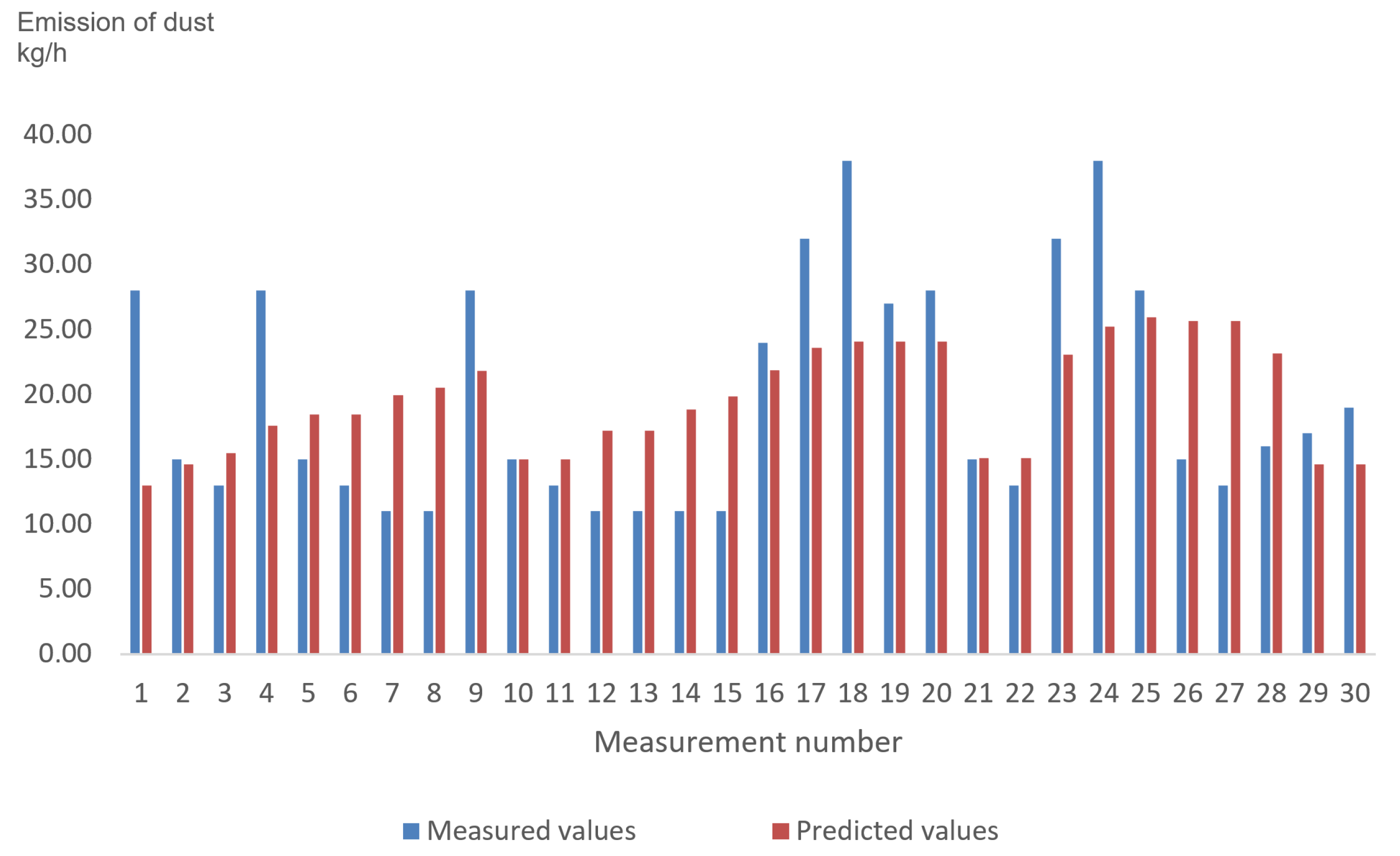

- Graphic comparison of the calculated values of the model with the measured data;

- Residual variance;

- Coefficient of random variation.

- Quality assessment of structural parameters, requiring:

- Determination of standard errors in the estimation of structural parameters;

- Conducting the significance test of estimated structural parameters.

3.2.1. Verification of the Degree of Compliance of the Model with the Measurement Data

3.2.2. The Importance of Structural Parameters

3.3. Uncertainty of the Measured Quantity

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Macuk, R.; Maćkowiak-Pandera, J.; Gawlikowska-Fryk, A.; Rubczyński, A. Transformacja Energetyczna w Polsce—Edycja 2019; Technical Report; Forum Energii: Warszawa, Poland, 2019. [Google Scholar]

- European Commission. Eurostat Database; Eurostat: Kirchberg, Luxembourg, 2020. [Google Scholar]

- GUS. Statistics Poland. Energy from Renewable Sources in 2018; Technical Report; GUS: Warszawa, Poland, 2020.

- GUS. Statistical Yearbook of the Republic of Poland 2019; Technical Report; GUS: Warszawa, Poland, 2018.

- Bartoszewicz-Burczy, H. Biomass potential and its energy utilization in the Central European countries. Energetyka 2012, 12, 860–866. [Google Scholar]

- Wiśniewski, G. Spalimy 10 Miliardów złotych. Współspalanie Wraca na Niespotykana̧ Skalȩ w Aukcjach 2020 na Energiȩ z OZE; CIRE: Warszawa, Poland, 2020. [Google Scholar]

- IEA. Coal Information: Overview, 2019 ed.; Technical Report; IEA: Paris, France, 2019. [Google Scholar]

- IEA. Coal 2019; Technical Report; IEA: Paris, France, 2019. [Google Scholar]

- Roni, M.S.; Chowdhury, S.; Mamun, S.; Marufuzzaman, M.; Lein, W.; Johnson, S. Biomass Co-Firing Technology with Policies, Challenges, and Opportunities: A Global Review. Renew. Sustain. Energy Rev. 2017, 78, 1089–1101. [Google Scholar] [CrossRef]

- Madanayake, B.N.; Gan, S.; Eastwick, C.; Ng, H.K. Biomass as an Energy Source in Coal Co-Firing and Its Feasibility Enhancement via Pre-Treatment Techniques. Fuel Process. Technol. 2017, 159, 287–305. [Google Scholar] [CrossRef]

- Cuellar, A.; Herzog, H. A Path Forward for Low Carbon Power from Biomass. Energies 2015, 8, 1701–1715. [Google Scholar] [CrossRef]

- Kleinhans, U.; Wieland, C.; Frandsen, F.J.; Spliethoff, H. Ash Formation and Deposition in Coal and Biomass Fired Combustion Systems: Progress and Challenges in the Field of Ash Particle Sticking and Rebound Behavior. Prog. Energy Combust. Sci. 2018, 68, 65–168. [Google Scholar] [CrossRef]

- Truong, A.H.; Patrizio, P.; Leduc, S.; Kraxner, F.; Ha-Duong, M. Reducing emissions of the fast growing Vietnamese coal sector: The chances offered by biomass co-firing. J. Clean. Prod. 2019, 215, 1301–1311. [Google Scholar] [CrossRef]

- Milićević, A.; Belošević, S.; Crnomarković, N.; Tomanović, I.; Tucaković, D. Mathematical modelling and optimisation of lignite and wheat straw co-combustion in 350 MWe boiler furnace. Appl. Energy 2020, 260, 114206. [Google Scholar] [CrossRef]

- Tan, P.; Ma, L.; Xia, J.; Fang, Q.; Zhang, C.; Chen, G. Co-firing sludge in a pulverized coal-fired utility boiler: Combustion characteristics and economic impacts. Energy 2017, 119, 392–399. [Google Scholar] [CrossRef]

- Smith, J.S.; Safferman, S.I.; Saffron, C.M. Development and application of a decision support tool for biomass co-firing in existing coal-fired power plants. J. Clean. Prod. 2019, 236, 117375. [Google Scholar] [CrossRef]

- Ko, S.; Lautala, P. Optimal Level of Woody Biomass Co-Firing with Coal Power Plant Considering Advanced Feedstock Logistics System. Agriculture 2018, 8, 74. [Google Scholar] [CrossRef]

- Golec, T. Współspalanie biomasy w kotłach energetycznych. Energetyka 2004, 7, 11–24. [Google Scholar]

- Sami, M.; Annamalai, K.; Wooldridge, M. Co-firing of coal and biomass fuel blends. Prog. Energy Combust. Sci. 2001, 27, 171–214. [Google Scholar] [CrossRef]

- Gad, S.; Pawlak, A. Wpływ spalania biomasy na bezpieczeństwo procesu technologicznego w elektrowni konwencjonalnej. Logistyka 2014, 3, 1864–1870. [Google Scholar]

- Steer, J.; Marsh, R.; Griffiths, A.; Malmgren, A.; Riley, G. Biomass co-firing trials on a down-fired utility boiler. Energy Convers. Manag. 2013, 66, 285–294. [Google Scholar] [CrossRef]

- Xu, W.; Niu, Y.; Tan, H.; Wang, D.; Du, W.; Hui, S. A New Agro/Forestry Residues Co-Firing Model in a Large Pulverized Coal Furnace: Technical and Economic Assessments. Energies 2013, 6, 4377–4393. [Google Scholar] [CrossRef]

- Kommalapati, R.; Hossan, I.; Botlaguduru, V.; Du, H.; Huque, Z. Life Cycle Environmental Impact of Biomass Co-Firing with Coal at a Power Plant in the Greater Houston Area. Sustainability 2018, 10, 2193. [Google Scholar] [CrossRef]

- Yang, B.; Wei, Y.M.; Hou, Y.; Li, H.; Wang, P. Life cycle environmental impact assessment of fuel mix-based biomass co-firing plants with CO2 capture and storage. Appl. Energy 2019, 252, 113483. [Google Scholar] [CrossRef]

- Zuwala, J.; Sciazko, M. Full-scale co-firing trial tests of sawdust and bio-waste in pulverized coal-fired 230t/h steam boiler. Biomass Bioenergy 2010, 34, 1165–1174. [Google Scholar] [CrossRef]

- Zheng, S.; Yang, Y.; Li, X.; Liu, H.; Yan, W.; Sui, R.; Lu, Q. Temperature and emissivity measurements from combustion of pine wood, rice husk and fir wood using flame emission spectrum. Fuel Process. Technol. 2020, 204, 106423. [Google Scholar] [CrossRef]

- Mehmood, S.; Reddy, B.V.; Rosen, M.A. Energy Analysis of a Biomass Co-firing Based Pulverized Coal Power Generation System. Sustainability 2012, 4, 462–490. [Google Scholar] [CrossRef]

- Polański, Z. Planowanie Doświadczeń w Technice; PWN: Warszawa, Poland, 1984. [Google Scholar]

- Montgomery, D. Design and Analysis of Experiments; John Wiley & Sons Inc.: New York, NY, USA, 2001. [Google Scholar]

- Myers, R.; Montgomery, D. Response Surface Methodology; Wiley & Sons Inc.: New York, NY, USA, 1995. [Google Scholar]

- StatSoft. Elektroniczny Podrȩcznik Statystyki PL; StatSoft: Warszawa, Poland, 2006. [Google Scholar]

- Kozioł, J.; Czubala, J. An optimisation strategy using probabilistic and heuristic input data for fuel feeding boilers with regard to the trading effects of CO2 allowances. Energy 2013, 62, 82–87. [Google Scholar] [CrossRef]

- Koziol, J.; Koziol, M. Determining operating characteristics of co-firing processes in grate furnaces. Fuel 2019, 258, 116164. [Google Scholar] [CrossRef]

- Mann, M.; Spath, P. A life cycle assessment of biomass cofiring in a coal-fired power plant. Clean Prod. Processes 2001, 3, 81–91. [Google Scholar] [CrossRef]

- Canalís, P.; Royo, J.; Sebastián, F. Influence of co-combustion in the efficiency of a pulverized coal boiler. In Proceedings of the 14th European Biomass Conference, Paris, France, 17–21 October 2005. [Google Scholar]

- EPA. Biomass Combined Heat and Power Catalog of Technologies; Technical Report; EPA: Washington, DC, USA, 2007.

- Valero, A.; Canalís, P.; Palacio, J.; Pascual, J.; Royo, J.; Sebastián, F.; Tapia, R. Co-Firing of Low Rank Coal and Biomass: A Chance For Biomass Penetration in the Renewables; Technical Report; Center of Research for Power Plant Efficiency: Zaragoza, Spain, 2020. [Google Scholar]

- Ścia̧żko, M.; Zuwała, J.; Pronobis, M. Zalety i wady współspalania biomasy w kotłach energetycznych na tle doświadczeń eksploatacyjnych pierwszego roku współspalania biomasy na skalȩ przemysłowa̧. Energetyka i Ekologia 2006, 3, 207–220. [Google Scholar]

- Nicholls, D.; Zerbe, J. Cofiring biomass and coal for fossil fuel reduction and other benefits-status of North American facilities in 2010. USDA For. Serv. Gen. Tech. Rep. PNW-GTR 2012, 867, 1–22. [Google Scholar] [CrossRef][Green Version]

- Zuwała, J. Wpływ współspalania biomasy z paliwami konwencjonalnymi na parametry eksploatacyjne pracy bloków energetycznych. Energetyka 2010, 2, 108–114. [Google Scholar]

- Oehlert, G.W. A First Course in Design and Analysis of Experiments; Technical Report; University of Minnesota: Minneapolis, MN, USA, 2010. [Google Scholar]

- Bartosiewicz, S. Estymacja Modeli Ekonometrycznych; PWE: Warszawa, Poland, 1989. [Google Scholar]

- Sobczyk, M. Statystyka; PWN: Warszawa, Poland, 1996. [Google Scholar]

- Welfe, W.; Welfe, A. Ekonometria Stosowana; PWE: Warszawa, Poland, 2004. [Google Scholar]

| No. | Coefficient Designation | Coefficient Values for | ||||

|---|---|---|---|---|---|---|

| Boiler Energy Efficiency, | Emission of CO kg/h, | Emission of NOx kg/h, | Emission of SO2 kg/h, | Emission of Dust kg/h, | ||

| 1 | 0.8688 | −311.8 | 1563 | 5320 | −0.5138 | |

| 2 | 0.0006 | 4.598 | −13.47 | −49.74 | 0.1185 | |

| 3 | −0.0006 | −1.651 | 1.594 | 26.60 | 0.4437 | |

| 4 | −1.085 × 10 | −0.01261 | 0.03571 | 0.1300 | −0.00011 | |

| 5 | 4.236 × 10 | 0.01471 | −0.02809 | −0.3471 | −0.00317 | |

| 6 | −8.760 × 10 | 0.001065 | 0.01429 | 0.08572 | 0.00082 | |

| Values Corresponding to the Designation of | |||||

|---|---|---|---|---|---|

| Boiler Energy Efficiency, | Emission of CO | Emission of NOx | Emission of SO2 | Emission of Dust | |

| 0.0000 | 1155 | 9084 | 529,000 | 71.07 | |

| 0.01 | 33.99 | 95.31 | 727.3 | 8.43 | |

| Values Corresponding to the Designation of | |||||

|---|---|---|---|---|---|

| Boiler Energy Efficiency, | Emission of CO | Emission of NOx | Emission of SO2 | Emission of Dust | |

| 0.92 | 69.17 | 447.9 | 1548 | 19.63 | |

| 0.01 | 0.49 | 0.21 | 0.47 | 0.43 | |

| No. | Indication of Estimate Error | Values of Errors in Determining | ||||

|---|---|---|---|---|---|---|

| Boiler Energy Efficiency, | Emission of CO | Emission of NOx | Emission of SO2 | Emission of Dust | ||

| 1 | 0.0250 | 161.5 | 453.0 | 3457 | 40.06 | |

| 2 | 0.0003 | 1.880 | 5.270 | 40.22 | 0.4661 | |

| 3 | 0.0002 | 1.005 | 2.965 | 22.62 | 0.2622 | |

| 4 | 8.323 × 10 | 0.0054 | 0.0151 | 0.1150 | 0.0013 | |

| 5 | 1.000 × 10 | 0.0065 | 0.0181 | 0.1382 | 0.0016 | |

| 6 | 7.680 × 10 | 0.0050 | 0.0139 | 0.1061 | 0.0012 | |

| No. | Indication of Estimate Error | Values of Errors in Determining | ||||

|---|---|---|---|---|---|---|

| Boiler Energy Efficiency, | Emission of CO | Emission of NOx | Emission of SO2 | Emission of Dust | ||

| 1 | || / | 34.75 | 1.930 | 3.451 | 1.539 | 0.0128 |

| 2 | || / | 2.000 | 2.446 | 2.556 | 1.237 | 0.2541 |

| 3 | || / | 3.000 | 1.561 | 0.5376 | 1.176 | 1.692 |

| 4 | || / | 1.304 | 2.335 | 2.365 | 1.130 | 0.00846 |

| 5 | || / | 4.236 | 2.263 | 1.552 | 2.511 | 1.981 |

| 6 | || / | 0.1141 | 0.2130 | 1.028 | 0.8079 | 0.6833 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozioł, J.; Czubala, J.; Kozioł, M.; Ziembicki, P. Generalized Energy and Ecological Characteristics of the Process of Co-Firing Coal with Biomass in a Steam Boiler. Energies 2020, 13, 2634. https://doi.org/10.3390/en13102634

Kozioł J, Czubala J, Kozioł M, Ziembicki P. Generalized Energy and Ecological Characteristics of the Process of Co-Firing Coal with Biomass in a Steam Boiler. Energies. 2020; 13(10):2634. https://doi.org/10.3390/en13102634

Chicago/Turabian StyleKozioł, Joachim, Joanna Czubala, Michał Kozioł, and Piotr Ziembicki. 2020. "Generalized Energy and Ecological Characteristics of the Process of Co-Firing Coal with Biomass in a Steam Boiler" Energies 13, no. 10: 2634. https://doi.org/10.3390/en13102634

APA StyleKozioł, J., Czubala, J., Kozioł, M., & Ziembicki, P. (2020). Generalized Energy and Ecological Characteristics of the Process of Co-Firing Coal with Biomass in a Steam Boiler. Energies, 13(10), 2634. https://doi.org/10.3390/en13102634