3.2. Slosh

Hydrodynamic pressures were recorded. In the case of deceleration, much higher pressures were produced because the fluid hits the valve with greater pressure compared to the acceleration scenario. Also, the valve opening pressures were reached only for the first and second compartments. This is because the valve is located towards the front of the tank in these compartments.

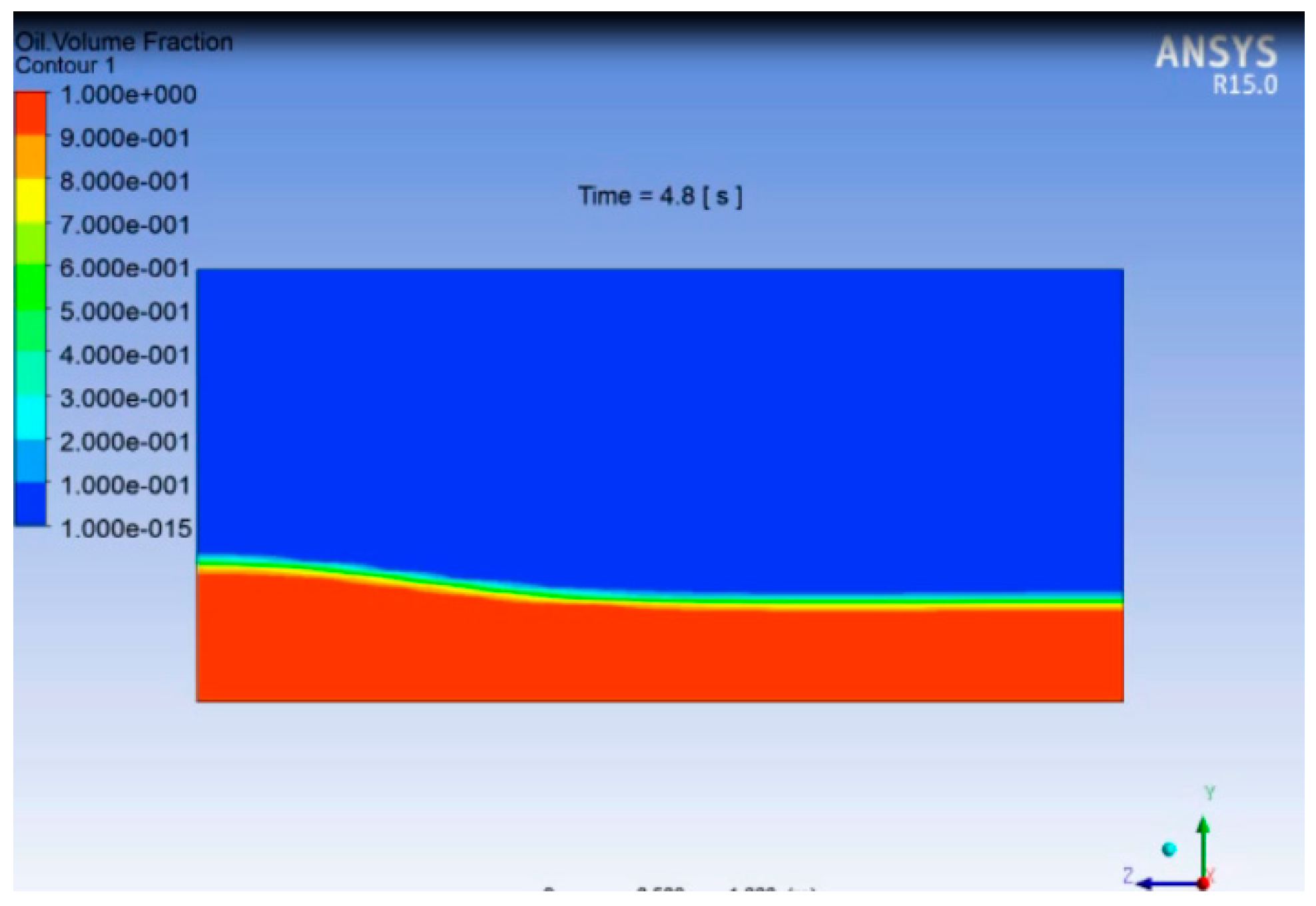

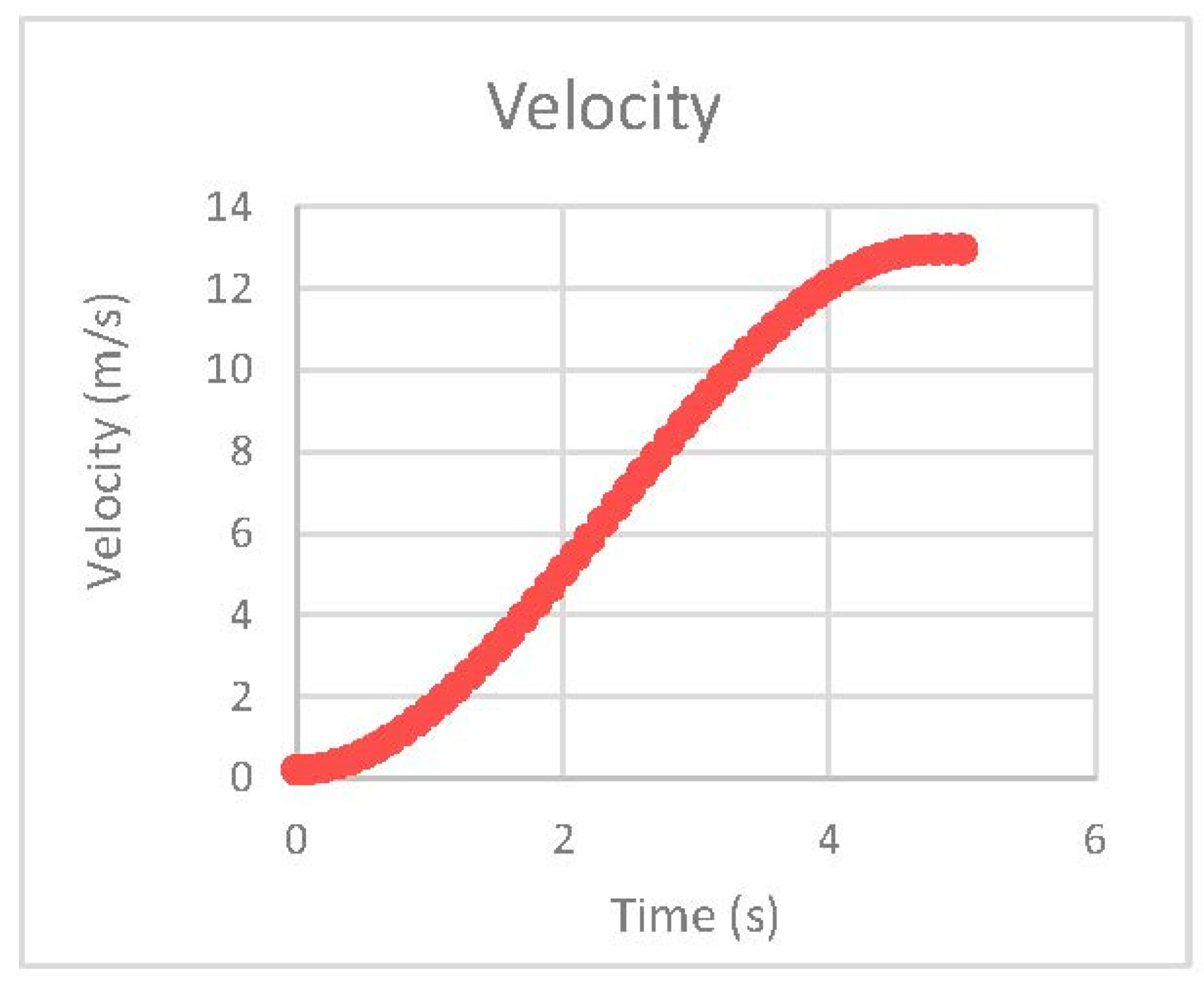

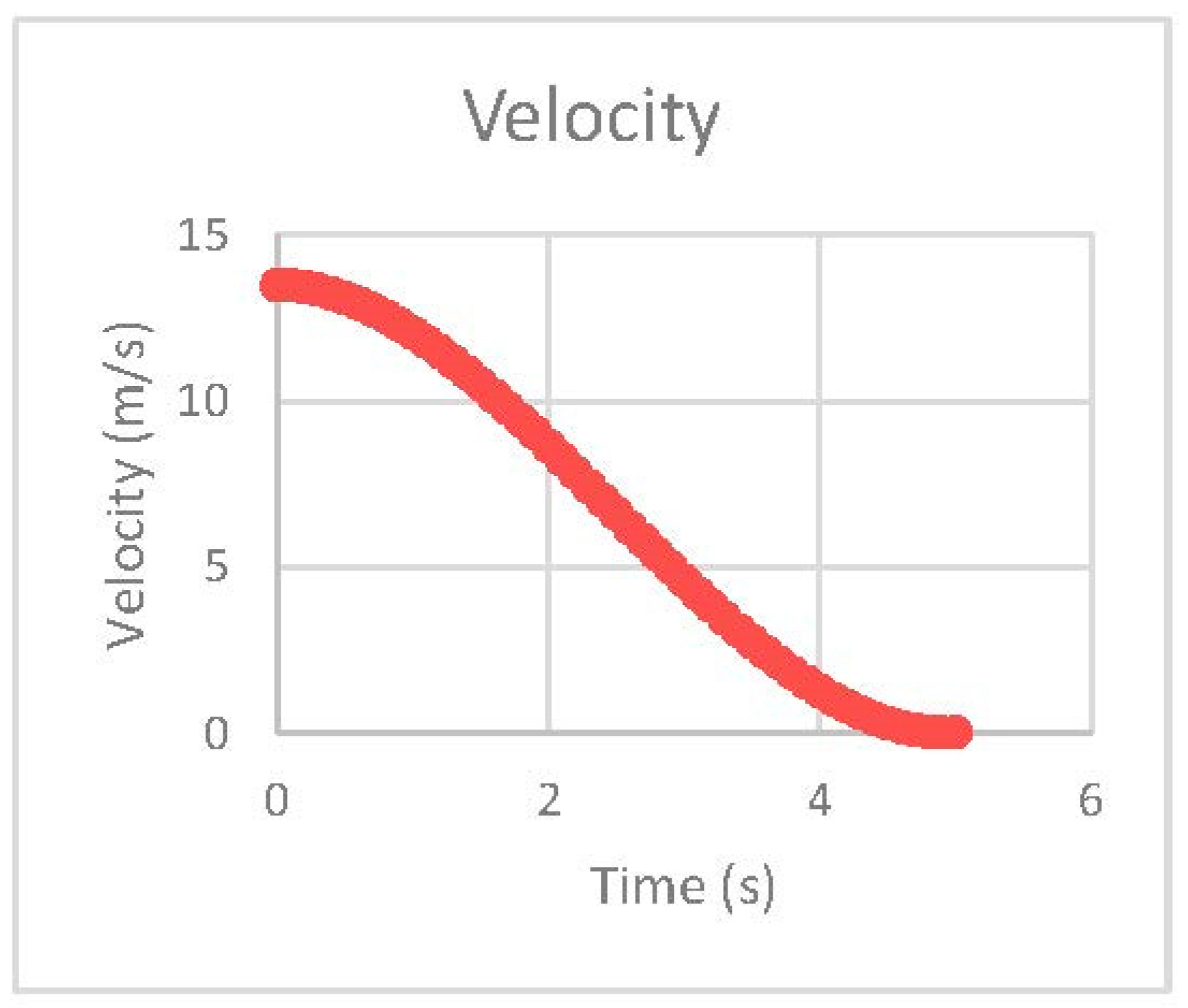

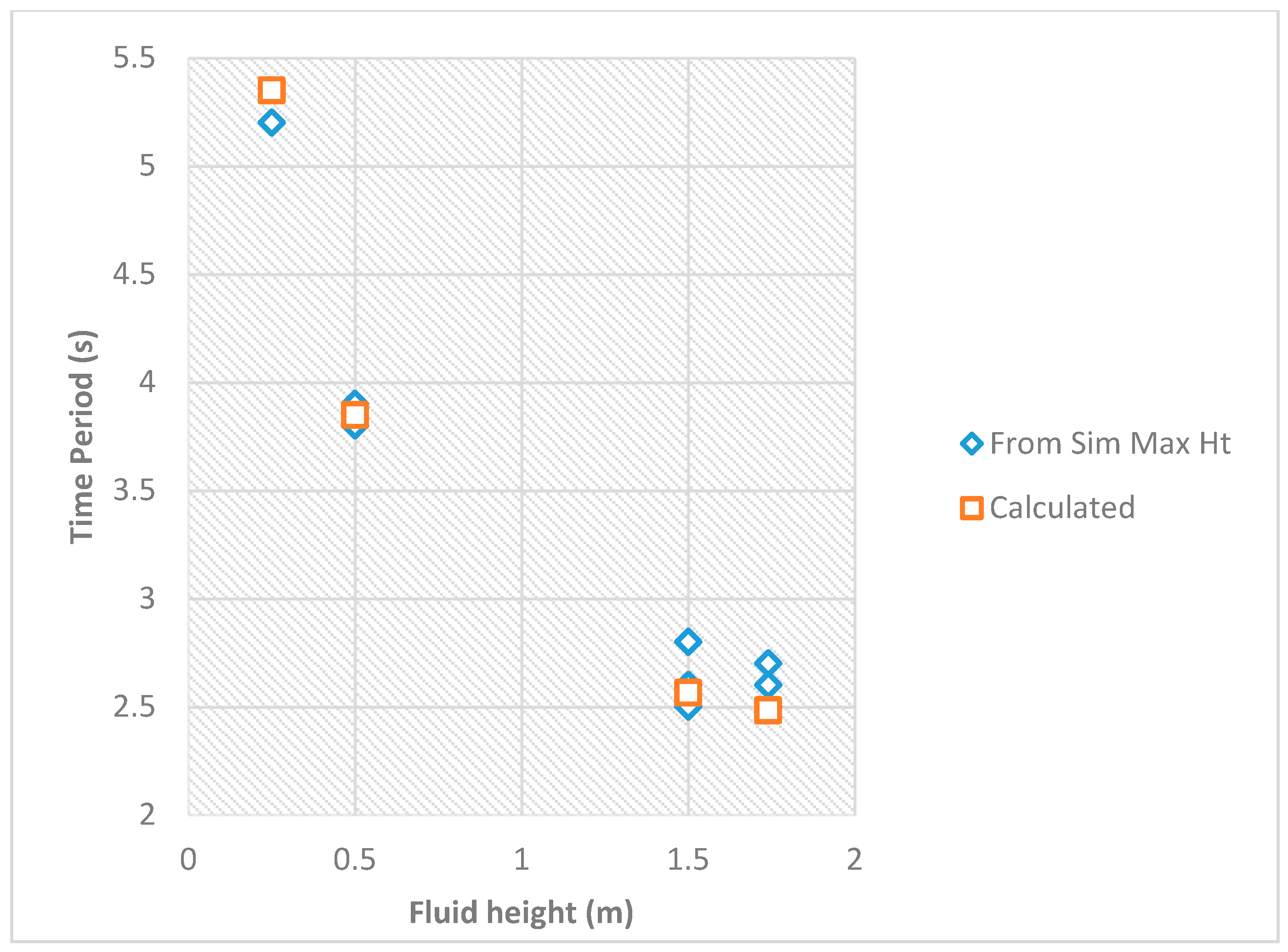

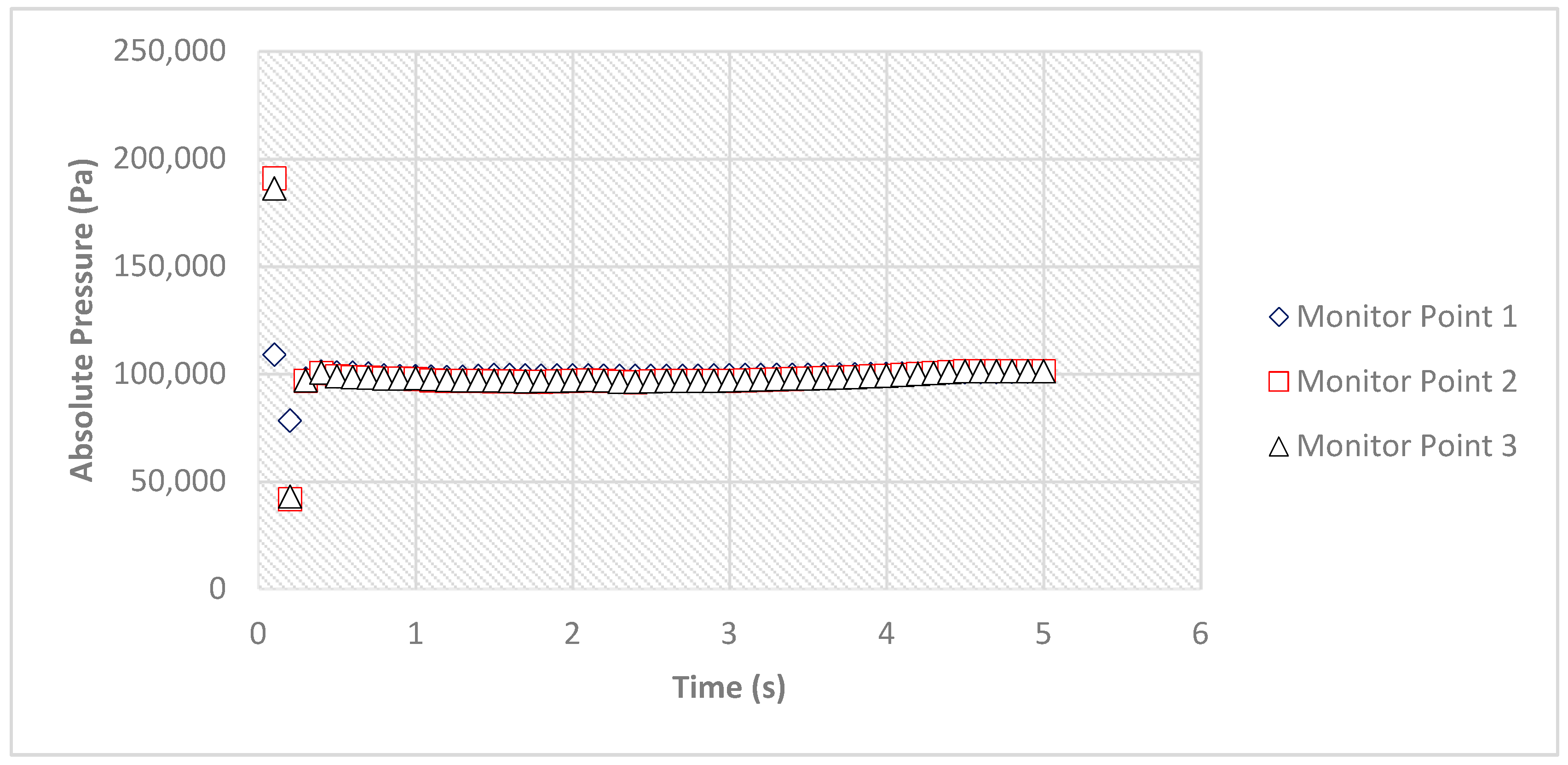

Case 1: Normal Acceleration

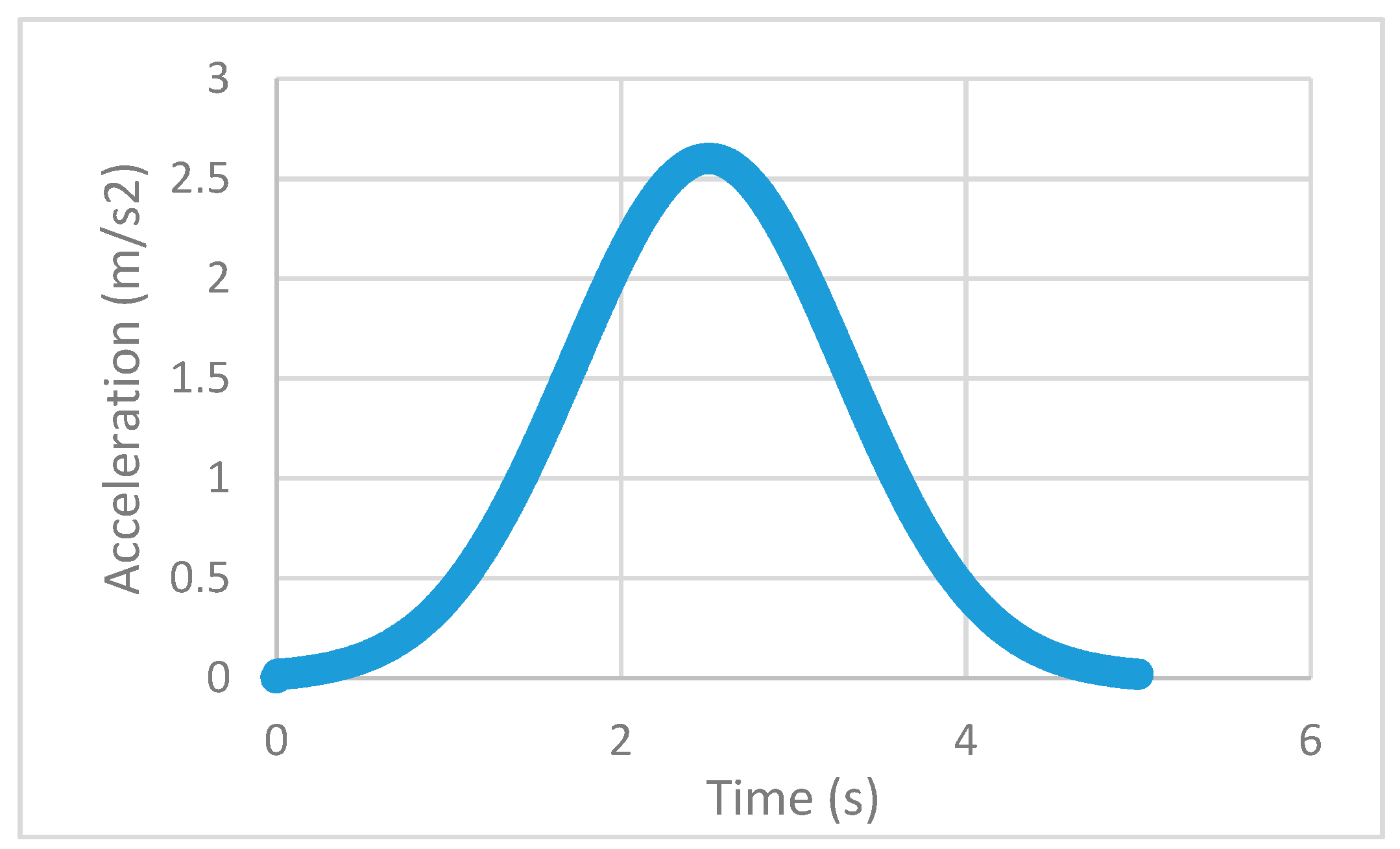

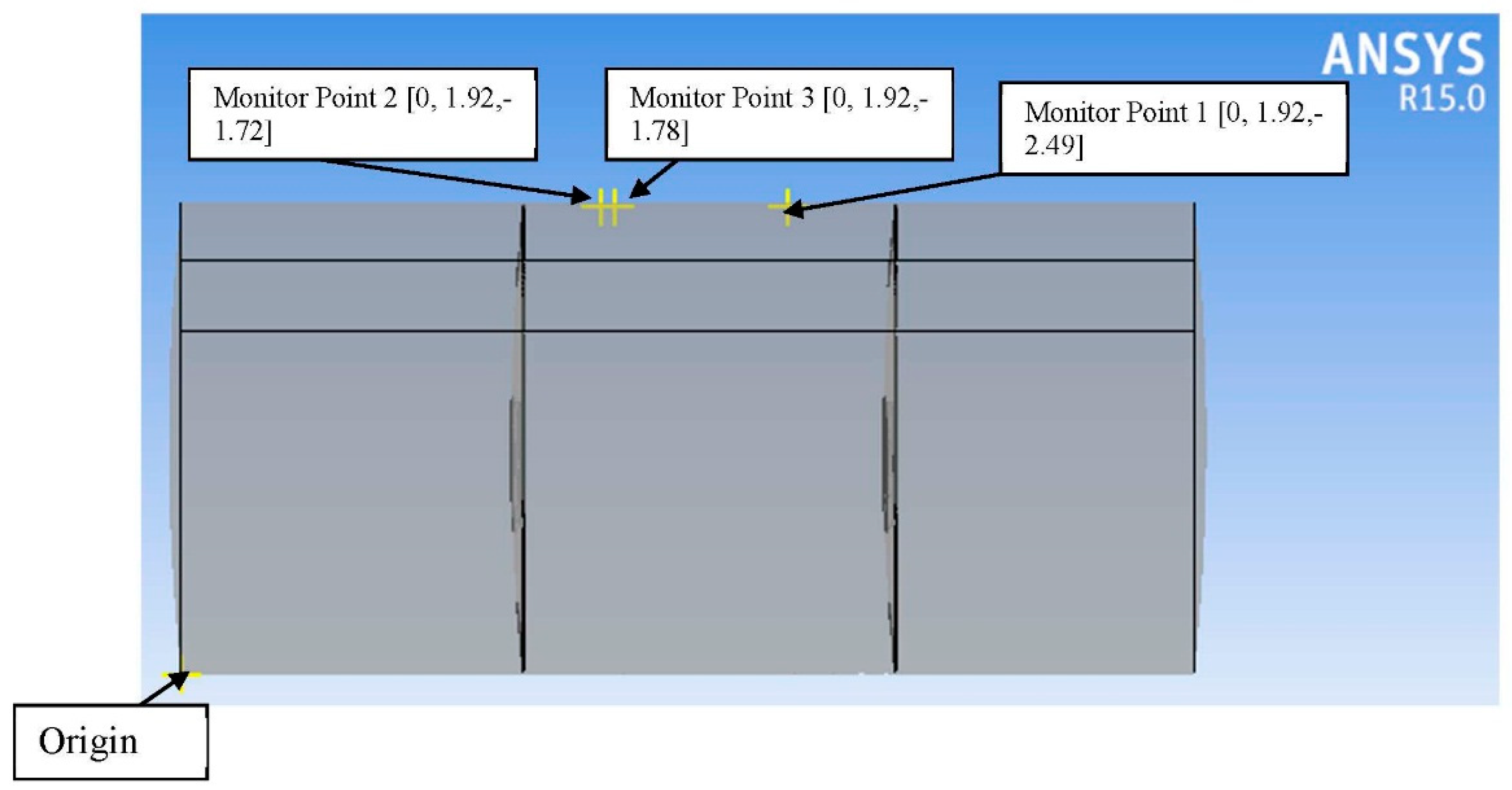

The slosh results i.e., the pressures generated with respect to time at all three monitor points for Case 1 are shown in

Figure 21. The opening pressure of the valve i.e., 111 kPa was not reached at any monitor point. The least pressures were produced at Monitor Point 1 i.e., third compartment. The reason was its location i.e., it was placed farthest from the left and the tanker was moving towards the left. However, a similar trend of pressures was obtained for Monitor Points 2 and 3.

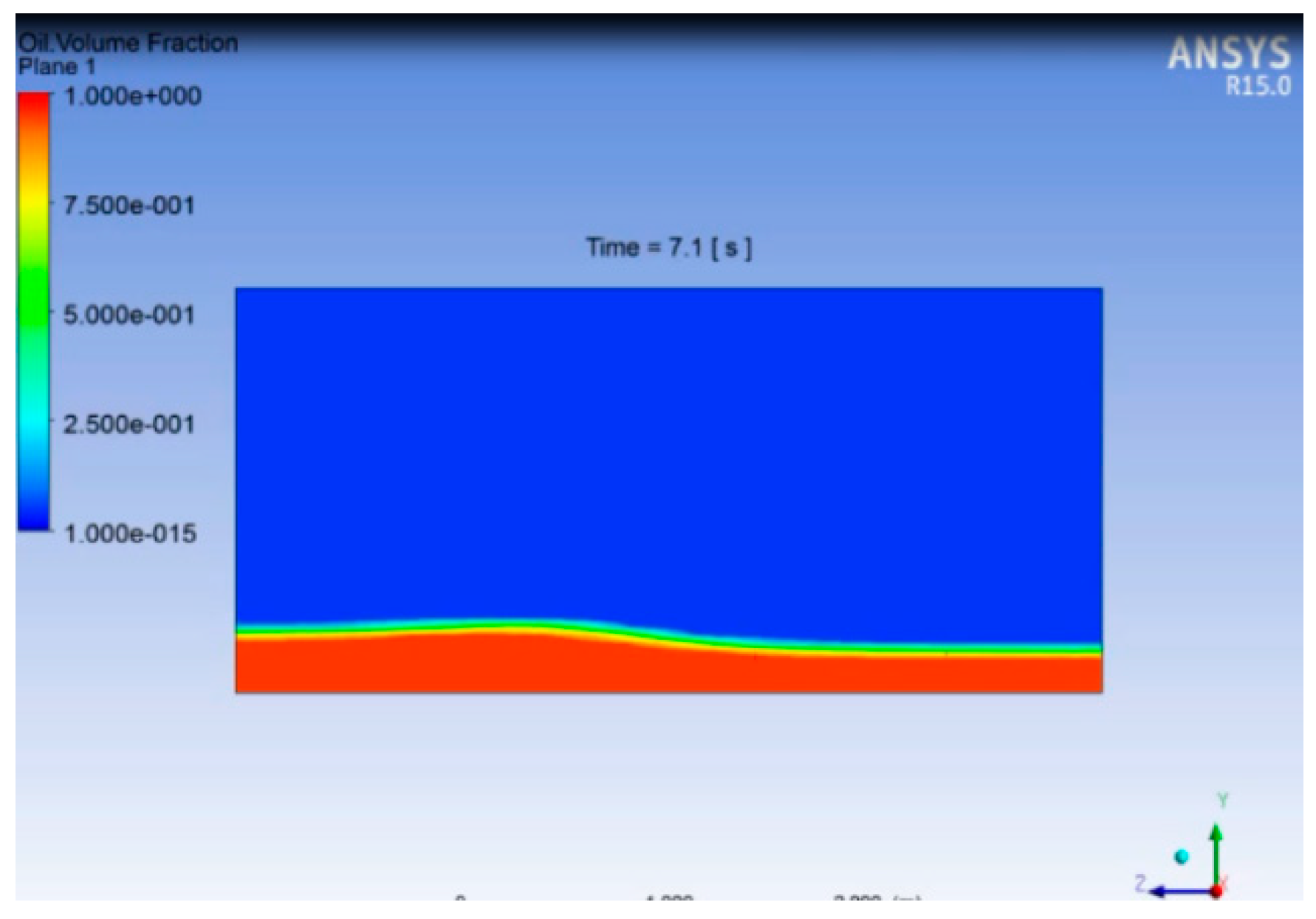

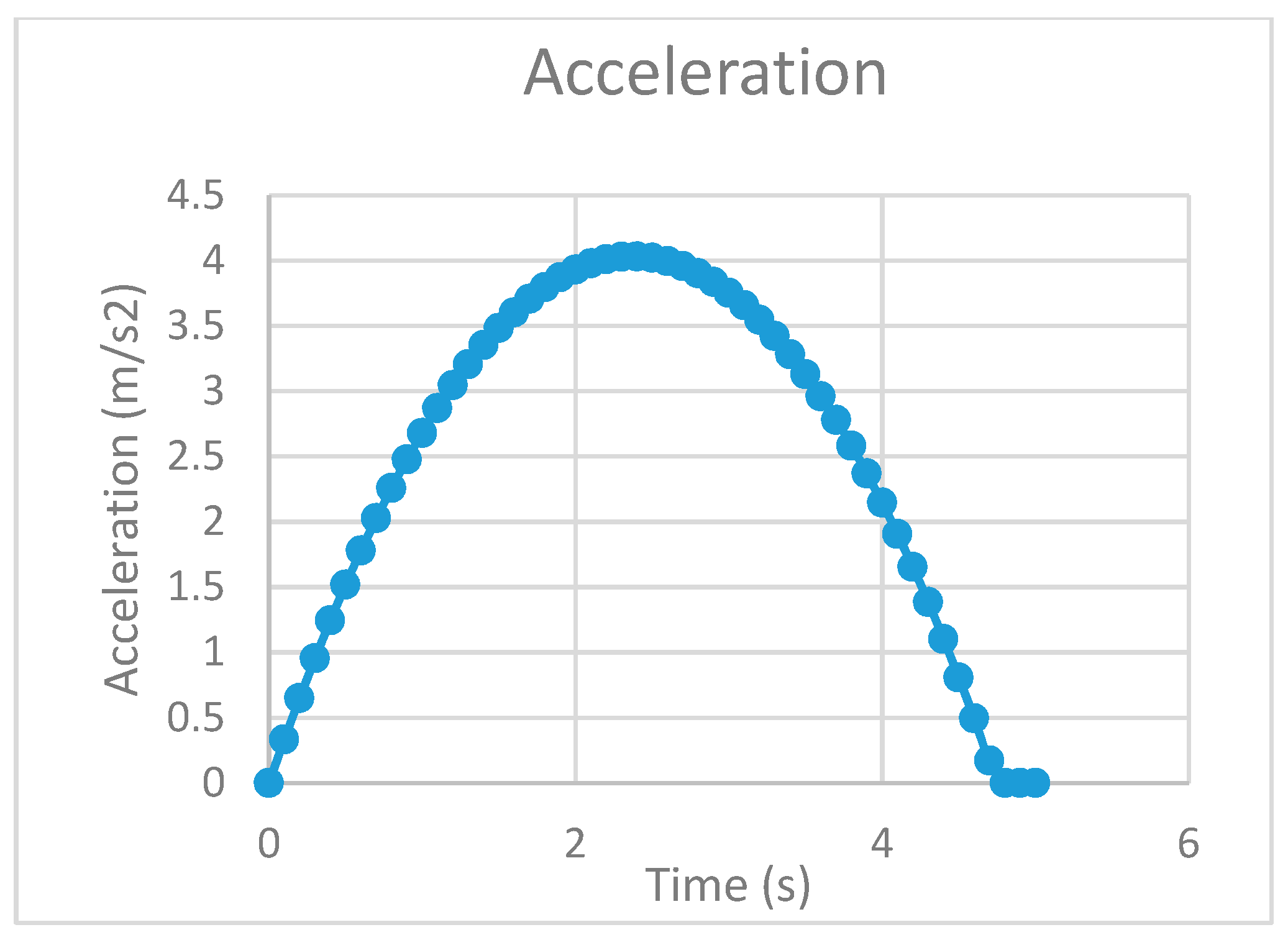

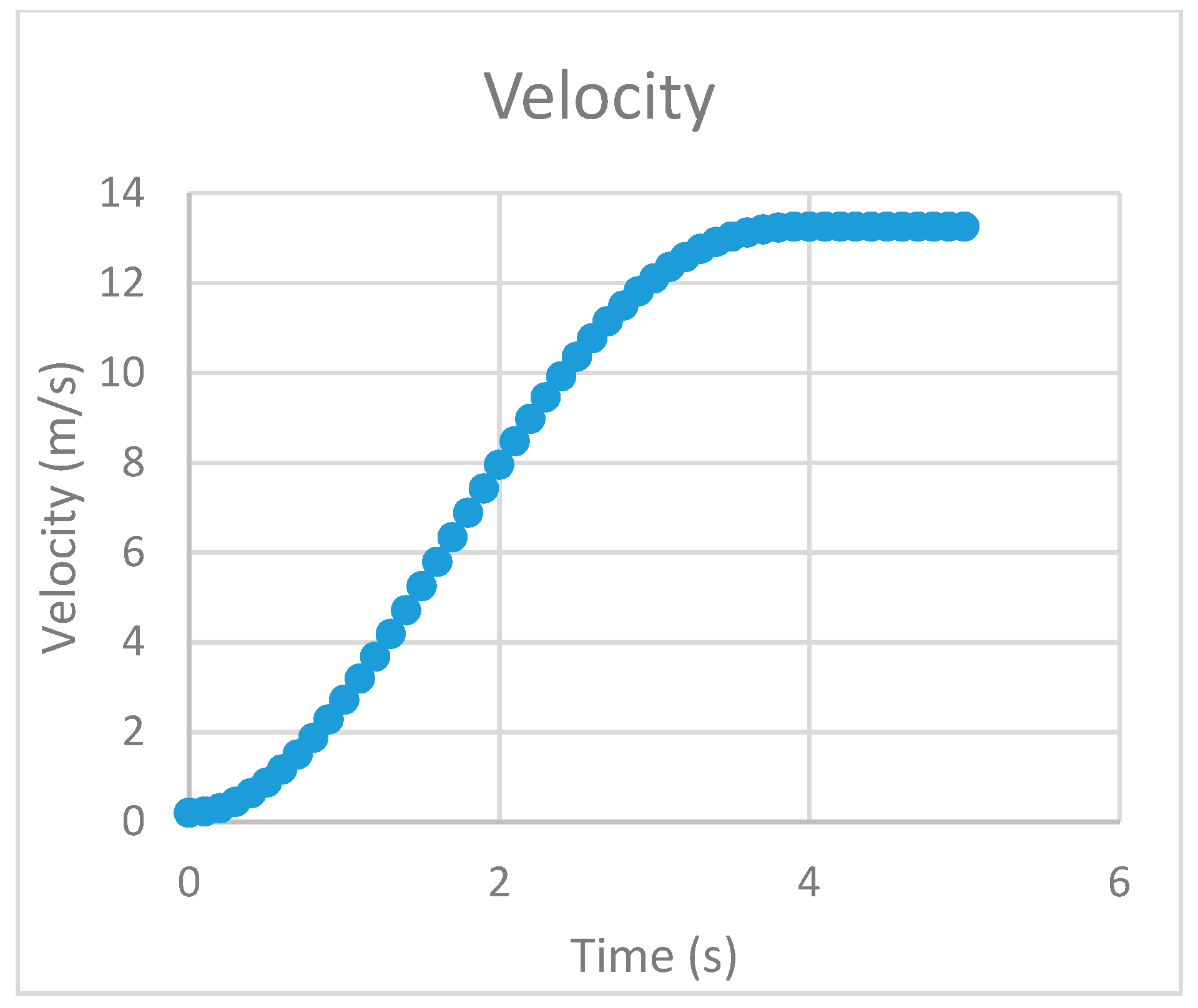

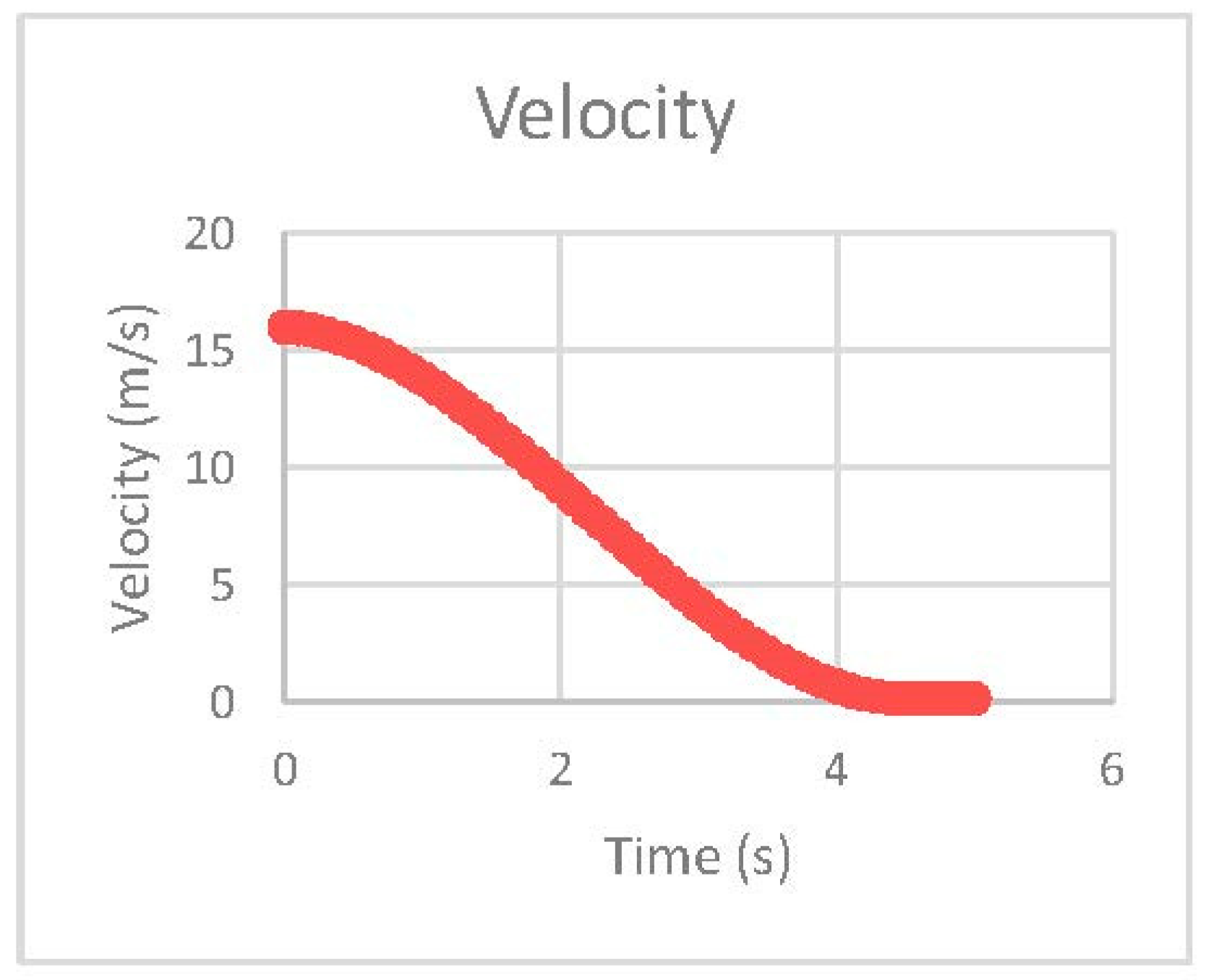

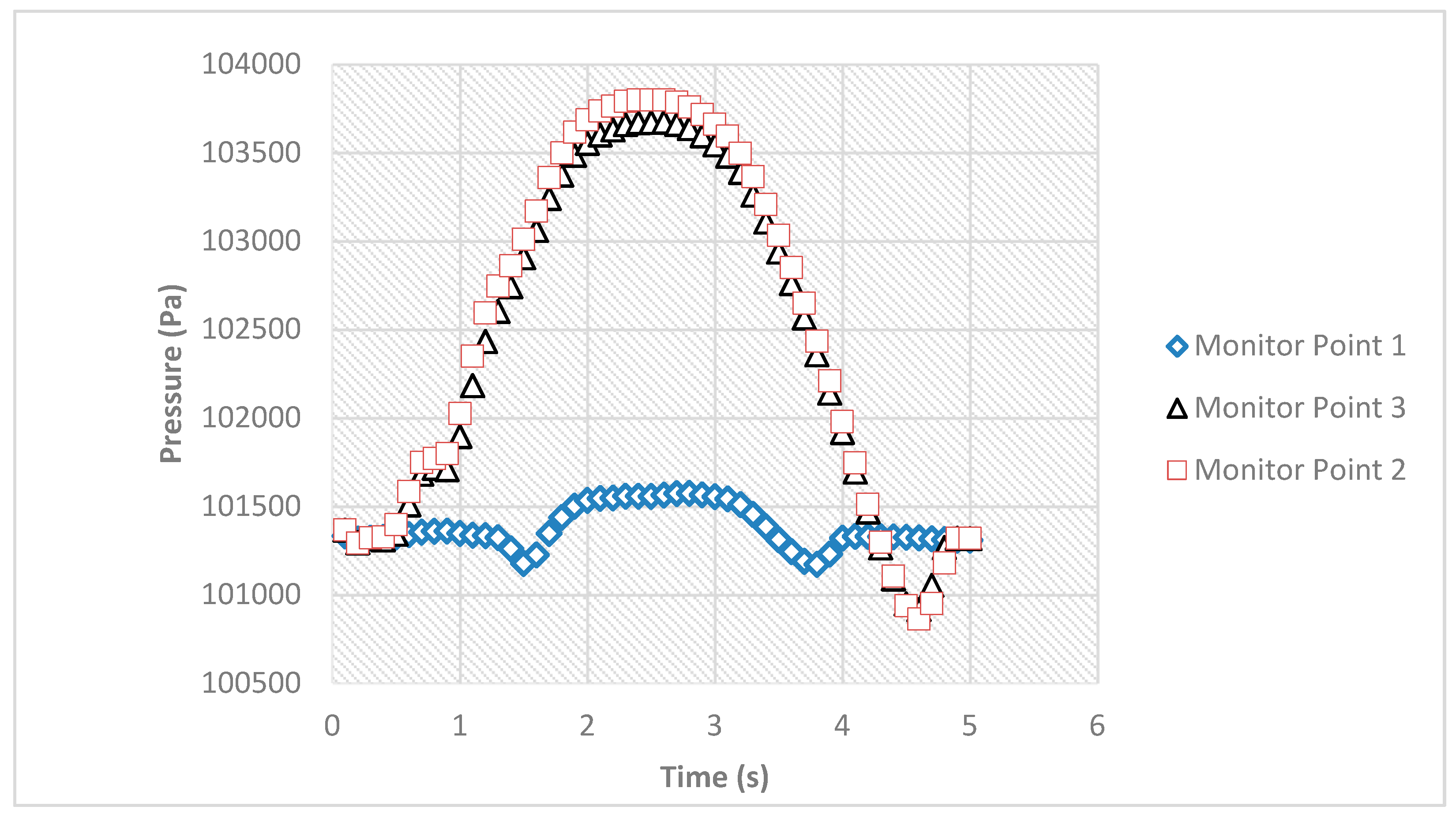

Case 2: Abnormal Acceleration

The slosh results i.e., the pressures generated with respect to time at all three monitor points for Case 2 are shown in

Figure 22. In this case, as well, the opening pressure of the valve did not reach any monitor point. Similar to case 1, the least pressures were generated in the third compartment.

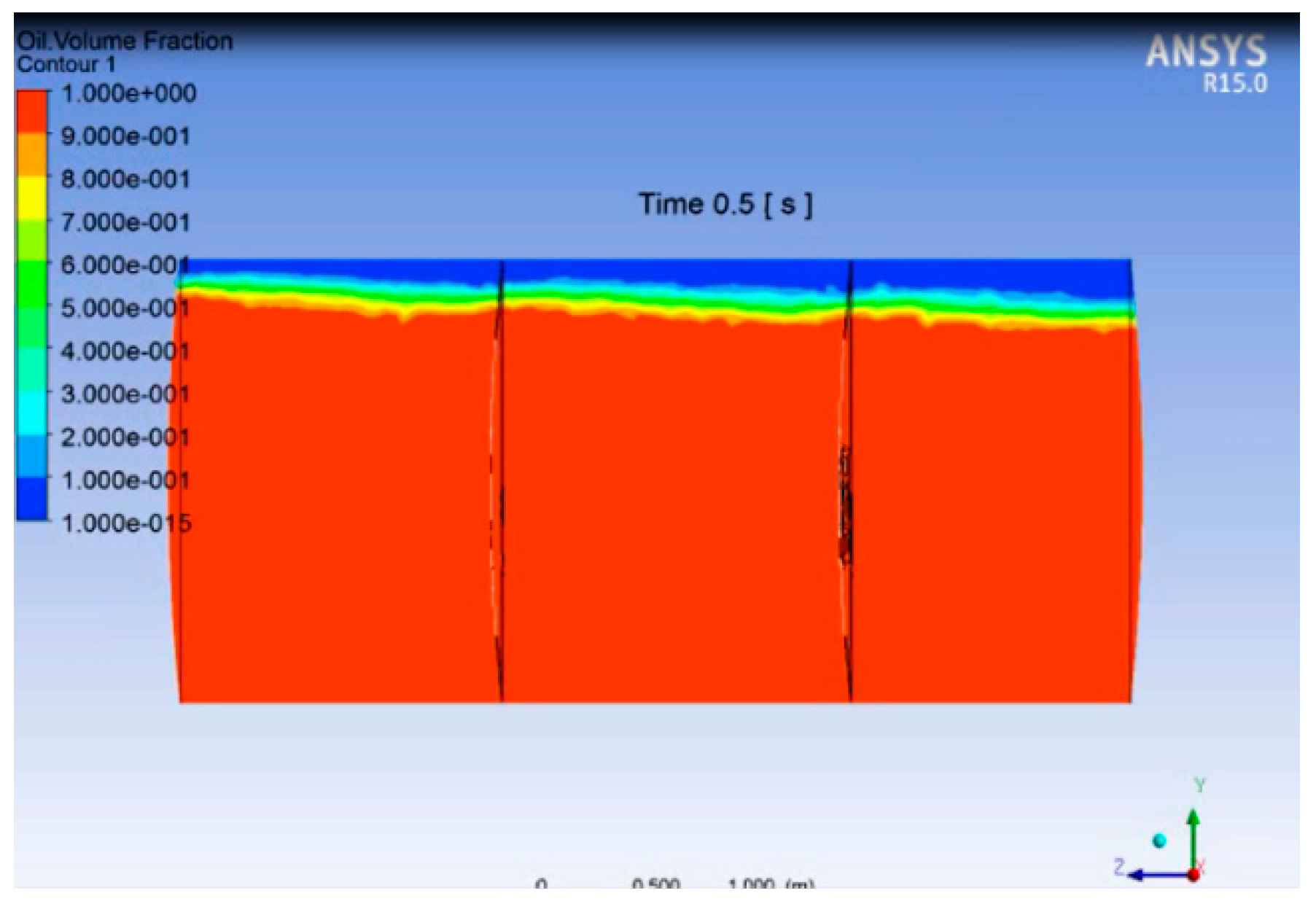

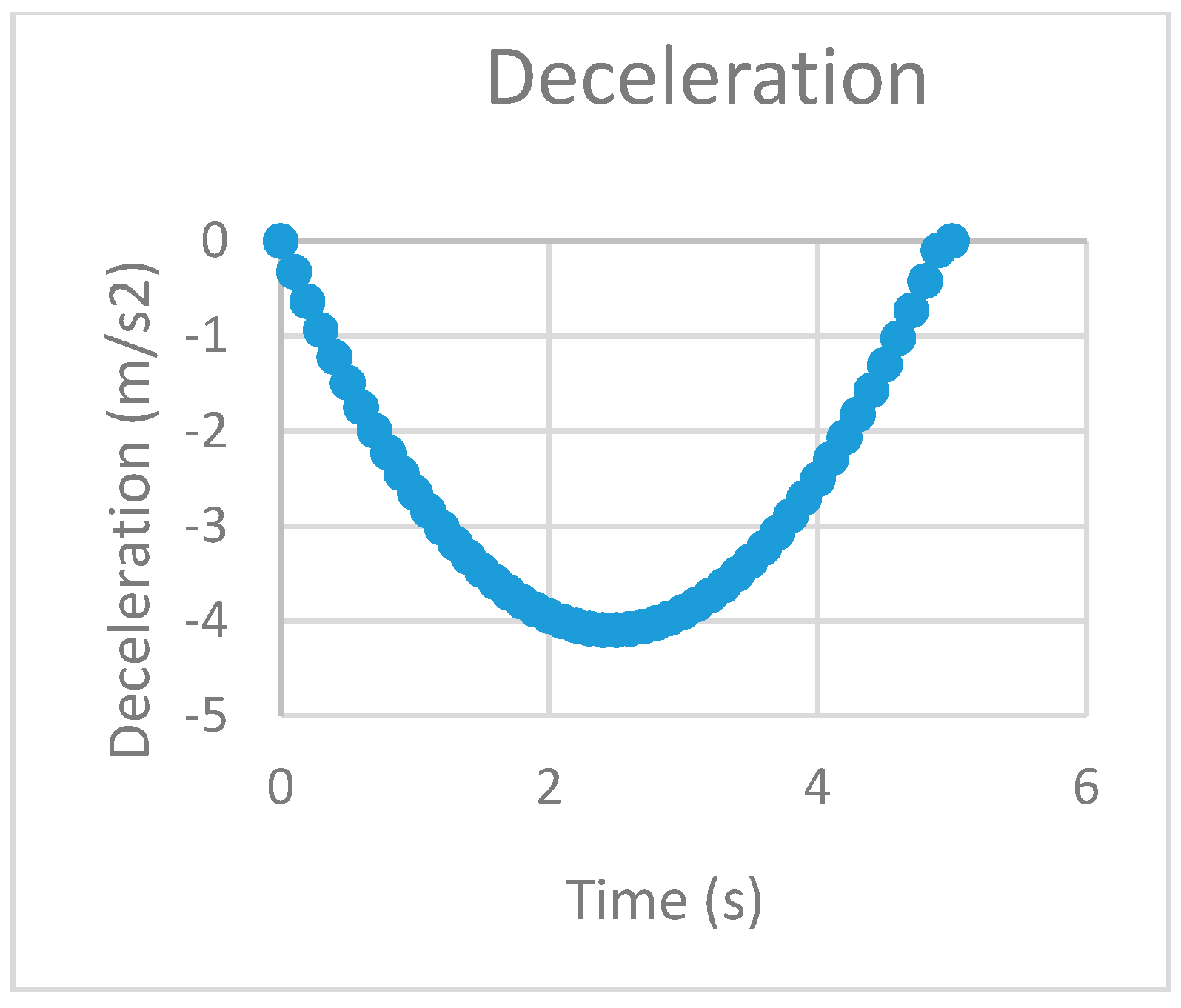

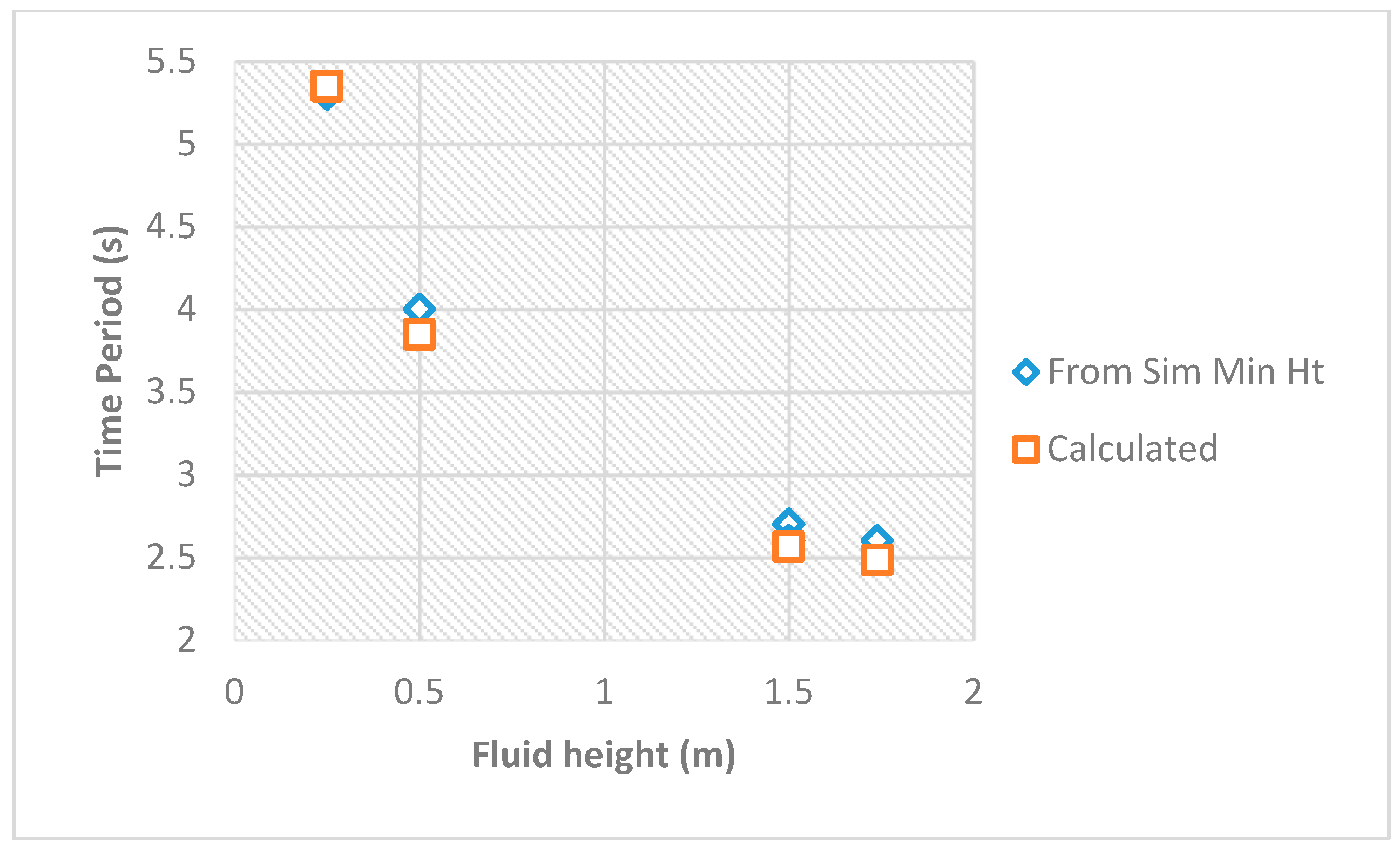

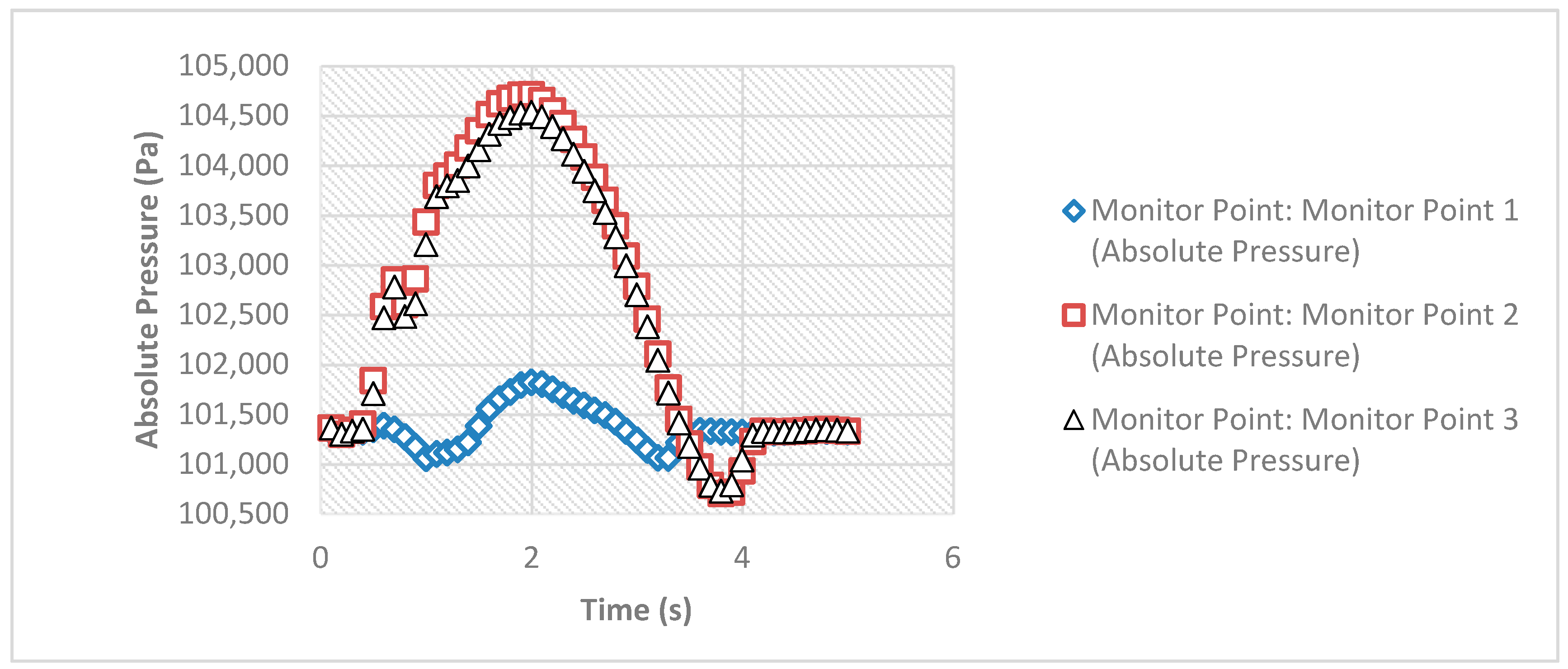

Case 3: Normal Deceleration

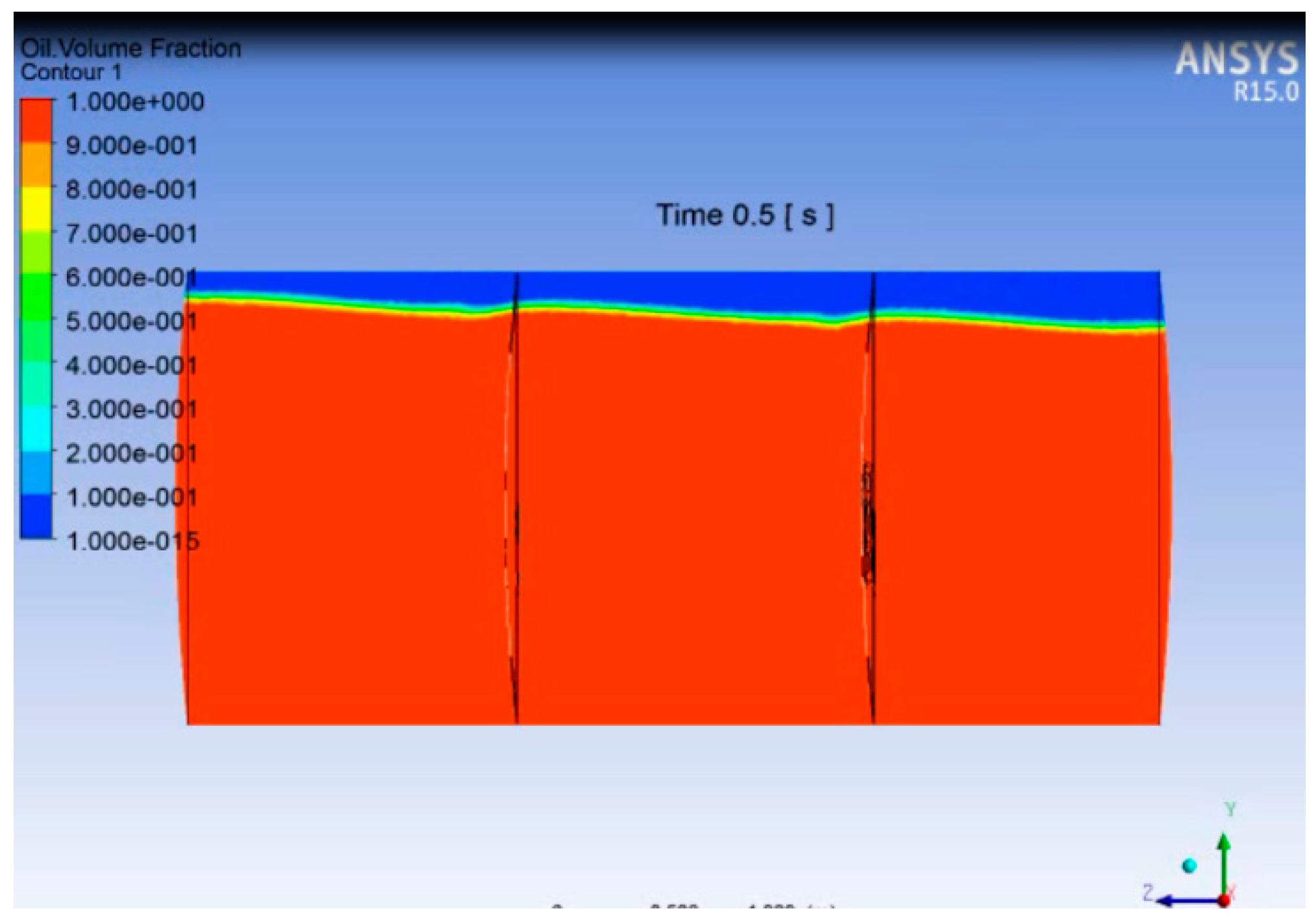

The slosh results i.e., the pressures generated with respect to time at all three monitor points for Case 3 are shown in

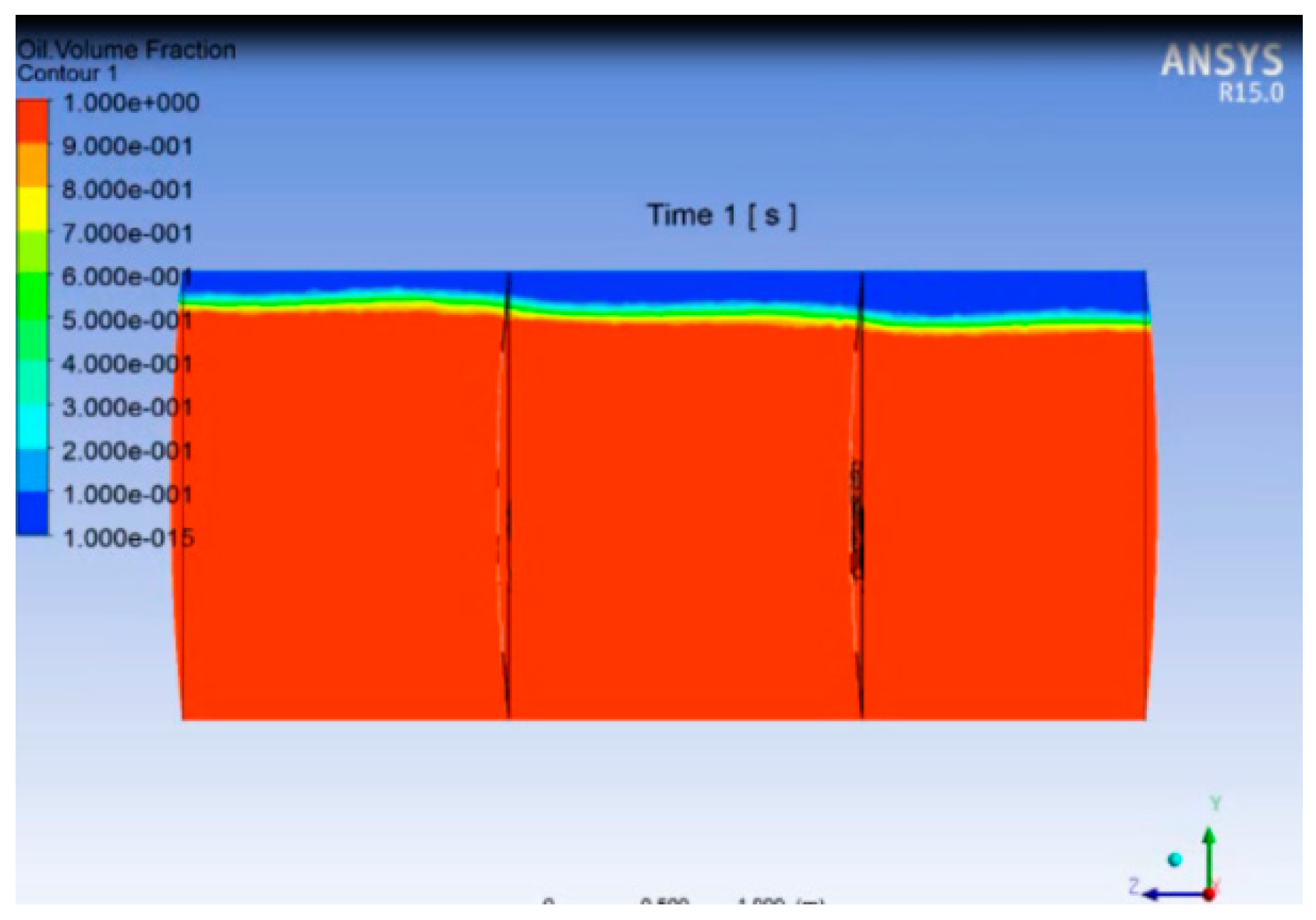

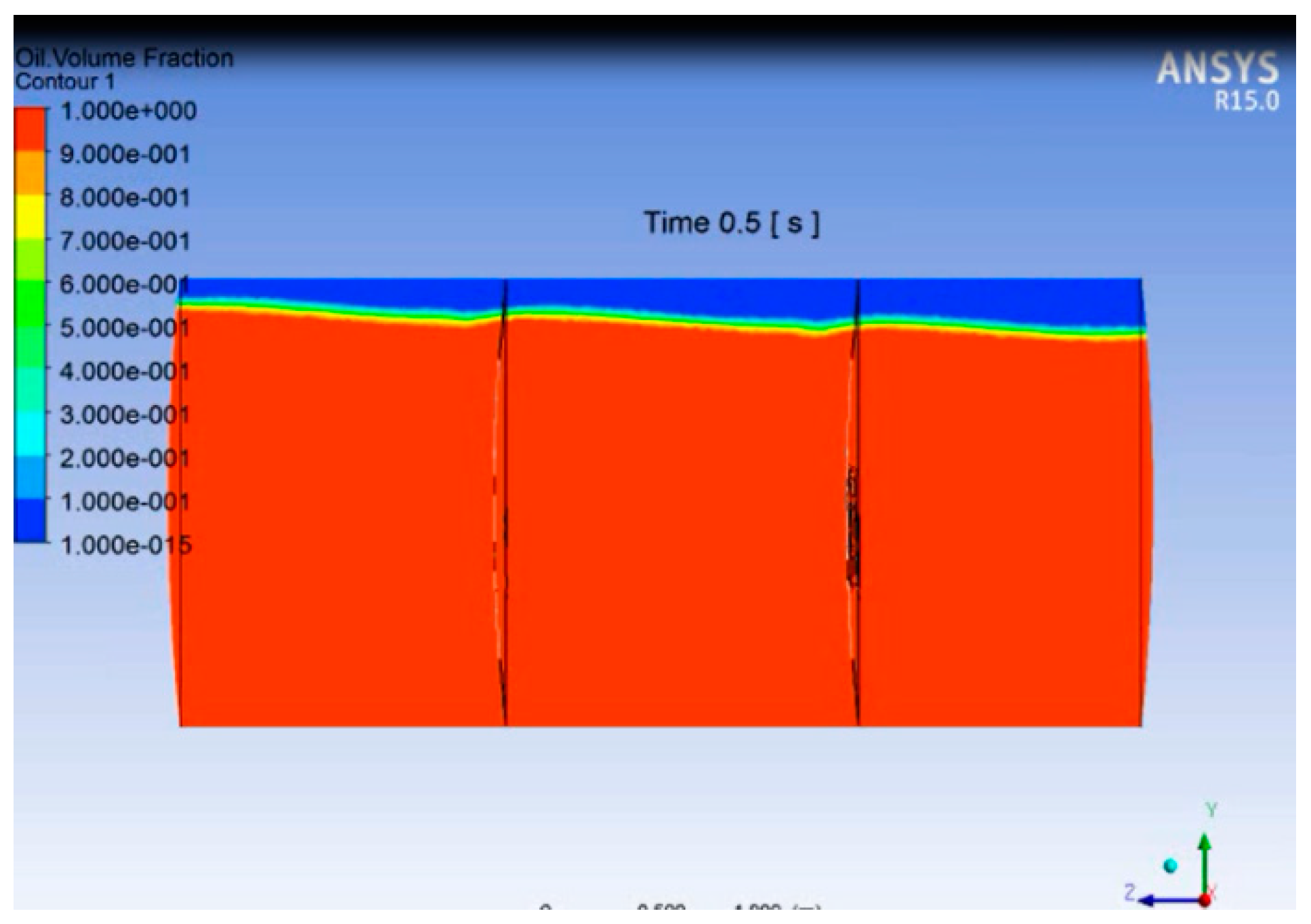

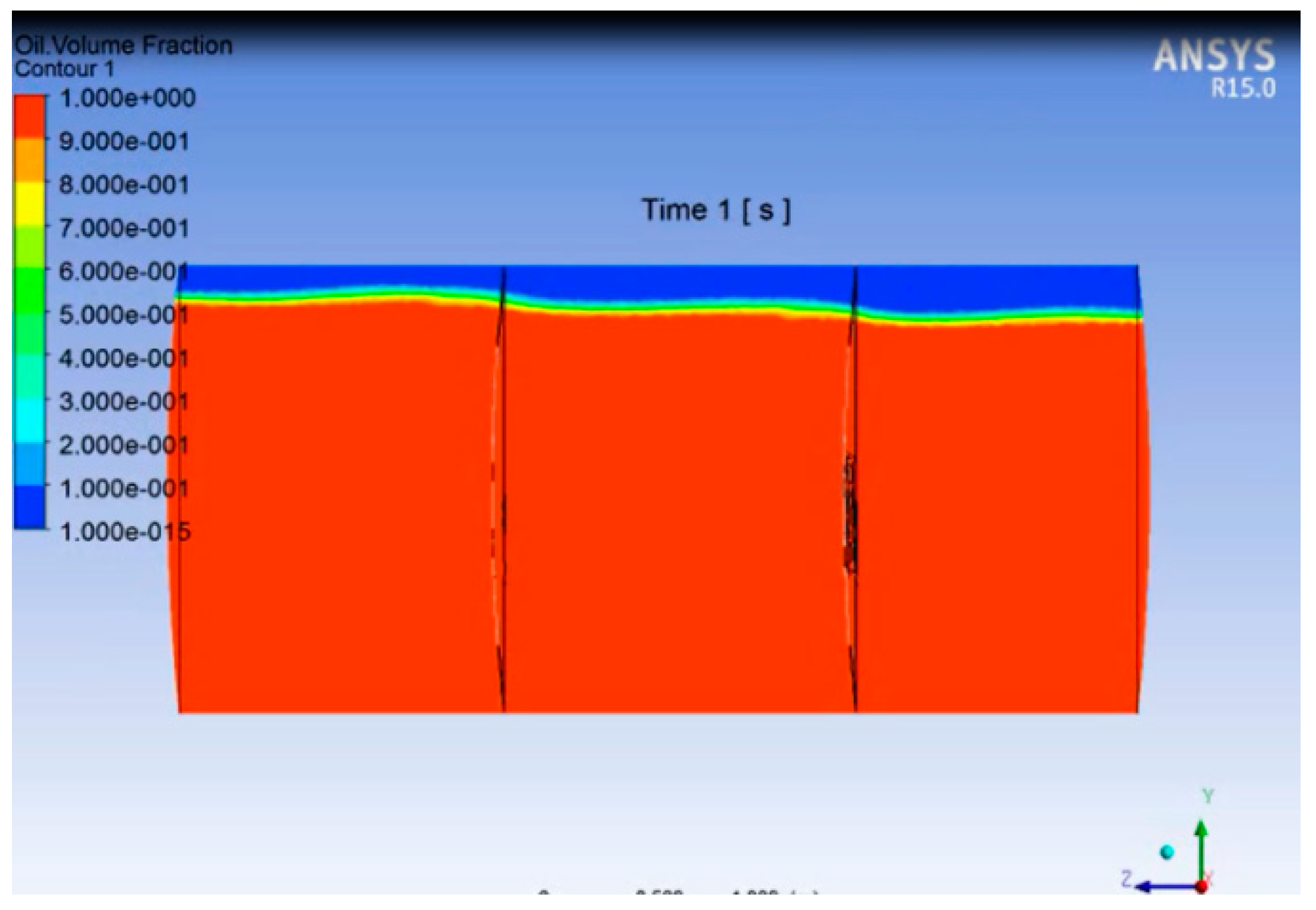

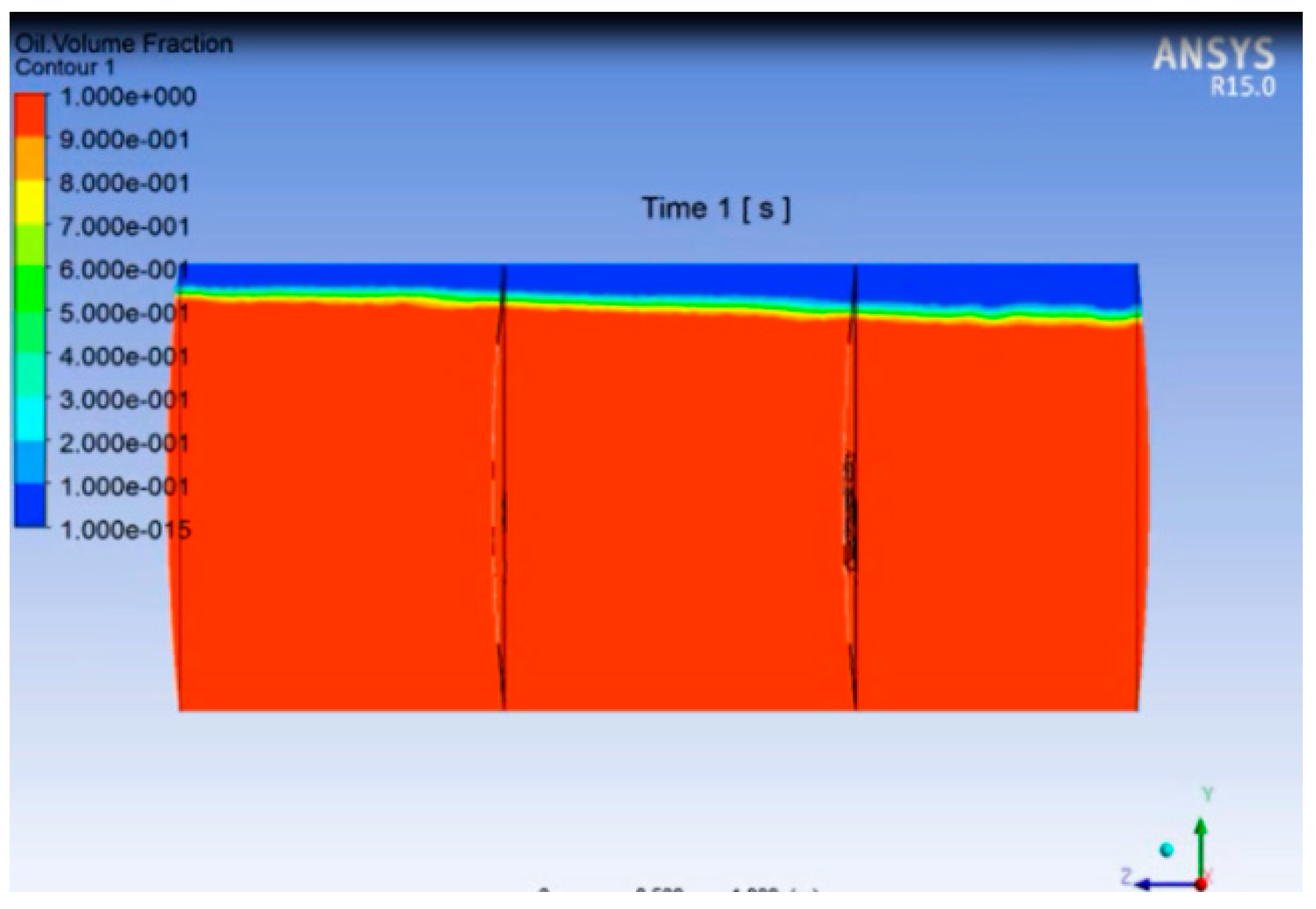

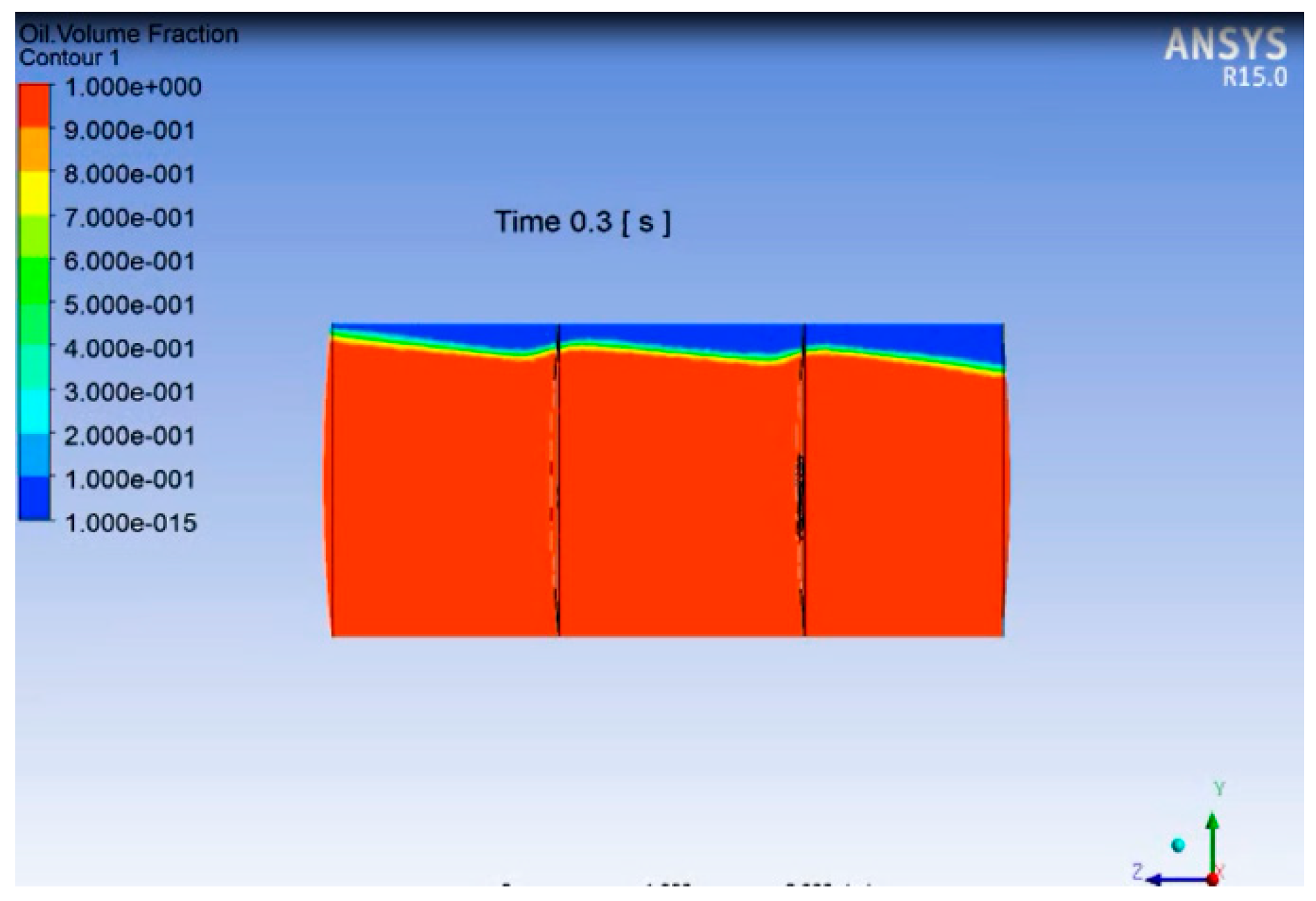

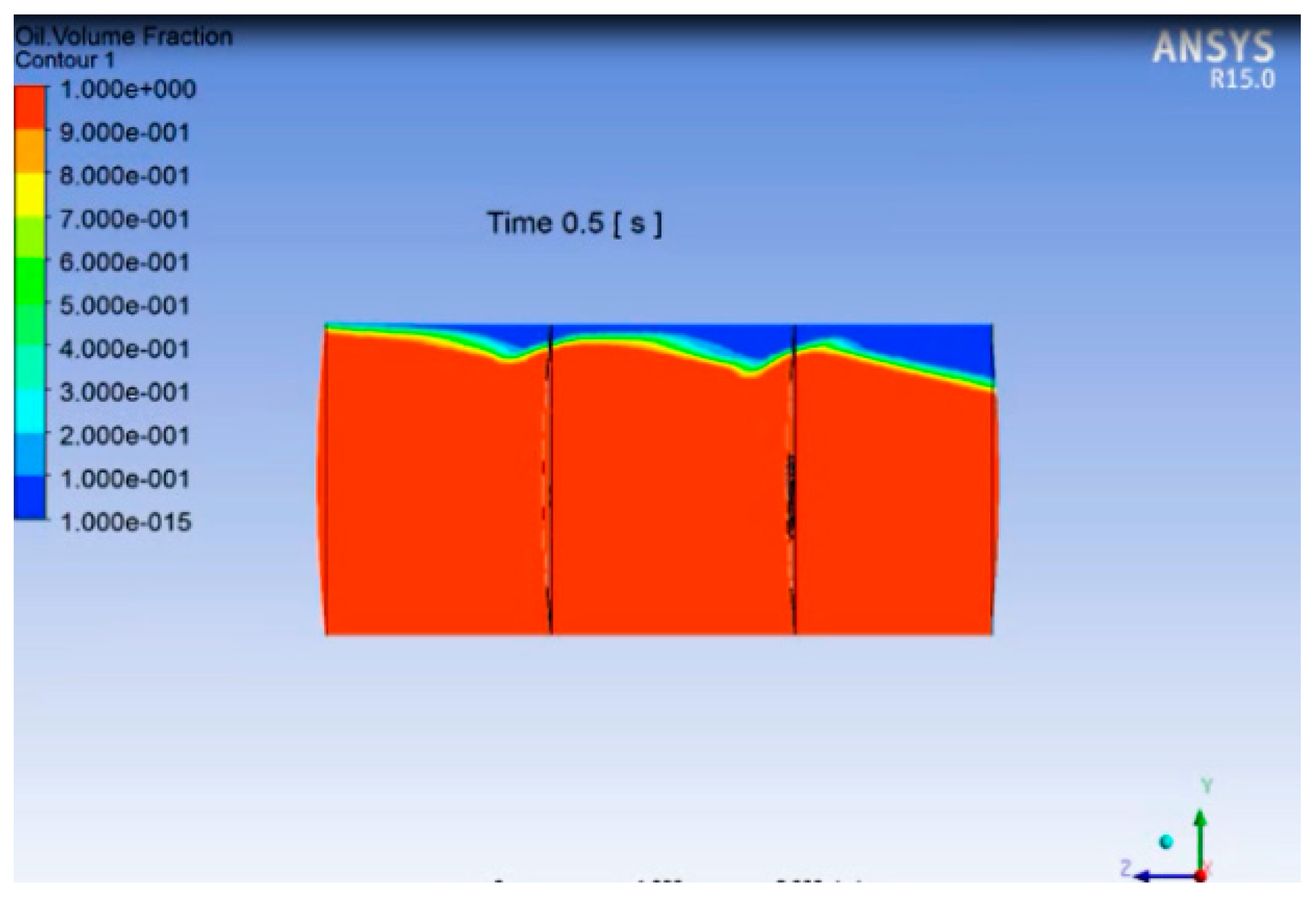

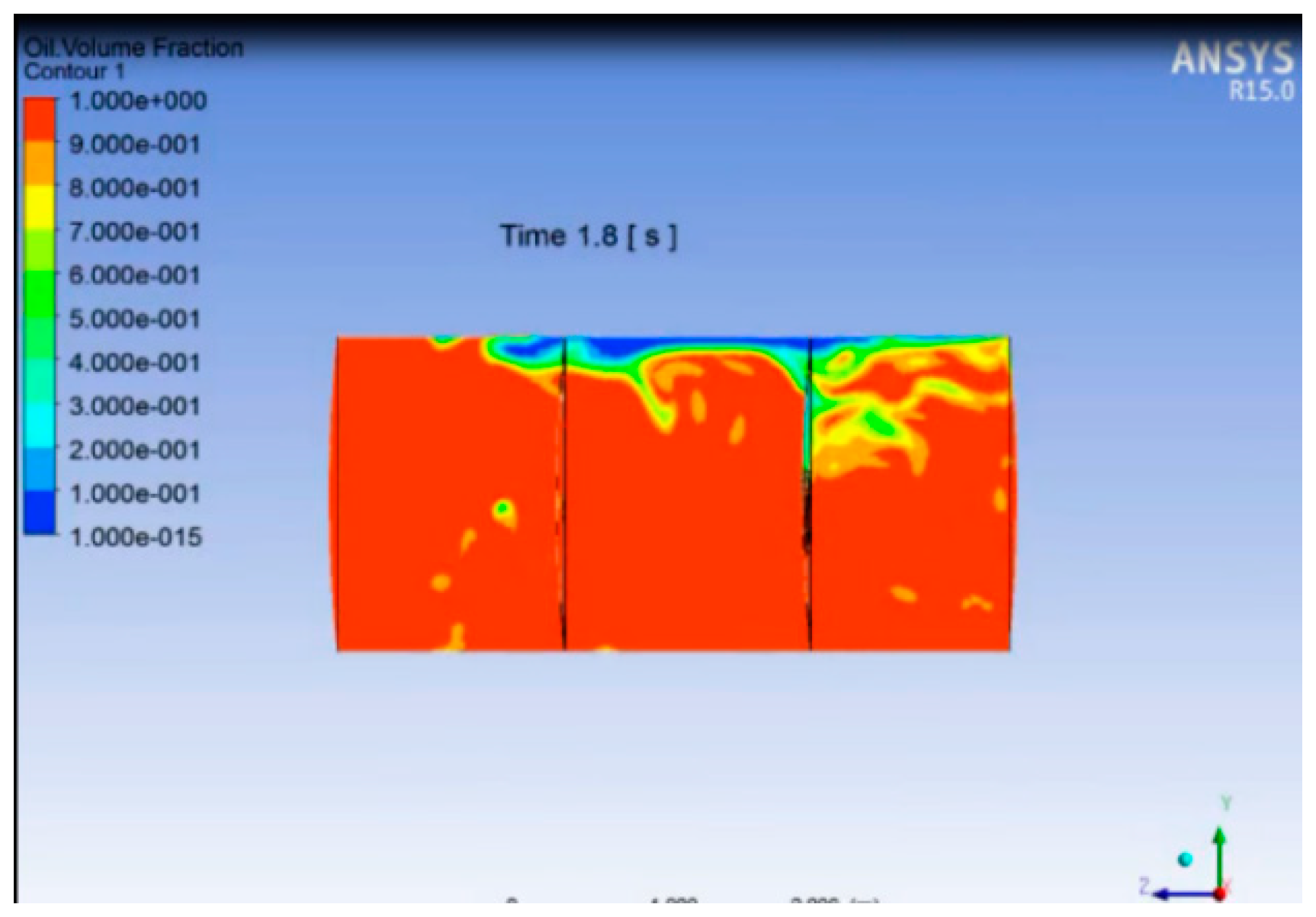

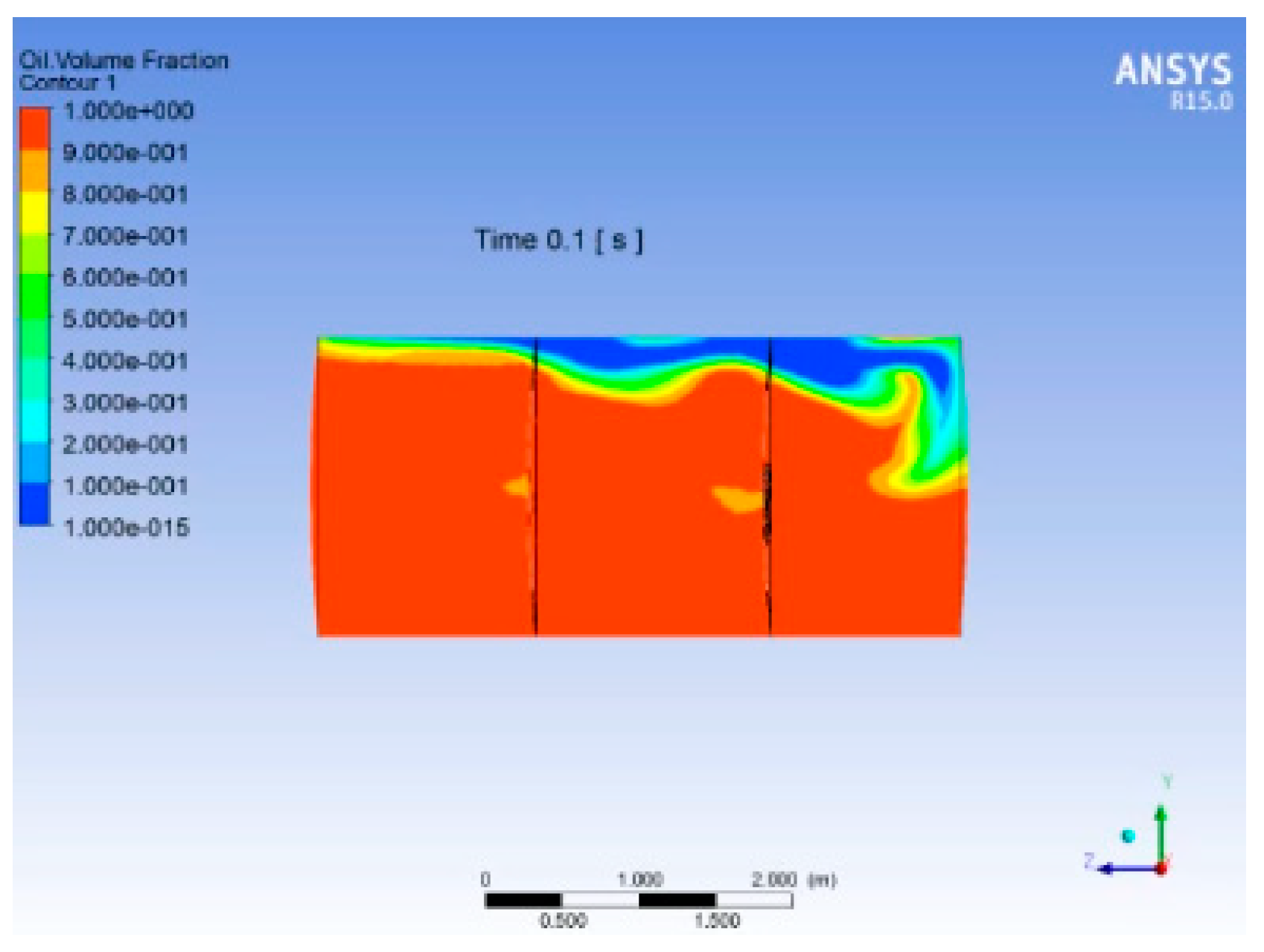

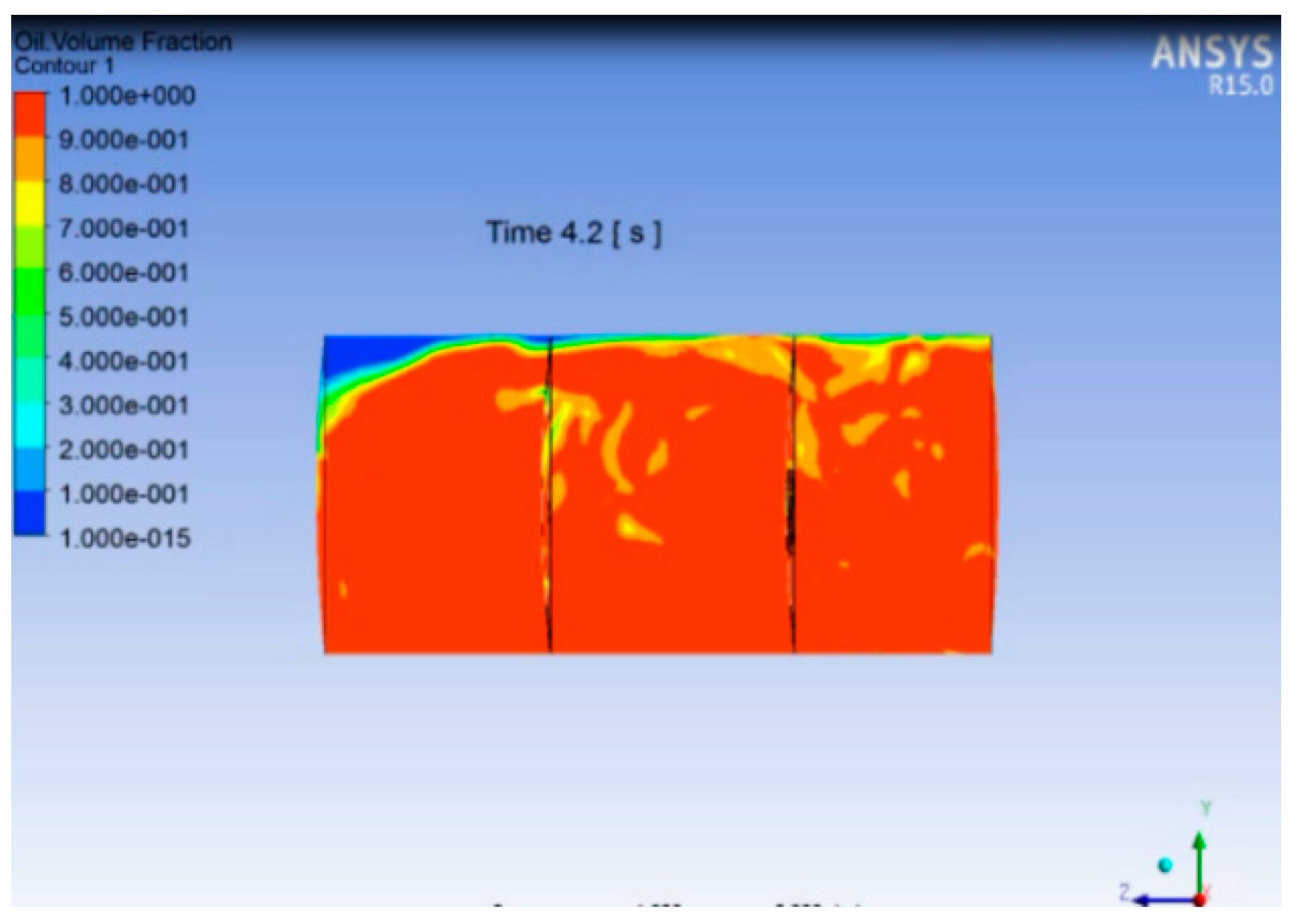

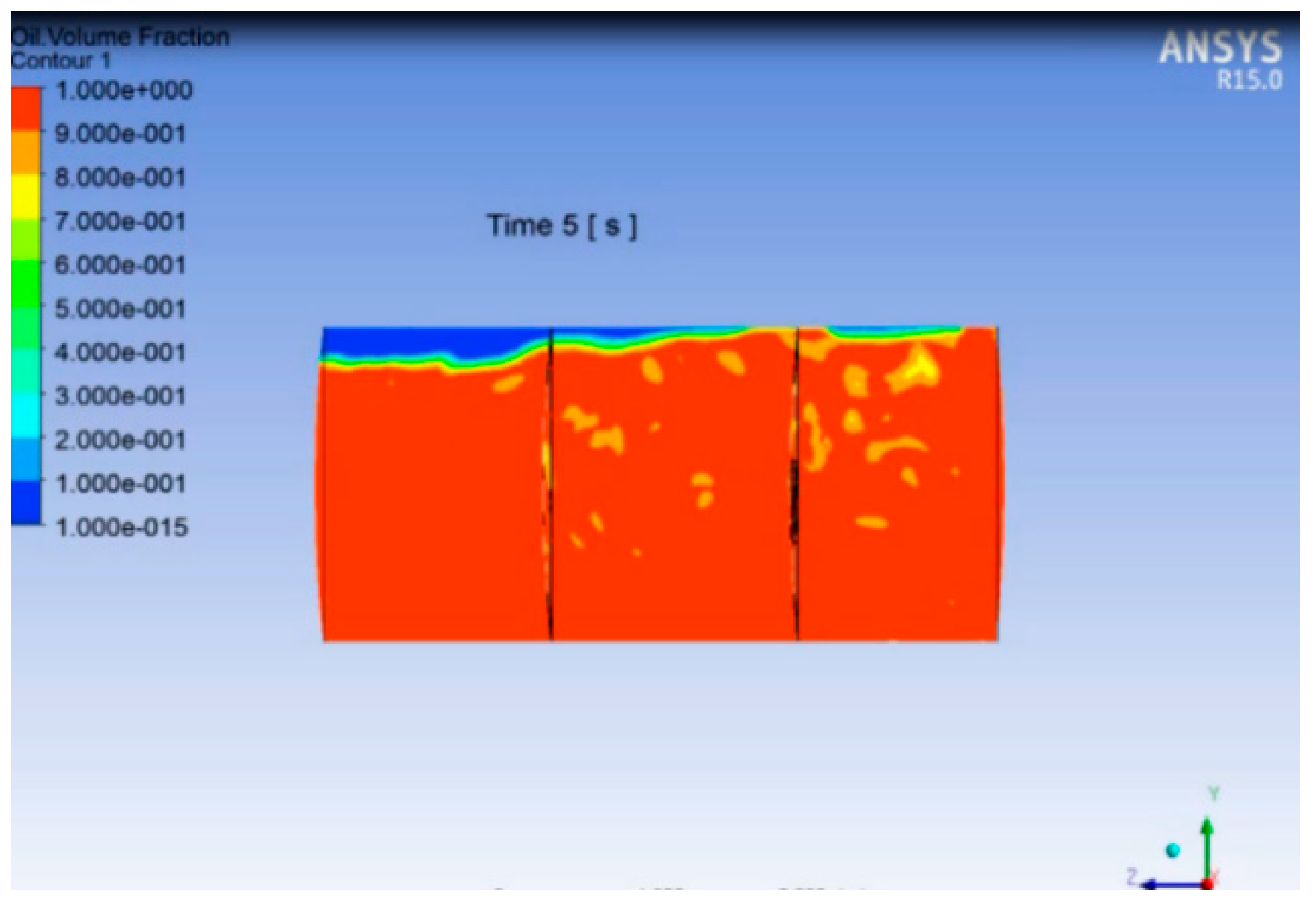

Figure 23. Opening pressures were exceeded for the first 0.2 s at point 2 and point 3. Also, an air pocket was found beneath the valve when the valve opens i.e., for the first 0.2 s (

Appendix A,

Figure A31). This confirms that the air/vapor mixture leaked out during that interval.

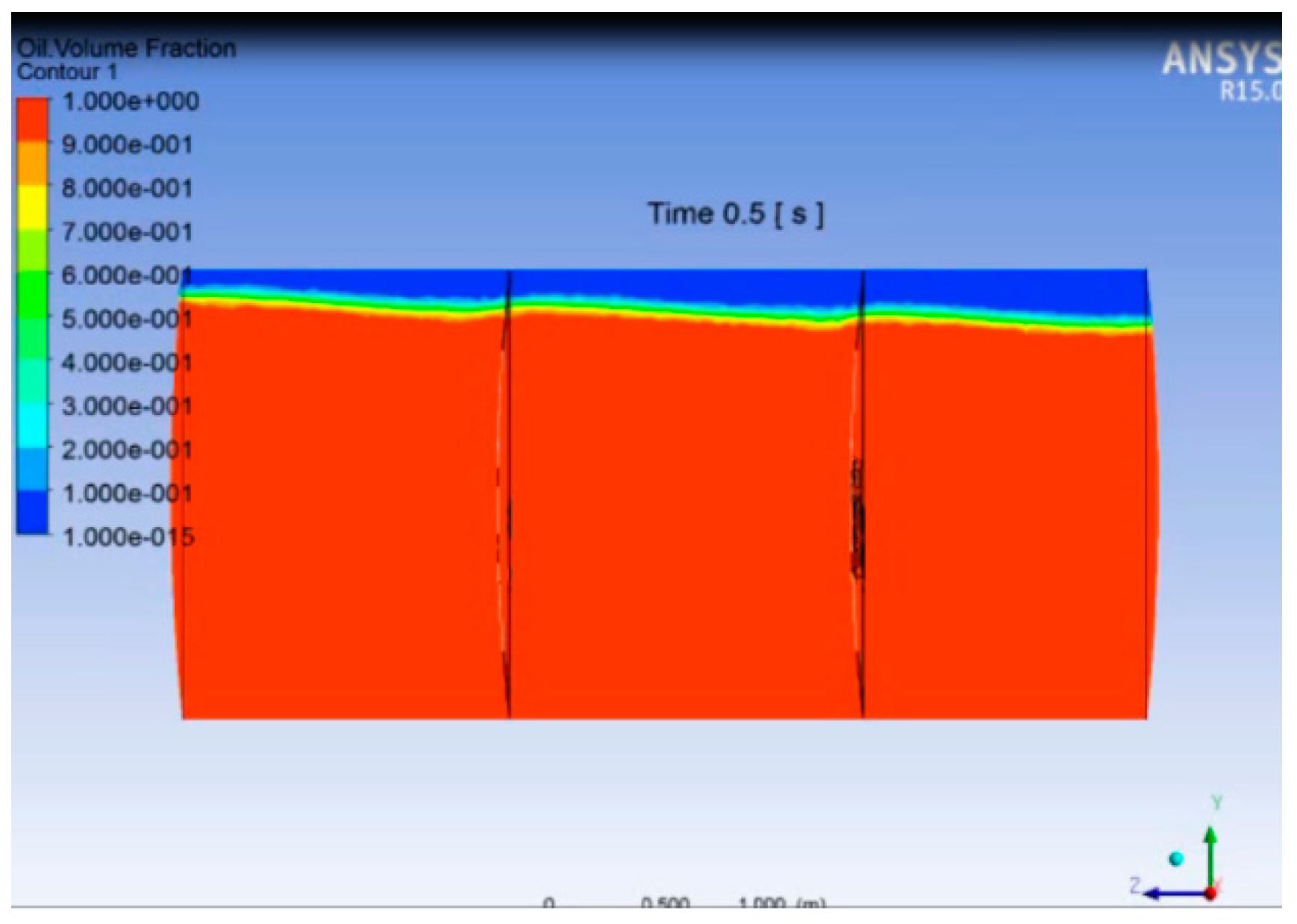

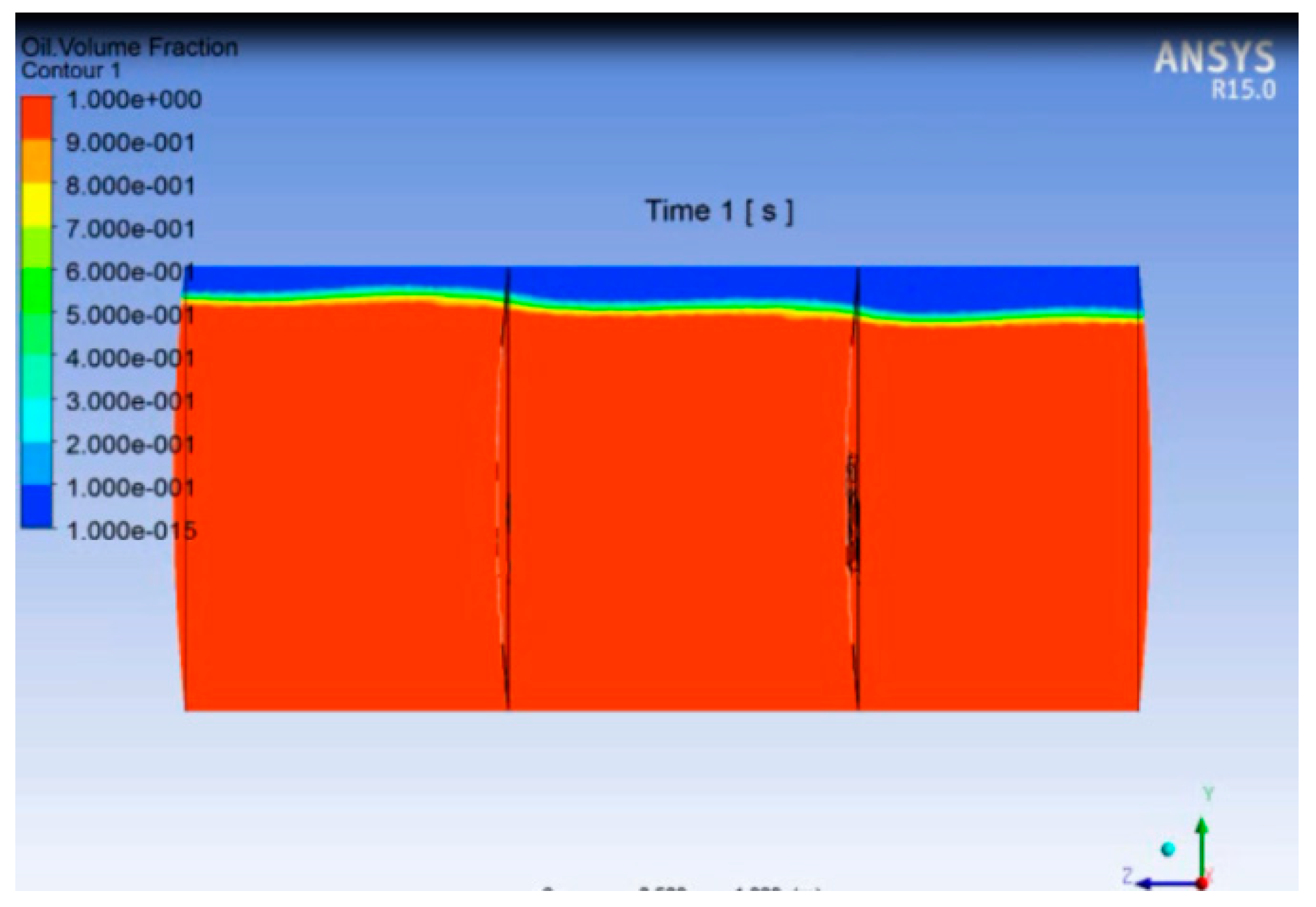

Case 4: Abnormal Deceleration

The slosh results i.e., the pressures generated with respect to time at all three monitor points for Case 4 are shown in

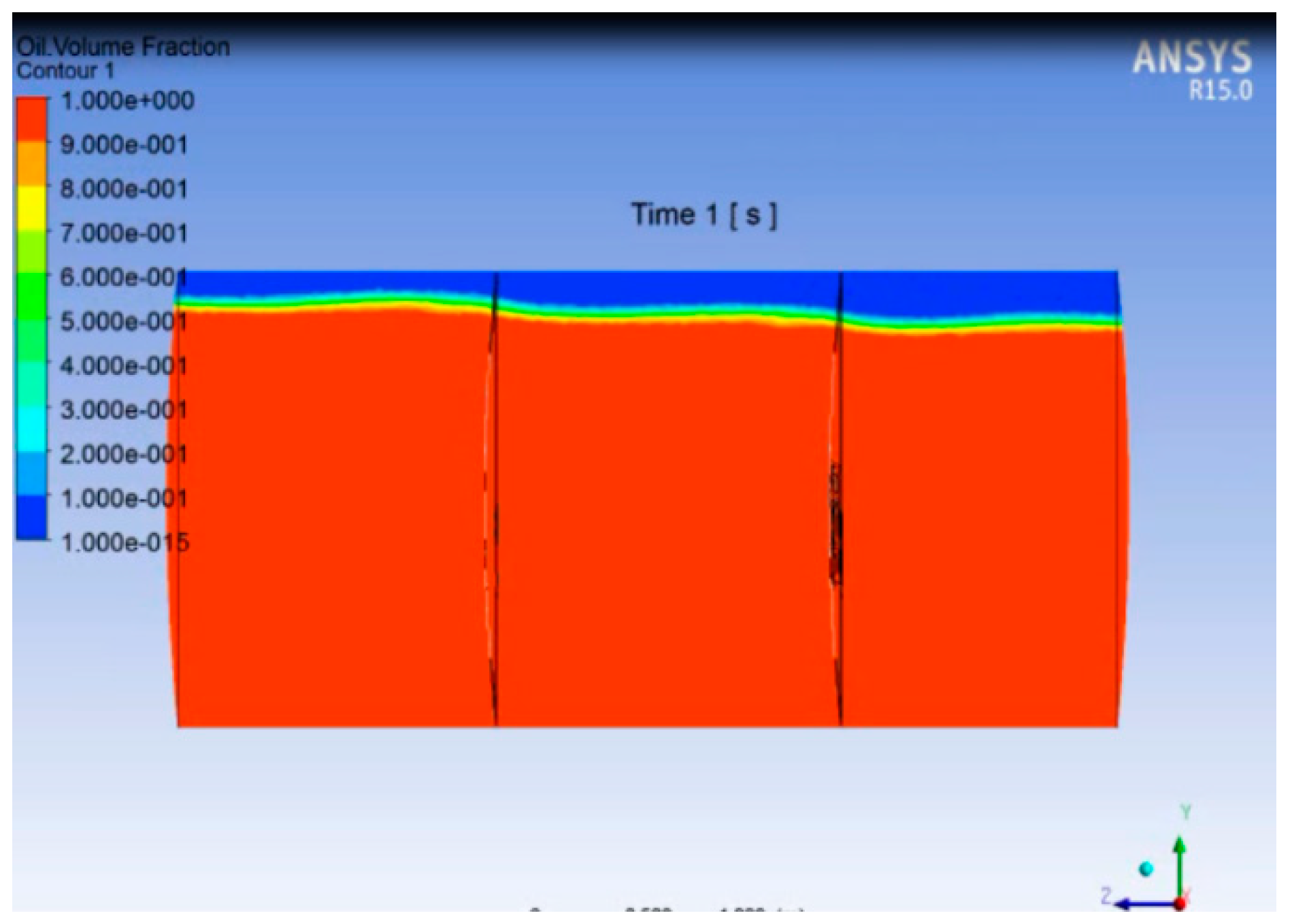

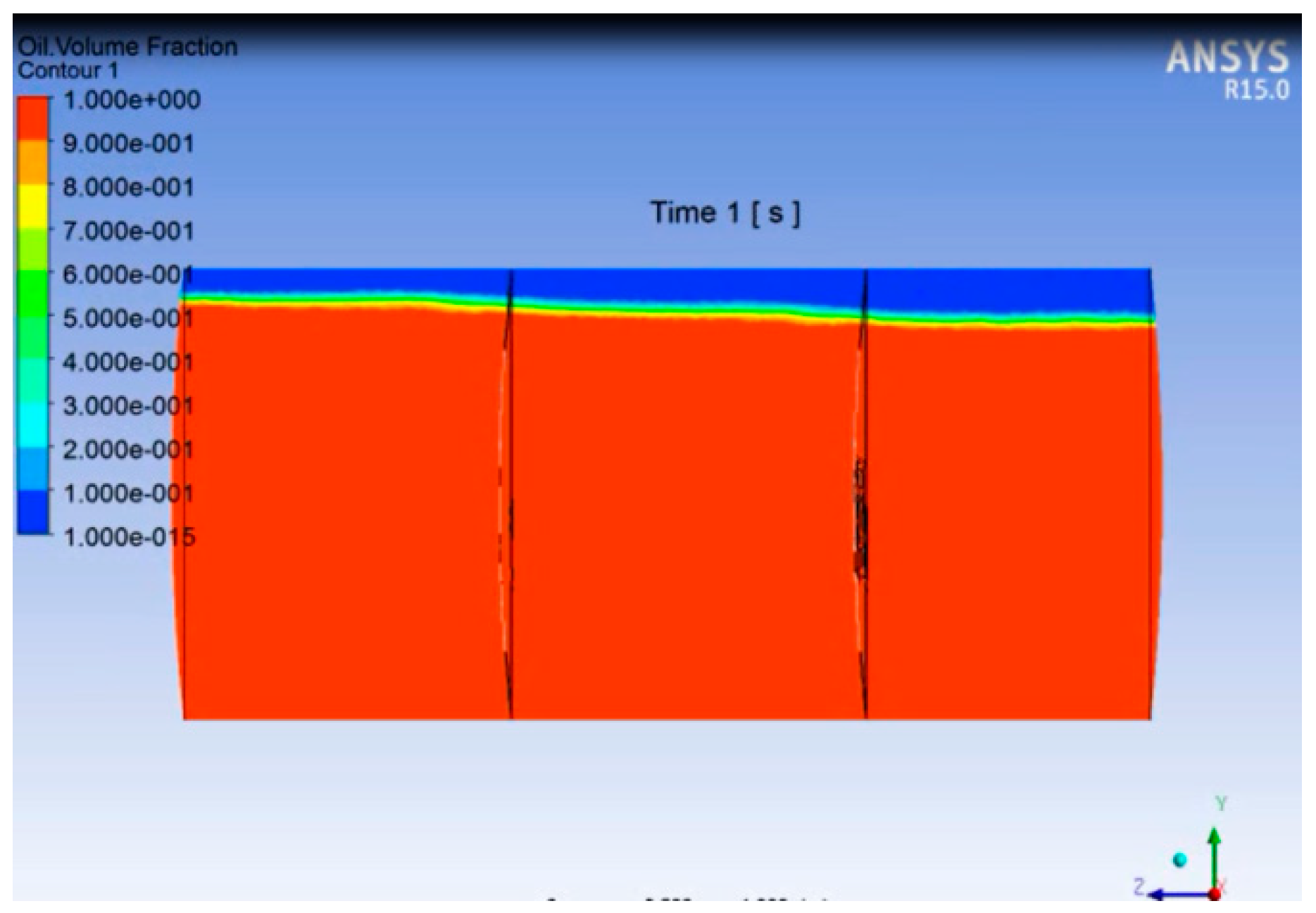

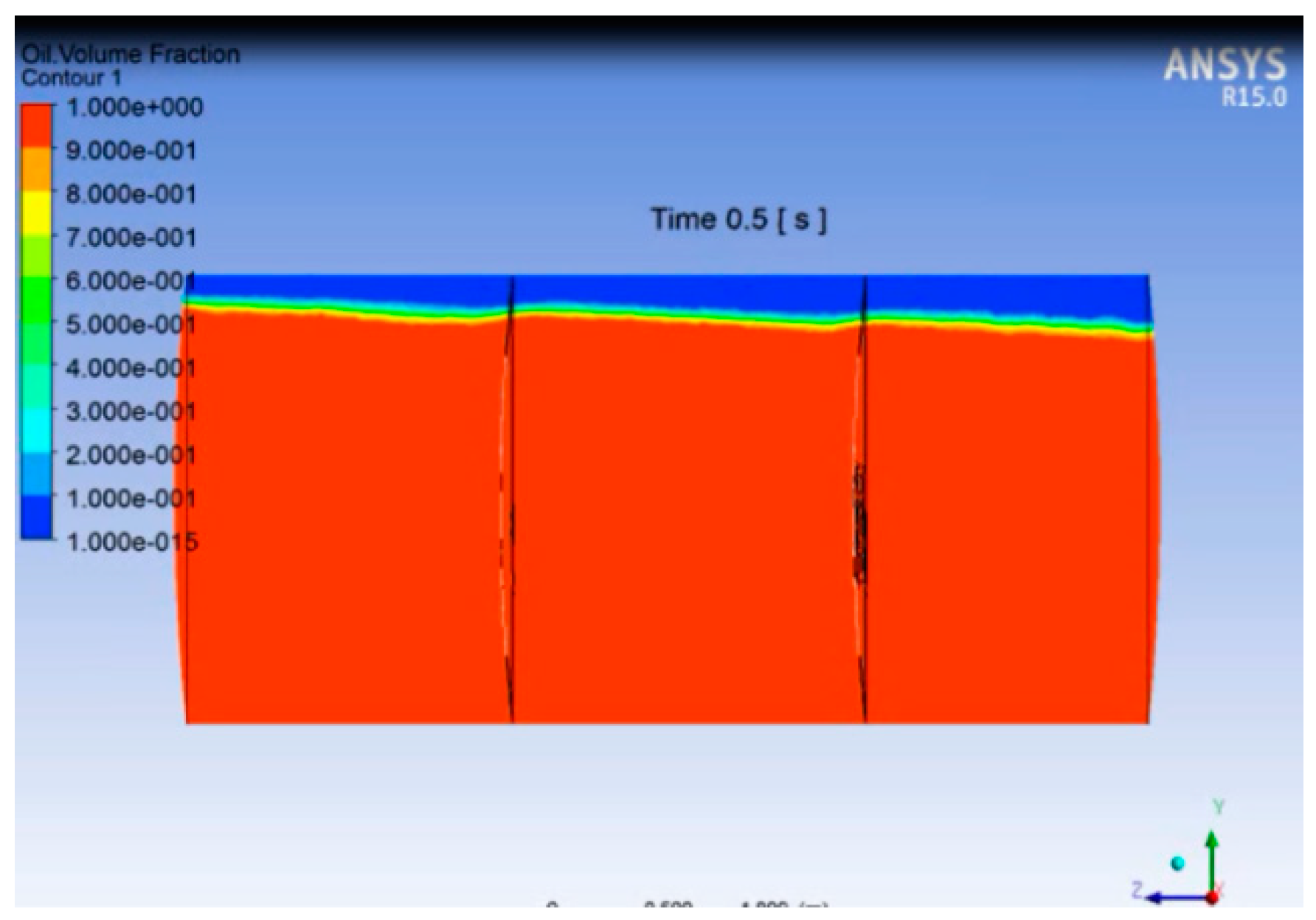

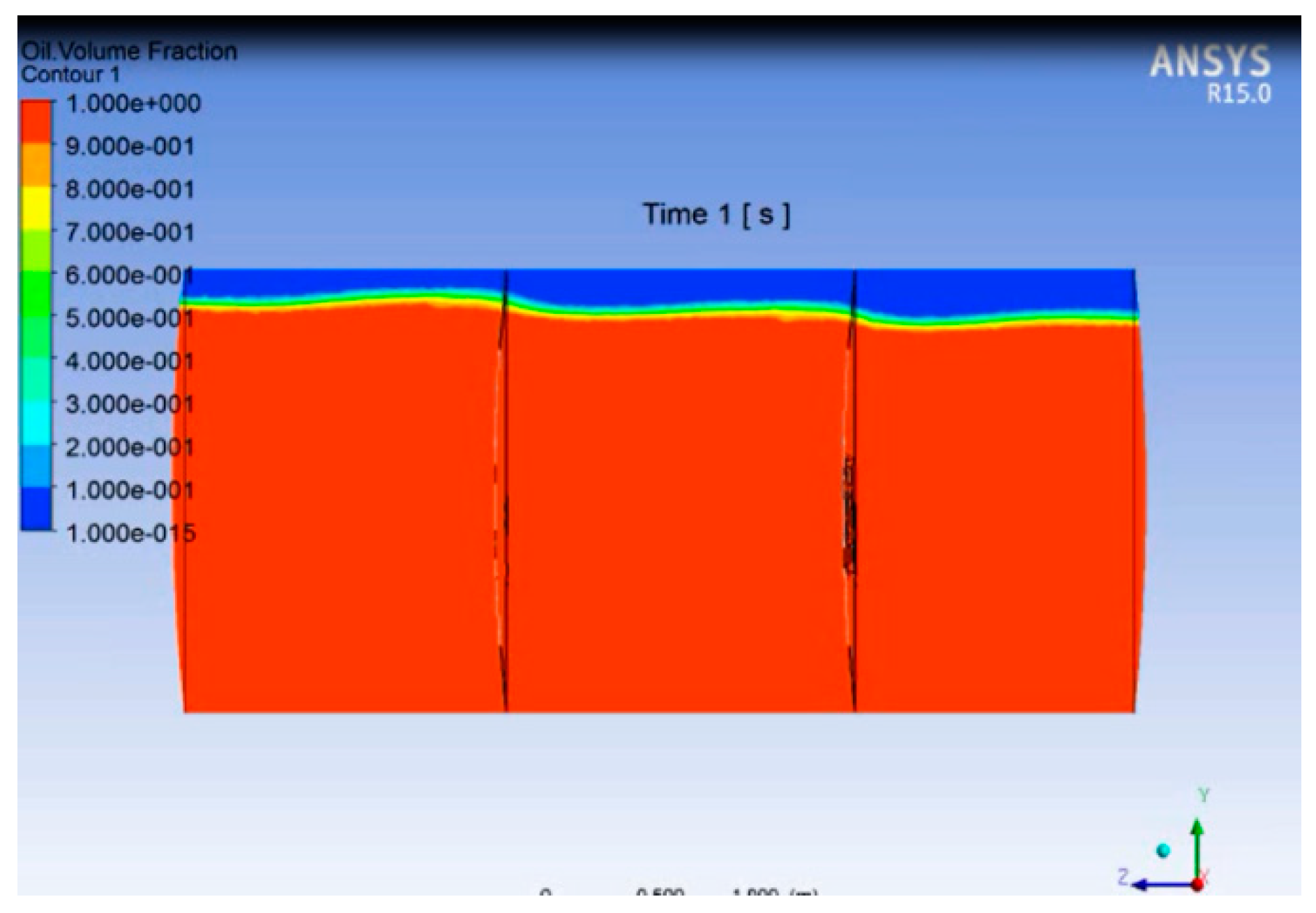

Figure 24. Similar to case 3, opening pressures were exceeded for the first 0.2 s at point 2 and point 3. However, the pressures reached in Case 4 were slightly higher than Case 3 due to the abnormal case. Also, an air pocket was found beneath the valve when the valve opened i.e., for the first 0.2 s (

Appendix A,

Figure A35). This confirms that the air/vapor mixture leaked out during that interval.

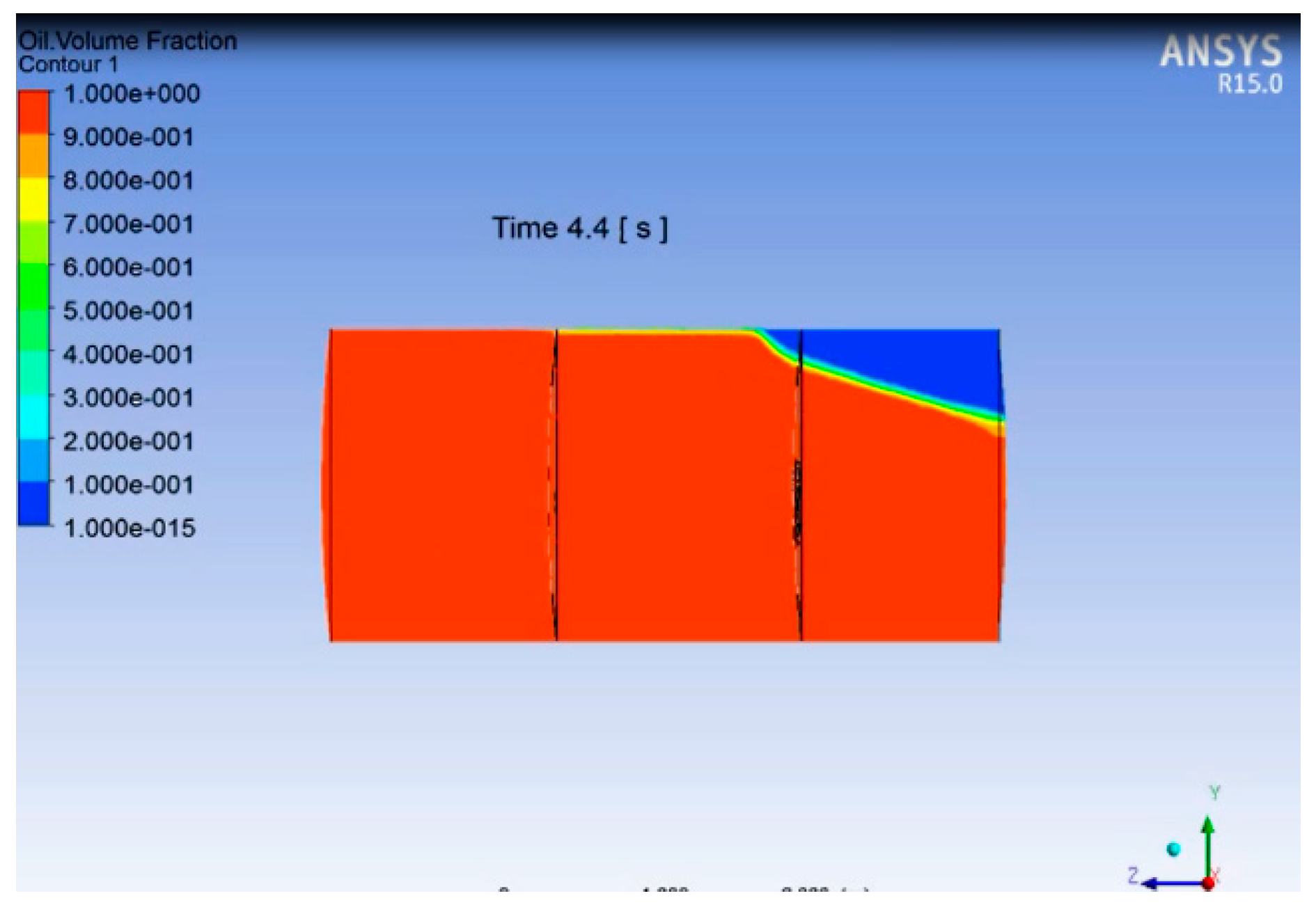

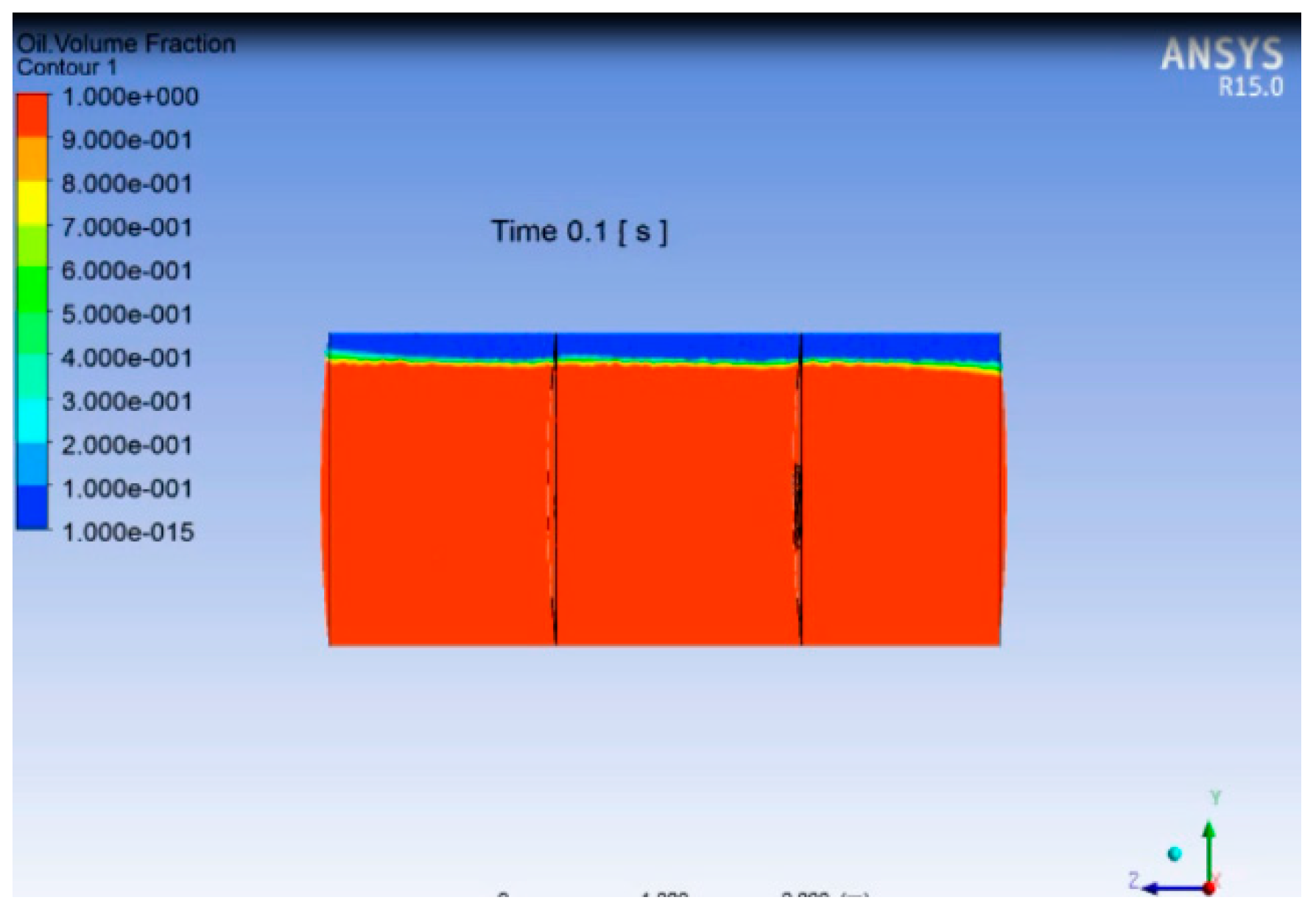

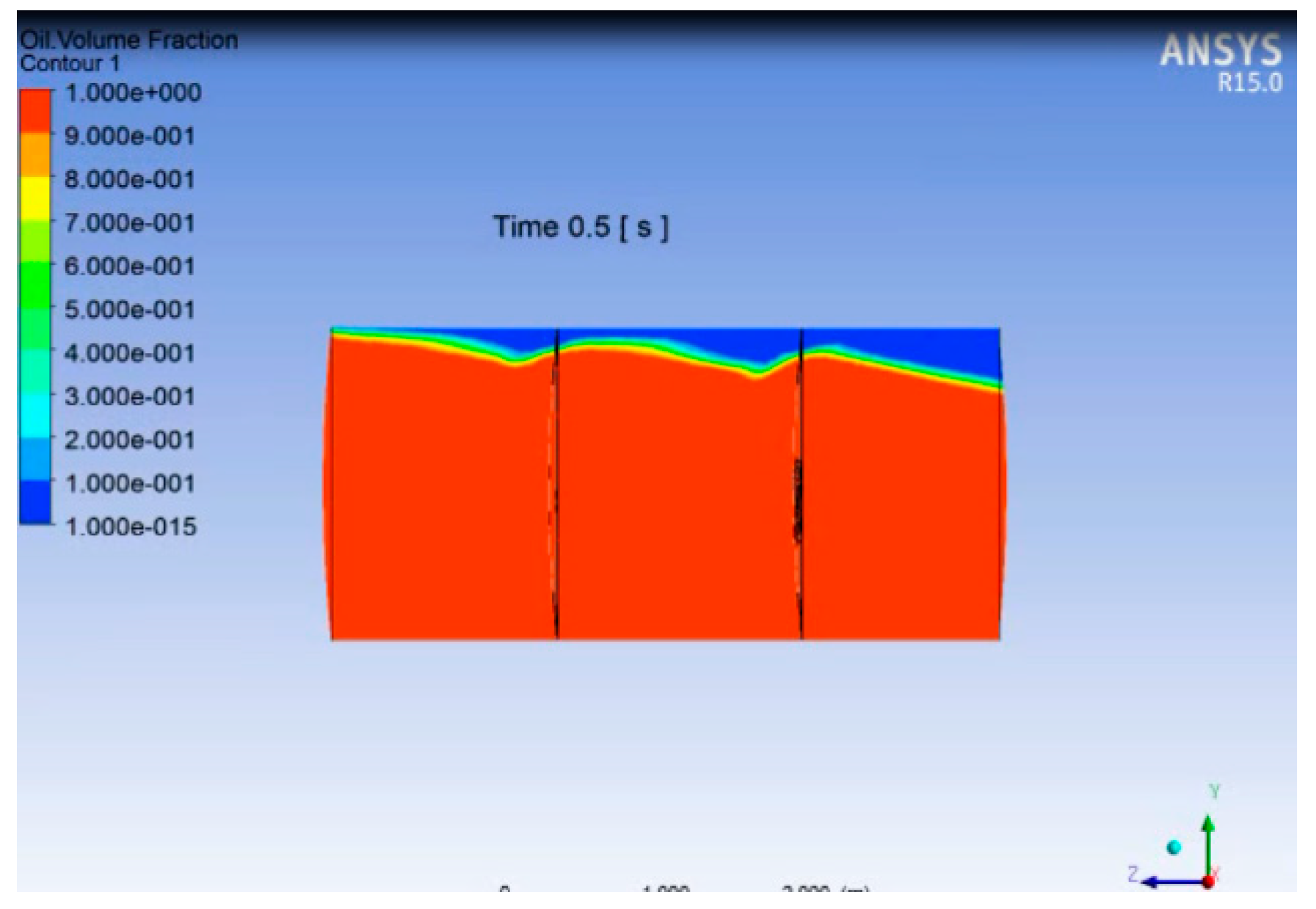

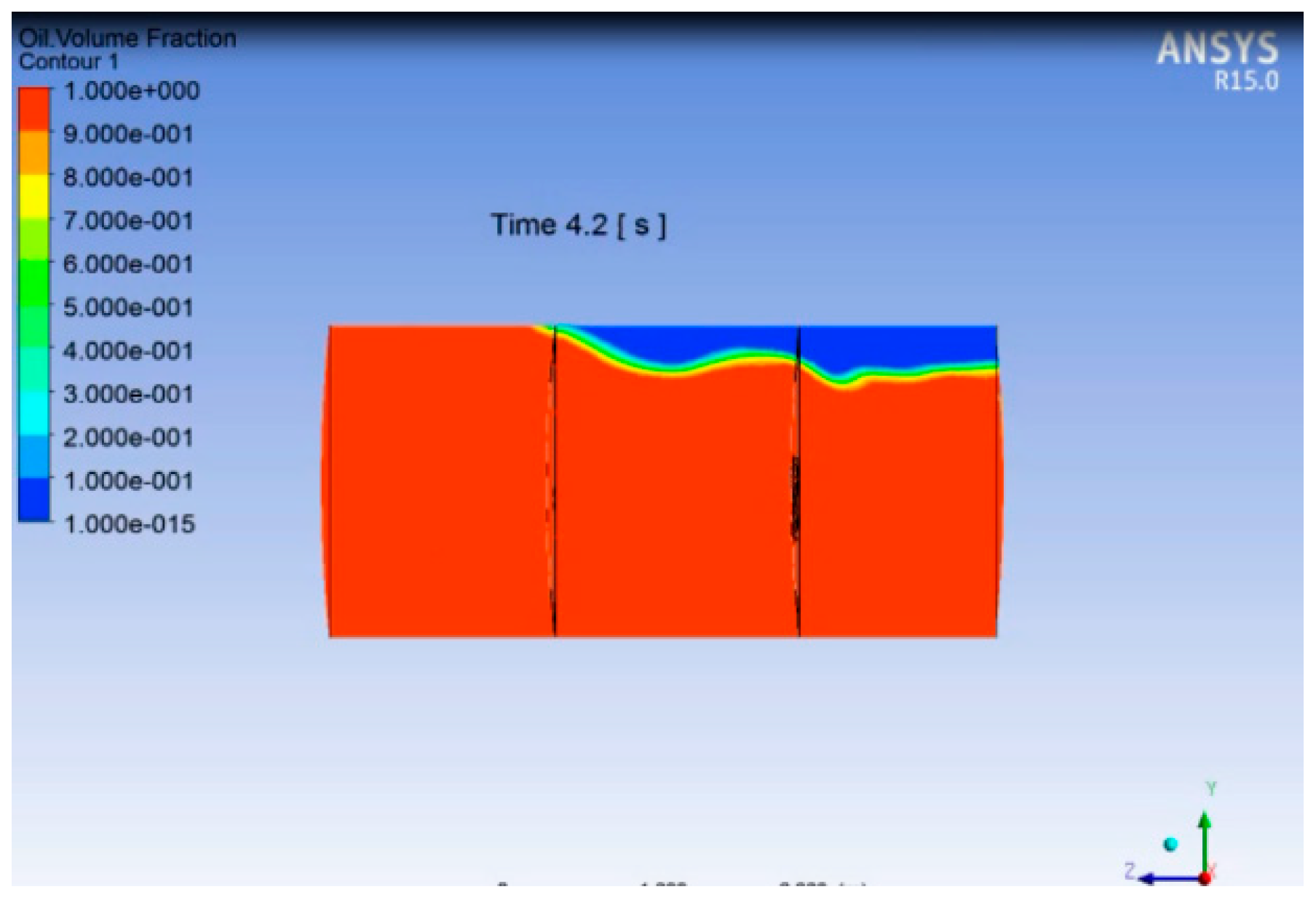

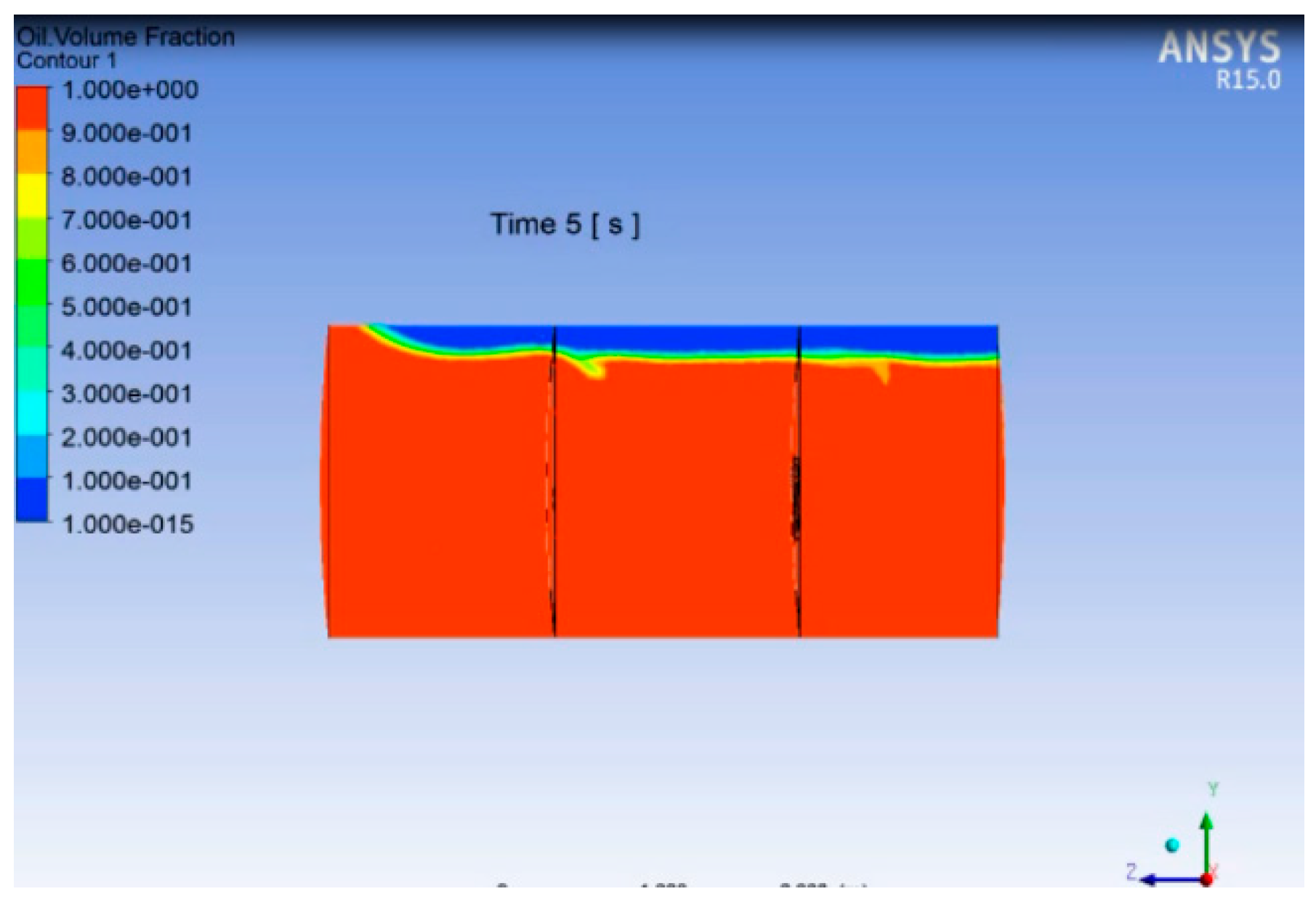

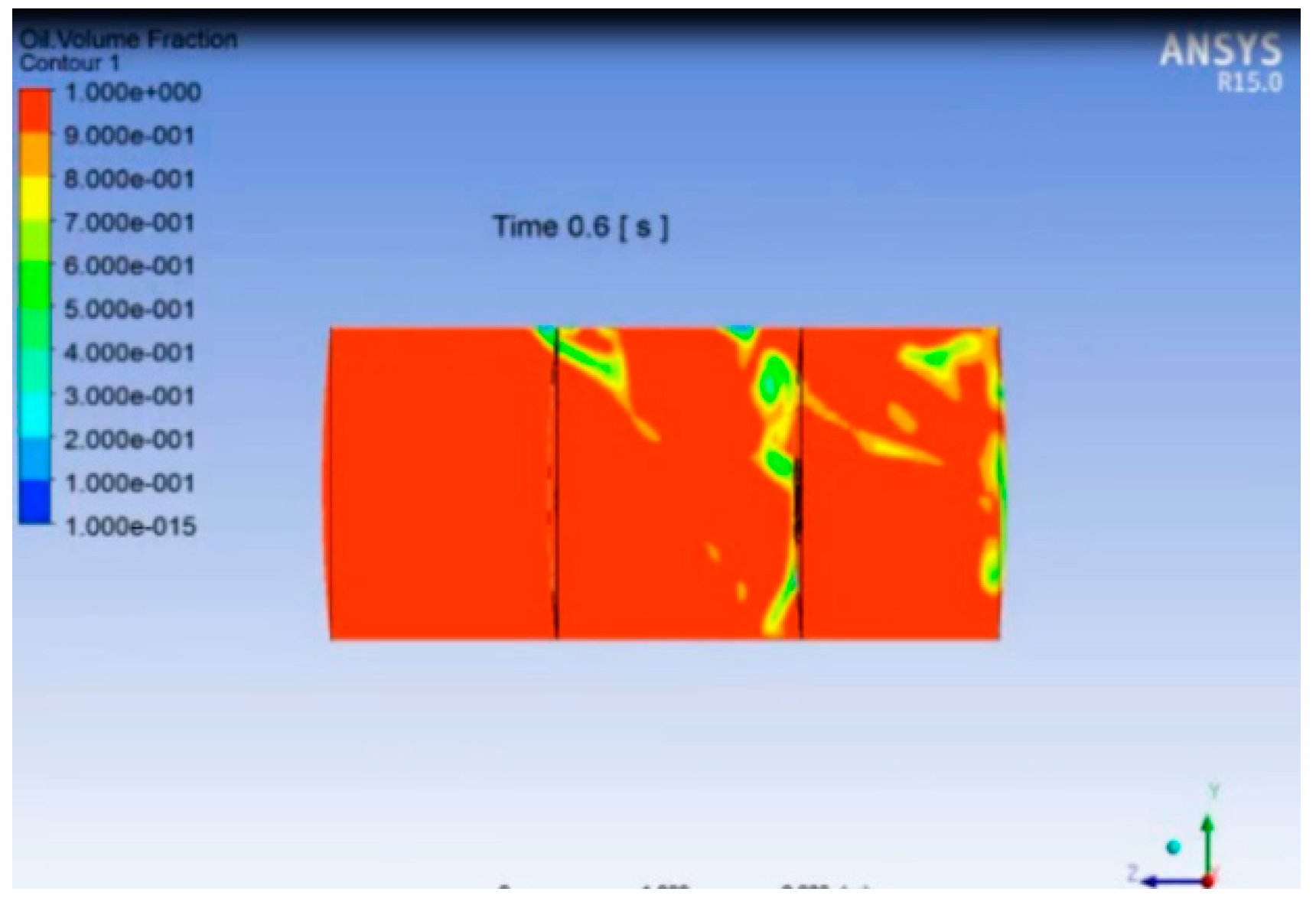

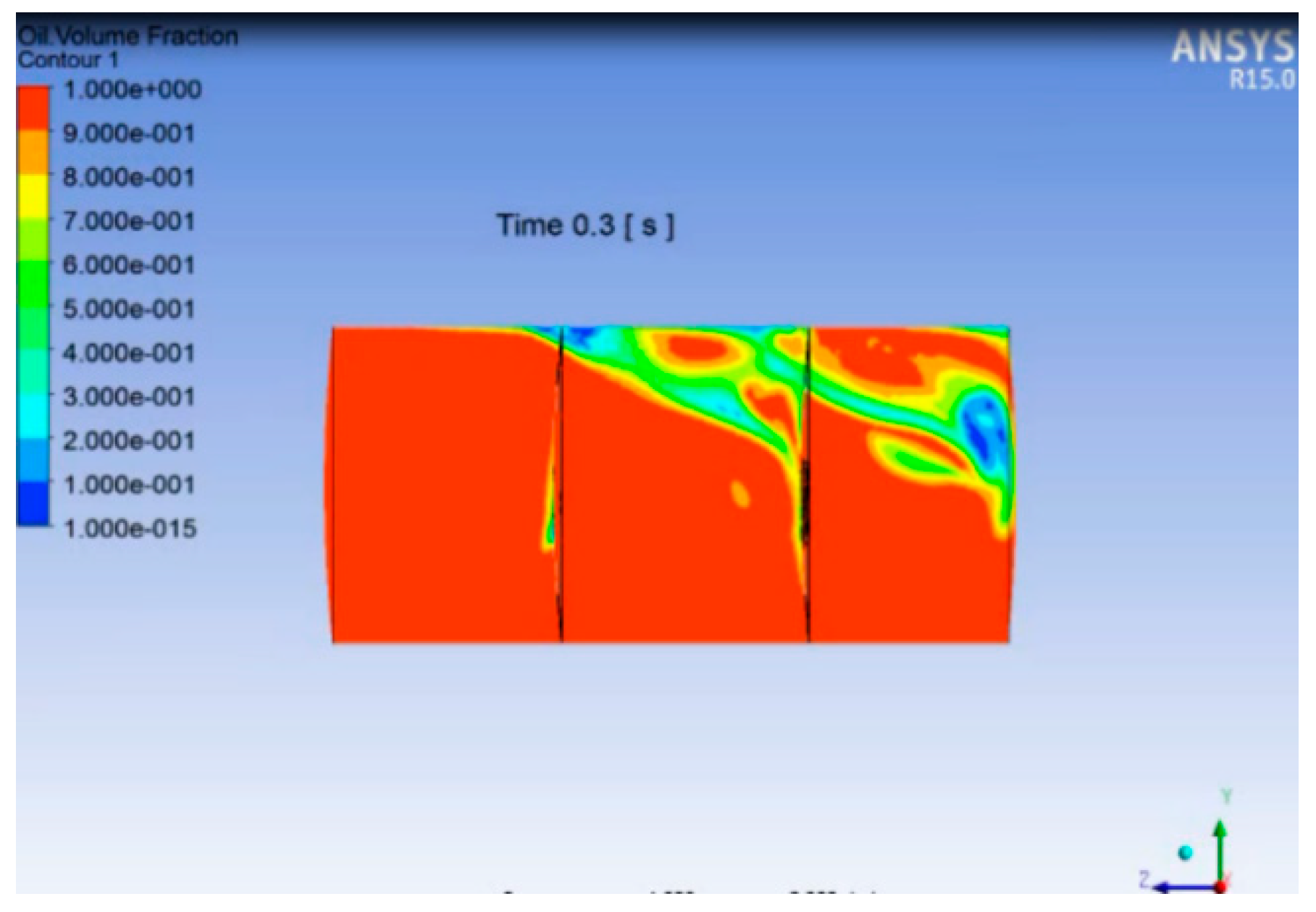

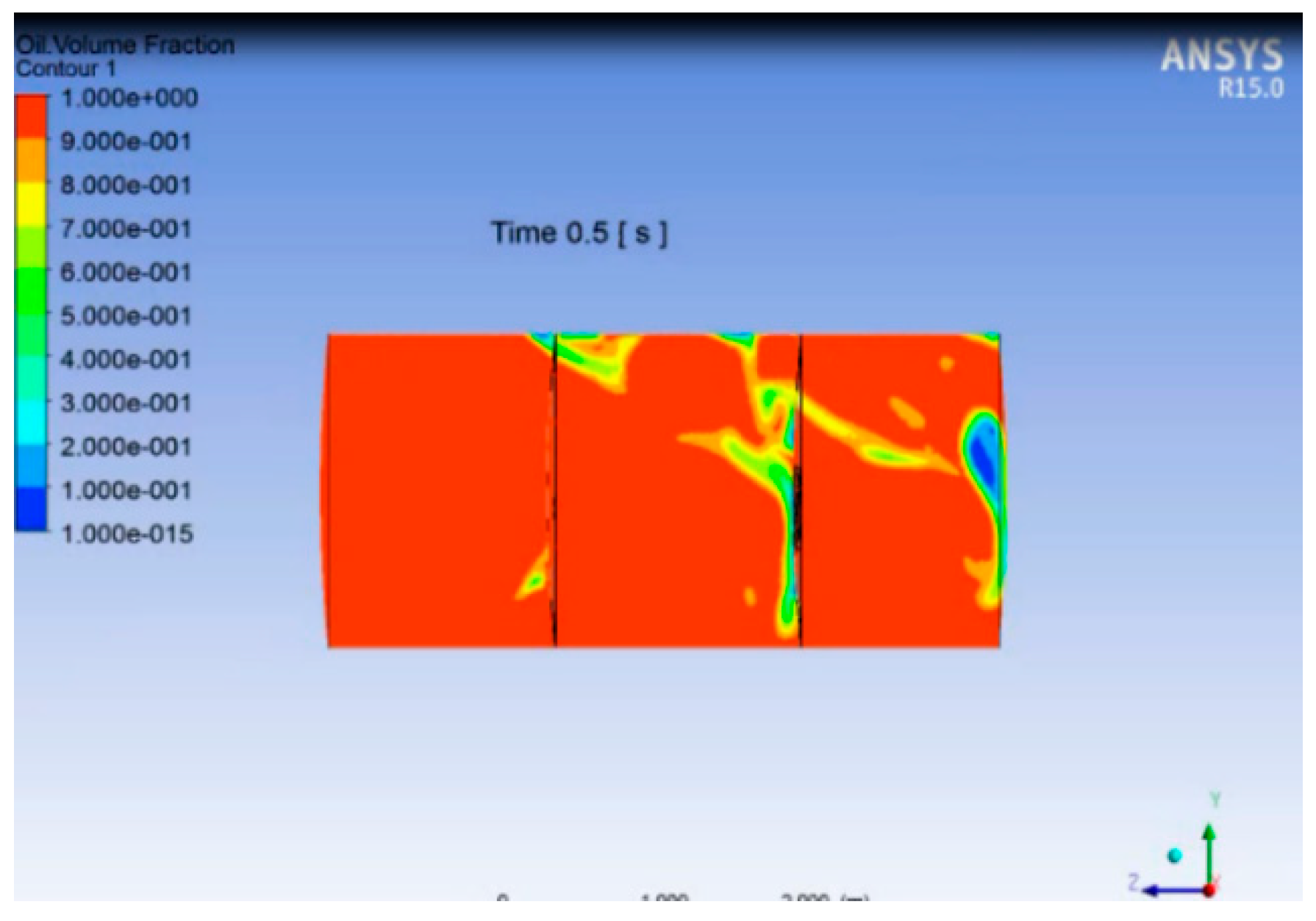

The slosh results showed that the valve of the last compartment did not open even in abnormal cases of acceleration and deceleration. However, the valve of the first and second compartments did open in both cases of deceleration. However, the duration in which the valve opened was less than 0.2 s. Screenshots from the simulation can be seen in

Appendix A.

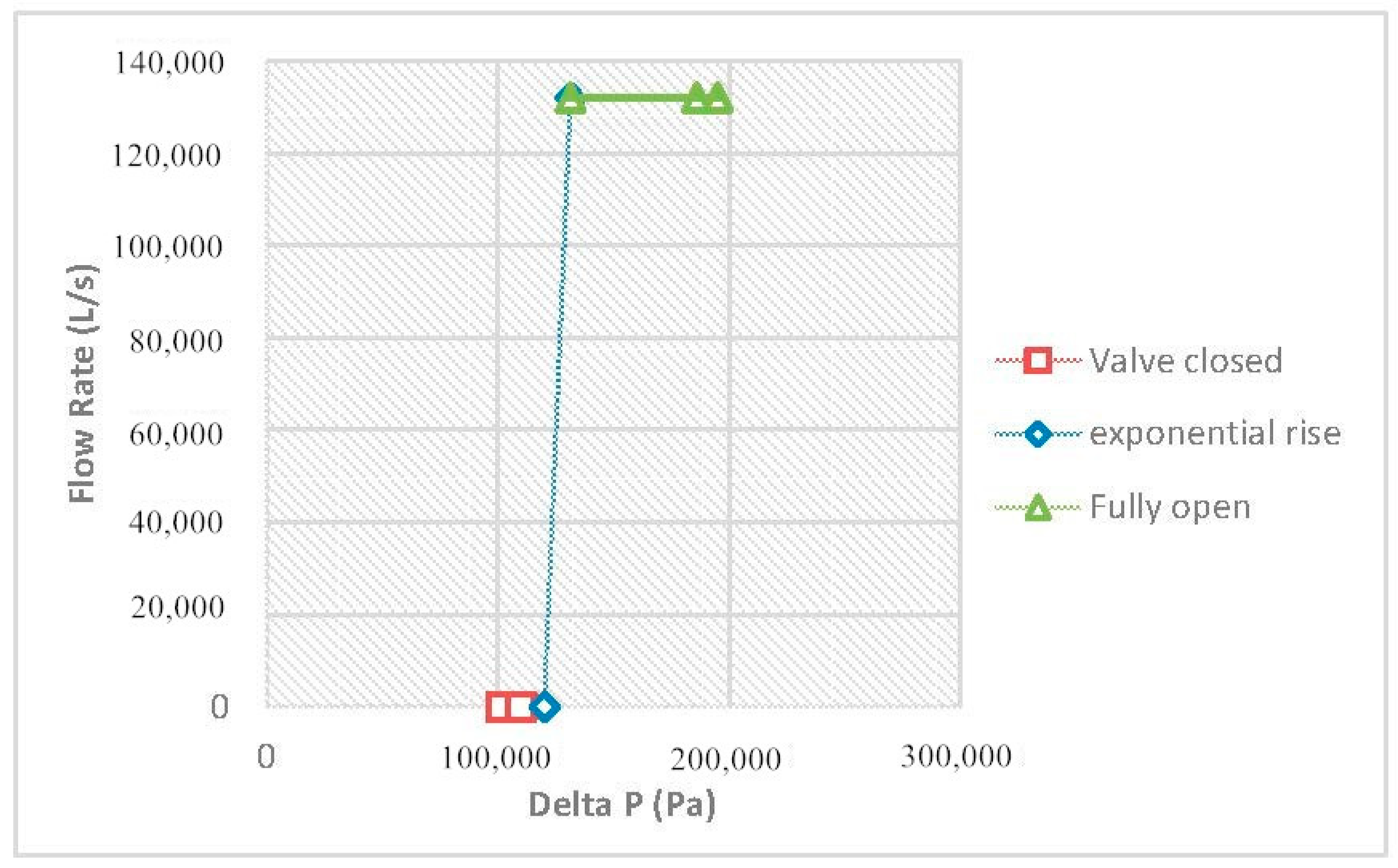

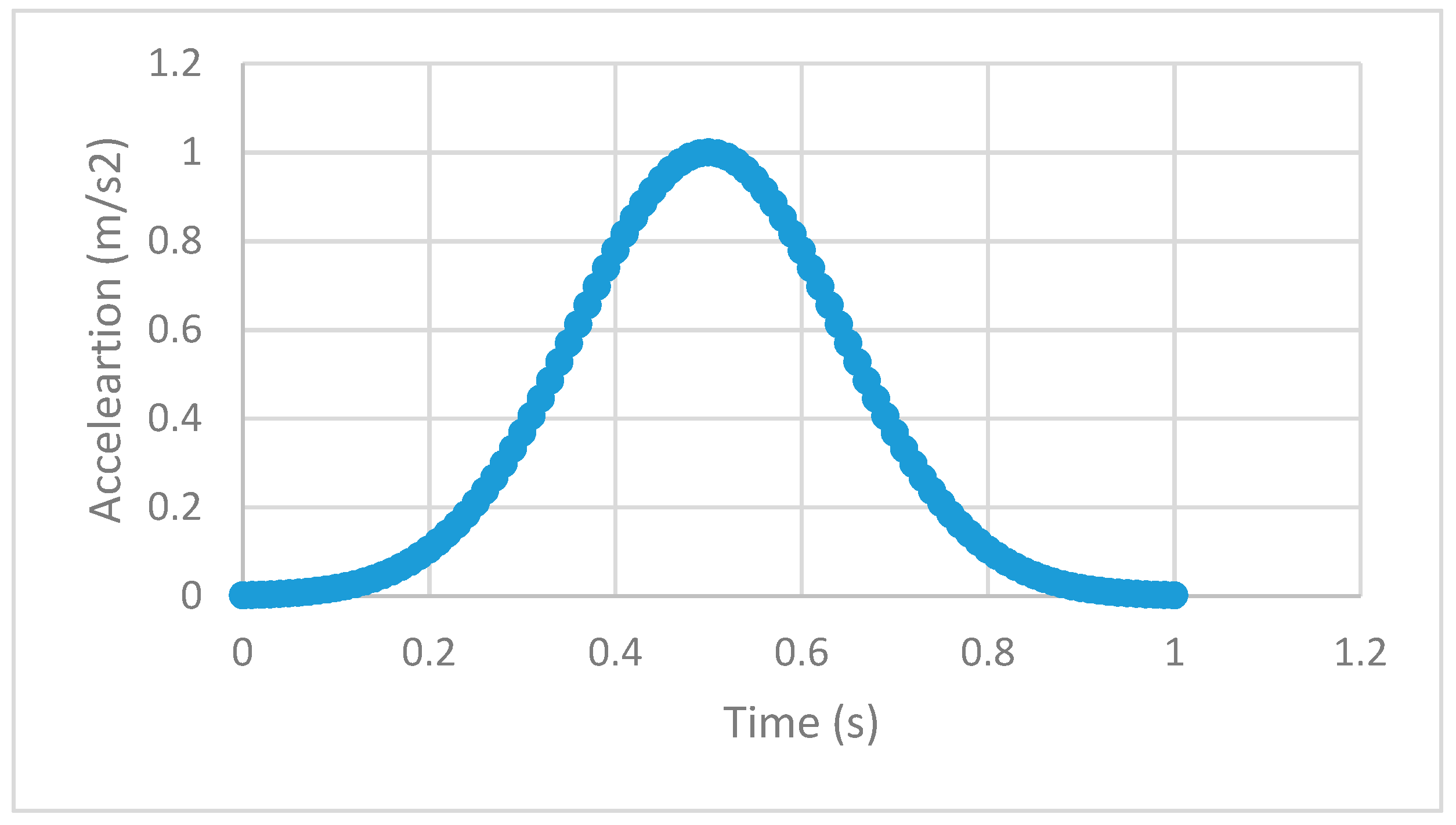

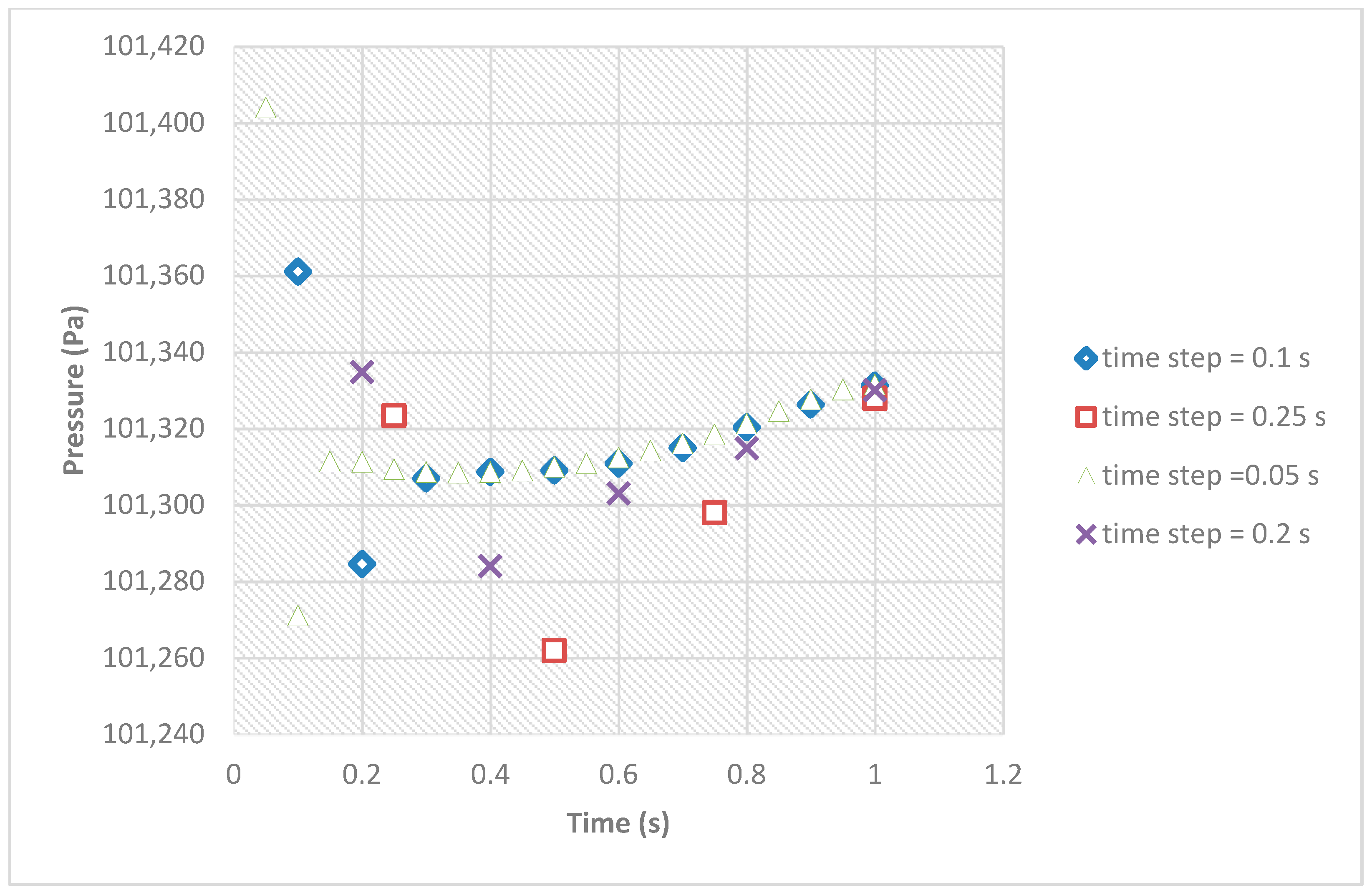

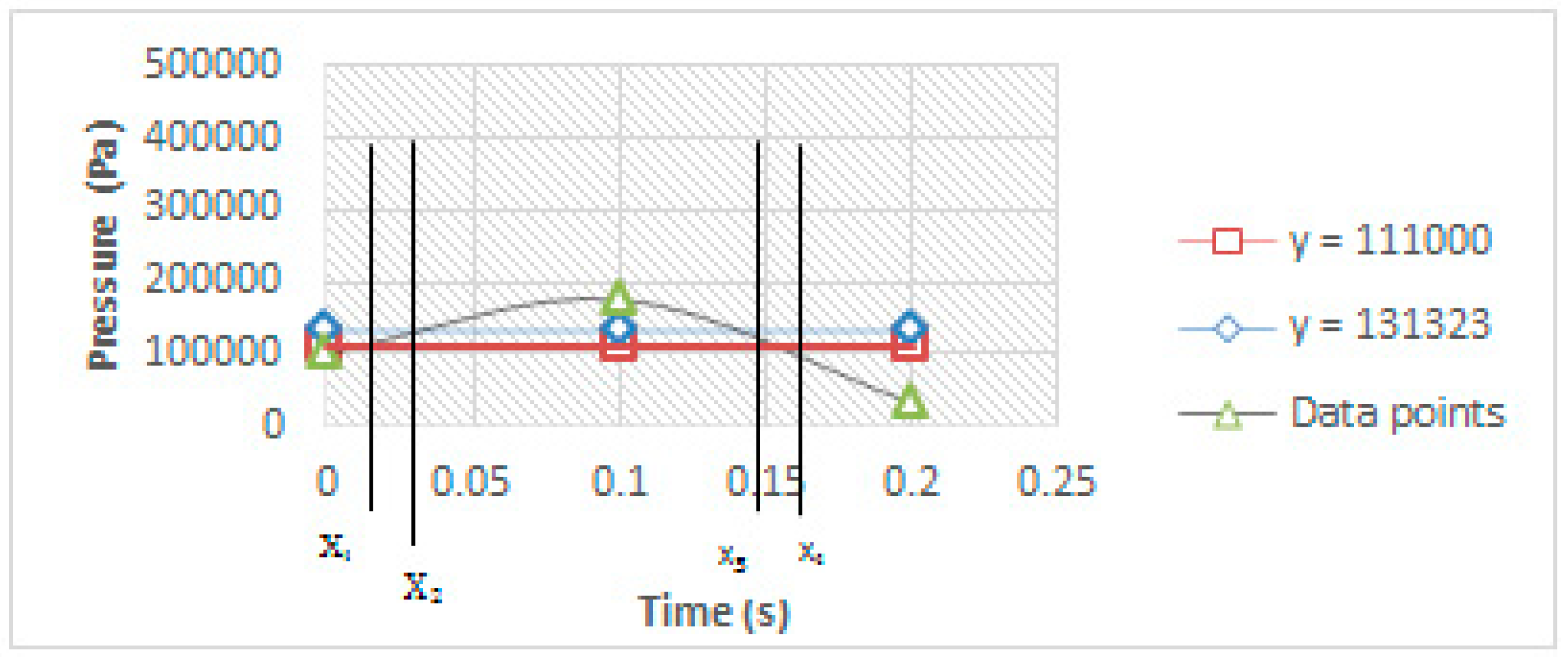

The pressure obtained from sloshing in the normal and abnormal cases of deceleration in compartment 1 and 2 exceeded the cracking pressure of the valve. At 0.1 s, the pressure was much higher than the cracking pressure. At 0.2 s, the pressure dropped down below atmospheric pressure. It rose to atmospheric pressure at 0.4 s and remained nearly at atmospheric pressure for the rest of the simulation time. Hence, to find the loss from the valve in the first 0.2 s, three data points were selected. One was atmospheric pressure at 0 s. The second and third were the pressures obtained from sloshing at 0.1 s and 0.2 s respectively. A curve fit was made to fit all three data points (

Figure 25). Two more lines were plotted:

Both these lines intersect the curve at two points. Hence, all four points were found using simultaneous equations. To do so, the quadratic equation was set equal to 111,000 and 131,323. x

1 and x

4 were obtained by finding the roots of the equation when the right-hand side of the equation was set equal to 111,000. Similarly, x

2 and x

3 were obtained by finding the roots of the equation when the right-hand side of the equation was set equal to 131,323. The quadratic equations and its roots for points 2 and 3 in the deceleration cases are summarized in

Table 8.

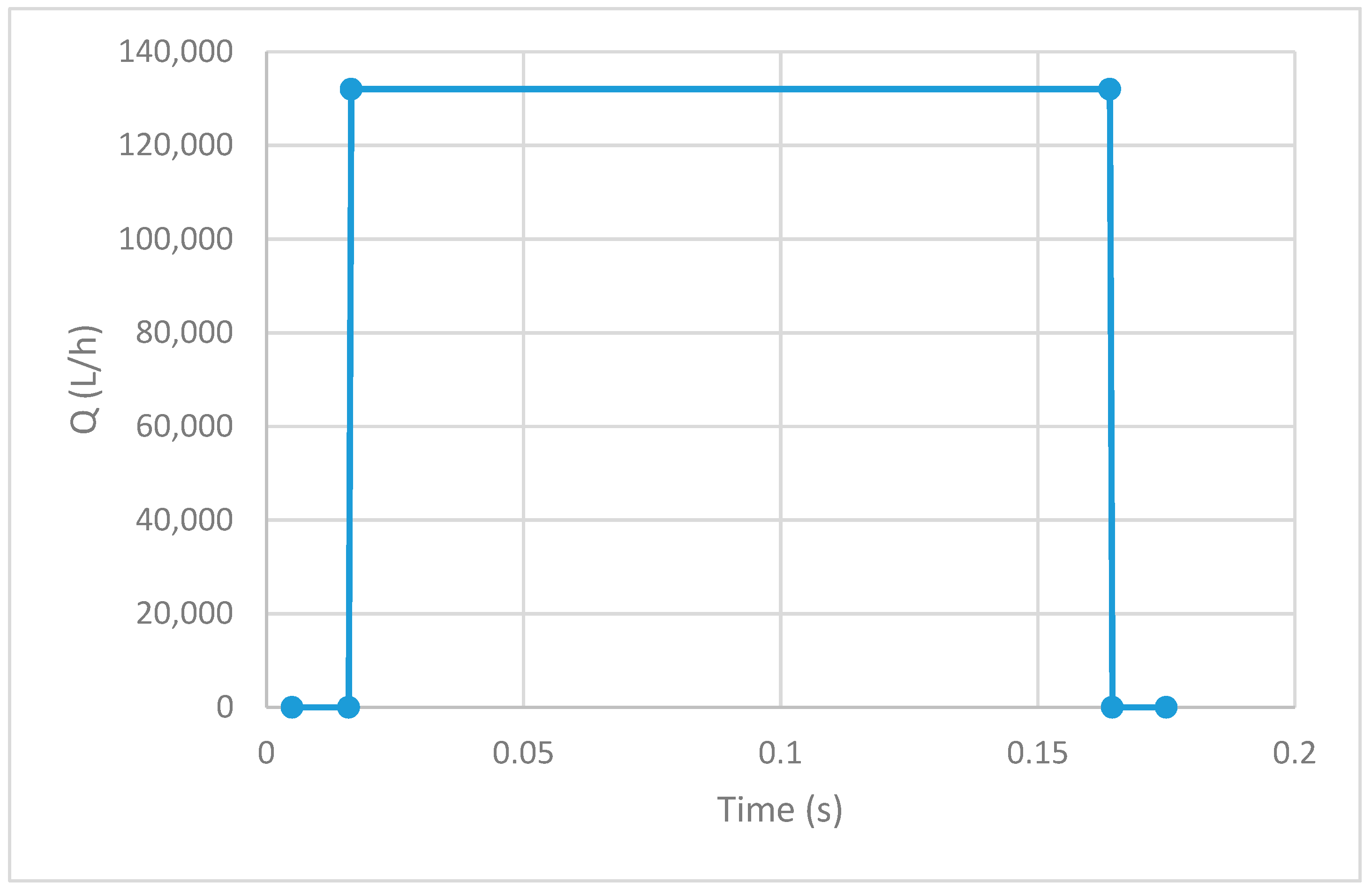

Figure 26 summarizes the flow rate in one case of deceleration between 0.1 s and 0.2 s. From x

1 to x

2, and from x

3 to x

4 the flow rate was found using the following equation of region 2:

This was because x1 intersected the curve at the point where the valve opened i.e., at 111,323 Pa. x2 intersected the curve at the point where the valve was fully open i.e. when the pressure reached 131,323 Pa. x3 intersected the curve at the point where the pressure came back to 131,323 Pa. x4 intersected the curve at the point where the pressure dropped back to 111,323 Pa.

From x2 to x3, the flow rate was found using the following value of the flow rate i.e., region 3:

As shown in

Figure 26, the loss from x

1 (0.0053 s) to x

2 (0.018 s) and from x

3 (0.152 s) to x

4 (0.165 s) was calculated using the equation of the flow rate of region 2. Additionally, from x

2 (0.018 s) to x

3 (0.152 s) was calculated using the equation of the flow rate of region 3.

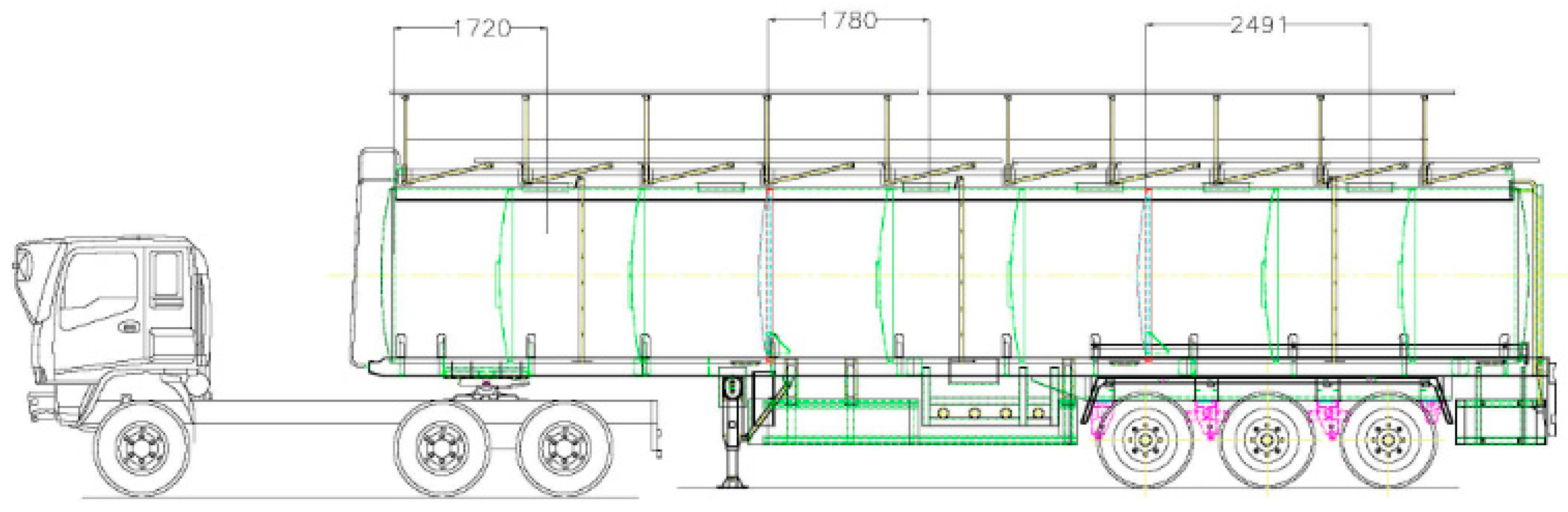

The loss obtained from all cases is summarized in

Table 9 below. A maximum of 0.009 L occurred in a normal case of deceleration per application of brakes from compartment 1 and a maximum of 0.0088 L occurred in a normal case of deceleration per application of brakes from compartment 2. Hence, if the tanker is assumed to brake 500 times over the whole trip, then, a loss of 9 L is obtained due to slosh.

A maximum of 0.01 L also occurred in the abnormal case of deceleration per application of brakes from compartment 1 and a maximum of 0.0096 L occurred in the abnormal case of deceleration per application of brakes from compartment 2. Hence, if the tanker is assumed to brake 500 times over the whole trip, then, a loss of 10 L is obtained due to slosh.

As shown in

Table 9, no loss was obtained from compartment 3 even in cases of deceleration because of the location of the P/V vent valve. The reason was that the valve was located farthest from the front of the compartment i.e., 2491 mm from the start of compartment 3.

The valves of the first and second compartments were placed at a distance of 1720 mm and 1780 mm respectively from the start of the compartment. Hence, moving the valve slightly along the longitudinal axis may change the loss results drastically.