Abstract

Siloxanes are among the most technologically troublesome trace compounds present in biogas. As a result of their combustion, hard-to-remove sediments are formed, blocking biogas energy processing devices and reducing the efficiency of biogas plants. The purpose of this study was to help investors and designers to choose the optimal technology for the adsorptive removal of volatile methylsiloxanes (VMSs) from biogas and to identify adsorbents worth further development. This paper critically reviews and discusses the state-of-the-art technologies for the adsorption removal of siloxanes from biogas, indicating potentially beneficial directions in their development and deficiencies in the state of knowledge. The origin of VMSs in biogas, their selected physicochemical properties, technological problems that they can cause and their typical versus limit concentrations in biogases are presented. Both the already implemented methods of adsorptive VMSs removal from landfill and sewage gases and the ones being under development are verified and systematized. The parameters and effectiveness of adsorption processes are discussed, and individual adsorbents are compared. Possible ways of regenerating spent adsorbents are evaluated and prospects for their application are assessed. Finally, zeolite-based adsorbents—which can also be used for biogas desulfurization—and adsorbents based on polymer resins, as being particularly active against VMSs and most amenable to multiple regeneration, are identified.

1. Introduction

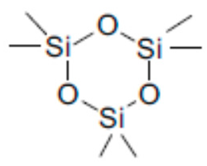

The most troublesome trace impurities present in biogas are volatile organic silicon compounds—siloxanes, which are oligomeric chemicals containing alternately connected silicon and oxygen atoms. Silicon atoms are additionally linked with hydrocarbon functional groups, mainly methyl (Table 1). In this case, considering their volatility under ambient conditions (Table 2), siloxanes are referred to as volatile methylsiloxanes (VMSs).

Table 1.

Nomenclature and formulas of main volatile methylsiloxanes (VMSs) detected in biogases.

Table 2.

Selected physicochemical properties of VMSs found in biogas, developed according to [1].

The main source of VMSs in biogas are personal care products, in which VMSs, owing to their unique characteristics such as: low surface tension, viscosity and chemical reactivity, high thermal stability, compressibility, spreadability and hydrophobicity (Table 2), have been rapidly increasingly used in recent years. Along with wastewater containing used cosmetics—especially shampoos, soaps, hair sprays, antiperspirants, etc.—VMSs end up in wastewater treatment plants (WWTPs), where, together with sediments, they get into the fermentation chambers and as a result of the elevated temperature are released into biogas. VMSs also get into the biogas in landfills, where cosmetics containers, together with their remains, are deposited. The growing presence of VMSs in the environment is also due to the rapidly growing production of silicone polymers—used in medicine, electronics and various everyday articles—for which VMSs are the basic building blocks.

As a result of biogas combustion, a part of the VMSs are transformed into crystalline silica which settles in the form of rough, hardly removable deposits in combustion chambers, heat exchangers, exhaust gas catalysts and on cylinder heads, valves, spark plugs, turbine blades, etc., reducing their performance and increasing servicing costs and air pollutants emissions. This is currently one of the main operational problems affecting biogas plants. The need for biogas purification from VMSs also arises from their potential toxic and carcinogenic properties found in animal studies in recent years. It has been shown that only a small fraction (<1%) of VMSs convert to SiO2 during biogas combustion [2]. The rest are emitted into the air, showing great potential for bioconcentration and bioaccumulation in the environment’s various compartments [3]. In addition, microcrystalline silica (<100 nm), which is the oxidation product of VMSs, has carcinogenic and mutagenic properties [4].

Adsorption, absorption and cooling methods have been commercially used to purify biogas from VMSs. However, owing to the uncomplicated service, high efficiency and moderate costs of such standard adsorbents as activated carbon and silica gel, carbon adsorption methods predominate.

The emerging methods (still under research), except for membrane and biological methods which are not promising so far, use unconventional adsorbents based on natural and synthetic zeolites and polymer resins.

2. VMSs Concentrations in Biogas

Most measurements of VMSs content in landfill gas (LFG) and in biogas from sewage sludge (SG) were carried out in Germany, with a much greater spread of results found in WWTPs (from zero to several hundred mg/m3) than in landfills (from several to several dozen mg/m3) [5]. For such a large data set (308 objects) the reported average total VMSs concentration of 14.9 mg/m3 in SG, seems representative. A higher average total VMSs content—24 mg/m3 (mainly D4—12.5 mg/m3, L2—6.1 mg/m3 and D5—4.7 mg/m3)—measured in LFG in Asten (Austria) was reported by Accettola and Haberbauer [6], while in SG the average concentration amounted to 7 mg/m3 (primarily D5—6.0 mg/m3 and D4—0.9 mg/m3). Even higher values for SG were indicated by Appels et al. [7]—30–50 mg/m3. Arnold & Kajolinna [8] showed that the concentration of VMSs in biogas usually does not exceed 10 mg/m3, although in the case of SG, peaks of up to 300–400 mg/m3 are possible. For example, 400 mg/m3 was recorded in the Trecatti WWTP in Great Britain, when the engine failed after 200 hours of operation [9]. In other tested WWTPs (Zurich, Neuburg, Saint-Truiden, Minworth) the total VMSs concentration ranged from 16 to 59.8 mg/m3, while in landfills in Berlin, Augsburg and Vienna it ranged from 4.8 to 36.3 mg/m3. A similar maximum VMSs concentration in SG as in Trecatti (314 mg/m3) was detected by Hepburn et al. [10]. A wide overview of VMSs concentration measurement results at Austrian, German and Finnish landfills and WWTPs was presented by Rasi et al. [11,12]. According to their research, in Finland the concentrations were in the range of 0.08–2.5 mg/m3 for both types of biogas, i.e., significantly below the values presented above. D5 predominated in SG (48–76%), constituting together with D4 (21–45%) over 90% of the total VMSs. The remaining 10% were: L2 (0–1%), D3 (1–4%) and L3 (0–6%). In LFG the VMS percentages were as follows: D4 (24–72%), L2 (28–40%), D5 (3–13%) and D3 (0–7%), i.e., VMSs characterized by higher vapor pressure and better water solubility predominated. Generally, VMSs concentrations in biogas depend on its origin and they range widely—typically from a few to several tens mg/m3. In LFG, where D4 and L2 predominate, they are usually lower than in SG (Table 3).

Table 3.

VMSs concentration ranges detected in biogas.

In order to minimize the hazards associated with the use of biogas energy, biogas power generation equipment manufacturers impose VMS level standards (Table 4).

Table 4.

VMSs concentration limits in biogas, recommended by some device manufacturers.

In many cases it is necessary to remove VMSs from biogas to prevent equipment blockage and meet the manufacturer's warranty requirements.

3. Adsorption of VMSs Using Activated Carbon

Activated carbon is formed in the processes of carbonization and thermal or chemical-thermal activation of such organic raw materials as fossil coals, wood and various types of organic waste. During these processes the organic matter is partially decomposed, and volatiles are removed, whereby the activated carbon acquires a proper porous structure. Carbonization is conducted at a temperature of 600–800 °C. Then the carbonizate is subjected to physical activation, i.e., further thermal treatment with steam or CO2 (400–500 °C) to eliminate the remaining volatiles, or to partial gasification at a temperature of 800–1000 °C. The alternative is chemical activation, i.e., roasting (500–900 °C) with the addition of zinc chloride, potassium sulfide, phosphoric acid or other chemicals [24]. All these processes lead to the formation of an extremely extensive internal structure consisting of a wide spectrum of micropores and mesopores. As a result, a universal adsorbent with the largest specific surface area—which can exceed 2000 m2/g—among all the known adsorbents is produced. Small activated carbon rolls with a diameter of about 1–2 mm and a length of up to 4 mm are most often used in gas cleaning processes. Activated carbon fibers are used less often, but they can be more effective in removing D4 than granular activated carbon [25,26]. The feature that particularly predisposes activated carbon to VMSs removal from biogas is its non-polar structure [27] promoting the adsorption of non-polar or weakly polar VMSs. Larger pore volumes, more suitable for the size of VMSs molecules, are obtained using chemical activation with H3PO4 [28]. Generally, many researchers indicate that adsorbent pores with a diameter of 1.7–6.0 nm are most suitable for the adsorption of VMSs whose molecule diameter is about 1 nm.

Depending on the method of activation (and/or impregnation), activated carbon can have an acidic or basic character. According to Gong et al. [29], activated carbon activity towards VMSs increases with the increasing pH of the bed. However, alkaline impregnation, which can be used for H2S removal, can reduce the adsorbent's active surface area and pore volume, which, in turn, can reduce its capacity to absorb VMSs [30].

The large diversity of activated carbon’s pores in comparison with other adsorbents is, unfortunately, also its disadvantage, being the main cause of its low selectivity. Besides the sulfur and chlorine compounds mentioned above, activated carbon has a high affinity for other VOCs, water steam and hydrocarbons—CH4 adsorption on activated carbon is greater than on silica gel and molecular sieve [24]. The presence of the above compounds in biogas, competing for a place in activated carbon’s micro- and mesopores, reduces its capacity to adsorb VMSs and directly affects the operating costs.

Activated carbon shows greater activity towards cyclic VMSs, which is connected with the changes they undergo on its surface and the displacement of the previously adsorbed lighter linear VMSs—e.g., L2 and L3—by heavier and less volatile cyclic VMSs—e.g., D4 and D5—or by other high-molecular aromatic VOCs and water vapor [31]. A way to reduce the above disadvantages is biogas pretreatment, consisting in condensation drying—usually up to RH (relative humidity) < 50%—during which interfering impurities and some VMSs are partly removed with the condensate.

A more serious disadvantage of activated carbon in the removal of VMSs is their transformation, consisting in the polymerization of cyclic VMSs into less volatile, heavier and hardly desorbable polydimethylsiloxanes [32] which block the adsorbent’s pores and prevent its effective thermal regeneration. This process is more intense on wood-based carbons activated with phosphoric acid than with water steam [33]. Chemical regeneration through the oxidation of the adsorbed VMSs (with O3, H2O2 or iron salts) also fails because the final reaction product is SiO2 which blocks pores [33,34].

4. Adsorption of VMSs Using Silica Gel

Silica gel is obtained by polymerizing silicic acid with H2SO4 or HCl to an amorphous gel having the molecular formula (SiO2)∙nH2O. This adsorbent is typically used in the form of beads with a diameter of 1–5 mm. It is characterized by high porosity and a polar structure. The latter feature endows silica gel with a special affinity for water, making it one of the most effective desiccants. Therefore, deep drying—below 10% RH—is required in order to effectively remove VMSs from biogas [14]. In comparison with activated carbon, silica gel is characterized by a smaller specific surface area (350–700 m2/g) and larger pore sizes, with the predominance of mesopores, which is beneficial for VMSs adsorption. Most researchers—e.g., [18,35,36]—indicate silica gel’s higher selectivity and affinity for VMSs (provided that the biogas is properly dried), especially in the case of lighter chain forms, such as L2. Since silica gel has a lower capacity to adsorb sulfur compounds, it can be more useful for the purification of LFG which usually contains less H2S. Most researchers also indicate that silica gel is more amenable to regeneration [14]. According to Yang [24], since silica gel’s adsorption forces are weaker, it should be easier to thermally regenerate than activated carbon.

In recent years, besides the use of conventional silica gel, attempts have been made to modify silica gel in order to improve its adsorption capacity and regenerability. By treating silica gel with acetic anhydride Liu et al. [37] obtained an interesting hydrophobic silica gel modification whose adsorption capacity, regardless of biogas humidity, amounted to 304 g/kg for L2 and to 916 g/kg for D4—much more than in the case of activated carbons. Its regeneration was trouble-free at a relatively low temperature of 110 °C.

5. Adsorption of VMSs Using Zeolites

Natural zeolites comprise hydrated alkali metal aluminosilicate minerals with a crystalline structure, such as modernite, chabasite, clinoptilolite, silicalite and others. Their activation is based on thermal treatment, as a result of which they lose water and acquire an ordered internal structure with uniform pore sizes (hence the name “molecular sieves”), whereby, as opposed to active carbons, they become selective adsorbents. Zeolites are also made synthetically—e.g., 3A, 4A, 5A, 10X, 13X, ZSM-5. Depending on the ratio of silicon to aluminum atoms, they can be hydrophobic (Si/Al>10) or hydrophilic (Si/Al < 1.5). Hydrophobic zeolites are more useful for removing nonpolar and weakly polar compounds, including VMSs. For example, zeolite such as ZSM-5 with a high Si/Al ratio (200) [38] can be used simultaneously for CO2 and H2O removal in the biogas upgrading process and for the removal of VMSs and H2S.

Zeolites are also characterized by high mechanical and thermal resistance (up to 600 °C). In comparison with activated carbon and silica gel, they have a comparable or slightly smaller specific surface area (370–910 m2/g). Owing to the uniform size of their pores they can work more efficiently if they are selected with regard to the composition of the particular biogas. Unlike silica gel, they can simultaneously remove H2S—thanks to their alkaline nature—and their affinity for CH4 is several times lower than for activated carbon [24].

The usefulness of zeolites for removing VMSs from biogas has been confirmed by numerous studies, e.g., [31,39,40]. Owing to their high thermal resistance they are also suitable for repeated thermal regeneration [25].

6. Adsorption of VMSs Using Activated Alumina

As recent research has shown one of the effective VMSs adsorbents is activated alumina [41,42], which is obtained by calcining hydrated aluminum hydroxide in the presence of oxygen at a temperature of about 400 °C. The resulting porous, crystalline structure is characterized by a distinct predominance of mesopores (3–7 nm) and a specific surface area of 200–250 m2/g. Further roasting (up to 800 °C) leads to an amorphous form with a larger specific surface area amounting to 300–400 m2/g.

The synthetic adsorbent based on alumina (Al120-8h) developed by Zhong et al. [41], due to its larger specific surface area and porosity, proved to be a better D4 adsorbent than the commercial activated alumina. Its advantage is the possibility of effective regeneration with no apparent VMSs polymerization effect. It should be noted, however, that due to its relatively large pores, activated alumina is better suited for cyclic VMSs.

7. Adsorption of VMSs Using Polymer Resins

Polymer adsorbents are obtained by polymerizing monomers, i.e., styrene cross-linked with divinylbenzene (DVB) and acrylates, in the presence of an organic solvent. Popular DVB-based resins include XAD-2 and XAD-4 hydrophobic polymers, whereas the ones based on acrylic ester (e.g., XAD-7) are hydrophilic [24]. Especially the former—as opposed to activated carbons and silica gel—are well suited for the purification of moist biogas, the more so because they are non-polar. Unfortunately, their thermal strength is low (<200 °C), which can potentially hinder the thermal desorption of some VMSs—see boiling point in Table 2. Owing to their dense cross-linking they are relatively stiff and mechanically strong. This also contributes to their high porosity and specific surface area (up to 1000 m2/g). In addition to the traditional polymer adsorbents mentioned above, in recent years new resins for VMSs adsorption have been synthesized. A particularly interesting series of adsorbents (PDVB-VI) based on the copolymerization of divinylbenzene with 1-vinylimidazole have been developed by Jafari et al. [43]. These adsorbents have an extremely large pore volume and specific surface area, whereby their adsorption capacity for VMSs is very high—in the order of 2000 g/kg. In addition, they can be effectively regenerated at a relatively low temperature (~100 °C), which indicates no polymerization of VMSs on their surface. The ease of regeneration of polymer adsorbents has also been confirmed by other authors [44,45]. Despite such advantageous characteristics, these adsorbents are not commercially used for gas purification due to their high price.

8. Comparison of the Adsorbents for VMSs Removal from Biogas

A comparative analysis of selected adsorbents, their effectiveness and advantageous/disadvantageous characteristics is presented in Table 5.

Table 5.

Summary review of the adsorbents for removing VMSs from biogas.

9. Conclusions

In general, owing to its simplicity, ease of use, low cost and availability and the possibility of simultaneously removing other undesirable biogas components, adsorption on activated carbon is most commonly used to remove VMSs from biogas. Considering the regeneration difficulties, its use seems to be justified in the case of low VMSs concentrations (<1 mg/m3) or when an economic analysis—covering the periodic replacement of the spent adsorbent and waste management—shows the simultaneous removal of hydrogen sulfide in the same apparatus to be cost-effective. The use of adsorption on activated carbon as the final biogas cleaning stage can be considered after the prior drying and removal of some VMSs, e.g., by absorption using SelexolTM [46] or oils. The main disadvantage of activated carbon in the considered application is the promotion of VMSs polymerization on its active surface, which quickly deactivates the adsorbent and practically prevents its regeneration. Moreover, the non-selectivity of activated carbon, due to the high diversity of its pores, results in quick bed saturation. Together with siloxanes other volatile compounds, including halides, hydrogen sulfide, ammonia, water vapor and even a small amount of methane, are adsorbed. All this entails additional expenditures on biogas pretreatment (drying, dedusting, the possible removal of competing impurities, and cooling) and frequent bed replacements. Another significant disadvantage of removing VMSs by means of activated carbon is the displacement of the previously adsorbed lighter and more volatile VMSs, e.g., L2, by heavier cyclic VMSs or by other VOCs. This can result in a sudden breakthrough of the bed. Although this technology is widespread, the effects of different ways of activating and impregnating activated carbons and of biogas composition and parameters on the efficiency of VMSs adsorption are still poorly understood. It is also unclear what conditions favor the polymerization of VMSs. Further research, especially on developing new methods, e.g., chemical methods (oxidation), of regenerating spent carbon and possible ways of its environmentally safe utilization, is needed. In the latter respect, chemically and biologically inert silica gels and zeolites, exhibiting similar VMSs adsorption properties as activated carbons, seem safer. Moreover, they are mechanically and thermally stronger and more easily regenerable, while their price is similar. Since in the case of silica gel it is necessary to deep dry biogas, zeolites seem to have greater potential as they can also be used for biogas desulphurization. They also show less affinity for methane. On the other hand, adsorbents based on alumina and polymer resins are most amenable to regeneration. According to the latest research results, polymer resins are particularly promising as they have the greatest potential for adsorbing VMSs and can be easily regenerated at relatively low temperatures.

Funding

This research received no external funding.

Conflicts of Interest

The author declares no conflict of interest.

References

- ChemSpider—Chemical Database. Royal Society of Chemistry, UK, Cambridge. Available online: http://www.chemspider.com/ (accessed on 15 December 2019).

- Tower, P. New technology for removal of siloxanes in digester gas results in lower maintenance costs and air quality benefits in power generation equipment. In Proceedings of the WEFTEC, 03–78th Annual Technical Exhibition and Conference, Los Angeles, CA, USA, 11–15 October 2003; pp. 2–8. [Google Scholar]

- Gaj, K. Properties, toxicity and transformations of VMSs in the environment. In Volatile Methylsiloxanes in the Environment; Homem, V., Ratola, N., Eds.; Book Series: The Handbook of Environmental Chemistry; Springer Nature Switzerland AG: Basel, Switzerland, 2018. [Google Scholar] [CrossRef]

- BSI. Nanotechnologies—Part 2: Guide to Safe Handling and Disposal of Manufactured Nanomaterials, PD 6699-2-2007; British Standards Institution: London, UK, 2007. [Google Scholar]

- Arnold, M. Reduction and monitoring of biogas trace compounds. In VTT Tiedotteita—RN 2496; VTT: Esbo, Finland, 2009. [Google Scholar]

- Accettola, F.; Haberbauer, M. Control of siloxanes. In Biofuels for Fuel Cells, Renewable Energy from Biomass Fermentation; Lens, P., Westermann, P., Habebauer, M., Moreno, A., Eds.; IWA Publishing: London, UK, 2005; pp. 445–454. [Google Scholar]

- Appels, L.; Baeyens, J.; Degreve, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Arnold, M.; Kajolinna, T. Development of on-line measurement techniques for siloxanes and other trace compounds in biogas. Waste Manag. 2010, 30, 1011–1017. [Google Scholar] [CrossRef]

- Dewil, R.; Appels, L.; Baeyens, J. Energy use of biogas hampered by the presence of siloxanes. Energy Convers. Manag. 2006, 47, 1711–1722. [Google Scholar] [CrossRef]

- Hepburn, C.; Martin, B.; Simms, N.; McAdam, E. Characterization of full-scale carbon contactors for siloxane removal from biogas using online Fourier transform infrared spectroscopy. Environ. Technol. 2014, 36, 178–187. [Google Scholar] [CrossRef]

- Rasi, S.; Lehtinen, J.; Rintala, J. Determination of organic silicon compounds in biogas from wastewater treatments plants, landfills, and co-digestion plants. Renew. Energy 2010, 35, 2666–2673. [Google Scholar] [CrossRef]

- Rasi, S.; Läntelä, J.; Rintala, J. Trace compounds affecting biogas energy utilisation—A review. Energy Convers. Manag. 2011, 52, 3369–3375. [Google Scholar] [CrossRef]

- Piechota, G.; Hagmann, M.; Buczkowski, R. Removal and determination of trimethylsilanol from the landfill gas. Bioresour. Technol. 2012, 103, 16–20. [Google Scholar] [CrossRef] [PubMed]

- Schweigkofler, M.; Niessner, R. Removal of siloxanes in biogases. J. Hazard. Mater. 2001, 83, 183–196. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, Z.; Hao, Z. Recent advances in technologies for the removal of volatile methylsiloxanes: A case in biogas purification process. Crit. Rev. Environ. Sci. Technol. 2019, 49, 2257–2313. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Dewil, R. Siloxane removal from biosolids by peroxidation. Energy Convers. Manag. 2008, 49, 2859–2864. [Google Scholar] [CrossRef]

- De Arespacochaga, N.; Valderrama, C.; Raich-Montiu, J.; Crest, M.; Mehta, S.; Cortina, J. Understanding the effects of the origin, occurrence, monitoring, control, fate and removal of siloxanes on the energetic valorization of sewage biogas—A review. Renew. Sustain. Energy Rev. 2015, 52, 366–381. [Google Scholar] [CrossRef]

- Wheless, E.; Pierce, J. Siloxanes in landfill and digester gas update. In Proceedings of the SWANA 27th LFG Conference, SCS Energy, San Antonio, CA, USA, 22–25 March 2004. [Google Scholar]

- GTI. Conduct a Nationwide Survey of Biogas Cleanup Technologies and Costs, Final Report; AQMD Contract #: 13432; Gas Technology Institute: Des Plaines, IL, USA, 2014. [Google Scholar]

- ADBA (Anaerobic Digestion and Bioresources Association). The Practical Guide to AD, Chapter 5: Producing and Using Biogas, UK. Available online: http://adbioresources.org/wp-content/uploads/2013/06/59-80_chapter5_v41.pdf (accessed on 10 November 2019).

- Svensson, M. Biomethane Standards: Gas Quality Standardisation of Biomethane, Going from National to International Level. European workshop Biomethane, Brussels. Green Gas Grids. 2014. Available online: https://scholar.google.com.hk/scholar?hl=zh-CN&as_sdt=0%2C5&q=Biomethane+Standards%3A+Gas+Quality+Standardisation+of+Biomethane%2C+Going+from+National+to+International+Level.&btnG= (accessed on 13 May 2020).

- Gaj, K. Applicability of selected methods and sorbents to simultaneous removal of siloxanes and other impurities from biogas. Clean Technol. Environ. Policy 2017, 19, 2181–2189. [Google Scholar] [CrossRef]

- Zamorska-Wojdyła, D.; Gaj, K.; Hołtra, A.; Sitarska, M. Quality Evaluation of Biogas and Selected Methods of its Analysis. Ecol. Chem. Eng. S 2012, 19, 77–87. [Google Scholar] [CrossRef]

- Yang, R.T. Adsorbents: Fundamentals and Applications; Wiley: Hoboken, NJ, USA, 2003. [Google Scholar]

- Ortega, D.R.; Subrenat, A. Siloxane treatment by adsorption into porous materials. Environ. Technol. 2009, 30, 1073–1083. [Google Scholar] [CrossRef]

- Giraudet, S.; Boulinguiez, B.; Le Cloirec, P. Adsorption and Electrothermal Desorption of Volatile Organic Compounds and Siloxanes onto an Activated Carbon Fiber Cloth for Biogas Purification. Energy Fuels 2014, 28, 3924–3932. [Google Scholar] [CrossRef]

- Soreanu, G.; Beland, M.; Falletta, P.; Edmonson, K.; Svoboda, L.; Al−Jamal, M.; Seto, P. Approaches concerning siloxane removal from biogas—A review. Can. Biosyst. Eng. 2011, 53, 8.1–8.18. [Google Scholar]

- Cabrera-Codony, A.; Clotas, E.S.; Ania, C.O.; Martín, M.J. Competitive siloxane adsorption in multicomponent gas streams for biogas upgrading. Chem. Eng. J. 2018, 344, 565–573. [Google Scholar] [CrossRef]

- Gong, H.; Chen, Z.; Fan, Y.; Zhang, M.; Wu, W.; Wang, W. Surface modification of activated carbon for siloxane adsorption. Renew. Energy 2015, 83, 144–150. [Google Scholar] [CrossRef]

- Finocchio, E.; Montanari, T.; Garuti, G.; Pistarino, C.; Federici, F.; Cugino, M.; Busca, G. Purification of Biogases from Siloxanes by Adsorption: On the Regenerability of Activated Carbon Sorbents. Energy Fuels 2009, 23, 4156–4159. [Google Scholar] [CrossRef]

- Matsui, T.; Imamura, S. Removal of siloxane from digestion gas of sewage sludge. Bioresour. Technol. 2010, 101, S29–S32. [Google Scholar] [CrossRef]

- De Arespacochaga, N.; Raich-Montiu, J.; Crest, M.; Cortina, J.L. Presence of Siloxanes in Sewage Biogas and Their Impact on Its Energetic Valorization. In Volatile Methylsiloxanes in the Environment; Homem, V., Ratola, N., Eds.; Book Series: The Handbook of Environmental Chemistry; Springer Nature Switzerland AG: Basel, Switzerland, 2019. [Google Scholar] [CrossRef]

- Cabrera-Codony, A.; Olmos, R.G.; Martín, M.J. Regeneration of siloxane-exhausted activated carbon by advanced oxidation processes. J. Hazard. Mater. 2015, 285, 501–508. [Google Scholar] [CrossRef] [PubMed]

- Cabrera-Codony, A.; Georgi, A.; Gonzalez-Olmos, R.; Valdés, H.; Martín, M.J. Zeolites as recyclable adsorbents/catalysts for biogas upgrading: Removal of octamethylcyclotetrasiloxane. Chem. Eng. J. 2017, 307, 820–827. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for transformation of biogas to biomethane. Biomass- Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- EPRI. Assessment of Fuel Gas Cleanup Systems for Waste Gas Fueled Power Generation. Electric Power Research Institute; 1012763, Technical Update; EPRI: Palo Alto, CA, USA, 2006. [Google Scholar]

- Liu, Y.-H.; Meng, Z.-Y.; Wang, J.-Y.; Dong, Y.-F.; Ma, Z.-C. Removal of siloxanes from biogas using acetylated silica gel as adsorbent. Pet. Sci. 2019, 16, 920–928. [Google Scholar] [CrossRef]

- Almeida, A.; Ribeiro, R.P.P.L.; Mota, J.P.B.; Grande, C.A. Extrusion and Characterization of High Si/Al Ratio ZSM-5 Using Silica Binder. Energies 2020, 13, 1201. [Google Scholar] [CrossRef]

- Sigot, L.; Ducom, G.; Benadda, B.; Laboure, C. Comparison of adsorbents for H2S and D4 removal for biogas conversion in a solid oxide fuel cell. Environ. Technol. 2015, 37, 86–95. [Google Scholar] [CrossRef]

- Montanari, T.; Finocchio, E.; Bozzano, I.; Garuti, G.; Giordano, A.; Pistarino, C.; Busca, G. Purification of landfill biogases from siloxanes by adsorption: A study of silica and 13X zeolite adsorbents on hexamethylcyclotrisiloxane separation. Chem. Eng. J. 2010, 165, 859–863. [Google Scholar] [CrossRef]

- Zhong, W.; Jiang, T.; Jafari, T.; Poyraz, A.S.; Wu, W.; Kriz, D.A.; Du, S.; Biswas, S.; Pettes, M.T.; Suib, S.L. Modified inverse micelle synthesis for mesoporous alumina with a high D4 siloxane adsorption capacity. Microporous Mesoporous Mater. 2017, 239, 328–335. [Google Scholar] [CrossRef]

- Nam, S.; Namkoong, W.; Kang, J.-H.; Park, J.-K.; Lee, N. Adsorption characteristics of siloxanes in landfill gas by the adsorption equilibrium test. Waste Manag. 2013, 33, 2091–2098. [Google Scholar] [CrossRef]

- Jafari, T.; Noshadi, I.; Khakpash, N.; Suib, S.L. Superhydrophobic and stable mesoporous polymeric adsorbent for siloxane removal: D4 super-adsorbent. J. Mater. Chem. A 2015, 3, 5023–5030. [Google Scholar] [CrossRef]

- Jung, H.; Lee, D.-Y.; Jurng, J. Low-temperature regeneration of novel polymeric adsorbent on decamethylcyclopentasiloxane (D5) removal for cost-effective purification of biogases from siloxane. Renew. Energy 2017, 111, 718–723. [Google Scholar] [CrossRef]

- Noshadi, I.; Kanjilal, B.; Jafari, T.; Moharreri, E.; Khakpash, N.; Jiang, T.; Suib, S.L. Hydrophobic mesoporous adsorbent based on cyclic amine–divinylbenzene copolymer for highly efficient siloxane removal. RSC Adv. 2016, 6, 77310–77320. [Google Scholar] [CrossRef]

- Ajhar, M.; Travesset, M.; Yüce, S.; Melin, T. Siloxane removal from landfill and digester gas—A technology overview. Bioresour. Technol. 2010, 101, 2913–2923. [Google Scholar] [CrossRef]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).