Optimization of Operating Parameters for Stable and High Operating Performance of a GDI Fuel Injector System

Abstract

1. Introduction

2. Design of the H.P. Injector Driving Circuit

2.1. Principle and Operation

2.2. Modeling and Characterization

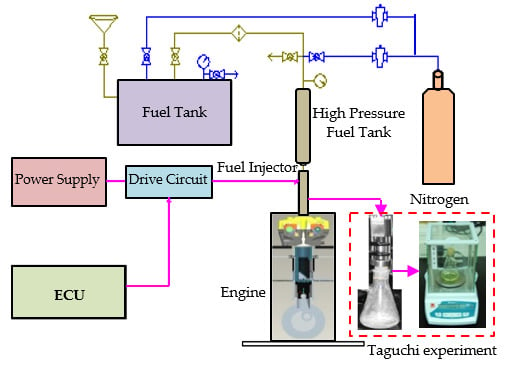

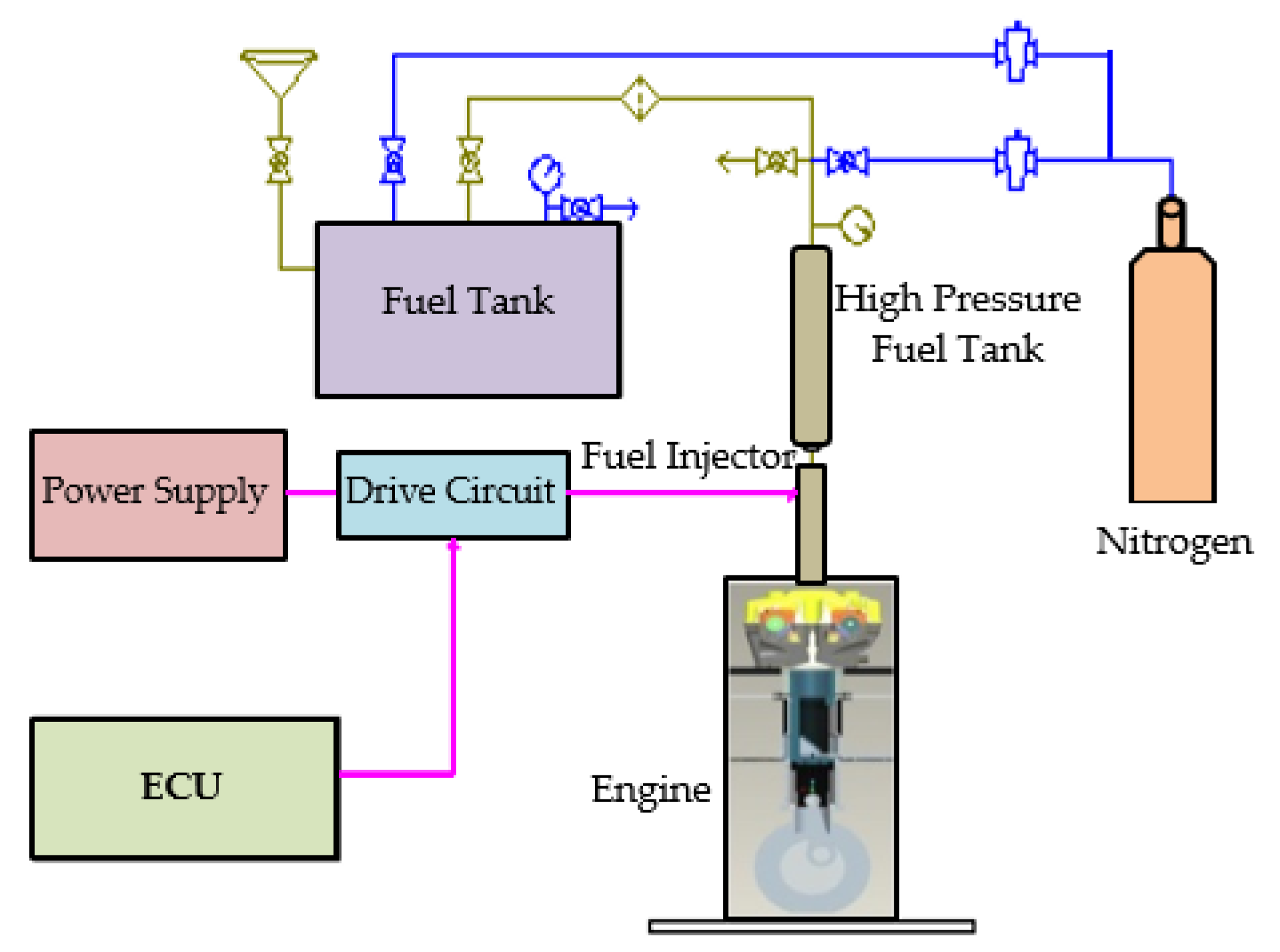

3. Experimental Configuration and Equipment

3.1. High-Pressure Fuel Supply System

3.2. General Operating Principle

3.3. Mathematical Model

4. Experimental Design and Data Analysis

4.1. Equations of β, Sd, and S/N Ratios

4.2. The First Taguchi Experiment

4.3. Confirmation Experiments

5. Conclusions

- This paper uses the orthogonal design experiment method, which can effectively list the percentage distribution of the results of all possible experiments, and then calculate the S/N ratios and β slopes of fuel injection quantity to determine the optimal injection factor levels. The significance of each control factor was confirmed by analysis of variation and optimal results were obtained.

- It was found that the turn-on time of first stage injector current was too short (only 180 μs). The smaller settings of second stage holding currents (3/4/5A) could not continuously and effectively hold the needle of the high-pressure injector, resulting in insufficient injection quantity (see Table 7). Thus, the settings of the second stage holding currents were enhanced as (200 μs and 4/5/6A) for the third confirmation experiment.

- The Taguchi method is simple and feasible for testing and optimizing the design of high-pressure fuel injector drivers. It is also very effective in saving unnecessary testing time in experiments. The factor category that affects fuel injection quantity can be obtained from the cross-comparison of S/N ratios and β slopes using variation analysis. Factors A and B have the highest contribution. The optimal settings for supply voltage, the first stage turn-on, and second stage holding currents of an injector were determined to reduce the range of variation.

- The fuel supply pressure (factor D) was achieved to determine the maximum sensitivity by comparing the S/N ratios and β slopes, and therefore to significantly affect the fuel injection quantity. In Section 2.2, the original waveform of the injector driving current designed by BOSCH was adopted and improved. As a design consideration, the second-stage injector holding current (factor C) was used to reduce the cost.

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | Description | Unit |

| H.P. | High-pressure | bar |

| GDI | Gasoline-direct-injection | |

| PM | Particulate matters | |

| MOSFET | Metal oxide semiconductor field effect transistor | |

| RLC | Second-order circuit | |

| IC | Integrated circuit | |

| PWM | Pulse width modulation | |

| ECU | Electronic control unit | |

| PCB | Printed circuit board | |

| rpm | Revolutions per minute | |

| Ip1 | First turn-on pulse signal | A |

| mfuel | Fuel injection mass | g |

| tp | Injection pulse duration | μs |

| S/N | Signal-to-noise | dB |

| ANOVA | Analysis of variance |

References

- Zhao, F.; Lai, M.C.; Harrington, D.L. Automotive spark-ignited direct-injection gasoline engines. Prog. Energy Combust. Sci. 1999, 25, 437–562. [Google Scholar] [CrossRef]

- Wang, C.; Xu, H.; Herreros, J.M.; Wang, J.; Cracknell, R. Impact of fuel and injection system on particle emissions from a GDI engine. Appl. Energy 2014, 132, 178–191. [Google Scholar] [CrossRef]

- Luo, H.; Nishida, K.; Uchitomi, S.; Ogata, Y.; Zhang, W.; Fujikawa, T. Effect of temperature on fuel adhesion under spray-wall impingement condition. Fuel 2018, 234, 56–65. [Google Scholar] [CrossRef]

- Luo, H.; Nishida, K.; Uchitomi, S.; Ogata, Y.; Zhang, W.; Fujikawa, T. Microscopic behavior of spray droplets under flat-wall impinging condition. Fuel 2018, 219, 467–476. [Google Scholar] [CrossRef]

- Leach, F.; Knorsch, T.; Laidig, C.; Wiese, W. A Review of the Requirements for Injection Systems and the Effects of Fuel Quality on Particulate Emissions from GDI Engines; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Raza, M.; Chen, L.; Leach, F.; Ding, S. A review of particulate number (PN) emissions from gasoline direct injection (GDI) engines and their control techniques. Energies 2018, 11, 1417. [Google Scholar] [CrossRef]

- Jiangjian, A.; Xiyan, B.G.; Chunde, C.Y. An Experimental Study on Fuel Injection System and Emission of a Small GDI Engine. In Proceedings of the 2nd IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications, Beijing, China, 13–16 August 2006; pp. 1–6. [Google Scholar]

- Zhang, X.; Palazzolo, A.; Kweon, C.B.; Thomas, E.; Tucker, R.; Kascak, A. Direct fuel injector power drive system optimization. SAE Int. J. Engines 2014, 7, 1137–1154. [Google Scholar] [CrossRef]

- Tsai, W.C.; Yu, P.C.; Chen, K.H.; Guo, C.J. Development and Calibration of PC_Based Control System to Improve the Performance and Emissions of a 500cc Motorcycle Engine. ICIC Express Lett. 2010, 4, 2219–2226. [Google Scholar]

- Tsai, W.C.; Yu, P.C. Design of the electrical drive for the high-pressure GDI injector in a 500cc motorbike engine. Int. J. Eng. Ind. 2011, 2, 70–83. [Google Scholar]

- Huang, D.; Ding, H.; Wang, Z.; Huang, R. Design of drive circuit for GDI injector. In Proceedings of the 2011 International Conference on Electric Information and Control Engineering (ICEICE), Wuhan, China, 15–17 April 2011; pp. 5821–5824. [Google Scholar]

- Qiang, C.; Zhang, Z.; Xie, N. Power losses and dynamic response analysis of ultra-high speed solenoid injector within different driven strategies. Appl. Therm. Eng. 2015, 91, 611–621. [Google Scholar]

- Lu, H.; Deng, J.; Hu, Z.; Wu, Z.; Li, L. Impact of control methods on dynamic characteristic of high speed solenoid injectors. SAE Int. J. Engines 2014, 7, 1155–1164. [Google Scholar] [CrossRef]

- Tsai, W.-C.; Zhan, T.-S. An Experimental Characterization for Injection Quantity of a High-pressure Injector in GDI Engines. J. Low Power Electron. Appl. 2018, 8, 36. [Google Scholar] [CrossRef]

- Ji, H.; Wei, M.; Liu, R.; and Chang, C. Drive Control Simulation and Experimental Studies on the Flow Characteristics of a Pump Injector. IEEE Access 2020, 8, 35672–35681. [Google Scholar] [CrossRef]

- Satkoski, C.; Shaver, G. Piezoelectric fuel injection: Pulse-to-pulse coupling and flow rate estimation. 568 IEEE-ASME T Mech. 2011, 16, 627–642. [Google Scholar] [CrossRef]

- Lochner, R.H.; Matar, J.E. Designing for Quality. An Introduction to the Best of Taguchi and Western Methods of Statistical Method Design; Chapman & Hall: London, UK, 1990. [Google Scholar]

- Ross, P.J. Taguchi Techniques for Quality Engineering, 2nd ed.; McGraw-Hill Inc.: New York, NY, USA, 1996. [Google Scholar]

- Hedayat, A.S.; Sloane, N.J.A.; Stufken, J. Orthogonal Arrays: Theory and Applications; Springer: New York, NY, USA, 1999. [Google Scholar]

- Lee, H.-H. Taguchi Methods: Principles and Practices of Quality Design; Gau Lih Book Co. Ltd.: Taipei, Taiwan, 2010. [Google Scholar]

- Tsai, W.C.; Wu, Z.H. Use of Taguchi Method to Optimize the Operating Parameters of a High-Pressure Injector Driving Circuit. Appl. Mech. Mater. 2011, 130–134, 2795–2799. [Google Scholar] [CrossRef]

| Labels | Control Factor | Units | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|

| A | Supply voltage | V | 55 | 60 | 65 |

| B | First stage current | A | 8 | 10 | 12 |

| C | Speed | RPM | 2400 | 6000 | 9000 |

| D | Fuel supply pressure | bar | 80 | 90 | 100 |

| L9 | M = 1200 μs | M = 1400 μs | M = 1600 μs | M = 1800 μs | M = 2000 μs | β | Sd | S/N | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | ||||||||||||||

| Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | ||||

| 1 | 11.331 | 11.265 | 11.401 | 11.367 | 13.124 | 13.211 | 13.121 | 13.087 | 15.119 | 15.398 | 15.243 | 15.133 | 17.149 | 16.943 | 17.043 | 17.198 | 19.079 | 19.178 | 19.086 | 18.984 | 9.490 | 0.117 | 38.197 |

| 2 | 12.266 | 12.305 | 11.253 | 12.278 | 14.029 | 14.993 | 14.095 | 14.084 | 16.398 | 16.432 | 16.289 | 16.341 | 18.397 | 18.345 | 18.434 | 18.376 | 20.600 | 20.498 | 20.675 | 20.532 | 10.219 | 0.298 | 30.703 |

| 3 | 15.398 | 15.302 | 15.407 | 15.374 | 14.617 | 14.598 | 14.681 | 14.677 | 16.637 | 16.703 | 16.749 | 16.598 | 18.938 | 18.821 | 19.078 | 18.987 | 20.963 | 21.078 | 20.898 | 20.877 | 10.731 | 1.185 | 19.141 |

| 4 | 12.635 | 12.643 | 12.598 | 12.698 | 14.690 | 14.672 | 14.735 | 14.683 | 16.935 | 17.103 | 16.943 | 16.881 | 19.305 | 19.434 | 19.406 | 19.287 | 21.411 | 21.501 | 21.478 | 21.378 | 10.653 | 0.168 | 36.048 |

| 5 | 11.594 | 11.601 | 11.577 | 11.612 | 13.439 | 13.407 | 13.486 | 13.507 | 15.896 | 15.843 | 15.971 | 15.799 | 17.755 | 17.687 | 17.854 | 17.789 | 19.808 | 19.764 | 19.854 | 19.932 | 9.836 | 0.202 | 33.734 |

| 6 | 12.234 | 12.246 | 12.308 | 12.209 | 14.363 | 14.384 | 14.401 | 14.334 | 16.307 | 16.391 | 16.402 | 16.251 | 18.541 | 18.398 | 18.601 | 18.579 | 20.526 | 20.411 | 20.576 | 20.654 | 10.257 | 0.083 | 41.880 |

| 7 | 11.912 | 11.983 | 11.871 | 11.923 | 13.849 | 13.879 | 13.911 | 13.861 | 15.888 | 15.838 | 15.909 | 15.793 | 18.040 | 18.165 | 17.986 | 18.109 | 20.001 | 20.134 | 20.165 | 20.012 | 9.984 | 0.114 | 38.871 |

| 8 | 12.904 | 12.891 | 11.032 | 12.911 | 14.885 | 14.906 | 14.867 | 14.919 | 17.111 | 17.071 | 17.045 | 16.972 | 19.445 | 19.395 | 19.502 | 19.487 | 21.549 | 21.689 | 21.601 | 21.587 | 10.704 | 0.429 | 27.937 |

| 9 | 11.746 | 11.735 | 11.762 | 11.741 | 13.795 | 13.832 | 13.763 | 13.781 | 15.638 | 15.731 | 15.593 | 15.691 | 17.761 | 17.846 | 17.702 | 17.802 | 19.655 | 19.743 | 19.632 | 19.753 | 9.838 | 0.070 | 43.001 |

| Labels | Variance | Freedom | Sum of Squares | F | Contribution |

|---|---|---|---|---|---|

| A | 0.5 | 2 | 0.2 | 0.03 | 2.72% |

| B | 6.1 | 2 | 3.1 | 0.34 | 28.64% |

| C | 0.6 | 2 | 0.3 | 0.04 | 3.53% |

| D | 77.6 | 2 | 38.8 | 4.35 | 97.13% |

| Factor | Original Design | New Design | ||||

|---|---|---|---|---|---|---|

| Response | Response | |||||

| Setting | S/N | β | Setting | S/N | β | |

| A | 1 | 29.1 | 10.147 | 2 | 37.0 | 10.249 |

| B | 1 | 37.5 | 10.042 | 1 | 37.5 | 10.150 |

| C | 1 | 35.8 | 10.150 | 2 | 36.4 | 10.236 |

| D | 1 | 38.1 | 9.721 | 1 | 38.1 | 9.721 |

| Average | 34.2 | 10.190 | 34.2 | 10.190 | ||

| Predicted value | 38.0 | 9.490 | 46.4 | 9.786 | ||

| Exp | M = 1200 μs | M = 1400 μs | M = 1600 μs | M = 1800 μs | M = 2000 μs | β | S | S/N | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | ||||||||||||||||||

| A | B | C | D | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | ||||

| Original | 1 | 1 | 1 | 1 | 11.775 | 11.792 | 11.732 | 11.727 | 13.409 | 13.416 | 13.354 | 13.342 | 15.321 | 15.303 | 15.278 | 15.287 | 17.037 | 17.028 | 17.007 | 17.005 | 18.933 | 18.927 | 18.923 | 18.911 | 9.530 | 0.175 | 34.713 |

| New | 2 | 1 | 3 | 1 | 12.739 | 12.638 | 12.691 | 12.813 | 14.925 | 14.876 | 15.012 | 14.957 | 17.036 | 17.102 | 16.998 | 17.086 | 18.972 | 18.987 | 19.051 | 19.093 | 21.509 | 21.598 | 21.481 | 21.551 | 10.666 | 0.138 | 37.779 |

| Labels | Factor | Units | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|

| A | Supply voltage | V | 55 | 60 | 65 |

| B | First-stage turn-on current | A | 8 | 10 | 12 |

| C | Second-stage holding current | A | *3 | *4 | *5 |

| 4 | 5 | 6 | |||

| D | Fuel pressure | bar | 80 | 90 | 100 |

| Exp | M = 1200 μs | M =1400 μs | M = 1600 μs | M = 1800 μs | M = 2000 μs | β | S | S/N | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | ||||||||||||||||||

| A | B | C | D | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | ||||

| Original | 1 | 1 | 1 | 1 | 11.693 | 11.713 | 11.643 | 11.674 | 13.272 | 13.288 | 13.038 | 13.131 | 15.280 | 15.295 | 15.166 | 15.236 | 16.991 | 16.959 | 16.993 | 17.018 | 18.965 | 18.975 | 18.954 | 18.988 | 9.499 | 0.156 | 35.680 |

| New | 3 | 1 | 1 | 3 | 6.901 | 7.009 | 7.753 | 7.749 | 7.229 | 7.396 | 7.898 | 7.784 | 7.402 | 7.718 | 7.205 | 7.386 | 7.307 | 7.779 | 7.522 | 7.722 | 7.744 | 8.037 | 7.693 | 7.997 | 4.598 | 1.204 | 11.642 |

| M = 1200 μs | M = 1400 μs | M = 1600 μs | M = 1800 μs | M = 2000 μs | β | Sd | S/N | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | |||||||||||||

| Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | ||||

| 1 | 11.693 | 11.713 | 11.643 | 11.674 | 13.272 | 13.288 | 13.038 | 13.131 | 15.280 | 15.295 | 15.166 | 15.236 | 16.991 | 16.959 | 16.993 | 17.018 | 18.965 | 18.975 | 18.954 | 18.988 | 9.499 | 0.160 | 35.457 |

| 2 | 12.841 | 12.854 | 12.849 | 12.864 | 14.478 | 14.503 | 14.543 | 14.558 | 16.596 | 16.629 | 16.612 | 16.631 | 18.394 | 18.428 | 18.504 | 18.535 | 20.479 | 20.527 | 20.545 | 20.564 | 10.351 | 0.231 | 33.040 |

| 3 | 13.205 | 13.284 | 13.268 | 13.358 | 15.083 | 15.118 | 15.177 | 15.197 | 17.014 | 17.025 | 17.228 | 17.274 | 19.023 | 19.045 | 19.297 | 19.348 | 21.128 | 21.151 | 21.414 | 21.456 | 10.731 | 0.246 | 32.780 |

| 4 | 12.729 | 12.778 | 12.793 | 12.806 | 14.521 | 14.540 | 14.579 | 14.644 | 16.763 | 16.789 | 16.825 | 16.863 | 18.679 | 18.695 | 18.832 | 18.851 | 20.915 | 20.934 | 20.992 | 21.037 | 10.480 | 0.126 | 38.421 |

| 5 | 12.306 | 12.286 | 12.358 | 12.339 | 13.876 | 13.904 | 14.060 | 14.061 | 15.905 | 15.947 | 15.966 | 16.002 | 17.683 | 17.716 | 17.812 | 17.842 | 19.627 | 19.681 | 19.719 | 19.743 | 9.942 | 0.219 | 33.122 |

| 6 | 12.651 | 12.675 | 12.747 | 12.773 | 14.534 | 14.579 | 14.649 | 14.678 | 16.486 | 16.536 | 15.592 | 16.638 | 18.506 | 18.536 | 18.685 | 18.733 | 20.439 | 20.493 | 20.617 | 20.657 | 10.335 | 0.282 | 31.270 |

| 7 | 12.419 | 12.428 | 12.385 | 12.402 | 14.169 | 14.179 | 14.176 | 14.182 | 16.295 | 16.323 | 16.263 | 16.288 | 18.174 | 18.187 | 18.175 | 18.178 | 20.206 | 20.253 | 20.253 | 20.309 | 10.154 | 0.120 | 38.555 |

| 8 | 13.016 | 13.043 | 13.045 | 13.067 | 14.783 | 14.834 | 14.895 | 14.916 | 17.092 | 17.128 | 17.118 | 17.155 | 19.096 | 19.145 | 19.168 | 19.235 | 21.282 | 21.327 | 21.325 | 21.383 | 10.682 | 0.125 | 38.652 |

| 9 | 12.462 | 12.438 | 12.442 | 12.446 | 14.237 | 14.254 | 14.269 | 14.294 | 16.158 | 16.196 | 16.203 | 16.229 | 18.007 | 18.024 | 18.067 | 18.090 | 19.894 | 19.932 | 19.939 | 19.965 | 10.089 | 0.212 | 33.541 |

| Factor | SS | DOF | Var | F | Confidence | Significant? |

|---|---|---|---|---|---|---|

| A | 19.4 | 2 | 9.7 | 2.997 | 83.98% | Yes |

| B | 33.7 | 2 | 16.8 | 5.211 | 92.31% | Yes |

| C | Pooled | No | ||||

| D | Pooled | No | ||||

| Error | 12.9 | 4 | 3.2 | S =1.8 | ||

| Total | 66.0 | 8 | 8.2 | *At least 80% confidence level | ||

| Factor | Original Design | New Design | ||||

|---|---|---|---|---|---|---|

| Setting | Response | Setting | Response | |||

| S/N | β | S/N | β | |||

| A | 1 | 32.6 | 10.205 | 3 | 36.0 | 10.185 |

| B | 1 | 37.3 | 10.002 | 1 | 37.3 | 10.002 |

| C | 1 | 34.9 | 10.170 | 1 | 34.9 | 10.170 |

| D | 1 | 33.7 | 9.808 | 3 | 36.2 | 10.633 |

| Mean value | 34.6 | 10.218 | 34.6 | 10.218 | ||

| Predicted value | 34.7 | 9.530 | 40.5 | 10.334 | ||

| Exp | M = 1200 μs | M = 1400 μs | M = 1600 μs | M = 1800 μs | M = 2000 μs | β | S | S/N | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | N1 | N2 | ||||||||||||||||||

| A | B | C | D | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | ||||

| Original | 1 | 1 | 1 | 1 | 11.775 | 11.792 | 11.732 | 11.727 | 13.409 | 13.416 | 13.354 | 13.342 | 15.321 | 15.303 | 15.278 | 15.287 | 17.037 | 17.028 | 17.007 | 17.005 | 18.933 | 18.927 | 18.923 | 18.911 | 9.530 | 0.175 | 34.713 |

| New | 3 | 1 | 1 | 3 | 12.581 | 12.578 | 12.521 | 12.527 | 14.348 | 14.352 | 14.307 | 14.322 | 16.537 | 16.551 | 16.514 | 16.515 | 18.491 | 18.502 | 18.476 | 18.481 | 20.616 | 20.618 | 20.614 | 20.609 | 10.309 | 0.103 | 40.021 |

| 3 | 1 | 3 | 3 | 12.754 | 12.747 | 12.724 | 12.735 | 14.569 | 14.584 | 14.609 | 14.598 | 16.649 | 16.653 | 16.685 | 16.686 | 18.724 | 18.713 | 18.767 | 18.757 | 20.727 | 20.724 | 20.791 | 20.783 | 10.426 | 0.117 | 39.031 | |

| Level | Calculated | Predicted | Difference | Improvement | |

|---|---|---|---|---|---|

| S/N | S/N | dB | |||

| Original | A1B1BC1D1 | 34.713 | 34.965 | −0.253 | 5.308 |

| Optimal | A3B1BC1D3 | 40.021 | 36.651 | 3.371 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, W.-C. Optimization of Operating Parameters for Stable and High Operating Performance of a GDI Fuel Injector System. Energies 2020, 13, 2405. https://doi.org/10.3390/en13102405

Tsai W-C. Optimization of Operating Parameters for Stable and High Operating Performance of a GDI Fuel Injector System. Energies. 2020; 13(10):2405. https://doi.org/10.3390/en13102405

Chicago/Turabian StyleTsai, Wen-Chang. 2020. "Optimization of Operating Parameters for Stable and High Operating Performance of a GDI Fuel Injector System" Energies 13, no. 10: 2405. https://doi.org/10.3390/en13102405

APA StyleTsai, W.-C. (2020). Optimization of Operating Parameters for Stable and High Operating Performance of a GDI Fuel Injector System. Energies, 13(10), 2405. https://doi.org/10.3390/en13102405