1. Introduction

Coal, as one of the most abundant, widely distributed, and economically used energy sources in the world, takes an important position in the energy structure. Numerous mines are required in coal mining, and as a significant means to improve coal productivity in mining areas, inclined shaft development is adopted by most of the mines. On 3 August 2013, the world’s first long-distance inclined shaft full-face tunnel boring machine (TBM) with independent intellectual property rights successfully rolled off the production line in Changsha, China. At present, TBM has been used to construct inclined shafts in the Bulianta Coal Mine in Inner Mongolia, Tashan Coal Mine in Shanxi, and Luobawan Coal Mine in Xinjiang. Compared with the traditional drilling and blasting method, TBM has the advantages of safety, speed, high quality, and environmental protection in the excavation of inclined shafts [

1,

2,

3]. However, due to the large buried depth, some engineering disasters such as water in rush and rock burst often occur when TBM crosses the aquifer and weak broken rock strata. Therefore, it is necessary to carry out advanced detection work to avoid the geological disasters and ensure the efficient and safe construction of the project [

4,

5,

6]. Advanced detection is to apply some technical means to predict and explain the integrity of the surrounding rock in front of the driving face and the possibility of disaster, thus as to provide the basis for selecting the proper excavation section and optimizing the construction scheme. At present, the TBM configurable advanced detection systems mainly include the reflected wave method, the electrical prospecting method, and the advanced horizontal drilling method.

The reflected wave method is a geophysical detection method based on the difference in elasticity and density of underground medium, which infers the attribute and state of underground rock strata by observing and analyzing the earth’s response to artificially excited seismic waves or sonic waves. Reflected wave method generally includes many different methods, such as horizontal sound probing (HSP) method, sonic soft-ground probing (SSP) method, tunnel seismic while drilling (TSWD) method, tunnel seismic prediction (TSP) method, and true reflection tomography (TRT) method. The TSP method is developed by Swiss company Amberg [

7]. During the tunnel construction, receiver holes and blasting holes are all arranged on the side wall behind the TBM within a certain range. Lin et al., and Liu et al., have accurately identified and located the tunnel fault zone with the TSP method, which verified the reliability and superiority of this method [

8,

9]. Although the TSP method has the advantages of long-distance prediction and large construction space, the collected data are poor in analysis and prone to be influenced by the subjective judgment of the detector. The TSWD method, which is named by Brückl et al., applies rock-breaking vibration as a seismic source for geological detection. Petronio et al., and Ewald et al., introduced TSWD method into TBM advanced detection, which has been applied to the tunnel construction in Italy and Austria [

10,

11,

12,

13]. This method has some difficulty in interpreting the passive seismic signals due to the constantly changing signal of the TBM vibration. Herrenknecht has proposed an SSP method in the drilling process. By arranging the source and detector of the observation system on the cutterhead, the geological information of several tens of meters in front of the driving face can be imaged [

14,

15]. However, since the SSP method only detects the uniformity or irregularity of the reflecting surface of the object, it is incapable of determining the scale and depth of the detected object. The TRT method, developed by National Security Agency (NSA) engineering company of the United States, is based on the propagation characteristics of the seismic wave in the media, which includes the amplitude, frequency, attenuation property, and receiving time, etc. [

16,

17]. However, the seismic wave caused by TRT is relatively weak and easy to be absorbed by unfavorable geological bodies such as fracture zones during the transmission process, which might lead to a short detection length. Of course, it is possible to use empirical mode decomposition (EMD) analysis and wavelet analysis to process TRT wave signals to improve detection accuracy [

18,

19]. The HSP method is proposed by the China Academy of Railway Sciences. By calculating the propagation characteristics of the high-frequency seismic waves emitted into the rock strata through the reflection signals of the seismic waves, the general geological conditions of the rock strata in front of the driving face can be learnt [

20]. However, the HSP method has poor reliability in judging whether it is a fault fracture zone or a rock fracture zone and cannot predict the state of underground water.

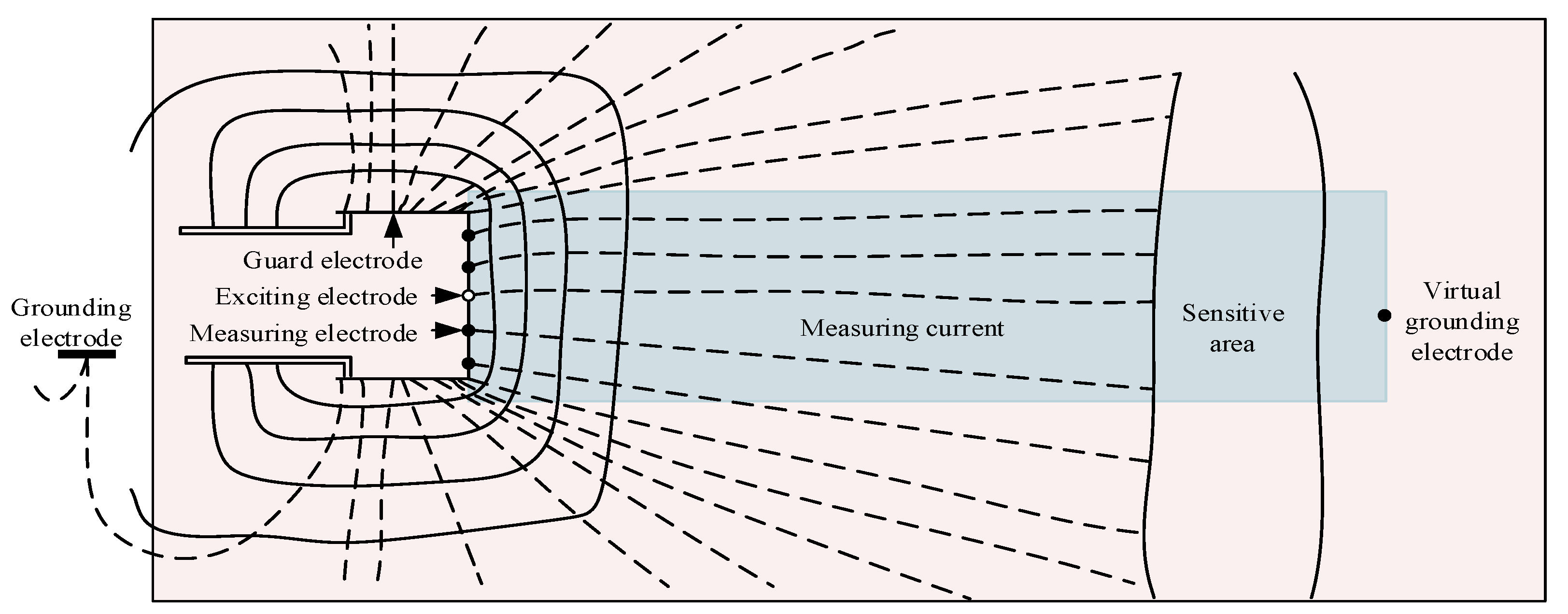

The electrical prospecting method is a geophysical detection method for ore prospecting and geological structure research through the difference in electrical properties of rocks and ores. The most commonly methods in electrical prospecting are direct current resistivity (DCR) method and induced polarization (IP) method [

21]. However, the DCR method is easy to be interfered by the anomalous body near survey lines behind the tunnel face, which can easily lead to the reduction of prediction accuracy and even false alarm [

22]. The bore-tunneling electrical ahead monitoring (BEAM) system is an IP method in focusing current frequency domain, which is developed by German company Geo Hydraulic Data. Its detection principle is to obtain the percentage frequency effect (PFE) value and apparent resistivity of rock mass pores by emitting the measuring current to the rock mass, and thereby to detect rock mass quality, voids, and water bodies in the rock mass according to these two parameters. The BEAM system is applied to tunnel construction under various complicated geological conditions, mainly including the Ginori tunnel in Italy, the Gotthard base tunnel in Switzerland and the Irlahul tunnel in Germany [

23]. The BEAM system has high detection sensitivity, good stability, and can realize real-time on-line detection. However, as it only uses the continuous detection results of different mileages, but not the tomography, to qualitatively infer the geological conditions in front of the tunnel face, the BEAM system has great problems in positioning accuracy, detection distance, resolution and so on. Zhao et al., has utilized the tomography technique to invert the resistivity distribution caused by the stress change of the force sensitive material, which provided a solution to the imaging problem of the BEAM system [

24].

The advanced horizontal drilling method is to carry out advanced horizontal drilling to determine the distribution of strata, the hardness of strata rocks, the integrity of rock masses and the position of faults and holes that may exist in front of the tunnel face by drilling speed testing, core taking rate statistics, core identification, and other means. As TBM often needs to be shut down and overhauled during the construction process, the multi-directional support hydraulic advanced geological drilling rig equipped on TBM is used for advanced drilling at the moment. However, due to its high cost, long time-consuming and small lateral detection range, this method has great application limitation in TBM tunnel advanced detection. Therefore, this method is commonly used in advanced detection in TBM tunnel construction together with other advanced geological prediction methods. Li has comprehensively analyzed and predicted the geological conditions in front of the tunnel face with transient electromagnetic method (TEM) and advanced horizontal drilling method [

25].

Based on the above research background, a coal mine inclined shaft advanced detection method based on shield cutterhead moving array electrodes is proposed, which can realize real-time imaging during TBM construction in order to realize rapid excavation and optimize safety plans and supporting measures in advance. First, aiming at the problem that the BEAM system cannot image because of the low utilization rate of the spatial distribution information, a diversified excitation and measurement mode with the cutters on the cutterhead as the exciting electrode and measuring electrode is proposed, which provides a calculation condition for resistivity imaging of the geological condition in front of the driving face. Then, a virtual grounding electrode equivalent model is proposed to improve the speed of inversion imaging. Finally, in order to verify the effectiveness of this method, the influence of the virtual grounding electrode on the inversion results at different positions is studied through a physical model test and a numerical inversion test.

3. Materials and Methods

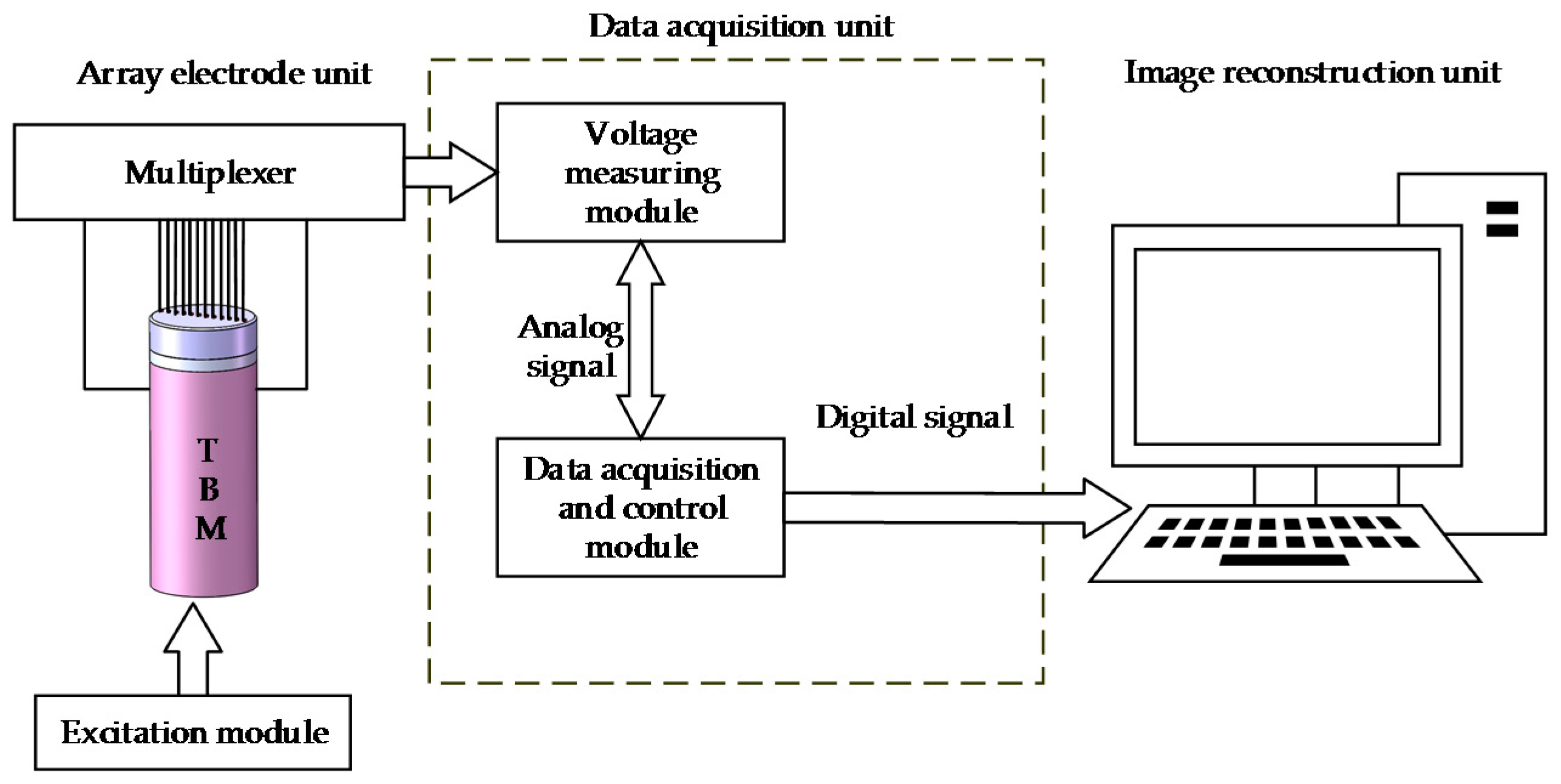

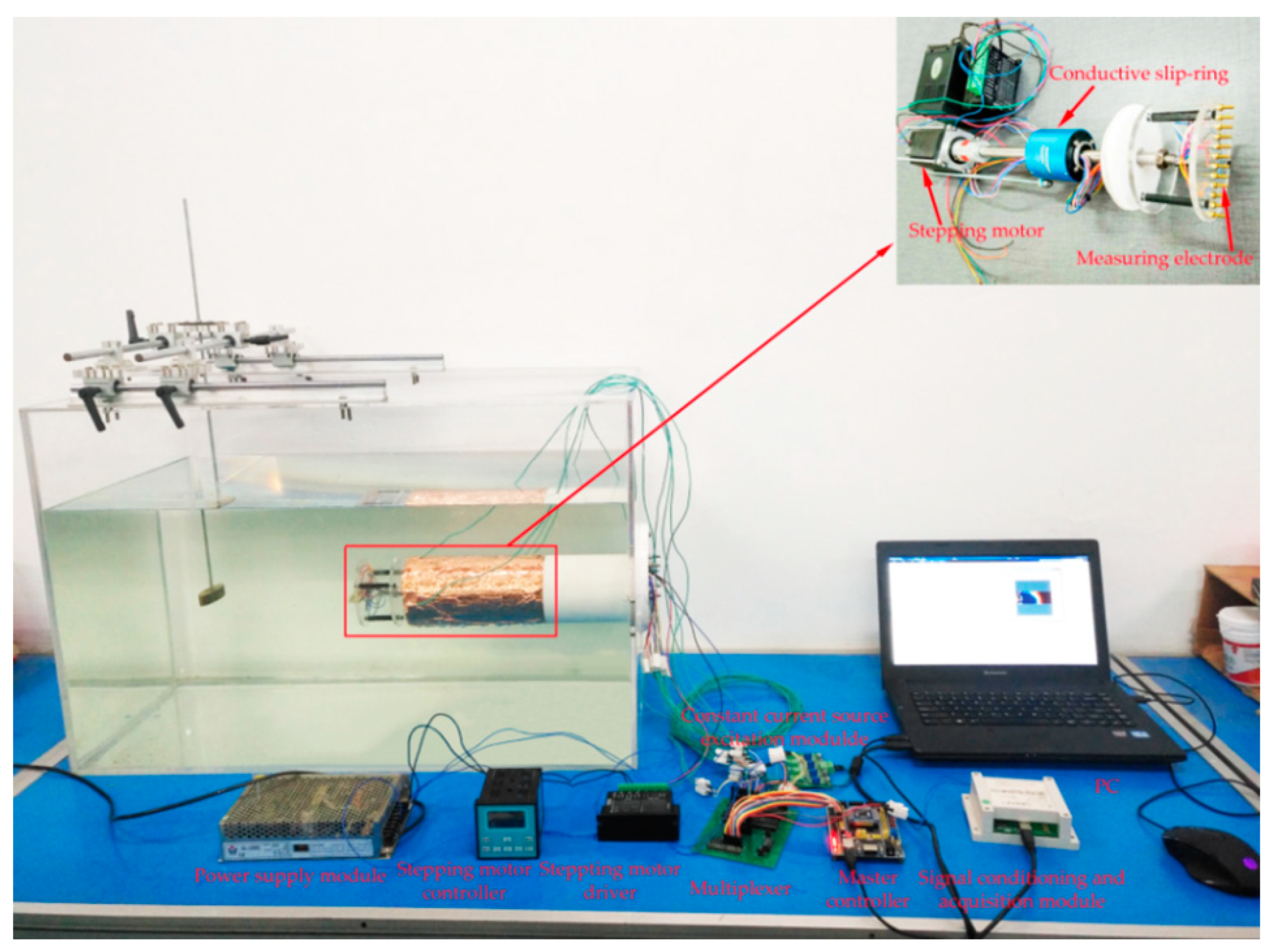

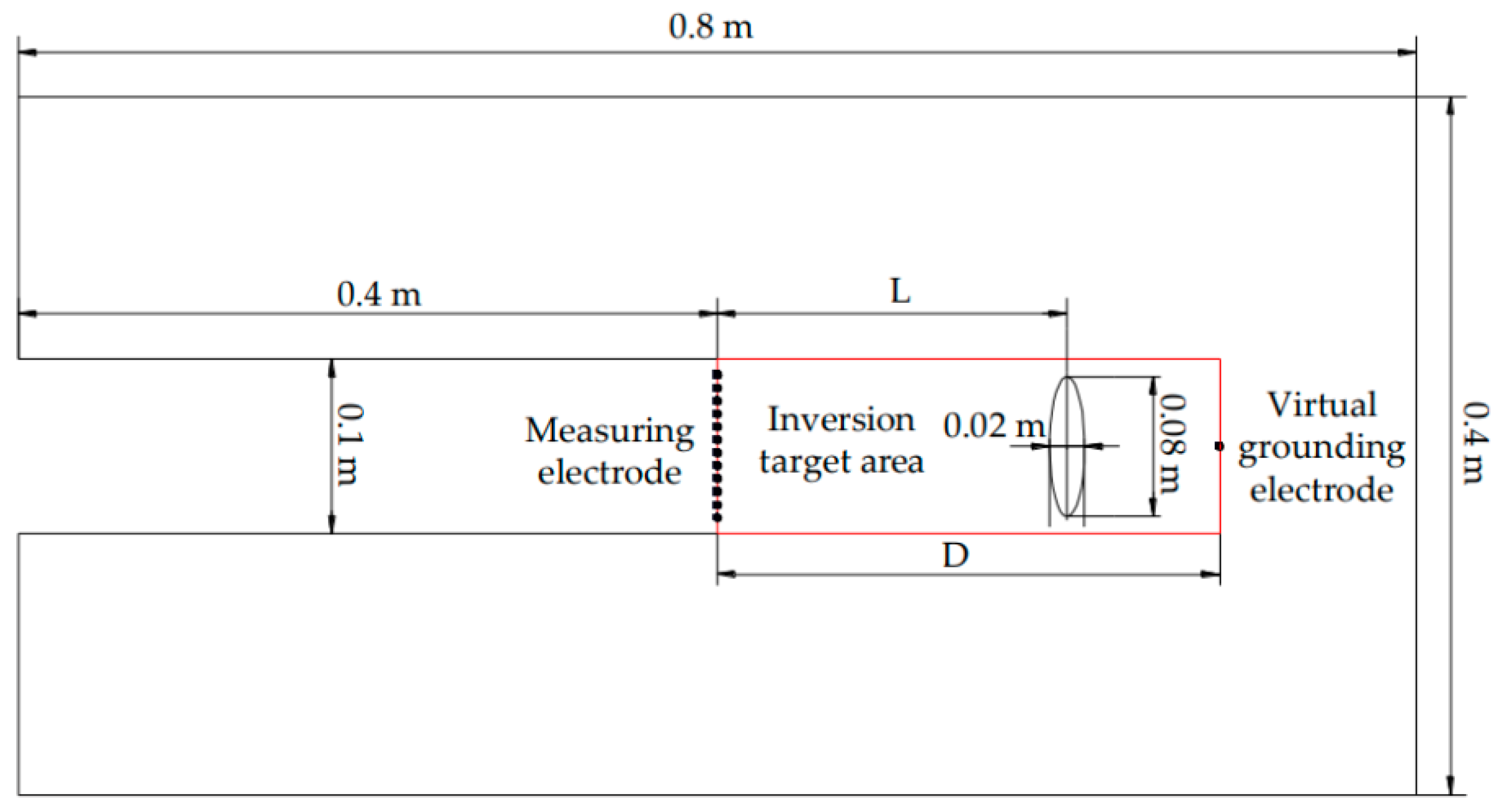

The physical model test device is shown in

Figure 4. The outer shell of the physical model is made of the acrylic plate with a length of 0.8 m, a width of 0.4 m, a height of 0.5 m, and a thickness of 0.008 m. An elliptical cylindrical brass with a major axis of 0.08 m, a minor axis of 0.02 m, a thickness of 0.02 m, and a resistivity of 0.05

was selected as the low resistivity anomalous body. A working platform, which can move along the X-Y-Z direction is installed on the acrylic box and can be used for clamping and moving various anomalous bodies. In order to make the electrode fully contact with the medium when the cutterhead rotates, water with a resistivity value of 20

is filled into the acrylic box as simulated surrounding rock, and the water level is 0.4 m. A polyvinyl chloride (PVC) pipe with an outer diameter of 0.1 m and an inner diameter of 0.09 m was fixed on the acrylic box to simulate the shield machine body. A layer of copper foil was pasted on the front end of the PVC pipe to simulate the shield with 4 copper electrodes being pasted around the simulated shield as the guard electrodes. The simulated cutterhead made of acrylic circular plate, with a thickness of 0.005 m and a diameter of 0.1 m, installed on the front end of the PVC pipe. We installed 12 copper bolts with a diameter of 0.003 m in the diameter direction of the simulated cutterhead as the measuring electrodes, and the distance between the 2 adjacent measuring electrodes was 0.008 m. The simulated cutterhead was fixed on a stainless-steel hollow shaft with a waterproof sealing bearing, a conductive slip-ring, a coupling and a stepping motor fixed on, wherein the conductive slip-ring is to prevent the wires connecting the measuring electrodes from winding together when the simulated cutterhead rotates. The stepping motor was connected with the driver and the controller to drive and control the simulated cutterhead. The distance from the simulated cutterhead to the left end of the acrylic box was 0.4 m, and the distance to the lower end of the acrylic box was 0.2 m. In addition, a copper bolt was also required to be installed on the acrylic box as the grounding electrode.

The system of the physical model test mainly included a power supply module, a master controller, a multiplexer, a constant current source excitation module, a signal conditioning, and an acquisition module and an imaging module. The power supply module used a switch mode power supply to provide different voltages. The master controller used MSP430F149 as the control chip, which has ultra-low power consumption. The multiplexer used a high-precision 16-channel multiplexer analog switch CD4067 to meet the switching and gating of 12 electrodes. The constant current source excitation module used a high-precision amplifier OP77, which can obtain current signals between 50 uA and 10 mA. The signal conditioning and acquisition module was divided into two parts: Signal conditioning and data acquisition. The signal conditioning part consisted of a first-stage amplifier circuit composed of an instrument amplifier with high input impedance and high common-mode rejection ratio and a second-stage program-controlled amplifier composed of a low input bias voltage, a broadband high-speed operational amplifier, and a numerical control potentiometer. The data acquisition part consisted of a voltage follower and a 24-bit high-precision digital-to-analog conversion chip ADS1256. The imaging module used a personal computer (PC) to display the imaging results. The working process of the system was as follows: When the system was powered on and received the command to start acquisition, the master controller controlled the constant current source excitation module to generate current excitation with specific parameters. Under the control of the master controller, the exciting current was sequentially released to each electrode through the multiplexer, and at the same time, the voltage signals at each measuring electrode were sent to the signal conditioning and acquisition module. After the processing and acquisition of the voltage signal were completed, the master controller transmitted the data to the PC for imaging in real time.

4. Results and Discussion

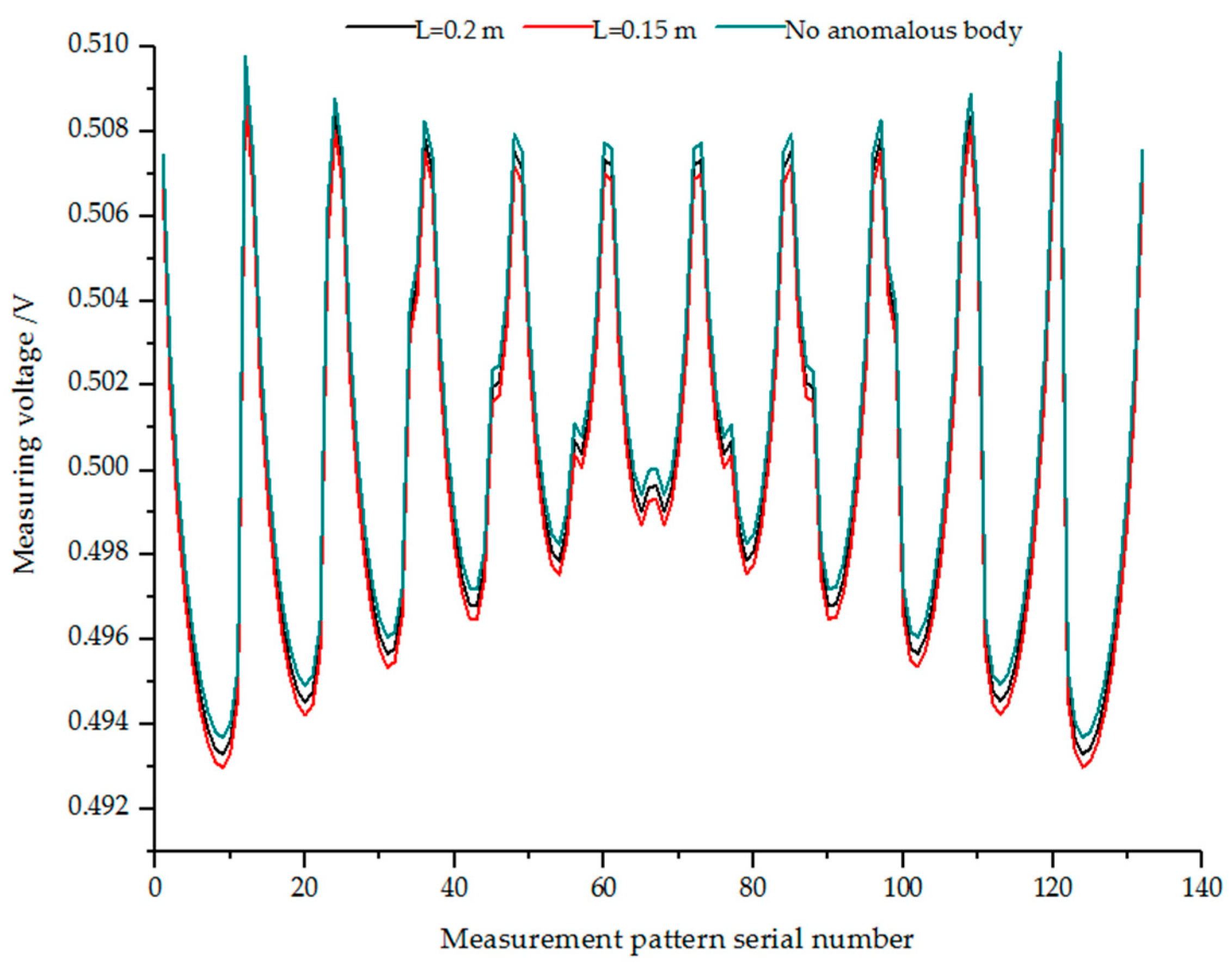

The anomalous body is located at the central axis of the cutterhead, and the distance between its geometric center and the cutterhead is L. The direct current supplied to the exciting electrode is

, and the direct current supplied to the guard electrode is

.

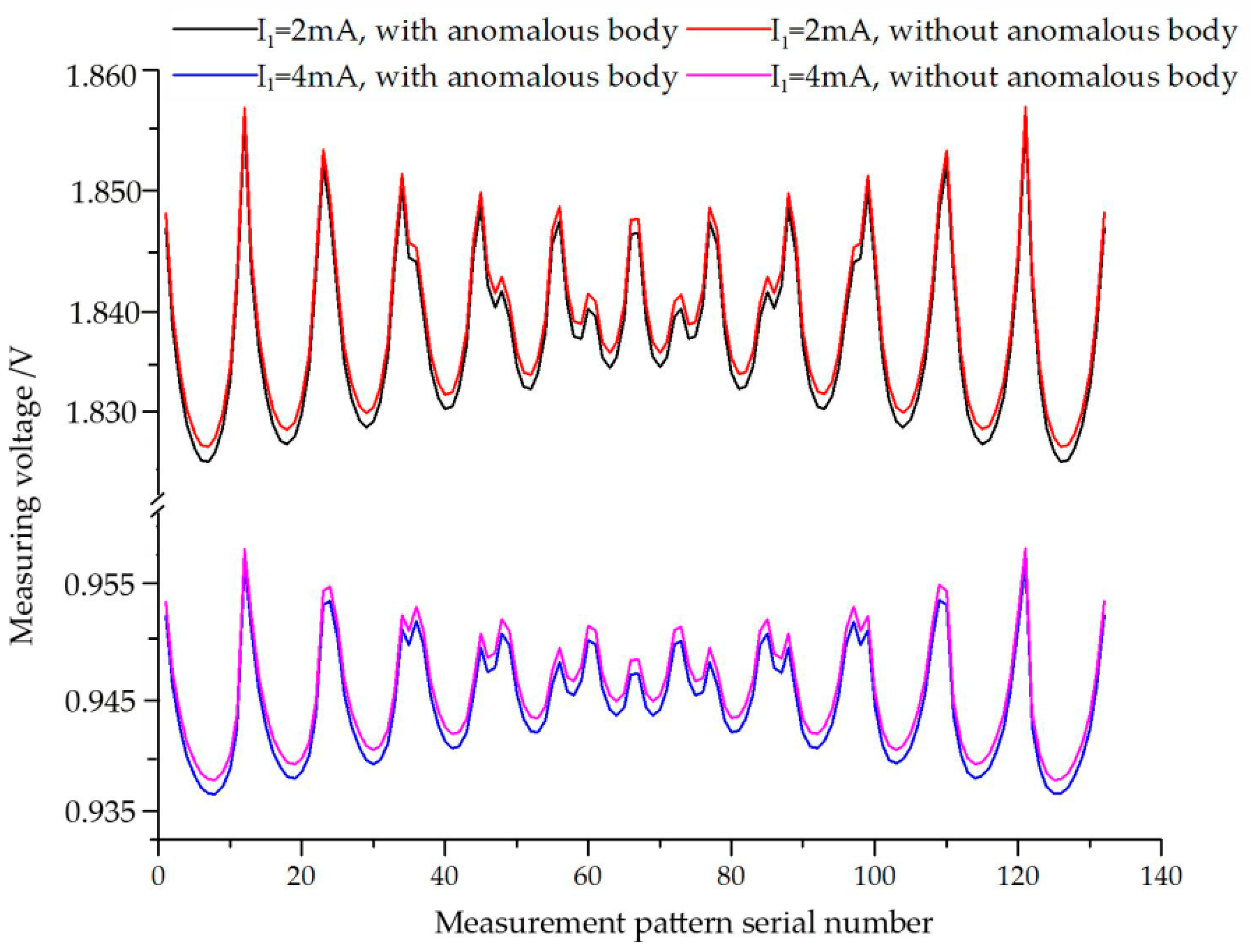

Figure 5 represents the measuring voltage at

1 mA when no anomalous body exists and the measuring voltage when L

0.15 m and 0.2 m, respectively.

Figure 6 represents the measuring voltage at

1 mA,

2 mA and 4mA when no anomalous body exists and the measuring voltage when L

0.15 m,

1 mA, and

2 mA and 4 mA, respectively.

Since 12 measuring electrodes are arranged on the cutterhead, according to the measuring method described in

Section 2.1, 11 voltage data can be obtained by supplying power to one measuring electrode at a time, and 132 voltage data can be obtained by supplying power to these 12 measuring electrodes in turn. As can be seen from

Figure 5 and

Figure 6, when the same amount of current is supplied to the exciting electrode and the guard electrode, the farther away the low resistivity anomalous body is from the cutterhead, the greater the voltage measured by each measuring electrode. When the distance of the anomalous body and the exciting current are constant, the measuring voltage is approximately proportional to the guard current. Since the 12 measuring electrodes are uniformly distributed around the center of the circle on the cutterhead, the voltages obtained from the 1st and 12th, 2nd and 11th, ..., 6th and 7th measurements are approximately equal.

After obtaining the voltage data, inversion imaging can be performed. In actual inversion, as the resistivity change of the elements far away from the anomalous body is slight, it does not need inversion calculation in the model units with very small resistivity changes. Consequently, the number of elements in the model will be greatly reduced, which is helpful to improve the inversion speed. According to the geometric dimensions and material properties of the physical model, a virtual ground electrode model is established as shown in

Figure 7. The area in the red rectangular wireframe in

Figure 7 is considered as the inversion target area. The width of the inversion target area is the diameter of the cutterhead of TBM, and the length is the distance between the virtual grounding electrode and the cutterhead.

Assuming that the distance from the virtual grounding electrode to the cutterhead is D.

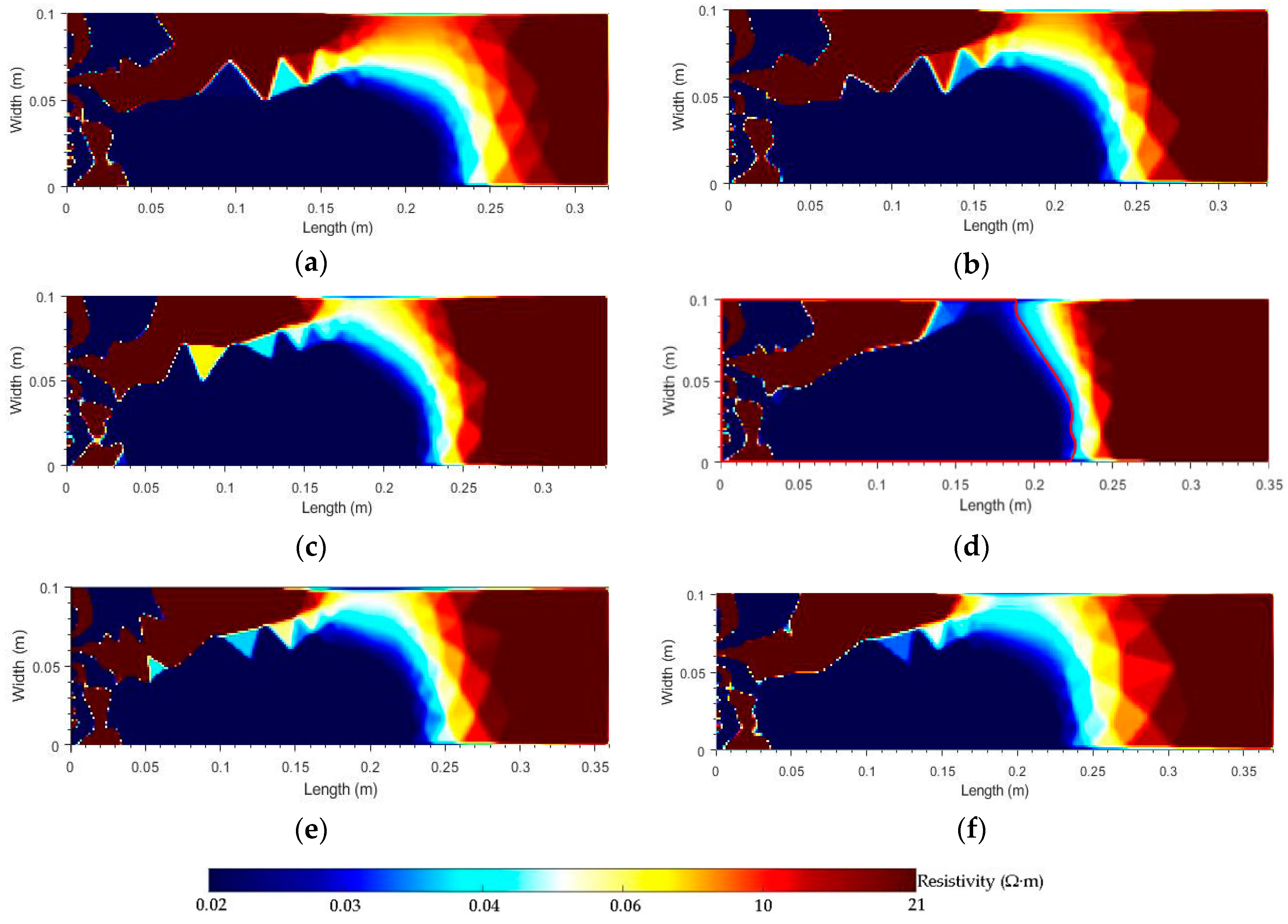

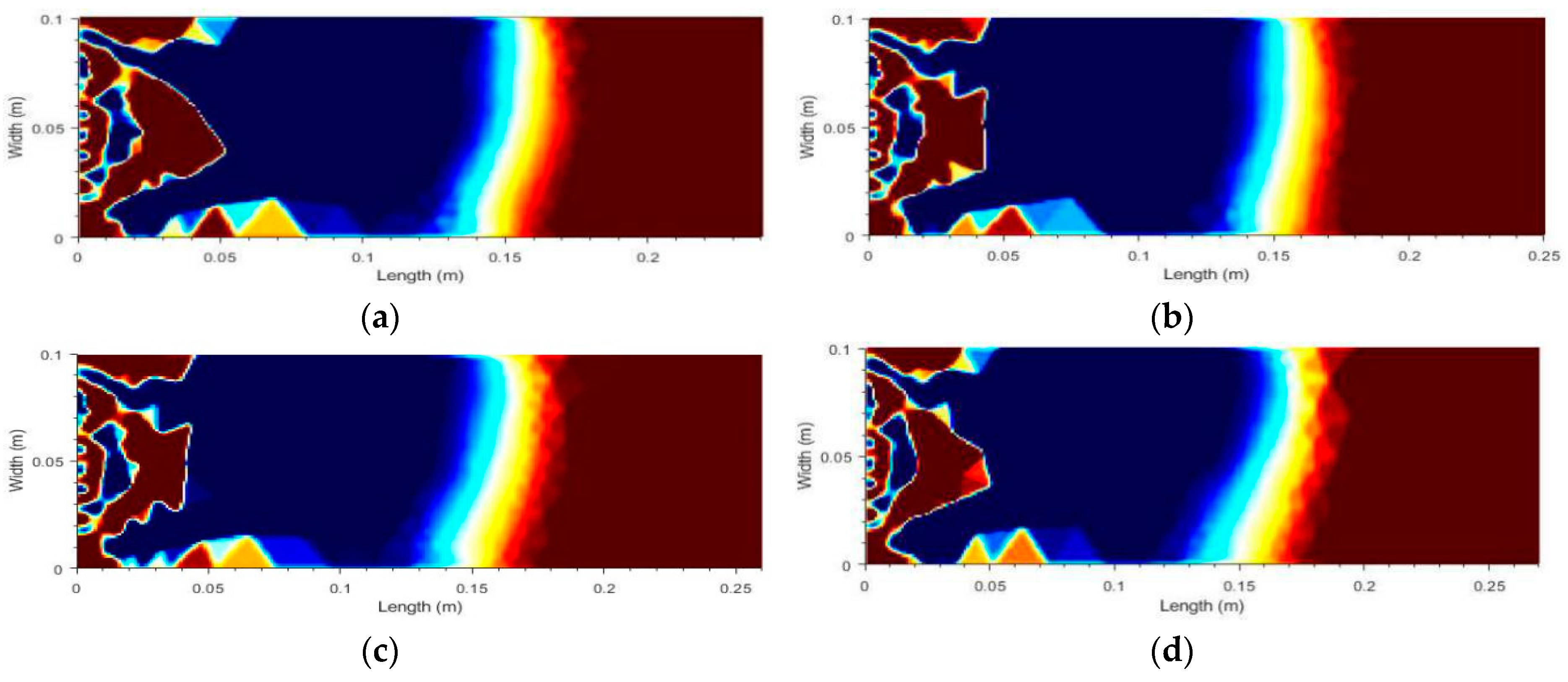

Figure 8 is the inversion results of the anomalous body at different distances when L

0.2 m and

1 mA.

Figure 9 is the inversion results of the anomalous body at different distances when L

0.15 m and

1 mA.

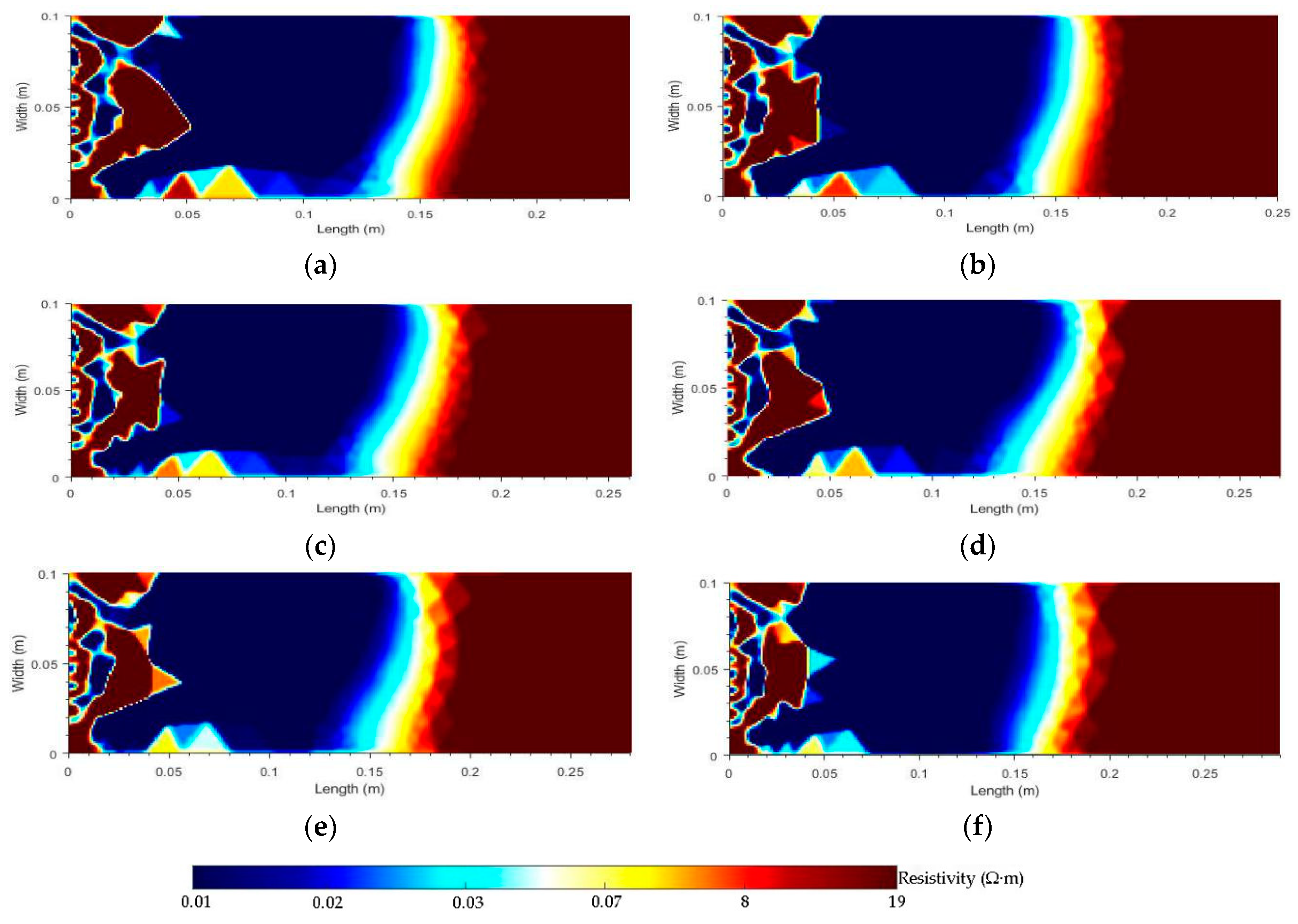

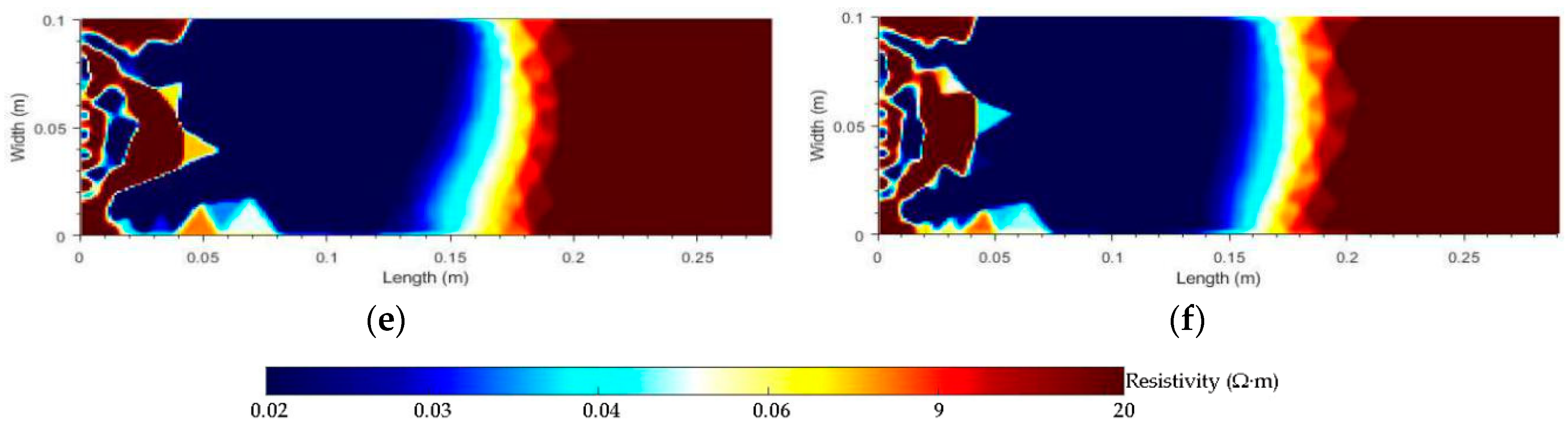

Figure 10 is the inversion results of the anomalous body at different distances when L

0.15 m,

1 mA and

2 mA.

Figure 11 is the inversion results of the anomalous body at different distances when L

0.15 m,

1 mA and

4 mA. As can be seen from

Figure 8,

Figure 9,

Figure 10, and

Figure 11, when L

0.2 m,

1 mA and D

0.35 m, the position of the anomalous body in the numerical inversion test is between 0.21 m and 0.23 m, and the relative error of the position of anomalous body in the physical model test is between 1% and 3%; when L

0.15 m,

1 mA and D

0.26 m, the position of the anomalous body in the numerical inversion test is between 0.145 m and 0.16 m, and the relative error of the position of anomalous body in the physical model test is between 0.5% and 1%; when L

0.15 m,

1 mA,

2 mA and D

0.26 m, the position of the anomalous body in the numerical inversion test is between 0.14 m and 0.17 m, and the relative error of the position of anomalous body in the physical model test is between 1% and 2%; when L

0.15 m,

1 mA,

4 mA and D

0.27 m, the position of the anomalous body in the numerical inversion test is between 0.148 m and 0.16 m, and the relative error of the position of anomalous body in the physical model test is between 0.2% and 1%. The position error of the anomalous body in the numerical inversion test and the physical model test is mainly caused by the interference of the electrochemical phenomenon in the water tank to the measuring voltage. The resistivity of the area between the anomalous body and the tunnel face is uneven, as shown in the red wireframe area of

Figure 8d. This is because when the inversion imaging is performed using the virtual grounding electrode equivalent model to replace the original guard electrode model, the measuring voltage in the presence of the guard electrode is used as the priori information of the inversion, which makes the apparent resistivity of the area between the anomalous body and the cutterhead smaller. With the increase of the guard current, the apparent resistivity of the area between the anomalous body and the cutterhead changes more regularly, and the position of the inverted anomalous body are more accurate.