1. Introduction

Railway transportation generates 3.6% of the total CO

2 emissions from the transport sector and constitutes 2.1% of the total transport energy consumption [

1]. Research in this area focuses on producing energy efficient trains by reducing the losses in converting the energy and minimizing train auxiliary consumption [

2]. The main challenge is to reuse the braking energy from the train by feeding it back to the network or storing it for later use [

3,

4,

5,

6,

7,

8]. The braking energy can be stored in stationary or on-board energy storage devices (ESD). The costs of the on-board ESDs may be higher than of way-side ESDs because they have to be embedded on every train instead of being placed at certain stations [

9]. The drawback of the stationary ESD [

10,

11,

12] is that the regenerated energy is sent via contact lines, which results in line losses. These losses can be reduced by using on-board ESDs [

13]. If the ESD is used on-board (distributed ESD), the power and required energy capacity is lower than for stationary ESD (centralized ESD) which results in lower initial costs, making such a solution more practical. An advantage of the on-board ESD [

14] is that in an event of a line power loss, the train is still able to be driven to a safe place allowing passengers to disembark [

15] or to be evacuated from a tunnel in an emergency. Additional advantages of on-board ESD are as follows [

16]:

reduction of peak-power demand and AC power supply of traction substations;

reduction of energy losses in catenary;

usage of a specific train’s on-board ESD by other trains;

reduction of maximum currents taken by trains from catenary (reduction of voltage drops in rails and stray currents);

reduction of over-voltages in a catenary;

opportunity to increase density of trains on the network without modernization of the power supply.

The main challenge in designing an on-board ESD is how to size it correctly as it depends on the vehicle characteristics and line details. The size will affect the payback period of the ESD and its ability to provide a return on investment. To help the designer make the best decision when designing an on-board ESD for a train, a simulation tool is needed. The simulation tool should be simple and efficient to use.

In [

17] the authors developed a simulation model of a single train simulator in Matlab/Simulink with the scope to analyse the performance of a tramway with an on-board ESD. An energy management strategy method is developed for predefined velocity cycles of a tramway. In the model the authors use predefined input power profiles measured in the Seville tramway and successfully determined the optimal size for the ESD. The model limitations are that the input data needs to be measured from the existing functional system, which limits the model functionality to a specific route and train. If a new system is to be designed, a simulation model is needed with the functionality to determine the train power profiles for different route options.

The authors in [

18] propose a Matlab/Simulink model for a metro-train simulator with an on-board ESD to reduce the network power demand and save energy. The Simulink model is interconnected with a physical model of a 3-phase motor-generator and an inverter that generates the current and power profiles for the simulation.

The scope of this paper is to present a simulation tool that incorporates all the requirements to design a functional train model, with an on-board ESD, that can be implemented in a programming language like C++ for its application in a physical rail transport system. The model formulas are presented and discussed in following sections. The accuracy of the train model is affected by the accuracy of the input data provided by the train and ESD manufacturers.

The main contributions of this paper are:

the proposal of a mathematical model and its application for analysis of an electrified urban railway system with on-board ESD; presentation of the simulation tool with its application for finding optimized solution for an on-board ESD that focuses on:

- ◾

reducing the cost,

- ◾

saving energy and improving ESD application effectiveness,

- ◾

considers the benefits due to CO2 emission reduction.

presentation and discussions of conclusions from a case study—application of the developed tool to analyse the effectiveness of installing an ESD on-board trains in a real metro system. This includes a presentation of influence of energy cost—with stabile or a sudden increase in energy prices and current costs of the European Emission allowances considered.

The paper is organized as follows: in

Section 2, the model equations are presented, and the input/output data are discussed together with the model constraints and assumptions. In

Section 3, the model equations are implemented in the programming language C++ describing the program working procedures. In

Section 4, the authors propose a new optimization method for sizing the ESD and reducing the costs. Finally, in

Section 5 a case study has been done for an assumed metro line and different ESD sizes have been analysed. To choose the most cost-effective option, a cost analysis has been made taking into consideration the energy price per kWh in Poland, with a sudden increase expected in 2019. A method has been proposed for the recuperation of train braking energy to improve the energy efficiency of the traction supply system. This gives additional environmental benefits by reducing the CO

2 emissions, what presents benefits in a decrease of European Emission allowances for CO

2 emission. Thus, return of the investment can be improved. The conclusions resulting from the work are presented in

Section 6.

3. Software Implementation

The simulation tool (Modeltrack) was created in the ‘DEV C++’ [

24] program. Modeltrack simulates a route of 6.9 km with seven train stations and on-board ESD in less than 1 s of a computer operation (650 s route time). The program creates a main object (MO, a train) with properties taken from input files and sets its initial parameters (

Figure 1). The program prepares two loops serving the route based on input data. First loop chooses the line by identifying the starting and finishing station. The second loop is the main loop counting MO data and checking the route between the stations.

In the main loop, the appropriate procedures are carried out sequentially as below:

Step 1: The program checks if it should start braking for to stop at the station—the procedure is to calculate trains’ braking distance from the current position. The procedure is performed when target velocity at the current position (needed to stop at the station) and actual velocity at the current position are different, then MO starts braking to meet its new target velocity. The acceleration reference value is recalculated in function of the line limitation (train running resistance) and train tractive effort [

25].

Step 2: The program checks if it should change the target velocity—the procedure takes place when the train has not yet started braking for the next stop or its velocity at a given moment of the route is 0. The procedure covers checking the current velocity restriction on the route from the input data, then it calculates at which moment the train will have a new target velocity. If the train is travelling on a line section with no velocity restriction the program will assign an appropriate target velocity.

Step 3: Update of the data responsible for the MOs’ resistances to motion—the procedure checks and calculates the current horizontal and vertical resistance acting on the MO. Therefore, new values of acceleration and delays are calculated.

Step 4: Counting control function—this sets the MO driving mode, i.e., whether the MO must brake (T2), accelerate (T1) or drive at a constant velocity (T0):

When the current velocity is smaller than the target velocity—the driving mode is T1;

When the current velocity is greater than the target velocity—the driving mode is T2;

When the current velocity is equal to the target velocity—the driving mode is T0.

Furthermore, the function calculates the use and loading of the ESD and the remaining MO values according to current data: energy, power, forces, current, time and prepares the output units value.

Step 5: Control of mean and total values—the program sums up the route values necessary to calculate the mean and total values.

The main loop is performed every meter until the train reaches the end station after its completion the program assigns the calculated values to a “csv” file type. The program calculates when the train needs to start braking to stop at the stations, it does this with an error of approximately ±2 m.

5. Case Study

The proposed ESD optimization techniques have been used for a case study on an assumed metro line, modelled in Modeltrack. The tested train is equipped with on-board ESD with a SC and no energy flow control was considered, the ESD charges from the network until between 100% and 50% of the capacity.

Table 1 presents typical train parameters used for simulation purposes.

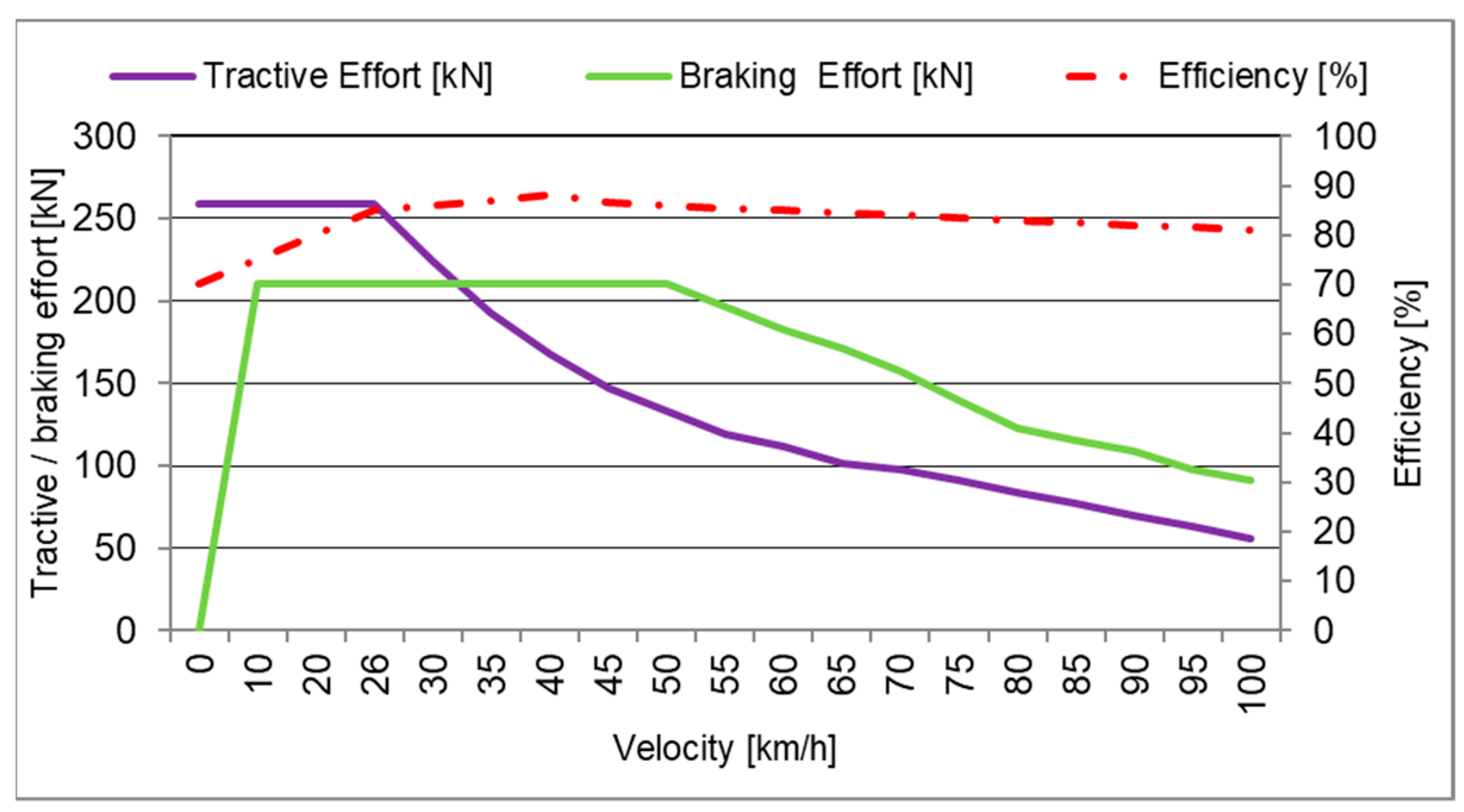

Figure 2 presents the assumed train tractive effort, braking effort and efficiency curves as a function of velocity. It can be noticed from

Figure 2 that the motor efficiency depends on the velocity of the train.

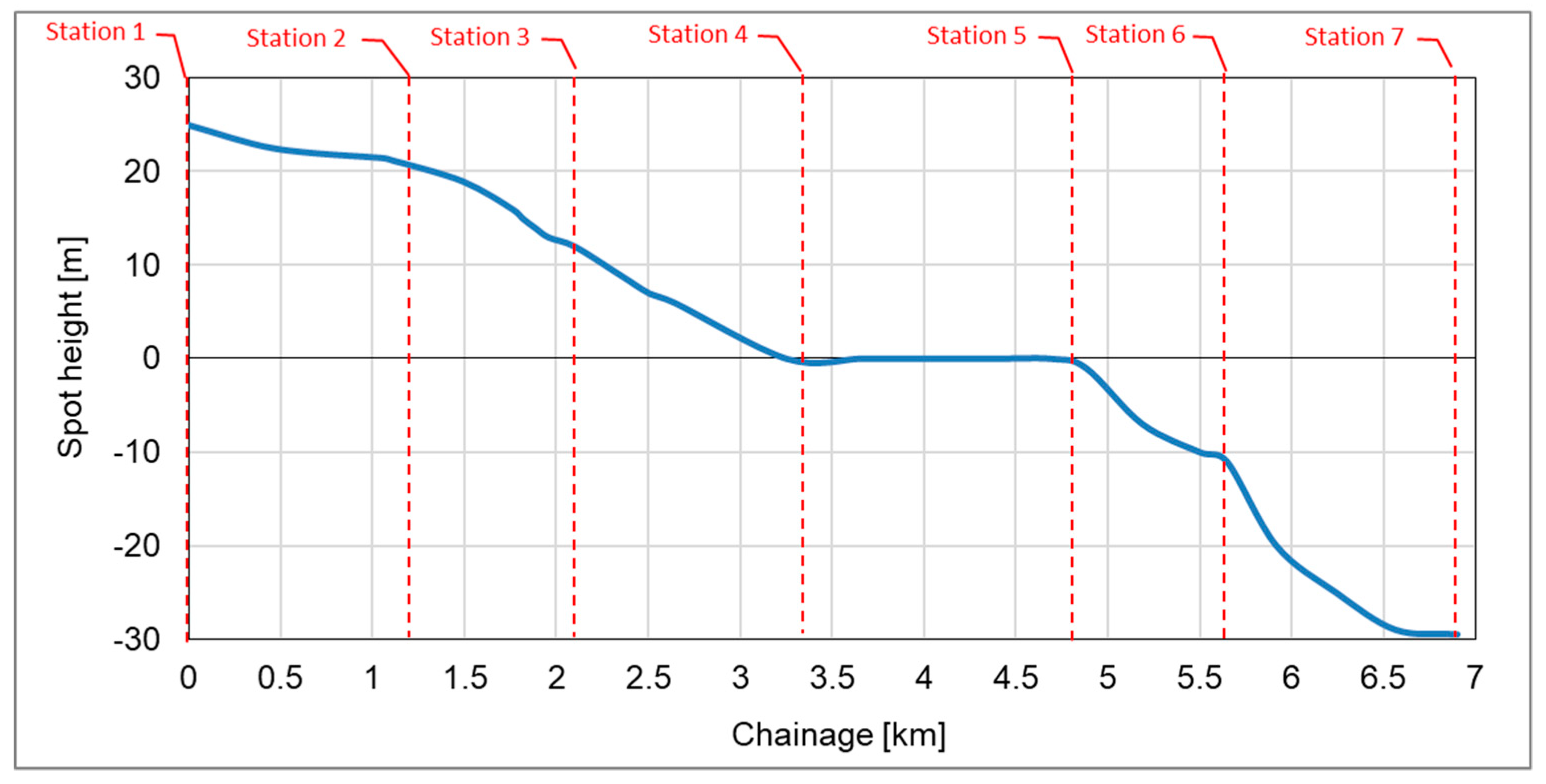

The proposed metro route gradients, stations and chainage are presented in

Figure 3.

For the simulation purposes it has been considered that the train is equipped with type BMOD0063 P125 B08SC modules manufactured by the company Maxwell Technologies (San Diego, CA, USA). The module parameters are: 125 V nominal voltage, 140 A continuous current, 1900 A maximum current, 144 Wh energy capacity and 61 kg mass [

27]. To achieve 750 V line voltage, 6 SC modules should be connected in series. The minimum SC voltage for a DC/DC converter to operate should not be less than 1/3 of nominal SC voltage (minimum 250 V). The SC cells suffers degradation over time, caused by current, temperature and other factors which influence the aging process (the capacity decreases and the internal resistance (ESR) increases). The aging process reduces the SC capacity by approximately 20% during the lifetime according to [

28]. The SC is capable of charging and discharging a high amount of energy in a short period of time, which may influence the overall lifetime if the maximum current is exceeded [

28].

The dimensions of a BMOD0063 P125 B08 SC module are: length 619 mm, width 265 mm and height 33.3 mm. The train has four motoring carriages and the SC modules are to be fixed on the roof of each carriage.

Table 2 presents three different options to be analyzed for the ESD with SC.

From

Table 3 it can be observed that for an ESD installed on train with four motoring carriages, the total energy capacity is 1.73 kWh for option I, 3.46 kWh for option II and 5.19 kWh for option III.

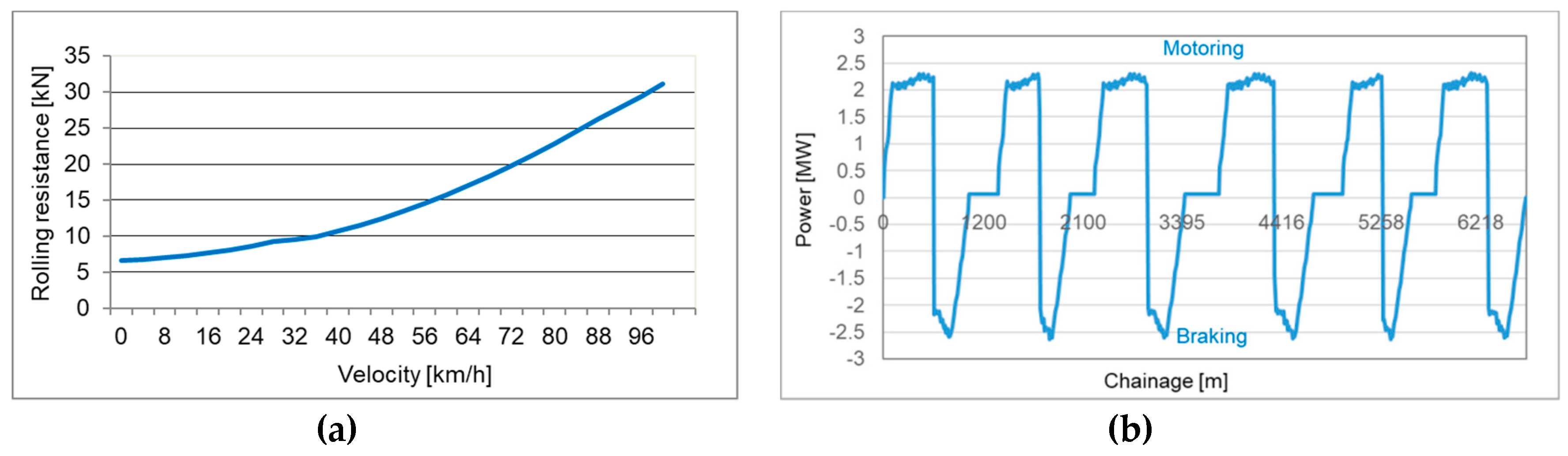

Figure 4 shows the calculated train rolling resistance against velocity and train power for braking and motoring against chainage.

The model validation is focused on assessing the impact of the model input data on the energy saving results. The following input parameters that may affect the energy savings results have been analysed:

different line length between train stops,

train maximum velocity,

train mass considering on-board ESD,

ESD energy capacity,

charging/discharging ESD current,

ESD minimum discharging voltage.

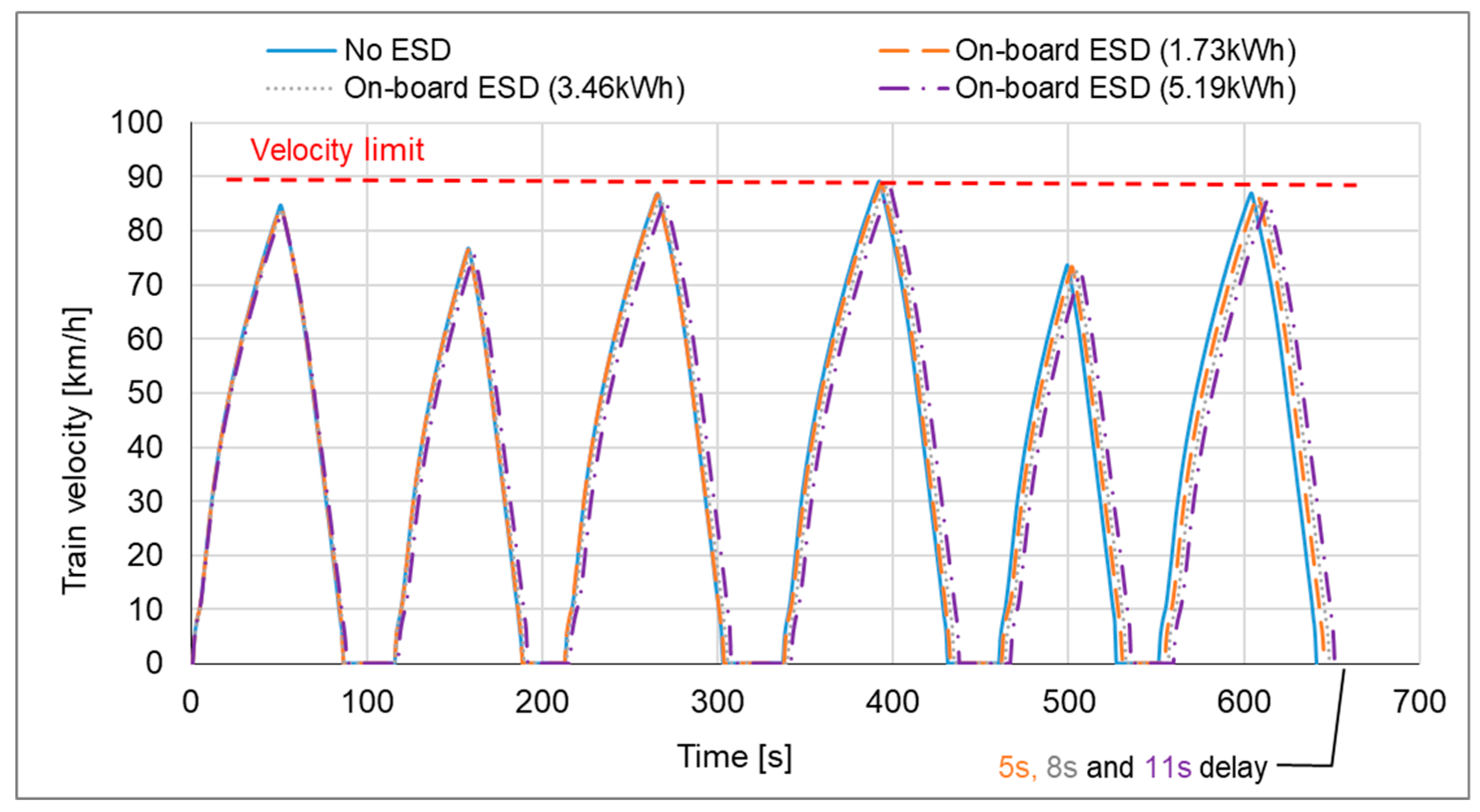

From

Figure 5 can be observed that the ESD size (increased mass) has a significant effect on the train dynamics and the route travelling time. The train equipped with on-board ESD with an energy capacity of 5.19 kWh suffers an increase in weight of 13.2 tonnes (3.3 tonnes × 4 motoring carriages) which causes a total route delay of 11 s. If the ESD energy capacity is decreased to 3.46 kWh (ESD mass of 8.8 tonnes) or 1.73 kWh (ESD mass of 4.4 tonnes) the total route delay decreases to 8 s and 5 s respectively.

Table 4 presents the simulation results including time (T) and average velocity (V

avg) for a train travelling from Station 1 (S1) to Station 7 (S7).

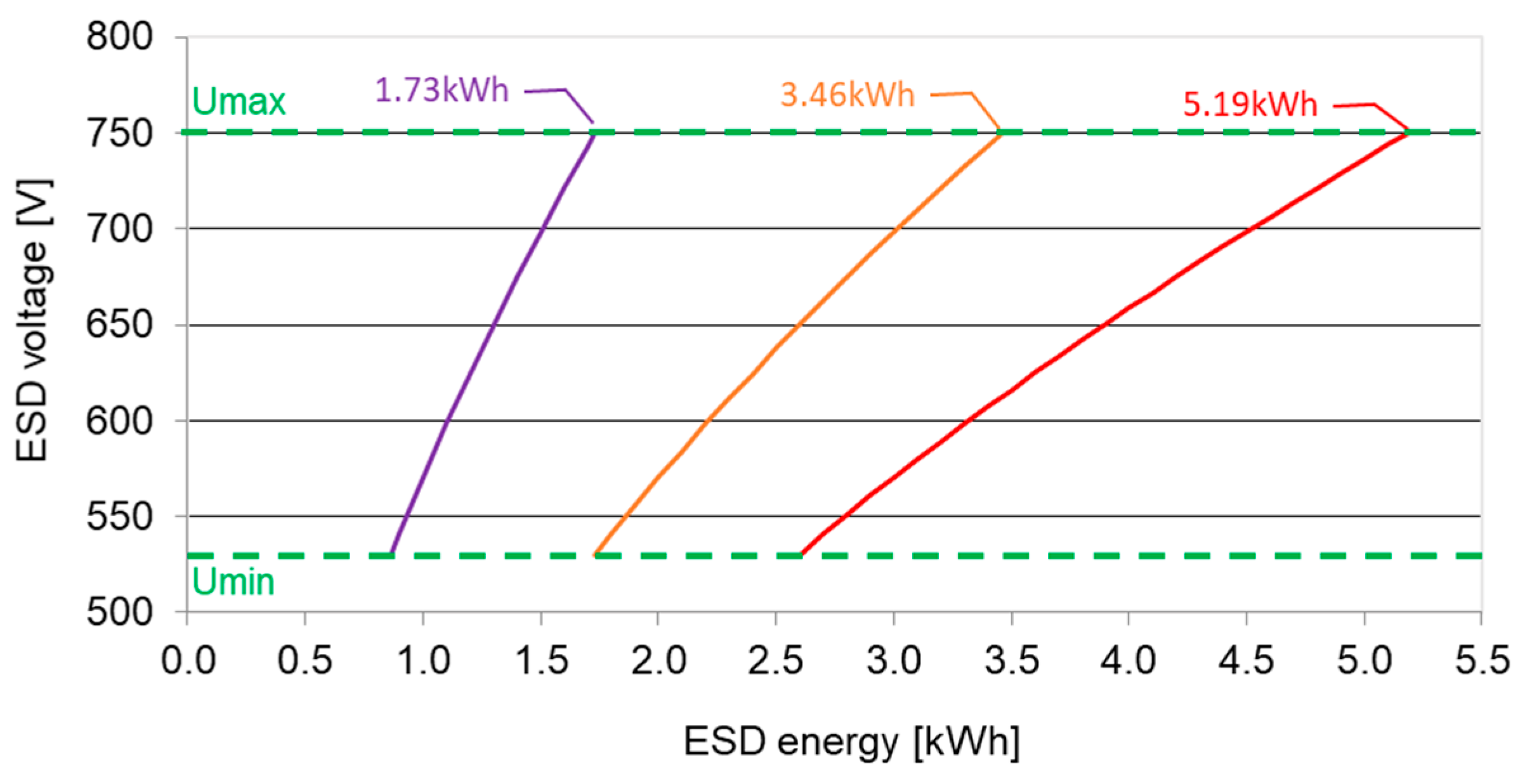

It is considered that for each ESD size, a converter is capable to keep minimum charging/discharging current corresponding to

Table 3. The voltage variation on terminals of SC in ESC is assumed to be between 530 V and 750 V. From

Figure 6 it may be observed that for a 50% DOD (depth of discharge) the ESD needs to discharge to 530 V which results in a 0.8 kWh of used energy for the 1.73 kWh size ESD, 1.8 kWh for the 3.46 kWh size ESD and 2.6 kWh for the 5.19 kWh size ESD.

The ESD efficiency for the SC and DC/DC converter combined is assumed to be 90% considering the energy losses for ESD charging and discharging.

The simulation results in

Table 5 show that if the train is equipped with the on-board ESD the train energy demand is reduced by 5%, 10.3% and 15.7% for the different ESD sizes.

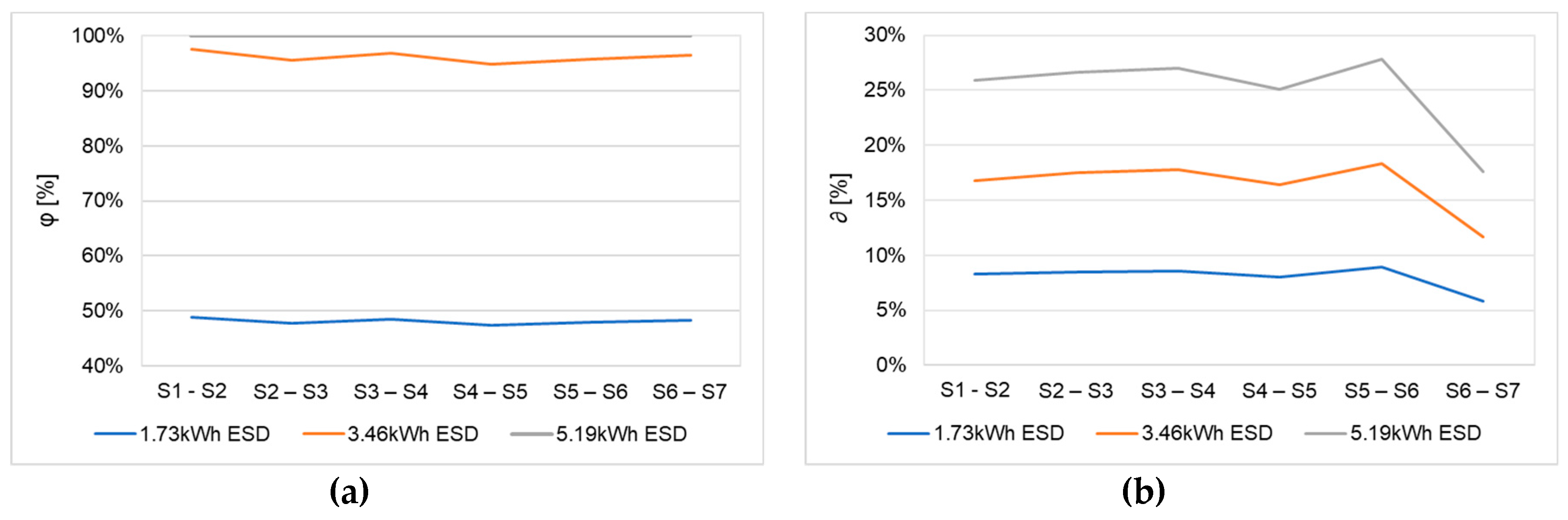

From

Figure 7 it may be observed that the power and energy optimization parameters are different for a train travelling between 2 stations. The power optimization parameter from

Figure 7a shows that to use whole braking power of a train (φ = 100%) the ESD power needs to be at a minimum of 2.6 MW which is achieved for the 5.19 kWh size ESD. The energy optimization parameter from

Figure 7b achieved a highest value of

for 5.19 kWh ESD which equals the amount of energy that is saved from train braking.

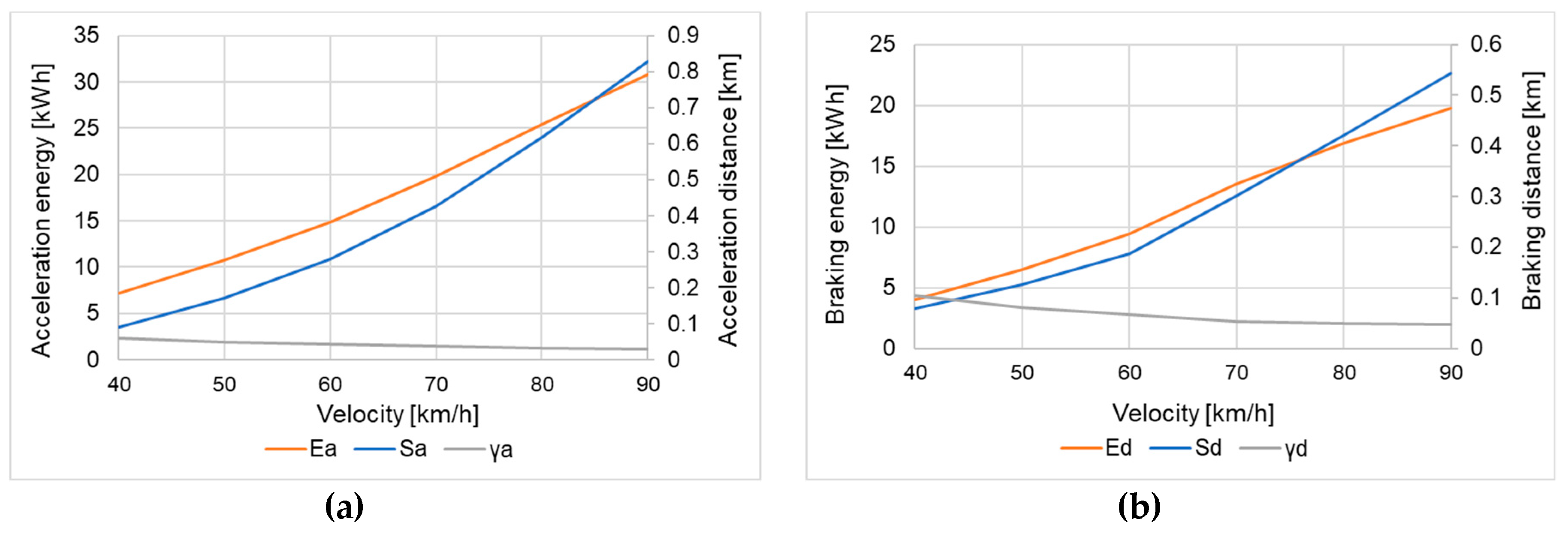

The energy required to accelerate a described train from 0 km/h to 90 km/h equals 30.8 kWh,

Figure 8a. From

Figure 8b it may be observed that the highest braking energy, 19.8 kWh, is achieved for a maximum speed of 90 km/h. It can be concluded that an important parameter to size the ESD are speed limits which affect the available train braking energy.

Table 6 presents assumed train operation parameters calculated for 1 year.

For further analysis the following economical assumptions were established. The price for the BMOD0063 P125 B08 single module

is approximately US

$ 4500, not including the converter and control system. The cost of the DC/DC converter and control system (C

conv) is assumed to be 20% of the total cost of the SC modules per carriage (approximately US

$ 51/kW which is a conservative estimate). In [

29] the authors consider the cost of a 2 MW DC/DC converter with a variable output voltage range between 400 V and 1500 V to be US

$ 69700 (approximately US

$ 35/kW). The ESD installation cost (C

inst) is assumed to be 10% of the total ESD cost. The service life of an SC module is 10 years or 1 million cycles [

28] (the product guaranty is 2 years in the European Union). The ESD maintenance cost for a 10-year period, which will cover the replacement costs of defective SC modules, is assumed to be 25% of the total ESD cost.

Table 7 gathers partial and total costs (C) of installation 3 types of ESD: Option I—1.73 kWh size ESD; Option II—3.46 kWh size ESD and Option III—5.19 kWh size ESD.

For industry purposes the cost of energy per kWh in Poland (θ) is approximately US

$ 0.09 [

30] with an assumed 3% per year inflation rate (δ) which will be added to the cost of energy.

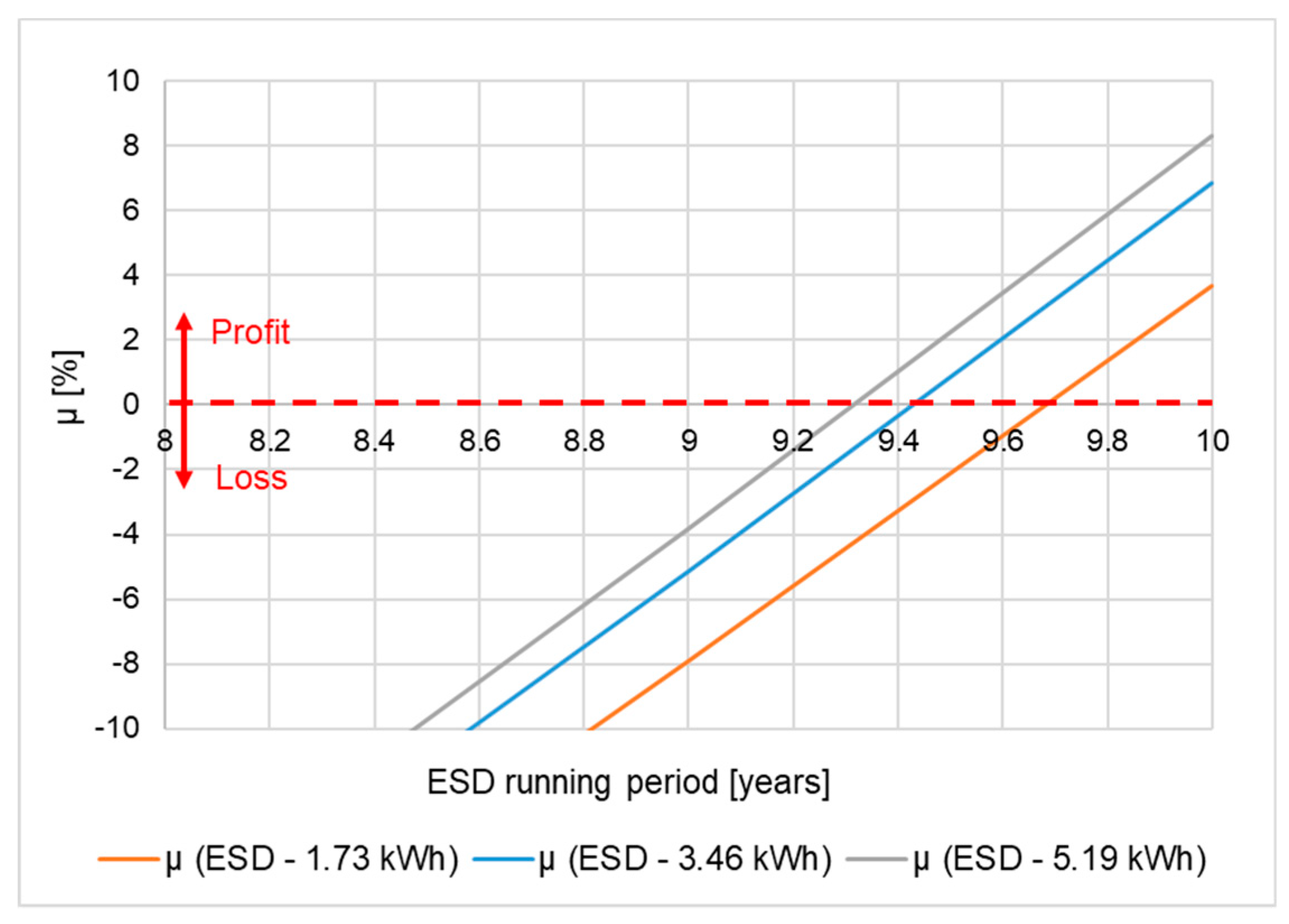

Table 8 presents the ESD costs and profit results during 10 years of operation. The profit coefficient

) from

Table 8 shows that the investment costs will be returned after approximately 10 years. The highest profit is achieved for option III, US

$ 131,000 with a total energy saved of 16.7 GWh.

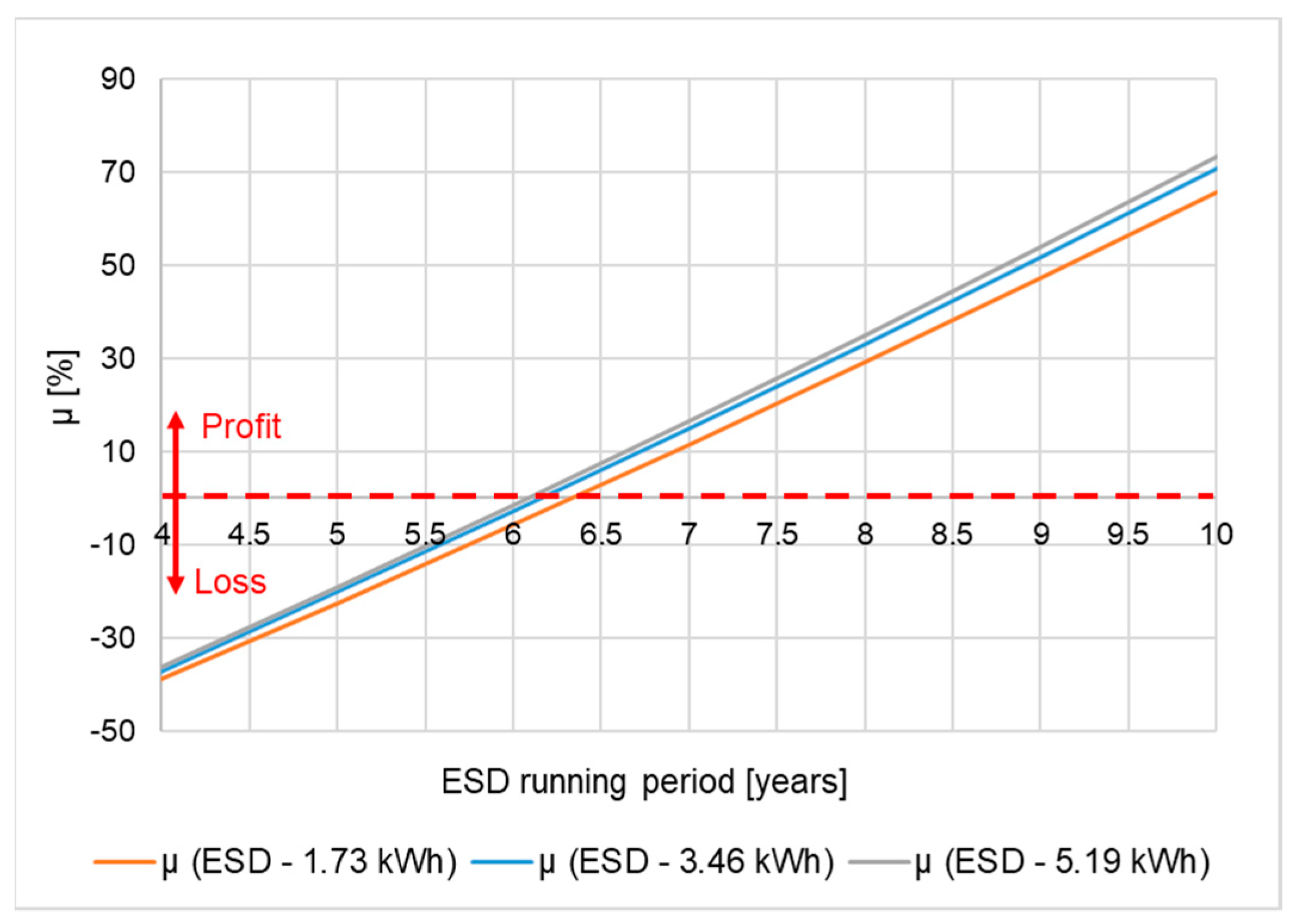

Figure 9 presents the results for the economic efficiency optimization parameter (μ = 4% for option I, μ = 7% for option II, μ = 8% for option III). Profit from the investment is achieved for option I after 9.7 years, for option II after 9.4 years and for option III after 9.3 years.

If we consider all the costs involved in the purchase, installation and maintenance of the ESD the payback period is ca. 9 years, which is close to the service life of an SC module. Further use of the ESD after this period will require replacement of the ESD modules, which will increase the total ESD costs. The on-board ESD needs to be optimally designed if it is expected to return a profit from its use.

In Poland the cost of energy per kWh for transport is expected to rise in 2019 by approximately 60% (new cost US

$ 0.144) [

31] compared with the price from 2018. If we consider the inflation rate 3% per year this can have a large impact on the use of the ESD. Further analyses on the impact of the increasing energy price on the use of on-board ESD for the case study is presented below. The highest profit is achieved for option III, US

$ 1.154 mln with a total energy saved of 16.7 GWh,

Table 9.

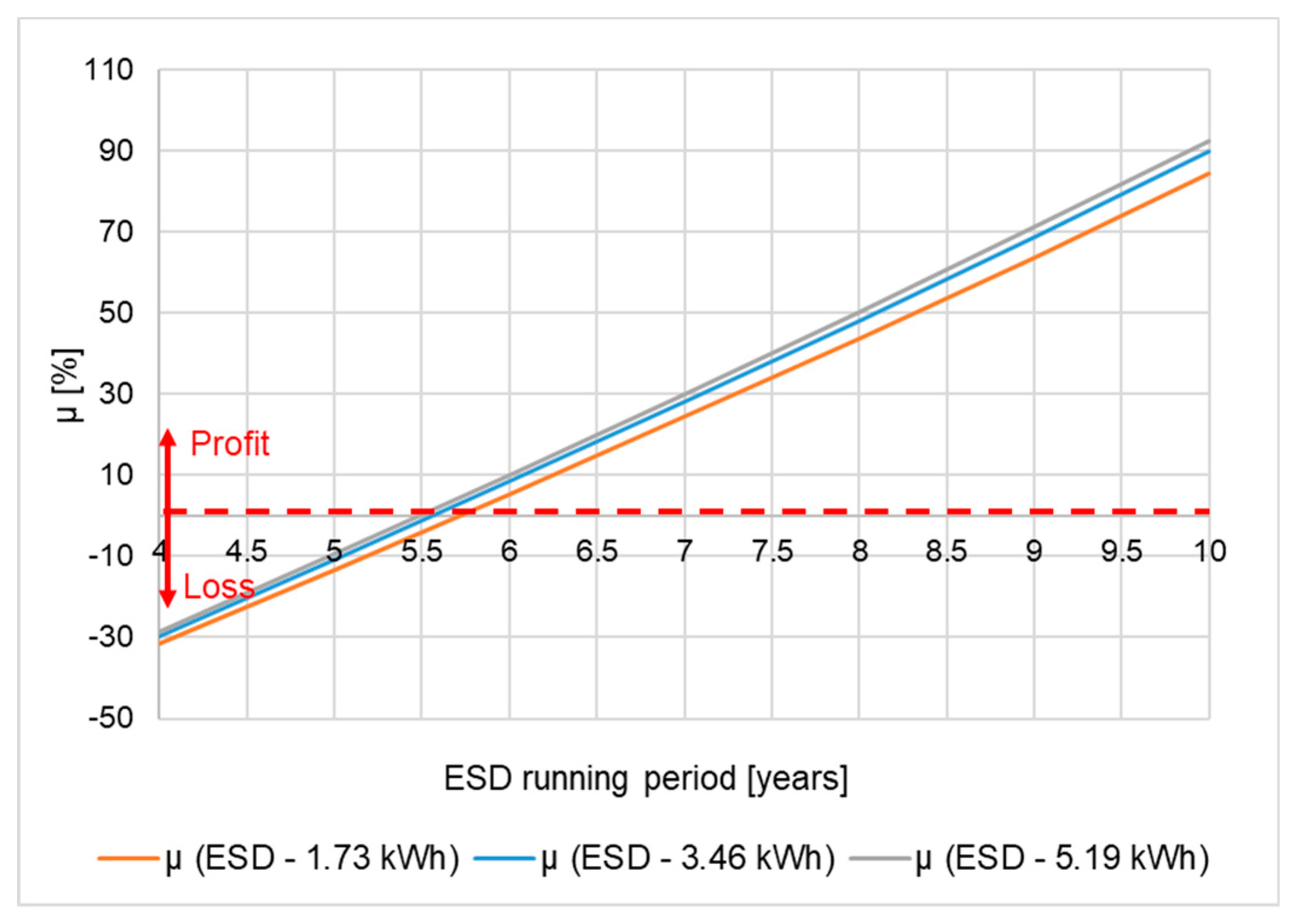

Figure 10 presents the results for the economic efficiency optimization parameter for the new energy price (μ = 66% option I, μ = 71% option II, μ =73 % option III). Profit from the investment is achieved for option I after 6.4 years, for option II after 6.2 years and for option III after 6.1 years.

From

Figure 10 it can be concluded that the new energy prices will reduce the ESD payback period by approximately 3 years to 6 years.

In Poland, for the production of 1 MWh of electrical energy, the CO

2 emissions are approximately 800 kg [

32]. The European Emission allowance on the 13th of February 2019 was 23.28 euro/tonne [

33]. An emission cost of US

$ 22.6/tonne (20 euro/tonne) was considered to calculate the additional profit from reduction of the energy by using an on-board ESD. In

Table 10 the profit from CO

2 emission reduction for a 10 years period of ESD running is calculated.

If the additional profit from the CO

2 emission reduction is added to the total profit, this will make the use of ESD more attractive to the transportation companies,

Table 11. The price of saved energy

in

Table 11 includes the additional profit from reduction of the CO

2 emissions from

Table 10.

Figure 11 presents the results for the economic efficiency optimization parameter for the new energy price, including the additional profit from the reduction of the CO

2 emission (μ = 84% option I, μ = 90% option II, μ = 92% option III). Profit from the investment is achieved for option I after 5.7 years, for option II after 5.6 years and for option III after 5.5 years.

From

Figure 11 it may be observed that the cost of CO

2 emissions has a significant impact on the payback time (reducing it by approximately 1 year) for the on-board ESD.

6. Conclusions

The paper presents an analysis of the effectiveness of an on-board ESD by enhancing the efficiency of braking energy re-use in an electrified transport system. A mathematical model of a train, equipped with the on-board ESD, was described and implemented in a program called Modeltrack simulation tool that was developed in C++. The undertaken simulation results show that an optimal sizing of the on-board ESD could increase effectiveness of energy use, cost savings and decarbonisation of electrified transport due to reduction of CO2 emissions.

Results of the case study undertaken with Modeltrack for an existing metro line, show that the energy that could be saved by the on-board ESD with a SC for a 10-year period is: 5.33 GWh (using ESD capacity 1.73 kWh), 10.98 GWh (using ESD capacity 3.46 kWh) and 16.7 GWh (using ESD capacity 5.19 kWh). With assumed DOD of 50%, the percentage of energy that is saved by the on-board ESD is between 5.79% and 27.83% of the total regenerated energy. It is comparable with data presented in [

14] received from Warsaw Tram Company, where some Pesa trams in service are equipped with ESD of 1 kWh energy capacity, have shown a reduction of global energy consumption by 8–9% due to ESD installation, while recuperating energy sent back to catenary was 24% of that taken from supply.

From

Figure 9, it can be concluded that the most cost-effective is option III with six SC modules connected in series and nine modules connected in parallel with a total of 216 SC modules per train (for four motoring carriages). For the energy price in 2018 in Poland the analysed on-board ESD would return a total profit of 8% (for 10 years of operation) considering the cost of a converter, control system installation and maintenance. With the new energy price expected for 2019 the return profit for option III is 73%,

Figure 10. If the additional profit from the reduction of CO

2 emissions is considered, the profit of the investment for option III is 92% and the payback time is reduced to only 5.5 years (

Figure 11).

The presented technique for sizing the ESD on-board of trains could help to undertake decisions about applying them in a specific transport system (depending on: type of trains, route and traffic service). The analysed case study considered additional aspects such as: sudden increase of electrical energy costs (as 60% in Poland in 2019) or CO2 emission reduction (European Emission allowance was over 23 euro/1 t of CO2 on the 13th of February 2019). These aspects could significantly improve the effectiveness of installations of distributed ESD on-board trains and reduce the period for a return on the investment.

The model may be used for analysis in the DC light transport (e.g., metro, tram) to optimize the design of an on-board ESD, to assess the energy savings and technical and economic effectiveness of the solution taking into account: type of the urban transport systems, traffic, energy costs, environmental aspect (CO2 reduction). Further research with application of the proposed model and its development will include: comparison analysis of effectiveness of on-board versus stationary (installed in power supply system) ESD, application of different types of hybrid ESD and influence of different algorithms of ESD control on power supply functioning in normal and emergency situations.