1. Introduction

Serious environmental challenges and a plummeting international oil price facing the market, have put the offshore oil industry in a dilemma: how to mitigate the CO

2 emissions from offshore oil projects without increasing the capital expenditure significantly [

1]. In Norway, about 62% of the carbon dioxide emissions in 2012 came from offshore oil extraction and processing tasks [

2]. As a result, a lot of efforts have been put into developing energy efficient technologies to mitigate the CO

2 emissions in offshore oil facilities. In general, the most feasible current ways to realize CO

2 emission reduction in a cost effective way include: (i) improving the efficiency of energy generation and utilization, (ii) the use of offshore energy generation technologies [

3].

The production system is a crucial part of offshore platforms and it is energy-intensive. Energy management is necessary to ensure the stability and safety of production system operations [

4,

5]. The fluids are extracted from wells and transported to the production system through manifolds. In the production system, oil, associated gas, and water in streams are separated and treated before being exported to the shore or released into the environment. Besides, the integrated energy system provides electrical power and heat required for operating the extraction, separation, and compression. Gas turbine generators and gas/oil fired boilers were employed as the electric and thermal energy sources, and the associated gases (

AS) was used as fuel for the generators [

6]. During oil production, the light hydrocarbons and other impurities dissolved or dispersed in the heavier hydrocarbon compounds (crude oil) are separated and released from well fluids under low-pressure conditions. This is called the associated gases. A flare gas recovery system (FGRS) is designed to minimize the amount of associated gas being flared either as a means of disposal or as a safety measure to relieve gas pressure. The methods used by FGRSs include gas collection, compression, electricity generation, and gas to liquid conversion, etc. For example, the associated gas can be injected to the existing gas distribution networks after exported from an offshore location, or it can be converted into electricity in offshore platforms and then transmitted to shore [

7]. If the volume of associated gas with oil production is high enough, it can also be liquefied for sale [

8,

9]. Additionally, considering that approximately 50% of the total energy supplied to offshore oil and gas platforms is lost through exhaust flues, waste heat recovery units (WHRU) are employed to reuse the heat in the waste gas [

10]. In [

11], a supercritical carbon dioxide Brayton cycle was tested in a WHRU, and it performed better for energy-saving and emission mitigating than a simple Brayton cycle. In [

12], a comparison between a single loop and a dual loop WHRU was conducted, and an organic Rankine cycle (

ORC) was recommended to be added into the single loop WHRU to improve its efficiency. In addition, a multi-objective optimization method was proposed to select the working fluid of an

ORC, considering efficiency, weight and space of an offshore platform, and the NSGA-II method was used to solve the optimization model [

13]. A detailed mathematical optimization model for a WHRU based on

ORC was presented to calculate the steady-state operational point of the WHRU, and the SQP solver was used to solve the model [

14]. Design, sizing, and operating of the multiple components of such systems are generally challenging, especially when multiple conflicting objectives are aimed. Optimisation techniques based on meta-heuristics population approaches such as the Genetic Algorithm and Particle Swarm Optimisation were used to deal with these issues [

15,

16]. In general, the

ORC was considered as a promising technology to utilize the medium-quality-heat sources with highest recovery efficiency in offshore oil industries [

17,

18]. Recently, carbon capture and storage (

CCS) systems have been installed in offshore platforms for further mitigation of CO

2 emissions. In [

19], the Exergy balance of two platform configurations, with and without

CCS, were assessed and the potential opportunities were found for improving the efficiency of the

CCS section. In [

1], a

CCS with the pre-treatment and post-combustion units was proposed, which reduces the CO

2 emissions of a platform in the North Sea by more than 15%. However, as a

CCS itself is an energy-intensive unit, the introduction of a

CCS reduces the CO

2 emissions, it also causes the deterioration of the energy efficiency of offshore platforms [

20].

It is noted that new technologies such as WHRU and

ORC are not widely implemented in offshore oil extraction and processing platform, and the implementation of CO

2-capture systems has not be proven offshore except for gas processing with high CO

2-contents. To explore the feasibility of these new technologies in marine engineering, this paper introduce the various abovementioned technologies into the Bohai oil and gas platform to modify the structure of the offshore platform energy system. Simultaneously, there are significant discrepancies between the available energy and the power demands. Hence, it is necessary to coordinate the use of various energies, i.e., electrical power, heat, associated gas, and imported fuel (diesel in most methods). In this paper, the energy system of the offshore oil extraction and processing platform is regarded as an Integrated Energy System (IES) for considering the coupling of multiple forms of energy [

21].

At present, many researchers have addressed the problem of the uncertainty planning of IES worldwide [

22]. A bi-level fuzzy programming method was developed in [

23] for energy systems planning and carbon dioxide mitigation under uncertainty, and the linear ranking function the first of Yager was used to solve the model. In [

24], a bi-objective mathematical model was presented for energy hub scheduling with consideration of preventive maintenance policy to determine the preventive maintenance cycles and the best strategy to allocate hub energy capacity under different demand scenarios, and CPLEX Optimizer of the General Algebraic Modeling System (GAMS) was used to solve the model based on the Epsilon-constraint method. The concept of probabilistic power flow in power systems was extended to IES because of the coupling relationship between power systems, thermal systems and natural gas systems [

25,

26]. A chance constrained and reliability programming optimization model was proposed for solving the long-term integrated energy planning problem and their performances in [

25], and then a chance constrained planning approach was proposed to minimize the investment cost of integrating new natural gas-fired generators, natural gas pipeline, compressors, and storage required to ensure desired confidence levels of meeting future stochastic power and natural gas demands in [

26]. A two-stage stochastic multi-objective optimization algorithm was proposed to solve the optimal capacity of the cogeneration system under uncertain energy demand, the “greedy” approach was used to solve the problem in [

27]. A robust optimization method incorporating piecewise linear thermal efficiency and electrical efficiency curves was proposed to deal with the uncertainties caused by energy supply, load prediction and equipment nonlinear efficiency, and a Monte Carlo simulation was adopted to sample random variables to demonstrate the effectiveness of the uncertain set in the robust optimization model in [

28], and a two-interval mixed integer linear programming model and its solution algorithm were proposed for planning integrated energy-environment system in [

29]. The uncertainties of energy supply, energy coupling, and load fluctuation have been considered in the mentioned papers. However, only energy systems are considered in most of studies, but the energy supply system is closely linked with the production system in offshore oil and gas production platform, and a closed-loop relationship between energy flow and material flow can be revealed. Due to the uncertainty of the production system is the most important factor for the offshore platform, it is essential to describe the relationship between energy supply system and production system, and explore the impact of this uncertainty on the planning of offshore platform energy supply systems, which are the innovations of this paper seldomly studied.

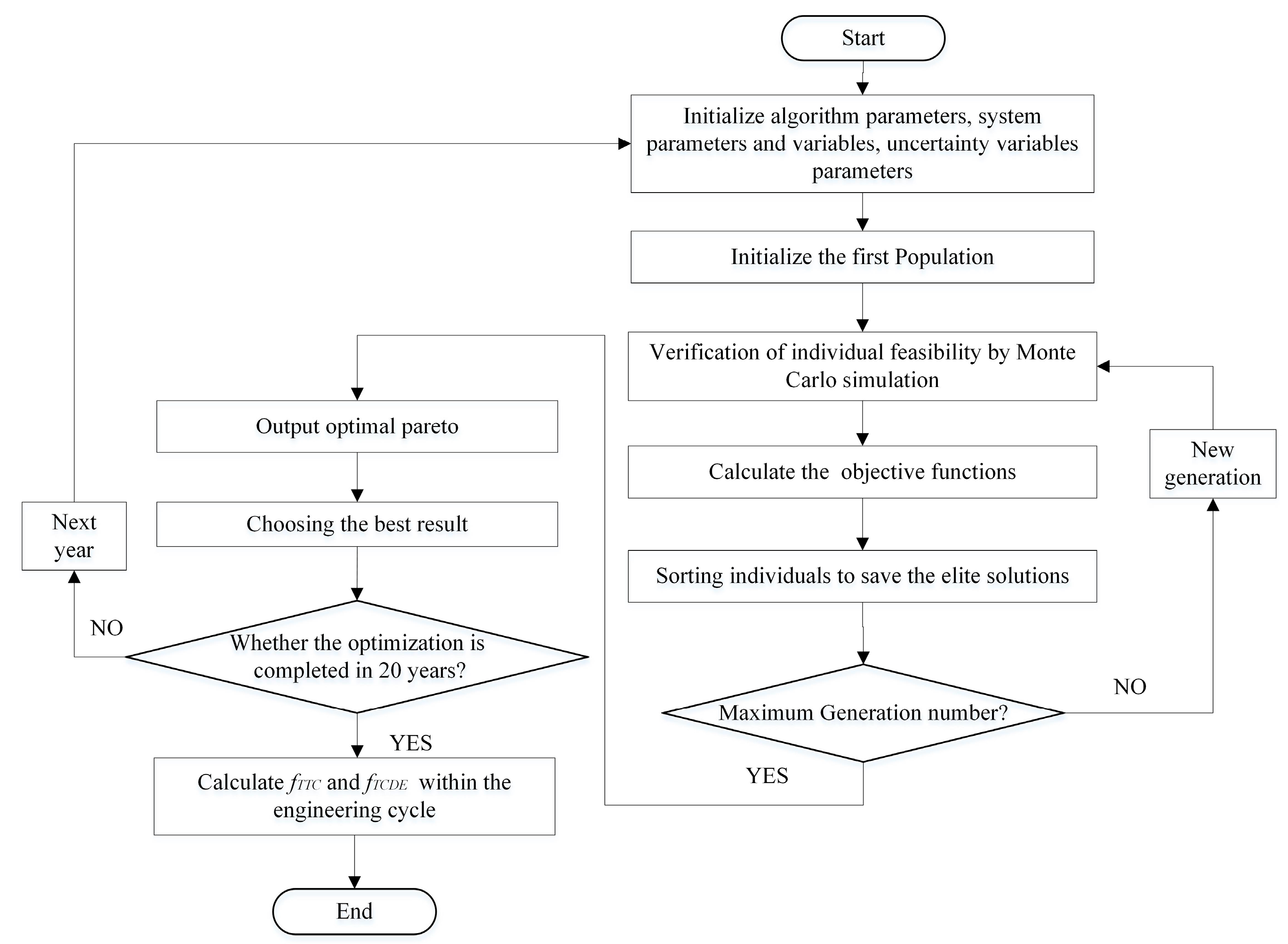

The main contributions of this paper are as follows: Firstly, based on the structural coupling features between IES and production system of offshore oil and gas platform, a generalized energy and material flow model is proposed, which describes the multi-energy coupling relationship and correlation between energy system and production system. The IES discussed in this paper includes multi-fuel gas turbines, waste heat boilers, ORC, CCS and power storage. Secondly, the energy-material flow and conversion relationship in production systems are quantitatively calculated based on enthalpy analysis. Thirdly, considering the energy-material balance constraints and the uncertainties of production system, a multi-objective stochastic planning model for the offshore IES is established, which takes economics and environmental protection into consideration. A Monte Carlo simulation based Non-dominated Sorting Genetic Algorithms II (NSGA-II) is proposed to solve the model. Finally, the validity and feasibility of the proposed methodology are demonstrated through an offshore oil and gas platform in Bohai, China.

This paper is organized as follows: the specific properties of the investigated system architecture and the proposed IES are described in

Section 2, followed by a generalized energy and material flow model and its mapping details in

Section 3.

Section 4 presents the stochastic multi-objective optimization method to plan the IES for the offshore oil project, and

Section 5 discusses the results of the optimization in detail. Concluding remarks are given in

Section 6.

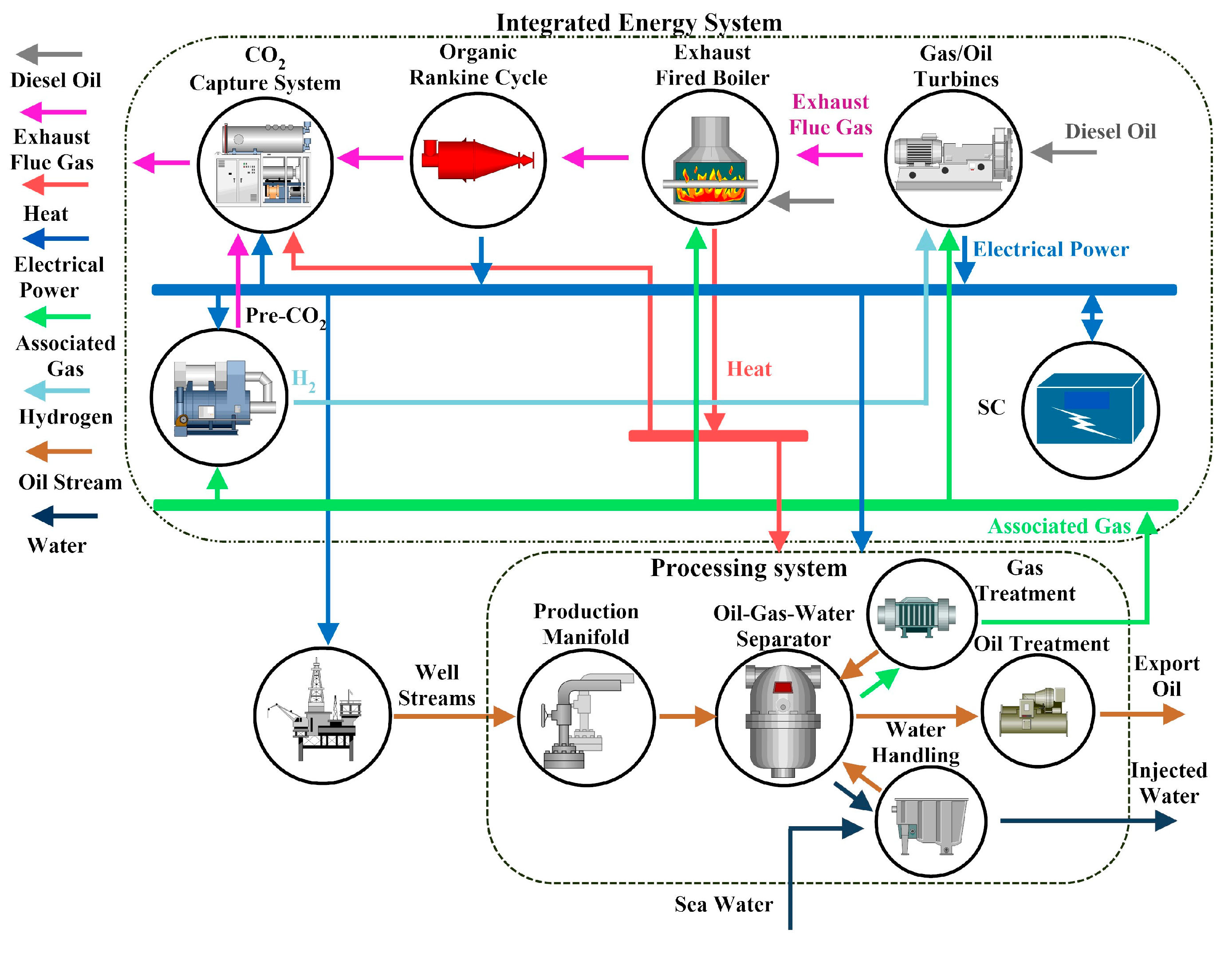

2. IESs for Offshore Oil Extraction and Processing

An existing offshore oil project, which consists of four offshore platforms, including one oil extraction and processing platform, one support and maintenance platform, one oil storage platform and one mooring platform is employed as a reference. The oil extraction and processing platform is also the central power platform which provides power for the other platforms through subsea cables. The platform facilities are characterized by a peak power demand of about 44 MW and a heating demand greater than 12 MW. The temperature range of heat loads is from 50 °C to 120 °C. Two turbines are used to generate power using diesel oil or gas. An exhaust fired boiler uses turbine exhaust with a temperature near 500 °C to heat oil and adjusts its combustion to ensure heat exchanger meet the load requirements. The thermal efficiency of the gas turbines varies from 27% to 32%. The total daily CO2 emissions produced reach about 300–500 tons, and more than 80% corresponds to the operation of gas turbines.

In this study, gas turbines are replaced by co-firing gas/oil turbines which can consume diesel, natural gas, and hydrogen. An

ORC is employed to recover the exhaust heat of the boiler at about 160 °C–220 °C to improve the thermal efficiency further. Therefore, the

ORC and the boiler constitute a heat recovery system of hierarchy, and the higher temperature (from 400 °C to 500 °C) and the lower temperature (from 160 °C to 220 °C) heat can be recovered simultaneously. Moreover, a two-level CO

2 capture unit proposed in [

1] for an oil platform is used to mitigate the emissions. The first level is a Pre-CO

2 capture unit with the structure presented in [

30], where natural gas is converted into hydrogen. The CO

2 generated in the conversion is absorbed by chemical absorption with triethanolamine and the hydrogen is fed to the turbines. The second level is a Post-CO

2 capture unit which is responsible for the carbon capture of the flue gas. A super-capacitor (

SC) based energy storage is used to balance the source and loads.

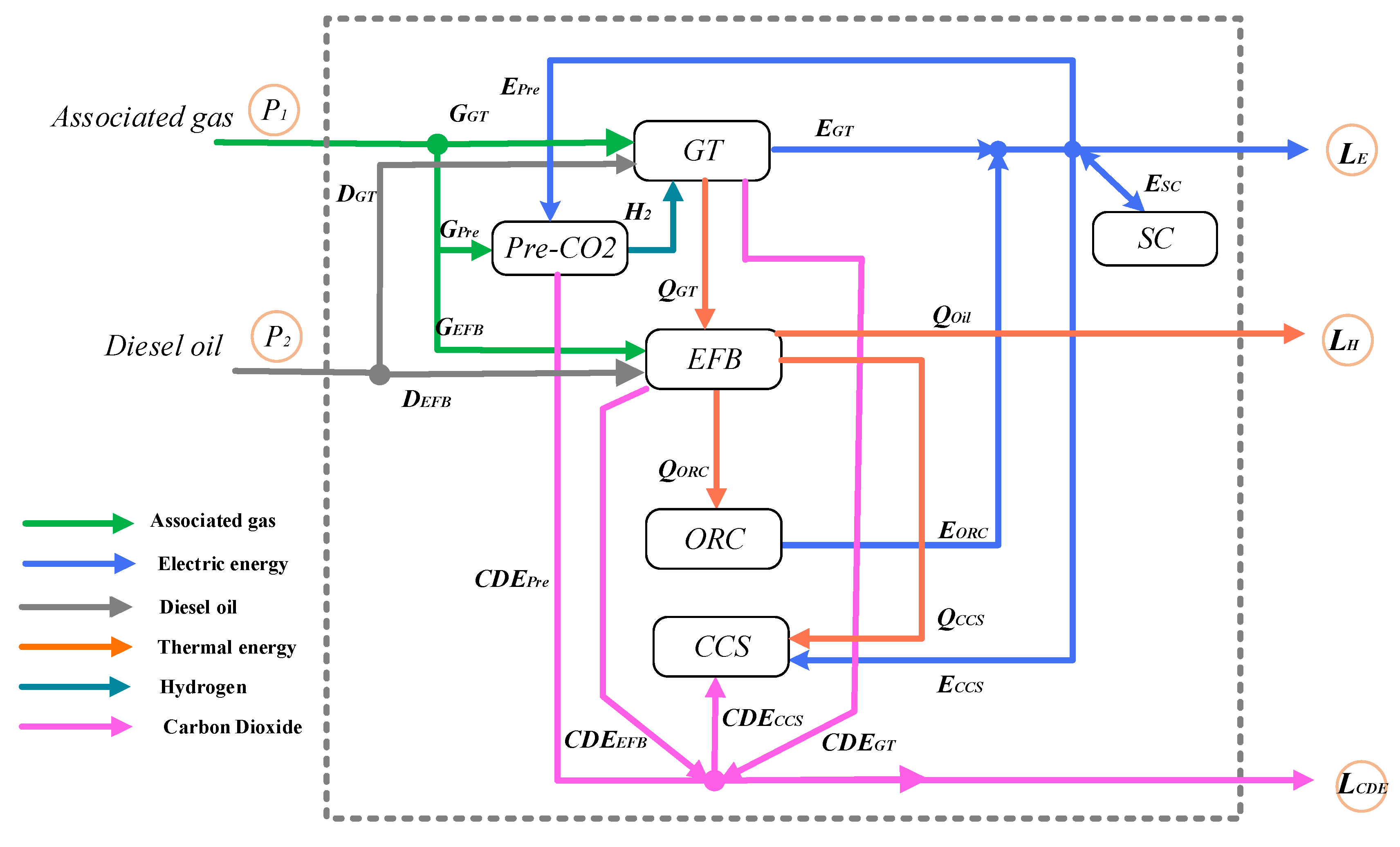

Figure 1 illustrates the proposed IESs and its relationship with the offshore oil extraction and processing system.

3. Generalized Energy and Material Flow Model

Different from multi-energy systems connected to electricity grids, the IESs for offshore oil platforms must run independently. They are sensitive to the fluctuations in extraction and processing systems. As a result, when a mathematic model is employed to describe such an IES shown in

Figure 1, the impact of extraction and processing systems on the electricity and thermal consumption cannot be neglected. Moreover, material flows in addition to energy flows need to be considered in an IES. For example, the process in

Figure 1 consumes the heat and electrical power generated from the IES and handles sea water and oil streams as well. At the same time, the processing system produces associated gas for the IES, which sends the energy to the processing system. Energy and material flow model of such a system can be represented by

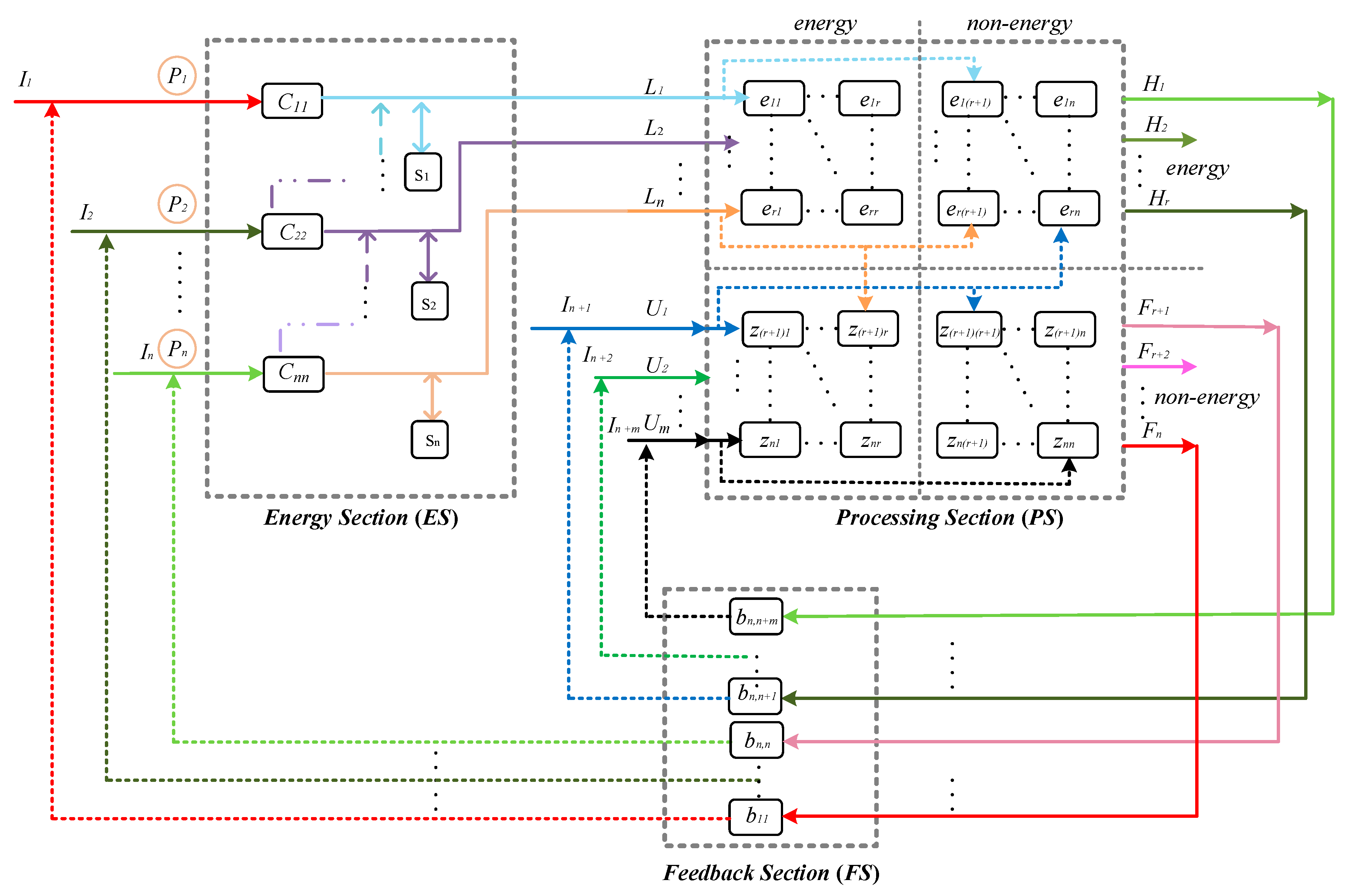

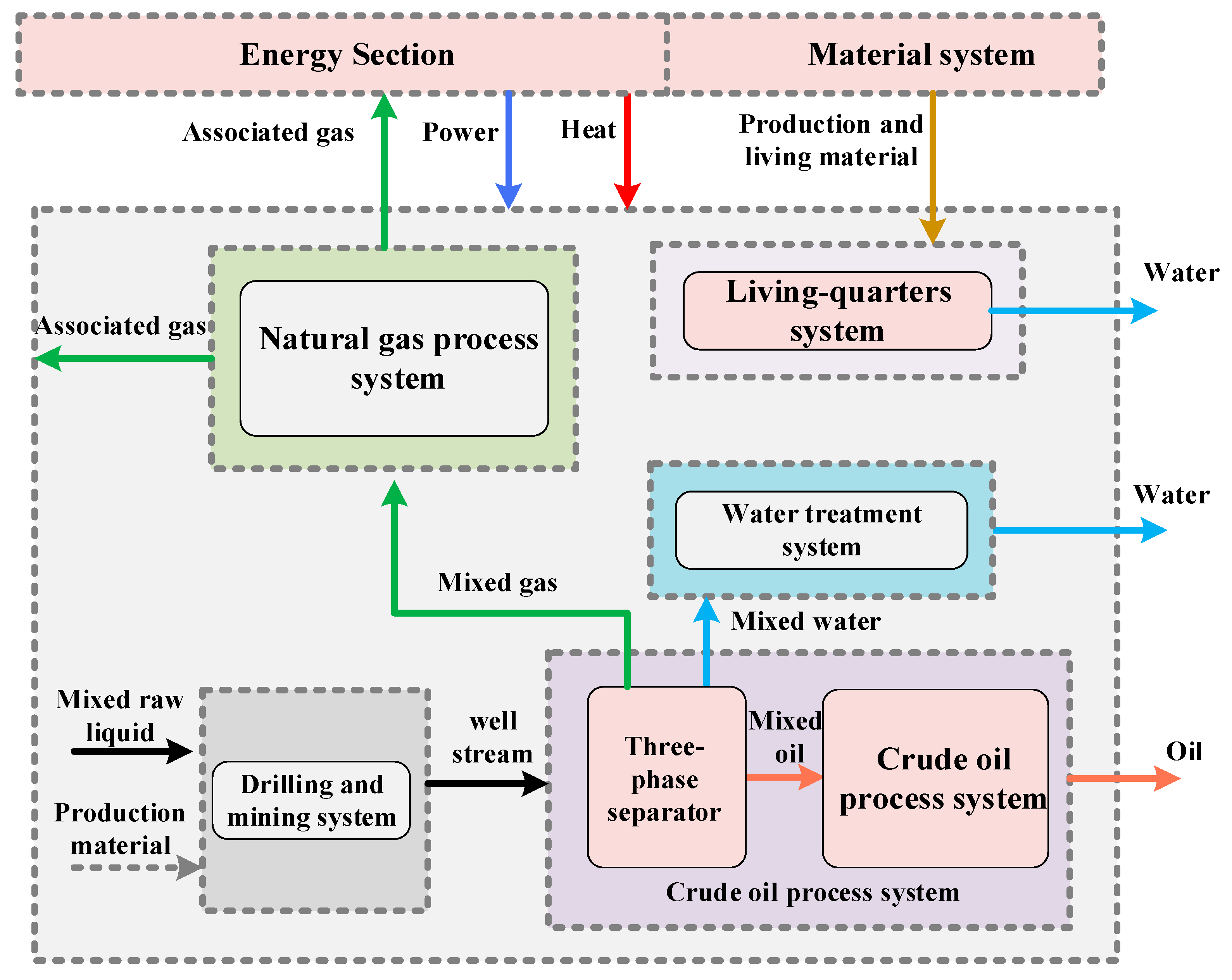

Figure 2.

In

Figure 2, the Energy Section represents IESs, such as the one in

Figure 1. Mathematically, the mapping of energies from the input to the output of the Energy Section can be described by an energy hub model, which provides the essential features of input and output, conversion, and storage of different energy carriers, shown as Equation (1) [

31]:

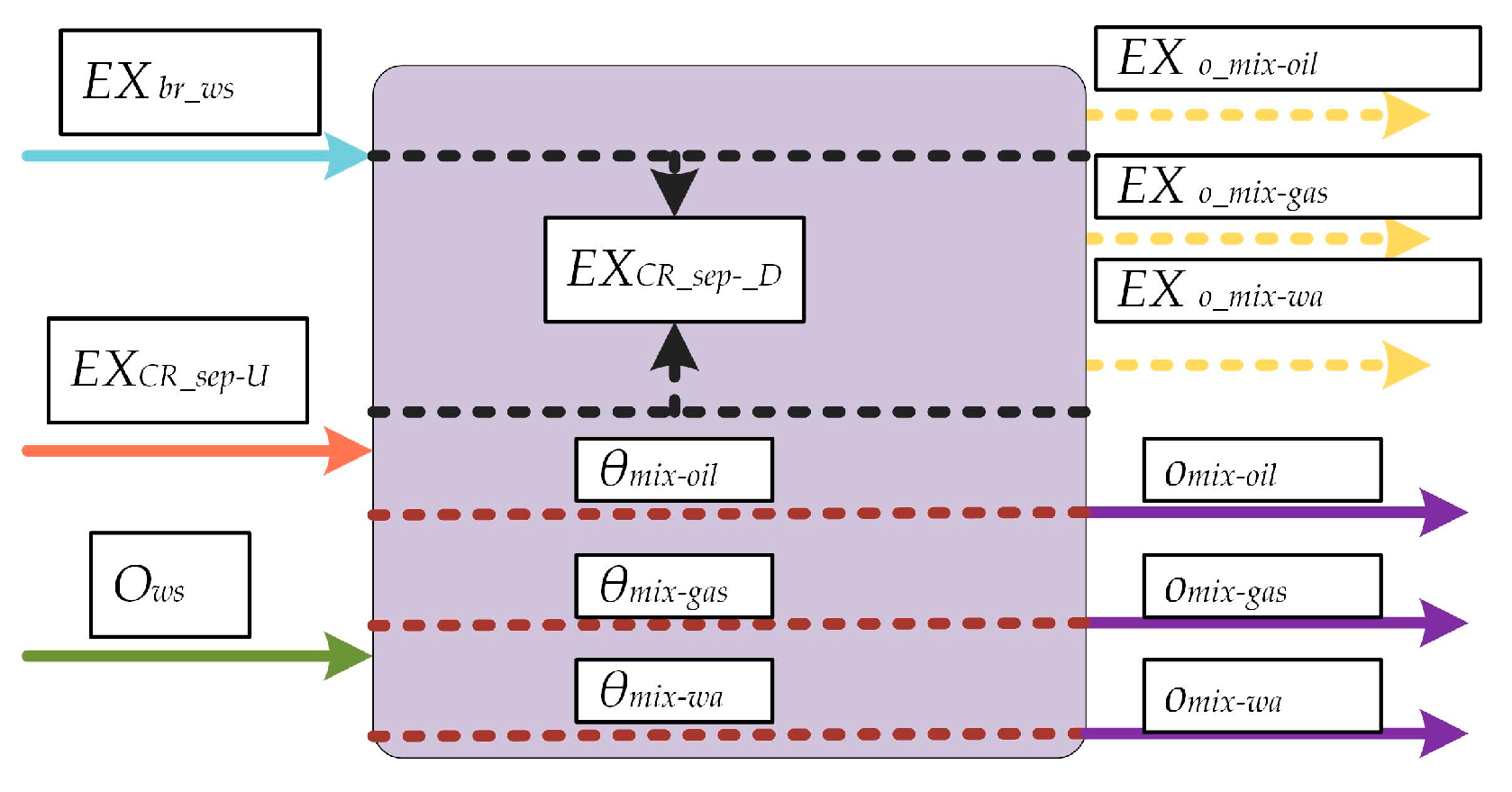

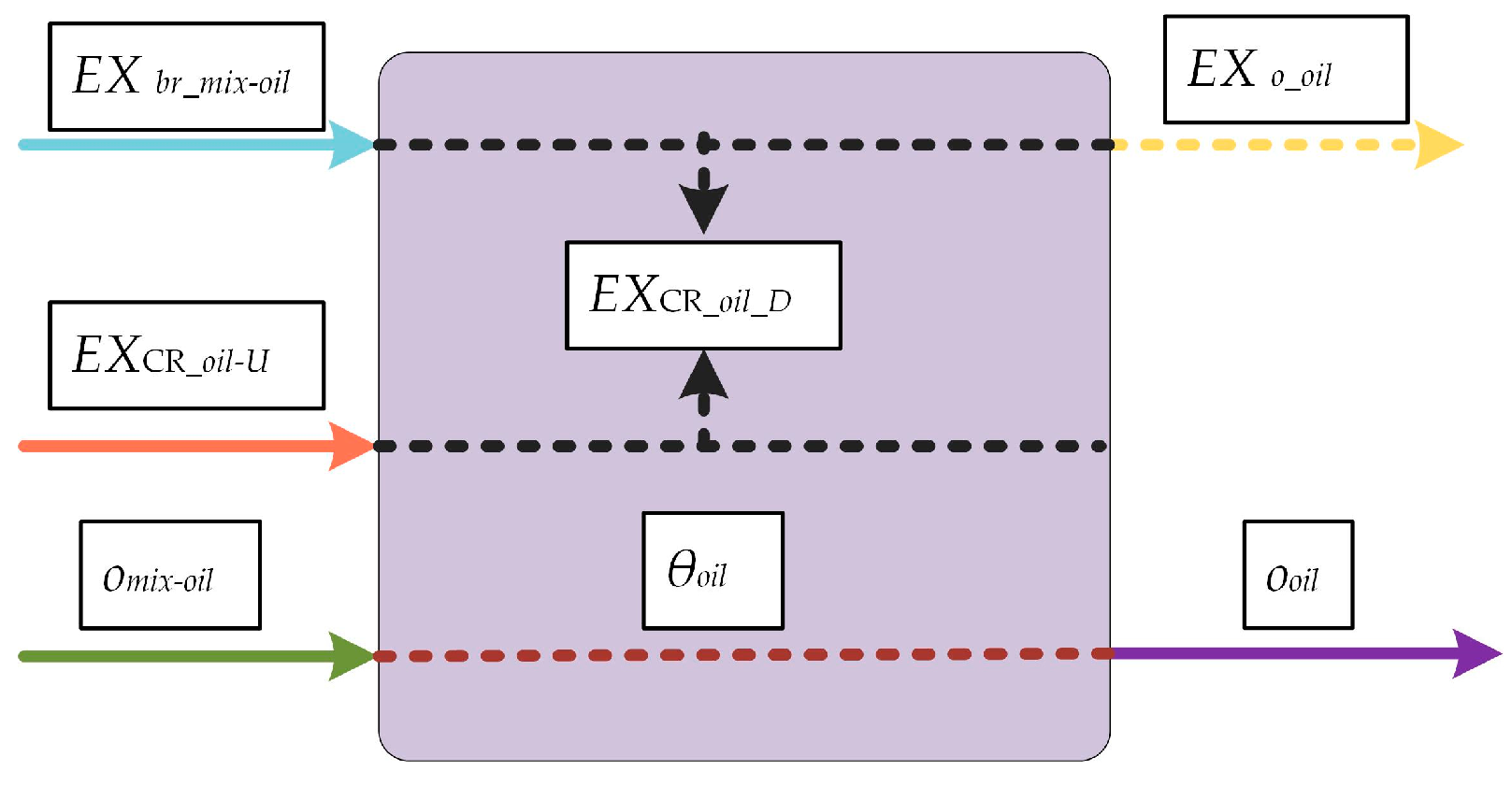

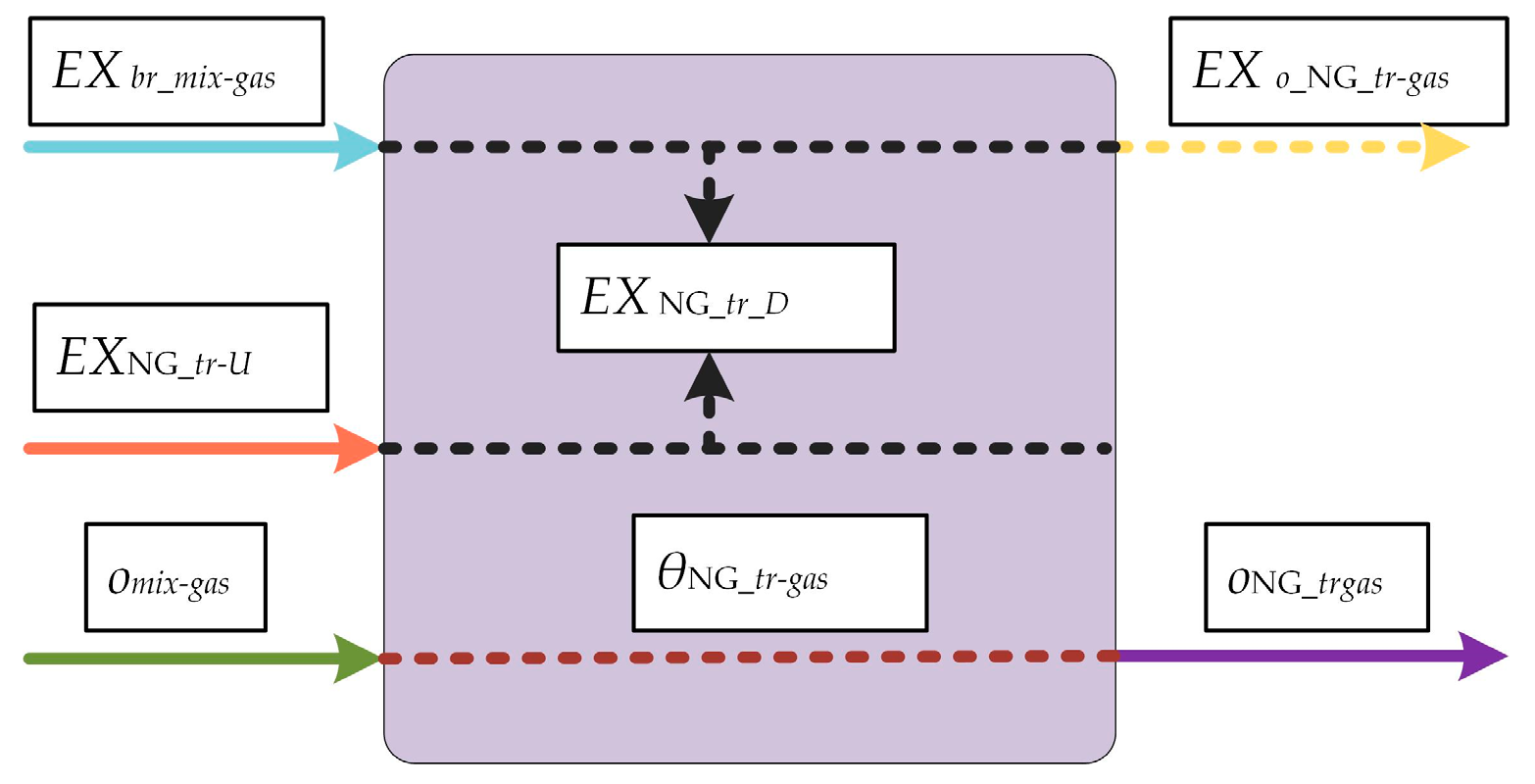

The Process Section denotes the process of production, e.g., the extraction and processing of oil, where the energies from Energy Section are consumed. Also, necessary materials used in the process are input into the Process Section, e.g., water and catalyst. In this section, a processing system can be divided into several sub-systems according to their functions, e.g., the Process Section in

Figure 1 includes a drilling and mining system, a crude oil process system, a natural gas system, a water treatment system, and a living-quarters system. Based on energy and material (non-energy) consumption in Process Section, a multi-input and multi-output mapping is developed as shown in

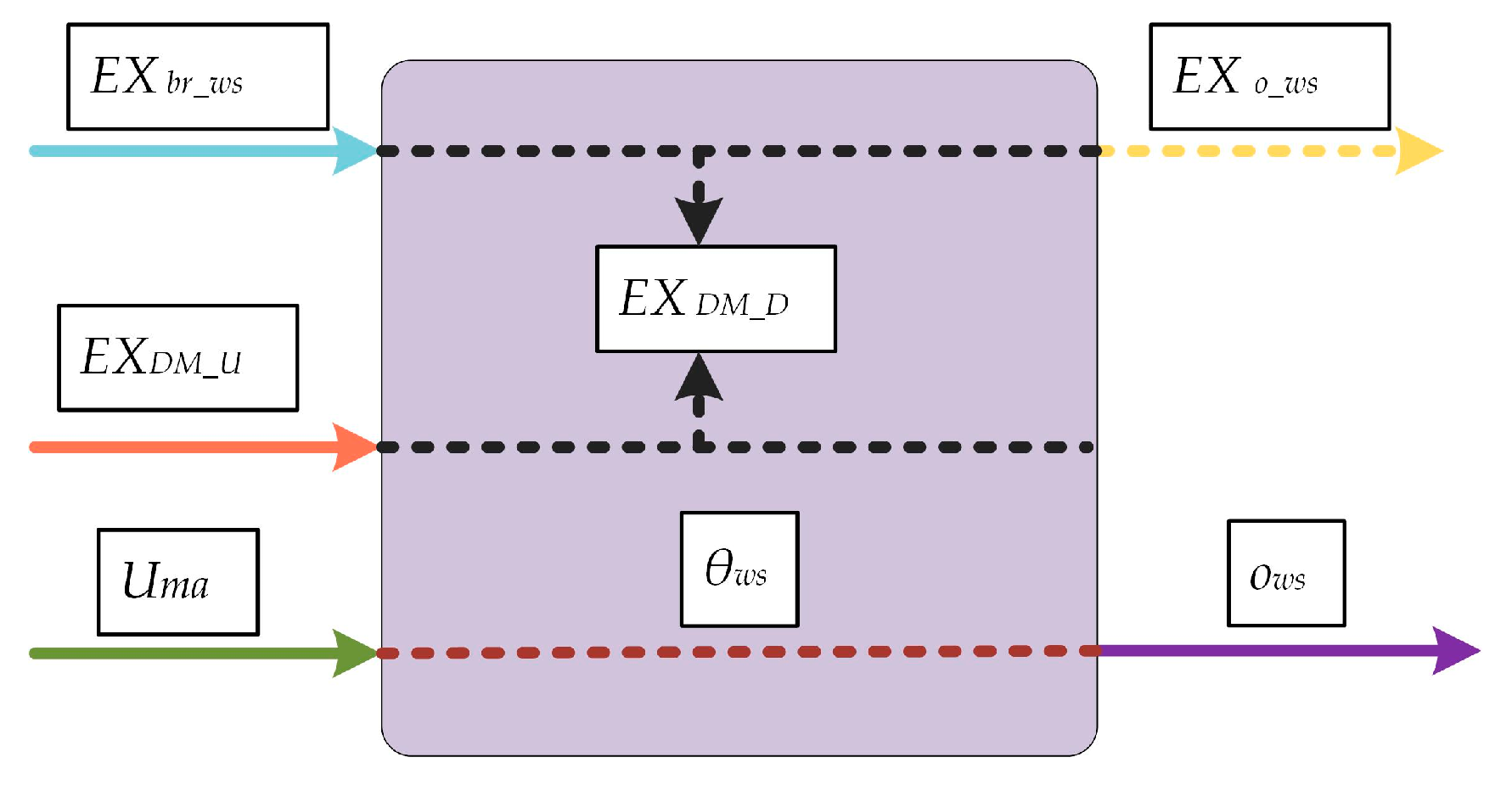

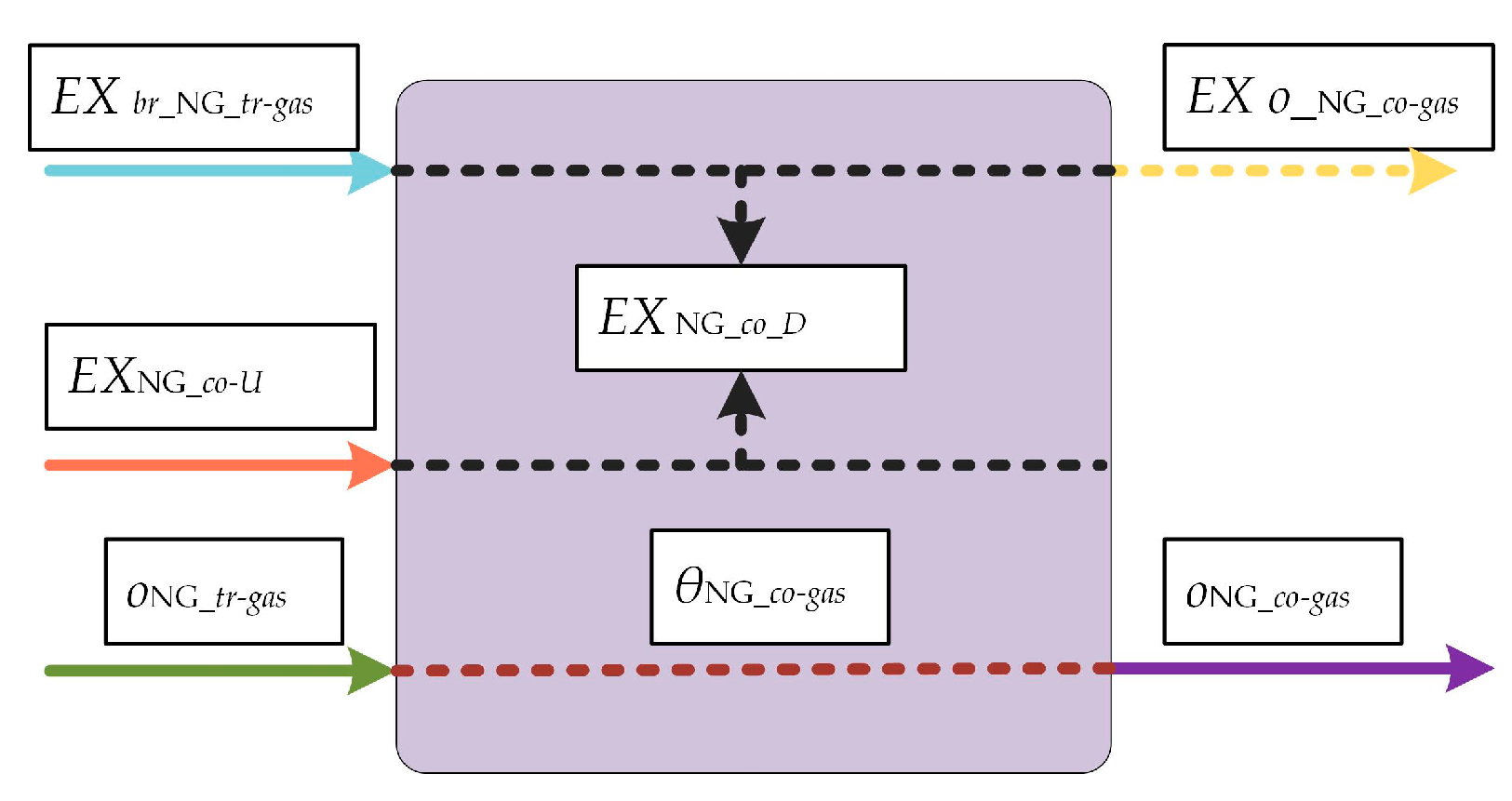

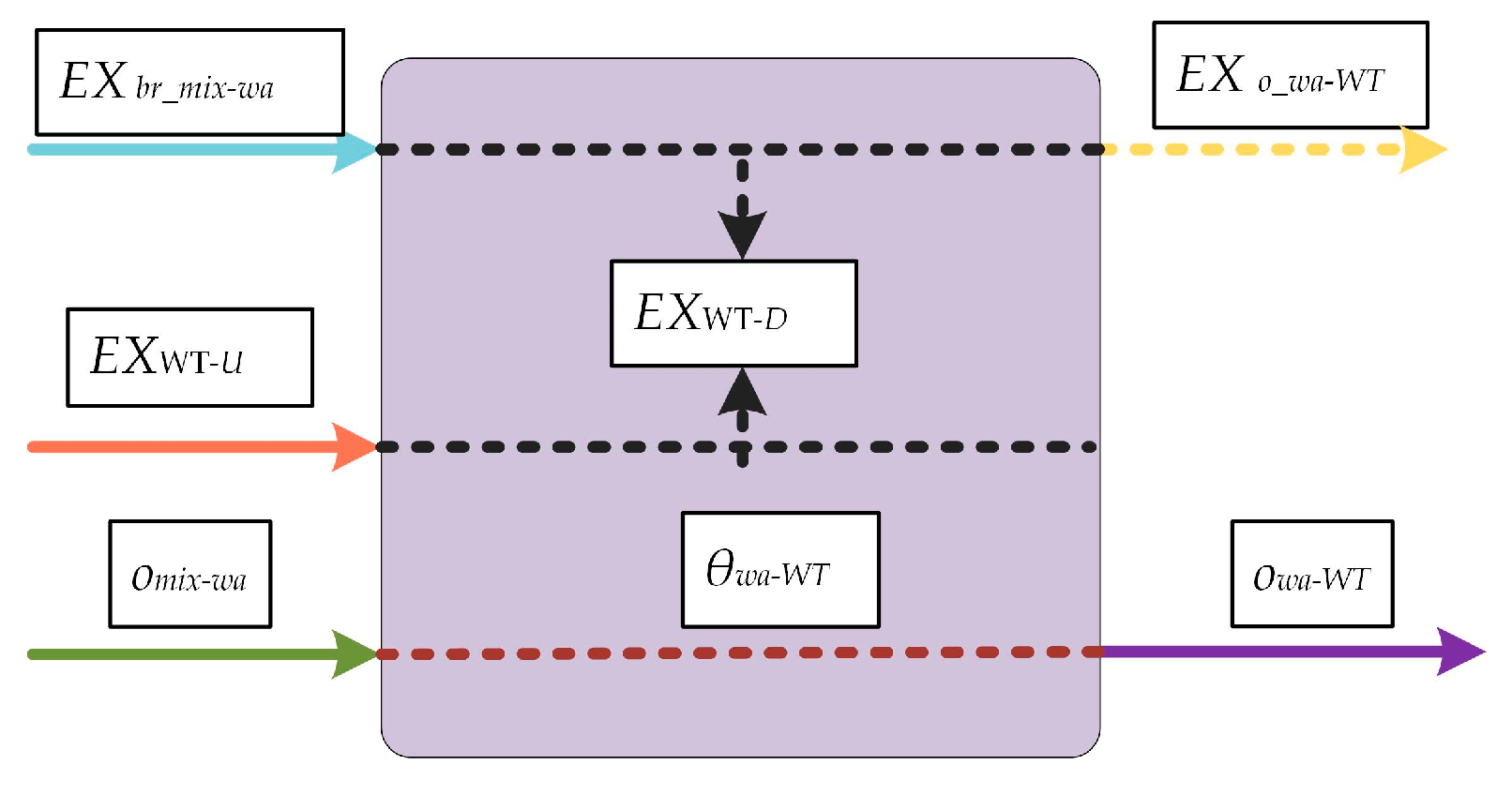

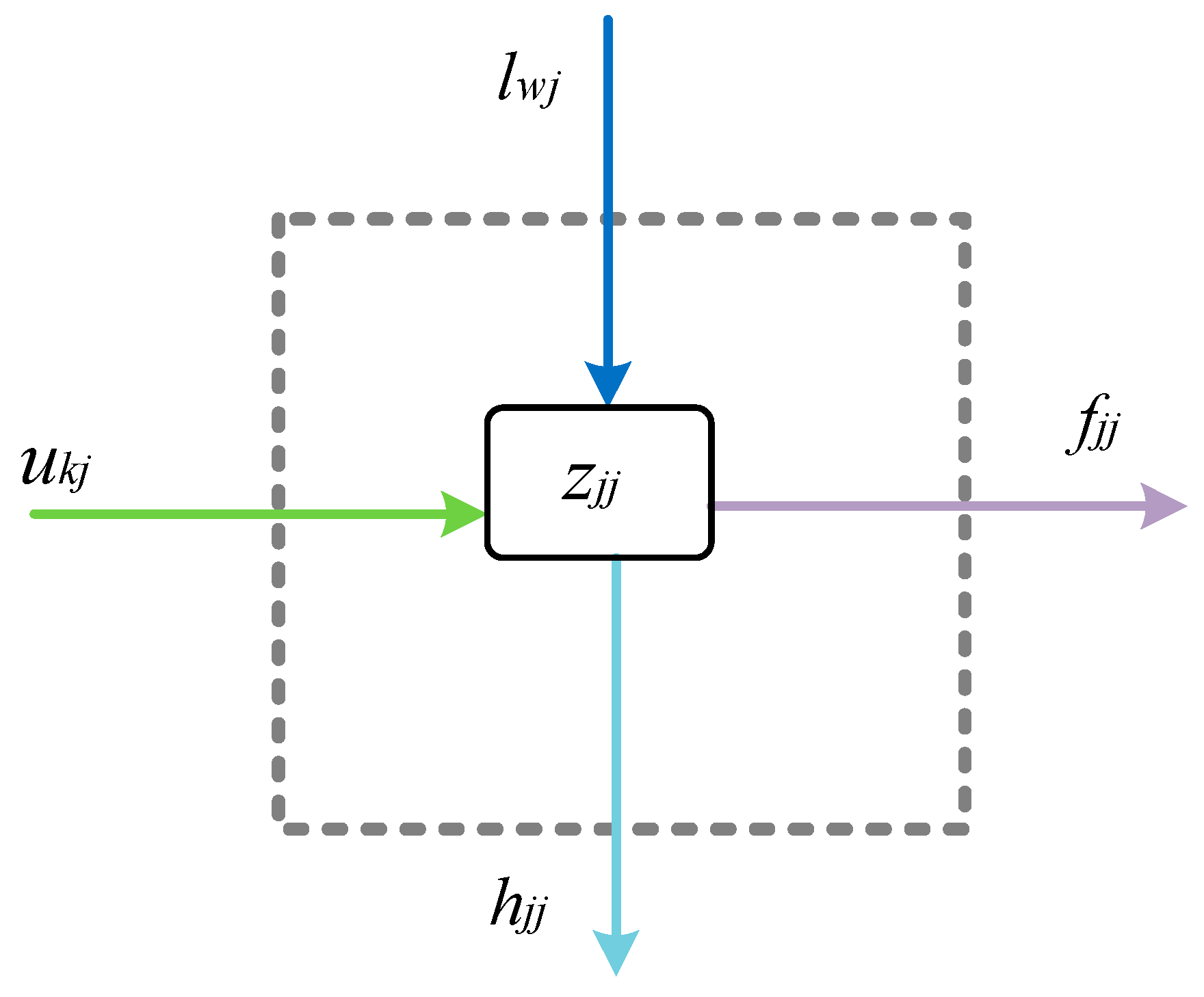

Figure 2. In the mapping of Process Section, an energy-material coupling element (EMCE) is defined, which represents the energy and non-energy relations of a sub-system.

Figure 3 shows a basic framework of an EMCE. The detail expression of an EMCE is decided by its sub-system, which can be a factor or a function. A sub-system can be one EMCE or multiple EMCEs. Equation (2) shows the mathematic details of the Process Section in

Figure 2. Here, an EMCE matrix,

Z, is introduced to describe the relationship between production outputs and the consumption of energies and materials in the Process Section.

Under certain conditions, the outputs of the Process Section can be inputs for the Energy System, e.g., water reused, associated gas, or oil used as fuel directly. Hence, the Feedback Section represents such feedbacks from the Process Section to the inputs of the Energy System. The feedbacks are shown as Equation (3). Since not all of the outputs are fed back to the Energy System,

B is a highly sparse matrix. When all entries of a column in

B are zero, the corresponding production are not fed back to the input:

Therefore, Equations (1)–(3) represent the generalized energy and material flow model (GEMFM) of an IES and processing system illustrated as

Figure 2.

5. Results

This study is based on an offshore oil extraction and processing site platform in the Bohai Sea area.

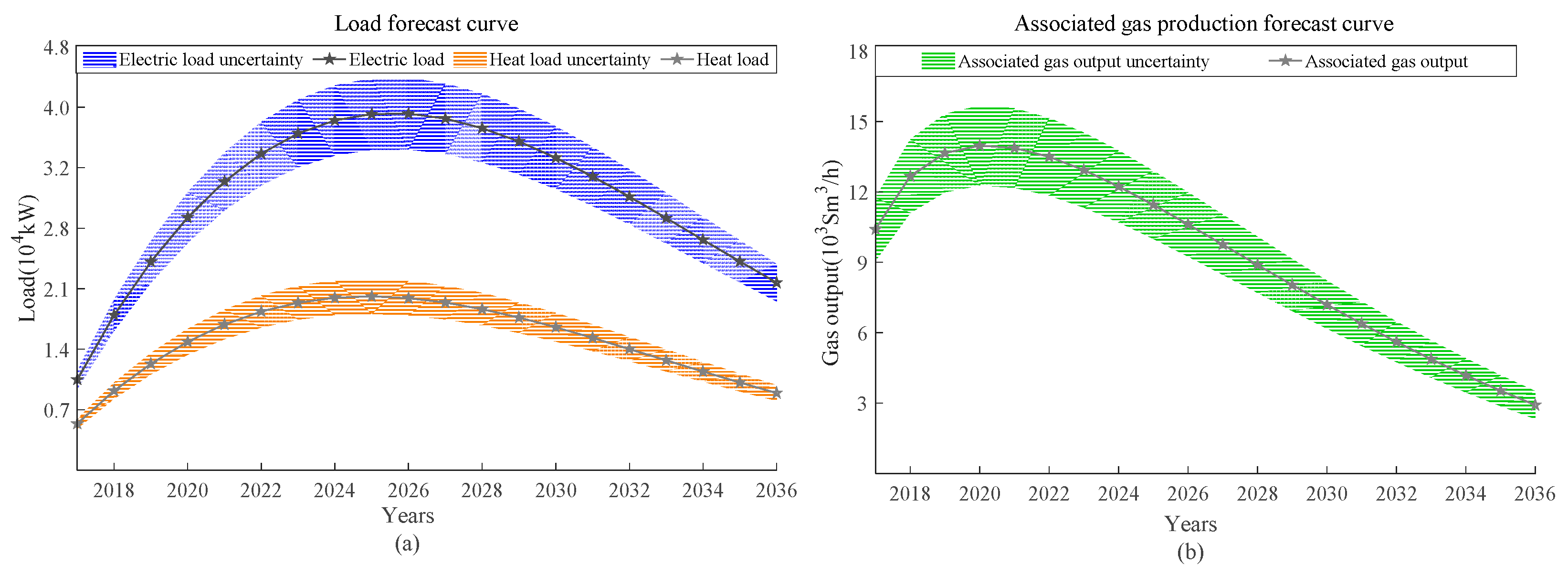

Figure 7 shows the estimated curve of electric and thermal load demands and associated gas production for this platform in the coming 20 years. According to

Figure 7a, electric load is over twice the thermal load, indicating the gas turbine on this platform produces abundant residual heat from flue gas. According to

Figure 7a, load demand in the planning period varies significantly, with a different reference load each year and culminating in the middle of the production period. To ensure the planned equipment capacity can meet the load demand of the platform in any period, this paper conducts verification against maximum reference load estimated for the offshore platform, i.e., electric load of 44,157 kW, thermal load of 14,100 kW and associated gas production of 9000 Sm

3/h. According to forecast in

Figure 7b, associated gas production is high in early production period but falls sharply afterward, suggesting associated gas may fall short of the demand of gas turbine in the middle and later periods of production, thus requiring diesel supply. Meanwhile, actual oil extraction may be different from the plan, which must be considered in planning. This study assumes that the mean of the random variables is ±10% of the predicted value, as shown in

Figure 7a,b.

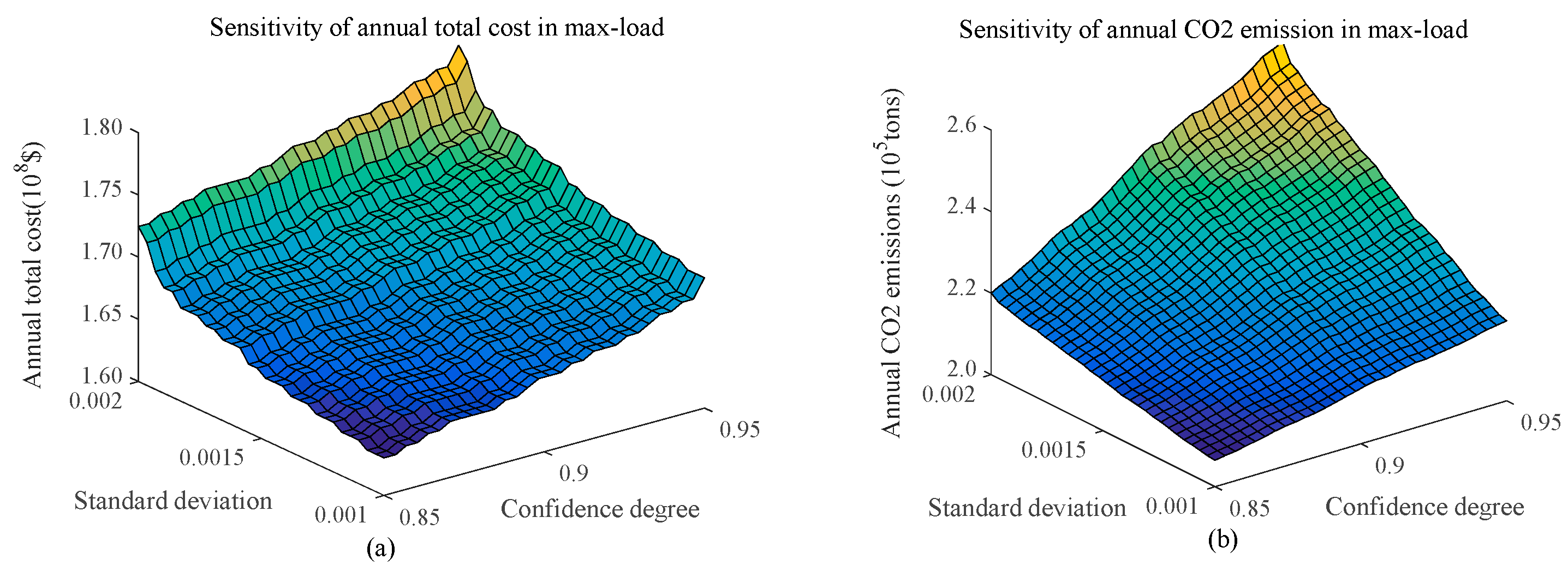

Figure 8 shows IESs sensitivity analysis at maximum reference load.

Figure 8a,b show analysis of sensitivity of annual total cost and annual carbon dioxide emissions. The standard deviation of random variables are 0.001–0.002 times the mean values, and confidence level of chance constraint discussed in this paper are 0.85–0.95.

Figure 8a,b show an increase in either joint distribution variance or confidence level of chance constraint leads to a rise in annual total cost and annual carbon dioxide emissions. Therefore, to address the uncertainty in offshore production and load, more investment needs to be made into the system to ensure stable production; meanwhile, ignoring the uncertainty in process and load may make IESs unable to satisfy the requirement of stable production. Since offshore platform IESs require high levels of safety and stability, this paper conducts optimization under a chance constraint confidence level of 0.95 and variance of 0.002.

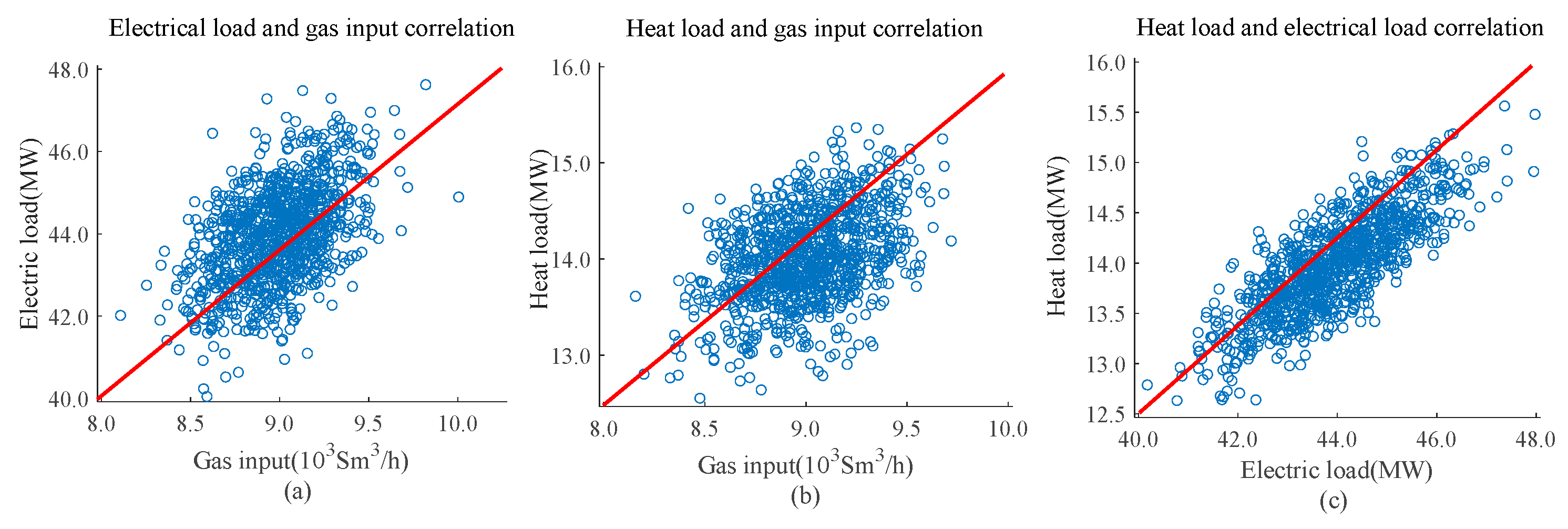

In a complicated and ever changing process of actual oil extraction, the changing gas-oil ratio and oil-water ratio make accurate forecast of associated gas production impossible, with an impact on IESs operating cost and CO

2 emissions. In addition, the electricity and thermal consumption of the offshore platform depends mainly on the real-time operating conditions of OEPS.

Figure 9 shows data samples of correlations between associated gas production and electric load (

Figure 9a), between associated gas production and thermal load (

Figure 9b), between electric load and thermal load (

Figure 9c). Distributed data closer to center line suggests a higher correlation between variables. It can be seen from the

Figure 9 that the electric and thermal loads are highly correlated to each other, while they have roughly the same correlation with the associated gas.

This paper adopts three methods to planning and design of energy supply system for this platform. Method 1 is an existing method for offshore platform; its energy supply system is Combined Heat and Power (CHP) system consisting of dual-fuel gas turbine and waste heat boiler; its equipment capacity is calculated using the method specified in design code [

6]. This method is deterministic planning. Moreover, Method 1 takes account of only cost-effectiveness while CO

2 emissions are not considered. Method 2 offers a stochastic planning method that takes account of random effects of electric and thermal loads and associated gas production, on the basis of Energy-Hub model as shown in

Figure 4. Method 3 offers a stochastic planning method that takes account of correlation between IESs and OEPS, on the basis of Generalized Energy and Material Flow Model (GEMFM) as shown in

Figure 2.

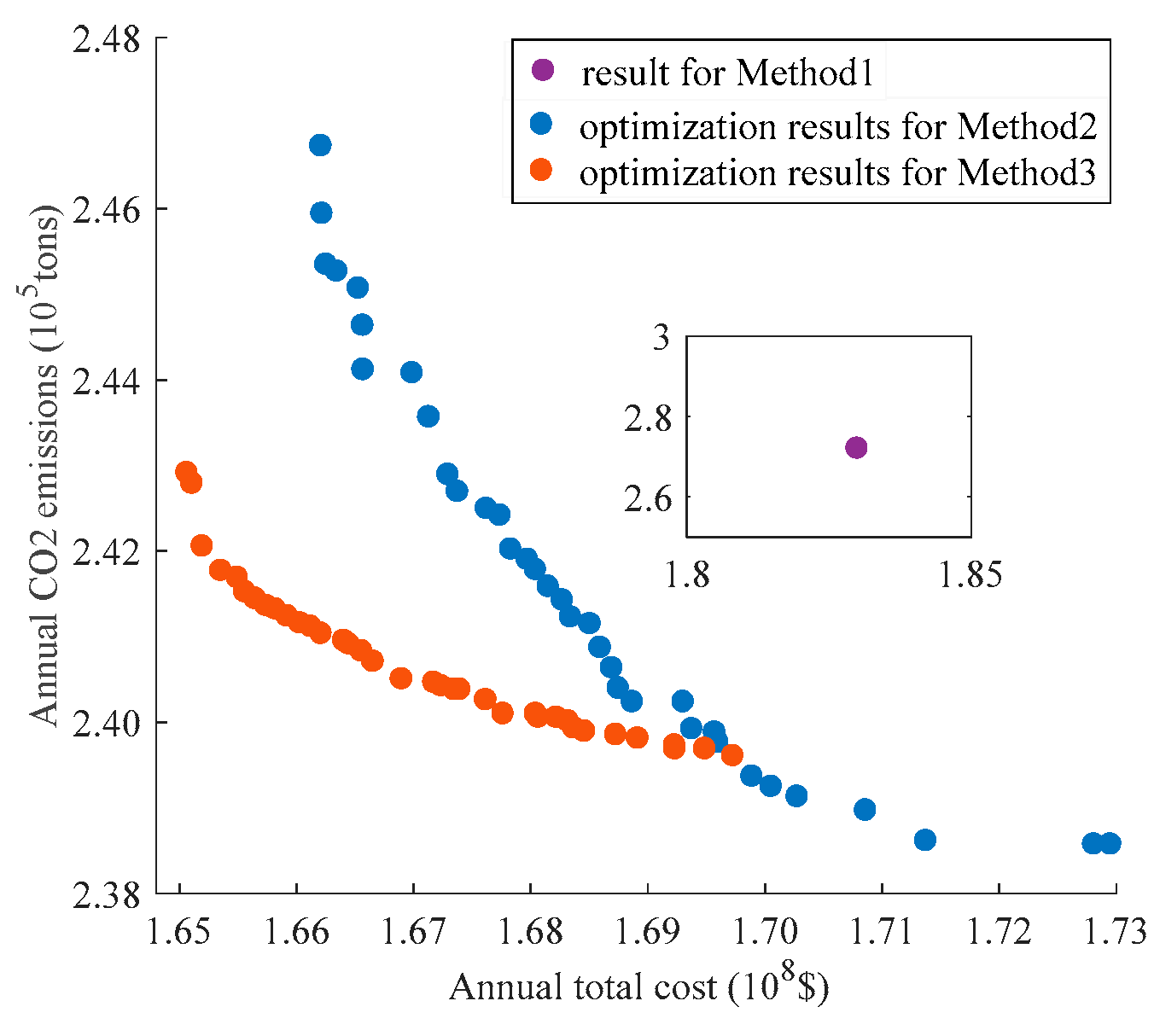

Figure 10 shows the planning results of annual average cost and annual emissions using the three methods at maximum reference load. According to

Figure 10, the results of methods 2 and 3 are better than those of Method 1, because: Method 1 is deterministic, requiring large spare capacity to ensure stability in energy supply for OEPS; in comparison with IESs, CHP is free of low-temperature waste heat recovery device (

ORC) and emission reduction measures (

CCS), resulting in more energy consumption and CO

2 emissions in Method 1 than in methods 2 and 3.

Figure 10 also suggests better results from Method 3 than from Method 2. This is because: when fluctuation in associated gas production affects electric and thermal loads of IESs, IESs can quickly respond to load fluctuation through

SC charging/discharging to meet the electricity demand of OEPS; the cascaded utilization of waste heat and diesel coordination and compensation in IESs weakens the secondary impact of fluctuation in associated gas production on load. Therefore, it is helpful to consider the impact of IESs -OEPS correlation on IESs optimization.

Table 2 shows the power and heat dispatch in energy system using three methods under maximum reference load. According to

Table 2, in Method 1, the dual-fuel gas turbine and waste heat boiler undertake all energy supply on the offshore platform; in methods 2 and 3, mixed gas turbine supplies about 90% of electricity for the platform as core equipment of power supply, while

ORC supplies about 12% of electricity using low temperature waste heat power generation. High temperature waste heat from the gas turbine is far greater than all the heat IESs needs, so the waste heat boiler can meet thermal load for the platform without refueling. Low temperature waste heat available to

ORC is in a large amount, but low temperature heat sources are not fully used due to restrictions on

ORC efficiency. Pre-CO

2 and

CCS processes consume about 5.8% of electricity;

CCS process consumes about 6.8% of heat energy.

Table 3 shows the comparison of energy system performances using three methods under maximum reference load. According to

Table 3, total power generating capacity and heat generating capacity in methods 2 and 3 are larger than in Method 1, consuming less total calorific value of fuel than in Method 1. This is because IESs generates power using low and medium temperature tail gas from the boiler through

ORC, resulting in higher energy efficiency and lower fuel consumption. In this case, associated gas production is not enough to meet the fuel demand of gas turbine, so diesel needs to be supplied. To ensure stable energy supply, the use ratio of associated gas is set as 0.9 or smaller (taken as 0.9 in this paper) while the unused portion is burned off.

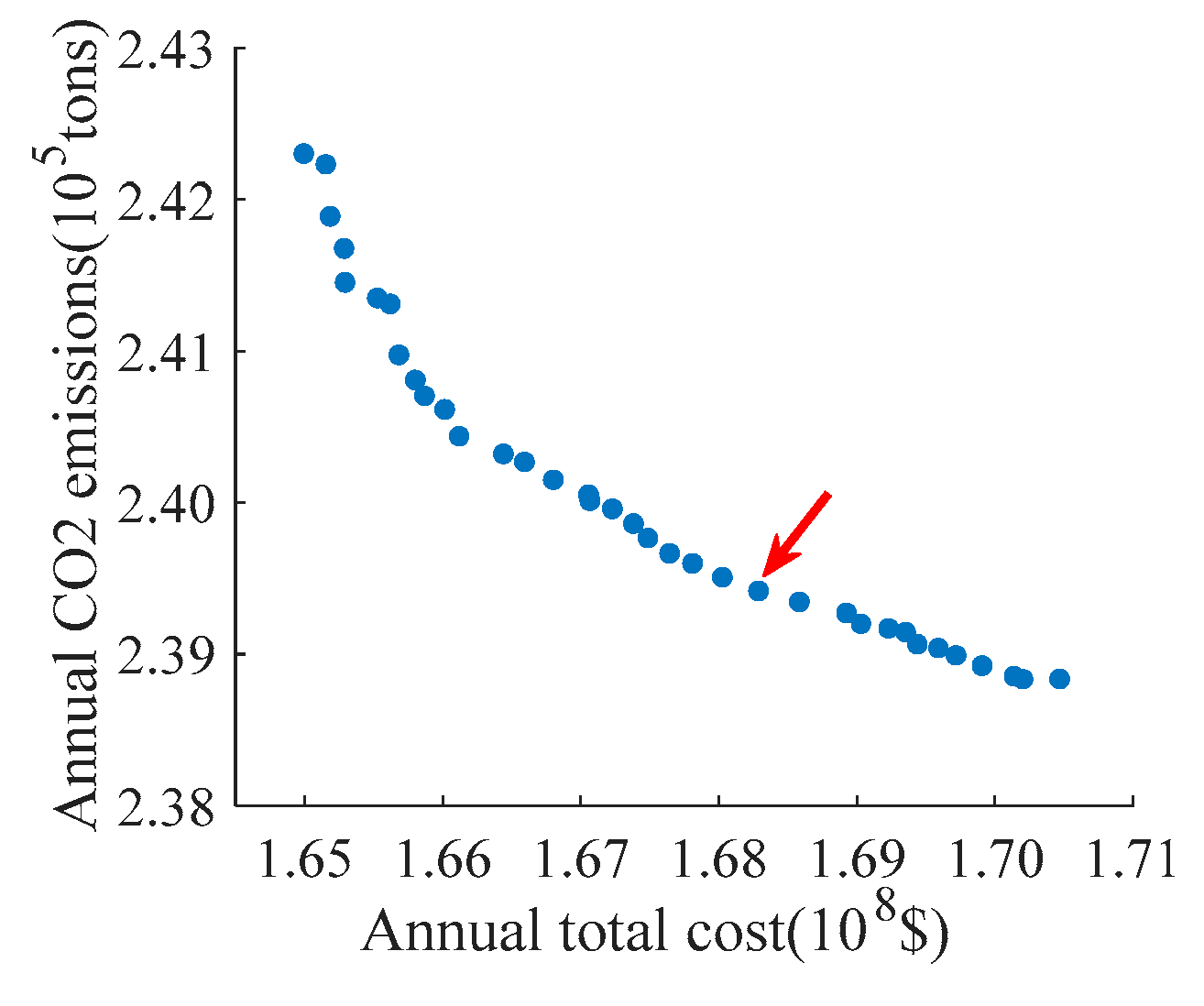

Figure 11 shows distribution of optimal solution set using Method 3. According to this figure, annual carbon dioxide emissions and annual total cost are in conflict with each other, forming a non-dominated relationship. The best solution is pointed by the red arrow.

Table 4 gives equipment components of energy system and the capital cost of the equipment components in the three methods. This article selects a co-firing gas turbine made by Siemens, which specific parameters are shown in

Appendix C.

Table 5 presents proportions of electricity and heat consumed by five subsystems of the offshore platform OEPS under maximum reference load in 2026. The drilling and mining system consumes the most electricity exergy, because the electric submersible pump for extraction of mixed fluid consumes large amounts of electricity. Crude oil process system consumes the most heat exergy because its three-phase separation unit and crude oil processing unit need large amounts of heat to meet the requirements for mixed fluid separation and crude oil processing.

Table 6 shows the exergy consumption of OEPS five subsystems using three methods under maximum reference load. According to

Table 6, OEPS consumes more heat and electricity exergy in methods 2 than in Method 3. The underline reason is that the associated gas production is less and OEPS process less oil and gas when the correlation is considered, hence it consumes less exergy energy.

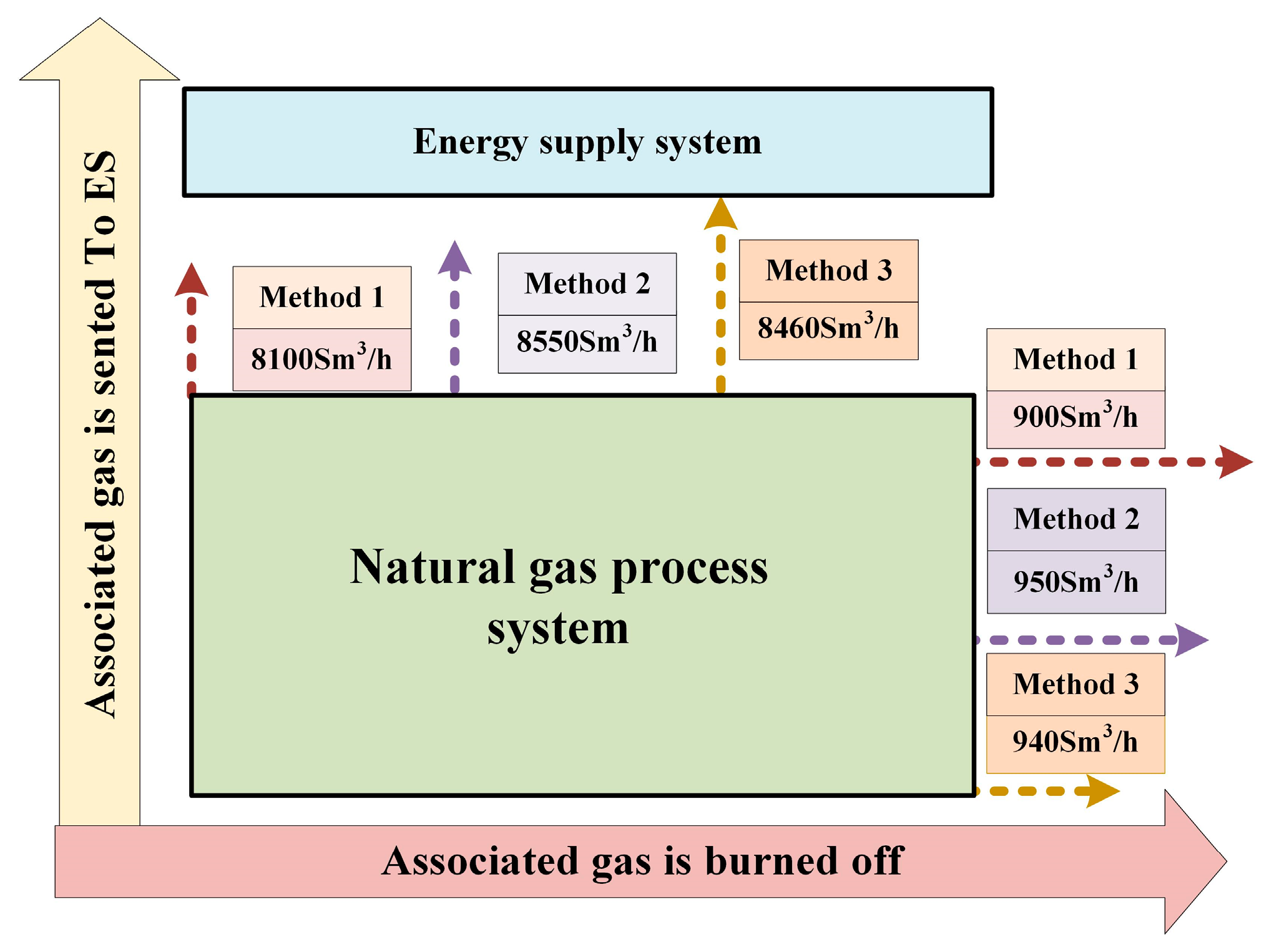

Figure 12 shows the dispatch of associated gas in the three methods. According to

Figure 12, the dispatch of associated gas can be divided into two parts: one part is delivered to IESs for power generation whereas the other is burned off. In general, comparison with Method 390 Sm

3/h more associated gas are allocated to IESs by Method 2, which means 332.5 kW of exergy, but it consumes more 1844 kW.

Table 7 gives the comparison of total cost and total CO

2 emissions in a 20-year planning period using the three methods. Method 3 entails the minimum total capital cost, total maintenance cost, total operating cost and total CO

2 emissions over the planning period, because it significantly cuts acquisition and installation costs for gas turbine and requires minimum diesel consumption over the planning period. Compared with Method 1, Method 2 can reduce 11.21% and 12.4% the total cost and CO

2 emissions, respectively. And the reduction of total cost and CO

2 emissions are 18.9% and 17.3% by Method 3, respectively. Hence, Method 3 is the most economy and environmental friendly planning method.