4.1. Comparative Analysis of Key Performance Indicators

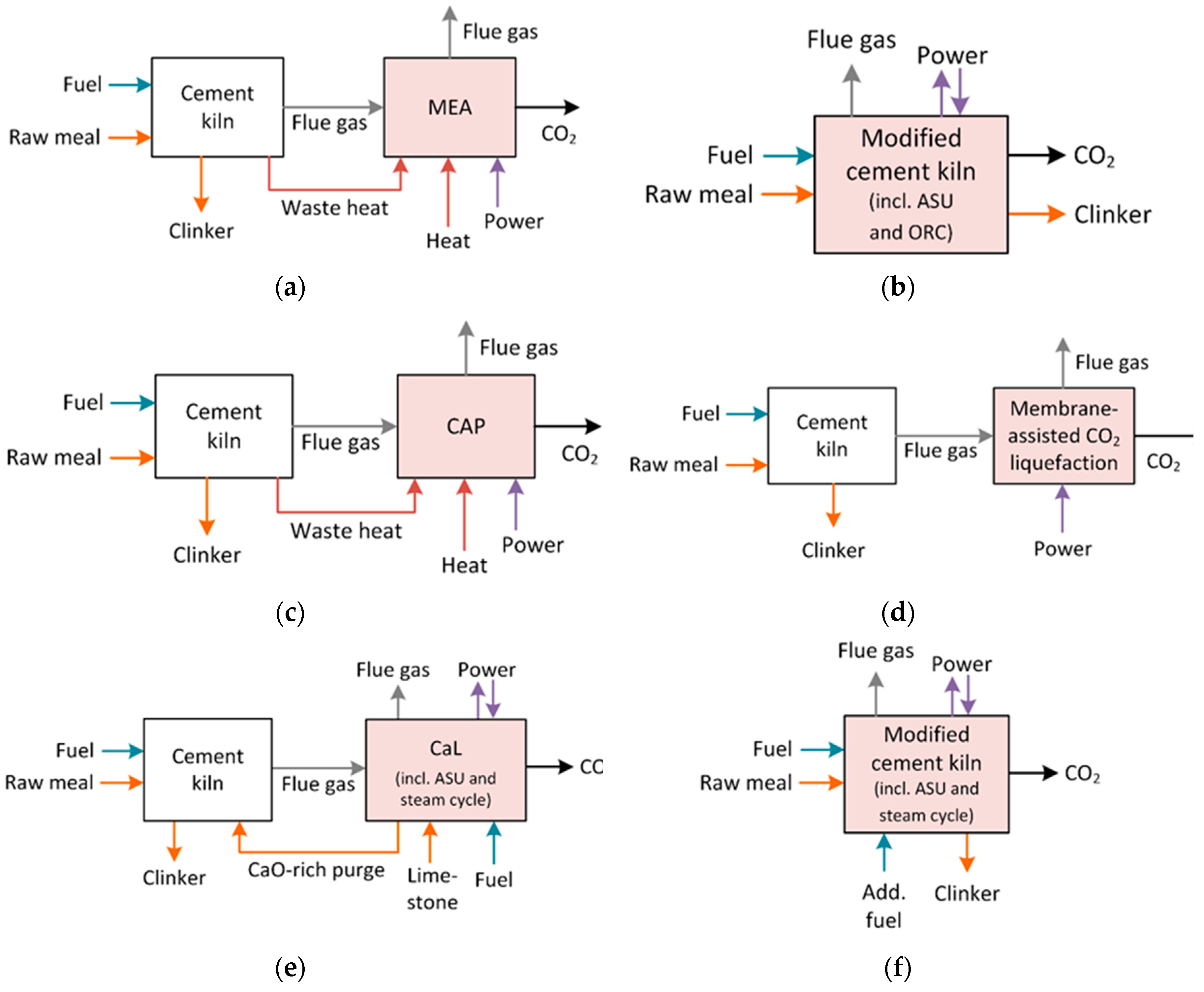

The KPIs employed to evaluate the economic performance of the cement plant with CO

2 capture are the cost of clinker and the cost of CO

2 avoided. The economic KPIs, as well as the total plant costs and annual OPEX for all the capture technologies and the reference cement plant without CO

2 capture are presented in

Table 6. Detailed equipment lists with estimated equipment costs and direct costs on component basis are provided as

Supplementary Material.

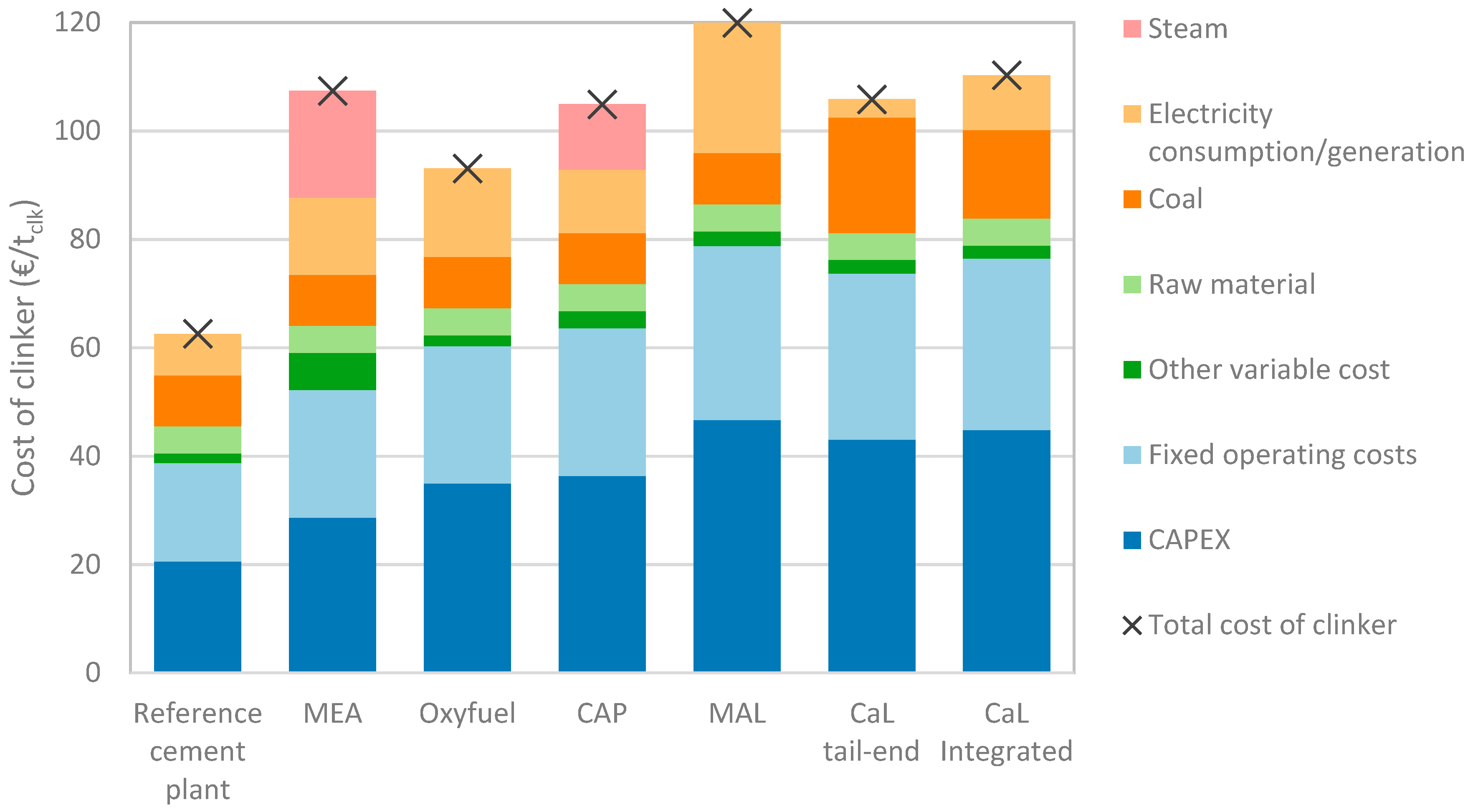

The cost evaluation shows that the reference capture technology, MEA, has the lowest total plant cost but also the highest annual OPEX. The MAL technology has the highest total plant cost, roughly three times higher the MEA technology. The oxyfuel and both CaL technologies have relatively low OPEX. In general, the cost of clinker increases with 49–92% from the 62.6 €/tclk in the reference cement plant when the investigated CO2 capture technologies are implemented. The cost of CO2 avoided ranges from 42 €/tCO2 for the oxyfuel technology to 84 €/tCO2 for the MAL technology, which is on a similar level as the CO2 avoidance cost for the MEA reference technology.

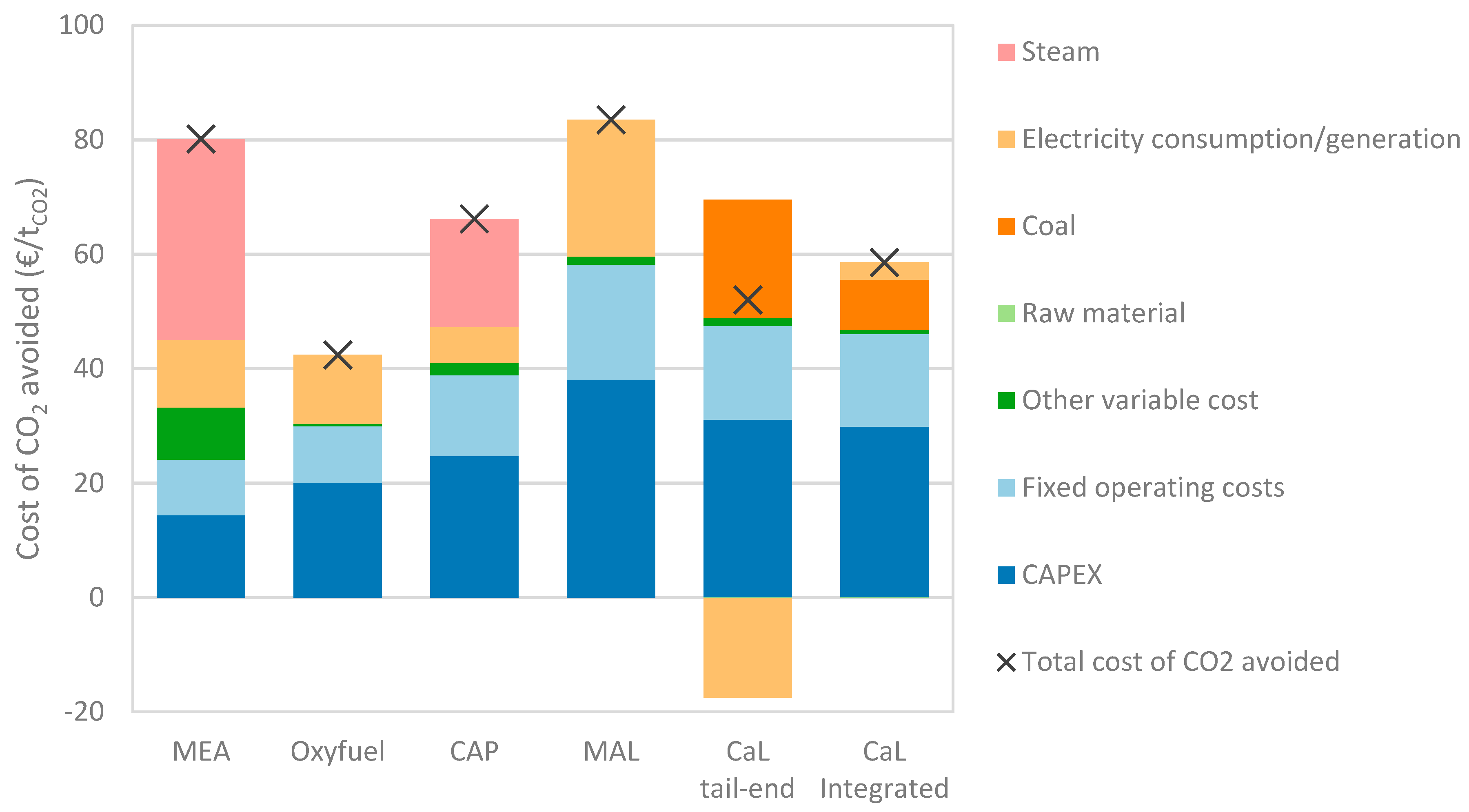

Figure 4 and

Figure 5 show the breakdown of the cost of clinker and of CO

2 avoided into the main cost factors. The oxyfuel technology shows the lowest cost of clinker compared to the other CO

2 capture technologies, both due to lower variable OPEX and lower CAPEX. The absorption-based technologies MEA and CAP as well as both CaL technologies have similar clinker costs, in the range of 105–110 €/t

clk. The CaL tail-end technology produces a significant amount of electricity which covers the electricity demand of the CO

2 capture process as well as a part of the cement plant’s demand. As a result, this technology shows a lower electricity cost per ton clinker than the reference cement plant. The MAL technology shows the highest cost of clinker, with CAPEX and fixed OPEX (directly related to the CAPEX) being the largest cost factors.

The most important contributions to the cost of CO

2 avoided differ among the capture technologies and illustrate the fundamental differences between most of the technologies. In the case of the reference technology MEA, steam contributes most to the cost of CO

2 avoided. The consumption of steam is responsible for a large increase in the cost of clinker compared to the reference cement plant. Additionally, it has a negative effect on the equivalent specific CO

2 avoided due to the emissions from the natural gas boiler. For practical reasons, the boiler flue gas is not treated in the capture plant according to the common framework, as mixing it with the cement flue gas has detrimental effects on the CO

2 concentration. Compared with the other capture technologies, the MEA-based capture has the lowest equivalent specific CO

2 avoided, as can be seen in

Table 2.

The oxyfuel technology has by far the lowest cost of CO2 avoided. It is mainly the CAPEX, and associated fixed OPEX, together with electricity consumption in the capture process that contribute to the CO2 avoided cost. The increase in electricity consumption contributes not only to an increase in the cost of clinker compared to the reference cement plant but also to a decrease in the equivalent specific CO2 avoided due to associated CO2 emissions.

In the case of the CAP, the cost of steam, as well as the CAPEX and fixed OPEX, are the most important factors. Compared to MEA, the cost of steam is significantly lower for the CAP due to its relatively low specific heat requirement. Hence, the equivalent specific CO

2 avoided of the CAP technology is about 15% higher than for MEA (cf.

Table 2). This contributes to the lower CO

2 avoidance cost observed for the CAP technology compared to the MEA reference technology.

For MAL, high CAPEX and associated fixed OPEX contribute the most to the cost of CO2 avoided. A significant share of the cost can also be attributed to the considerable electricity consumption of the capture process and the associated indirect CO2 emissions which consequently have a negative effect on the equivalent specific CO2 avoided.

For both calcium looping technologies, the increase in coal consumption compared with the reference cement plant contributes significantly to the cost of CO

2 avoided, together with the increase in CAPEX. Both CaL technologies generate a significant amount of electric power, with the generation in the tail-end case even covering the demand of the capture process and a part of the cement plant’s demand. As a result, the cost of electricity per ton clinker is lower in the CaL tail-end case compared with the reference cement plant. This in turn leads to negative CO

2 avoidance costs associated with electricity consumption, as shown in

Figure 5. For an extensive discussion on the economic analysis of the CaL cement plants, the reader is referred to the study of De Lena et al. [

37].

Several studies on economic assessments of CO

2 capture from cement have been published in the literature and recently gathered in a review by the IEAGHG [

38]. The results presented here are in line with the literature, although a direct comparison of cost estimates is challenging, due to variations in the level of detail, in the methodology and in the assumptions applied by the different studies. Most cost analyses have been carried out for MEA-based CO

2 capture, where various process configurations and assumptions have been considered. Therefore, a large range of CO

2 avoidance cost is reported for this technology, from around 75–170 €/t

CO2 [

38].

Fewer studies have analysed the cost of the oxyfuel technology. The IEAGHG [

10] reported lower CAPEX than in this work (around 14% lower in €/t

clk), with the main difference being a lower cost estimated for the ASU and the CPU. On the other hand, the study reported around 8% higher CO

2 avoidance cost than in this work. Gerbelová, van der Spek and Schakel [

14] estimated the CAPEX to be around 2% lower than estimated in this work, but they did not report on the CO

2 avoidance cost.

Ozcan [

11] reported on CAPEX for a calcium looping tail-end process, although the process configuration is slightly different from what is presented in this paper, with the flue-gas to be treated extracted between two preheating stages and not downstream of the preheater. The difference in CAPEX, in €/t

clk, ranges from −5% to 11%, depending on the amount of CaO-rich purge from the calcium looping process that is added to the raw meal in the cement plant.

Considering membrane-based technologies, literature cost estimates for cement applications are difficult to compare with the results presented here, as they are based on different process concepts than considered in this work. For the CAP and integrated calcium looping technologies, detailed cost analyses comparable with the work presented here are not available in the literature.

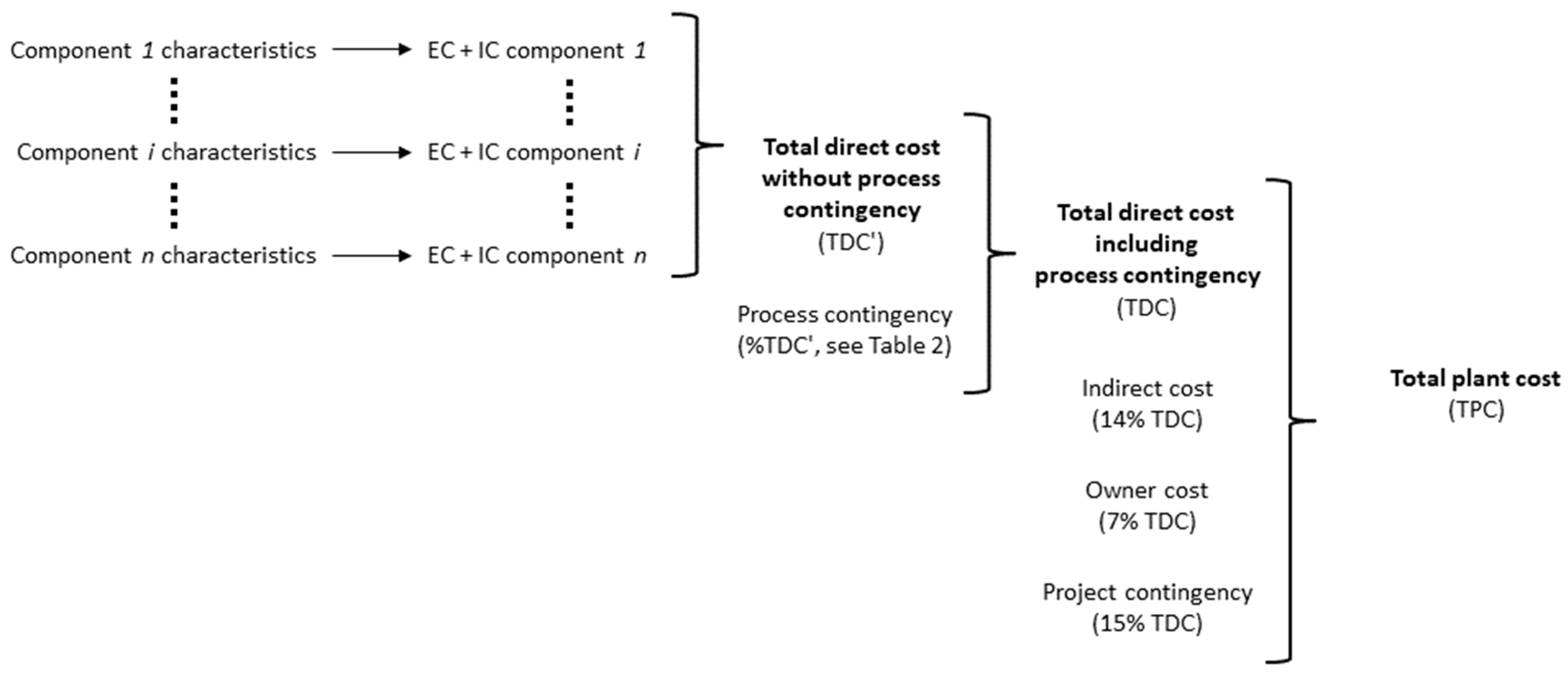

Through the conduction of the current techno-economic analysis, several possibilities for improved cost performance or to reduce uncertainties in cost estimates have been identified.

For several technologies, it was observed that process contingencies contributed heavily to the CAPEX. The process contingencies account for costs that are unknown, and the relative amount of unknown costs are assumed to be higher for technologies with lower maturity (cf.

Table 3). The process contingencies are particularly high for the oxyfuel, the MAL and the integrated CaL technologies, where they directly account for about 22%, 30% and 20% of the TDC for these technologies, respectively. In addition, elements of the fixed OPEX are calculated as a factor of the CAPEX, such that the process contingencies overall account for 14%, 20% and 15% of the CO

2 avoidance cost for the oxyfuel, MAL and the integrated CaL technologies. Increasing technology maturity by further development and demonstration of the technologies for cement applications would reduce the uncertainty of the costs, and possibly lower the overall cost estimates of the technologies.

The technical evaluation reported on in Part 1 showed that steam generation in a NG boiler contributed to a significant share of equivalent specific CO

2 emissions for the solvent technologies MEA and CAP. To reduce these emissions and potentially decrease the cost of CO

2 avoided, it could be considered to mix the flue gas from the NG boiler with those from the cement plant and thereby capture the CO

2 from the NG boiler in the post-combustion process. Furthermore, in cement plants which use raw material with low moisture content, a larger amount of waste heat would be available for steam generation at lower cost and lower associated CO

2 emissions compared to the NG boiler steam generation. This is for instance the case for the previously mentioned Norcem cement plant in Brevik, where it has been found that use of the plant waste heat for solvent regeneration can cover the heat demand for capturing ~40% of the emitted CO

2 [

13]. Thus, the solvent based technologies will have a better techno-economic performance when retrofitted to such plants.

The oxyfuel technology is shown to have the lowest cost of CO2 avoided, and has both relatively low OPEX and CAPEX, even though maturity related process contingencies do contribute significantly to the CAPEX. It should however be noted that there are several important aspects regarding retrofitability of the technology with the cement plant which could affect the cost process performance, such as potential impacts on the reliability of cement production due to substantial modifications of the core production process, that have not been considered in calculation of the economic KPIs.

For the MAL technology, CAPEX is the single largest cost factor. In this context, the membrane performance is essential as it strongly influences the energy performance of the whole process and consequently the size and cost of several of the most capital-intensive process equipment. The MAL process design was restricted to the specific membrane type that was tested within CEMCAP. A screening of different membranes, preferably with testing in real conditions at a cement plant to increase technology maturity and reduce uncertainties, in addition to further optimization of the system could result in better technical performance and lower costs than observed here.

For the calcium looping technologies, CAPEX and the consumption of coal are the largest cost factors, although in the tail-end configuration, the large coal consumption is effectively counterbalanced by the consequent production of electricity and the associated negative CO

2 avoidance costs (cf.

Figure 5). In the integrated configuration, the CAPEX together with the capital-related fixed OPEX account for nearly 80% of the cost of CO

2 avoided. Further development of this technology on a larger scale is therefore essential to increase maturity, reduce uncertainties and potentially bring about cost reductions.

4.2. Sensitivity Analysis

Various assumptions on cost parameters are essentially dependent on the geographic location of the cement plant and the time at which the cost analysis is performed. The effect of this variability on the economic KPIs was investigated by varying the following parameters in the suggested ranges:

Coal price: +/− 50% of the reference cost

Steam supply: +/− 50% of the reference cost

Electricity price: +/− 50% of the reference cost

CAPEX of CO2 capture technologies: +35/−15%

Carbon tax: 0–100 €/tCO2

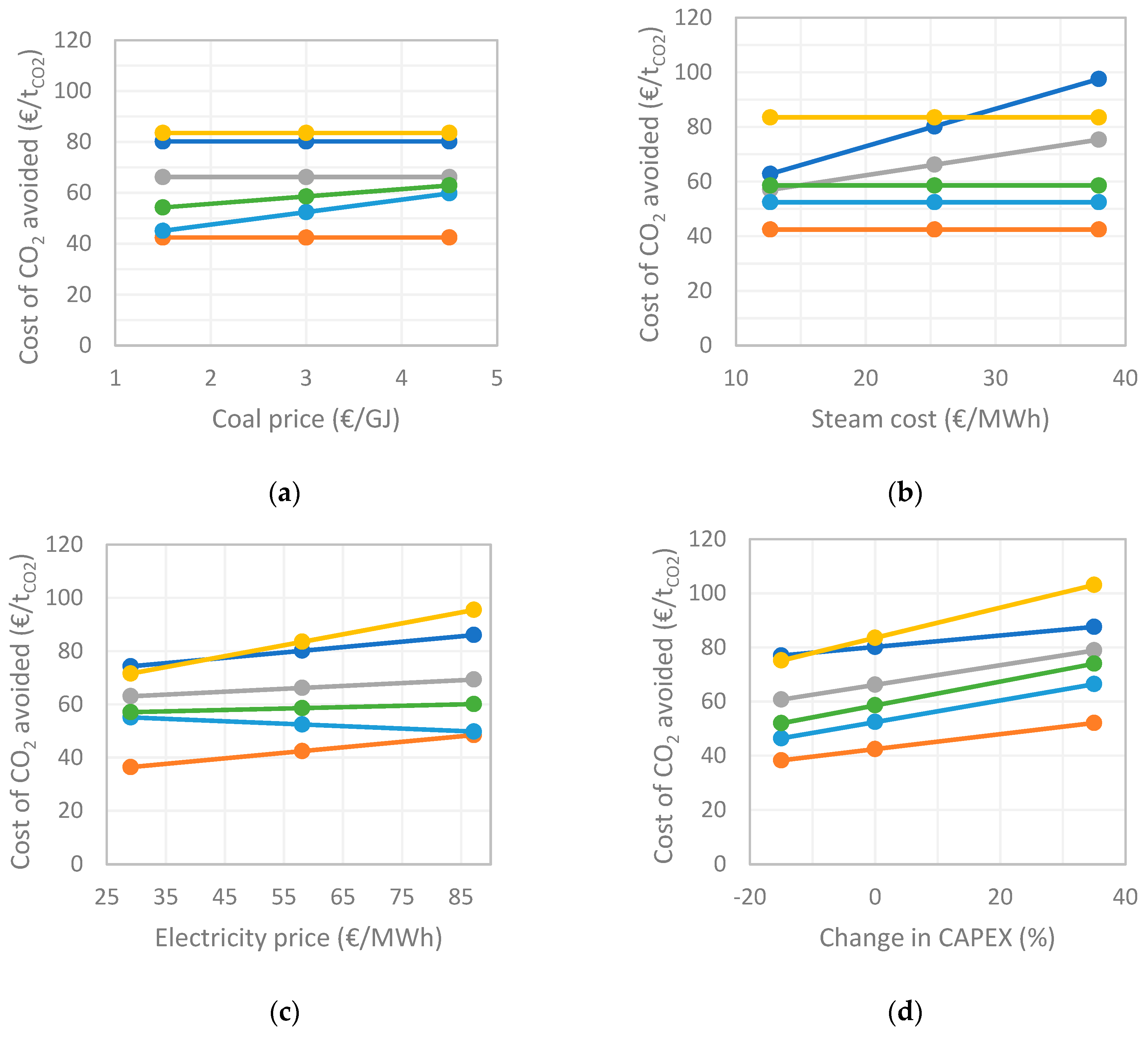

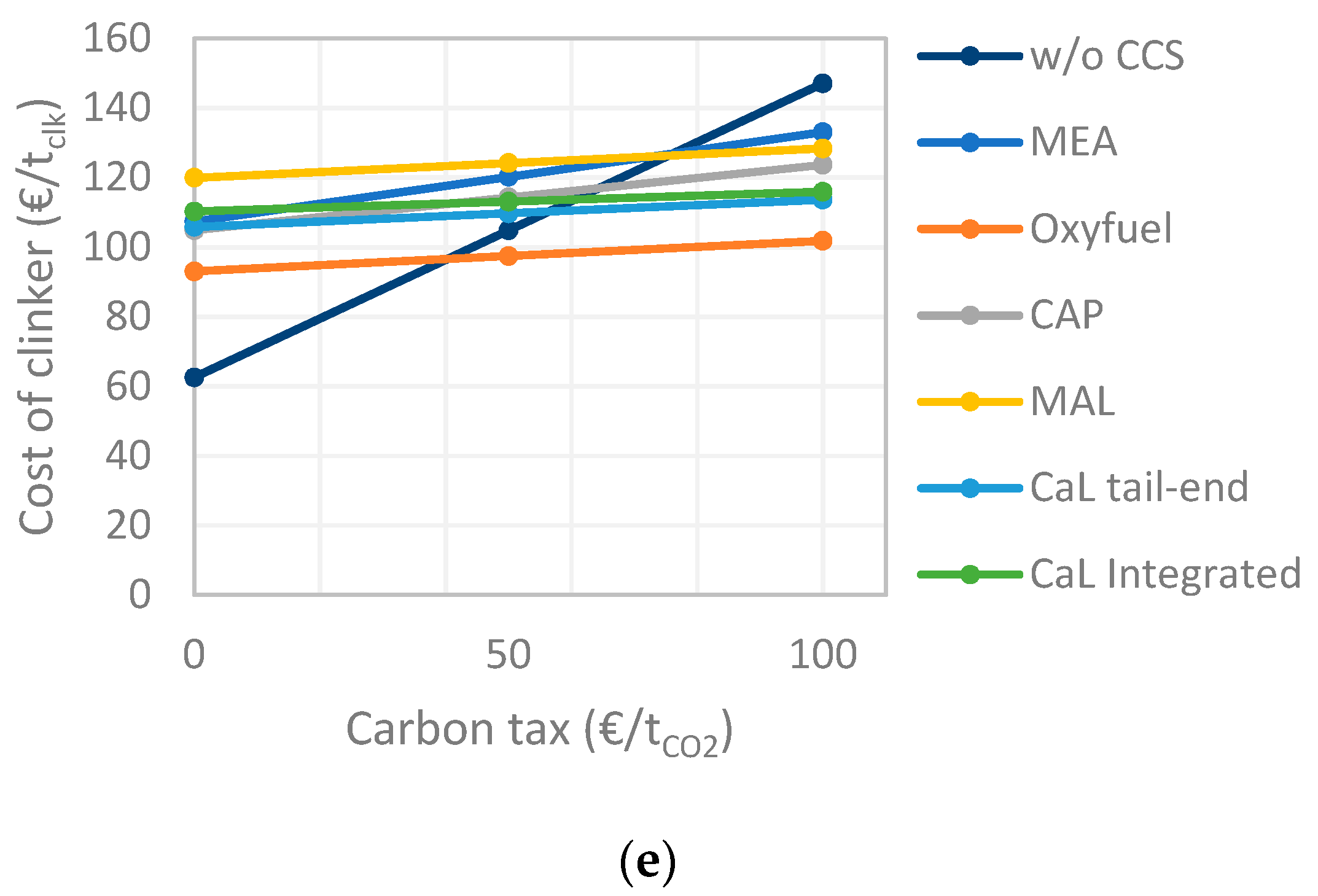

The sensitivity of the cost of CO

2 avoided to the coal price, steam cost, electricity price and a change in CAPEX are shown in

Figure 6 as well as the sensitivity of the cost of clinker to a carbon tax. The cost of coal affects the CaL processes, due to the significant increase in fuel consumption associated with the CaL technology. The MEA, CAP and MAL technologies are unaffected by the cost of coal since these technologies do not require additional coal consumption.

The cost of steam naturally only affects the absorption-based MEA and CAP technologies, especially the MEA technology due to its relatively high steam requirement. At the lower end of the steam cost range, the cost of CO2 avoided with MEA, CAP, and integrated CaL are almost the same.

Electricity intensive technologies, such as oxyfuel and MAL, are naturally the most sensitive to the price of electricity. The increase in electricity price decreases the cost of CO2 avoided for the CaL tail-end technology, in contrast to all the other technologies. This is because the electricity generated in the CaL process covers a part of the cement plant’s demand and therefore the CO2 avoidance cost associated with electricity is negative for the CaL tail-end technology.

The most capital-intensive technologies, MAL and both CaL processes, are most sensitive to a change in the CAPEX estimate. The oxyfuel and CAP technologies are also significantly affected while the smallest effect is seen for MEA, which has the lowest CAPEX. It should be noted that the estimated fixed OPEX are also affected by a change in the CAPEX.

If a carbon tax is implemented on the direct CO2 emissions from the cement plant, the cost of clinker for the reference cement kiln will increase. At a tax level of around 40 €/tCO2, the cost of clinker (excluding costs for CO2 transport and storage) with oxyfuel technology becomes lower than in the reference cement kiln, and at roughly 60 €/tCO2 the CAP and both CaL technologies will have a lower cost of clinker compared with the cement kiln without CO2 capture. For MEA and MAL, a carbon tax of around 75 €/tCO2 would be required for a clinker cost lower than that of the reference cement kiln. Due to the direct CO2 emissions from on-site steam generation for CO2 capture with MEA and CAP, and therefore higher direct CO2 emissions, these technologies are more sensitive to a carbon tax than the other CO2 capture technologies.

4.3. Alternative Scenarios for CO2 Capture

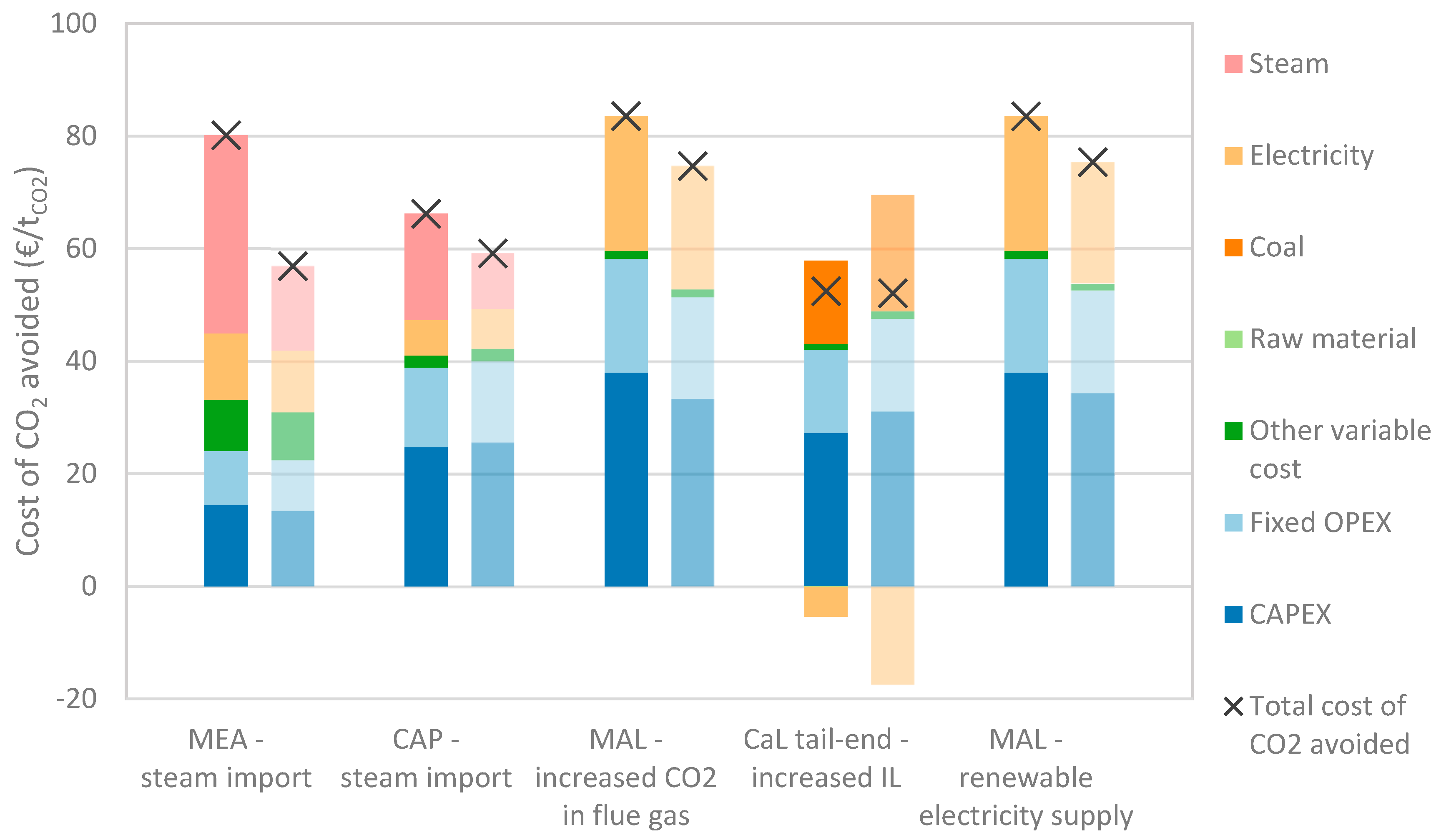

The results presented for the baseline scenario consider 90% CO

2 avoided from the cement plant flue gases, CO

2 transport by pipeline and, when required, steam being provided by a natural gas fired boiler. However, other scenarios for CO

2 capture have also been investigated within the CEMCAP project. This includes scenarios with higher CO

2 content in the flue gas, partial-scale capture, ship transport, different characteristics of the power generation system, steam import for solvent-based technologies, variations in air leakage in the oxyfuel cement plant and variations in the amount of sorbent purge used as raw material in the calcium looping tail-end configuration. Selected technology-specific scenarios which showed a significantly different composition or a change in the cost of CO

2 avoided are highlighted here, while the complete analysis of all scenarios can be found in the CEMCAP report by Voldsund et al. [

39]. The cost of CO

2 avoided for the highlighted scenarios are presented in

Figure 7 together with the cost of CO

2 avoided calculated for the baseline scenario for comparison (presented previously in

Figure 5).

For certain cement plants, it might be possible to import steam from an external coal-fired combined heat and power plant, instead of on-site generation from natural gas, to supply the MEA and CAP technologies. By doing so, the cost of steam could be reduced substantially [

15] and consequently the cost of CO

2 avoided, as illustrated in the sensitivity analysis in

Figure 6. Furthermore, depending on the power plant efficiency, the equivalent CO

2 avoided could be increased, leading to a further reduction of the specific cost of CO

2 avoided. The cost of CO

2 avoided for MEA and CAP when importing steam from a coal-fired CHP at a roughly 50% reduced cost and with around 20% lower CO

2 emissions per MWh

th compared to steam from NG boiler [

15] is shown in

Figure 7. This results in 20% reduction in CO

2 avoided cost for MEA and 10% for CAP. The lower cost reduction for CAP compared with MEA is explained by CAPs significantly lower steam requirement. However, it should be mentioned that fewer than 10% of the existing cement plants in Europe are in close proximity to CHP plants.

An increased CO

2 content in the flue gas, which could be possible in a cement plant with e.g., increased maintenance to reduce air leak in the clinker burning line, was shown to benefit the CO

2 capture performance, and in particular the MAL technology. An increase in flue gas CO

2 content from the baseline scenario with an average of 20 mol% to a scenario with 22 mol% improves the process performance. In particular, the electricity requirement is reduced and the more efficient process results in reduced design capacity for most of the process equipment. As a result, the cost of CO

2 avoided is about 10% lower for the higher flue gas CO

2 content, 74.7 compared to 83.5 €/t

CO2 for the lower CO

2 content, as shown in

Figure 7. Under these conditions, the MAL technology was found to outperform the reference technology MEA, which is not as strongly affected by the applied increase in CO

2 content of the flue gas (the cost of CO

2 avoided for MEA was found to decrease with <1%).

In the CaL tail-end configuration, the solid CaO-rich purge from the capture process is added to the raw meal in the cement kiln. The amount of Ca fed to the cement kiln from the sorbent purge to the total amount of Ca fed to the kiln is defined as the integration level (IL) between the tail-end calcium looping system and the kiln. The process presented in this paper has an IL of 50%. Designing for a lower IL will result in a larger potential for power generation from waste heat and could result in the cement plant being a net electricity producer with revenues for electricity export. The cost of CO

2 avoided for the Cal tail-end configuration when designed for 20% IL is shown in

Figure 7. With this design, the CaL system requires significantly more fuel compared with the 50% IL design, but is also a net producer of electricity. This could be an important feature for a plant located in a region with high electricity prices and/or where the produced electricity substitutes generation with significantly higher specific CO

2 emissions. However, under the conditions applied in the cost analysis a similar balancing effect between the fuel consumption and electricity generation is seen in both designs and the cost of CO

2 avoided is calculated to be about the same, 52 €/t

CO2.

The characteristics of the power generation system in terms of efficiency and specific CO

2 emissions will depend on the geographical location of the cement plant and have an impact of the cost of CO

2 avoided, especially for electricity intensive technologies such as the MAL technology. The cost of CO

2 avoided for the MAL technology when electricity is generated solely from renewables, and with the same selling price is shown in

Figure 7. The resulting CO

2 avoidance cost of 75.4 €/t

CO2 is around 10% lower than calculated for the baseline scenario.

The investigation of alternative scenarios for CO2 capture illustrates that the selection of a capture technology will depend strongly on plant-specific and local area characteristics, such as flue gas composition, vicinity to a potential steam exporter and electricity market conditions.