1. Introduction

Global warming continues to be one of the main problems the planet is facing, and transport is one of the most damaging sectors. According to reports by the International Energy Agency (IEA), in 2015, 32,250 MtCO

2 were emitted by combustible fuel throughout the planet (44.9% by coal, 34.6% by oil, 19.9% by gas, and 0.6% by other fuels [

1]). Of these emissions, the transport sector is the second largest producer, contributing 24% of the total, only behind the electricity and heat sector, which contributes 42%.

Table 1 provides a breakdown of the various types of transport that contribute to CO

2 emissions, which clearly highlights road transport as the largest contributor, with 5800 MtCO

2 [

2,

3]. Road transport emissions cause two fundamental problems: (1) local order, since transport causes high levels of noise and pollution in urban areas (PM

10, PM

2.5, NOx, HC, CO), and (2) the global emissions of CO

2 into the atmosphere.

Despite the introduction of increasingly rigorous regulations aimed at controlling polluting emissions from conventional vehicles (powered by Internal Engine combustion (ICE) to diesel and gasoline), the underlying problem is the failure to consolidate already proposed policies to achieve a fundamental change in the use of alternative technologies. For example, the European Union (EU), looking at Horizon 2020, ruled on April 23, 2009 to implement the “DIRECTIVE 2009/28/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL, on the promotion of the use of energy from renewable sources and amending and subsequently” [

4], which makes reference to public transport, in particular, providing incentives for its use, the application of energy efficient technologies, and the use of renewable sources in the sector, in order to reduce the dependency on petroleum.

Analysing the subject at a local level (Spain), in 2013, 239.7 MtCO

2 were emitted by all sectors, and the largest CO

2-emitting sectors in Spain were transport (34.1%) and power generation (20.4%). Industry accounted for 16.6%, followed by other energy industries (including refining) producing 7.9%, households producing 6.6%, and the commercial sector producing 6.5% of the total [

5]. The transport sector shows a similar trend at the world level, with road transport being the most representative in the contribution of CO

2, emitting 81.08 MtCO

2 of the 86.13 MtCO

2 total. In other words, this type of transport represents 94% of all the emissions of the sector.

The main cause of these high CO2 emissions in the transport sector is the excessive use of energy vectors from non-renewable sources, especially gasoline and diesel. The problem of energy dependency is crucial in countries such as Spain that lack these resources, and are forced to import them. Therefore, it is essential to look for alternative sources and methods in order to reduce the demand for this type of resource.

Public transport via urban buses plays a fundamental role in society, as it is an efficient means to move a considerable number of people throughout a city. With the current occupation rate in relation to cars, a standard full urban bus could remove more than 40 cars from the city [

7], which would considerably improve traffic problems, reduce noise pollution, improve air quality, and reduce pollution and greenhouse gas (GHG) emissions.

Considering society’s current mobility needs, the frequency of bus use has increased. As increasing the frequency increases the volume of the fleet, producing more emissions levels with conventional fleets. As such, a current theme is the promotion of sustainable mobility via various non-traditional solutions [

8], where electric vehicles play a fundamental role. This type of vehicle has multiple advantages over conventional ICE powered vehicles such as no noise, no point of use emissions, high global performance, and principally not relying on petroleum.

Certain types of 100% electric powered urban buses are available on the market. They tend to have two configurations. The first consists of equipping the bus with a low capacity battery pack, compensated with high power. This type of configuration does not allow long journeys, and the vehicle needs to be recharged after just a few kilometres (between seven and 10 km). Its advantage is that charging only takes a few minutes and does not require a heavy large battery pack. However, its drawback is the need for an extensive infrastructure grid, which may incur high costs. The second configuration, which is analysed in this paper, involves equipping the bus with a large high-capacity battery pack [

9], which allows travel for many kilometres. Once the working day is complete, it is charged, usually from the electric grid.

Currently, there are various original equipment manufacturers (OEMs) that produce electric buses solely powered using high-capacity batteries. Travel tends to be a minimum of 200 km, and Proterra (Proterra Inc., Burlingame, CA, USA) showcased a vehicle that can reach up to 563 km on one charge [

10]. Consumption ratios tend to be between 0.9 and 1.8 kWh/km.

Table 2 shows some models currently available on the market.

The estimated energy consumption during a driving cycle is highly important for these vehicles, as they operate in heavy traffic areas within the urban environment and have an extensive working day, meaning that the real travel distance can be less than claimed by the manufacturer. An example of this is the urban buses operating in Copenhagen, Denmark, where BYD k9 vehicles (BYD Auto, Shenzhen, Guangdong, China) were tested on different bus lines, with the results showing that, with heavy traffic, the consumption ratio varied between 1.24 and 1.77 kWh/km [

11]. In other words, the autonomy is between 183 and 261 km for this vehicle, and the average error shows differences of up to 26.8% in relation to the manufacturer figures.

Simulation is a useful tool to estimate the energy consumed by an electric vehicle during a driving cycle. Prior studies, where electrically powered vehicle models have been implemented using AVL Cruise software (AVL, Graz, Austria), have proven this. For example, Varga [

12] estimated the consumption of electric light-duty vehicles under the New European Driving Cycle (NEDC); the models used were the Citroen C-Zero, Mitsubishi i-MiEV, Renault Kangoo ZE, and Renault Fluence ZE. The results showed differences below 1.9% between the measured and simulated energy consumption. Another study was carried out by Rodrigues et al. [

13] where they replaced a conventional taxi fleet by electric vehicles. The results showed that a light electric vehicle consumed up to eight times less energy than a petrol powered vehicle, with the advantages of not emitting CO

2, NOx, HC, CO, and suspended particles (PM

2.5, PM

10).

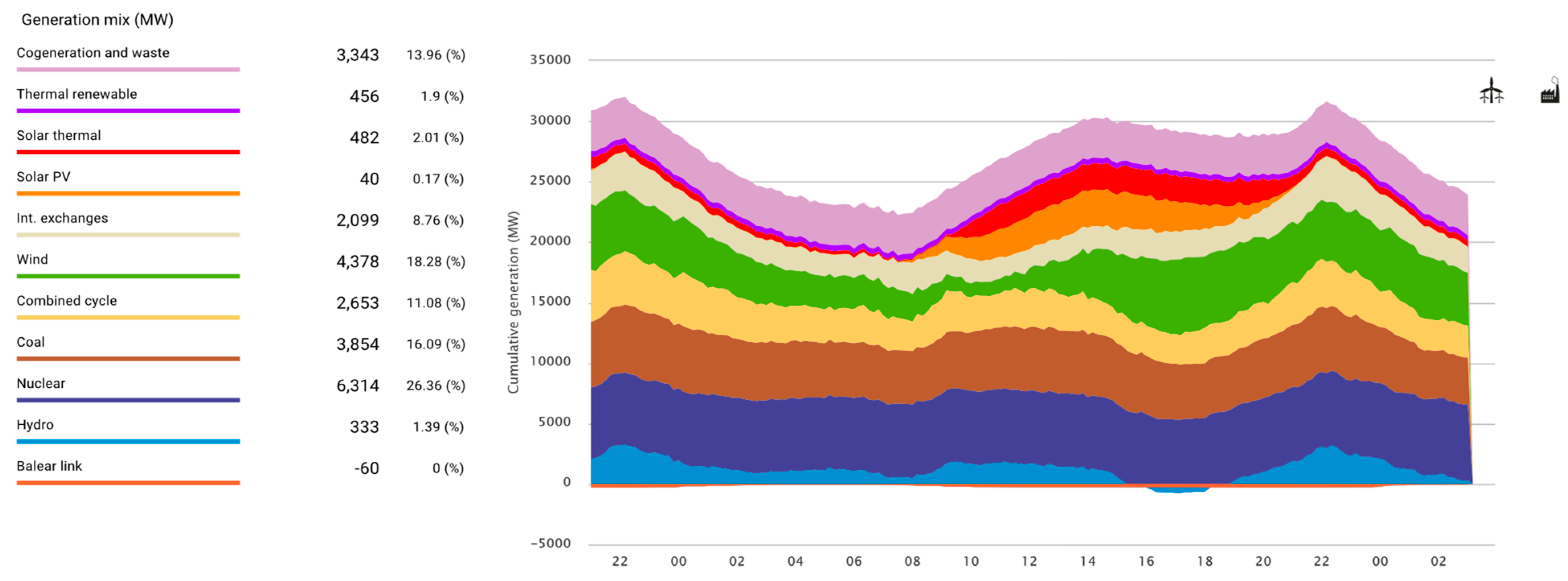

The electric vehicle concept consists of it being charged using the electric grid, meaning it is important to estimate the emissions they cause. The national energy matrix is one of the principal sectors involving a country’s social and economic development. Electric energy is an energy vector generated using primary resources (coal, oil, gas, wind, waste, solar, etc.), recorded in real-time from energy power stations. Electric power sources must have the following features: supply safety, quality, and diversification, so that its structure produces various types of electric power sources in order to minimize its impact on the environment. Furthermore, electric energy should allow economic competitiveness with suitable costs. Currently, there are important considerations and commitments in accordance with the Paris COP 21 [

27] as well as the European Union energy strategy (2020 climate and energy package) [

28], which aims to reduce greenhouse effect gas emissions with the aim of minimizing harmful changes to the planet.

The Spanish electricity mix has electrical power stations including coal; fuel/gas combined cycle, which uses non-renewable resources (coal, natural gas, liquefied petroleum gas, petroleum, and derivatives); nuclear power stations (uranium-based); and electric power stations using renewable energy such as hydraulic, wind, photovoltaic solar (PV), thermal solar, biogas, and biomass. Renewable energies (excluding hydraulic that existed previously) have been implemented based on a legal framework that provided incentives for their introduction, with the aim was not being exclusively energy dependent on non-renewable sources.

Table 3 shows the nominal installed power values for each type of power station and their electric energy contribution in 2017.

The Spanish electricity mix is quite diverse as there are 12 types of power station. This has occurred because Spain was one of the pioneers in the inclusion of alternatives energies in the national energy mix, with 104 GW total currently installed, of which 98.87 GW is produced on the Iberian Peninsula in Spain. The energy demand covered in 2017 was 248.4 TWh, of which 33.7% was met using renewable energies, whereas 66.3% was using conventional energy.

A controversial issue related to electric vehicles is the life cycle of batteries and how it affects CO

2 emission intensity. The battery lifespan leads to comparison with several technologies, mainly diesel and petrol vehicles. Studies in which the complete life cycle of an electric vehicle has been analysed showed that contamination by lithium batteries is only 13% of the vehicle’s total CO

2 emission intensity [

31].

A strength of the electric vehicle in comparison to traditional technologies is that it depends the electricity mix of a country. In the European Union, the Polish have the highest emission factor (650 g CO2/kWh). Despite this, if electric vehicles are incorporated into this electricity mix, their CO2 emission intensity is 25% less polluting than a light diesel vehicle. As the average emission factor is 300 g CO2/kWh, the European Union goal to reach 200 g CO2/kWh by 2030 further supports the use of electric vehicles.

Having viewed the current situation in relation to electric vehicles and its application in urban buses, this paper aims to characterise, via simulation, a conceptual model with this type of powertrain. The parameters and specifications are set to those determined for this type of vehicle. To estimate the energetic behaviour, the city of Madrid urban route is used as a reference, specifically the C1 circular line, which is considered as the most representative. The company charged with managing this transport is Madrid Municipal Transport Company (EMT), which has 2050 buses and 209 routes. Its importance in the city`s transport system is so significant that it carried 430 million passengers in 2016 [

32].

The proposed approach for an urban bus with a large high-capacity battery pack is based on EMT’s intent to gradually electrify its fleet (strategic plan 2017–2020 [

33]), where 15 electric buses with characteristics like the proposed conceptual model have recently been acquired. The current percentage of the fleet with vehicles of this type is 1.76%, corresponding to 36 units.

The electric urban bus completes a traditional working day (16–18 h), then the electric energy consumed is recharged to complete a new working day. As a conceptual framework, this type of vehicle should be charged using the electric grid, so that the search for primary energy sustainability can be recommended. The current Spanish electricity mix has a representative contribution of renewable energies and the night time is a good time for the vehicles to be connected to the electric system.

The final part of this paper considers the gradual replacement of the fleet and its effect on the reduction of CO2 emissions.

2. Methodology

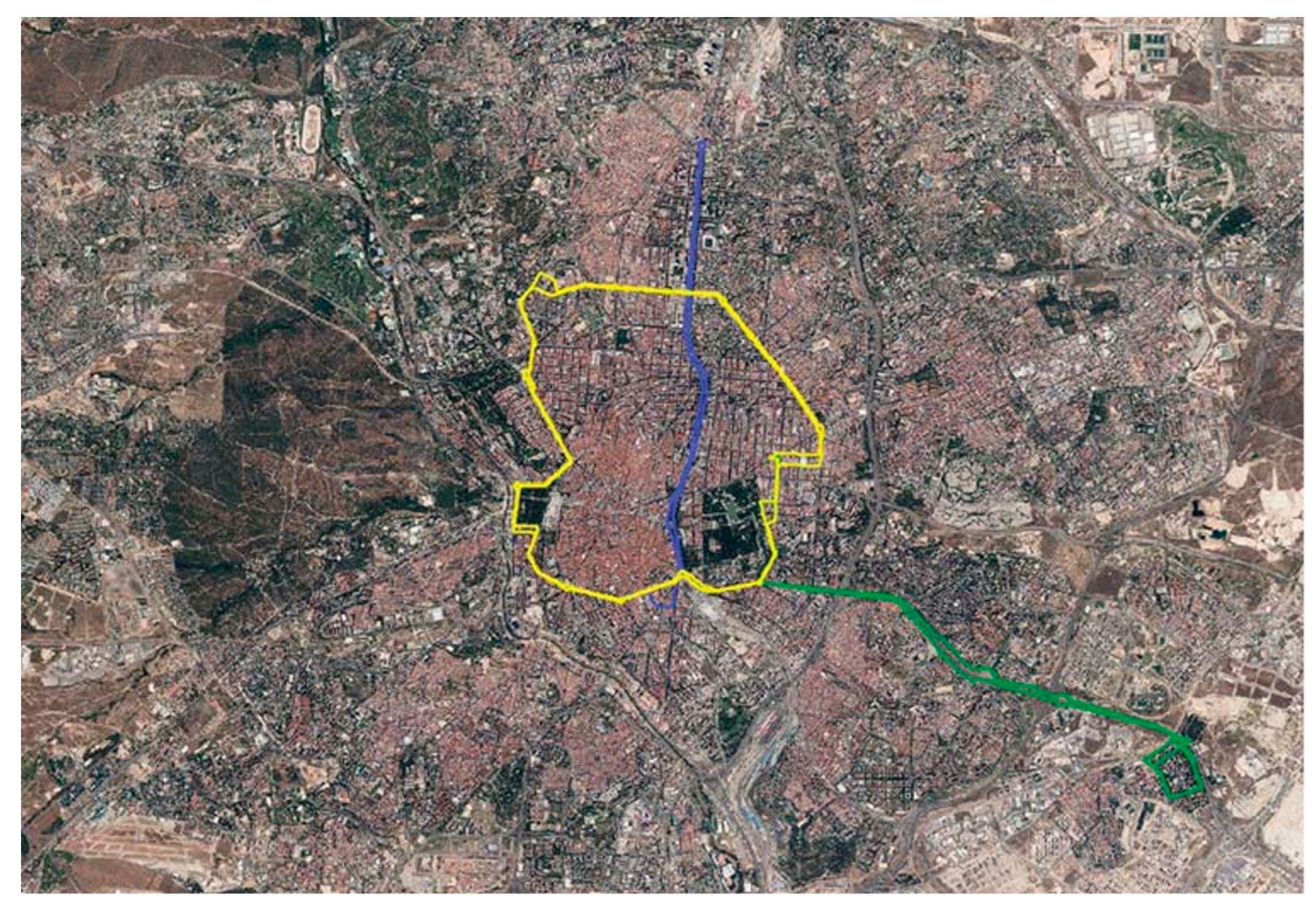

Experimental data obtained from real drive conditions were used as a starting point. These routes were selected from the three most significant clusters; the routes correspond to the 27, 63, and C1 (

Figure 1) bus lines in the city of Madrid [

34], which were chosen because they resemble 53% of bus routes in the urban area that circulate in Madrid. Our work is based on previous studies [

34,

35,

36,

37,

38] developed by the University Institute for Automobile Research, Technical University of Madrid (INSIA) and applied to the EMT bus fleet, where 30 lines were tested using on-board equipment. These conditions allowed us to mimic reality, including all sources of variability, such as environmental conditions and traffic, driver behaviour, highly transitory operation, and the variable operating conditions of the vehicles.

The measurements were recorded when the bus was in service; movement cycles and stop periods can be distinguished and these periods are called kinematic micro-cycles. The movement cycles are characterised by variables such as total time, constant speed times, acceleration and deceleration process times, and average acceleration and deceleration times.

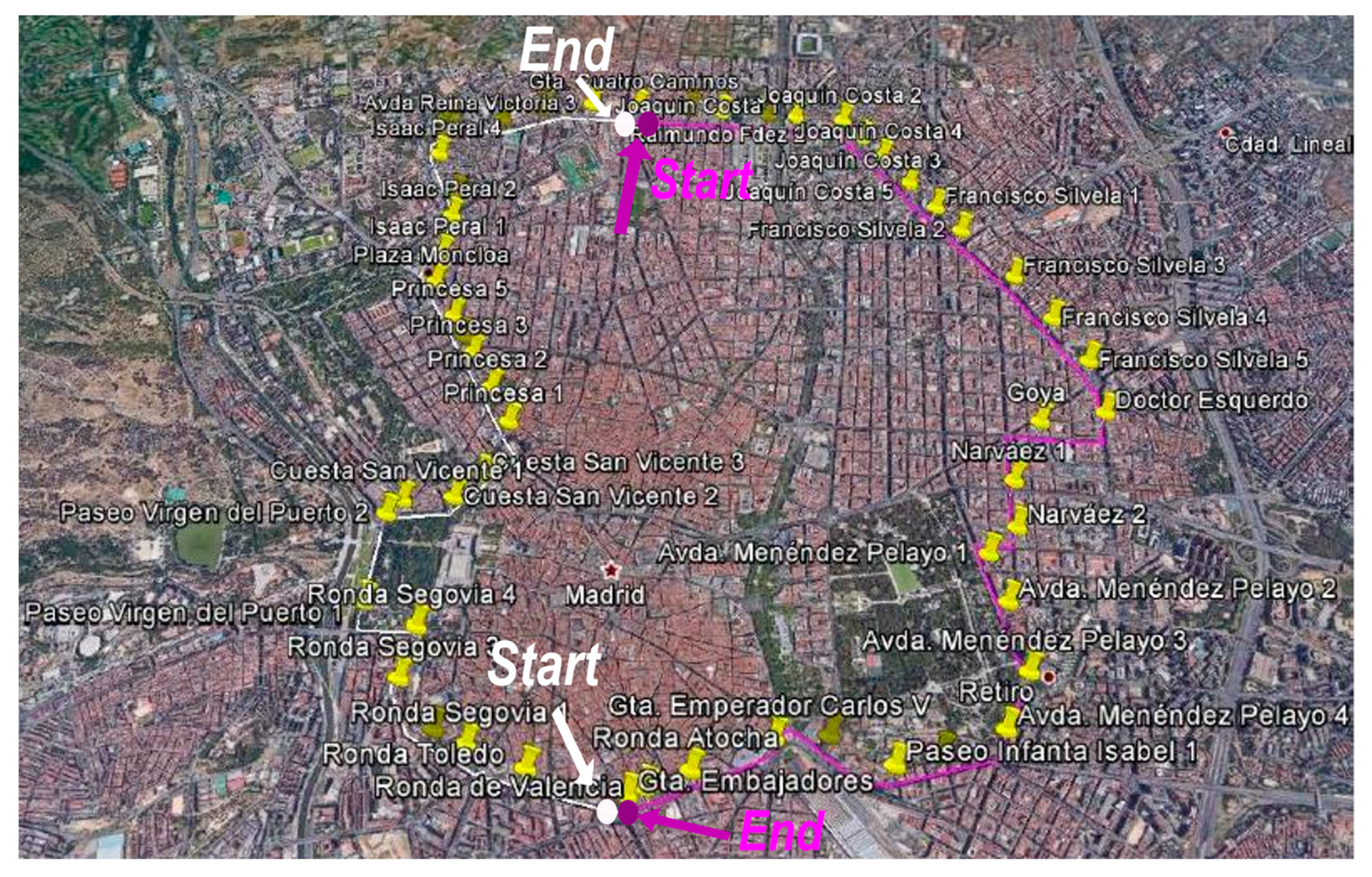

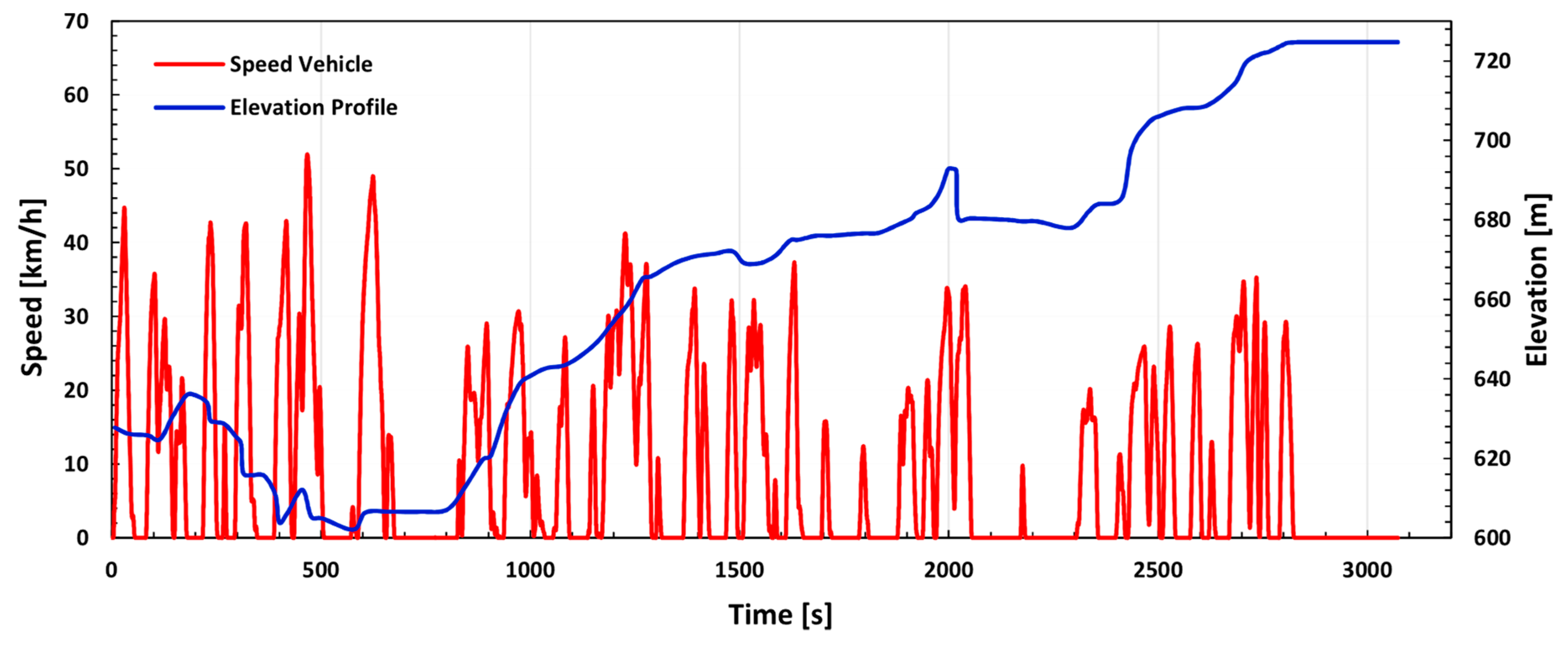

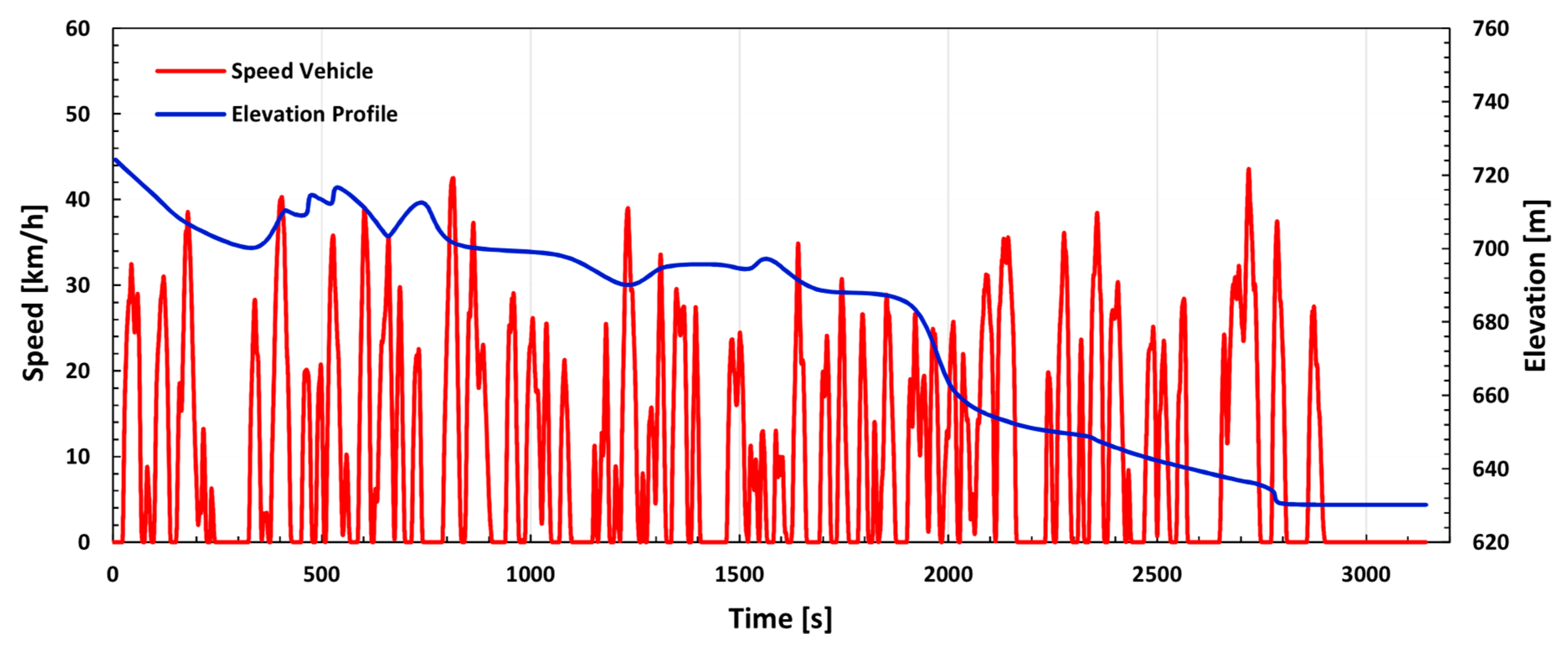

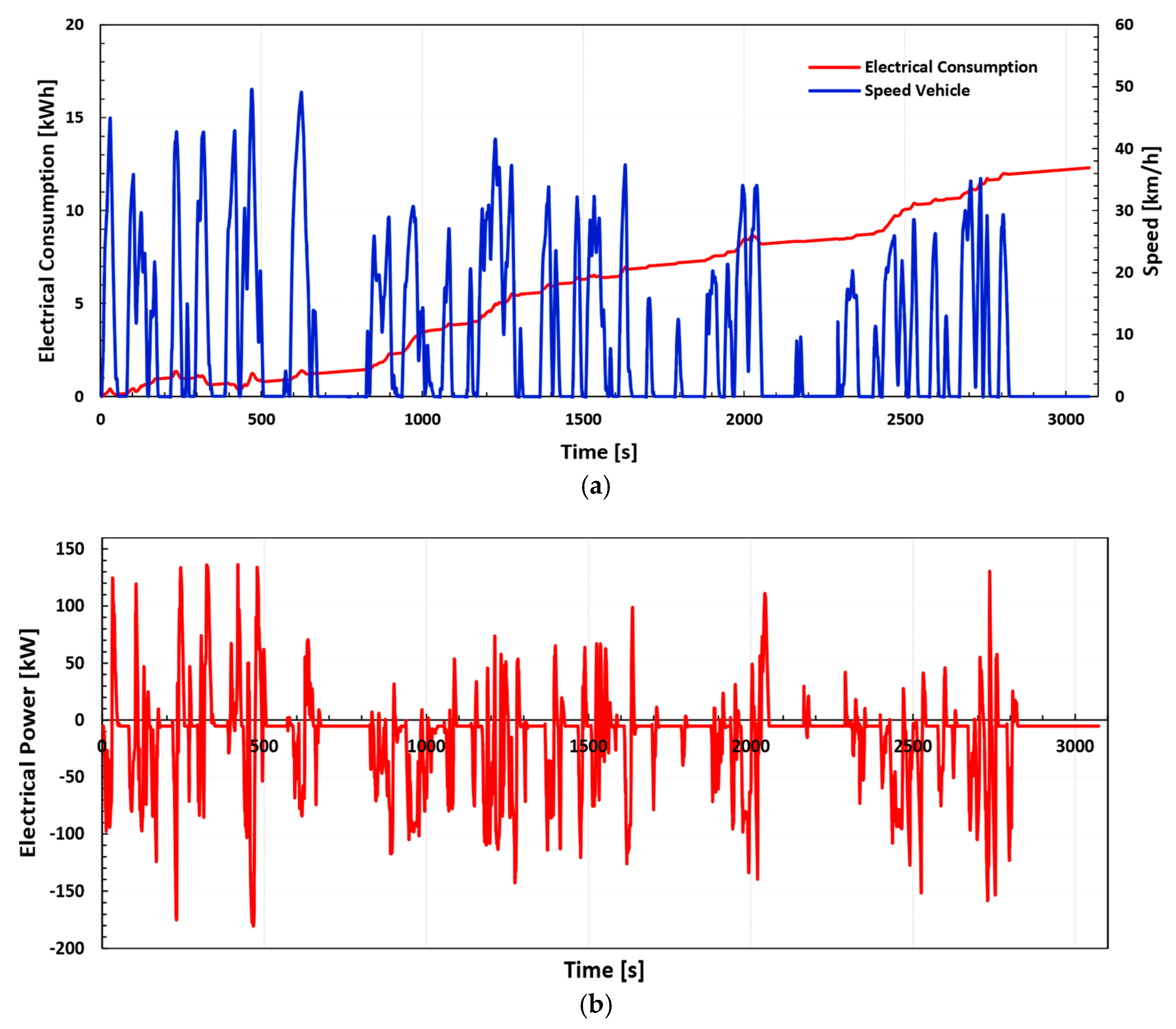

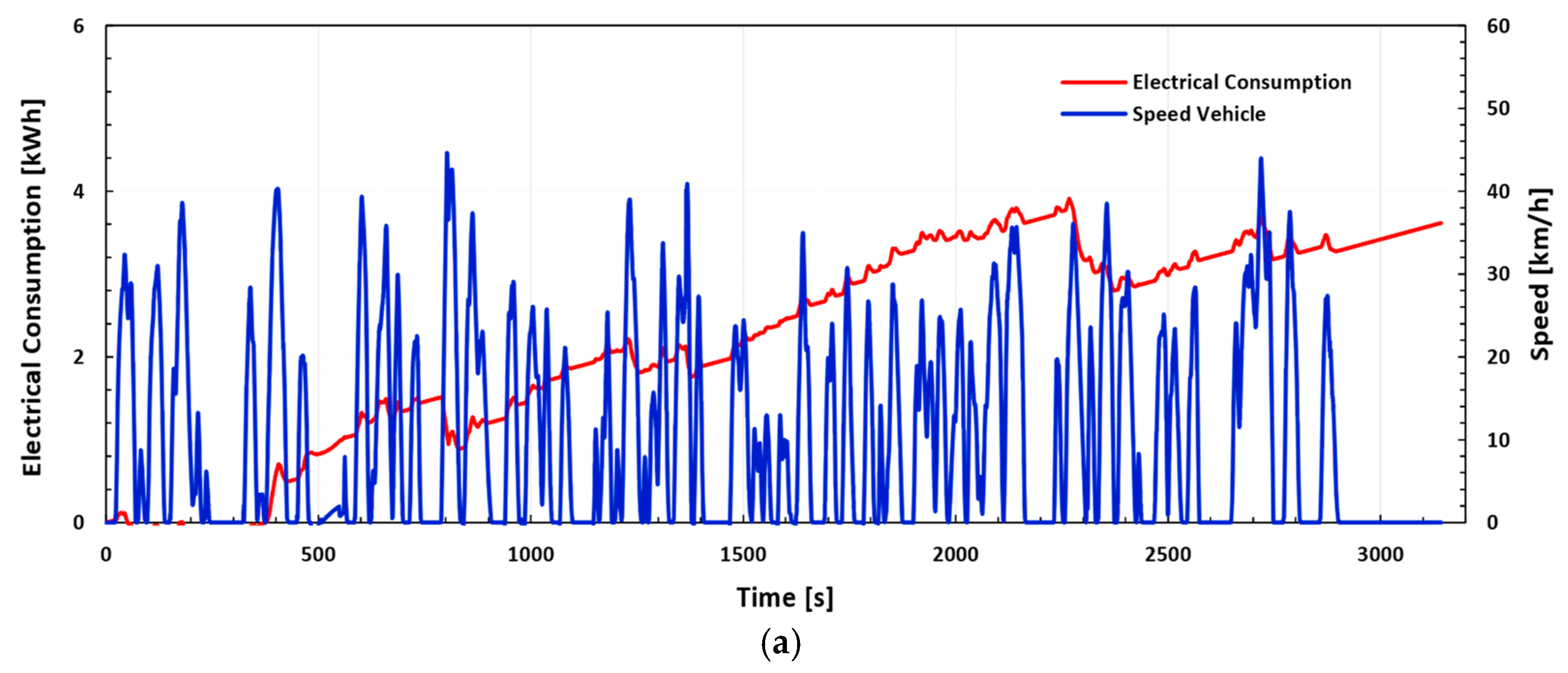

The data obtained from the C1 circular line (

Figure 2) were chosen and the speed and height profile are depicted in

Figure 3 and

Figure 4, respectively. This driving cycle is variable and best represents the different operational conditions within the city’s urban environment. The route was divided into an outgoing itinerary (route 1) and an incoming itinerary (route 2).

Table 4 provides a summary of the data obtained from the trials.

2.1. Design of the Propulsion System

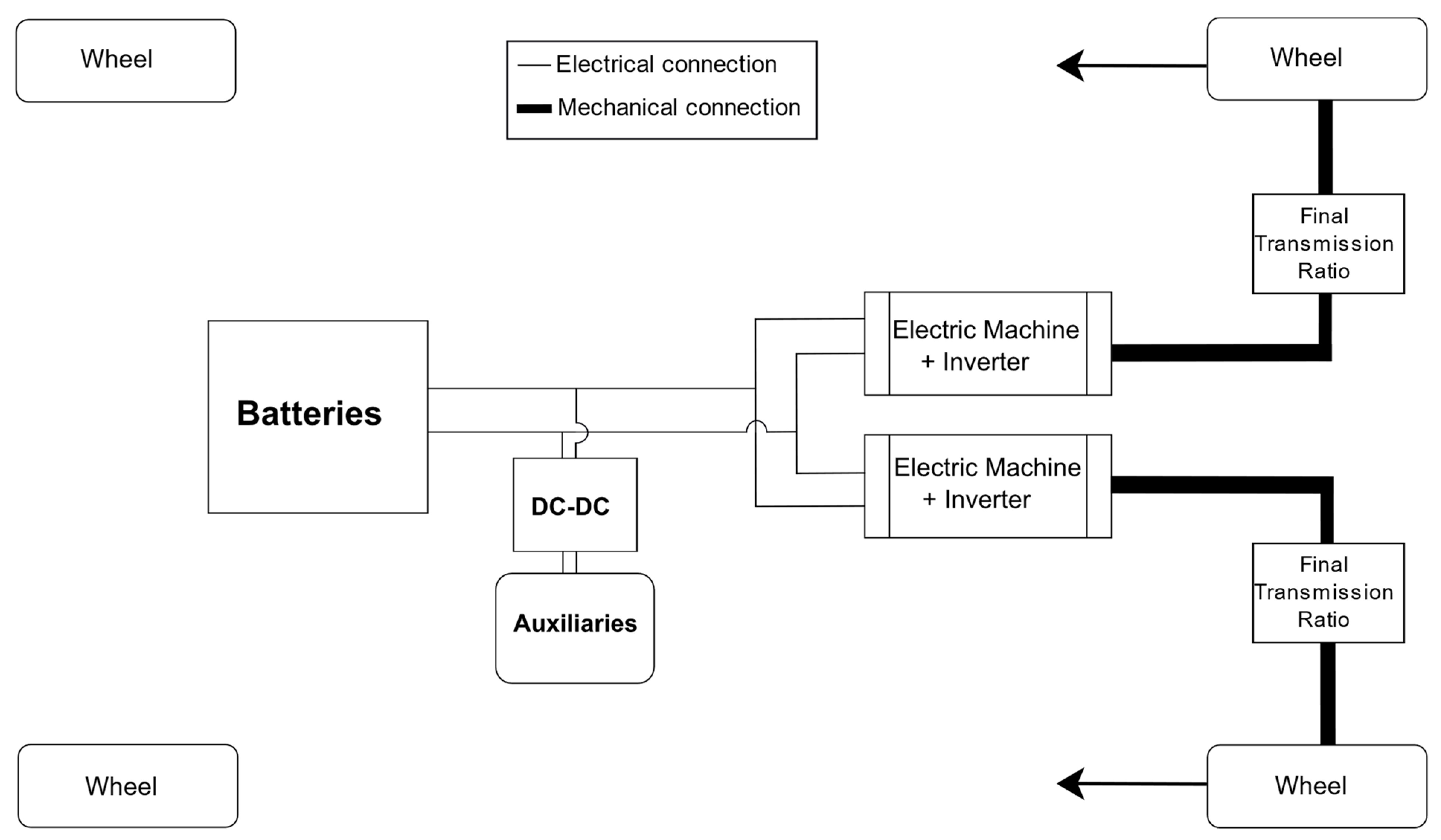

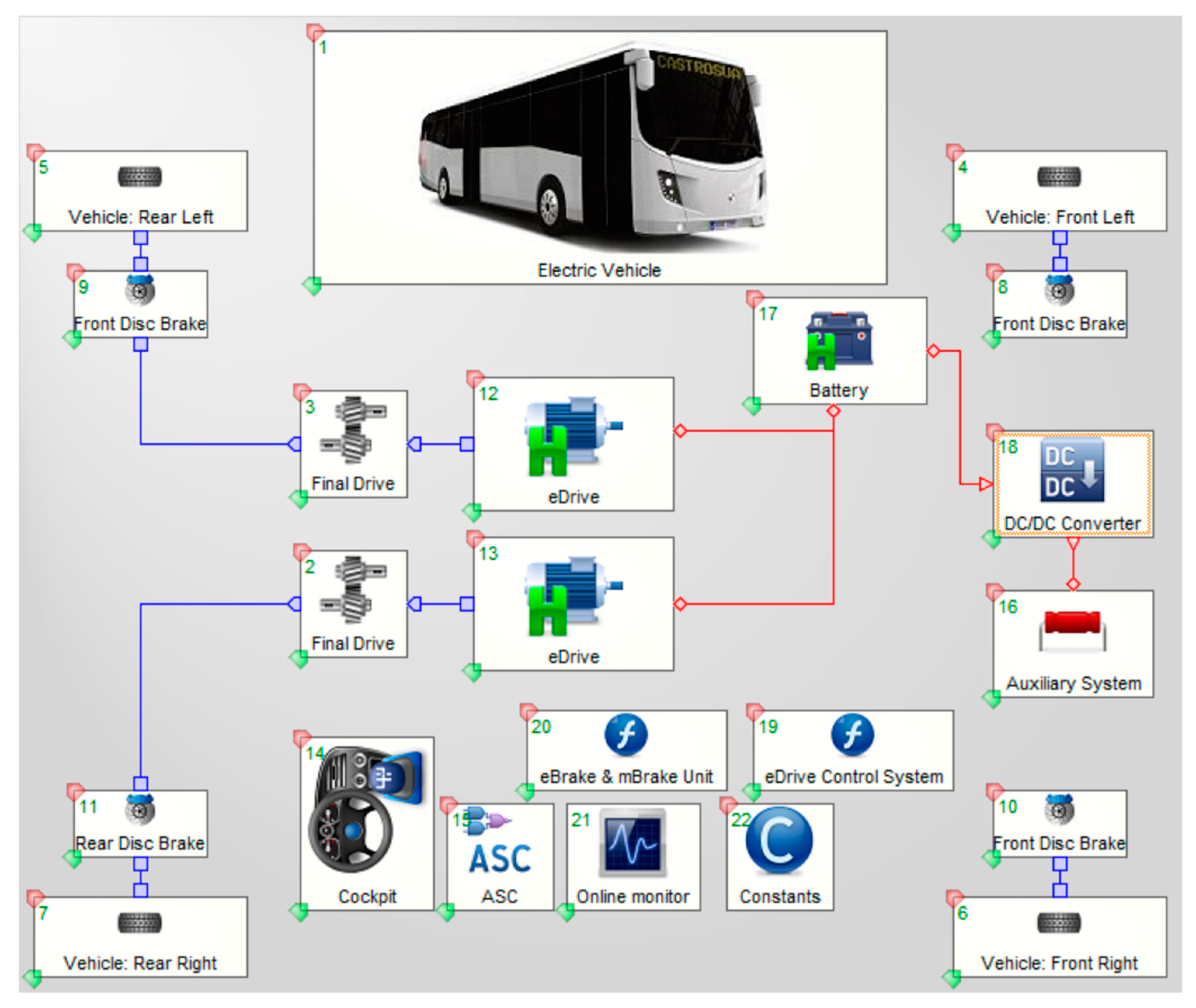

The configuration of the system is shown in

Figure 5. The powertrain was composed of: energy storage unit or batteries, electric machines, DC–DC converters, DC–AC inverter, auxiliary systems, and final transmission ratio. The optimal design of the powertrain depends, to a large extent, on the correct analysis of the longitudinal vehicular dynamics [

39,

40]. To calculate the tractive effort necessary for the movement of the vehicle, the resistant forces that must overcome were analysed (

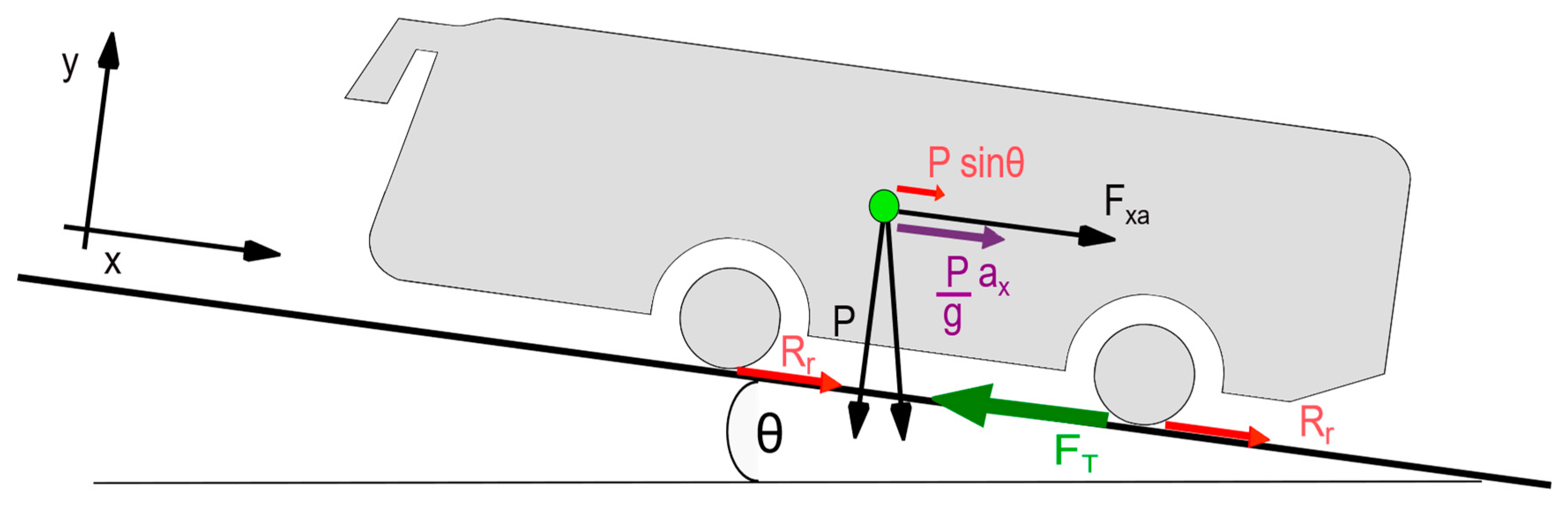

Figure 6), including: rolling resistance, aerodynamic drag, gravitational resistance, and resistance to inertia. Applying Newton’s second law and the Euler equation, we have:

where

m is gross mass,

is longitudinal acceleration,

is the mass factor,

is the tractive effort developed by a traction motor on driven wheels,

is rolling resistance,

is aerodynamic drag, and

is gravitational resistance.

So, the tractive effort is equal to:

is estimated by the following expression:

where

is the moment of inertia of the masses that turn with the wheels with respect to their rotary axes,

is the moment of inertia of the transmission components,

is the kinematic radius equivalent to the radius of the wheel under a load, and

is the final transmission ratio.

Alternatively, the tractive effort

can be calculated once the powertrain has been dimensioned through the following expression:

where

is the moment of inertia of the masses that turn with the wheels with respect to their rotary axes,

is the moment of inertia of the transmission components, and

is the radius under load (effective radius of the driven wheels).

2.1.1. Performance criterion

For heavy vehicle applications, particularly in relation to human transport in urban environments, we complied with the following general and specific conditions for this study case:

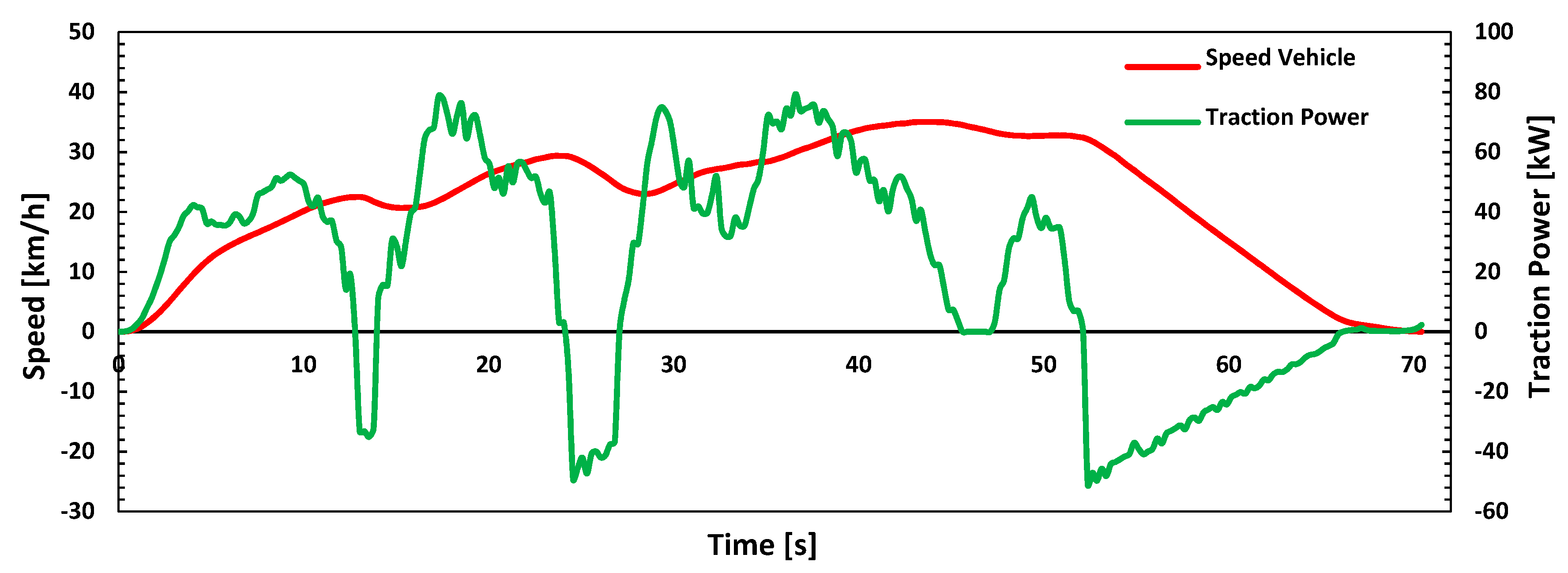

The drive cycles are normally repeated using the same pattern: cycles between one and three minutes as a maximum, with speeds below 60 km/h (

Figure 7).

Numerous stops are used that reduce the average power used during traction; however, there is an increase in the number of accelerations and decelerations.

There are high autonomy needs given that the service duration tends to be around 18 h, the working day is from 5:30 a.m. to 11:30 p.m., meaning the window of connection to the electric grid is limited to between 12:30 and 4:30 a.m., considering time losses due to logistics.

There is high energy consumption from auxiliary systems, so when sizing the energy storage system, attention should be paid to this variable.

Performance criteria are limited to the speed requirements in urban areas, where buses rarely reach speeds of 60 km/h given the short distances between stops, as well as other factors such heavy traffic and speed restrictions. The criteria that were considered when designing the powertrain were: maximum speed, acceleration, and maximum slope [

41,

42,

43].

Table 5 shows the urban bus conceptual model specifications.

The power can be estimated under the aforementioned criteria. The tractive power required for the maximum speed is determined using the following equation:

where

is the tractive power for the maximum speed,

is the gravity acceleration,

is the rolling resistance coefficient,

is the aerodynamic drag coefficient,

is the air density,

is the frontal area, and

is the maximum speed.

The tractive power required for acceleration is considered the acceleration time from zero up to a specified speed (65 km/h). Equation (6) states this as:

The tractive power required for acceleration () in this equation is applied to a specific acceleration standard, where is the acceleration time employed, which is 28 s in this case. is defined based on how long it takes the vehicle to reach its maximum speed from its initial speed equal to 0 km/h. is the base speed of the vehicle (15 km/h) and is the final speed (65 km/h) and is the maximum speed of the vehicle.

For the tractive power required for a maximum slope (18%), the speed at which this section is travelled (15 km/h) is considered. In this case, the aerodynamic resistance can be ignored as the progress along elevated inclines occurs at reduced speeds. The equation is set as:

where

θ is the angle of the slope to be overcome and

is the speed the bus must travel to overcome the slope (base speed in this application). The results show that the tractive power required for maximum speed (

) is 52 kW for an acceleration (

) of 142 kW and for a maximum slope (

) of 132 kW.

2.1.2. Vehicle Transmission

The vehicle transmission regulates the transfer of power (torque and speed) from the electric machine to the wheels. For this, a gear system is normally used, and for electric vehicles, a single gear change may be necessary. However, this depends on the torque and speed of the vehicle. If the constant power range is large, it may provide enough high torque at low revolutions; otherwise, a multiple gearbox should be used.

The size of the electric machine in nominal power terms is linked to the mechanical power and efficiency. These are obtained based on the nominal efficiency minimum requirements, which should comply with IE2 efficiency levels as of June 16, 2011 in accordance with the European Commission [

44]. The efficiency for this type of motor is around 94%. The following equation determines the electric power of the machine:

where

is the electrical power,

is the mechanical power,

is the efficiency of the electric machine,

is the tractive power required for acceleration, and

is the drivetrain efficiency.

The maximum motor torque characteristic is described via the correlations between the output torque, the output power, and the angular speed. The motor output torque is calculated using the following expression:

where

is the output torque,

is the angular motor speed,

is the final transmission ratio,

is the angular speed of the wheel,

is the linear vehicle speed,

is the nominal radius of the driven wheels, and

is the longitudinal sliding (0.1–0.3).

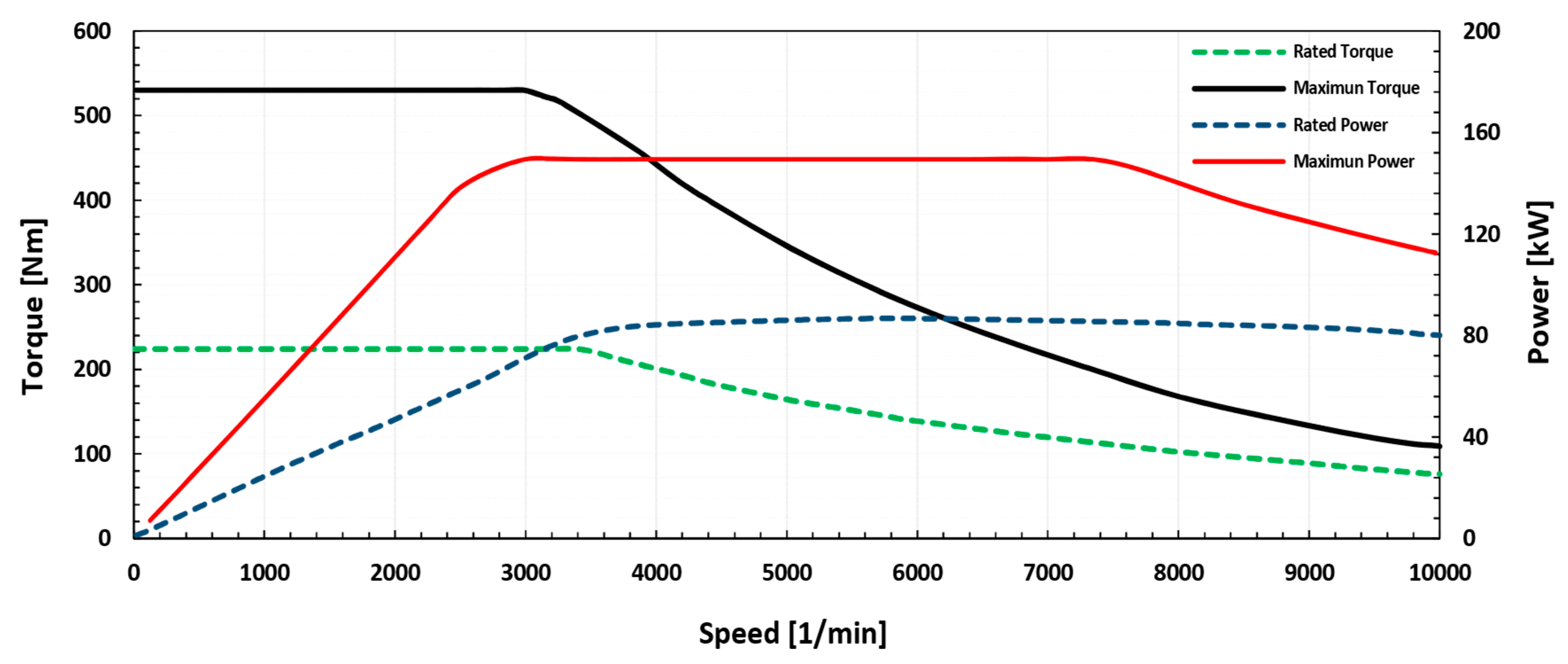

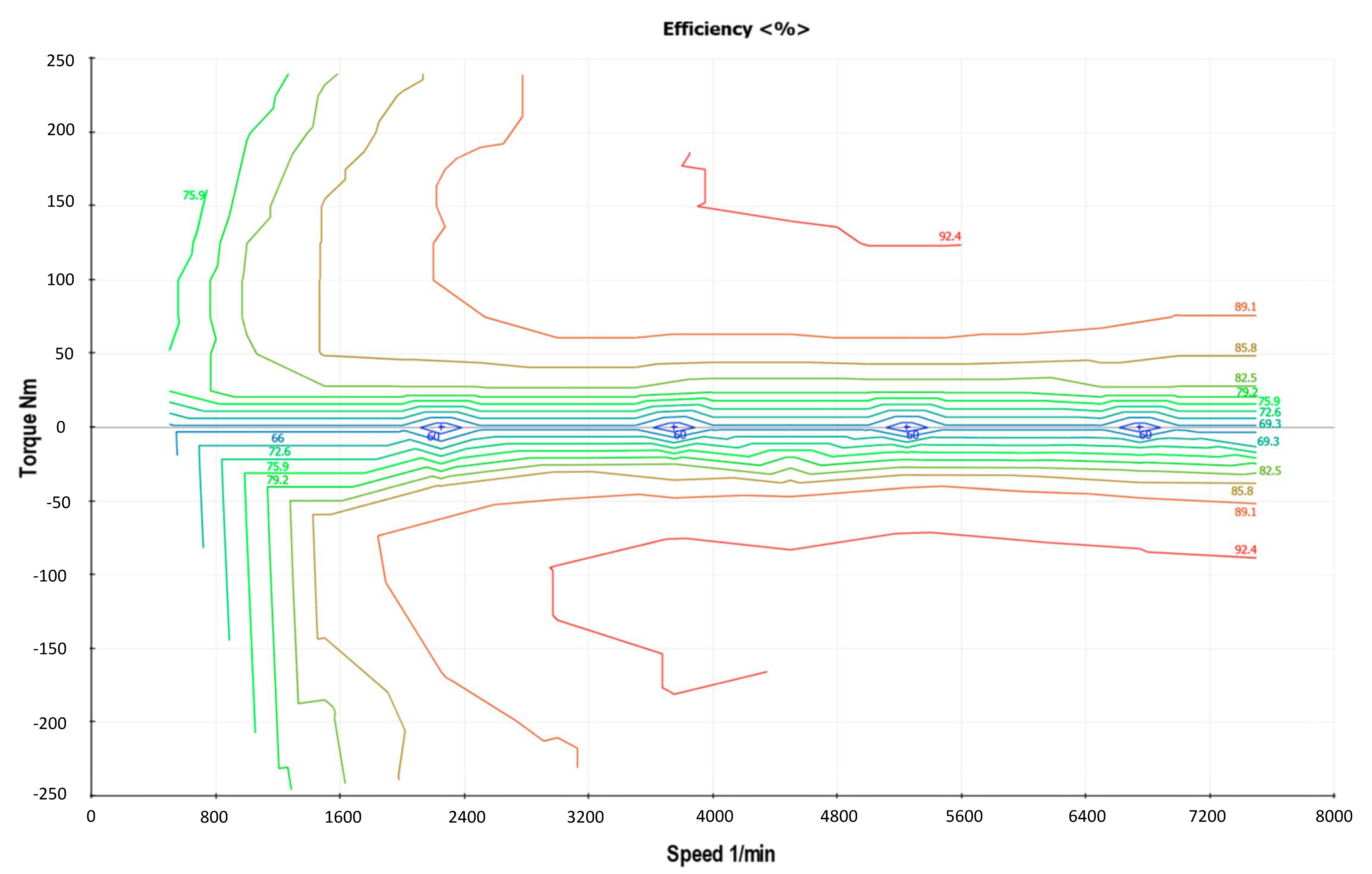

The above calculations determine that the electric machine power should be around 157 kW and the required torque should be 152 Nm. To complete the simulation, the characteristics of two motors connected to each rear wheel were chosen. The nominal power of each was 85 kW with a nominal torque of 220 Nm. The total nominal power was 170 kW and 440 Nm total nominal torque. The characteristic curve of this motor can be seen in

Figure 8, where the torque and maximum power are 530 Nm and 150 kW, respectively, for each motor, which cover the full range of requirements.

Table 6 shows the details of the characteristics of this component.

2.1.3. Auxiliary System

The energy consumption estimates for the auxiliary components (interior and exterior lighting, refrigeration pump, electrical steering, air conditioning, pneumatic brakes) are of great importance because the vehicle energy is limited, and recharging can take a long time. As the vehicle is in constant operation throughout the day, the energy consumption of the auxiliary systems may be high, from 20 to 40 kWh/100 km for this type of vehicle according to the IEA [

46].

Gao et al. estimated the energy consumption of the auxiliary systems as 3980.2 kJ and 4812.1 kJ (1.1 kWh and 1.33 kWh, respectively) for two different types of powertrains for urban routes in China according to the China Typical Bus Driving Cycle CTBDC), which has an approximate time of 1300 s. However, during these tests, operation of air-conditioning was not included [

47,

48].

According to Miranda et al., the instant peak power of all the auxiliary systems together did not exceed 10 kW on an 11-km-long urban bus route in Brazil. The vehicle consumed 17.6 kWh of net energy with the auxiliary systems consuming 2.46 kWh for 1250 s during the route. These values represented 14% of the total energy consumption of the system, with a total consumption ratio of the vehicle of 1.6 kWh/km [

49].

Gao et al. estimated the power of auxiliary systems on series and parallel hybrid buses as being 2.29 kW [

50], with 3.75 kW for electric buses [

51], as opposed to Göhlich et al., who found power consumption of 6 kW for the auxiliary systems [

52].

Based on the literature, a value of 5 kW of power is proposed for the auxiliary systems. For the model to be more accurate, we decided that the power will be constant during the full journey, so that it will represent extreme energy consumption in the simulation model.

2.1.4. Battery Model

The battery power should be in excess or equal to the electric machine’s power (

) plus the auxiliary system’s power

meaning the battery power should be at least 175 kW. The following equation estimates the above:

The output power on the battery terminals during the running of the routes is calculated using the following equation:

The first term represents the power necessary for traction, which is equal to the resistance power over the loss of power in transmission and the electric machine, represented by their efficiencies

and

, respectively. The second term represents the power of consumption of the auxiliary components, which is considered constant in this model. The regenerative braking power during the driving cycle at the battery terminals can be expressed as:

where the slope, acceleration, or even both are negative;

(

) it is the regenerative braking factor, which is an applied braking effort function of the design and control of the braking system in a way that allows the estimate of the braking percentage to be recovered when using the electric machine.

The energy supplied by the battery during the driving cycle is determined using the following equation:

The first term represents the energy necessary for traction and the energy consumed by the auxiliary systems, whereas the second term is the energy recovered by the regenerative braking effect. For the analysis of this model, a battery capacity of 324 kW was determined, which is within an acceptable range for this type of vehicle (

Table 2).

Lithium-iron phosphate batteries were proposed during the design. The energy density oscillates between 80 and 130 Wh/kg with peak power between 200 and 300 W/kg [

53]. With a capacity of 324 kWh, the battery power is between 747 and 810 kW, allowing the maximum power requirement to be covered at all times.

The state of charge (SOC), which is the current energy capacity held by the battery (expressed as a percentage, where 100% means full and 0% means empty), is determined as:

where

is the state of charge,

is the battery discharge power for the traction and accessories,

is the battery charge power from regenerated kinetic energy, and

is the battery’s energy storage capacity.

Table 7 summarizes the design parameters chosen in the powertrain.

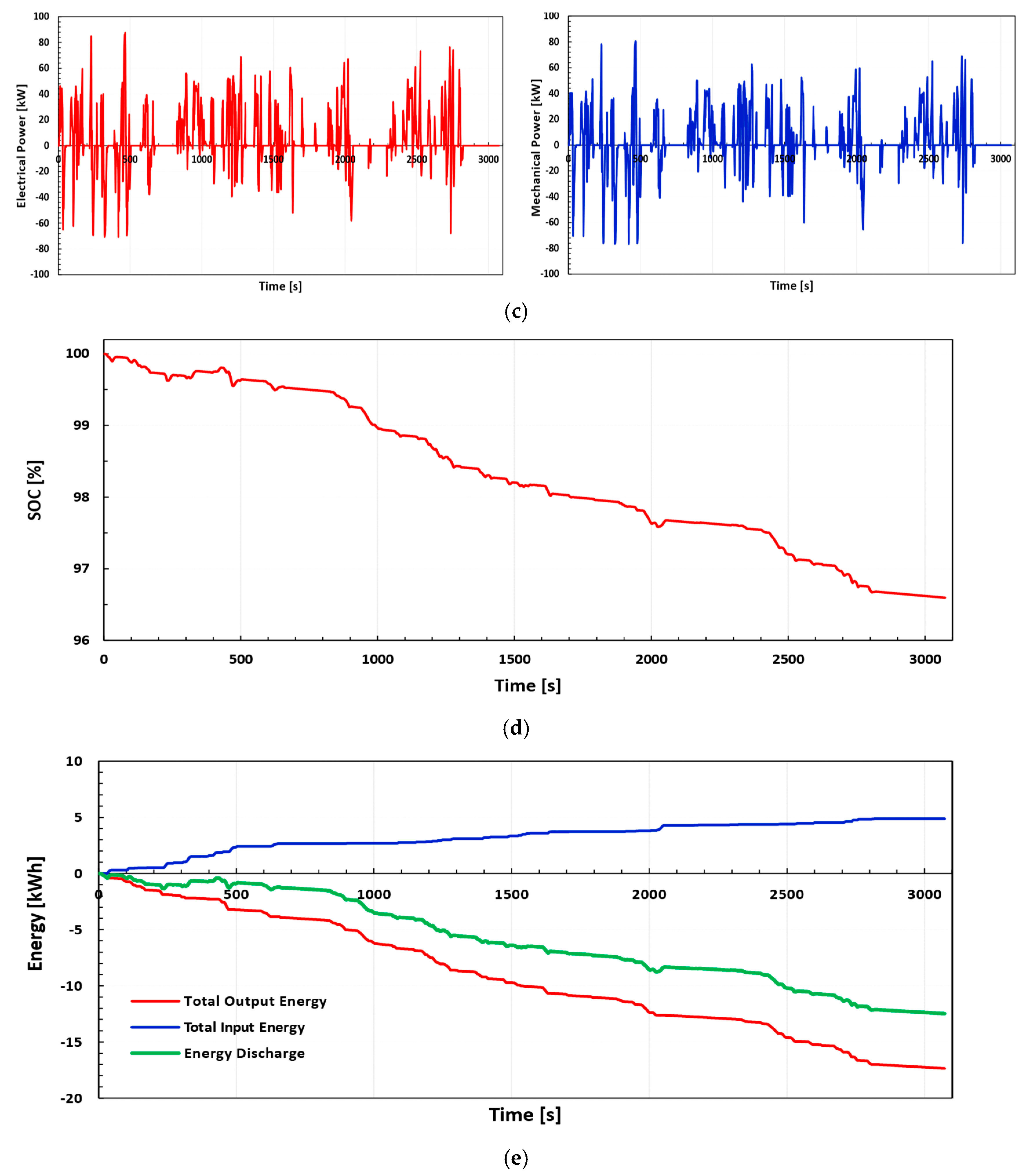

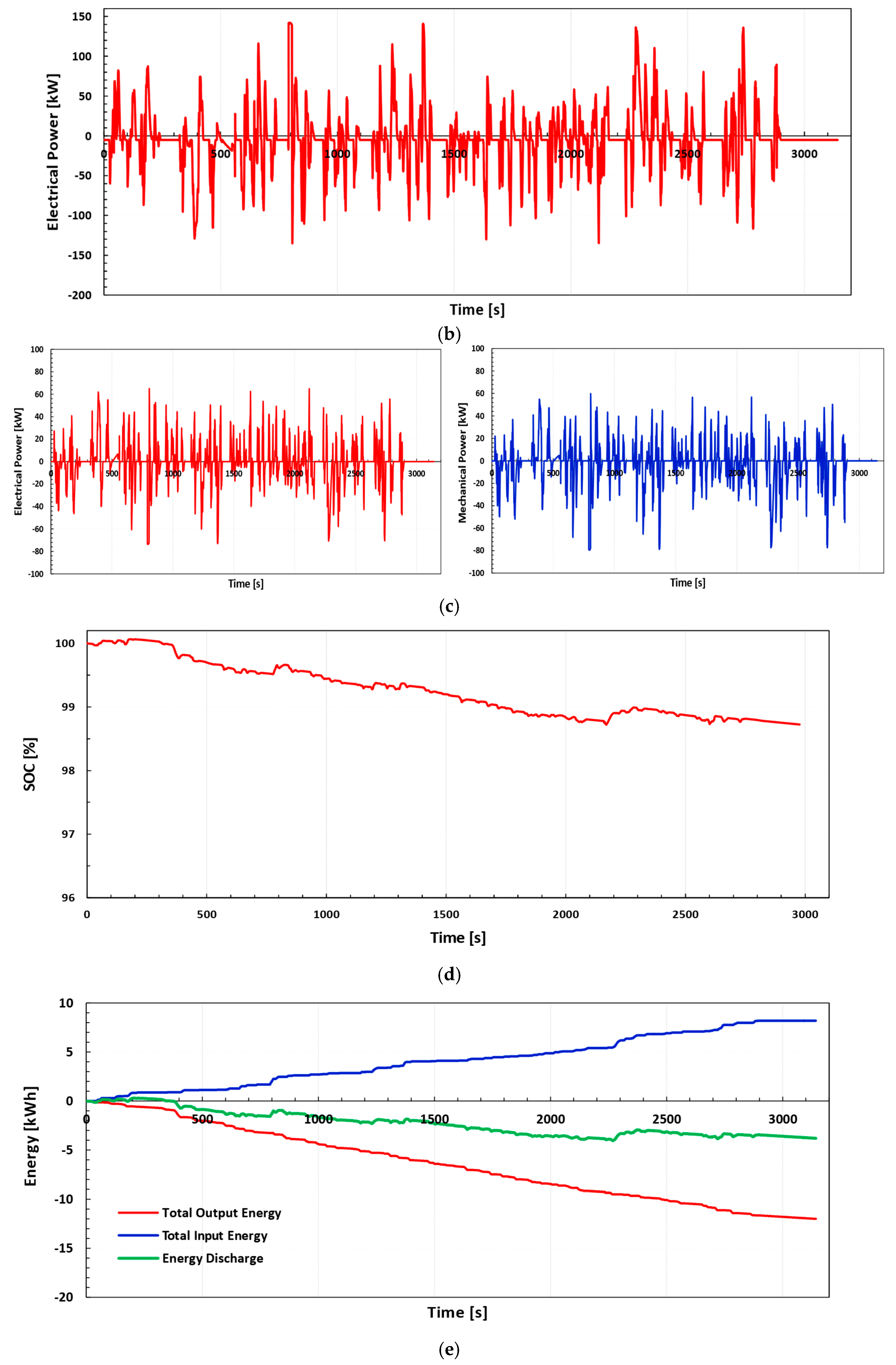

2.2. Model Simulation

Once the design parameters were established, AVL Cruise software (Version 2017, AVL, Graz, Austria) was used. This program has specific routines to calculate energy consumption of conventional, hybrid, and electric vehicles [

43]. The model proposed can be seen in

Figure 9, where the parameters and design specifications explained in previous paragraphs are depicted, including the speed and height profiles of the C1 circular line. The two routes have a total distance of 17.52 km over 6216 s’ running time (1 h, 43 min, and 36 s), including two stops over 240 s at the end of each route, which represents a short rest period for the driver or a personnel change. The objective is for the software to determine the electric energy consumption of the conceptual model proposed.

The software calculates the resistance forces via various models. We used the physical model that estimates resistant forces (

) on the vehicle plant (block one) using the following equation:

where

is the forces due to additional traction and

is the forces due to additional push.

Rolling resistance

is calculated separately on each tyre (blocks 4–7), where the transient model is defined. When this model is activated, the rolling resistance is calculated using a detailed resistance model:

where

is the Steady-state rolling resistance,

is the empirical rolling resistance coefficient,

is the actual tire temperature, and

is the stabilized tire temperature.

The electric machine (blocks 12 and 13) may function as an electric motor or generator that has characteristic curves for each modality. The block has two components included: a DC–AC inverter and the electric motor. To calculate losses of power and torque, a model is used with an efficiency characteristic map. The motor electric power is calculated as:

which is an alternative expression to Equation (8) that uses AVL Cruise and where

represents lost power due to losses in iron, copper and those caused by friction. Considering the signs convection, if

> 0, the motor operates in motor mode to propel the vehicle, whereas if

< 0 the motor operates in generator mode, recovering part of the kinetic energy produced by the decelerations. The mechanical power can be obtained using Equation (10) as:

The mechanical power depends strictly on angular velocity

motor torque

, and the efficiency depending on the motor’s characteristic map, which is a function of these three parameters. The efficiency map of the electric machine is shown in

Figure 10.

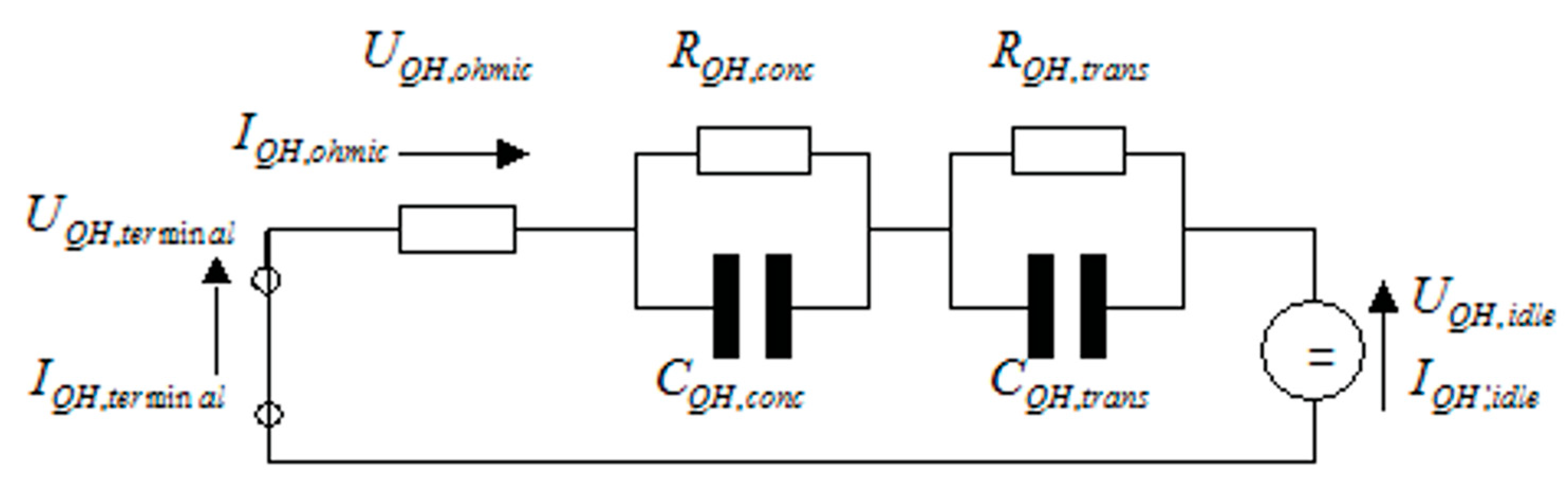

The battery (block 17) was treated as a model that consists of a source of power and resistance. The resistance model allowed us to consider the complex internal processes of the battery (

Figure 11). Two optional resistor–capacitor (RC) elements were added to describe the concentration overvoltage and the transition over-voltage [

54]. The dependence on temperature in resistance can be activated as an option. Individual cells may be modelled as well as combinations thereof, meaning any module may be constructed. A thermal model describes the batteries thermal behaviour. Here, heat caused by losses and cooling caused by convection were considered. This model allows the use of “the temperature and SOC-dependent” option. As such, the resistance and capacitances are dependent on temperature

and the charge status

. The equation concerning output voltage on a battery cell (

) is:

where

is the idle voltage of a cell,

is the actual temperature of the battery,

is the state of charge of a cell,

is the actual current through the cell,

is the internal resistance,

is the charge of the capacitance for concentration overvoltage,

is the capacitance concentration overvoltage,

is the charge of the capacitance for transfer overvoltage, and

is the capacitance transfer overvoltage.

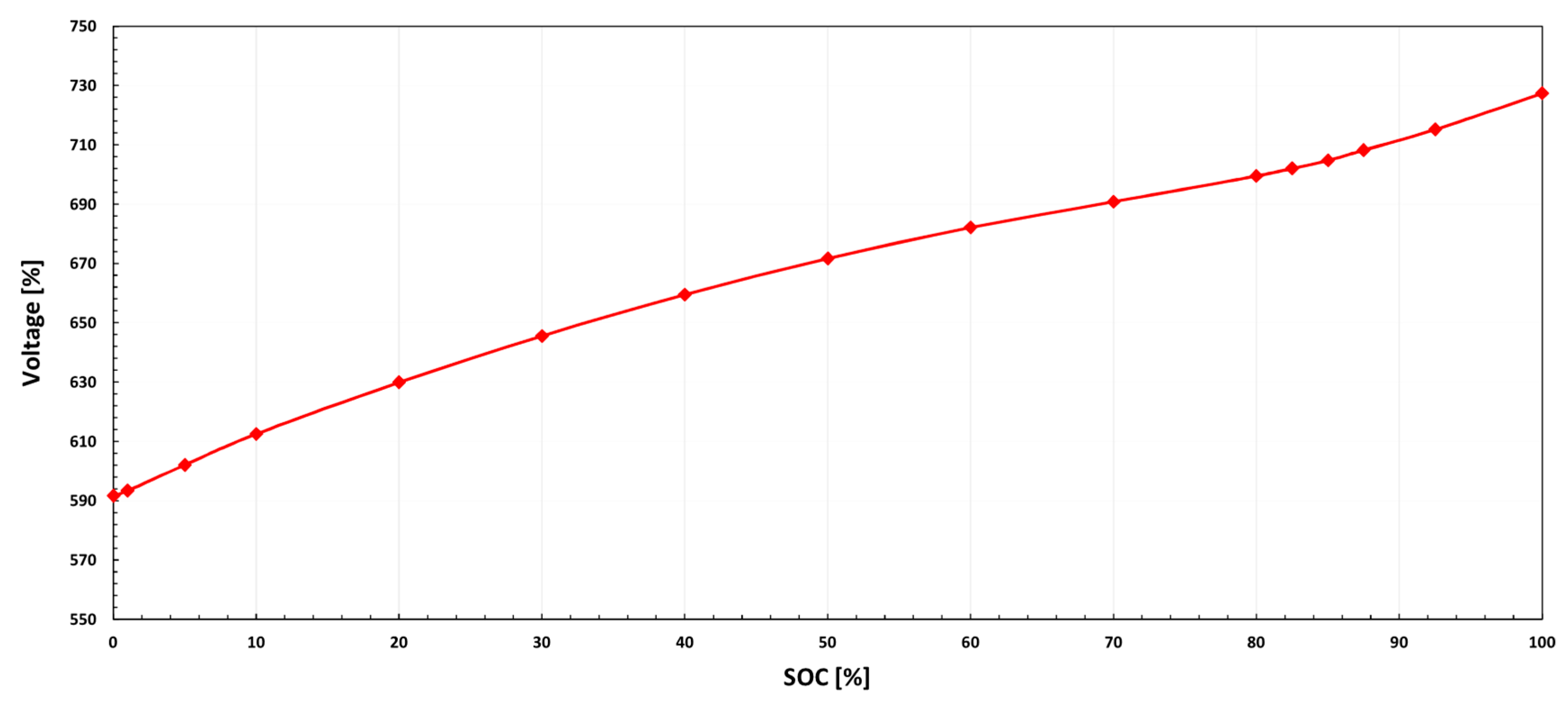

The SOC curve (

Figure 12) of the battery pack was loaded into the simulation tool, which is dependent on the chosen battery technology.

The auxiliary systems are defined in the model as consumers of electricity. They are symbolised by a single block (block 16) that represents an ohmic resistance where there are losses in electric current, meaning there is power consumption. The software allows setting the resistance value as constant, or via characteristics curves. In the model concerned, we used constant resistance, considering an average working power during the complete cycle. The instant current can be calculated using the following equation:

where

is the current,

is the net voltage, and

is the actual internal resistance.

The model shows supplementary components, such as the final drive (blocks 2 and 3), that represent the final transmission ratio of the vehicle. The vehicle’s brakes (blocks 8–11) are described using braking data and dimensions as well as a specific braking factor. The cockpit (block 14) is the component charged with connecting the driver to the vehicle; connections form using the data bus. The ASC (block 15) represents the component that controls the individual wheel friction coefficients. If a friction coefficient exceeds the maximum transferable value, the accelerator position will vary. The DC–DC converter (block 18) is a component that is used to transform, in a highly efficient manner, continuous current voltages. Its function in this model was to set the voltage for the auxiliary systems, allowing the correct flow of energy in the data bus system.

The eDrive control system (block 19) and eBrake and mBrake unit (block 20), are functions defined by the user, with its programming using C language. The eDrive function corresponds to control of the electric motor and the eBrake function acts on regenerative braking control.

The monitor (block 21) allows viewing certain calculation results while the simulation is running. Finally, block 22 provides the constants, where the values are defined and may be used by other blocks using the data bus.

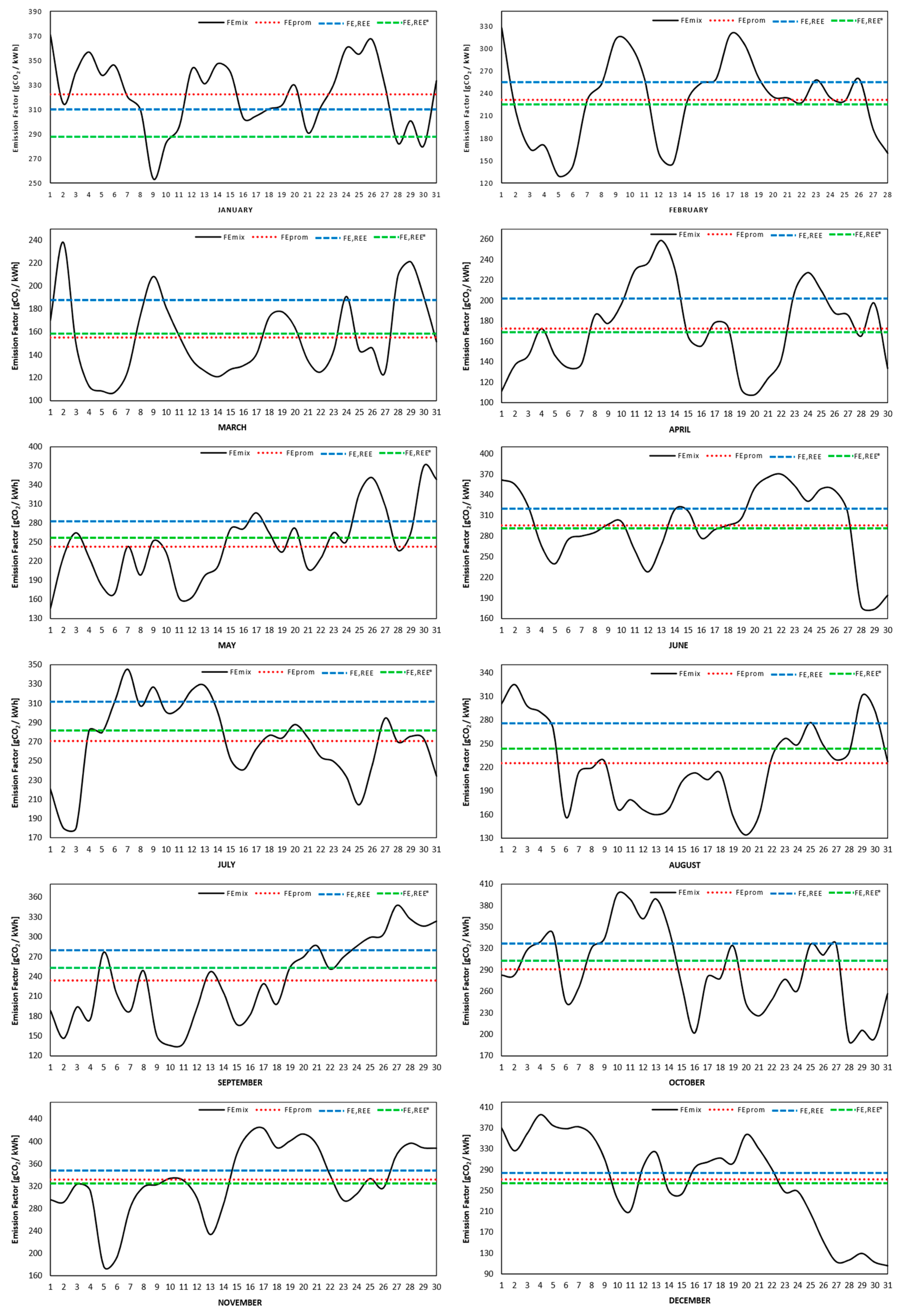

2.3. Determination of CO2 Emission for Electric Urban Buses by the Grid Power Generation

The emission component to be measured was CO

2; there was no database for the emission factors of the other power generation components [

12,

13]. To determine the CO

2 emissions of an electric vehicle, the electric generation should be considered. For this case, we studied the emission factors (FE) of the Spanish electricity mix. The emission factor of each power station must be associated with its contribution in terms of energy for the electric grid. The emission factors of the various power stations according to the Electric Grid of Spain (REE) [

29] is shown in

Table 8.

The intensity of the CO

2 emission due to charging in relation to the electricity mix was established using the following equation:

where

is the CO

2 emission intensity (gCO

2/km),

is the electricity mix emission factor (gCO

2/kWh), and

is the required electric charge from the electricity mix (kWh/km).

The electricity mix emission factor

depends on the type of power stations. The efficiency of each component of the electric grid and the vehicle charging system should be considered (

Table 9). These items make up the complete energy transport process, from the generation at the power stations up to the electric bus batteries.

is calculated using the following equations:

where

is the wall-socket electricity requirement,

is the well-to-tank efficiency,

is the efficiency of transmission,

is the efficiency of distribution,

is the efficiency of the charger (connector-battery), and

is the battery efficiency when charged.

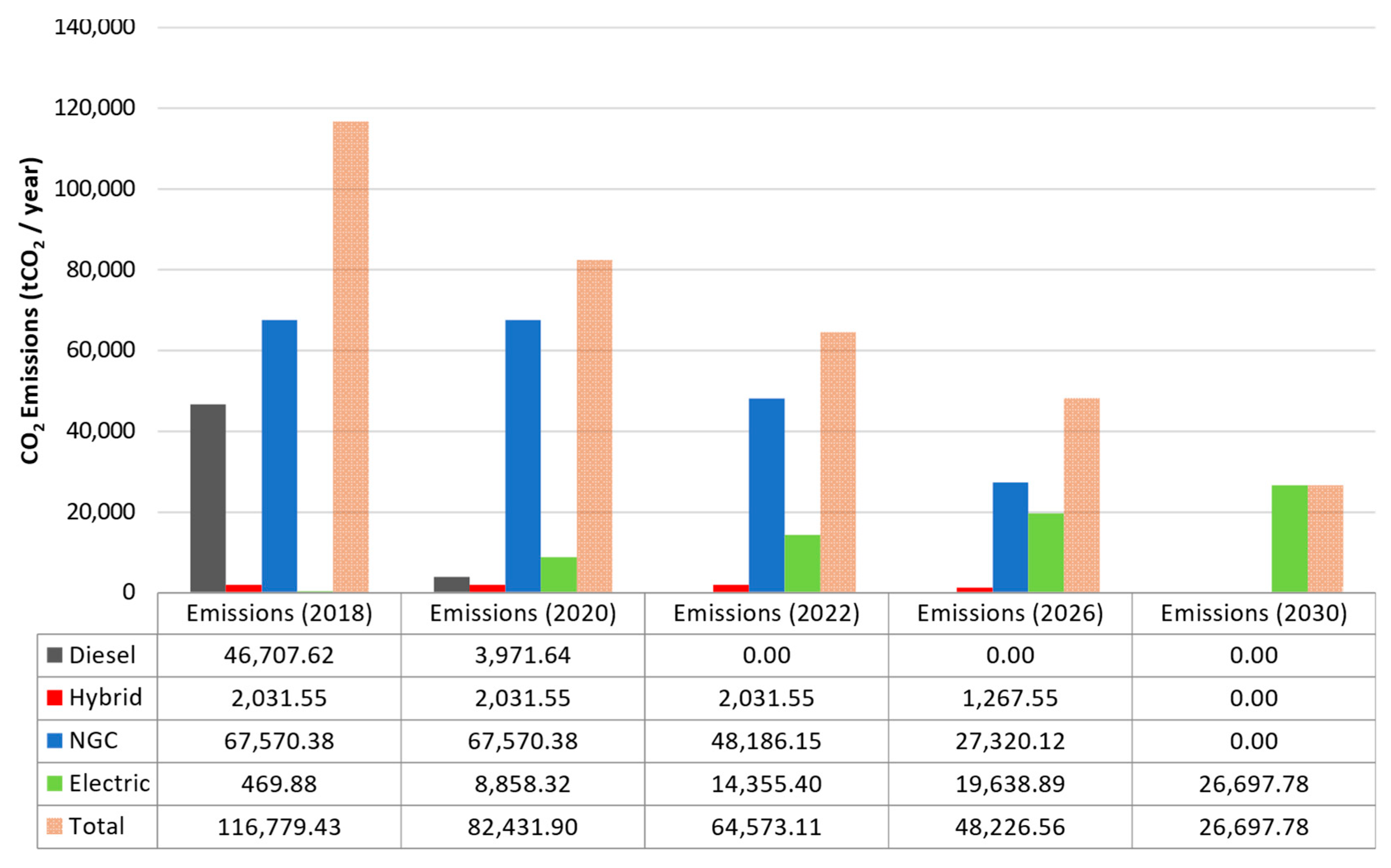

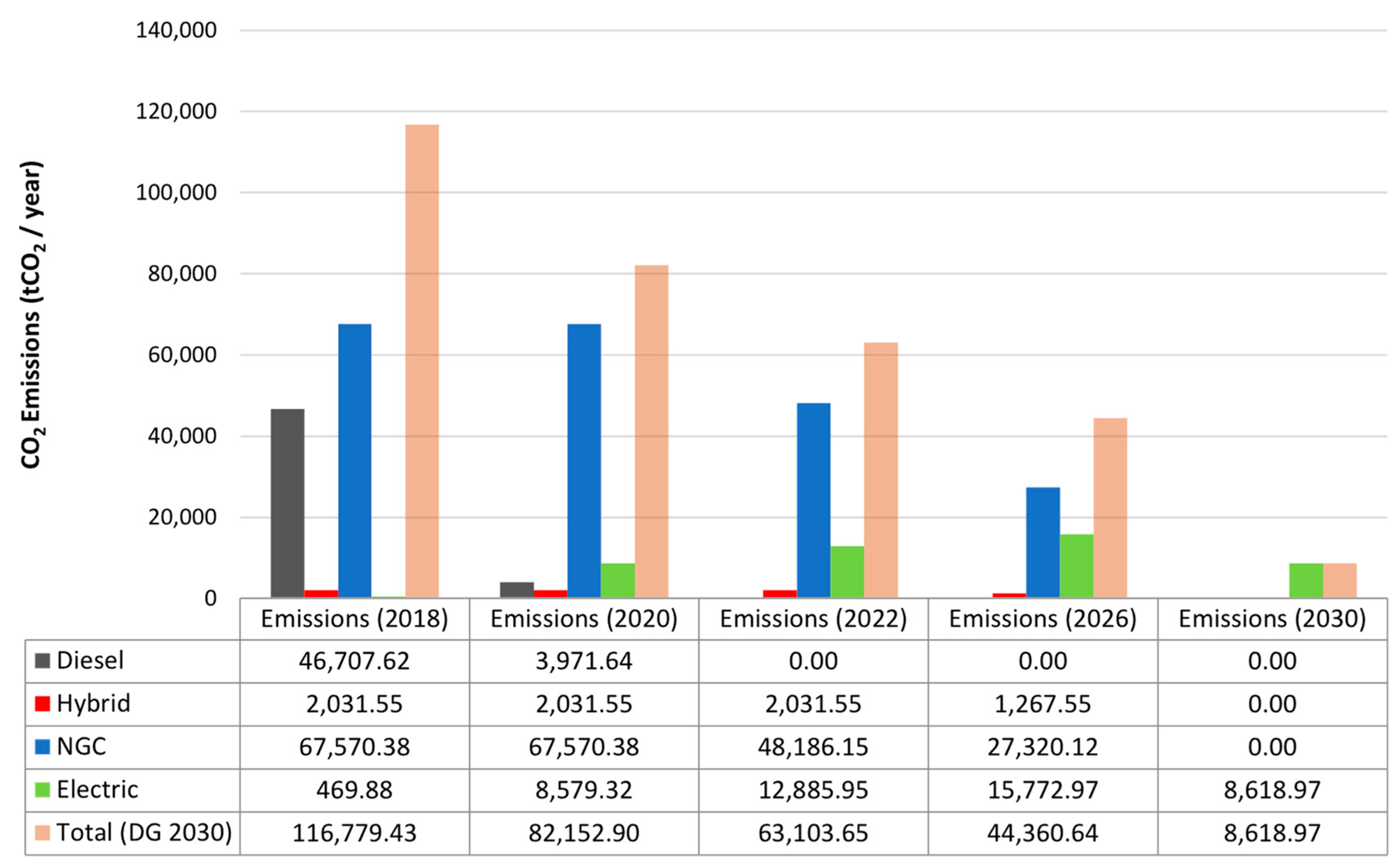

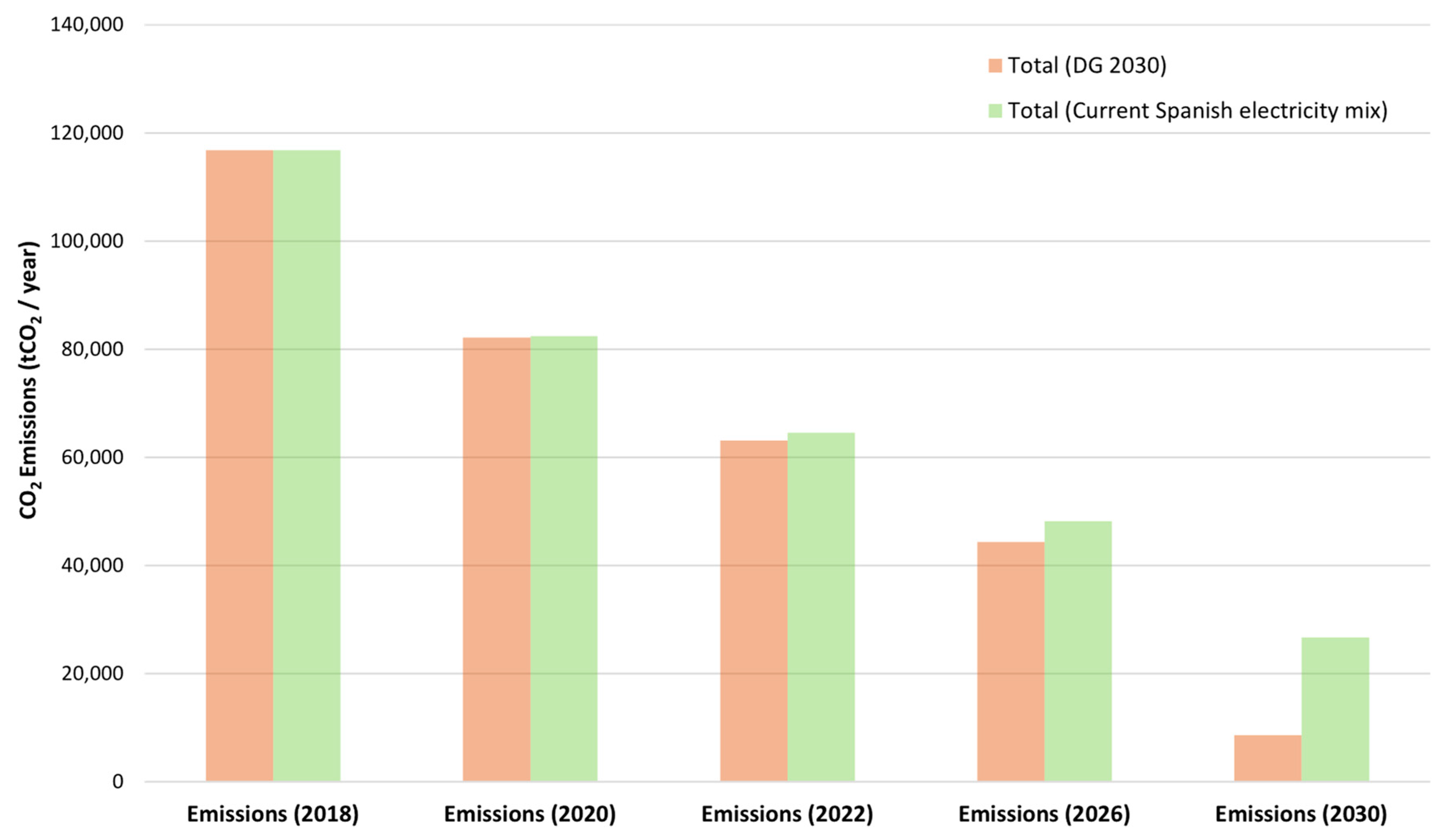

Definition of Scenarios

A gradual replacement of the fleet was considered, then we estimated the CO

2 emissions for the base year (2018) and those in 2020 (phase 1), 2022 (phase 2), 2026 (phase 3), and 2030 (phase 4). For the analysis, various data were obtained from scientific literature, OEMs, and EMT reports. For energy consumption and the intensity of the CO

2 emissions, the fleet of buses were taken as a start point in previous studies [

57,

58,

59], where the estimates were calculated based on an analysis of the well-to-tank (WTT) and tank-to-wheel (TTW). The number of daily routes per vehicle was 20, with an occupation rate of 60% [

60], energy consumption of each technology related to the fleet was considered constant in time, and the vehicles were grouped in four categories based on the EMT (compressed natural gas (CNG), diesel, hybrid, electric) [

60]. Finally, the Spanish electricity mix data from 2017 were used, which were updated by the REE [

29].

However, a change in the electricity mix is expected, which will allow the decarbonization of the electricity sector until 2030, which includes the sustainable contribution of renewable energy sources. According to expert reports, in 2030 under the DG2030 scenario, the contribution of electricity generation from renewable energies will be 62%, while that of non-renewable energies will be only 38%. This argument is analysed in results section, considering the changes that will occur in the electric mix under the 2030 distributed generation scenario, proposed by the Ten-Year Network Development Plan 2018 [

61]. This is a baseline scenario upon which most of the electrical simulation exercises were based.

Table 10 shows the installed power sources in the electric mix until the year 2030, whereas

Table 11 forecasts the generation of electric power until the year 2030 foreseen under the DG2030 scenario.

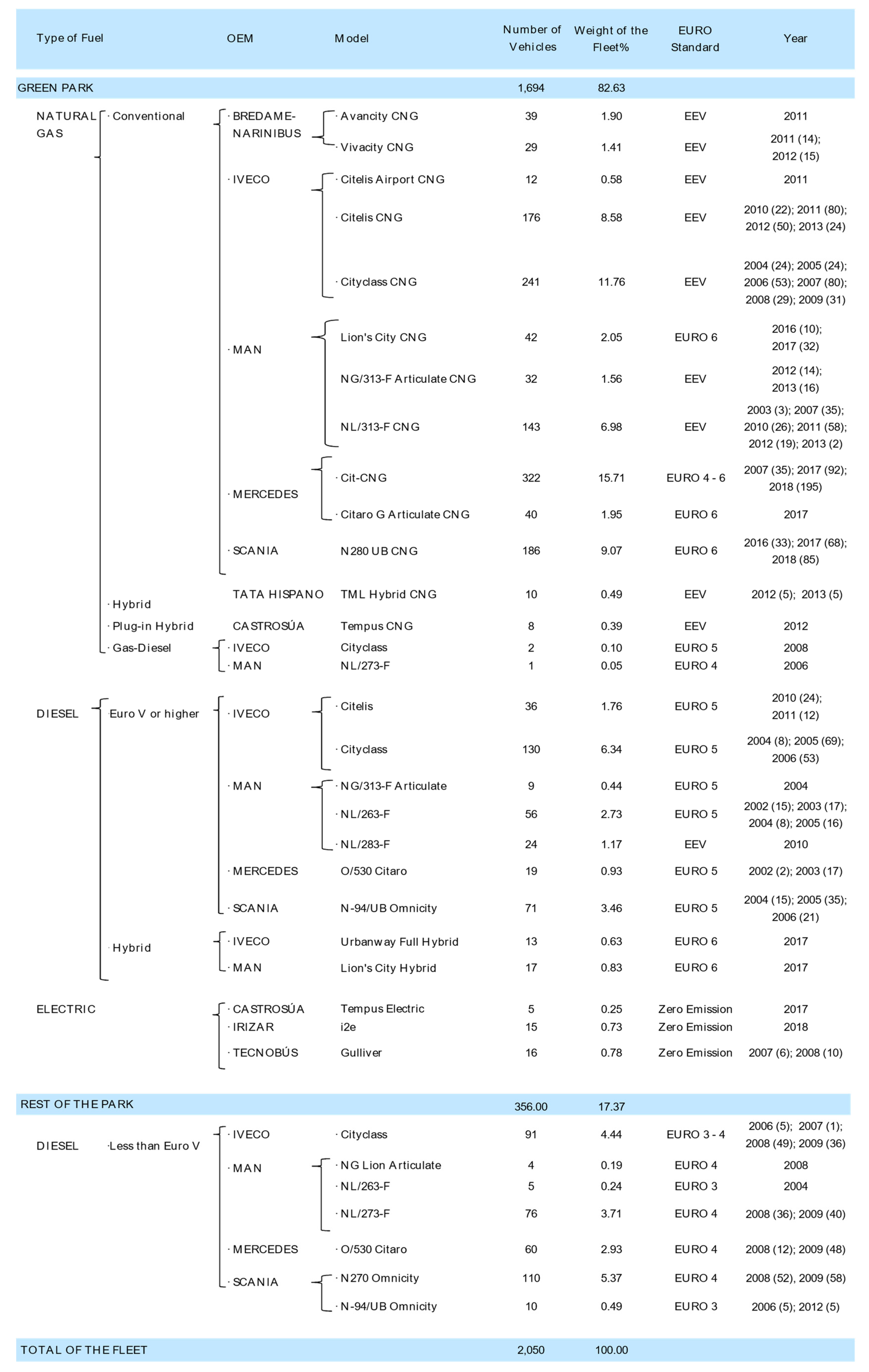

The fleet includes vehicles with various technologies, which the EMT calls the Green Park Fleet: CNG buses, diesel buses with Euro V and VI standards, pure electric buses, as well as CNG hybrid buses, while the rest of the fleet are classified as diesel buses that comply with the EURO III and IV standard.

Figure 13 shows the makeup by technology of the EMT’s current fleet.

Phased replacement means there must be a gradual transition in technology change.

Figure 12 shows that there is a large section of new buses as well as buses that are almost 15 years old. The phases are detailed as:

Phase 1: Corresponding to the year 2020. In this phase, all diesel buses with a standard below EURO V are replaced, as well as diesel buses registered before 2010 and CNG-diesel vehicles. In this first phase, 644 buses are replaced, corresponding to 31.42% of the total fleet.

Phase 2: Corresponding to the year 2022. In this phase, the remaining buses only powered by diesel are replaced, as are electric buses from 2007 and 2008 (fleet renewal) and CNG buses from on or before 2010. Here, we replace 438 units corresponding to 21.36% of the total fleet.

Phase 3: Corresponding to the year 2026. CNG buses from 2016 or before and CNG hybrid vehicles are replaced. In this phase, 406 buses are replaced corresponding to 19.80% of the total fleet.

Phase 4: Corresponding to the year 2030. In this final phase, all buses from 2017 and 2018 are replaced, which corresponds to 562 units, which is 27.41% of the total fleet. The electric buses replaced during these years correspond to fleet renewal, which means that by 2030, the fleet will be 100% electric.