1. Introduction

Energy demand management, also known as demand-side management (DSM) or demand-side response (DSR), is the modification of consumer demand for energy through various methods such as financial incentives and behavioral change through education [

1]. Usually, the goal of demand-side management is to encourage the consumer to use less energy during peak hours, or to move the time of energy use to off-peak times such as nighttime and weekends. Peak demand management does not necessarily decrease total energy consumption but could be expected to reduce the need for investments in networks and/or power plants for meeting peak demands [

2]. An example is the use of energy storage units to store energy during off-peak hours and discharge them during peak hours [

3]. A newer application for DSM is to aid grid operators in balancing intermittent generation from wind and solar units, particularly when the timing and magnitude of energy demand do not coincide with the renewable generation [

4].

The American electric power industry originally relied heavily on foreign energy imports, whether in the form of consumable electricity or fossil fuels that were then used to produce electricity. During the time of the energy crises in the 1970s, the federal government passed the public utility regulatory policies act (PURPA), hoping to reduce dependence on foreign oil and to promote energy efficiency and alternative energy sources. This act forced utilities to obtain the cheapest possible power from independent power producers, which in turn promoted renewables and encouraged the utility to reduce the amount of power they need, thereby pushing forward agendas for energy efficiency and demand management [

5]. The term DSM was coined following the time of the 1973 energy crisis and the 1979 energy crisis. Governments of many countries mandated the performance of various programs for demand management. An early example is the National Energy Conservation Policy Act of 1978 in the United States (US), preceded by similar actions in California and Wisconsin. Demand-side management was introduced publicly by the electric power research institute (EPRI) in the 1980s [

6]. Currently, DSM technologies are becoming increasingly feasible due to the integration of information and communications technology and the power system, leading to new terms such as integrated demand-side management (IDSM) or smart grid.

With recent development in DSM technologies in distribution networks, the reduction in energy consumption is the prime motive of the research due to the depletion of conventional energy resources. Researchers presented extensive work for improvement in energy efficiency to reduce the operating cost simultaneously. However, the objective functions developed by different researchers may differ from each other, depending upon the operating constraints and requirements. The energy efficiency performance in power delivery is not limited to a reduction in loss; rather, it depends upon several other parameters and load type or load class [

7,

8]. The practical loads can be divided into residential, commercial, and industrial loads [

9]. With these load classes, in Reference [

10], a heuristic optimization technique was presented for DSM to reduce the peak demand, whereas, in Reference [

11], the perspectives of energy efficiency ere studied.

Costanzo et al. [

12] revealed that the estimated power consumption in worldwide buildings leads to approximately 40% of global energy consumption. Also, Agnetis et al. [

13] emphasized the reduction of the greenhouse effect through dynamic DSM and developed a heuristic algorithm for real-time application, but it had the limitation of computational power and memory size. Palensky et al. [

14] observed that the rise in technology generation is not a problem, but grid capacity is a major concern. Therefore, DSM helps to overcome this problem. Here, the authors categorized the DSM into energy efficiency, time of use, demand response (DR), and spinning reserve.

Kuzlu et al. [

15] forecasted that, in upcoming decades, the world energy consumption is expected to rise by 53% at the rate of 2.3% per year from now to 2035. This would be the reason for cascading failure and, hence, blackouts. Here, the authors developed a cost-effective home energy management (HEM) system. Furthermore, Mondal et al. [

16] observed that DSM is an important feature in a smart grid as it allows flexible energy demand. Conversely, Tsagarakis et al. [

17] revealed that the electricity cost not only consists of the price of electricity but also includes the environmental costs.

Marcello et al. [

18] presented operating strategies for resource management of DSM, where energy efficiency, along with comfort level, was addressed in the problem formulation. In this paper, we consider the proposed strategies as per the time of the day, which means the energy consumption needs to be managed with every change in operating conditions. Singh and Jha [

19] developed a multi-objective approach for DSM by using several indices. These indices were developed to reduce the peak load demand and usability with renewable energy resources using the teaching–learning process algorithm.

Hao et al. [

20] revealed that the heating, ventilation, and air-conditioning (HVAC) systems are important aspects for energy management, and the authors proposed a transactive control approach of a commercial building through demand response. However, the authors in Reference [

21] developed multifrequency agent coordination for DSM in electrical grids with high penetration rates of distributed and local generation. Facchini et al. [

22] described the need for operating schedules for energy management for domestic purposes while satisfying the user’s constraints on the maximum tolerable delays. Here, the authors tried to minimize the operating cost by reducing the peak demand for a given duration. Similarly, in Reference [

23], an energy service model was presented for residential buildings for energy service for the hourly variation of the demand for energy that realizes the service in the presence of distributed energy resources.

The authors in Reference [

24] presented the demand response in three different scenarios by considering (a) benchmarking without demand response and utility choice, (b) without demand response and with utility choice, and (c) in the coordination of demand response and utility choice. However, the ultimate aim was to reduce the peak load and, hence, the energy consumption, whereas the social and technical standards were not emphasized in these works. Also, in the survey work in Reference [

25], several method issues and future perspectives in the DSM-based approaches were presented, which has a limited scope as most of the aspects were considered by different studies in their work. In Reference [

26], an air-conditioning load was considered for demand response and to identify the variation in demand versus temperature. This analysis revealed that the demand is not fixed as the rated value of the power component; rather, it needs to consider the environmental constraints while implementing the demand response approaches for DSM. Moreover, the authors in Reference [

27] proposed a pricing schemes to encourage the participation of different consumers in demand response by providing them with a list of price plans. Here, customers were classified based upon the level of load adjustment, cost analysis, and the elasticity coefficient. Here also, the load characteristics and their dependence on different constraints were emphasized. Piette et al. [

28] presented an infrastructure model for automated demand response. In this scenario, a new Internet of things (IoT)-based infrastructure was also developed by the researcher for energy internet in Reference [

29].

In this paper, the authors conferred that the energy demand has a relationship with the environmental conditions, and several plots were presented showing the relationship between energy and temperature and humidity. However, in this work, demand response or DSM was not implemented; rather, direct control of the load was actuated through the internet and smart devices. Therefore, this work had a limited scope of energy efficiency, which focused on energy consumption by changing the status of the control switch from OFF to ON and vice versa, and it is best suitable for the area where a single person is involved, or a defined set of rules are followed. Conversely, the practical loads were not of any specific type, and the load growth of these loads concerning time was neither uniform nor did it follow the same pattern as earlier [

30,

31]. Considering several aspects, the authors in Reference [

32] presented an extensive review on the energy internet for its smart management, and several issues were discussed, which include cost, reliability, scalability, data access, and weather as the prime factors for energy internet. However, the real behavior of people in the building was also presented for energy and cost-saving in Reference [

33], whereas, in References [

34,

35,

36,

37,

38], different criteria for the installation of various components were suggested.

From the related literature, it can be observed that energy efficiency is a cost-effective means of energy-saving. Also, saving a single unit of energy is always viewed as an energy resource. In practice, a commercial building is believed to have several electrical components that operate together but that have different energy consumption as per the environmental and technical aspects, which include light intensity, heating, ventilation (air circulator), and air conditioning (i.e., L-HVAC). However, the requirement of power equipment in a specified area depends upon the number of persons involved in a specific area, technical standards, surrounding environmental conditions, and the availability of the supply. Therefore, considering these aspects, the aims of this work can be summarized as follows:

To determine the energy efficiency of lighting, ventilation, and air conditioning (LVAC), concerning the task areas and non-task areas in a commercial and residential building.

To recommend consumption levels suitable for various activities under different operating and environmental conditions.

To determine the overall energy efficiency of LVAC systems using measurements and methods suitable for field conditions with and without DSM before auditing and after auditing.

To formulate the problem for energy efficiency under the above different objectives with social, environmental, and technical constraints of DSM, which include the number of persons involved, surrounding temperature and humidity, the lumens per watt, air circulation in cubic feet per minute, cooling per unit area or volume, energy consumption in a specified area, etc.

3. Data Collection and Analysis

The energy data were collected from the D-Block of Thapar Institute of Engineering and Technology, Patiala. The building data related to the room size were obtained by measurement, and the number of power components were obtained by observation, whereas the energy data were collected from Monday to Friday on an hourly basis between 9:00 a.m. and 5:00 p.m. from the meter reading. These energy data included the consumption due to fans, lighting systems, and air conditioners installed in the D-Block. Throughout one year, three different seasons were considered according to normal, moderate, and severe environmental conditions. Because of this issue, the energy data for August 2018, January 2019, and April 2019 were collected on an hourly basis. The academic institution is a commercial building, and the energy consumption mainly depends upon the temperature, humidity, and the number of persons present in working hours between 9:00 a.m. to 5:00 p.m. Thus, the energy data were segregated for lights, fans, and the ACs.

Table 2 shows the size of the room and the number of lighting sources (i.e., tube-light and compact fluorescent lamp (CFL)), ACs, and fans in a sample building under consideration in this work.

3.1. Energy Data Analysis

For the analysis of energy data, three months of energy consumption were recorded based on the weekday average and the monthly average. This energy data analysis was recorded under the variation in environmental conditions in summer (April), rainy (August), and winter (January) seasons in the Indian scenario.

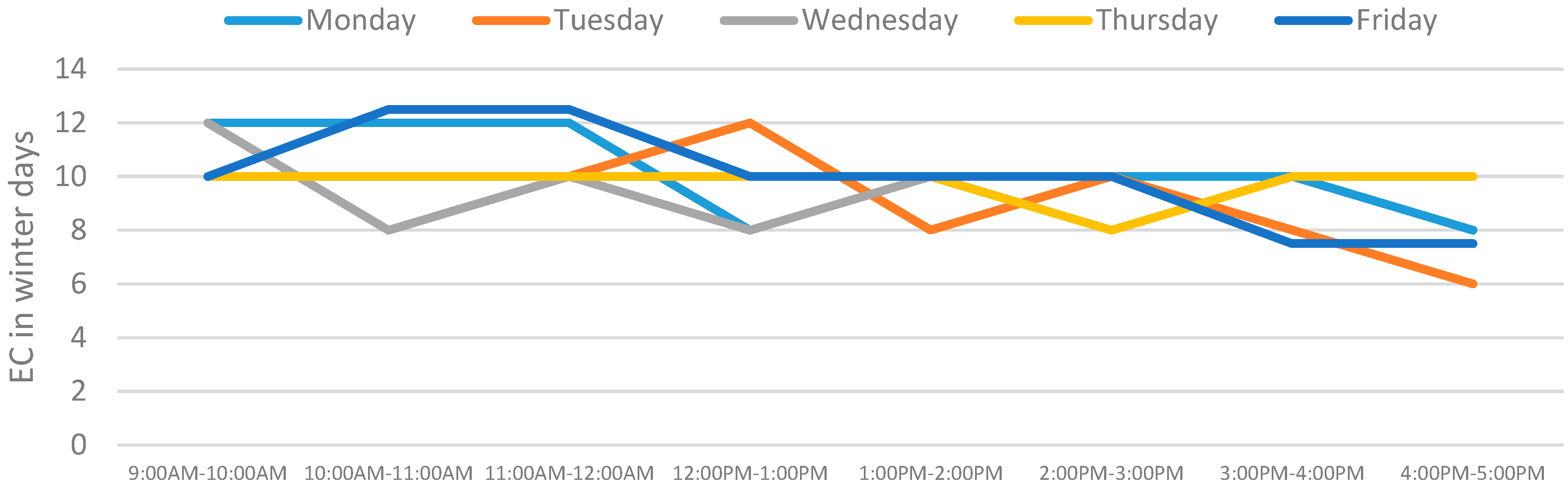

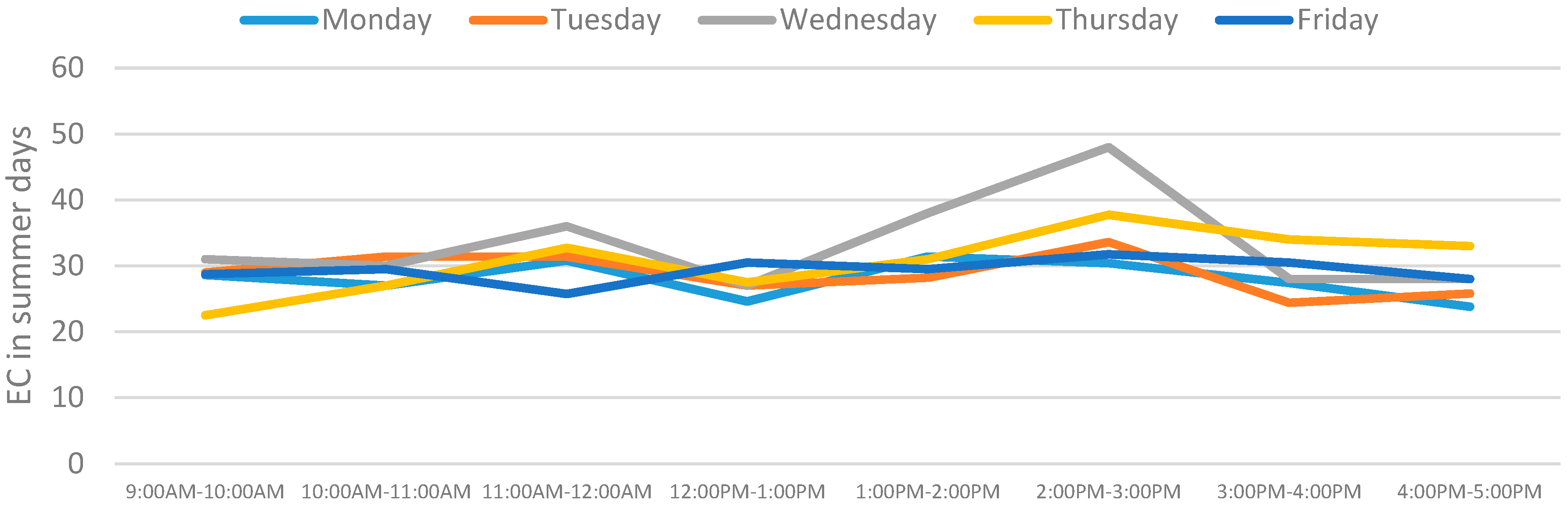

Figure 1,

Figure 2 and

Figure 3 represent the variation of average energy consumption for all Mondays, Tuesdays, Wednesdays, Thursdays, and Fridays in summer, rainy, and winter seasons, respectively. From the data, it can be observed that there is a significant variation in energy consumption from 9:00 a.m. to 5:00 p.m., and it is different on different days of the week.

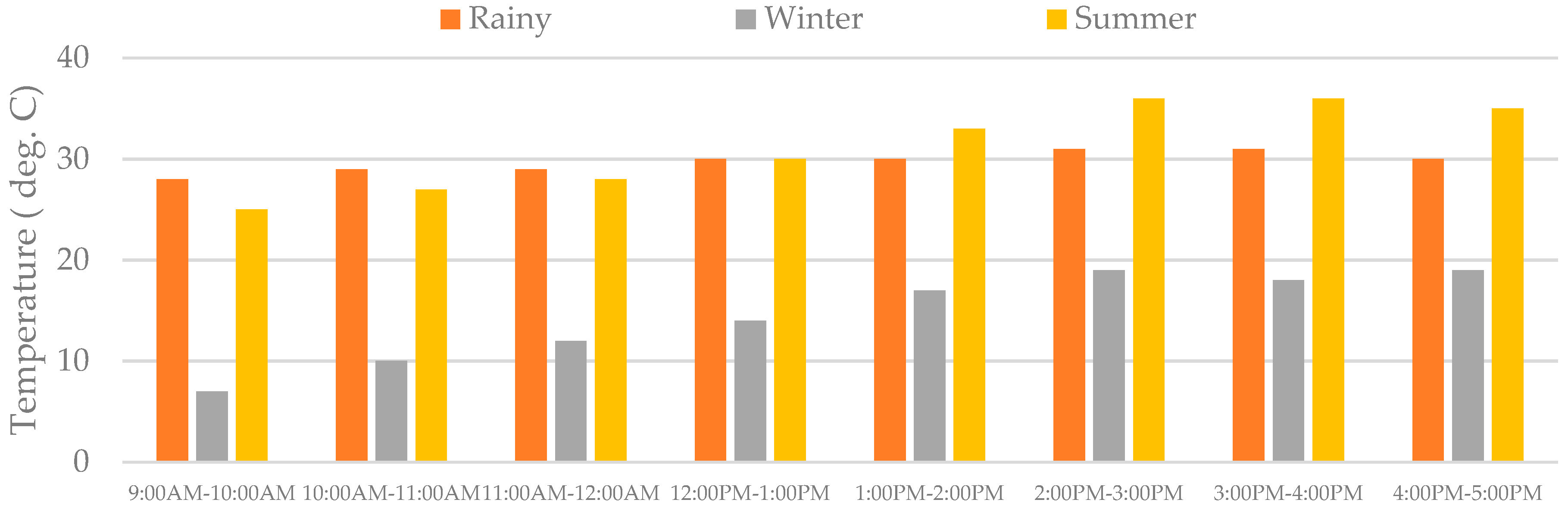

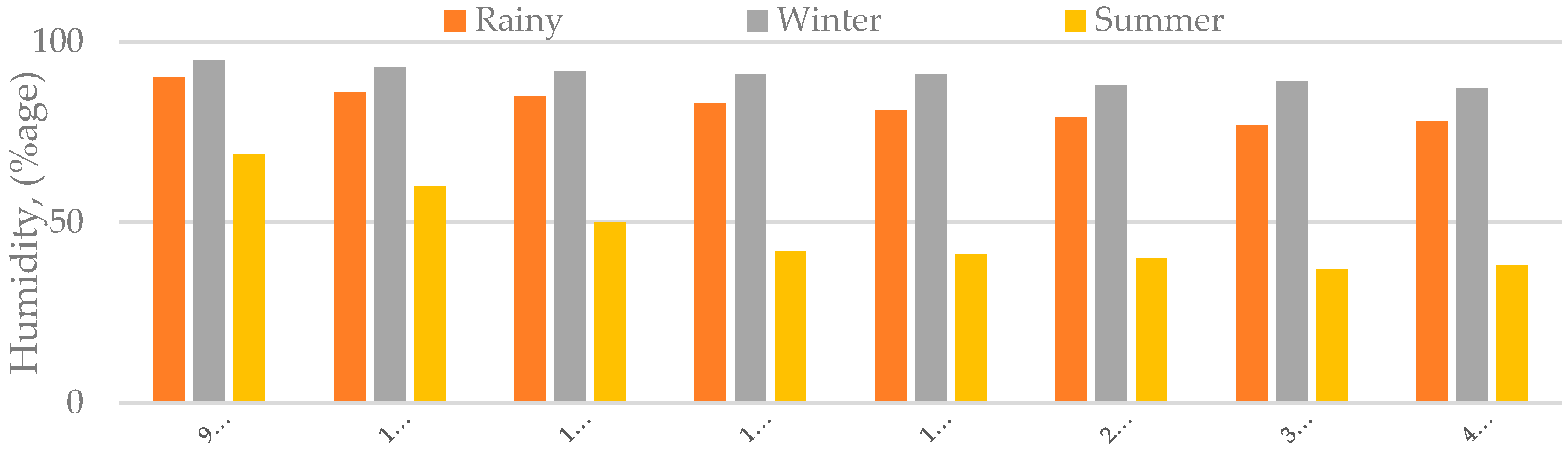

In addition to the above analysis, the monthly variation in energy consumption is shown in

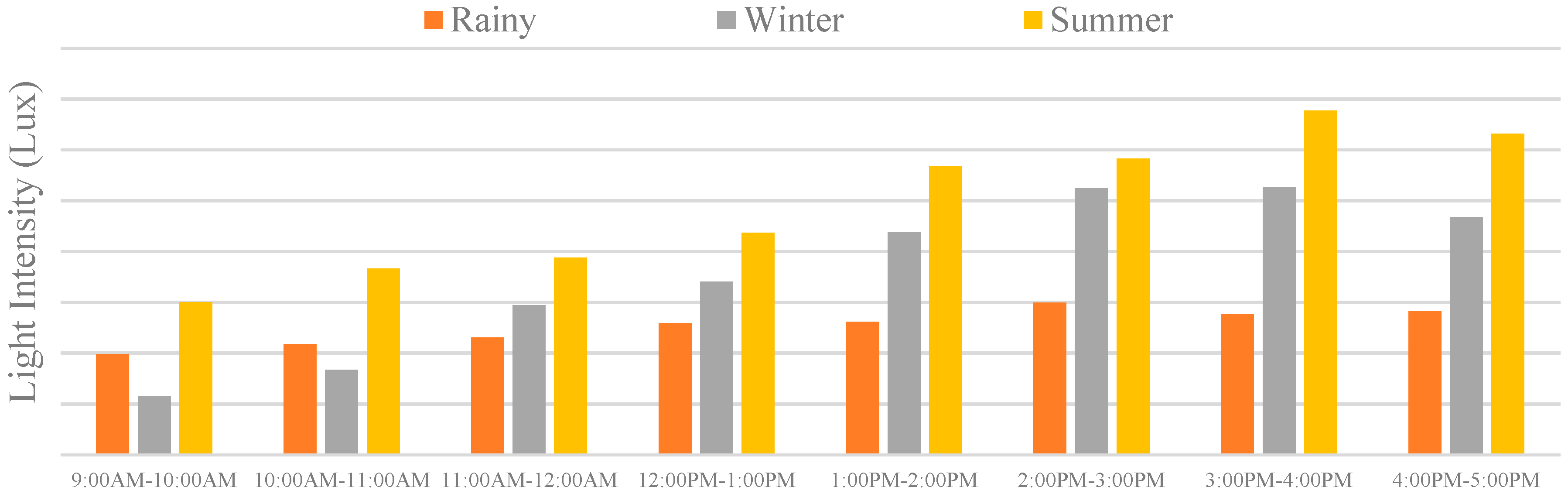

Table 3. Also, temperature, humidity, and luminous intensity due to sunlight were evaluated in rainy, winter, and summer seasons, as shown in

Figure 4,

Figure 5 and

Figure 6. Here also, these data were taken on an hourly basis, i.e., from 9:00 a.m. to 5:00 p.m. These data give the information of load variation of a complete day, which further helps in load shifting at the time of peak loads.

3.2. Energy Auditing of the Lighting System

In practice, all of the light emitted by the lamp does not reach the work area. Some light is absorbed by the luminaire, walls, floors, roof, etc. The illuminance measured in lumens/m2, i.e., lux, indicates how much light, i.e., lumens, is available per square meter of the measurement plane. Target luminous efficacy (lm/watts) of the light source is the ratio of lumens that can be made available at the work plane under the best luminous efficacy of source, room reflectance, mounting height, and the power consumption of the lamp circuit. Over time, the light output from the lamp is reduced, the room surfaces become dull, and luminaries become dirty; hence, the light available on the work plane deviates from the target value. The ratio of the actual luminous efficacy on the work plane and the target luminous efficacy at the work plane is defined as the installed load efficacy ratio (ILER).

Table A1 (

Appendix A) shows the variation in the coefficient of utilization when effective floor cavity reflectance is taken as 20%.

Table 4,

Table 5 and

Table 6 show the readings of monthly data, which include the average light intensity and its value in task and non-task areas, lumens,

ILE and

ILER, and the diversity factor for each room of the sample building in rainy, winter, and summer seasons respectively.

From the results shown in

Table 4,

Table 5 and

Table 6, it can be observed that the value of average illuminance is different in different seasons for the same room. It further tends to vary the ILE, ILER, and DF. A lower value of ILER indicates that the luminous efficacy of the installed luminaires is poor, whereas a low value of DF is the indication of uniform distribution of light intensity in the specified area irrespective of the task and non-task areas.

Table 7 shows the various parameters of room index (

RI) and room cavity ratio (RCR), as well as

IMPs for task and non-task areas, which were obtained based upon the size of the room. Based upon the data available in

Table 4,

Table 5 and

Table 6 the number of luminaires (

NL) was calculated with a poor value of average light intensity so that the minimum illuminance could be maintained even under the worst conditions.

3.3. Energy Auditing of Ventilation System

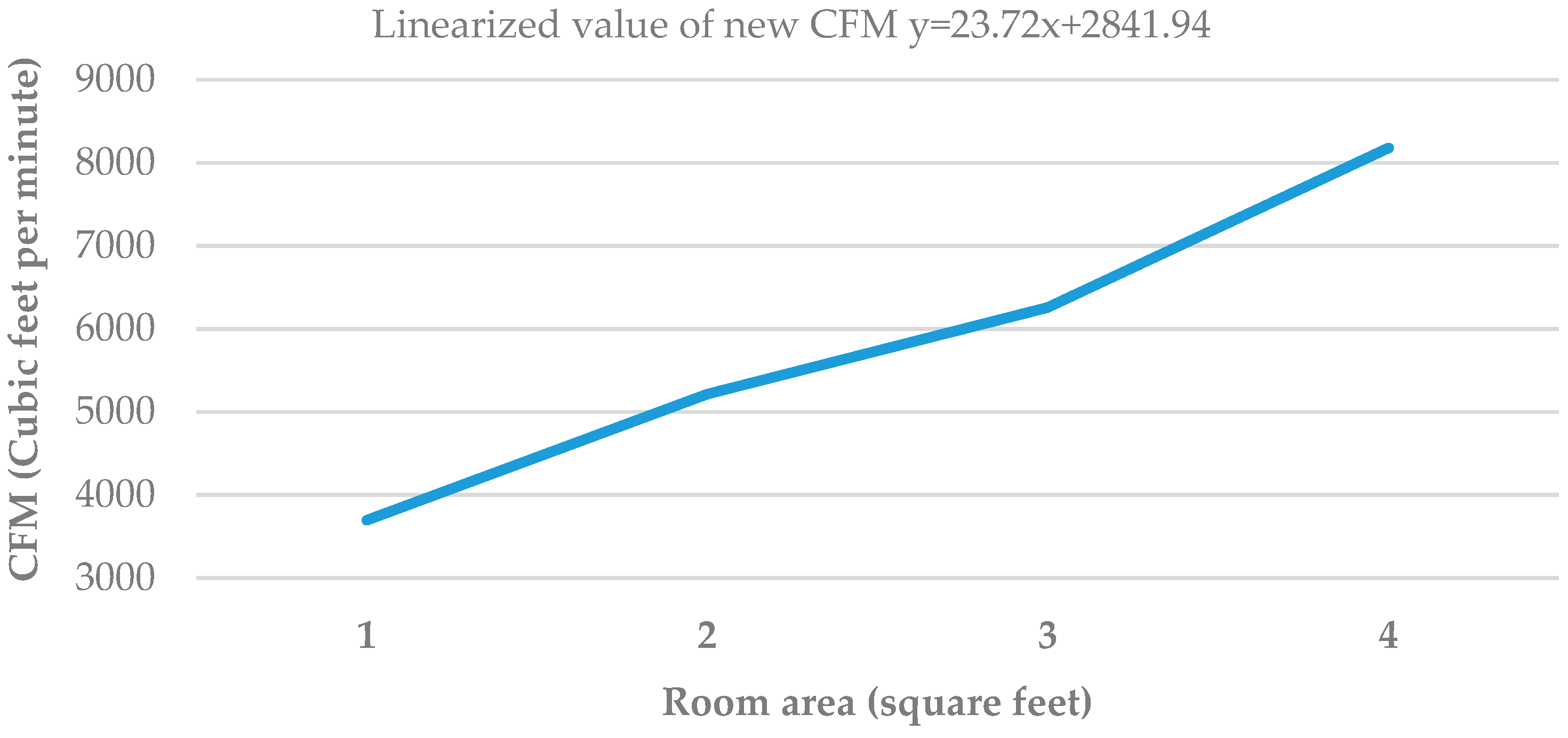

Linearization of CFM for Fan Requirement

Table 8 shows the recommended level of cubic feet per minute (CFM) of air circulation in a specified area. These data were available for the limited size of the rooms, whereas, in the analysis, the room size was a little big and, therefore, a linear aggression function was derived using Equations (20)–(22). These data give information about the number of fans that should be installed as per the recommendation in a specified area. The linearized function is derived as

where

m represents the slope of the line, and

b represents the

y-intercept (

y-value for which

x is 0).

In Equation (20),

is the predicted value of

y. The linear regression line is the representation of Equation (20) in which

m and

b are obtained using Equations (21) and (22), and, from the calculation, their values were found to be 23.72 and 2841.94, respectively.

Figure 7 shows the graph between the area of a room (in square feet) and the CFM (cubic feet/min).

Table 9 shows the room area and volume for the calculation of CFM required in a specified area, which further helps in the calculation of the number of fans. Here, it can be observed that the number of fans which should be installed in each room was different, which was obtained using linear regression. As a result, two rooms having the same area would also have the same number of fans according to this criterion.

3.4. Energy Auditing of the Air Conditioning System

Table 10 shows the auditing details of the AC installation. Here, the rooms equipped with ACs were taken into consideration, whereas the other rooms in which ACs are not installed, were ignored.

For AC recommendations, four different criteria were studied as shown in

Table 10. From the analysis, it can be observed that the number or size of ACs was different in each specified area. In the second column of

Table 10, the BTU recommendation is shown, which was decided based upon the room size. The equivalent representation of the BTU was also converted into kW of its rating for comparison with other criteria.

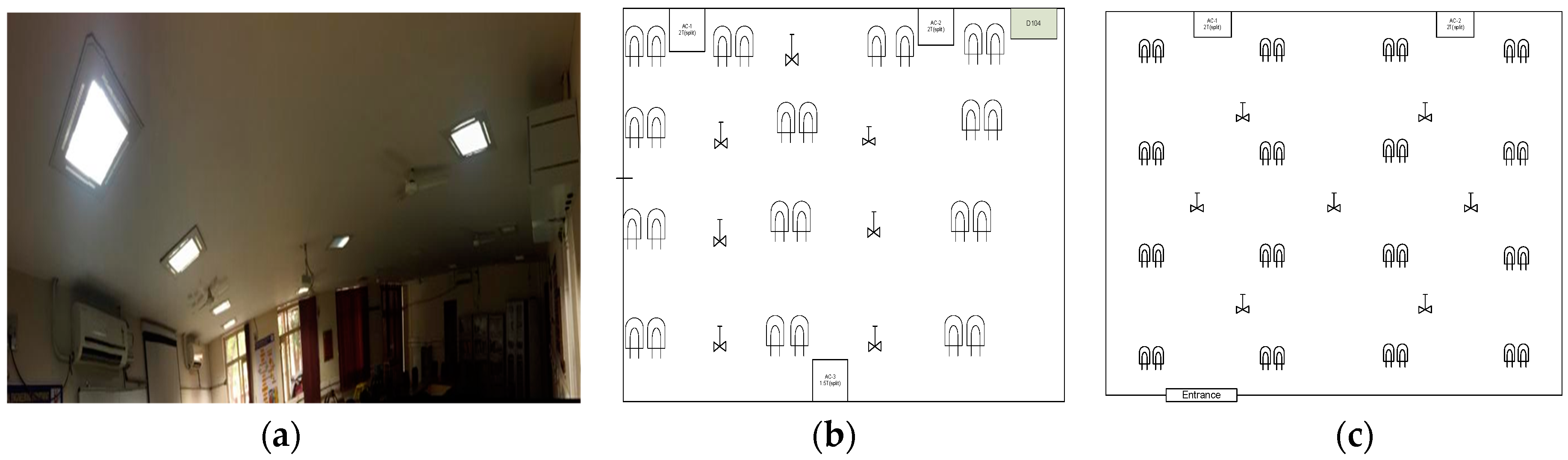

Figure 8 shows the physical layout of the power components in a sample room in the commercial building. Before auditing, the power components were placed at random, whereas, after auditing, they were placed uniformly such that the

ILER, DF, CFM, and BTU requirements could be maximized in the task area.

4. Energy Efficiency with DSM

DSM is a cost-effective means to reduce peak load demand by reshaping the load profile [

10]. However, in commercial and residential buildings, load shifting is rare; rather, it needs to be managed according to the requirement. This allows operating the number of power components based on the framework designed for their operating schedule. The operating schedule of various components may vary with application and their recommendation for specific purposes. In this scenario, operating schedules applicable under some circumstances, at the same time, may be different from other systems of the same size. Therefore, the implementation of DSM schemes should have the flexibility to meet the objective of power-saving and, hence, to improve energy efficiency without affecting the comfort level [

12].

The objective function for DSM was formulated for energy-saving to minimize the cost of the customer electricity bill. Therefore, the DSM problem for energy-saving is described in Equation (23).

In the proposed work, the load demand (Prt) was calculated for each room; therefore, r varied from one to NR, i.e., the number of rooms in a sample building, and energy efficiency was evaluated for , i.e., the duration in a day where t varies from 1–8. Conversely, is the energy price at the time t, which in this case was the same for all loads; however, in practice, it may be different in the case of DR-based DSM approaches. The objective function was subject to the following constraints:

Energy consumption: The new energy consumption (EC) should be less than the existing consumption, which is represented in Equation (24).

Illuminance level: The light intensity of the light source is different, and it is also affected by the power rating. Therefore, the illuminance level should be maintained between the minimum and the maximum level, which is represented in Equation (25).

Persons involved: The number of persons (

Np) involved in a specified area varies throughout the day. Therefore, the minimum and maximum numbers need to be defined before the DSM implementation, which is represented in Equation (26).

Temperature and humidity: The number of fans and ACs to be operated can be affected by the surrounding temperature (

ST) and the humidity (

H). However, the humidity level in both winter and rainy seasons is usually high; however, the operation of fans and ACs can only be affected on rainy days due to high temperatures. Therefore, before imposing the constraint of humidity, the surrounding temperature needs to be considered, which is represented in Equations (27) and (28).

Equations (24) and (25) represent the technical constraints where energy consumption affects the objective function, whereas Equation (26) represents the social constraint, which mainly depends upon the human being involved in a specified area. However, Equations (27) and (28) represent the environmental constraints, as temperature varies from severe cold to severe heat with different levels of humidity.

4.1. Operating Scenario for DSM

In commercial and residential buildings, power consumption mainly depends upon the number of persons involved, surrounding temperature and humidity, and the luminous intensity due to sunlight [

23]. Therefore, the energy data of three months in a year were collected under three different seasonal changes, i.e., January (severe cold), April (moderate), and August (severe heat), as described in

Section 3. This was done to show the significant variation in load demand under moderate, comfortable, and severe environmental conditions. The energy data under these three conditions were averaged, and the operating scenario for DSM schemes was developed, as shown in

Table 11, for the operation of power components before energy auditing and after energy auditing.

The operating scenario, described in

Table 11, represents the initial solution for the maximum number of lights, fans, and ACs that can be operated for the predefined strength, i.e., number of persons in a specified area. However, during operation, the above scenario can be adjusted with a minimum step size of

1 to limit the violation of the constraints.

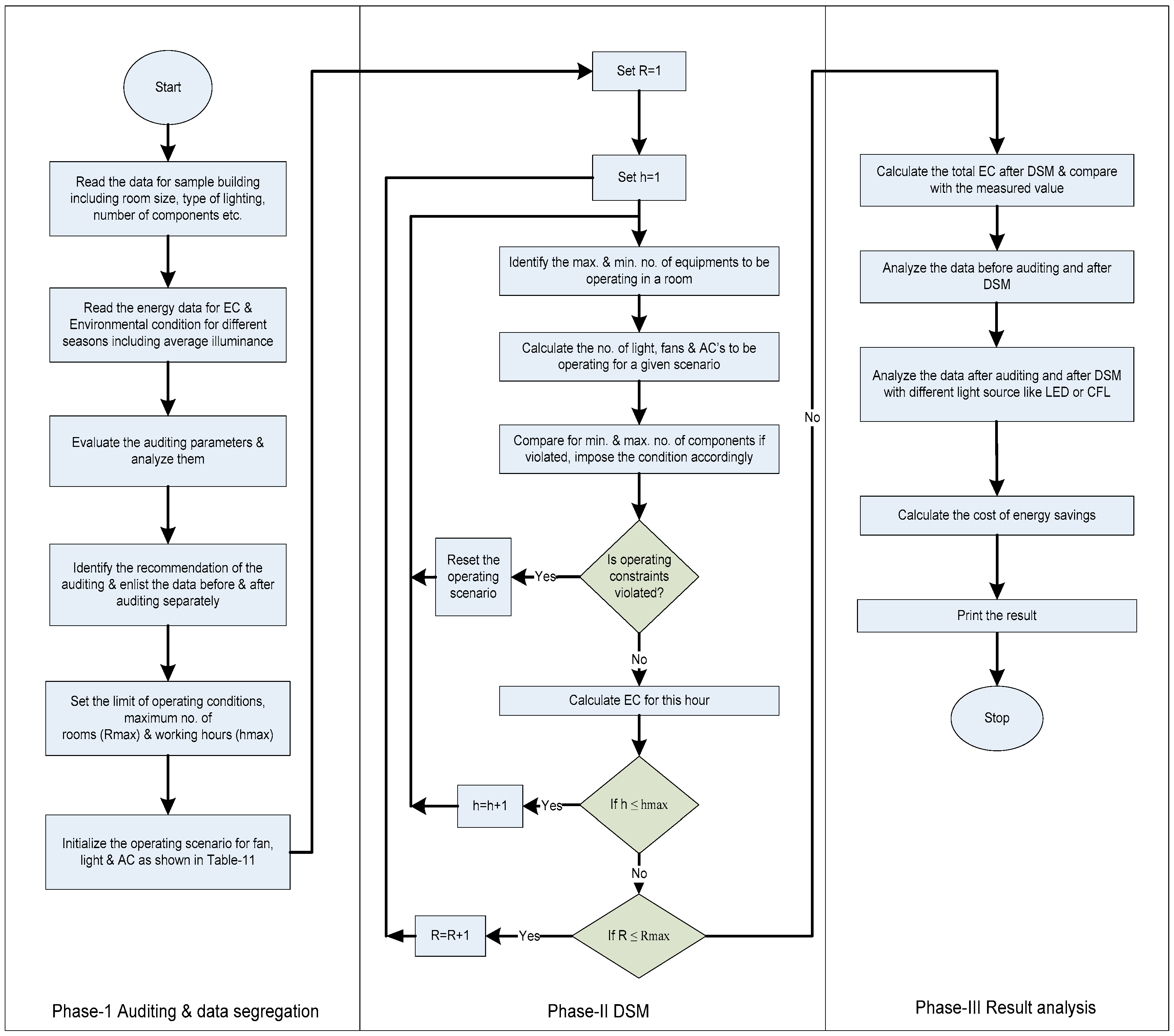

4.2. Proposed DSM-Based Algorithm and its Flowchart

In

Section 3, strategic auditing was presented for different seasons, and the results in

Table 4,

Table 5,

Table 6,

Table 7,

Table 8,

Table 9 and

Table 10 show that there is significant variation in different auditing parameters. Therefore, auditing before DSM does not only tell us about the immediate scope of energy-saving; rather, it helps to develop a framework of the operating scenario and constraints in the DSM approach. Based upon the findings from strategic auditing and the operating scenario for DSM, an algorithm was developed, and

Figure 9 shows the flowchart of the proposed DSM approach.

The steps involved in the proposed DSM-based algorithm are described below.

Read the actual data before auditing the sample building, including the size of the rooms, number of persons involved in each room, number of power components and their specifications, types of rooms, and the time of operation.

Read the measurement data for energy consumption and the surrounding environment in different seasons for the analysis.

Calculate the various auditing parameters using Equations (1)–(19).

Identify the recommendations of strategic auditing and enlist the number of power components in each room with their power ratings.

Enlist the above data before auditing and after auditing separately.

Set the limits for operating constraints, the maximum number of rooms (Rmax), and working hours (hmax).

Initialize the operating scenario for fans, lights, and ACs, as shown in

Table 11.

Initialize the number of rooms and set R = 1.

Initialize the working hours and set h = 1.

Define the maximum and the minimum number of components to be operated in a specific room.

Calculate the number of lights, fans, and ACs to be operating for a given scenario.

Compare the components in steps 10 and 11; then, impose the conditions as per step 10 for maximum and minimum limits accordingly.

Check operating constraints; if violated, adjust the operating scenario and repeat steps 9–12; otherwise, go to the next step.

Calculate the energy consumption due to fans, lights, and ACs, as well as the energy-saving for this hour.

Check for h ≤ hmax; if yes, set h = h + 1 and repeat steps 10–14; otherwise, go to the next step.

Check for R ≤ Rmax; if yes, set R = R + 1 and repeat steps 9–15; otherwise, go to the next step.

Calculate cumulative energy-saving in a day and a year using Equation (23) and compare with the measured value.

Calculate the cost of saving.

Stop.

5. Result Analysis for DSM Before Auditing

The energy efficiency was evaluated before and after auditing.

Table 12,

Table 13 and

Table 14 show the results for the DSM scheme before auditing for three different seasons in a year. The various parameters like strength ratio (SR), temperature in °C, relative humidity, luminous intensity (LI), energy consumption of light (ECLT), energy consumption of ACs (ECAT), energy consumption of fans (ECFT), total energy consumption (ECTT) which is the sum of ECLT, ECAT and ECFT, energy consumption with DSM (ECWDSM) and the savings as the difference of ECTT and ECWDSM.

The cumulative energy-saving, shown in the last row of

Table 12,

Table 13 and

Table 14, in rainy and summer seasons was found to be 31.34 and 36.67 kWh, respectively, whereas, in the winter, it was −29.24 kWh. This issue indicates that, with DSM, the energy consumption reduced in rainy and summer seasons, whereas it increased in the winter season. This is because, in the winter season, the weather conditions are very cold, and the maximum light source requires operation to maintain the recommended level of illuminance. Also, at the same time there is no scope of energy-saving due to fans and ACs because they remain OFF in the winter season.

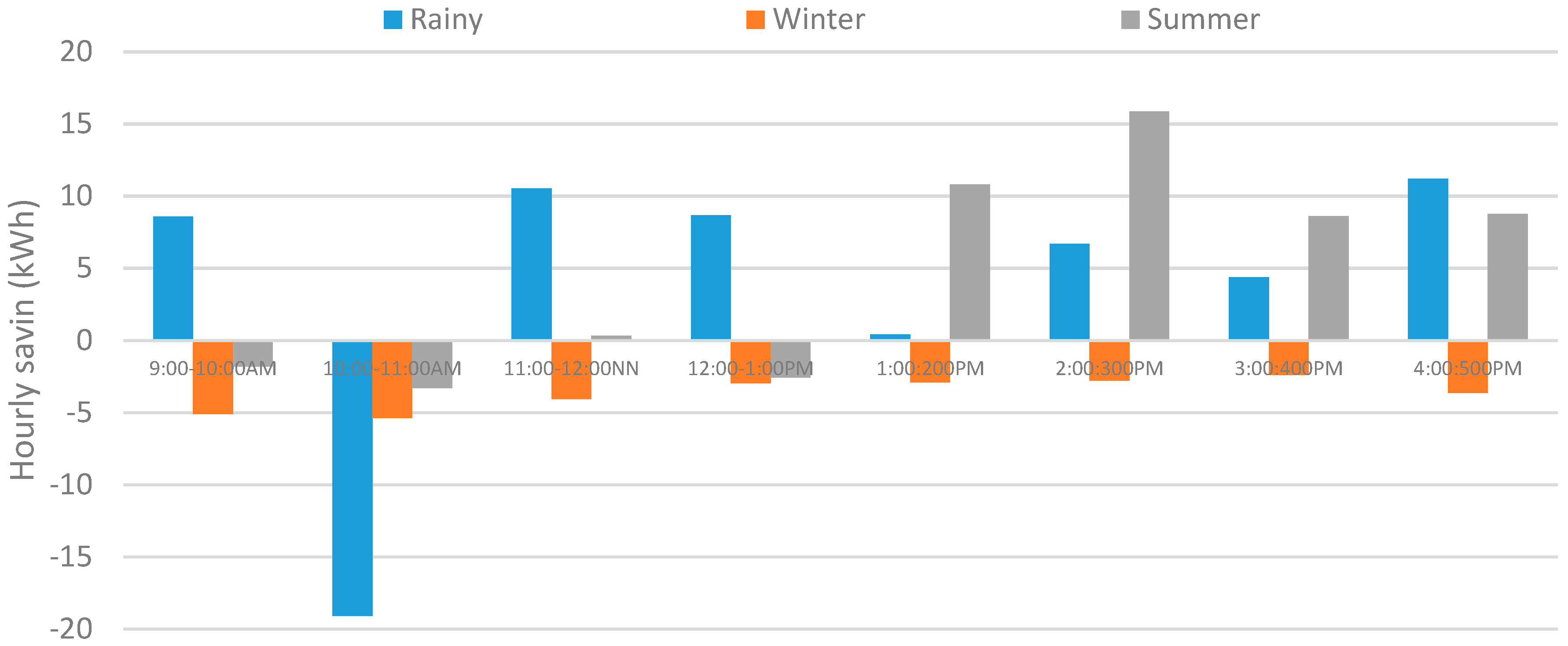

Figure 10 represents the variation of hourly energy-saving in different seasons, as shown in the last row of

Table 12,

Table 13 and

Table 14. Here, it can be noted that the energy consumption reduced from 9:00 a.m. to 10:00 a.m. in the rainy season, whereas it increased in the summer and winter seasons, even after DSM. Furthermore, the energy-saving (in blue color) in different hours in the rainy season was found to be different. Also, from 10:00 a.m. to 11:00 a.m., the energy-saving was found to be negative, which means that consumption is higher even after DSM for this duration. Similarly, in summer, the energy-saving, shown in gray color, varied differently throughout the day and, the energy-saving (in orange color) in winter was negative concerning the consumption before DSM. However, the cumulative saving in three different seasons was found to be positive for the proposed DSM approach.

8. Conclusions

This paper presented the energy efficiency evaluation of a commercial building with strategic energy auditing and demand-side management (DSM) under different environmental conditions. The environmental conditions were divided into three seasons in a year. For energy efficiency evaluation, a strategic energy auditing was performed to identify various parameters such as lumens per watt, illuminance in work and non-working areas, and load efficacy, thereby leading to the development of operating strategies for power components. Here, the DSM was implemented before and after strategic auditing, and the comparison of the results was also presented. From the results, it was observed that, in the commercial building, the scope of energy-saving in different seasons varied with operating constraints including temperature, humidity, number of persons, and the technical standards. The scope of energy-saving before auditing and after auditing was also found to be different. The variation in energy-saving is not only seasonal; rather, it may also vary with the time of operation and the state of the economy throughout the day. This requires conducting regular auditing of the energy-intensive building and constraining the implementation of the recommendations. Results also showed that the total number of components required reduced in the proposed approach, which reduces energy consumption and, hence, improves energy efficiency without affecting the desired level of comfort. However, in the proposed approach, the system voltage profile was considered as fixed, whereas, in practice, the operation of various power components may change with the change in system voltage profile, which can also affect energy efficiency. Therefore, a comprehensive analysis of energy efficiency with voltage variation in different seasons needs to be evaluated in the future.