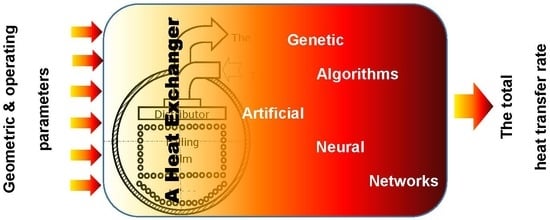

A General Approach in Optimization of Heat Exchangers by Bio-Inspired Artificial Intelligence Methods

Abstract

1. Introduction

2. Material and Methods

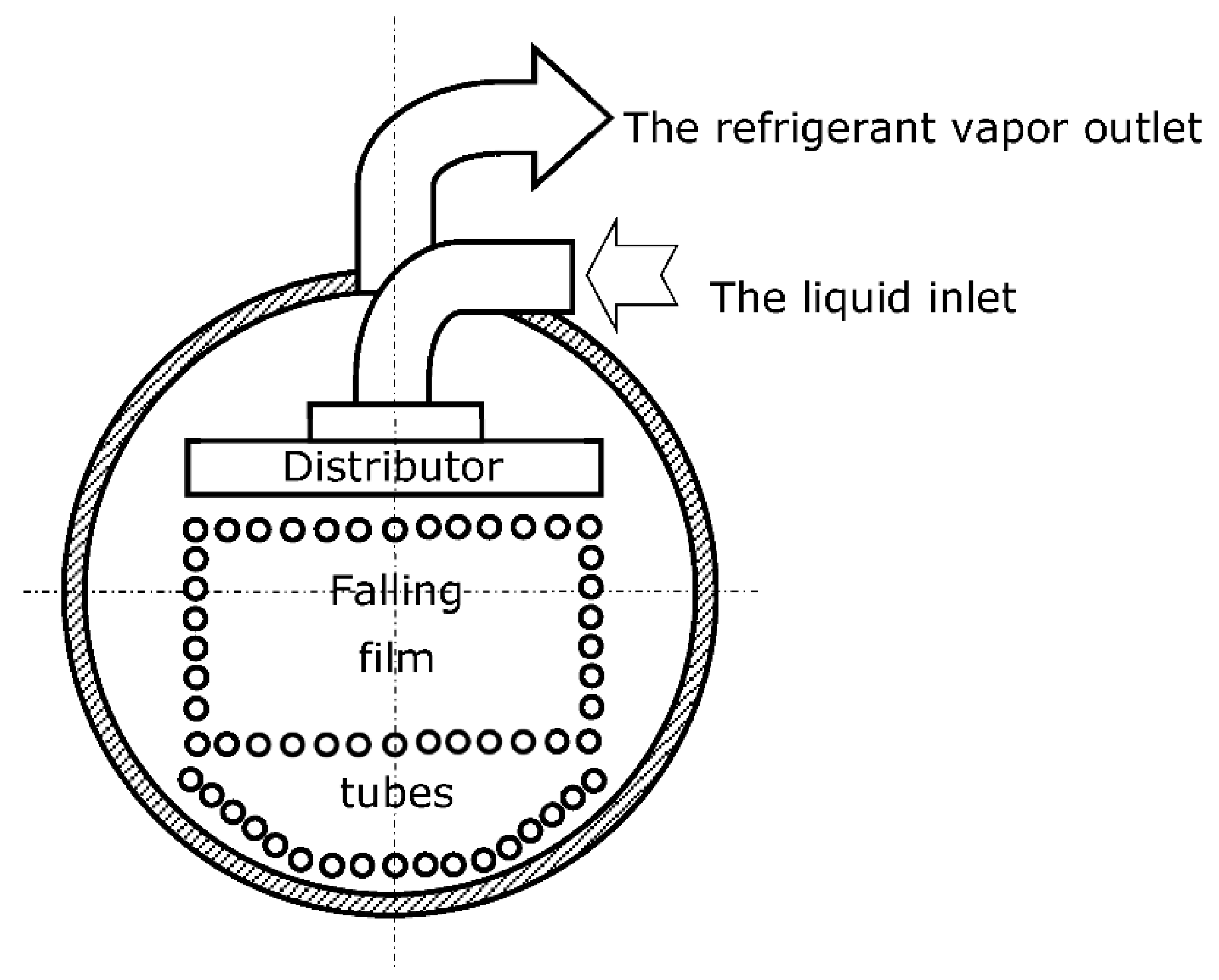

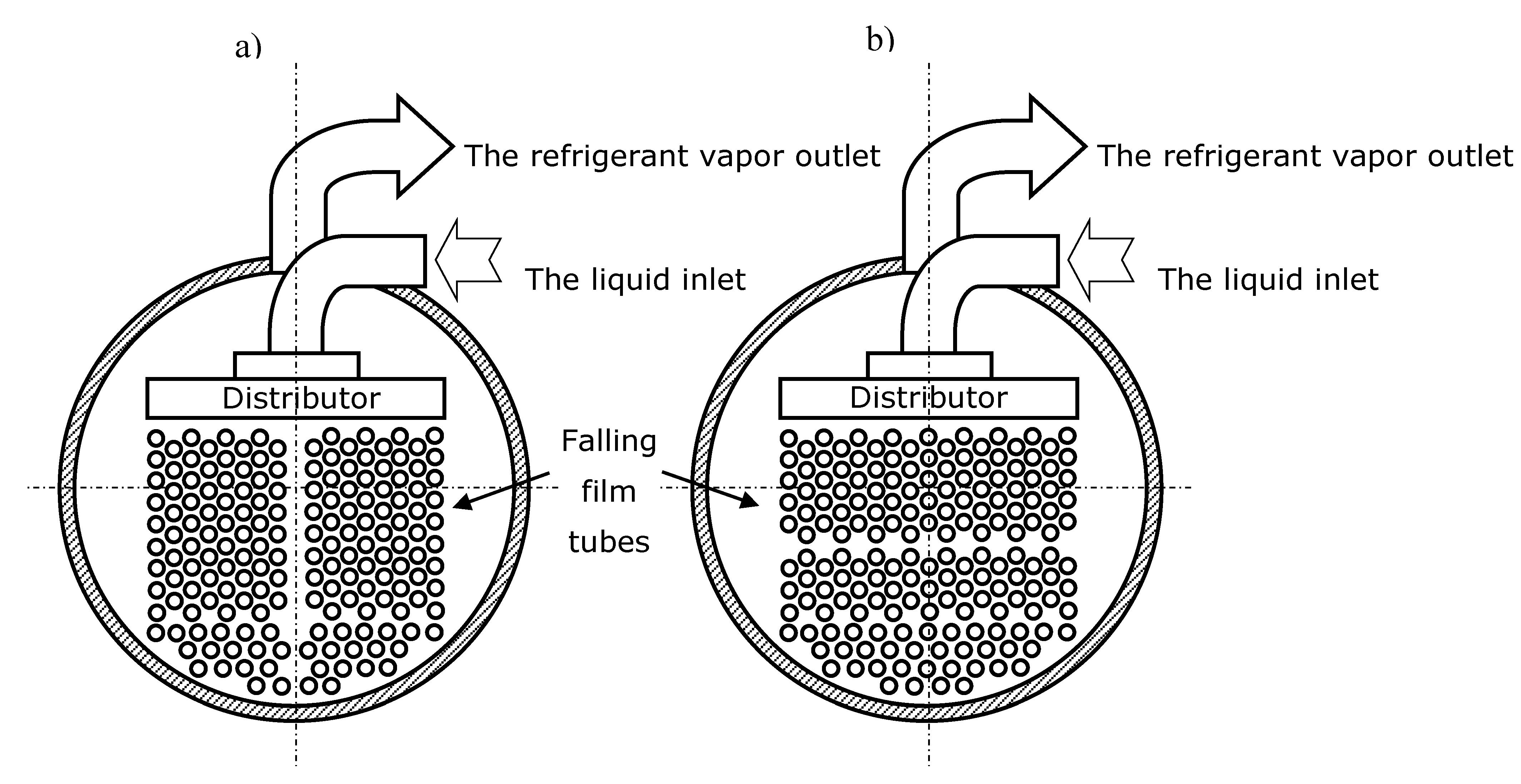

2.1. An Object of Investigation

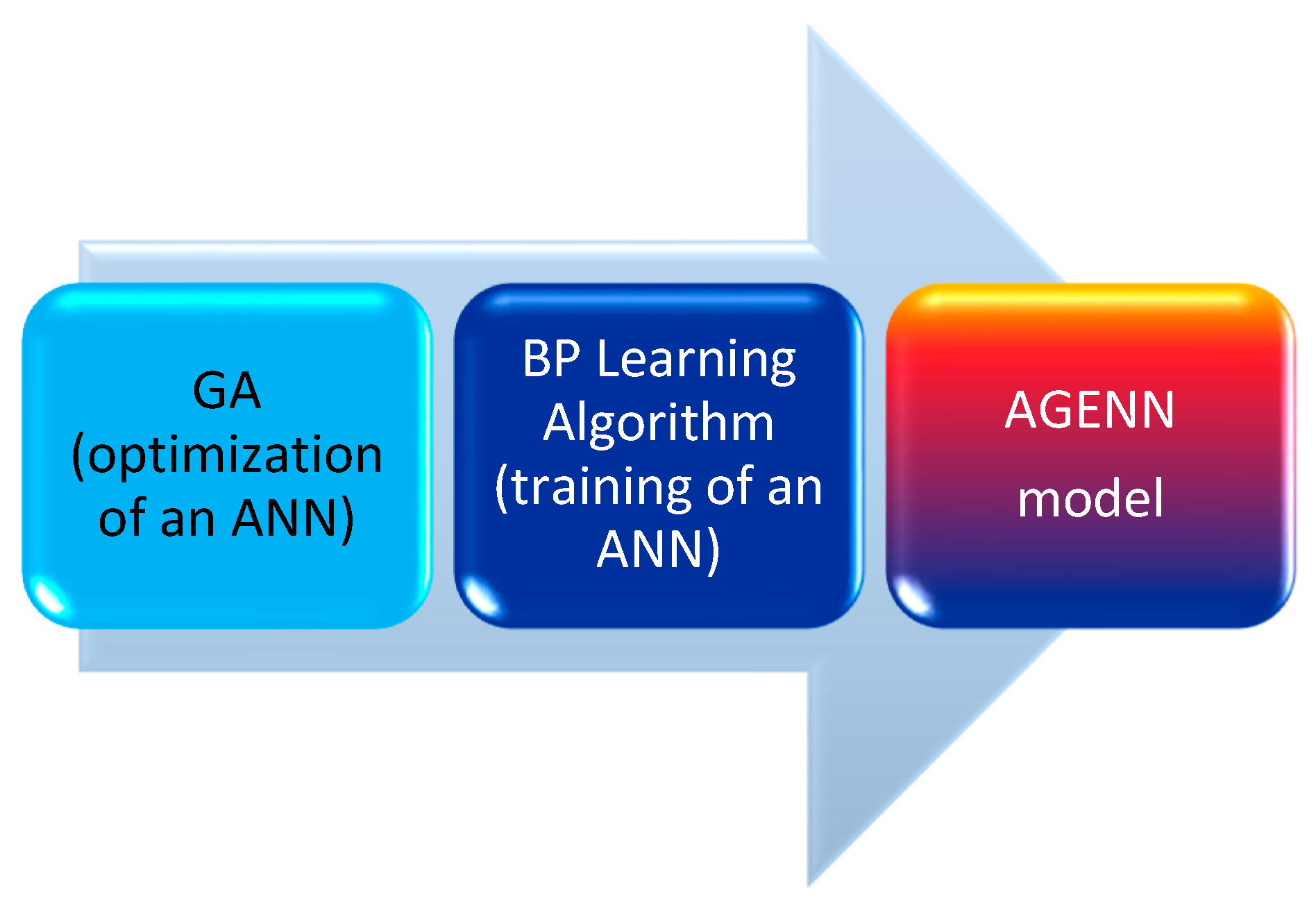

2.2. The Bio-Inspired Optimization Methods

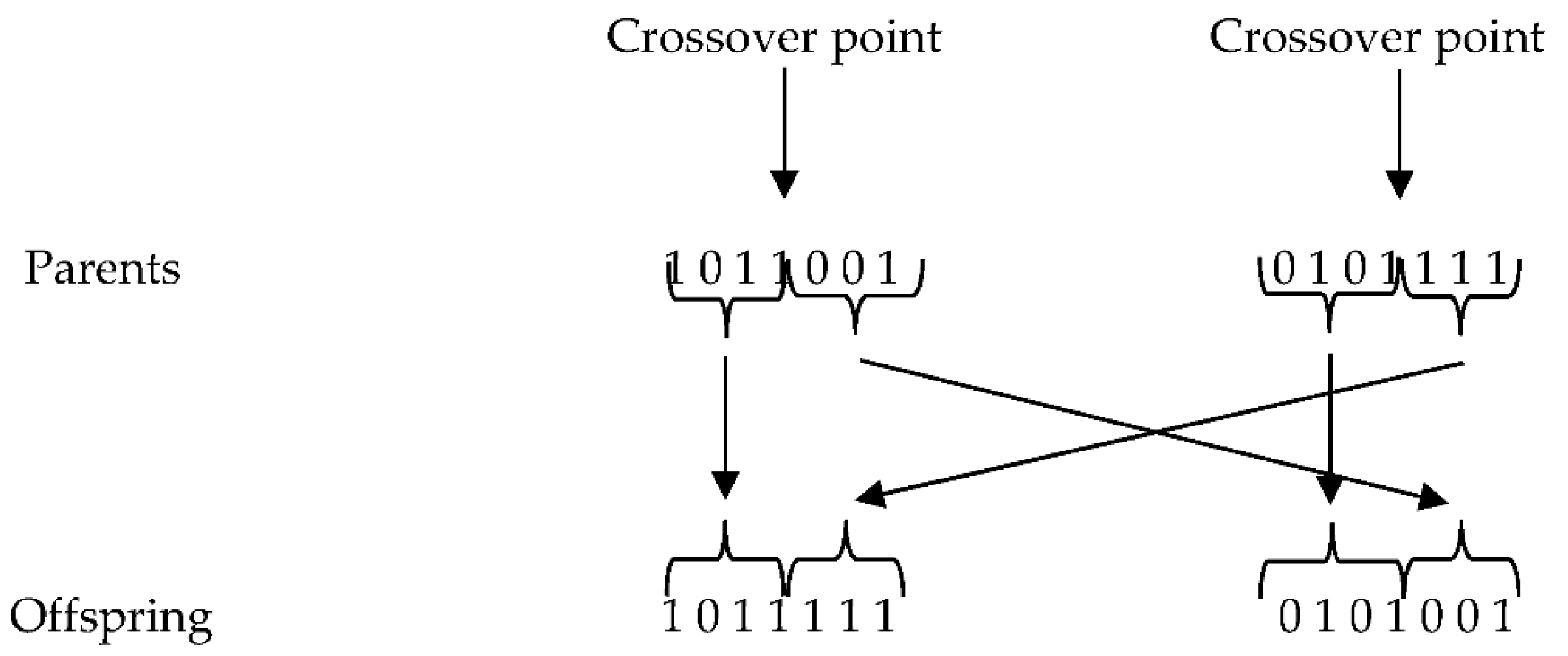

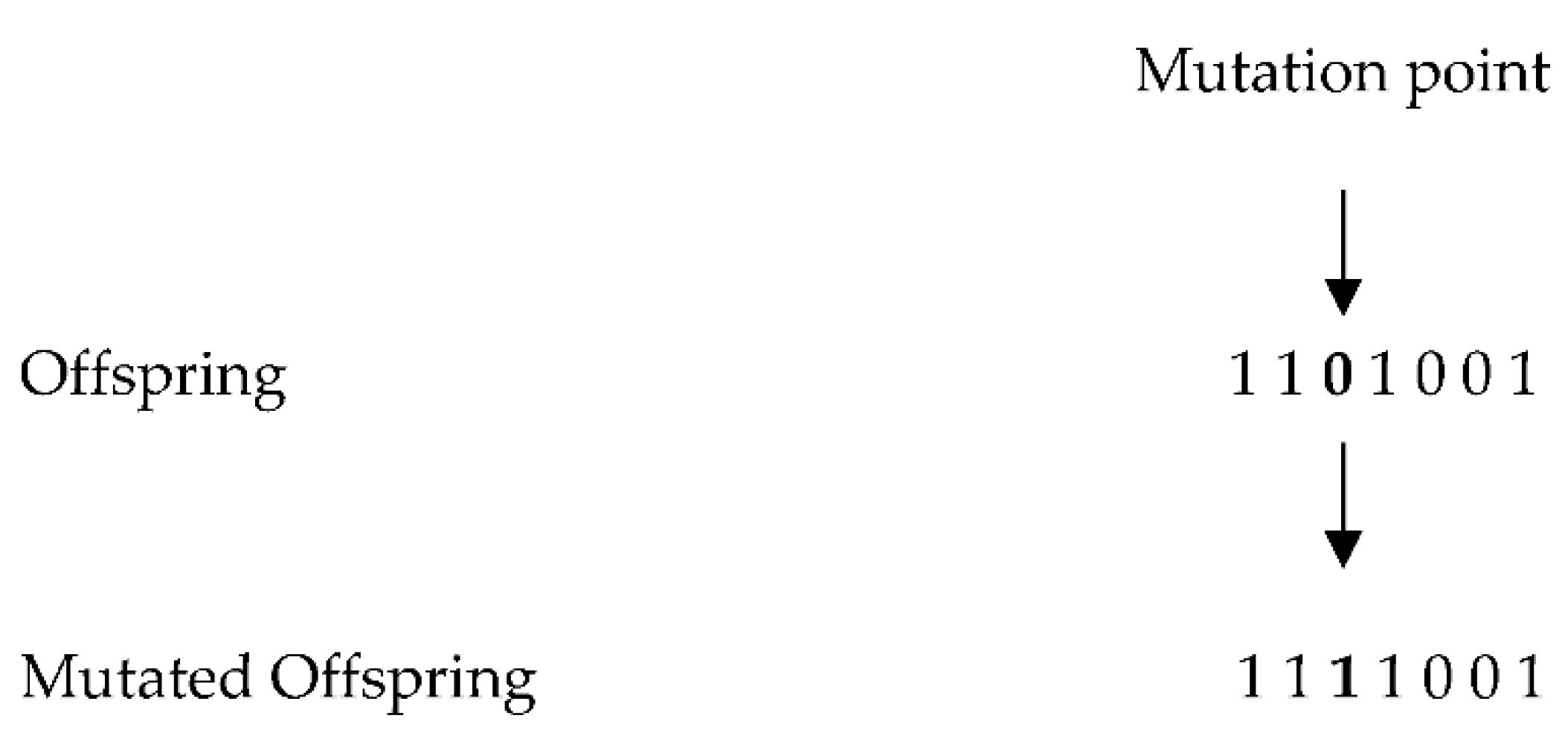

2.2.1. Genetic Algorithms Approach

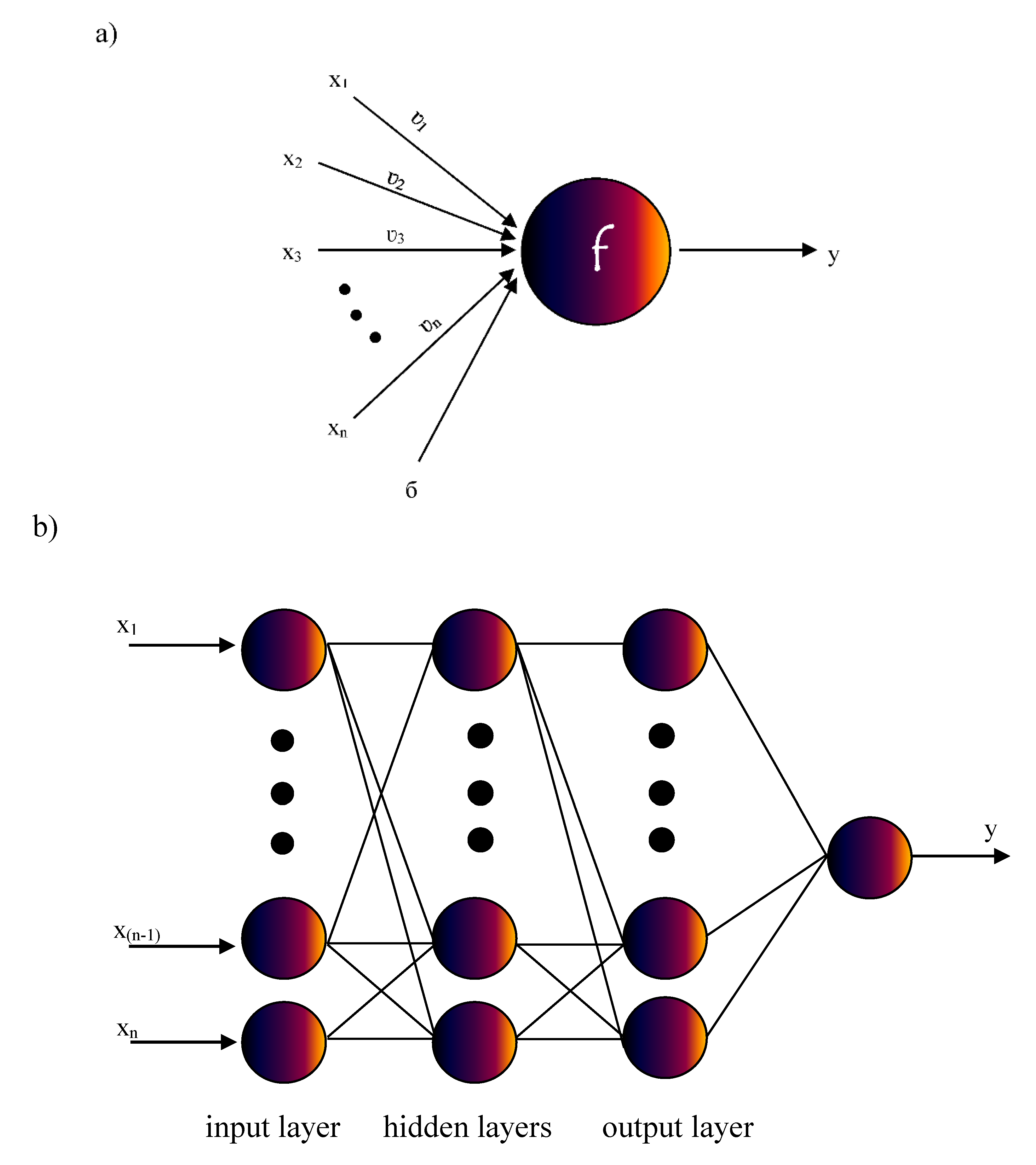

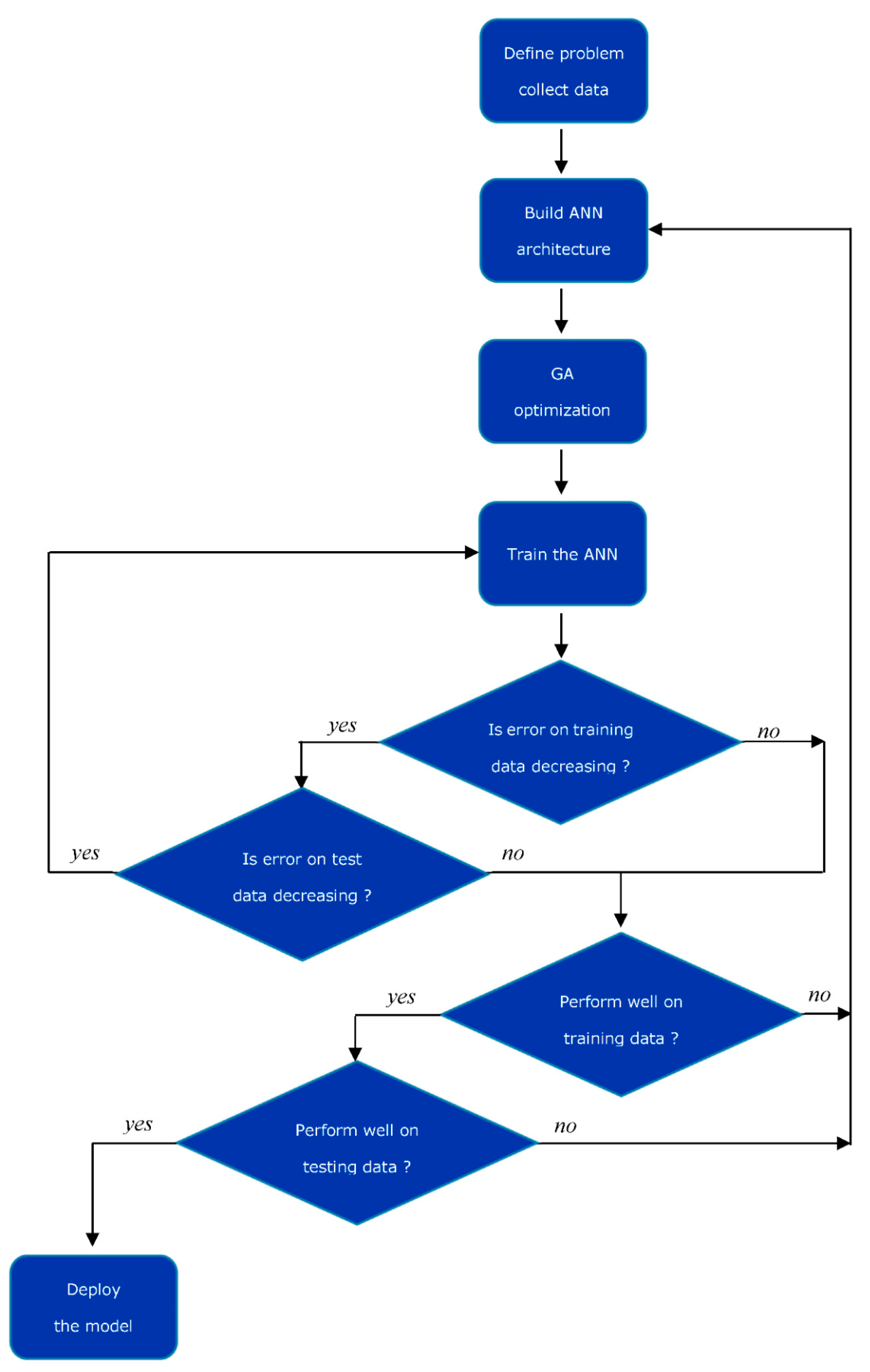

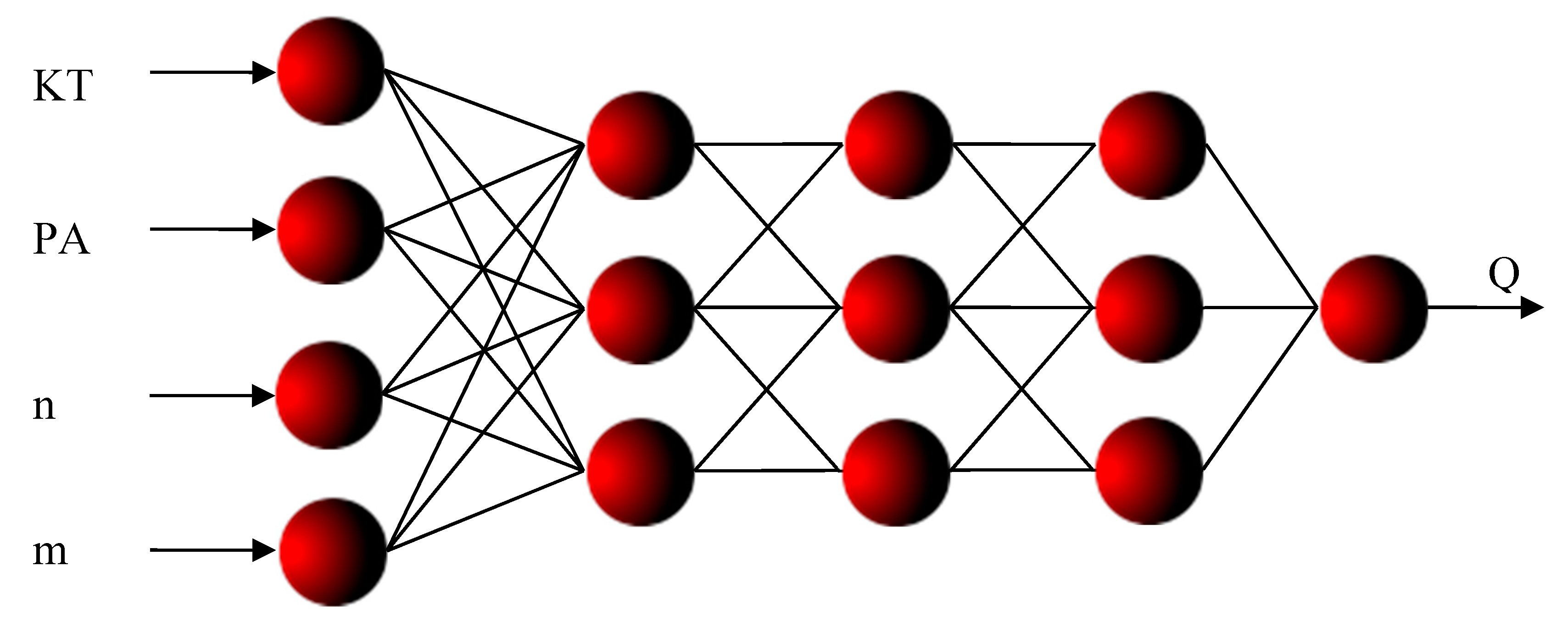

2.2.2. Neurocomputing Approach

3. Results and Discussion

3.1. Application of the Method

3.2. Validation of the Model

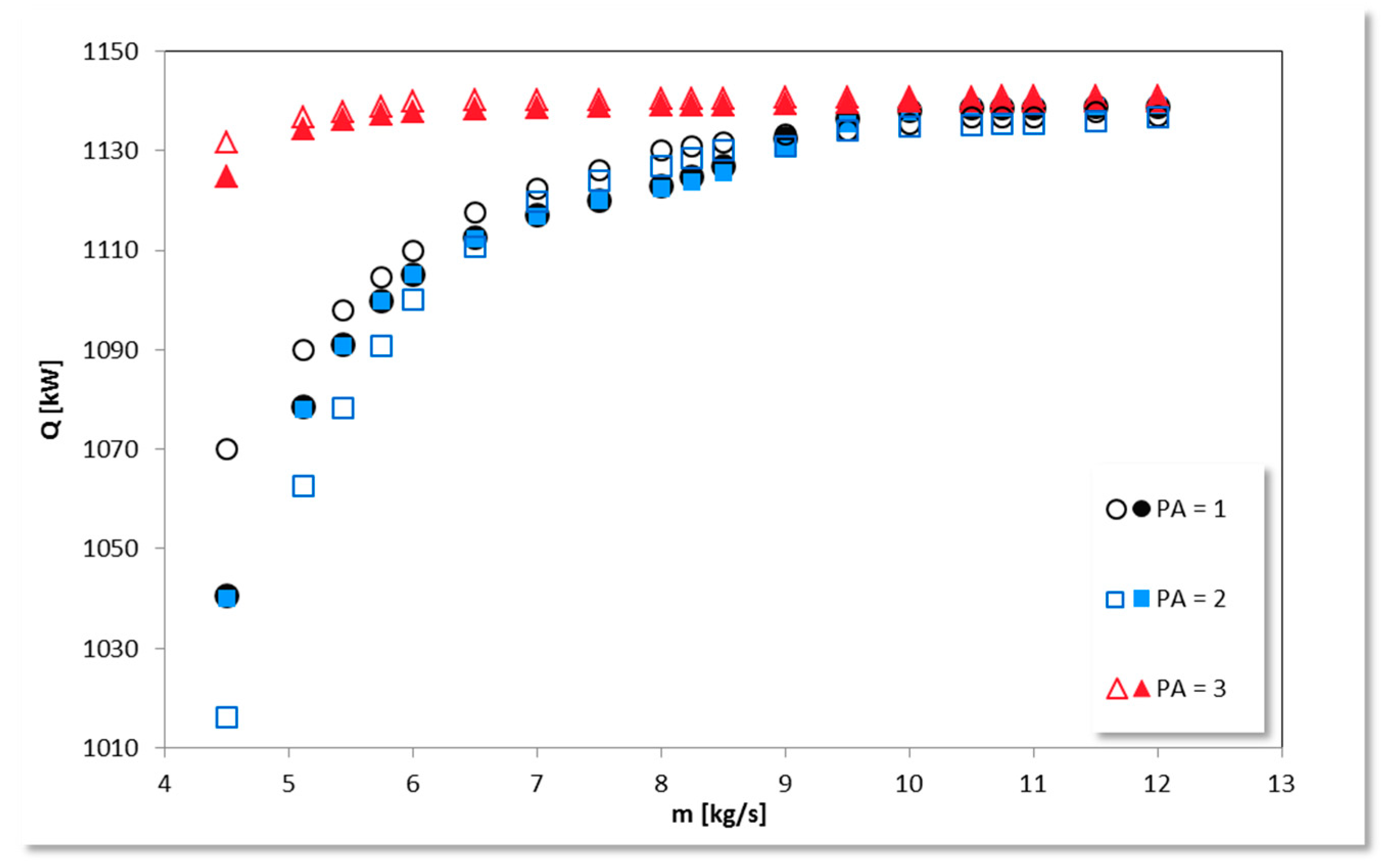

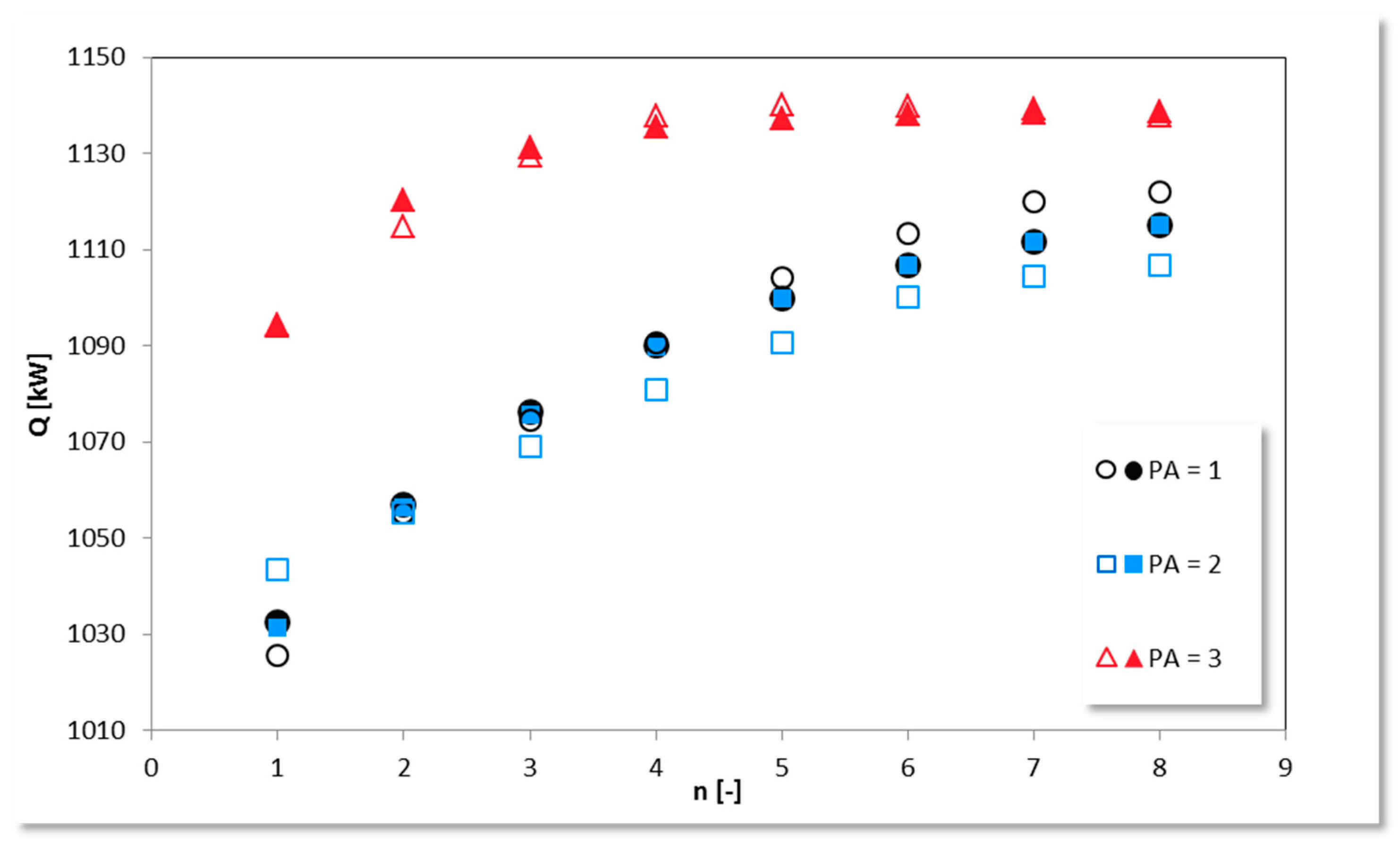

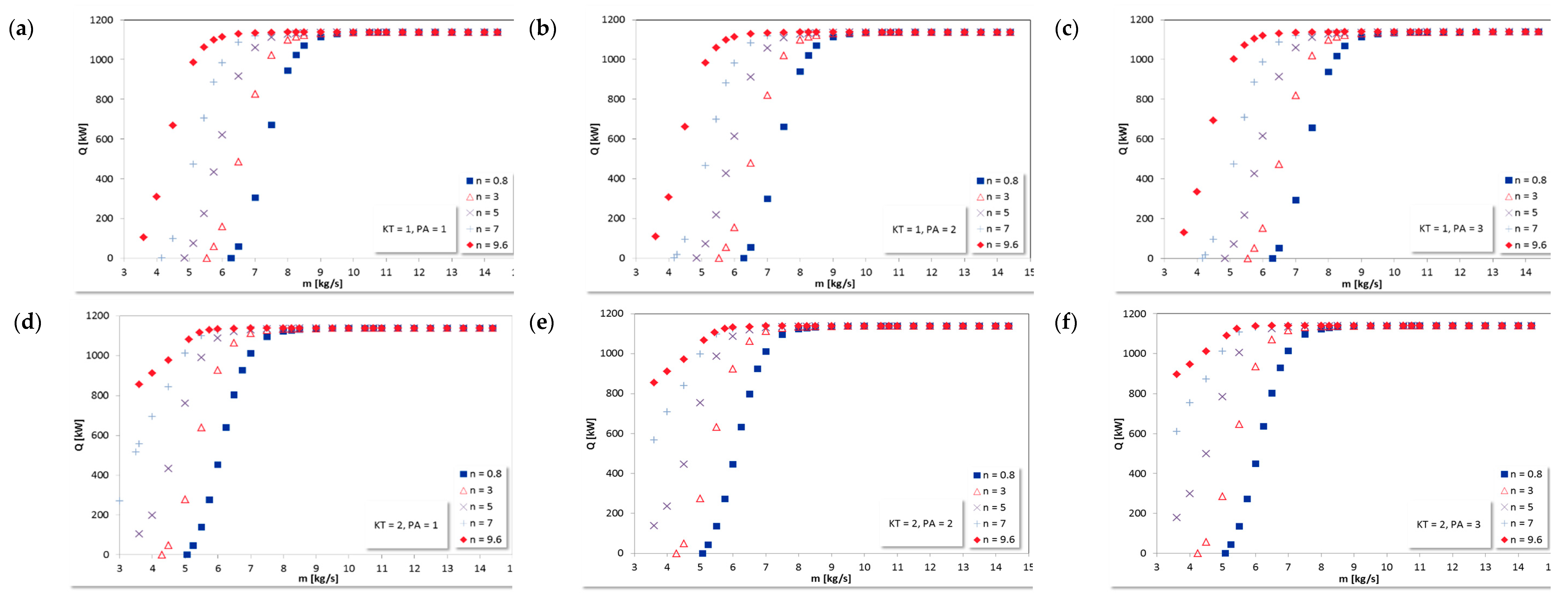

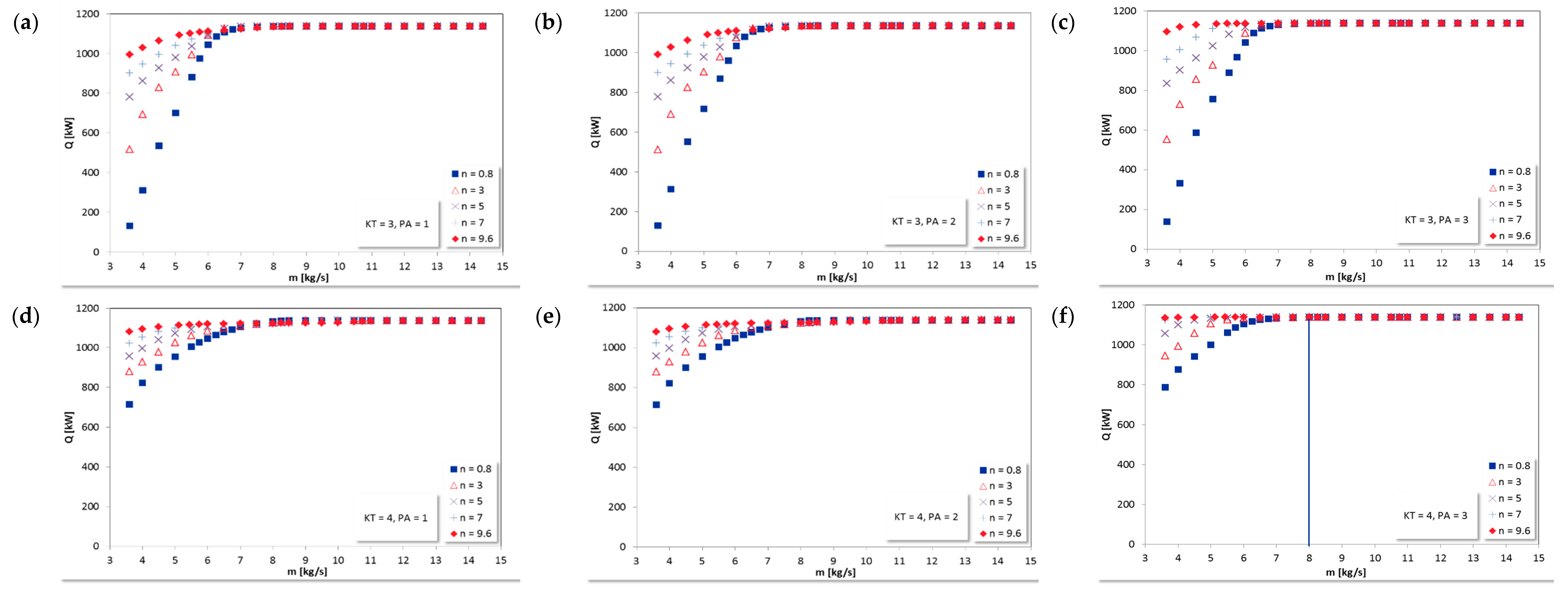

3.3. Effect of the Evaporator Design and Operating Parameters on the Heat Transfer Rate

3.3.1. Effect of Kinds of Tubes and Tube Pass Arrangements

3.3.2. Effect of the Number of Flooded Tube Rows and the Refrigerant Mass Flow Rates

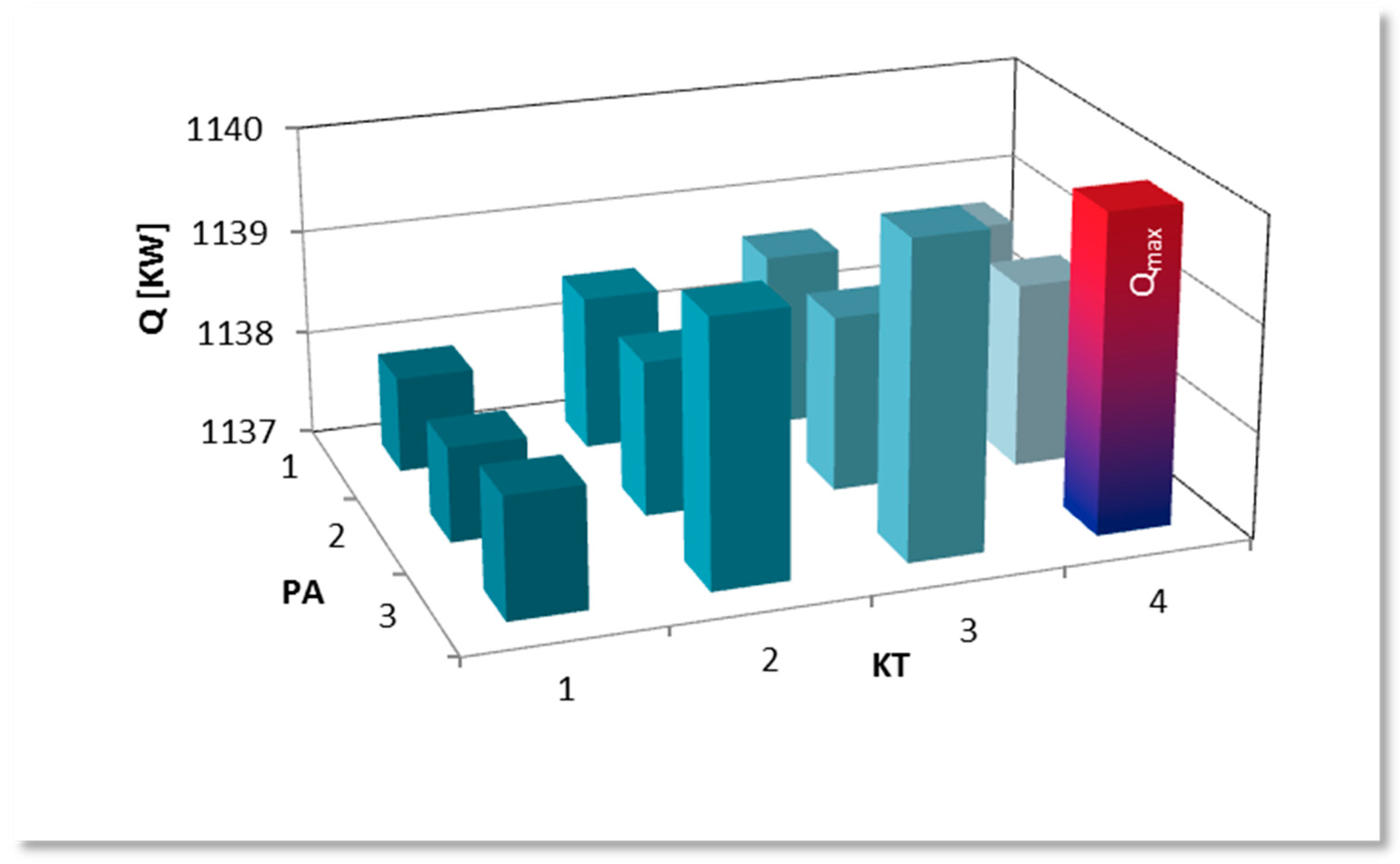

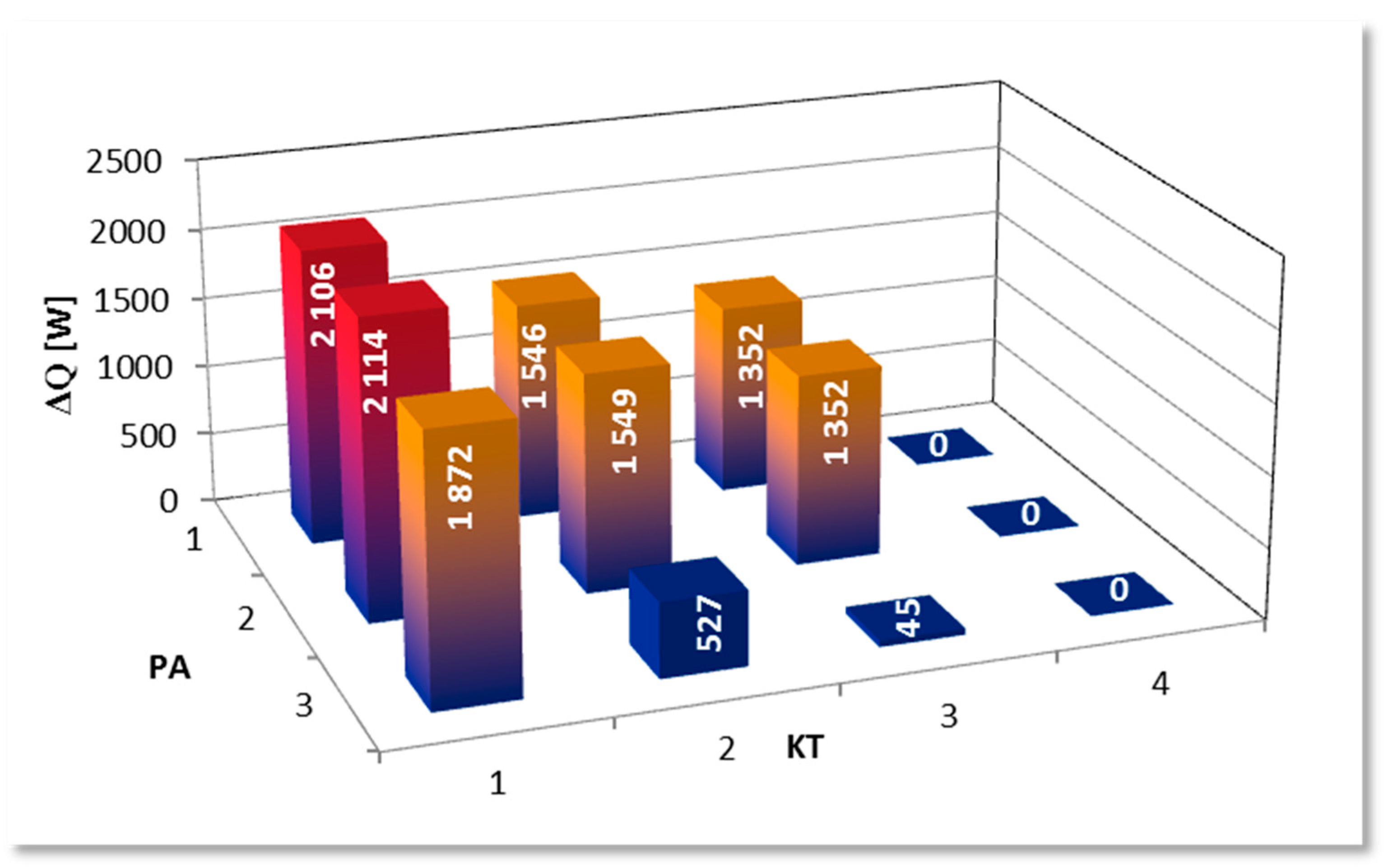

4. The Best Strategy for Heat Transfer Efficiency of the Evaporator

5. Conclusions

Funding

Conflicts of Interest

Abbreviations

| A | Heat transfer area, m2 |

| Dinn | Inside tube diameter, m |

| Dot | Outside tube diameter, m |

| Dr | Root diameter, m |

| Drh | Nominal height of a ridge, m |

| Err | Error of prediction |

| Activation function | |

| F | Equivalent inner surface area, m2/m |

| Fcorr | Correction factor |

| Fin | Number of fins per inch |

| GCf | General control factor |

| h | Enthalpy, J/kg |

| Kn | Nearest neighbor parameter,- |

| l | learning rate |

| LMDT | Log Mean Temperature Difference, K |

| m | Liquid refrigerant mass flow rate, kg/s |

| mf | Mutation factor |

| n | Number of flooded heat transfer tube rows |

| niter | Maximum number of iterations |

| npop | Population size |

| nr | Maximum number of reseed |

| ns | Maximum storage |

| Q | Total heat transfer rate of the evaporator, kW |

| rf | Reseed fraction, - |

| Rfo | Fouling factor, m2 K/W |

| Rwall | Thermal resistance of the wall, m2·K/W |

| s | signal |

| sm | Screening module,- |

| so | Screening offset |

| T | Temperature, K |

| U | Overall heat transfer coefficient, W/m2·K |

| x | Input |

| y | Output |

| Greek symbols | |

| α | Convection heat transfer coefficient, W/m2·K |

| б | Biases of neurons |

| δ | Relative error, % |

| ε | Heat exchanger effectiveness |

| µ | Momentum |

| ʋ | Weight connecting a neurons i on layer K with a neuron j from layer K + 1 |

| τ | An epoch |

| Subscripts | |

| CF, PF | counter-flow, parallel-flow |

| d | desired |

| p | predicted |

| i, j | numbers of neurons, i = 0–3, j = 0–2 |

| inn | inner surface of the wall |

| K | number of a layer, K = 0–3 |

| m | mean |

| max | maximum |

| opt. | optimum |

| ot | outer surface of the wall, |

| Acronyms | |

| AI | Artificial Intelligence |

| AGENN | Genetic Algorithms combined with Artificial Neural Networks |

| ANN | Artificial Neural Networks |

| BP | Back-propagation method |

| CFD | Computational Fluid Dynamics |

| CFB | Circulating Fluidized Bed |

| EHP | Enhanced High Performance |

| GA | Genetic Algorithms |

| GMDH | Group Method of Data Handling |

| KT | Kind of tubes |

| NN | Neural networks |

| NTU | Number of Transfer Units |

| NSGA | Non-Dominated Sorting Genetic Algorithm |

| PA | Tube pass arrangement |

Appendix A

References

- Lienhard, J.H. A Heat Transfer Textbook, 4th ed.; Phlogiston Press: Cambridge, MA, USA, 2016; ISBN 978-0-486-31837-0. [Google Scholar]

- Kakaç, S.; Liu, H.; Pramuanjaroenkij, A. Heat Exchangers: Selection, Rating, and Thermal Design, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2012; ISBN 978-1-4665-5616-4. [Google Scholar]

- Shah, R.K.; Sekulic, D.P. Fundamentals of Heat Exchanger Design; John Wiley & Sons: Hoboken, NJ, USA, 2003; ISBN 978-0-471-32171-2. [Google Scholar]

- Cengel, Y.A.; Ghajar Afshin, J. Heat and Mass Transfer. Fundamentals & Application, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2015. [Google Scholar]

- Cengel, Y.A. Heat transfer. A Practical Approach, 2nd ed.; International Edition; Mc-Graw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. A novel approach for performance improvement of liquid to vapor based battery cooling systems. Energy Convers. Manag. 2019, 187, 191–204. [Google Scholar] [CrossRef]

- Choudhury, B.; Saha, B.B.; Chatterjee, P.K.; Sarkar, J.P. An overview of developments in adsorption refrigeration systems towards a sustainable way of cooling. Appl. Energy 2013, 104, 554–567. [Google Scholar] [CrossRef]

- Kishore, R.A.; Davis, B.; Greathouse, J.; Hannon, A.; Kennedy, D.E.; Millar, A.; Mittel, D.; Nozariasbmarz, A.; Kang, M.G.; Kang, H.B.; et al. Energy scavenging from ultra-low temperature gradients. Energy Environ. Sci. 2019, 12, 1008–1018. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, J.; Yang, W.; Logan, E.B. A thermally regenerative ammonia-based battery for efficient harvesting of low-grade thermal energy as electrical power. Energy Environ. Sci. 2015, 8, 343–349. [Google Scholar] [CrossRef]

- Marschewski, J.; Brenner, L.; Ebejer, N.; Ruch, P.; Michel, B.; Poulikakos, D. 3D-printed fluidic networks for high-power-density heat-managing miniaturized redox flow batteries. Energy Environ. Sci. 2017, 10, 780–787. [Google Scholar] [CrossRef]

- Wang, R.Z.; Xia, Z.Z.; Wang, L.W.; Lu, Z.S.; Li, S.L.; Li, T.X.; Wu, J.Y.; He, S. Heat transfer design in adsorption refrigeration systems for efficient use of low-grade thermal energy. Energy 2011, 36, 5425–5439. [Google Scholar] [CrossRef]

- Li, X.H.; Hou, X.H.; Zhang, X.; Yuan, Z.X. A review on development of adsorption cooling—Novel beds and advanced cycles. Energy Convers. Manag. 2015, 94, 221–232. [Google Scholar] [CrossRef]

- Garg, P.; Orosz, M.S. Economic optimization of Organic Rankine cycle with pure fluids and mixtures for waste heat and solar applications using particle swarm optimization method. Energy Convers. Manag. 2018, 165, 649–668. [Google Scholar] [CrossRef]

- Bowman, R.A.; Mueller, A.C.; Nagle, W.M. Mean temperature difference in design. Trans. ASME 1940, 62, 283–294. [Google Scholar]

- Sanaye, S.; Hajabdollahi, H. Thermal-economic multi-objective optimization of plate fin heat exchanger using genetic algorithm. Appl. Energy 2010, 87, 1893–1902. [Google Scholar] [CrossRef]

- de Souza-Santos, M.L. Proposals for power generation based on processes consuming biomass-glycerol slurries. Energy 2017, 120, 959–974. [Google Scholar] [CrossRef]

- Blaszczuk, A.; Nowak, W.; Krzywanski, J. Effect of bed particle size on heat transfer between fluidized bed of group b particles and vertical rifled tubes. Powder Technol. 2017, 316, 111–122. [Google Scholar] [CrossRef]

- Błaszczuk, A.; Krzywański, J. A comparison of fuzzy logic and cluster renewal approaches for heat transfer modeling in a 1296 t/h CFB boiler with low level of flue gas recirculation. Arch. Thermodyn. 2017, 38, 91–122. [Google Scholar] [CrossRef]

- Muskała, W.; Krzywański, J.; Rajczyk, R.; Cecerko, M.; Kierzkowski, B.; Nowak, W.; Gajewski, W. Investigation of erosion in CFB boilers. Rynek Energii 2010, 87, 97–102. [Google Scholar]

- Muskała, W.; Krzywański, J.; Sekret, R.; Nowak, W. Model research of coal combustion in circulating fluidized bed boilers. Chem. Process Eng. Inz. Chem. I Proces. 2008, 29, 473–492. [Google Scholar]

- Zylka, A.; Krzywanski, J.; Czakiert, T.; Idziak, K.; Sosnowski, M.; Grabowska, K.; Prauzner, T.; Nowak, W. The 4th Generation of CeSFaMB in numerical simulations for CuO-based oxygen carrier in CLC system. Fuel 2019, 255, 115776. [Google Scholar] [CrossRef]

- Ceribeli, K.B.; de Souza-Santos, M.L. Effect of dry-solid content level in feeding slurry of municipal solid waste consumed by FSIG/GT power generation process; a theoretical study. Fuel 2019, 254, 115727. [Google Scholar] [CrossRef]

- Markides, C.N.; Smith, T.C.B. A dynamic model for the efficiency optimization of an oscillatory low grade heat engine. Energy 2011, 36, 6967–6980. [Google Scholar] [CrossRef]

- Solanki, R.; Mathie, R.; Galindo, A.; Markides, C.N. Modelling of a two-phase thermofluidic oscillator for low-grade heat utilisation: Accounting for irreversible thermal losses. Appl. Energy 2013, 106, 337–354. [Google Scholar] [CrossRef]

- Sah, R.P.; Choudhury, B.; Das, R.K.; Sur, A. An overview of modelling techniques employed for performance simulation of low–grade heat operated adsorption cooling systems. Renew. Sustain. Energy Rev. 2017, 74, 364–376. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Glaznev, I.S.; Girnik, I.S. Optimization of adsorption dynamics in adsorptive chillers: Loose grains configuration. Energy 2012, 46, 484–492. [Google Scholar] [CrossRef]

- Chorowski, M.; Pyrka, P. Modelling and experimental investigation of an adsorption chiller using low-temperature heat from cogeneration. Energy 2015, 92, 221–229. [Google Scholar] [CrossRef]

- Ocłoń, P.; Łopata, S. Study of the Effect of Fin-and-Tube Heat Exchanger Fouling on its Structural Performance. Heat Transf. Eng. 2018, 39, 1139–1155. [Google Scholar] [CrossRef]

- Ji, W.-T.; Zhao, E.-T.; Zhao, C.-Y.; Zhang, H.; Tao, W.-Q. Falling film evaporation and nucleate pool boiling heat transfer of R134a on the same enhanced tube. Appl. Therm. Eng. 2019, 147, 113–121. [Google Scholar] [CrossRef]

- Cheppudira Thimmaiah, P.; Sharafian, A.; Huttema, W.; Osterman, C.; Ismail, A.; Dhillon, A.; Bahrami, M. Performance of finned tubes used in low-pressure capillary-assisted evaporator of adsorption cooling system. Appl. Therm. Eng. 2016, 106, 371–380. [Google Scholar] [CrossRef]

- Thimmaiah, P.C.; Sharafian, A.; Rouhani, M.; Huttema, W.; Bahrami, M. Evaluation of low-pressure flooded evaporator performance for adsorption chillers. Energy 2017, 122, 144–158. [Google Scholar] [CrossRef]

- Cheppudira Thimmaiah, P.; Sharafian, A.; Huttema, W.; McCague, C.; Bahrami, M. Effects of capillary-assisted tubes with different fin geometries on the performance of a low-operating pressure evaporator for adsorption cooling system applications. Appl. Energy 2016, 171, 256–265. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Myat, A.; Chun, W.G.; Ng, K.C. Bubble-assisted film evaporation correlation for saline water at sub-atmospheric pressures in horizontal-tube evaporator. Appl. Therm. Eng. 2013, 50, 670–676. [Google Scholar] [CrossRef]

- Jin, P.-H.; Zhao, C.-Y.; Ji, W.-T.; Tao, W.-Q. Experimental investigation of R410A and R32 falling film evaporation on horizontal enhanced tubes. Appl. Therm. Eng. 2018, 137, 739–748. [Google Scholar] [CrossRef]

- Abed, A.M.; Alghoul, M.A.; Yazdi, M.H.; Al-Shamani, A.N.; Sopian, K. The role of enhancement techniques on heat and mass transfer characteristics of shell and tube spray evaporator: A detailed review. Appl. Therm. Eng. 2015, 75, 923–940. [Google Scholar] [CrossRef]

- Zhao, C.-Y.; Ji, W.-T.; Jin, P.-H.; Tao, W.-Q. Heat transfer correlation of the falling film evaporation on a single horizontal smooth tube. Appl. Therm. Eng. 2016, 103, 177–186. [Google Scholar] [CrossRef]

- Li, W.; Wu, X.-Y.; Luo, Z.; Yao, S.; Xu, J.-L. Heat transfer characteristics of falling film evaporation on horizontal tube arrays. Int. J. Heat Mass Transf. 2011, 54, 1986–1993. [Google Scholar] [CrossRef]

- Yang, L.; Wang, W. The heat transfer performance of horizontal tube bundles in large falling film evaporators. Int. J. Refrig. 2011, 34, 303–316. [Google Scholar] [CrossRef]

- Yang, L.; Song, X.; Xie, Y. Effect of the Dryout in Tube Bundles on the Heat Transfer Performance of Falling Film Evaporators. Procedia Eng. 2017, 205, 2176–2183. [Google Scholar] [CrossRef]

- Hou, H.; Bi, Q.; Zhang, X. Numerical simulation and performance analysis of horizontal-tube falling-film evaporators in seawater desalination. Int. Commun. Heat Mass Transf. 2012, 39, 46–51. [Google Scholar] [CrossRef]

- Wunder, F.; Enders, S.; Semiat, R. Numerical simulation of heat transfer in a horizontal falling film evaporator of multiple-effect distillation. Desalination 2017, 401, 206–229. [Google Scholar] [CrossRef]

- Kharangate, C.R.; Mudawar, I. Review of computational studies on boiling and condensation. Int. J. Heat Mass Transf. 2017, 108, 1164–1196. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, R.; Niu, R. Numerical simulation of horizontal tube bundle falling film flow pattern transformation. Renew. Energy 2015, 73, 62–68. [Google Scholar] [CrossRef]

- Ren, C.; Wan, Y. A new approach to the analysis of heat and mass transfer characteristics for laminar air flow inside vertical plate channels with falling water film evaporation. Int. J. Heat Mass Transf. 2016, 103, 1017–1028. [Google Scholar] [CrossRef]

- Benim, A.C.; Chattopadhyay, H.; Nahavandi, A. Computational analysis of turbulent forced convection in a channel with a triangular prism. Int. J. Therm. Sci. 2011, 50, 1973–1983. [Google Scholar] [CrossRef]

- Ocłoń, P.; Łopata, S.; Nowak, M.; Benim, A.C. Numerical Study on the Effect of Inner Tube Fouling on the Thermal Performance of High-Temperature Fin-and-Tube Heat Exchanger. Available online: https://www.researchgate.net/publication/268506448_Numerical_study_on_the_effect_of_inner_tube_fouling_on_the_thermal_performance_of_high-temperature_fin-and-tube_heat_exchanger (accessed on 13 February 2019).

- Sosnowski, M.; Krzywanski, J.; Grabowska, K.; Gnatowska, R. Polyhedral meshing in numerical analysis of conjugate heat transfer. EPJ Web Conf. 2018, 180, 02096. [Google Scholar] [CrossRef]

- Ocłoń, P.; Łopata, S.; Chłosta, K. Experimental and Numerical Investigation of Flow Distribution within the Heat Exchanger with Elliptical Tubes. Procedia Eng. 2016, 157, 428–435. [Google Scholar] [CrossRef]

- Grabowska, K.; Sosnowski, M.; Krzywanski, J.; Sztekler, K.; Kalawa, W.; Zylka, A.; Nowak, W. Analysis of heat transfer in a coated bed of an adsorption chiller. MATEC Web Conf. 2018, 240, 01010. [Google Scholar] [CrossRef]

- Grabowska, K.; Sosnowski, M.; Krzywanski, J.; Sztekler, K.; Kalawa, W.; Zylka, A.; Nowak, W. The Numerical Comparison of Heat Transfer in a Coated and Fixed Bed of an Adsorption Chiller. J. Therm. Sci. 2018, 27, 421–426. [Google Scholar] [CrossRef]

- Shah, M.M. A correlation for heat transfer during boiling on bundles of horizontal plain and enhanced tubes. Int. J. Refrig. 2017, 78, 47–59. [Google Scholar] [CrossRef]

- Krzywanski, J.; Wesolowska, M.; Blaszczuk, A.; Majchrzak, A.; Komorowski, M.; Nowak, W. The Non-Iterative Estimation of Bed-to-Wall Heat Transfer Coefficient in a CFBC by Fuzzy Logic Methods. Procedia Eng. 2016, 157, 66–71. [Google Scholar] [CrossRef]

- Dang, T.; Nguyen, H.; Nguyen, G. Experimental Investigations for Fluid Flow Characteristics of Refrigerant R134a in a Microtubes Evaporator. In Proceedings of the 2018 4th International Conference on Green Technology and Sustainable Development (GTSD), Ho Chi Minh City, Vietnam, 23–24 November 2018; pp. 385–390. [Google Scholar]

- Halon, T.; Pelinska-Olko, E.; Szyc, M.; Zajaczkowski, B. Predicting Performance of a District Heat Powered Adsorption Chiller by Means of an Artificial Neural Network. Energies 2019, 12, 3328. [Google Scholar] [CrossRef]

- Kim, J.-H.; Seong, N.-C.; Choi, W. Modeling and Optimizing a Chiller System Using a Machine Learning Algorithm. Energies 2019, 12, 2860. [Google Scholar] [CrossRef]

- Karami, A.; Rezaei, E.; Rahimi, M.; Zanjani, M. Artificial Neural Modeling of the Heat Transfer in an Air Cooled Heat Exchanger Equipped with Butterfly Inserts. Int. Energy J. 2012, 13, 21–28. [Google Scholar]

- Amiri, A.; Karami, A.; Yousefi, T.; Zanjani, M. Artificial neural network to predict the natural convection from vertical and inclined arrays of horizontal cylinders. Pol. J. Chem. Technol. 2012, 14, 46–52. [Google Scholar] [CrossRef]

- Lin, L.; Wang, X. Design for refrigerator evaporator superheat based on direct adaptive fuzzy controller. In Proceedings of the 2016 Chinese Control and Decision Conference (CCDC), Yinchuan, China, 28–30 May 2016; pp. 6297–6300. [Google Scholar]

- Krzywanski, J.; Grabowska, K.; Herman, F.; Pyrka, P.; Sosnowski, M.; Prauzner, T.; Nowak, W. Optimization of a three-bed adsorption chiller by genetic algorithms and neural networks. Energy Convers. Manag. 2017, 153, 313–322. [Google Scholar] [CrossRef]

- Shi, H.; Ma, T.; Chu, W.; Wang, Q. Optimization of inlet part of a microchannel ceramic heat exchanger using surrogate model coupled with genetic algorithm. Energy Convers. Manag. 2017, 149, 988–996. [Google Scholar] [CrossRef]

- Darvish Damavandi, M.; Forouzanmehr, M.; Safikhani, H. Modeling and Pareto based multi-objective optimization of wavy fin-and-elliptical tube heat exchangers using CFD and NSGA-II algorithm. Appl. Therm. Eng. 2017, 111, 325–339. [Google Scholar] [CrossRef]

- Chitgar, N.; Emadi, M.A.; Chitsaz, A.; Rosen, M.A. Investigation of a novel multigeneration system driven by a SOFC for electricity and fresh water production. Energy Convers. Manag. 2019, 196, 296–310. [Google Scholar] [CrossRef]

- Yin, Q.; Du, W.-J.; Ji, X.-L.; Cheng, L. Optimization design and economic analyses of heat recovery exchangers on rotary kilns. Appl. Energy 2016, 180, 743–756. [Google Scholar] [CrossRef]

- Yin, Q.; Du, W.-J.; Cheng, L. Optimization design of heat recovery systems on rotary kilns using genetic algorithms. Appl. Energy 2017, 202, 153–168. [Google Scholar] [CrossRef]

- Dezan, D.J.; Salviano, L.O.; Yanagihara, J.I. Heat transfer enhancement and optimization of flat-tube multilouvered fin compact heat exchangers with delta-winglet vortex generators. Appl. Therm. Eng. 2016, 101, 576–591. [Google Scholar] [CrossRef]

- Saldanha, W.H.; Soares, G.L.; Machado-Coelho, T.M.; dos Santos, E.D.; Ekel, P.I. Choosing the best evolutionary algorithm to optimize the multiobjective shell-and-tube heat exchanger design problem using PROMETHEE. Appl. Therm. Eng. 2017, 127, 1049–1061. [Google Scholar] [CrossRef]

- Cartelle Barros, J.J.; Lara Coira, M.; de la Cruz López, M.P.; del Caño Gochi, A. Sustainability optimisation of shell and tube heat exchanger, using a new integrated methodology. J. Clean. Prod. 2018, 200, 552–567. [Google Scholar] [CrossRef]

- Roy, U.; Pant, H.K.; Majumder, M. Detection of significant parameters for shell and tube heat exchanger using polynomial neural network approach. Vacuum 2019, 166, 399–404. [Google Scholar] [CrossRef]

- Roy, U.; Majumder, M. Evaluating heat transfer analysis in heat exchanger using NN with IGWO algorithm. Vacuum 2019, 161, 186–193. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, N.; Liu, Z.; Liu, W. Numerical analysis and optimization study on shell-side performances of a shell and tube heat exchanger with staggered baffles. Int. J. Heat Mass Transf. 2018, 124, 247–259. [Google Scholar] [CrossRef]

- Bahiraei, M.; Khosravi, R.; Heshmatian, S. Assessment and optimization of hydrothermal characteristics for a non-Newtonian nanofluid flow within miniaturized concentric-tube heat exchanger considering designer’s viewpoint. Appl. Therm. Eng. 2017, 123, 266–276. [Google Scholar] [CrossRef]

- Salam, Z.; Ahmed, J.; Merugu, B.S. The application of soft computing methods for MPPT of PV system: A technological and status review. Appl. Energy 2013, 107, 135–148. [Google Scholar] [CrossRef]

- Krzywanski, J.; Fan, H.; Feng, Y.; Shaikh, A.R.; Fang, M.; Wang, Q. Genetic algorithms and neural networks in optimization of sorbent enhanced H2 production in FB and CFB gasifiers. Energy Convers. Manag. 2018, 171, 1651–1661. [Google Scholar] [CrossRef]

- Kar, A.K. Bio inspired computing—A review of algorithms and scope of applications. Expert Syst. Appl. 2016, 59, 20–32. [Google Scholar] [CrossRef]

- Krzywanski, J. Modeling of Energy Systems with Fixed and Moving Porous Media by Artificial Intelligence Methods; University of Warmia and Mazury in Olsztyn: Olsztyn, Poland, 2018; ISBN 978-83-60493-05-2. [Google Scholar]

- Zhao, C.-Y.; Ji, W.-T.; Jin, P.-H.; Zhong, Y.-J.; Tao, W.-Q. Experimental study of the local and average falling film evaporation coefficients in a horizontal enhanced tube bundle using R134a. Appl. Therm. Eng. 2018, 129, 502–511. [Google Scholar] [CrossRef]

- Edalatpour, M.; Liu, L.; Jacobi, A.M.; Eid, K.F.; Sommers, A.D. Managing water on heat transfer surfaces: A critical review of techniques to modify surface wettability for applications with condensation or evaporation. Appl. Energy 2018, 222, 967–992. [Google Scholar] [CrossRef]

- Rix, J.; Haas, S.; Teixeira, J. Virtual Prototyping: Virtual Environments and the Product Design Process; Springer: New York, NY, USA, 2016; ISBN 978-0-387-34904-6. [Google Scholar]

- Patterson, J.; Gibson, A. Deep Learning: A Practitioner’s Approach; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2017; ISBN 978-1-4919-1423-6. [Google Scholar]

- Rutkowski, L. Computational Intelligence: Methods and Techniques; Springer Science & Business Media: Boston, NY, USA, 2008; ISBN 978-3-540-76288-1. [Google Scholar]

- Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Żyłka, A.; Sztekler, K.; Kalawa, W.; Wójcik, T.; Nowak, W. Modeling of a re-heat two-stage adsorption chiller by AI approach. MATEC Web Conf. 2018, 240, 05014. [Google Scholar] [CrossRef]

- Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Zylka, A.; Sztekler, K.; Kalawa, W.; Wójcik, T.; Nowak, W. An Adaptive Neuro-Fuzzy model of a Re-Heat Two-Stage Adsorption Chiller. Therm. Sci. 2019, 23, 1053–1063. [Google Scholar] [CrossRef]

| Tube Dimensions | Kind of Tube | ||||

|---|---|---|---|---|---|

| Plain | Turbo B | Turbo BII | Turbo EHP | ||

| Outside dimen-sions | Dot, mm | 19.500 | 19.500 | 19.500 | 19.500 |

| Dr, mm | - | 17.250 | 17.270 | 17.800 | |

| Fin | - | 40 | 48 | 42 | |

| Inside dimen-sions | Dinn, mm | 17.780 | 16.050 | 16.050 | 16.540 |

| Drh, mm | - | 0.508 | 0.356 | 0.406 | |

| F, m2/m | 0.0558 | 0.0770 | 0.080 | 0.080 | |

| Parameter | Value |

|---|---|

| niter | 1500 |

| npop | 33 |

| ns | 333 |

| rf | 1 |

| nr | 2 |

| sm | On |

| so | 1 |

| mf | 5 |

| GCf | 0.25 |

| Kn | 2 |

| inf | 1 |

| finf | 0.1 |

| Input Parameter | Value |

|---|---|

| Kind of tubes, KT * | 1, 2, 3, 4 |

| Tube pass arrangement, PA ** | 1, 2, 3 |

| Number of flooded heat transfer tube rows, n | 1, 2, 3, 4, 5, 6, 7, 8 |

| Liquid refrigerant mass flow rate, m, kg/s | 4.5–12 |

| Weights, υi,K,j * | |

|---|---|

| υ0,0,0 | −3.810 |

| υ0,0,1 | 1.305 |

| υ0,0,2 | 10.634 |

| υ1,0,0 | −10.013 |

| υ1,0,1 | −0.007 |

| υ1,0,2 | 0.519 |

| υ2,0,0 | −2.125 |

| υ2,0,1 | 0,859 |

| υ2,0,2 | 3.013 |

| υ3,0,0 | −3.154 |

| υ3,0,1 | 2.700 |

| υ3,0,2 | −9.283 |

| υ0,1,0 | −1.911 |

| υ0,1,1 | −4.618 |

| υ0,1,2 | 2.567 |

| υ1,1,0 | 9.920 |

| υ1,1,1 | 7.640 |

| υ1,1,2 | −10.019 |

| υ2,1,0 | −4.603 |

| υ2,1,1 | 1.021 |

| υ2,1,2 | 2.377 |

| υ0,2,0 | −2.405 |

| υ0,2,1 | 3.727 |

| υ0,2,2 | −8.748 |

| υ1,2,0 | −4.121 |

| υ1,2,1 | 6.328 |

| υ1,2,2 | −10.000 |

| υ2,2,0 | −7.475 |

| υ2,2,1 | −3.965 |

| υ2,2,2 | −5.002 |

| υ0,3,0 | 0.897 |

| υ1,3,0 | 3.541 |

| υ2,3,0 | 1.132 |

| Neuron biases, бi,K * | |

| б0,1 | 10.036 |

| б1,1 | 2.755 |

| б2,1 | −7.759 |

| б0,2 | 6.695 |

| б1,2 | 1.904 |

| б2,2 | 4.489 |

| б0,2 | −9.814 |

| б1,2 | −4.486 |

| б2,2 | 6.041 |

| б0,3 | 2.530 |

| Inputs, Outputs, Error | KT | PA | N | m | Qd | Qp | δ | |

|---|---|---|---|---|---|---|---|---|

| Data | - | - | - | kg/s | kW | % | ||

| Data not used for training the ANN | 4 | 2 | 5 | 10 | 1134.9 | 1137.8147 | ‒0.26 | |

| 4 | 3 | 5 | 5.12 | 1136.6 | 1134.3085 | 0.20 | ||

| 4 | 1 | 3 | 5.75 | 1074.4 | 1076.1096 | ‒0.16 | ||

| 4 | 1 | 6 | 5.75 | 1113.3 | 1106.7961 | 0.58 | ||

| 4 | 2 | 4 | 5.75 | 1080.9 | 1089.7294 | ‒0.82 | ||

| 4 | 3 | 2 | 5.75 | 1114.9 | 1120.3034 | ‒0.49 | ||

| 4 | 3 | 7 | 5.75 | 1139.3 | 1138.4263 | 0.08 | ||

| Data used for trainingthe ANN | 1 | 1 | 5 | 5.75 | 425 | 433.977 | ‒2.11 | |

| 2 | 1 | 5 | 5.75 | 1051 | 1052.118 | ‒0.11 | ||

| 3 | 1 | 5 | 5.75 | 1066 | 1063.146 | 0.27 | ||

| 4 | 1 | 5 | 5.75 | 1105 | 1099.907 | 0.46 | ||

| 4 | 2 | 5 | 5.75 | 1090 | 1099.704 | ‒0.89 | ||

| 1 | 3 | 5 | 5.75 | 426 | 427.600 | ‒0.38 | ||

| 2 | 3 | 5 | 5.75 | 1080 | 1063.684 | 1.51 | ||

| Input Parameter | Value |

|---|---|

| Kind of tubes, KT * | 1–4 |

| Tube pass arrangement, PA ** | 1–3 |

| Number of flooded heat transfer tube rows, n | 0.8–9.6 |

| Liquid refrigerant mass flow rate, m, kg/s | 3.6–14.4 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krzywanski, J. A General Approach in Optimization of Heat Exchangers by Bio-Inspired Artificial Intelligence Methods. Energies 2019, 12, 4441. https://doi.org/10.3390/en12234441

Krzywanski J. A General Approach in Optimization of Heat Exchangers by Bio-Inspired Artificial Intelligence Methods. Energies. 2019; 12(23):4441. https://doi.org/10.3390/en12234441

Chicago/Turabian StyleKrzywanski, Jaroslaw. 2019. "A General Approach in Optimization of Heat Exchangers by Bio-Inspired Artificial Intelligence Methods" Energies 12, no. 23: 4441. https://doi.org/10.3390/en12234441

APA StyleKrzywanski, J. (2019). A General Approach in Optimization of Heat Exchangers by Bio-Inspired Artificial Intelligence Methods. Energies, 12(23), 4441. https://doi.org/10.3390/en12234441