Analytical Study of Tri-Generation System Integrated with Thermal Management Using HT-PEMFC Stack

Abstract

1. Introduction

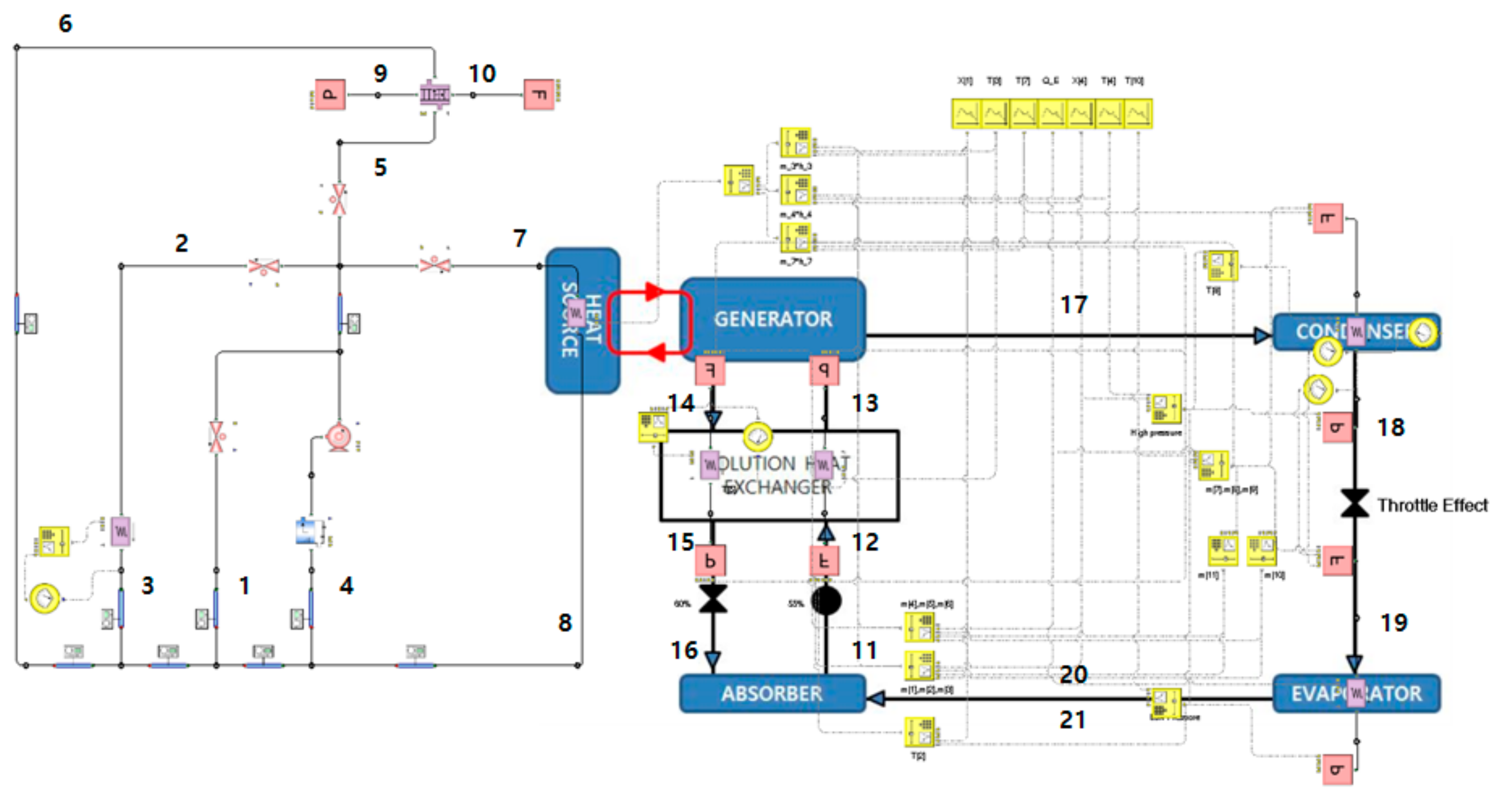

2. Tri-Generative System Description Based on HT-PEMFC System

3. Tri-Generative System Modeling

3.1. Stack Thermal Management and CHP System Cycle

3.2. LiBr-Water Absorption Refrigerator Cycle

4. Results and Discussions

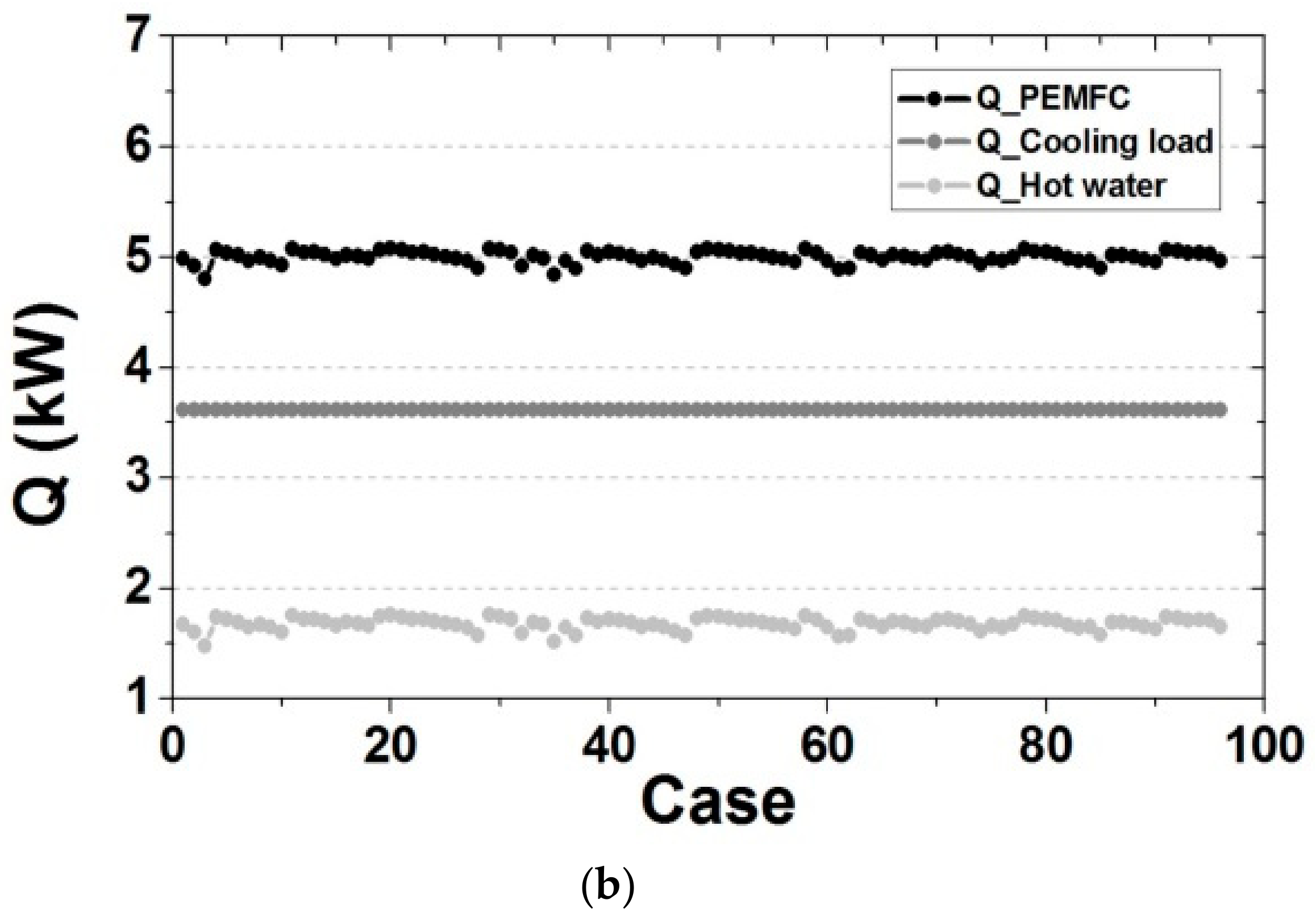

4.1. Selection of Appropriate Cooling Capacity

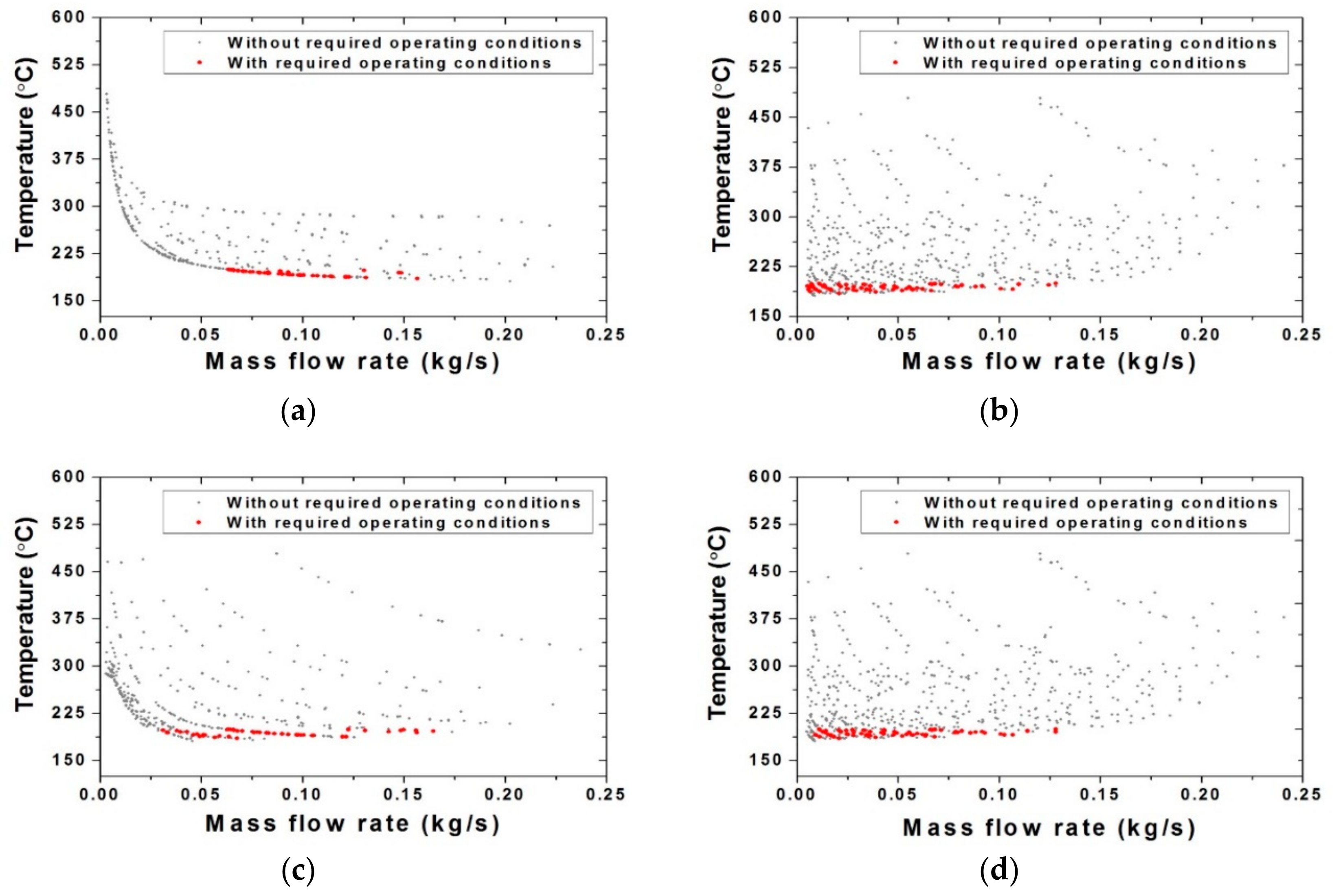

4.2. Comparison of Operation Conditions of Absorption Cooling System

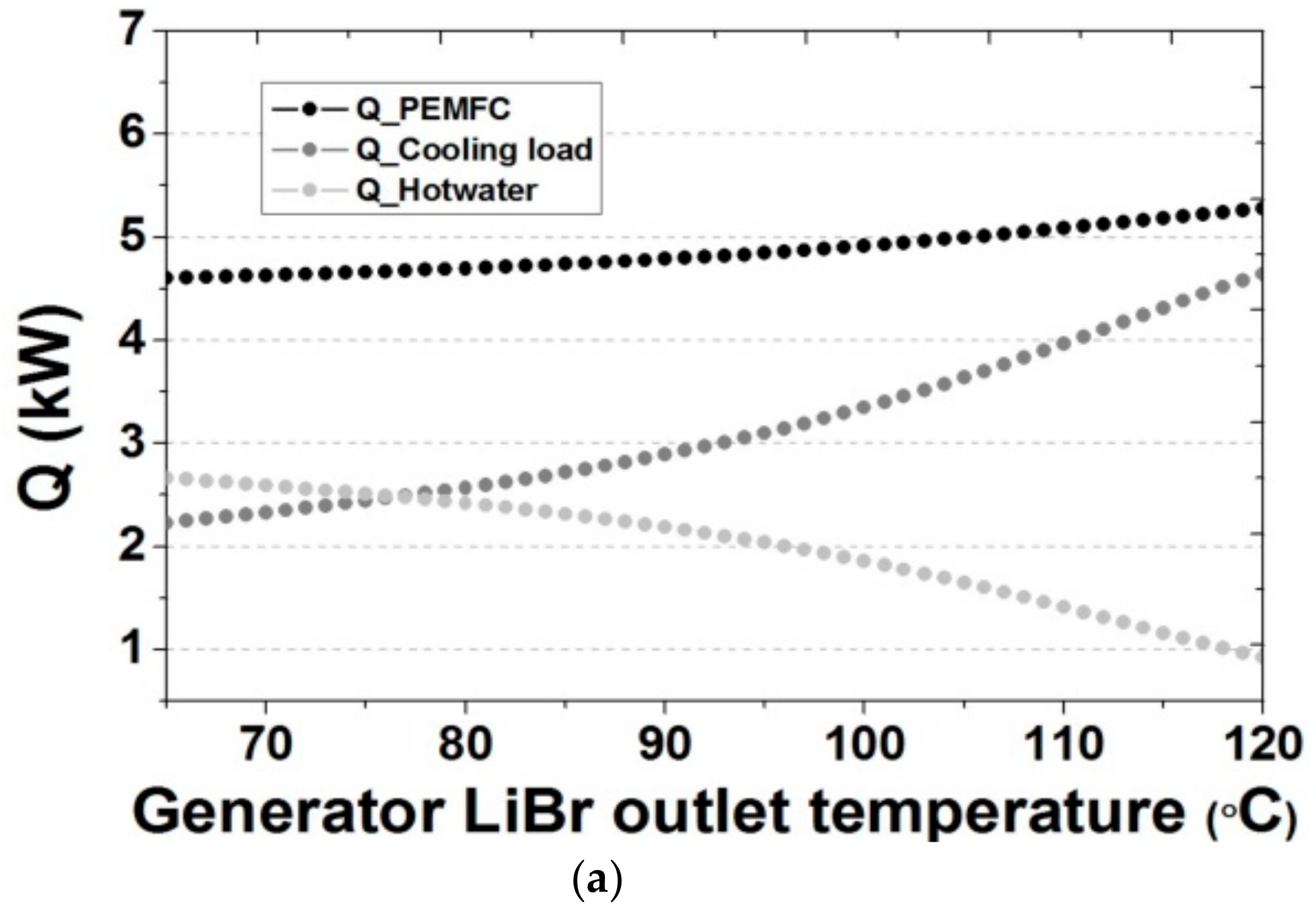

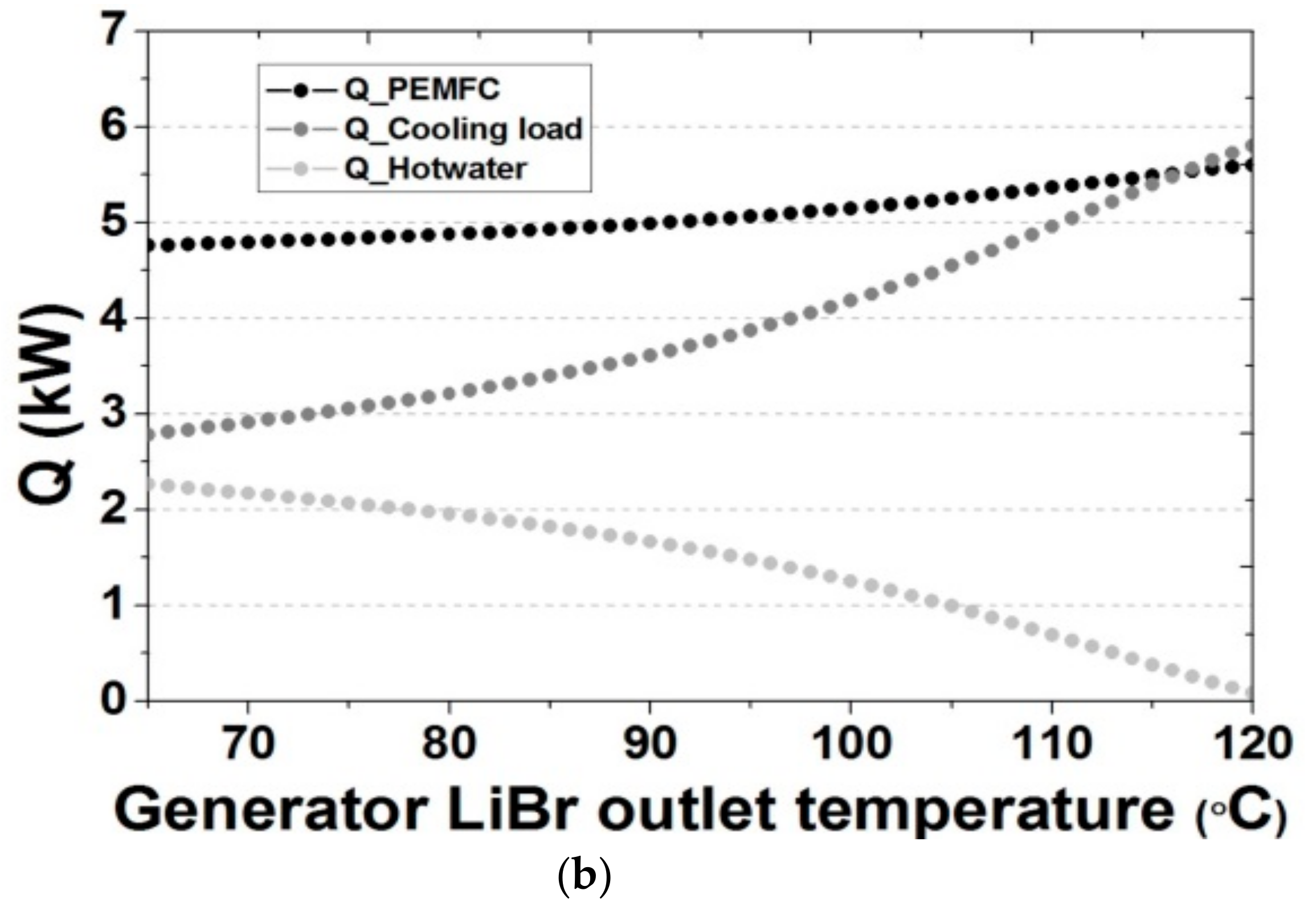

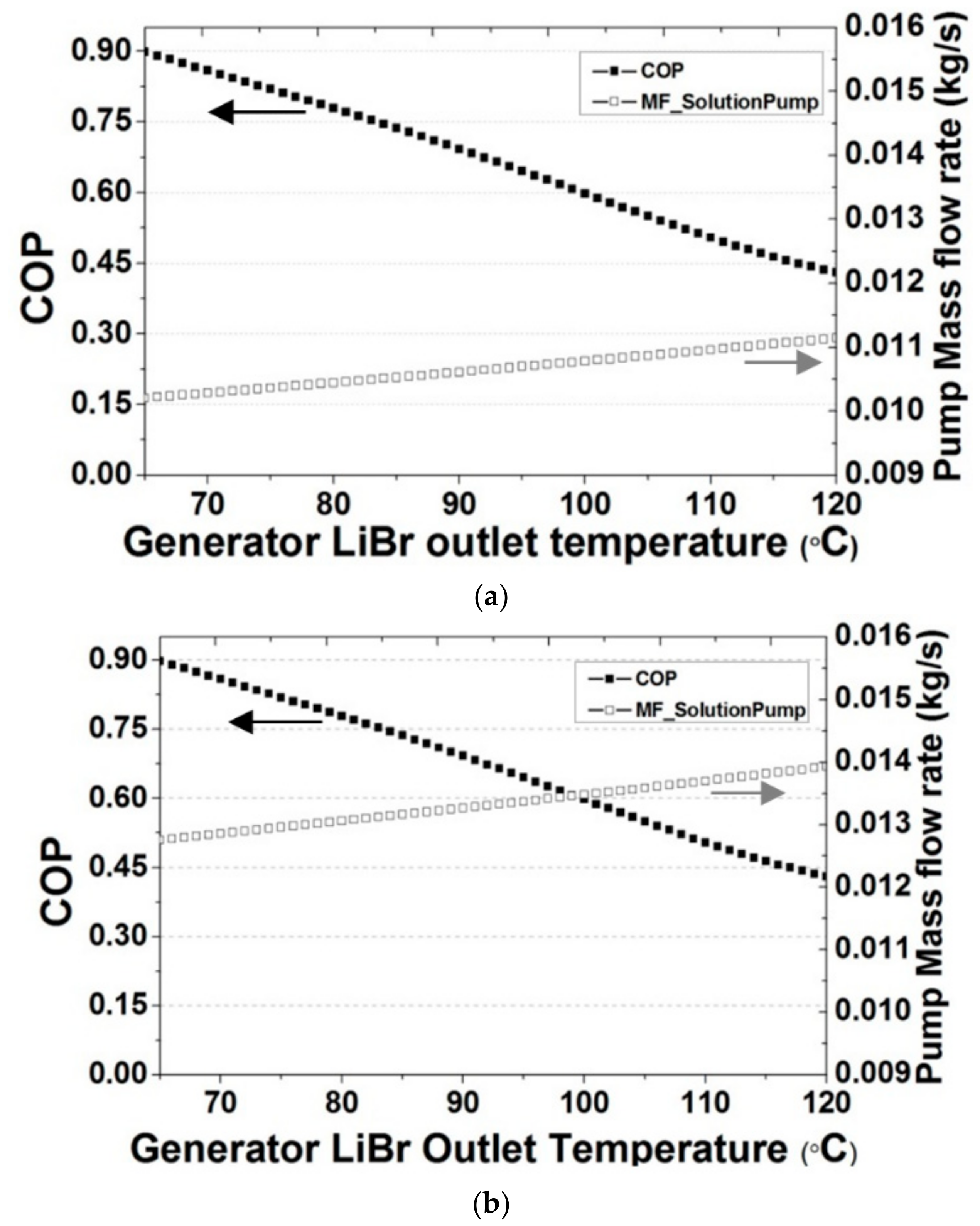

4.2.1. LiBr Aqueous Solution Temperature in Generator

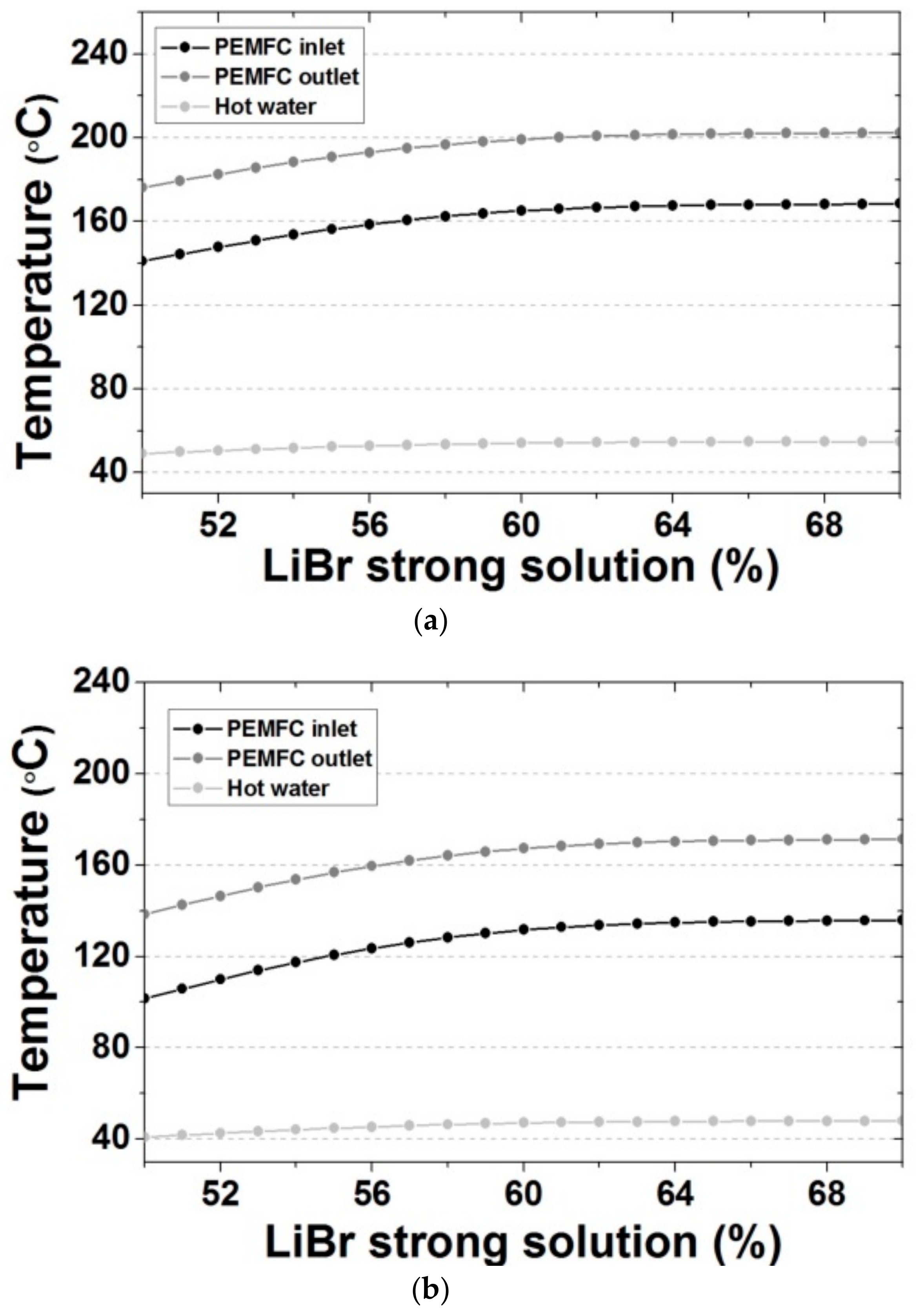

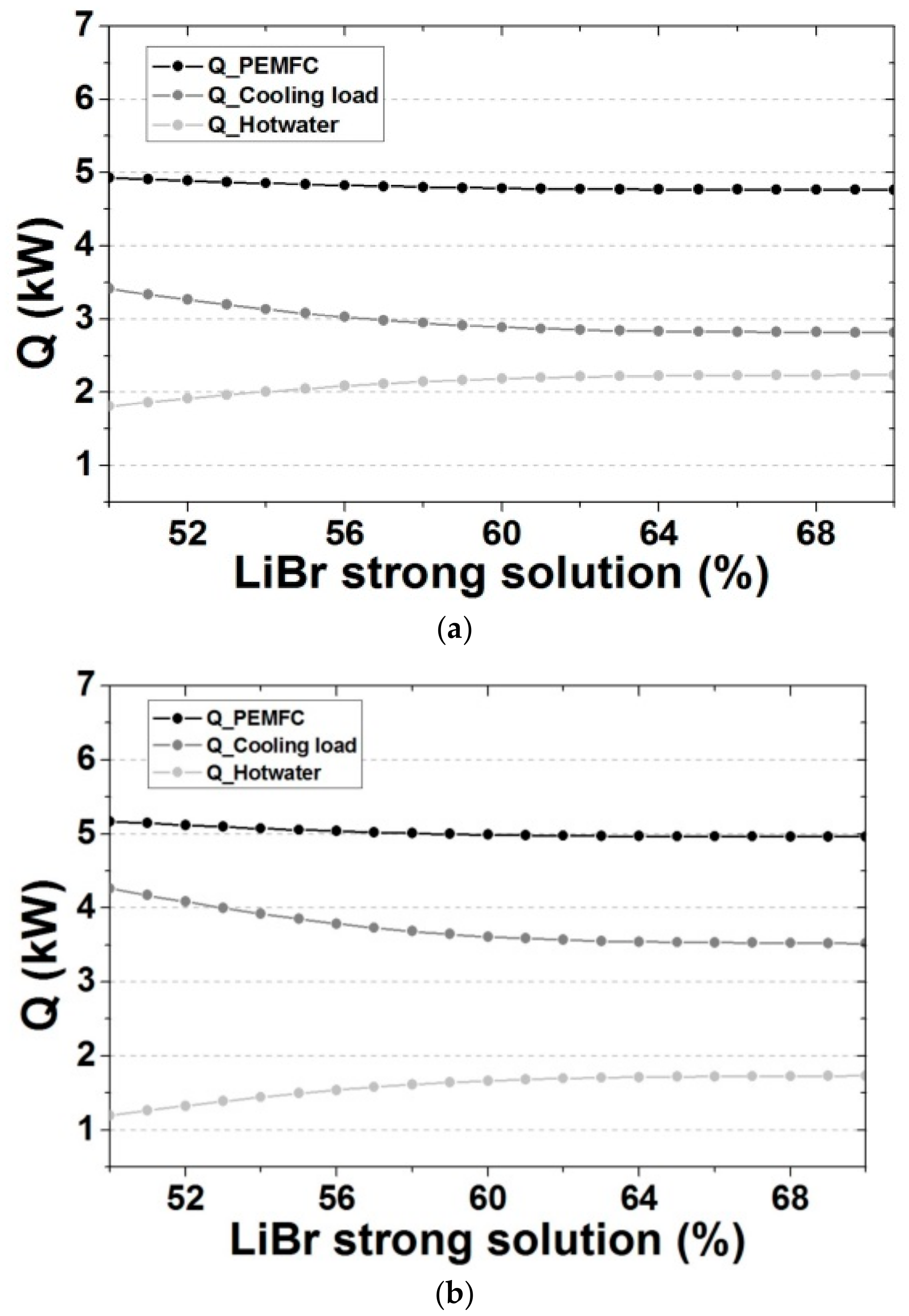

4.2.2. Concentration of LiBr Aqueous Solution

5. Conclusions

- (1)

- We modeled the integrated thermal management tri-generative system, including a high-temperature PEMFC stack heating model and absorption cooling model, to compare the suitable operating conditions according to the stack waste heat and partial load.

- (2)

- When the appropriate operating range of the 5 kW high-temperature PEMFC stack model is set to about 150–160 °C, the applied cooling capacity ranged from approximately 2.0 to 2.5 kW, allowing us to set a proper flow control distribution for the partial thermal management fluid in the model.

- (3)

- When a 2.5 kW absorption cooling capacity is applied, considering the stack thermal management, if the operating temperature of LiBr aqueous solution at the outlet of the generator is judged to be in the appropriate range from 94 to 97 °C, then COP is expected to range from approximately 0.6–0.65.

Author Contributions

Funding

Conflicts of Interest

References

- UK DECC. The Carbon Plan: Delivering Our Low Carbon Future; Presented to Parliament Pursuant to Sections 12 and 14 of the Climate Change Act 2008 Amended 2nd December 2011 from the Version Laid before Parliament on 1st December 2011; UK DECC: London, UK, 2011. [Google Scholar]

- Ellamla, H.R.; Staffell, I.; Bujlo, P.; Pollet, B.G.; Pasupathi, S. Current status of fuel cell based combined heat and power systems for residential sector. J. Power Sources 2015, 293, 312–328. [Google Scholar] [CrossRef]

- Fu, L.; Zhao, X.; Zhang, S.; Jiang, Y.; Li, H.; Yang, W. Laboratory research on combined cooling, heating and power (CCHP) systems. Energy Convers. Manag. 2009, 50, 977–982. [Google Scholar] [CrossRef]

- Cardona, E.; Piacentino, A. A methodology for sizing a trigeneration plant in mediterranean areas. Appl. Therm. Eng. 2003, 23, 1665–1680. [Google Scholar] [CrossRef]

- Ziher, D.; Poredos, A. Economics of a trigeneration system in a hospital. Appl. Therm. Eng. 2006, 26, 680–687. [Google Scholar] [CrossRef]

- Cardona, E.; Piacentino, A.; Cardona, F. Energy saving in airports by trigeneration. Part I: Assessing economic and technical potential. Appl. Therm. Eng. 2006, 26, 1427–1436. [Google Scholar] [CrossRef]

- Mago, P.J.; Fumo, N.; Chamra, L.M. Performance analysis of CCHP and CHP systems operating following the thermal and electric load. Int. J. Energy Res. 2009, 33, 852–864. [Google Scholar] [CrossRef]

- Tichi, S.; Ardehali, M.; Nazari, M. Examination of energy price policies in Iran for optimal configuration of CHP and CCHP systems based on particle swarm optimization algorithm. Energy Policy 2010, 38, 6240–6250. [Google Scholar] [CrossRef]

- De Lorenzo, G.; Fragiacomo, P. Electrical and thermal analysis of an intermediate temperature IIR-SOFC system fed by biogas. Energy Sci. Eng. 2018, 6, 60–72. [Google Scholar] [CrossRef]

- Verhaert, I.; Mulder, G.; De Paepe, M. Evaluation of an alkaline fuel cell system as a micro-CHP. Energy Convers. Manag. 2016, 126, 434–445. [Google Scholar] [CrossRef]

- Kwan, T.H.; Yao, Q. Exergetic and temperature analysis of a fuel cell-thermoelectric device hybrid system for the combined heat and power application. Energy Convers. Manag. 2018, 173, 1–14. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Sadeghzadeh, M.; Rahimi, A.; Pouriman, M. Technical performance analysis of a combined cooling heating and power (CCHP) system based on solid oxide fuel cell (SOFC) technology—A building application. Energy Convers. Manag. 2019, 198, 111767. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Derakhshan, E. Thermo-environ-economic evaluation of a trigeneration system based on thermoelectric generator, two-bed adsorption chiller, and polymer exchange membrane fuel cell. Energy Convers. Manag. 2019, 180, 269–280. [Google Scholar] [CrossRef]

- Cozzolino, R. Thermodynamic Performance Assessment of a Novel Micro-CCHP System Based on a Low Temperature PEMFC Power Unit and a Half-Effect Li/Br Absorption Chiller. Energies 2018, 11, 315. [Google Scholar] [CrossRef]

- Dicks, A.; Pointon, K.; Siddle, A. Intrinsic reaction kinetics of methane steam reforming on a nickel/zirconia anode. J. Power Sources 2000, 86, 523–530. [Google Scholar] [CrossRef]

- Bhatia, K.K.; Wang, C.-Y. Transient carbon monoxide poisoning of a polymer electrolyte fuel cell operating on diluted hydrogen feed. Electrochim. Acta 2004, 49, 2333–2341. [Google Scholar] [CrossRef]

- Araya, S.S.; Andreasen, S.J.; Kær, S.K. Experimental Characterization of the Poisoning Effects of Methanol-Based Reformate Impurities on a PBI-Based High Temperature PEM Fuel Cell. Energies 2012, 5, 4251–4267. [Google Scholar] [CrossRef]

- Devanathan, R. Recent developments in proton exchange membranes for fuel cells. Energy Environ. Sci. 2008, 1, 101. [Google Scholar] [CrossRef]

- Chandan, A.; Hattenberger, M.; El-Kharouf, A.; Du, S.; Dhir, A.; Self, V.; Pollet, B.G.; Ingram, A.; Bujalski, W. High temperature (HT) polymer electrolyte membrane fuel cells (PEMFC)—A review. J. Power Sources 2013, 231, 264–278. [Google Scholar] [CrossRef]

- Authayanun, S.; Im-Orb, K.; Arpornwichanop, A. A review of the development of high temperature proton exchange membrane fuel cells. Chin. J. Catal. 2015, 36, 473–483. [Google Scholar] [CrossRef]

- Liang, H.; Su, H.; Pollet, B.G.; Pasupathi, S. Development of membrane electrode assembly for high temperature proton exchange membrane fuel cell by catalyst coating membrane method. J. Power Sources 2015, 288, 121–127. [Google Scholar] [CrossRef]

- Rosli, R.; Sulong, A.; Daud, W.; Zulkifley, M.; Husaini, T.; Rosli, M.; Majlan, E.; Haque, M.; Rosli, M. A review of high-temperature proton exchange membrane fuel cell (HT-PEMFC) system. Int. J. Hydrogen Energy 2017, 42, 9293–9314. [Google Scholar] [CrossRef]

- Korsgaard, A.R.; Bang, M.; Kær, S.K.; Nielsen, M.P. Modeling of CO Influence in PBI Electrolyte PEM Fuel Cells. In Proceedings of the ASME 2006 4th international conference on fuel cell science, engineering and technology, Irvine, CA, USA, 19–21 June 2006; pp. 911–915. [Google Scholar]

- Arsalis, A.; Nielsen, M.P.; Kær, S.K. Modeling and off-design performance of a 1kWe HT-PEMFC (high temperature-proton exchange membrane fuel cell)-based residential micro-CHP (combined-heat-and-power) system for Danish single-family households. Energy 2011, 36, 993–1002. [Google Scholar] [CrossRef]

- Chang, H.; Wan, Z.; Zheng, Y.; Chen, X.; Shu, S.; Tu, Z.; Chan, S.H.; Chen, R.; Wang, X. Energy- and exergy-based working fluid selection and performance analysis of a high-temperature PEMFC-based micro combined cooling heating and power system. Appl. Energy 2017, 204, 446–458. [Google Scholar] [CrossRef]

- Rogers GF, C.; Mayhew, Y.R. Thermodynamic and Transport Properties of Fluids; Blackwell: Hoboken, NJ, USA, 1995. [Google Scholar]

- ASHRAE. ASHRAE Handbook-1993 Fundamentals; ASHRAE: Atlanta, GA, USA, 1993. [Google Scholar]

| Parameters | Values |

|---|---|

| Number of cells, N | 80 |

| Operating temperature, Tcell (°C) | 160 |

| Current density, I (A/cm2) | 0.85 |

| Air stoichiometry, λair | 3 |

| Single cell active area, Acell (cm2) | 100 |

| Open circuit Voltage, Vocv (V) | 0.95 |

| Ideal gas constant, R (J/mol·K) | 8.314 |

| Faraday constant, F | 96,485.3 |

| Exchange current density, I0 (A/cm2) | 0.000202 |

| Anode charge transfer coefficient, αa | 0.5 |

| Cathode charge transfer coefficient, αc | 0.25 |

| Hydrogen electro-oxidation rate constant, keh, (A/cm2) | 1.63818 |

| Hydrogen surface coverage, θh2 | 0.14212 |

| High heating Value of hydrogen, HHV (kJ/mol) | 282.63 |

| Parameters | Values |

|---|---|

| Absorption cooling capacity, Qe (kW) | 3 |

| Evaporator outlet temperature, T20 (°C) | 6 |

| Generator solution outlet temperature, T14 (°C) | 90 |

| LiBr weak solution mass fraction, X11 (%) | 55 |

| LiBr strong solution mass fraction, X14 (%) | 60 |

| Generator solution inlet temperature, T13 (°C) | 65 |

| Generator vapor outlet temperature, T17 (°C) | 85 |

| Liquid mass flow rate from evaporator, | 0.025 × |

| Point | Pressure (kPa) | Temperature (°C) | Enthalphy (kJ/kg) | LiBr (%) | Mass Flow (kg/s) |

|---|---|---|---|---|---|

| 11 | 0.9343 | 34.86 | 83.02 | 55 | 0.01591 |

| 12 | 9.657 | 34.86 | 83.02 | 55 | 0.01591 |

| 13 | 9.657 | 65 | 145.4 | 55 | 0.01591 |

| 14 | 9.657 | 90 | 212.2 | 60 | 0.01459 |

| 15 | 9.657 | 54.75 | 144.2 | 60 | 0.01459 |

| 16 | 0.9343 | 44.49 | 144.2 | 60 | 0.01459 |

| 17 | 9.657 | 85 | 2627 | 0 | 0.001326 |

| 18 | 9.657 | 44.31 | 189 | 0 | 0.001326 |

| 19 | 0.9343 | 6 | 189 | 0 | 0.001326 |

| 20 | 0.9343 | 6 | 2512 | 0 | 0.001294 |

| 21 | 0.9343 | 6 | 25.16 | 0 | 0.00003235 |

| Parameters | Values |

|---|---|

| Heat balance of total system (kW) | ±0.5 |

| TEG temperature, TTEG (°C) | -7 < TTEG |

| Stack outlet temperature, TS-out (°C) | 150 < TS-Out < 200 |

| Hot water temperature, Thw (°C) | 40 < Thw |

| Parameters | Values |

|---|---|

| Absorption cooling capacity, Qe (kW) | 1.5, 2.0, 2.5, 3.0 |

| TEG valve open ratio for stack cooling, ORTM | 0.1, 0.3, 0.5, 0.7, 0.9 |

| TEG valve open ratio for pump bypass, ORIC | |

| TEG valve open ratio for hot water (or heat), ORCHP | |

| TEG valve open ratio for absorption cooling, ORCCP | |

| TEG pump power, PTEG (kW) | 0.288 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, H.S.; Shin, Y.H. Analytical Study of Tri-Generation System Integrated with Thermal Management Using HT-PEMFC Stack. Energies 2019, 12, 3145. https://doi.org/10.3390/en12163145

Kang HS, Shin YH. Analytical Study of Tri-Generation System Integrated with Thermal Management Using HT-PEMFC Stack. Energies. 2019; 12(16):3145. https://doi.org/10.3390/en12163145

Chicago/Turabian StyleKang, Hyun Sung, and Yoon Hyuk Shin. 2019. "Analytical Study of Tri-Generation System Integrated with Thermal Management Using HT-PEMFC Stack" Energies 12, no. 16: 3145. https://doi.org/10.3390/en12163145

APA StyleKang, H. S., & Shin, Y. H. (2019). Analytical Study of Tri-Generation System Integrated with Thermal Management Using HT-PEMFC Stack. Energies, 12(16), 3145. https://doi.org/10.3390/en12163145