Diesel Mean Value Engine Modeling Based on Thermodynamic Cycle Simulation Using Artificial Neural Network

Abstract

1. Introduction

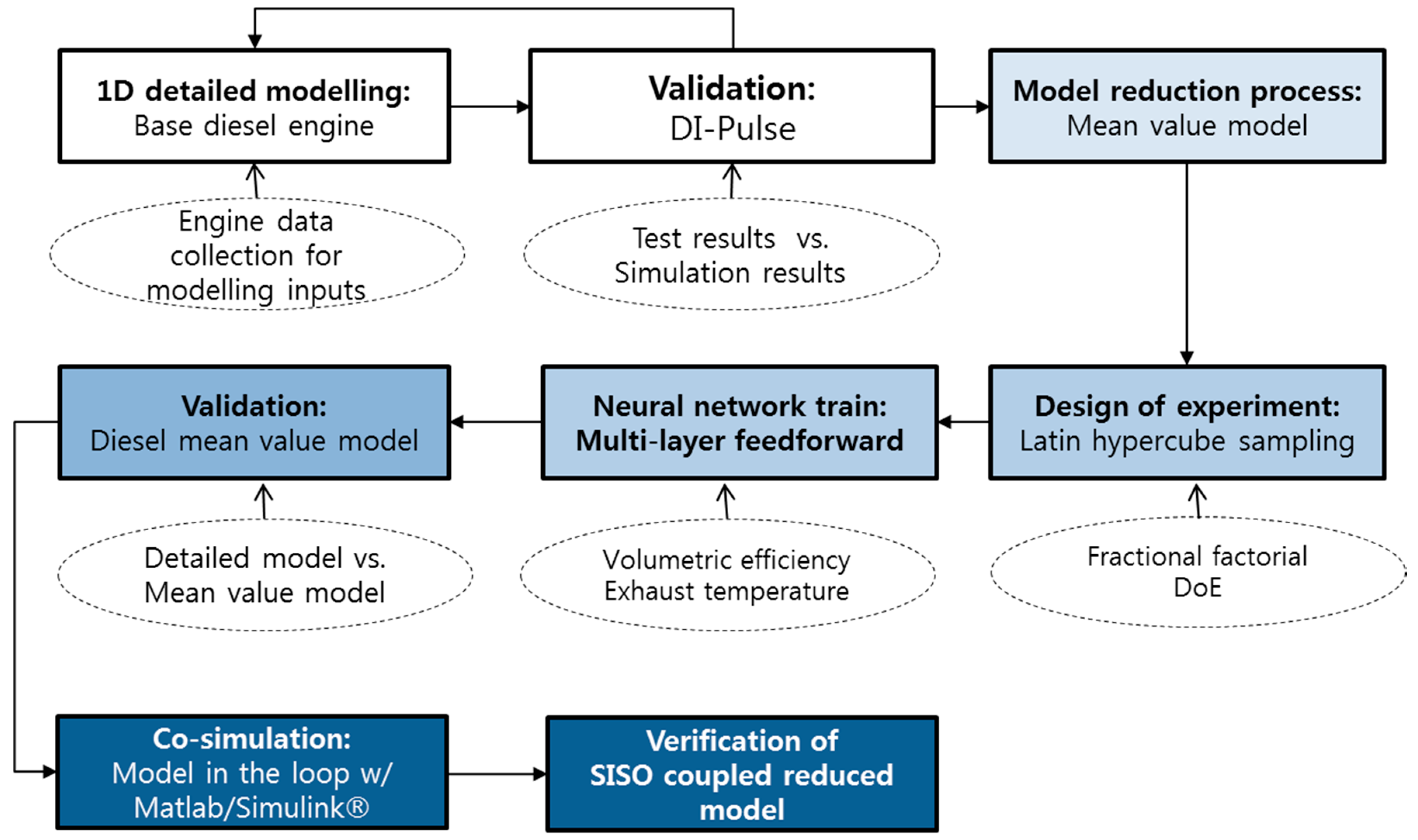

2. Methodology

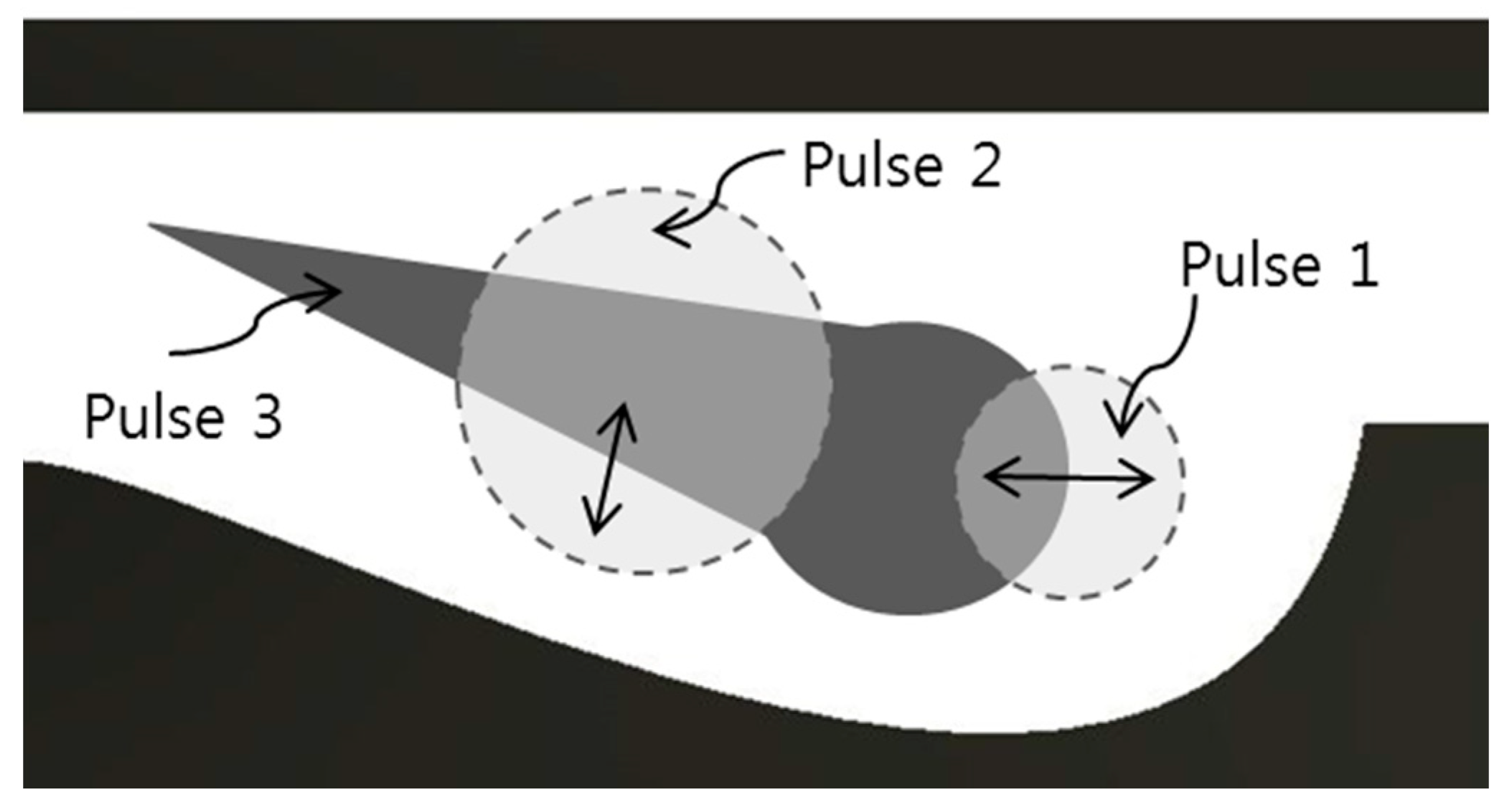

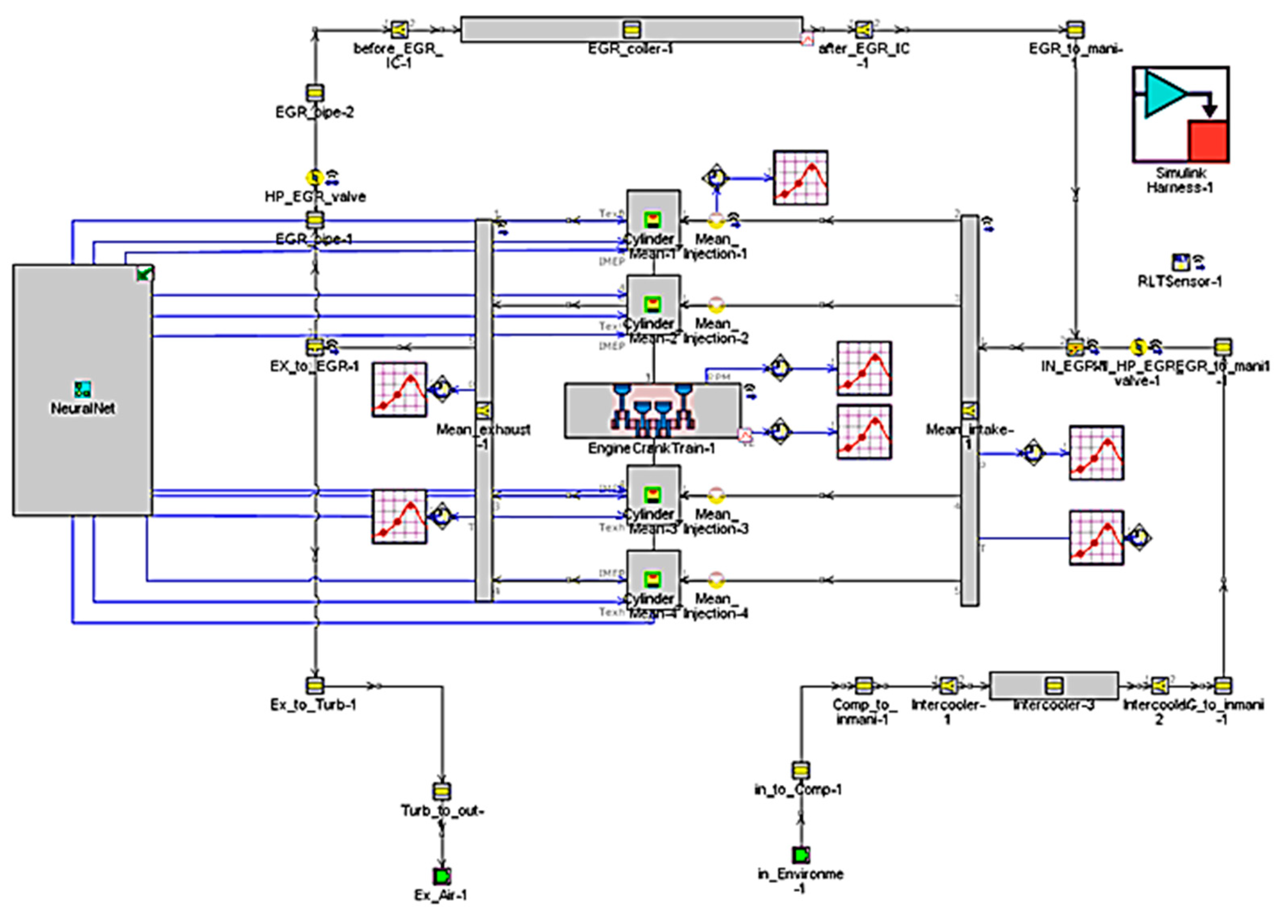

2.1. Detailed Engine Modeling

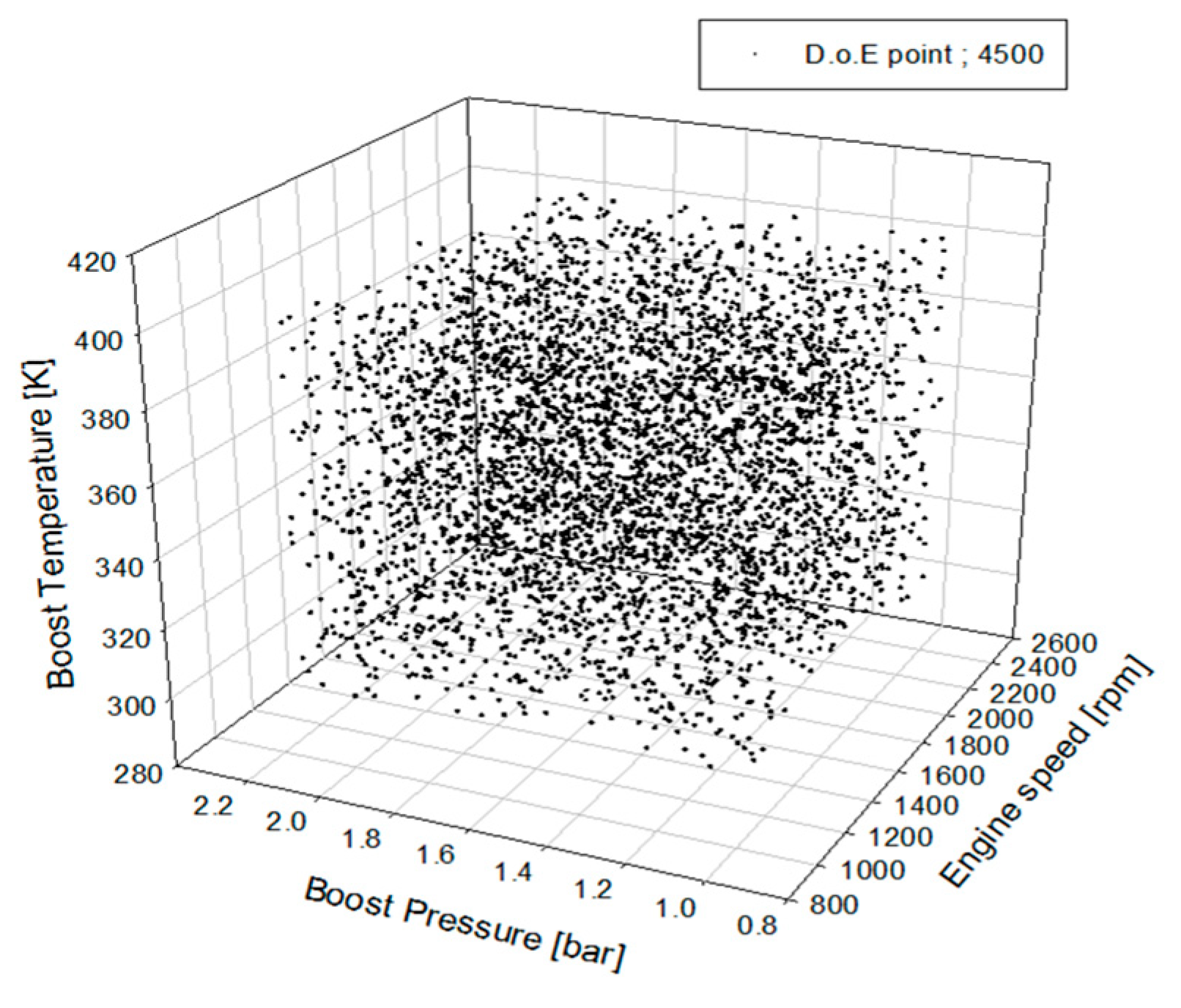

2.2. Design of Experiments (DoE)

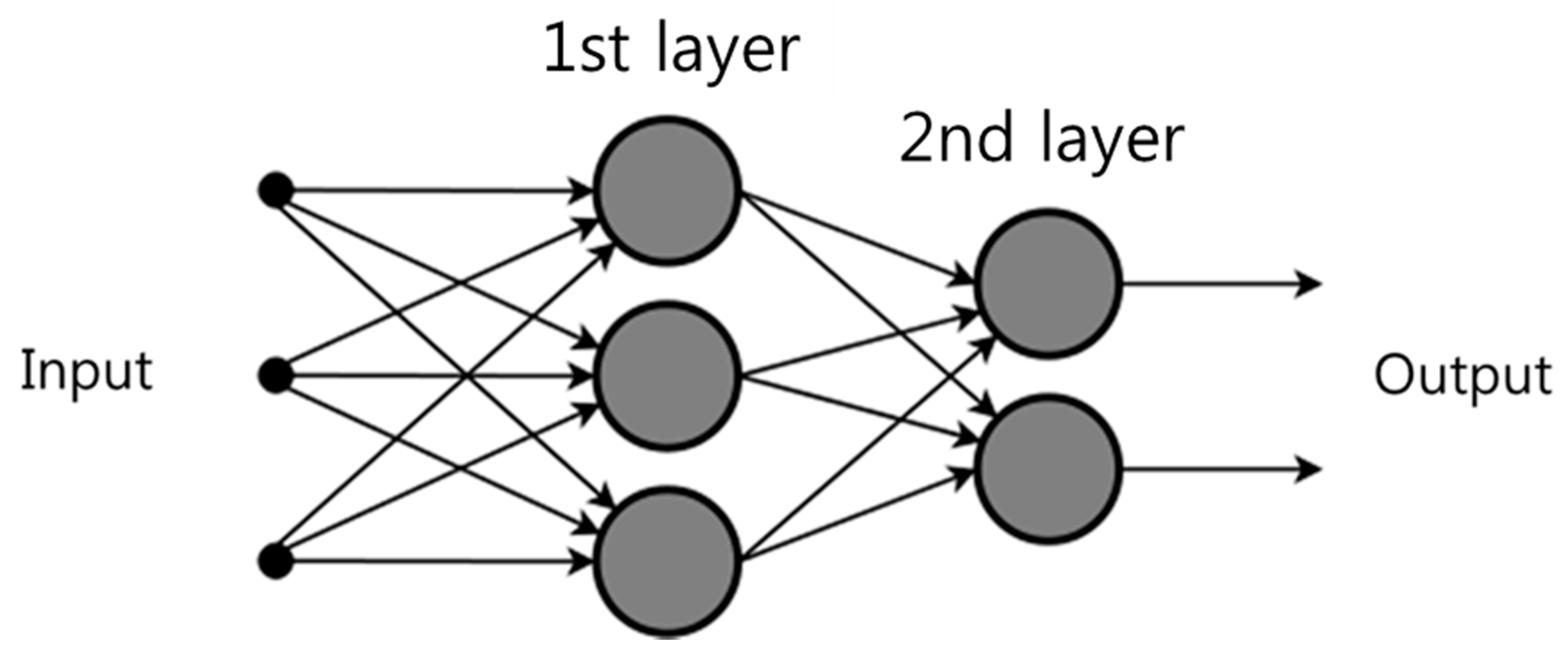

2.3. Mean Value Engine Model

2.4. Single-Input Single-Output (SISO) Control Logic Coupled Mean Value Model

3. Results and Discussions

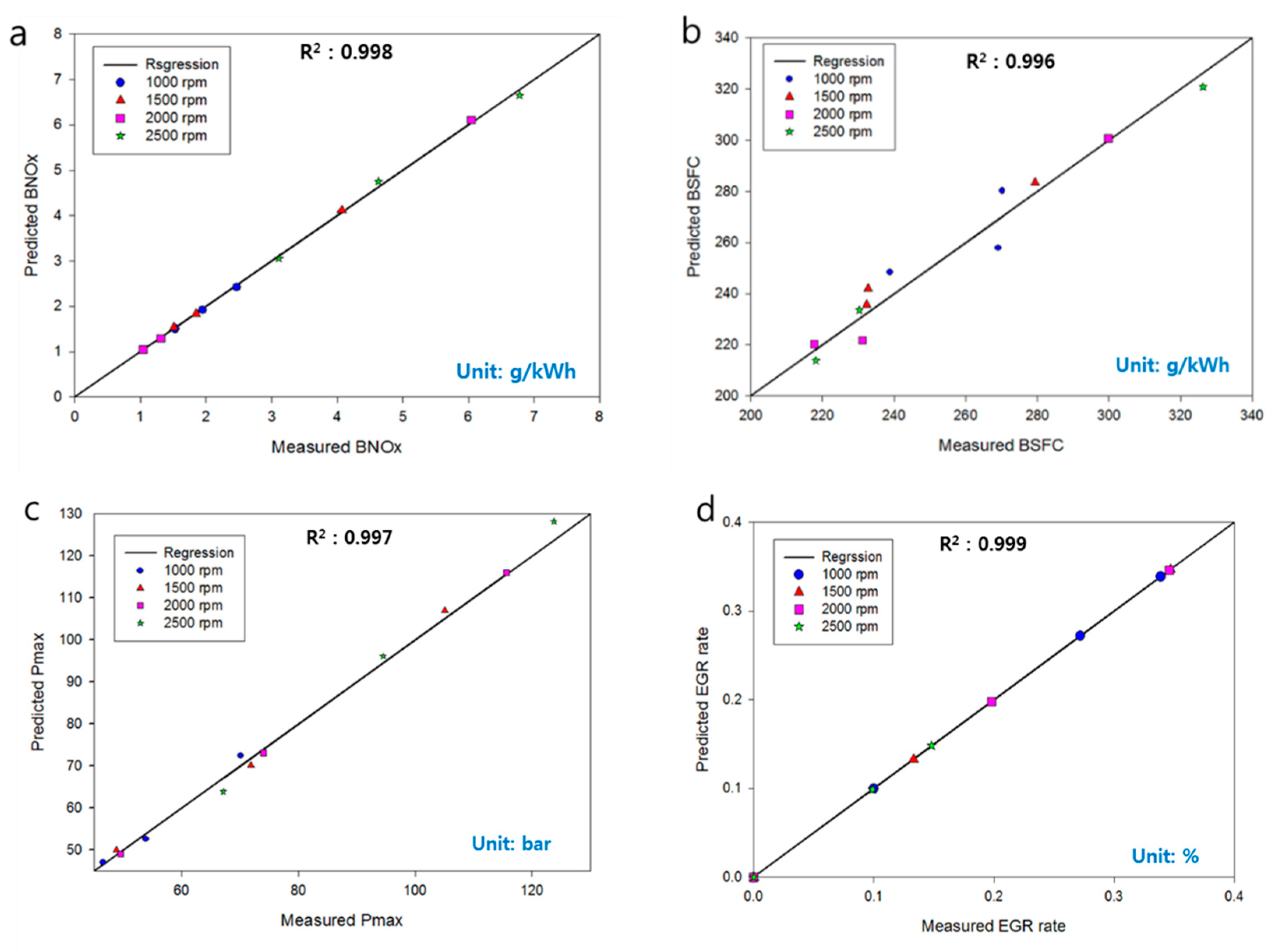

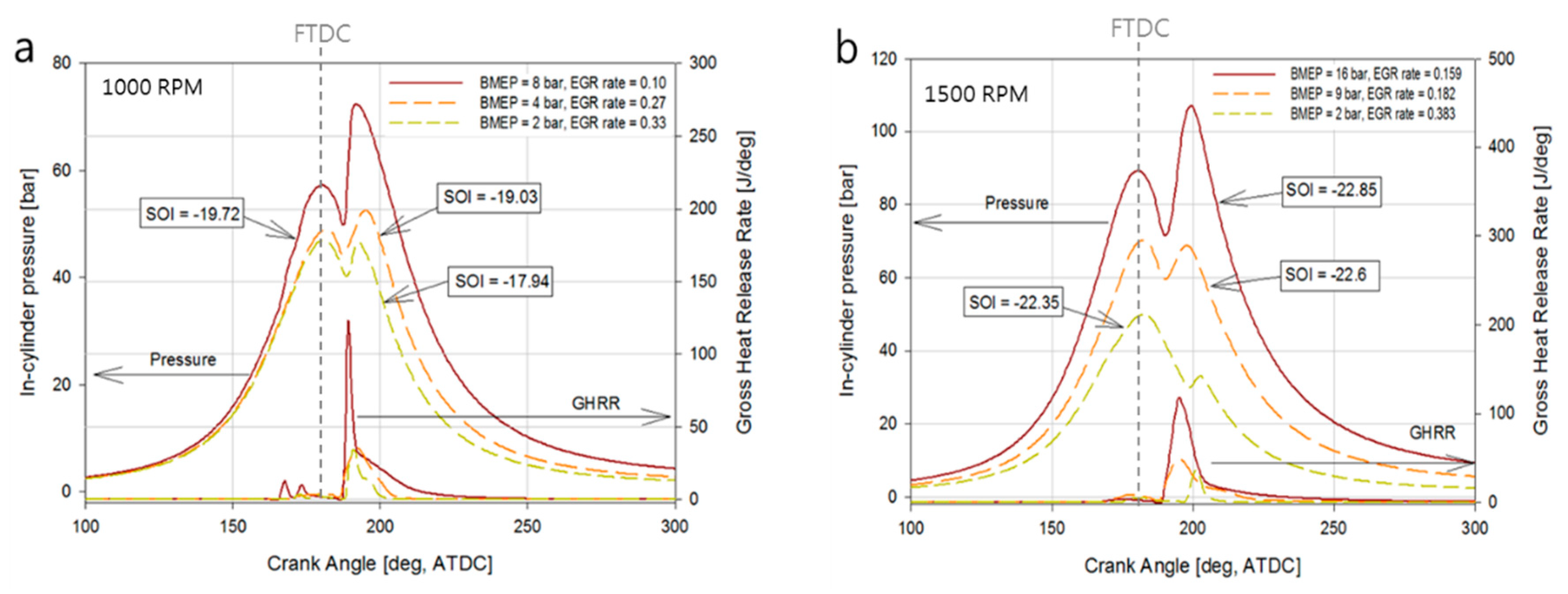

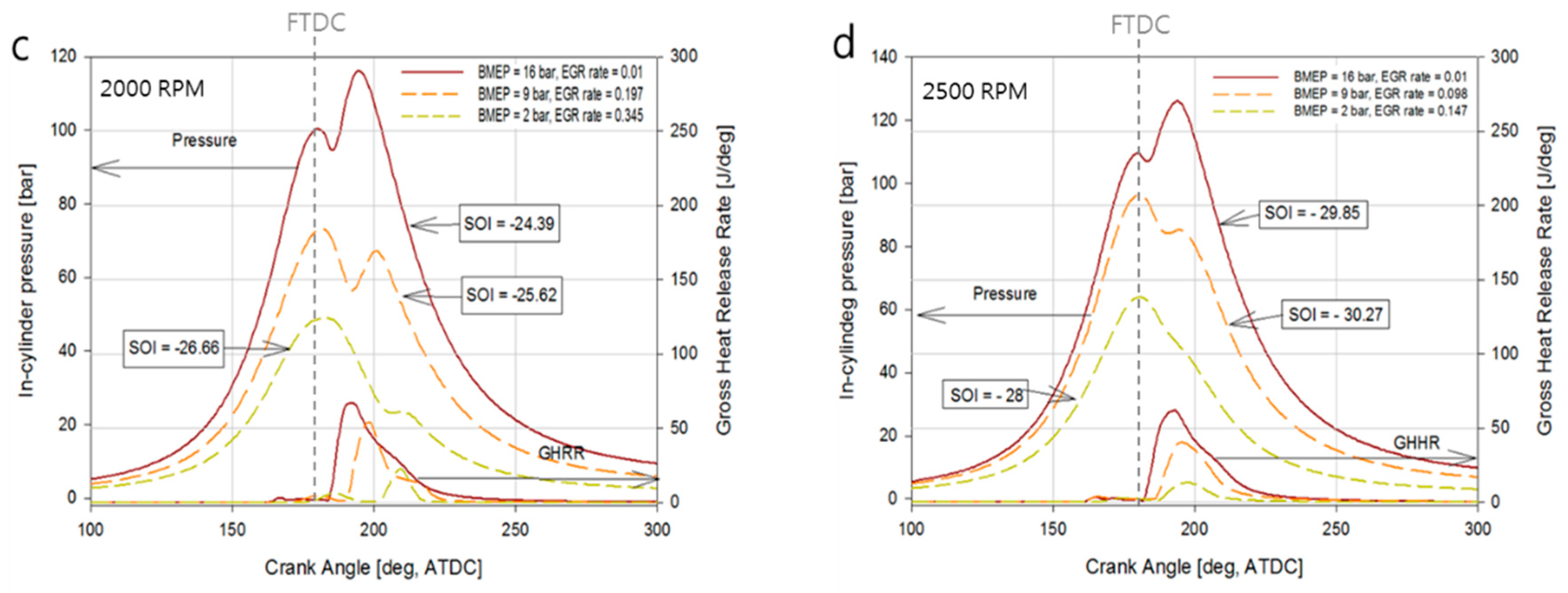

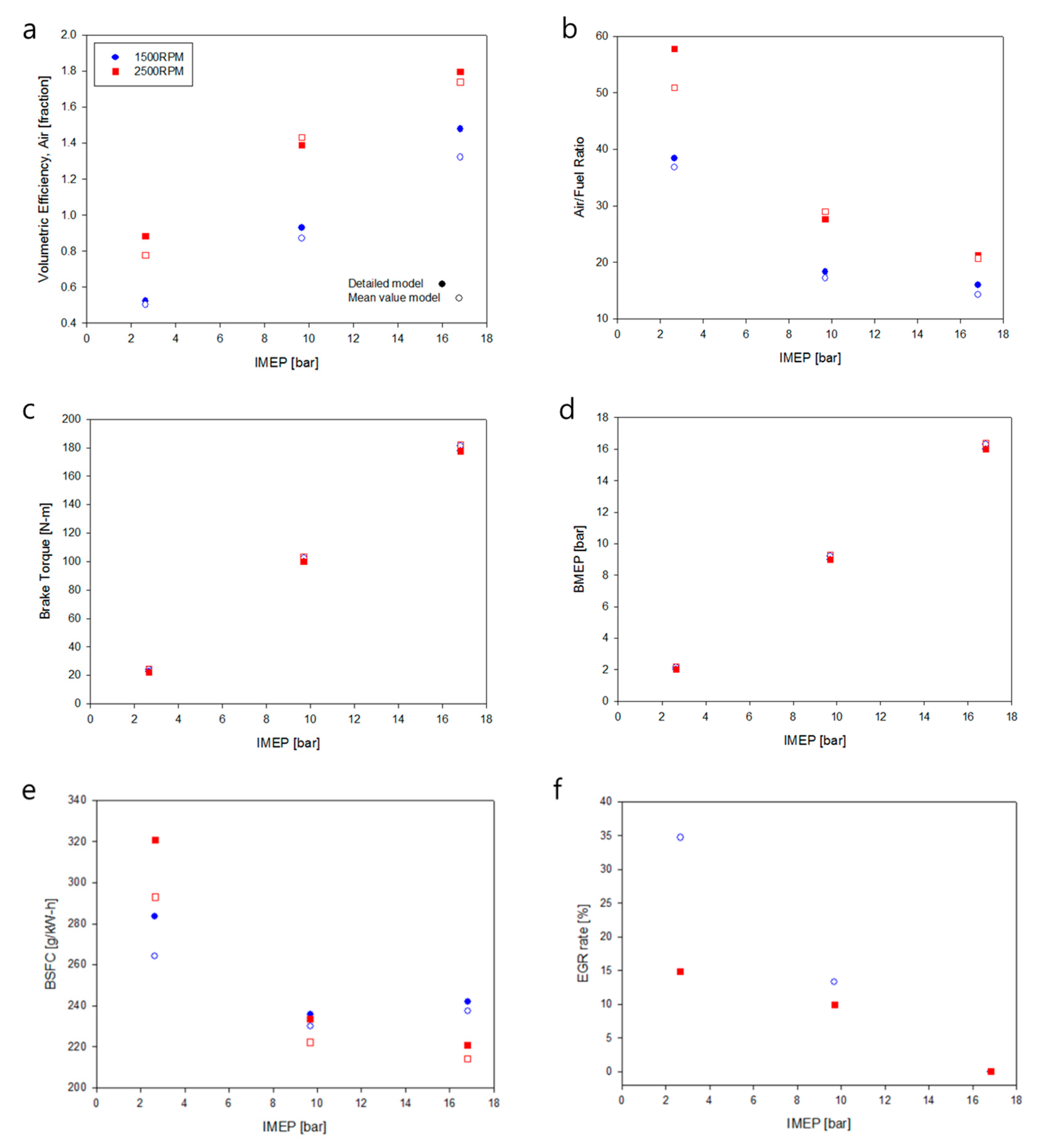

3.1. Detailed Model Validation Results and Model Reduction

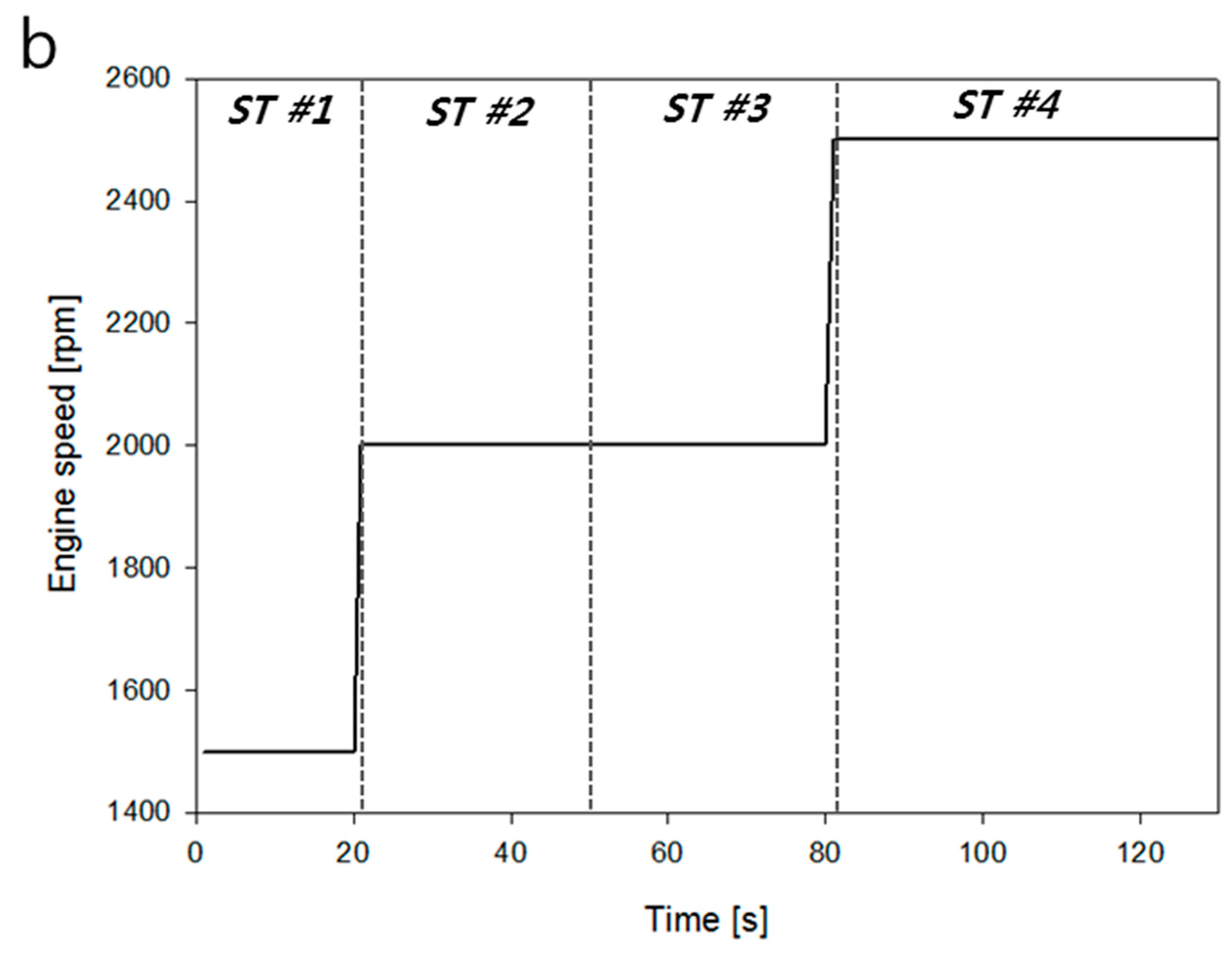

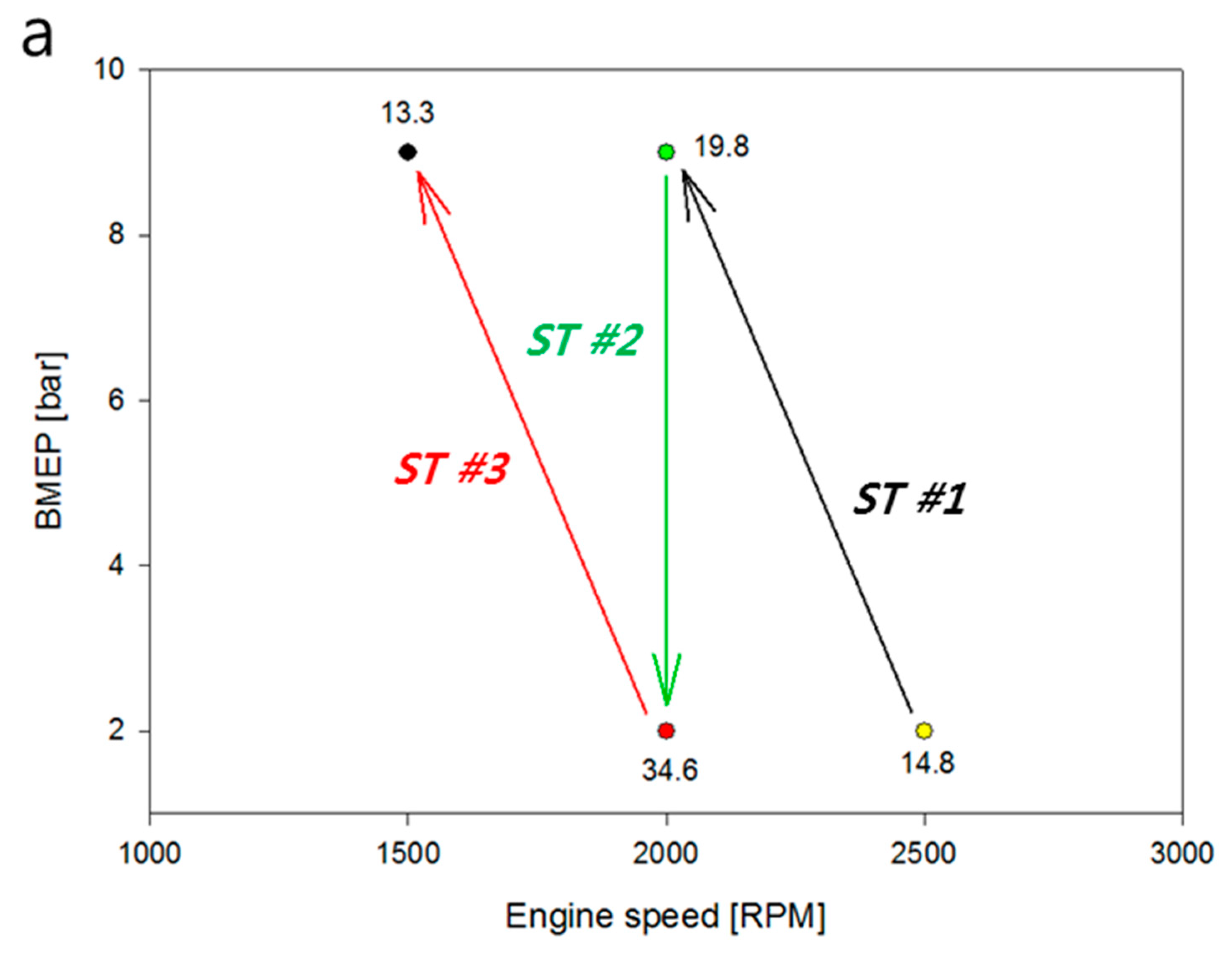

3.2. Step-Transient Results with Single-Input Single-Output (SISO) Coupled Mean Value Model-in-the-Loop

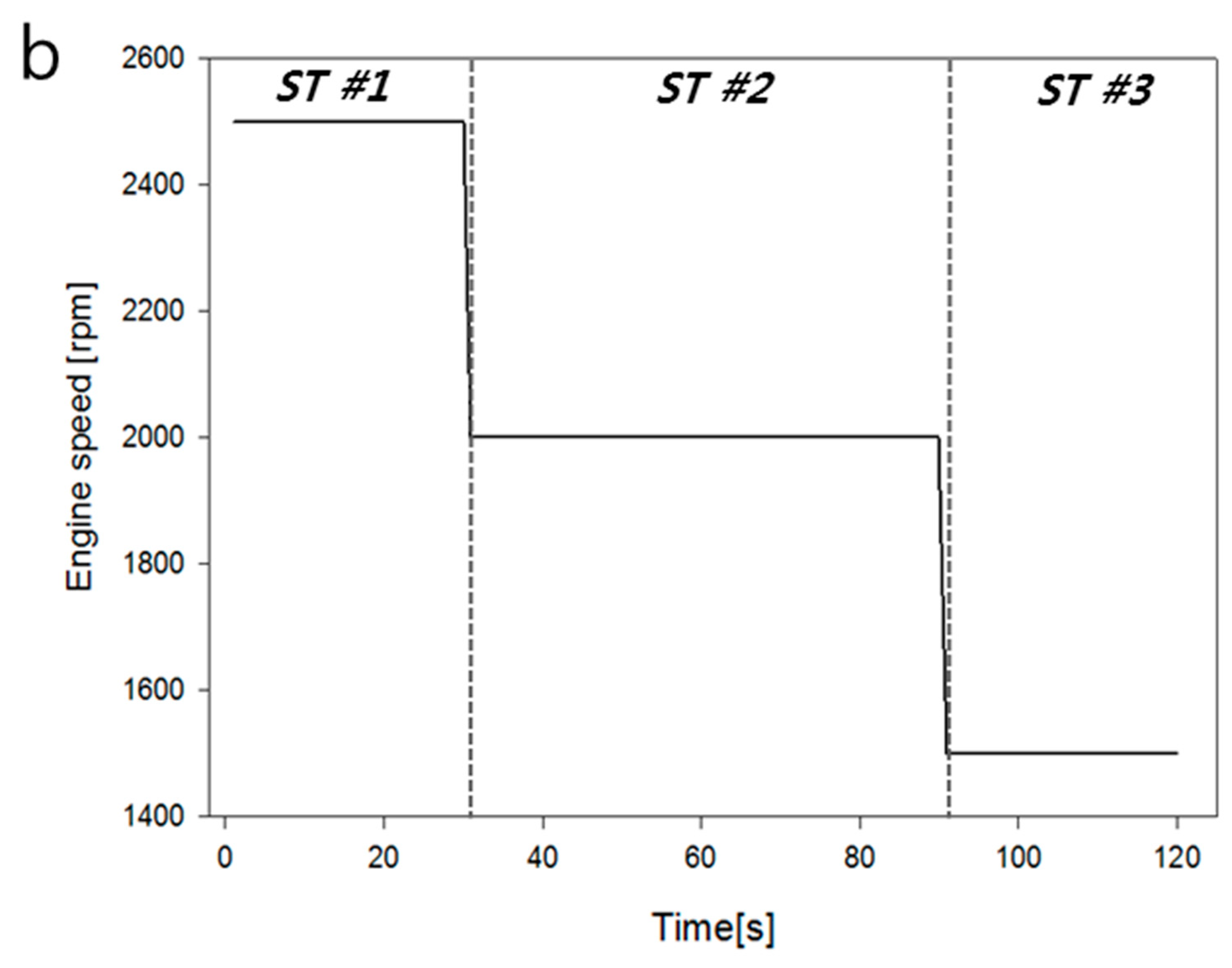

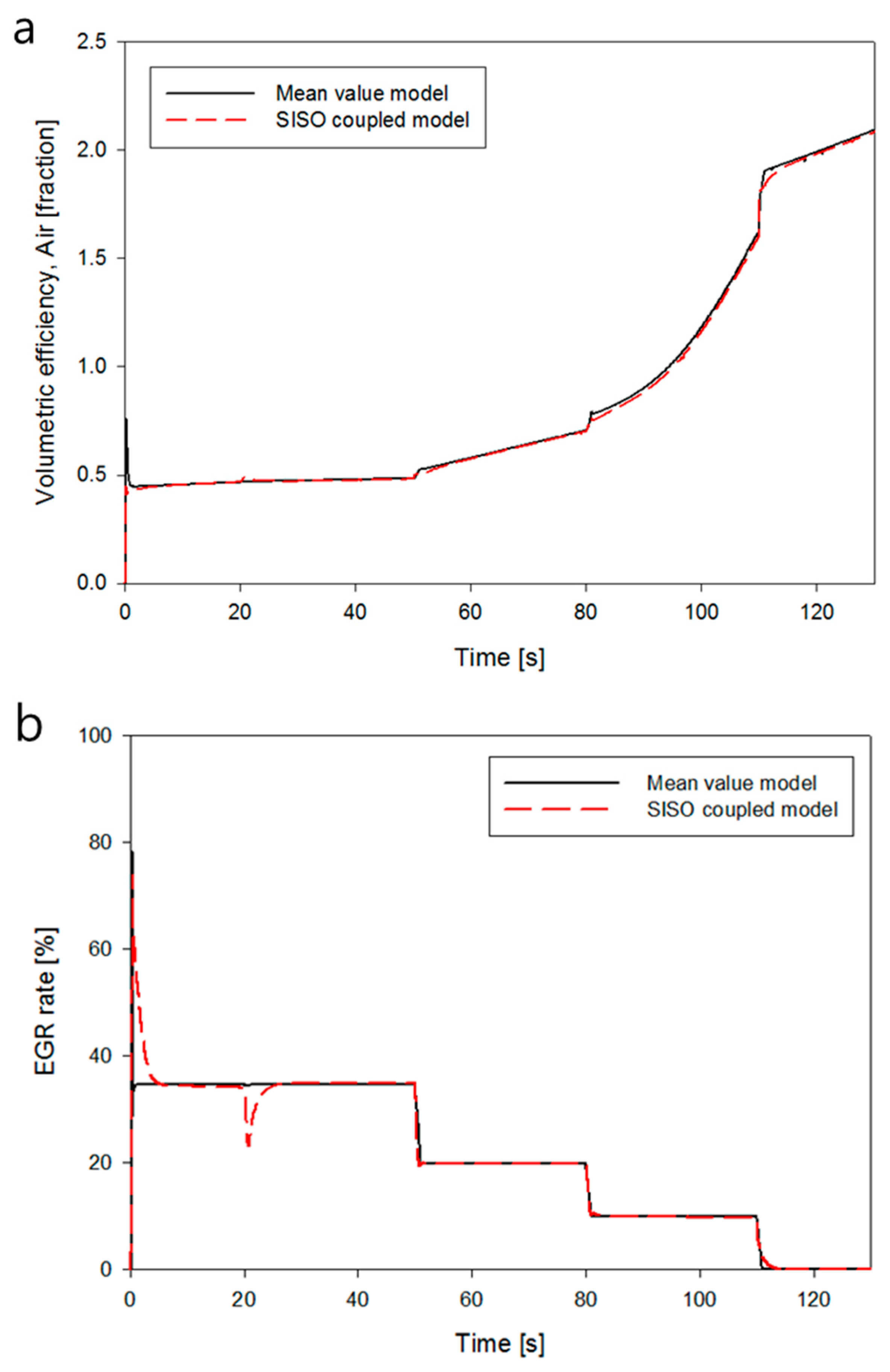

3.2.1. Step-Transient for Acceleration

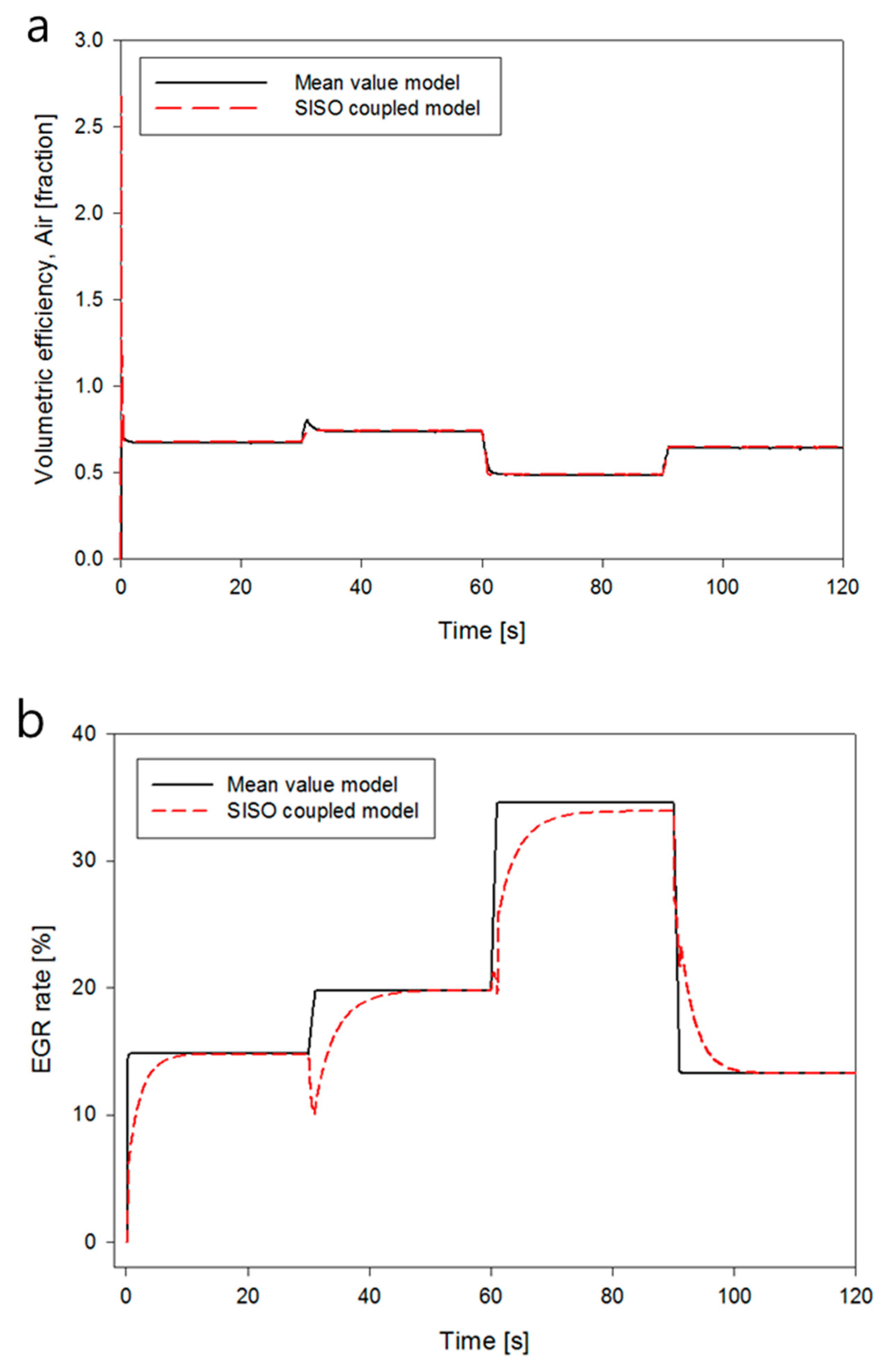

3.2.2. Step-Transient for Deceleration

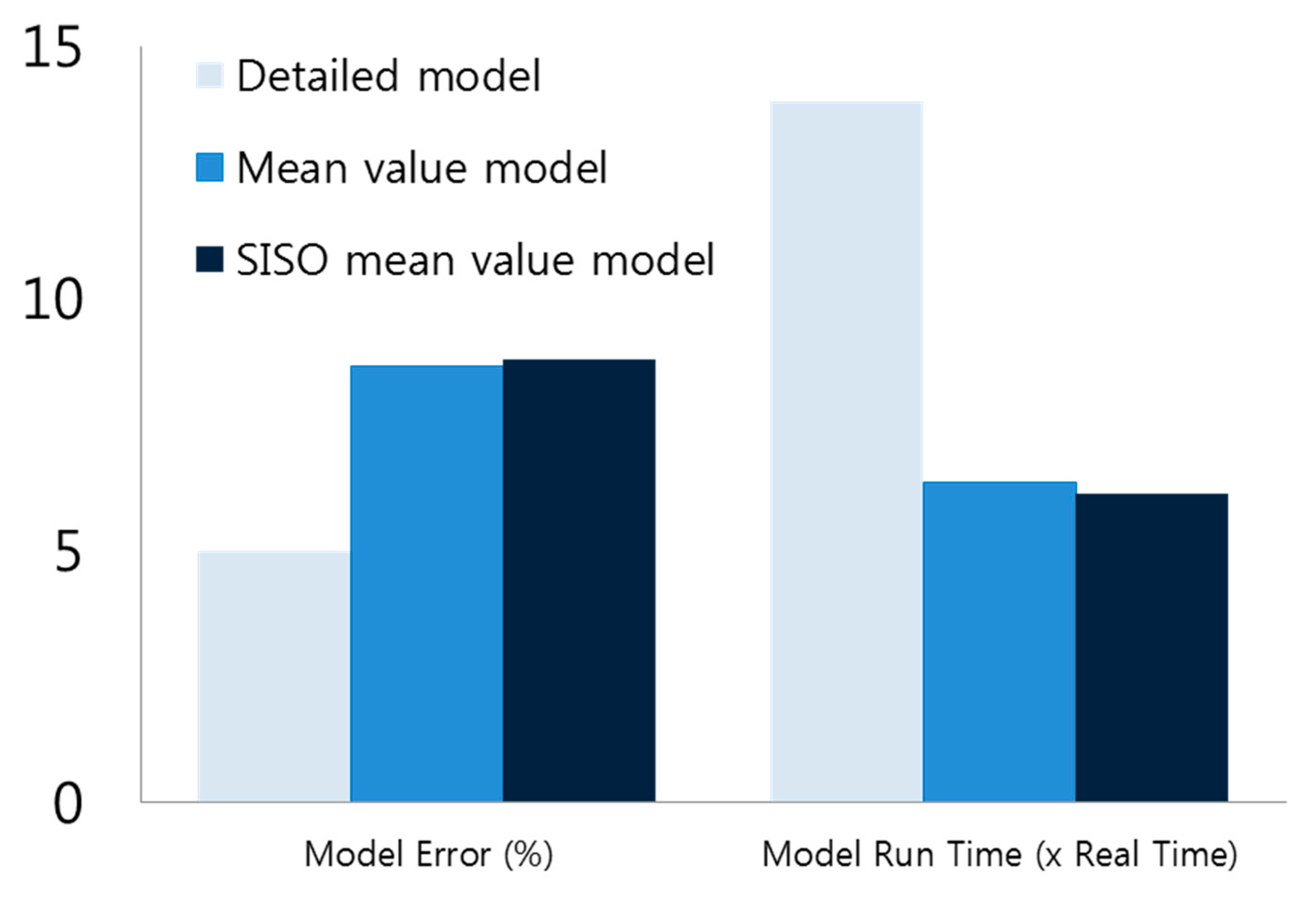

3.3. Model Accuracy and Execution Speed Trade-off

4. Conclusions

- A detailed model was constructed using the DI-pulse mode to describe the diesel combustion mode to construct the base model of the plant model. The four correction multipliers of the DI-pulse mode were optimized for each operating point using the Latin hypercube method.

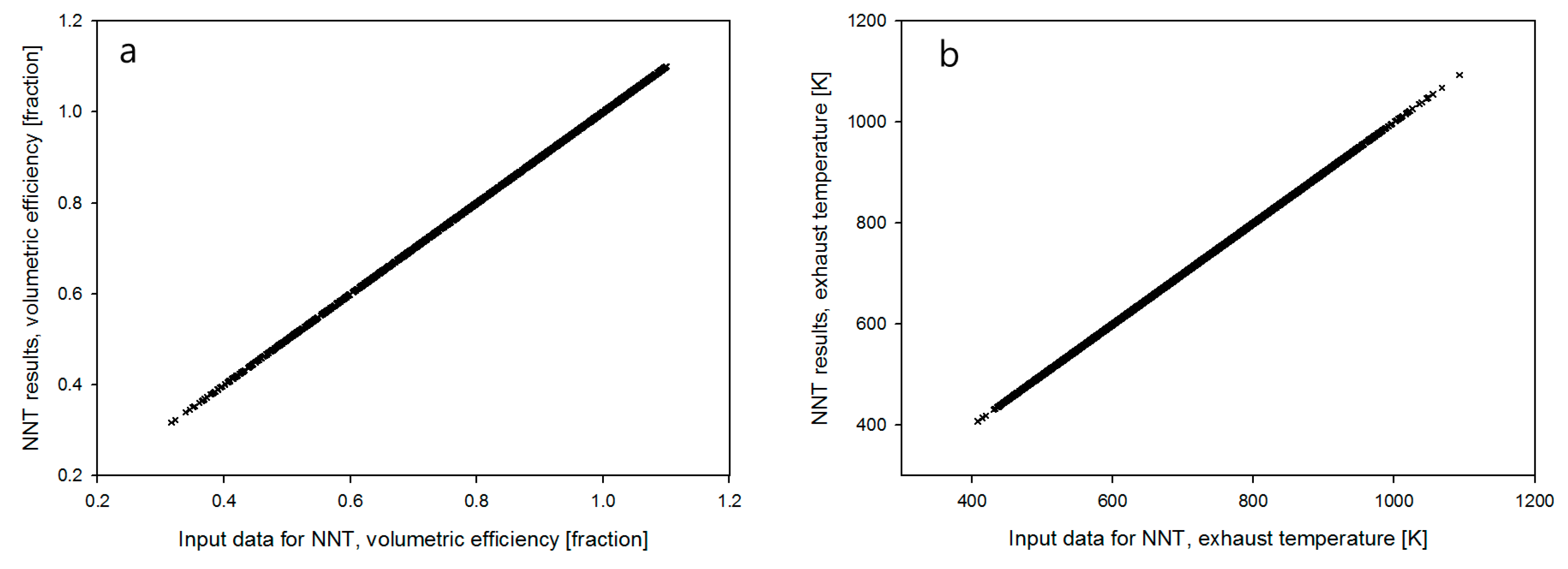

- The diesel mean-valued engine model was simplified by bundling together the flow components of the intake and exhaust manifolds. Artificial neural networks were also used to approximate the simulation results of the detailed model for the input variables—i.e., the volumetric efficiency and the exhaust gas temperature—of the mean value cylinder model. The artificial neural network training method uses a multi-layer feed-forward method that calculates results simply without circulation. As shown in Figure 8 for the exhaust gas temperature, the simulated values of the detailed model were not sufficient and the 1200–1400 K range of the exhaust gas temperature training could not be predicted.

- Acceleration condition description simulation allows model-based control to follow the target value well. However, as shown in Figure 12, the EGR ratio showed overshoot and undershoot owing to slight changes in the volumetric efficiency over the initial 10 s in the ST # 1 and ST # 2 zones. This response characteristic appears because the proportional band of the PID controller is narrow and the integration time is long. All the sections have a response delay but the target EGR percentage value is reached within 10 s.

- The response characteristics of the EGR logic were confirmed through the simulation of the deceleration condition with complex changes. As shown in Figure 13a, unlike in the case of the acceleration conditions, the volumetric efficiency can confirm the undershoot response characteristics in the entire speed change period. Moreover, the tendency of undershoot is larger than the change in the acceleration condition. This indicates that the PID controller responds slowly but weakly owing to its weak motion.

- The accuracy of the diesel average value model in Figure 14 showed a loss of approximately 3%, owing to the volumetric efficiency loss of the cylinder when compared with that of the diesel detailed model. However, in the case of the simulation run-time of the mean value model, the flow component shortening of the intake/manifold and the artificial neural network reduce the engine performance by approximately two times because of the intuitive prediction of the engine’s main performance parameters. Furthermore, the SISO coupled mean value model constructed in the study has a good balance between model accuracy and execution speed.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ANN | Artificial neural network |

| BMEP | Brake mean effective pressure |

| BNOx | Brake-specific nitric oxides |

| BSFC | Brake-specific fuel consumption |

| CI | Compression ignition |

| CRDI | Common rail direct injection |

| DI | Direct injection |

| DoE | Design of experiment |

| EGR | Exhaust gas recirculation |

| FFNN | Feed-forward neural network |

| FMI | Function mock-up interface |

| FTDC | Firing top dead center |

| HiL | Hardware-in-the-loop |

| IMEP | Indicated mean effective pressure |

| MVM | Mean value model |

| NEDC | New European driving cycle |

| NOx | Nitric oxides |

| PID | Proportional integral derivative |

| RMS | Root mean square |

| RPM | Revolution per minute |

| SISO | Single-input single-output |

| ST | Step-transient |

| TDC | Top dead center |

References

- Heidrich, L.; Shyrokau, B.; Savitski, D.; Ivanov, V.; Augsburg, K.; Wang, D. Hardware-in-the-loop test rig for integrated vehicle control systems. IFAC Proc. Vol. 2013, 46, 683–688. [Google Scholar] [CrossRef]

- Yu, M.X.; Tang, X.Y.; Lin, Y.Z.; Wang, X.Z. Diesel engine modeling based on recurrent neural networks for a hardware-in-the-loop simulation system of diesel generator sets. Neurocomputing 2018, 283, 9–19. [Google Scholar] [CrossRef]

- Yi, L.; He, H.; Peng, J. Hardware-in-loop simulation for the energy management system development of a plug-in hybrid electric bus. Energy Procedia 2016, 88, 950–956. [Google Scholar] [CrossRef]

- Maroteaux, F.; Saad, C. Combined mean value engine model and crank angle resolved in-cylinder modeling with NOx emissions model for real-time Diesel engine simulations at high engine speed. Energy 2015, 88, 515–527. [Google Scholar] [CrossRef]

- He, Y.; Lin, C.-C. Development and Validation of a Mean Value Engine Model for Integrated Engine and Control System Simulation; SAE Technical Paper; SAE: Troy, MI, USA, 2007. [Google Scholar]

- Lujan, J.M.; Climent, H.; Garcia-Cuevas, L.M.; Moratal, A. Volumetric efficiency modelling of internal combustion engines based on a novel adaptive learning algorithm of artificial neural networks. Appl. Therm. Eng. 2017, 123, 625–634. [Google Scholar] [CrossRef]

- Uzun, A. Air mass flow estimation of diesel engines using neural network. Fuel 2014, 117, 833–838. [Google Scholar] [CrossRef]

- Zarghami, M.; Hosseinnia, S.H.; Babazadeh, M. Optimal Control of EGR System in Gasoline Engine Based on Gaussian Process. IFAC-Pap. Online 2017, 50, 3750–3755. [Google Scholar] [CrossRef]

- Roy, S.; Banerjee, R.; Bose, P.K. Performance and exhaust emissions prediction of a CRDI assisted single cylinder diesel engine coupled with EGR using artificial neural network. Appl. Energy 2014, 119, 330–340. [Google Scholar] [CrossRef]

- Theotokatos, G.; Guan, C.; Chen, H.; Lazakis, I. Development of an extended mean value engine model for predicting the marine two-stroke engine operation at varying settings. Energy 2018, 143, 533–545. [Google Scholar] [CrossRef]

- Turkson, R.F.; Yan, F.; Ali, M.K.A.; Hu, J. Artificial neural network applications in the calibration of spark-ignition engines: An overview, Engineering Science and Technology. Int. J. 2016, 19, 1346–1359. [Google Scholar]

- Isermann, R.; Sequenz, H. Model-based development of combustion-engine control and optimal calibration for driving cycles: General procedure and application. IFAC-Pap. Online 2016, 49, 633–640. [Google Scholar] [CrossRef]

- Li, W.L.; Zhang, X.B.; Li, H.M. Co-simulation platforms for co-design of networked control systems: An overview. Control Eng. Pract. 2014, 23, 44–56. [Google Scholar] [CrossRef]

- Quaglia, D.; Muradore, R.; Bragantini, R.; Fiorini, P. A SystemC/Matlab co-simulation tool for networked control systems. Simul. Model. Pract. Theory 2012, 23, 71–86. [Google Scholar] [CrossRef]

- Rao, K.D. Modeling, simulation and control of semi active suspension system for automobiles under matlab simulink using pid controller. IFAC Proc. Vol. 2014, 47, 827–831. [Google Scholar] [CrossRef]

- Casoli, P.; Gambarotta, A.; Pompini, N.; Riccò, L. Development and application of co-simulation and “control-oriented” modeling in the improvement of performance and energy saving of mobile machinery. Energy Procedia 2014, 45, 849–858. [Google Scholar] [CrossRef]

- Xie, H.; Li, S.; Song, K.; He, G. Model-based decoupling control of VGT and EGR with active disturbance rejection in diesel engines. IFAC Proc. Vol. 2013, 46, 282–288. [Google Scholar] [CrossRef]

- Cieslar, D.; Dickinson, P.; Darlington, A.; Glover, K.; Collings, N. Model based approach to closed loop control of 1-D engine simulation models. Control Eng. Pract. 2014, 29, 212–224. [Google Scholar] [CrossRef]

- Nylén, A.; Henningsson, M.; Cervin, A.; Tunestál, P. Control Design Based on FMI: A Diesel Engine Control Case Study. IFAC-Pap. Online 2016, 49, 231–238. [Google Scholar]

- Gupta, H.N. Fundamentals of Internal Combustion Engines; PHI Learning Pvt. Ltd.: Delhi, India, 2012. [Google Scholar]

- Miller, R.; Davis, G.; Lavoie, G.; Newman, C.; Gardner, T. A Super-Extended Zel’dovich Mechanism for NOx Modeling and Engine Calibration; SAE Transactions: Troy, MI, USA, 1998; pp. 1090–1100. [Google Scholar]

- Park, S.; Song, S. Model-based multi-objective Pareto optimization of the BSFC and NOx emission of a dual-fuel engine using a variable valve strategy. J. Nat. Gas Sci. Eng. 2017, 39, 161–172. [Google Scholar] [CrossRef]

| Item | Specification |

|---|---|

| Displacement volume | 1.4 L |

| Compression ratio | 17:1 |

| Injection type | Common rail direct injection |

| EGR system | HP EGR |

| Turbocharger | Waste-gate type |

| Engine Speed (rpm) | BMEP (bar) |

|---|---|

| 1000 | 2, 4, 8 |

| 1500 | 2, 9, 16 |

| 2000 | 2, 9, 16 |

| 2500 | 2, 9, 16 |

| Engine Speed (rpm) | (1000–2500) |

| Total Fueling (mg) | (3–38) |

| Injection Timing (ATDC, after top dead center, deg.) | (−35–0) |

| Exhaust Gas Recirculation (EGR) Rate (fraction) | (0–0.39) |

| Boost Pressure (bar) | (1–2.5) |

| Boost Temperature (K) | (300–410) |

| Back Pressure (bar) | (1–1.35) |

| Back Temperature (K) | (430–770) |

| Case Number | Engine Speed (rpm) | BMEP (Brake Mean Effective Pressure) (bar) | Fuel Mass Rate (cycle/mg) | Total Exhaust Gas Recirculation (EGR) Rate (%) |

|---|---|---|---|---|

| Case 1 | 1500 | 2 | 5.52 | 34.7 |

| Case 2 | 1500 | 9 | 20.51 | 13.3 |

| Case 3 | 1500 | 16 | 37.55 | 0 |

| Case 4 | 2500 | 2 | 6.19 | 14.8 |

| Case 5 | 2500 | 9 | 20.01 | 9.9 |

| Case 6 | 2500 | 16 | 34.01 | 0 |

| Engine Speed (rpm) | BMEP (Brake Mean Effective Pressure) (bar) | Fuel Mass Rate (cycle/mg) | Total Exhaust Gas Recirculation (EGR) Rate (%) |

|---|---|---|---|

| 1500 | 2 | 5.52 | 34.7 |

| 2000 | 2 | 5.81 | 34.6 |

| 2000 | 9 | 19.33 | 19.8 |

| 2500 | 9 | 20.01 | 9.9 |

| 2500 | 16 | 34.01 | 0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, E.; Park, J. Diesel Mean Value Engine Modeling Based on Thermodynamic Cycle Simulation Using Artificial Neural Network. Energies 2019, 12, 2823. https://doi.org/10.3390/en12142823

Ko E, Park J. Diesel Mean Value Engine Modeling Based on Thermodynamic Cycle Simulation Using Artificial Neural Network. Energies. 2019; 12(14):2823. https://doi.org/10.3390/en12142823

Chicago/Turabian StyleKo, Eunhee, and Jungsoo Park. 2019. "Diesel Mean Value Engine Modeling Based on Thermodynamic Cycle Simulation Using Artificial Neural Network" Energies 12, no. 14: 2823. https://doi.org/10.3390/en12142823

APA StyleKo, E., & Park, J. (2019). Diesel Mean Value Engine Modeling Based on Thermodynamic Cycle Simulation Using Artificial Neural Network. Energies, 12(14), 2823. https://doi.org/10.3390/en12142823