Experimental Comparison of Two-Level Full-SiC and Three-Level Si–SiC Quasi-Z-Source Inverters for PV Applications

Abstract

1. Introduction

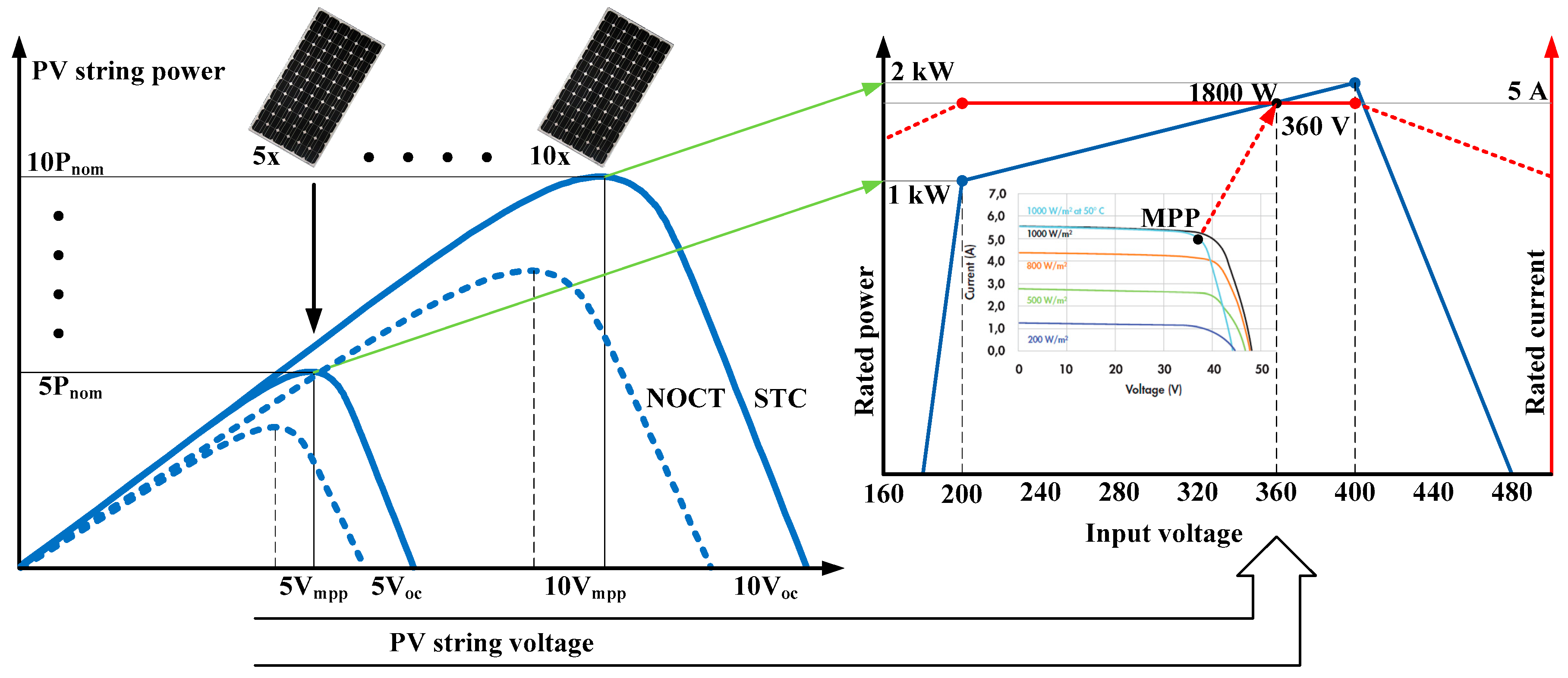

2. Case Study System

2.1. System Parameters and Specifications

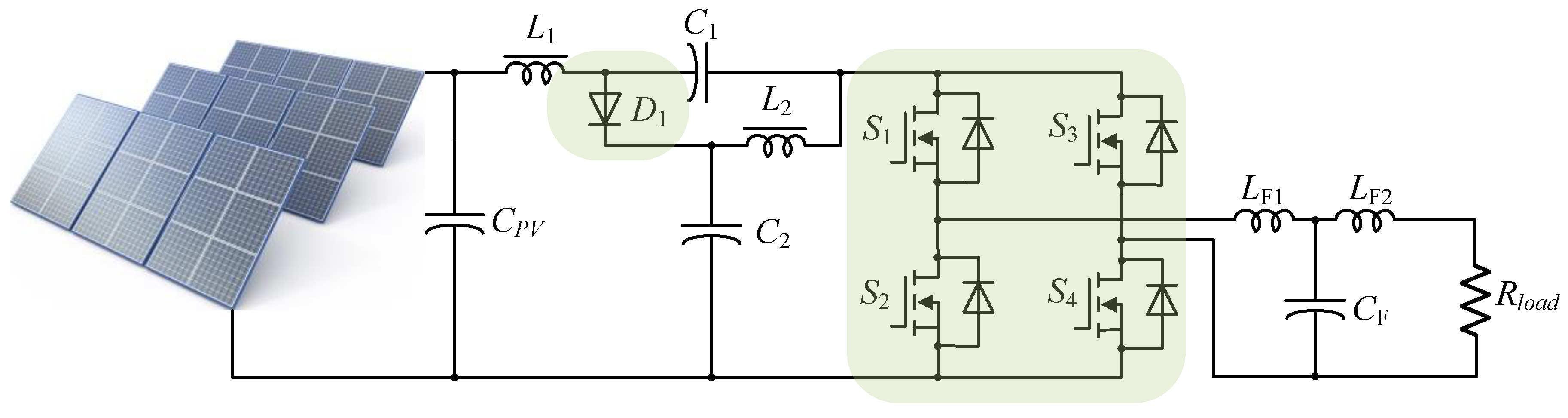

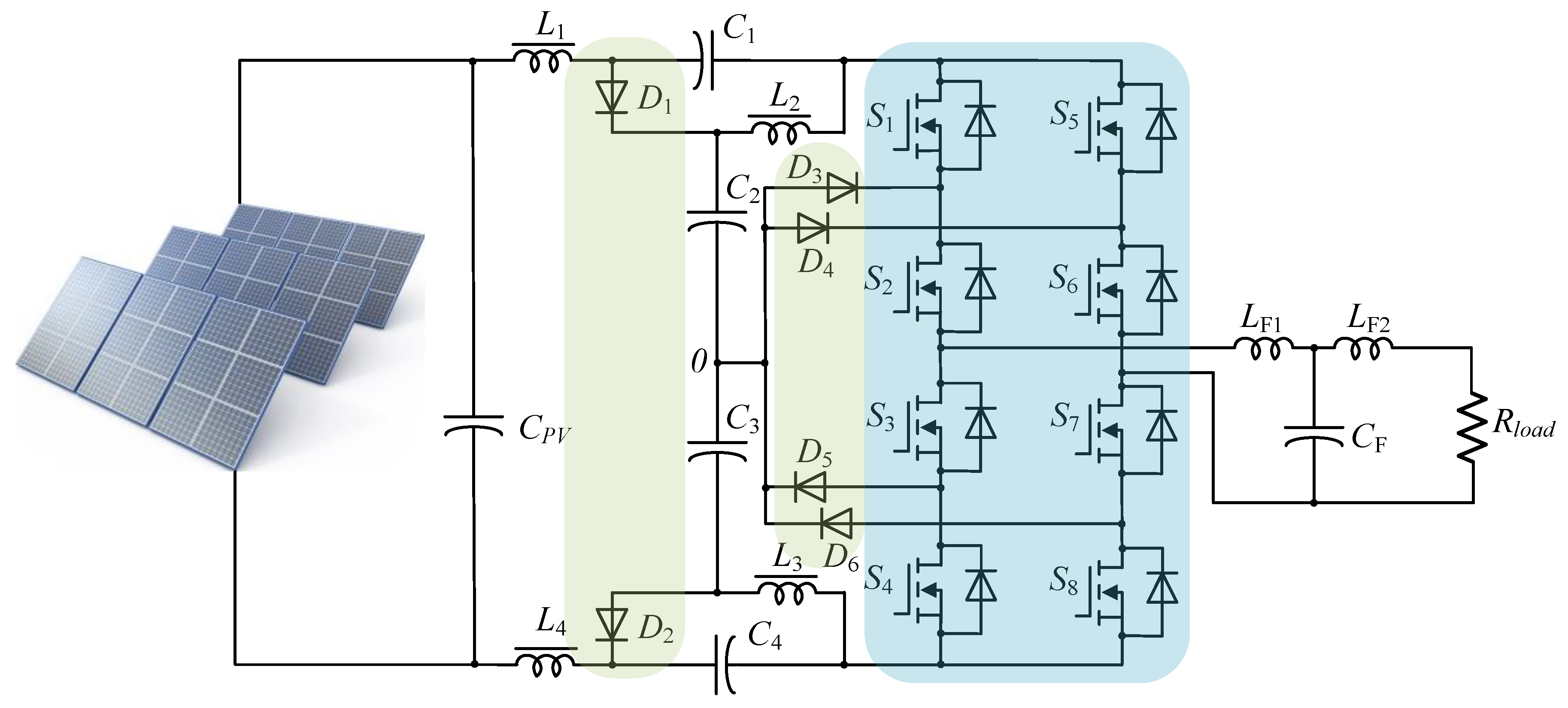

2.2. Description of Topologies

3. General Design Guidelines

3.1. Selection of Passive Components

3.2. Selection of Semiconductor Devices and Heatsinks

4. Experimental Study

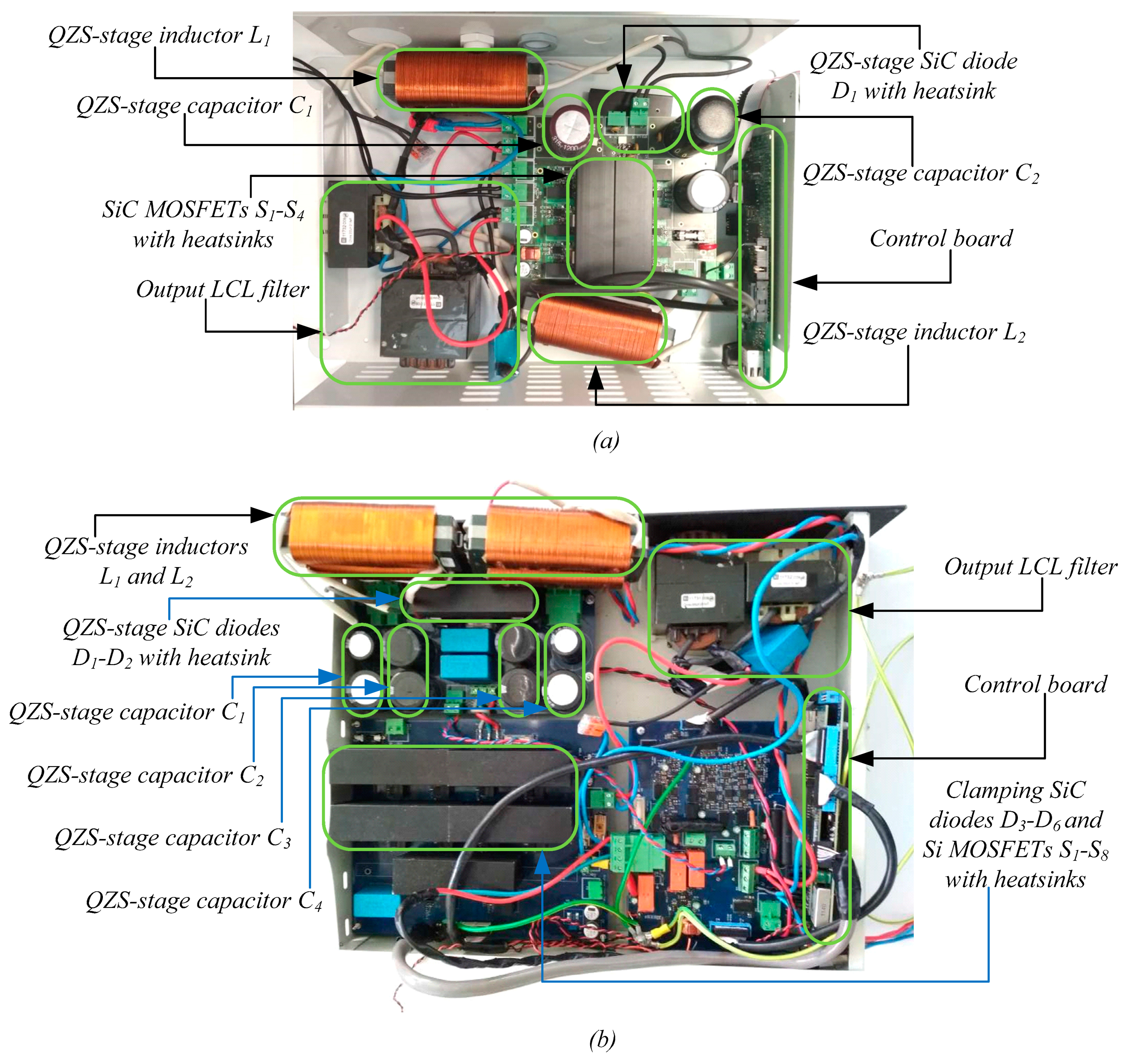

4.1. Experimental Setup and Tested Prototypes Description

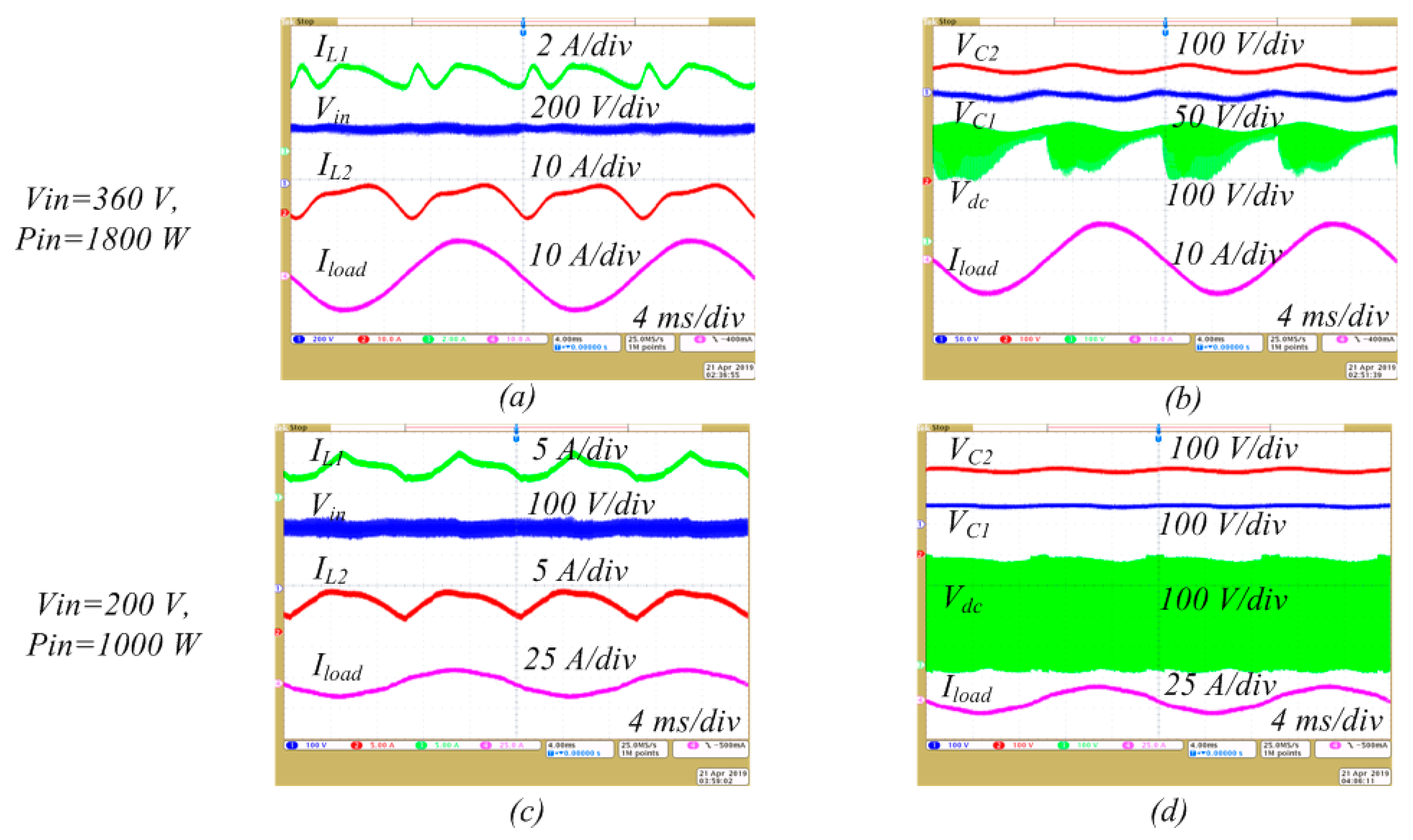

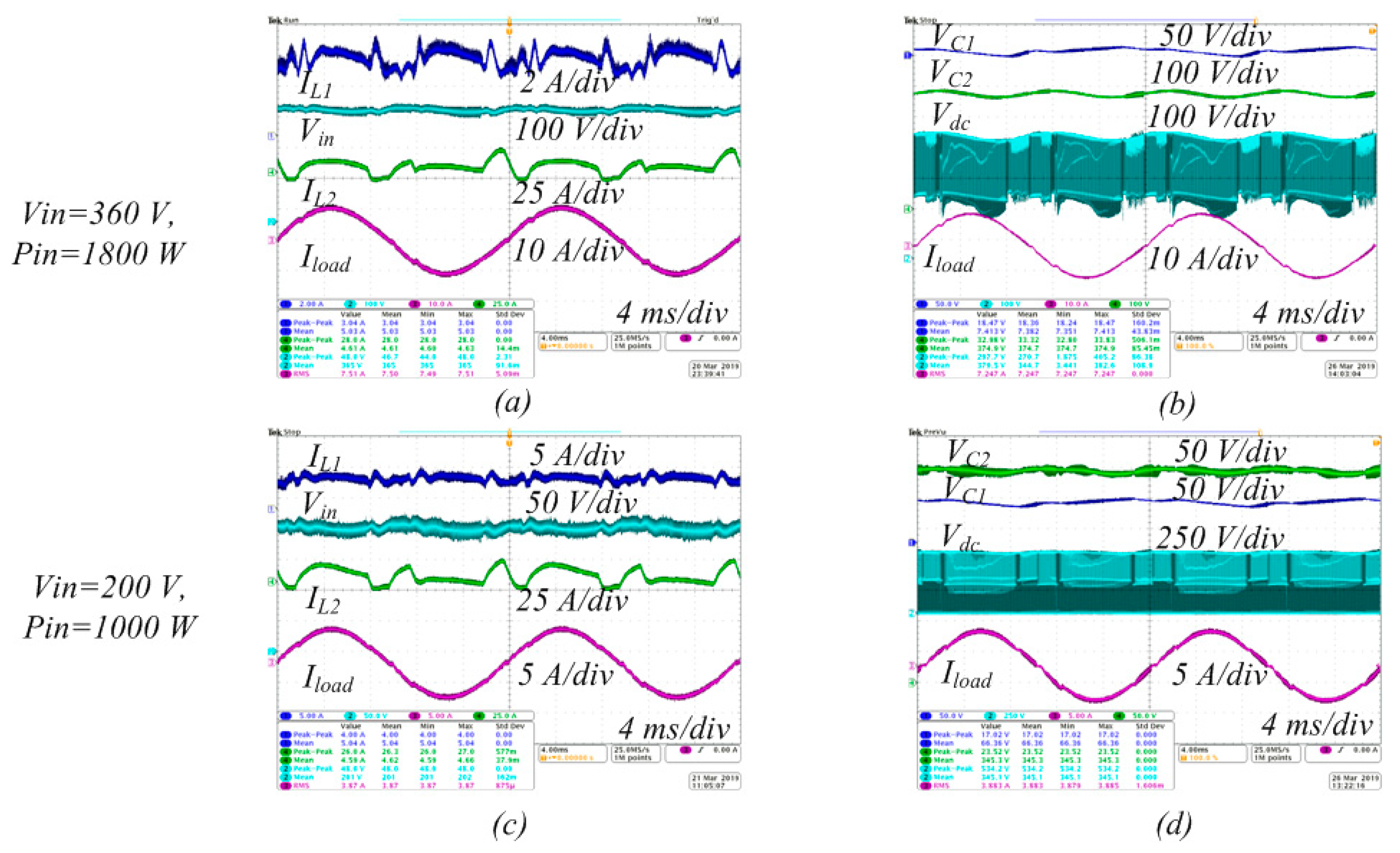

4.2. Operation Waveforms and Characteristics of the Prototypes

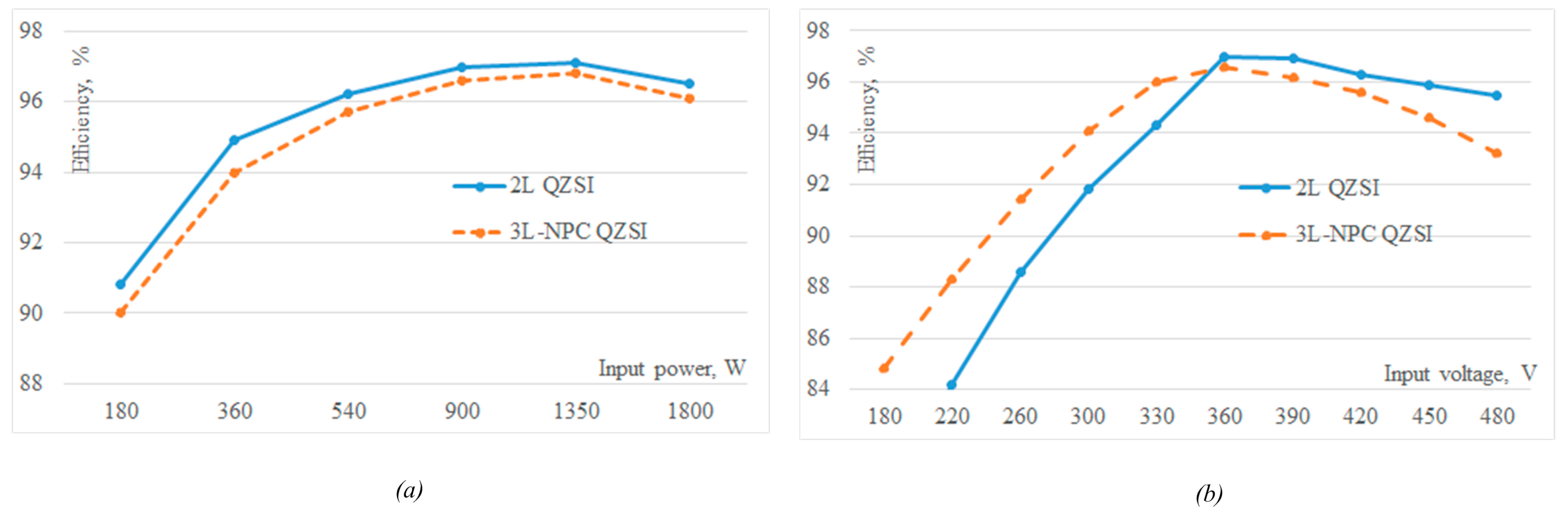

4.3. Efficiency Evaluation

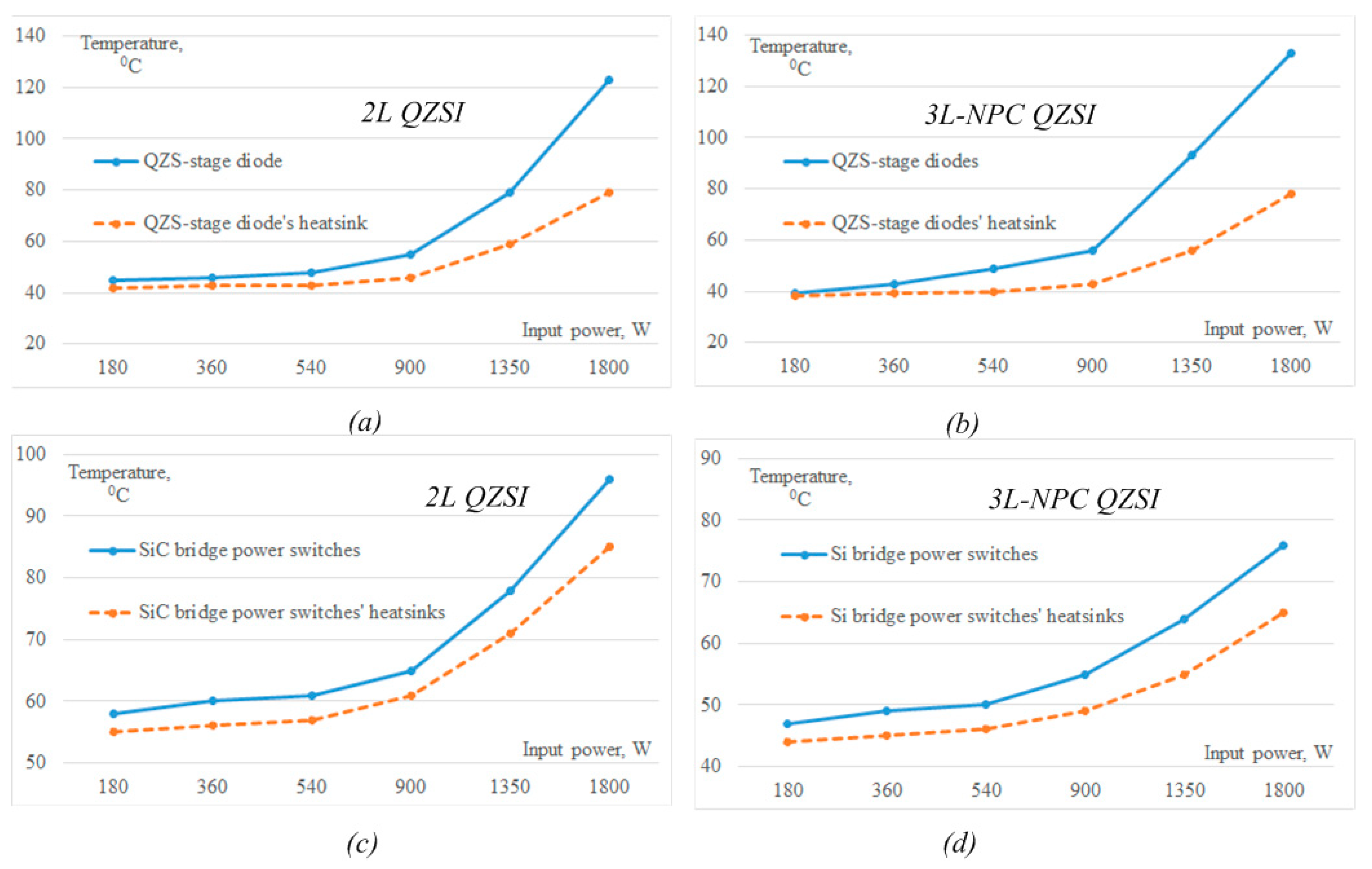

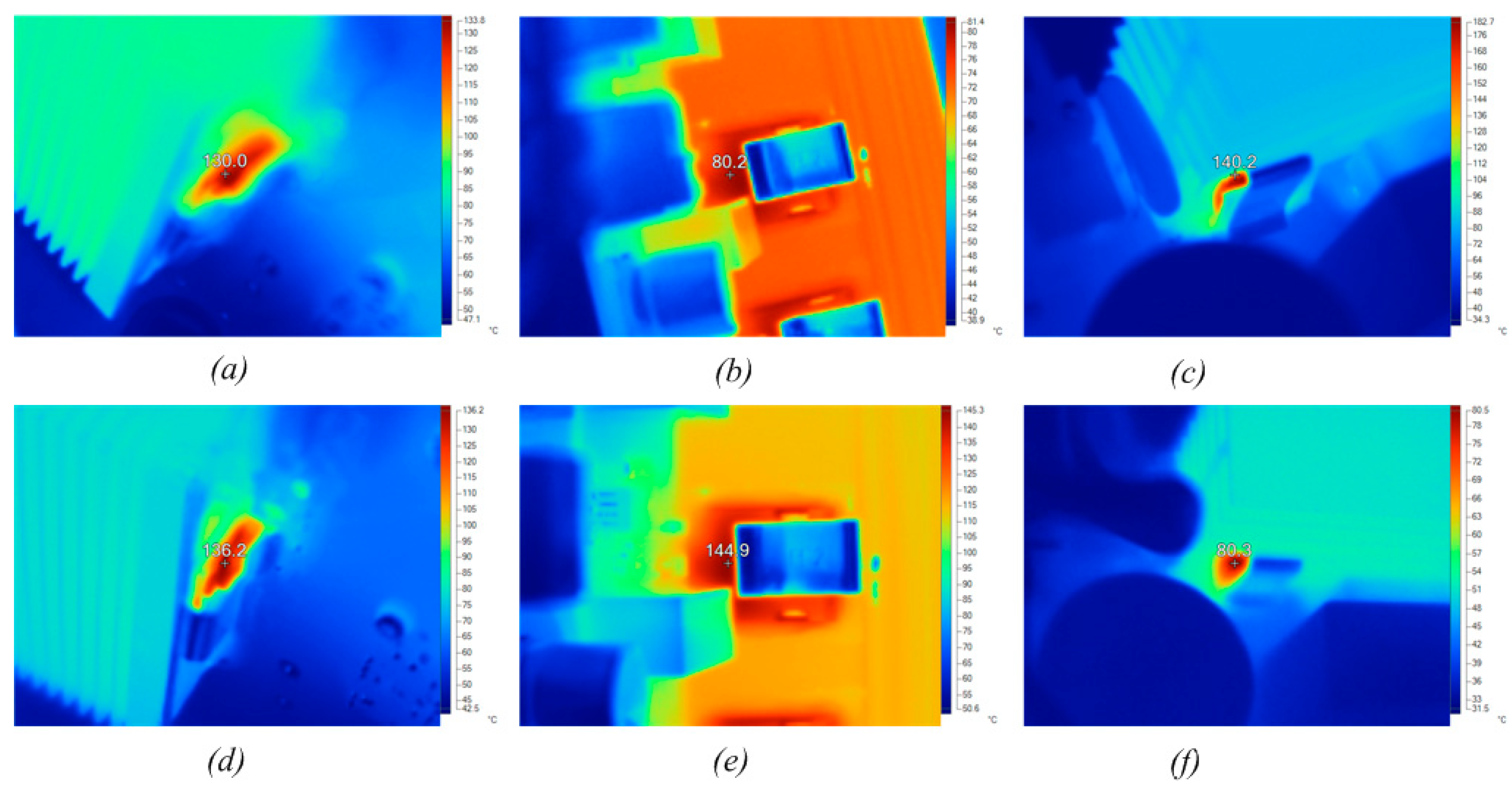

4.4. Evaluation of Temperature Behavior of Semiconductors and Heatsinks

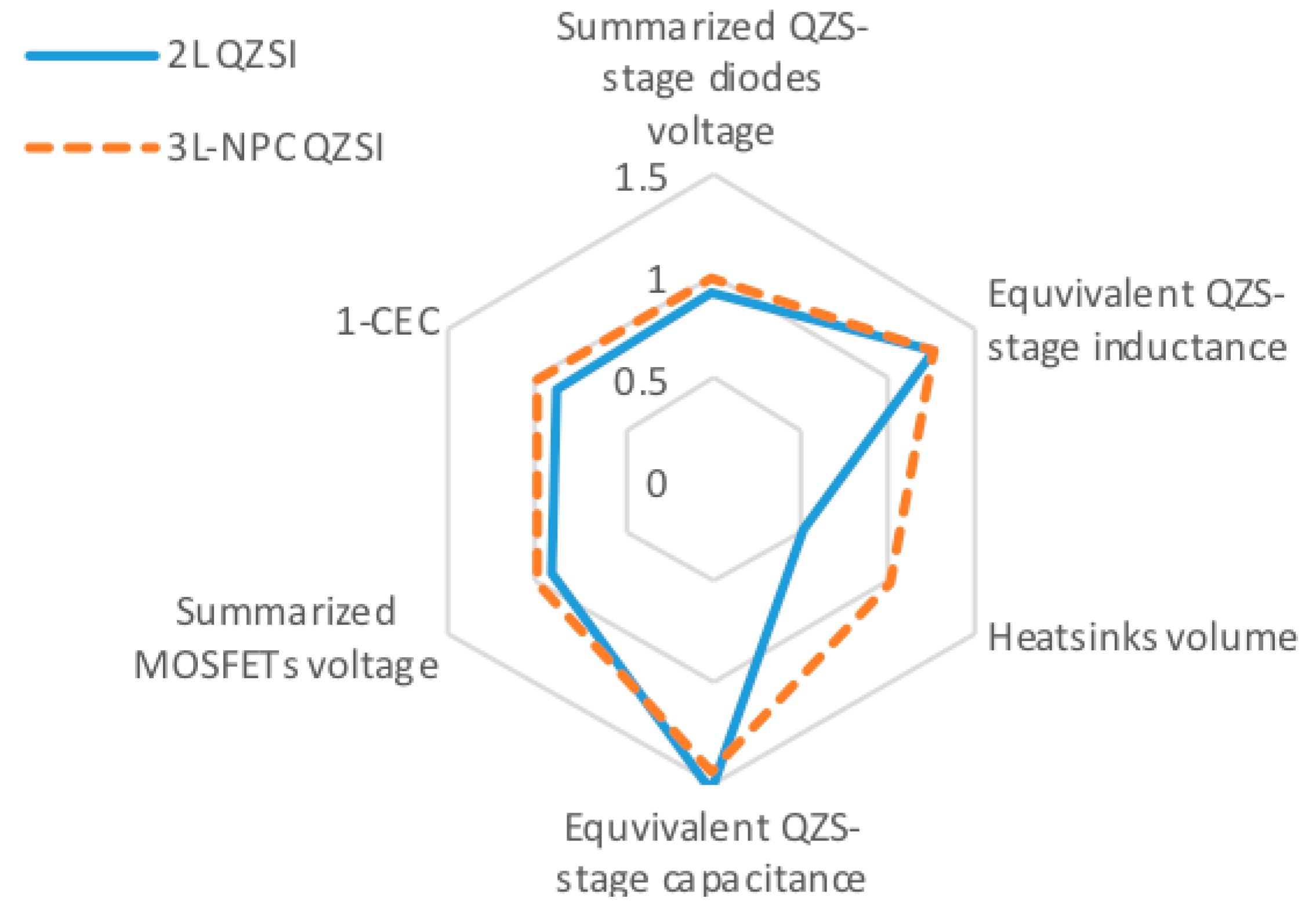

5. Comparative Analysis

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ghosh, R.; Wang, M.; Mudiyula, S.; Mhaskar, U.; Mitova, R.; Reilly, D.; Klikic, D. Industrial Approach to Design a 2-kVa Inverter for Google Little Box Challenge. IEEE Trans. Ind. Electron. 2018, 65, 5539–5549. [Google Scholar] [CrossRef]

- Tang, Y.; Yao, W.; Loh, P.C.; Blaabjerg, F. Highly reliable transformerless photovoltaic inverters with leakage current and pulsating power elimination. IEEE Trans. Ind. Electron. 2016, 63, 1016–1026. [Google Scholar] [CrossRef]

- Kjaer, S.B.; Pedersen, J.K.; Blaabjerg, F. A Review of Single-Phase Grid-Connected Inverters for Photovoltaic Modules. IEEE Trans. Ind. Appl. 2005, 41, 1292–1306. [Google Scholar] [CrossRef]

- Peng, F.Z. Z-Source Inverter. IEEE Trans. Ind. Appl. 2003, 39, 504–510. [Google Scholar] [CrossRef]

- Li, Y.; Anderson, J.; Peng, F.Z.; Liu, D. Quasi-Z-Source Inverter for Photovoltaic Power Generation Systems. In Proceedings of the 2009 Twenty-Fourth Annual IEEE Applied Power Electronics Conference and Exposition, Washington, DC, 15–19 February 2009; pp. 918–924. [Google Scholar] [CrossRef]

- Husev, O.; Roncero-Clemente, C.; Romero-Cadaval, E.; Vinnikov, D.; Stepenko, S. Single phase three-level neutral-point-clamped quasi-Z-source inverter. IET Power Electron. 2015, 8, 1–10. [Google Scholar] [CrossRef]

- Husev, O.; Blaabjerg, F.; Roncero-Clemente, C.; Romero-Cadaval, E.; Vinnikov, D.; Siwakoti, Y.P.; Strzelecki, R. Comparison of Impedance-Source Networks for Two and Multilevel Buck–Boost Inverter Applications. IEEE Trans. Power Electron. 2016, 31, 7564–7579. [Google Scholar] [CrossRef]

- Abdelhakim, A.; Davari, P.; Blaabjerg, F.; Mattavelli, P. Switching Loss Reduction in the Three-Phase Quasi-Z-Source Inverters Utilizing Modified Space Vector Modulation Strategies. IEEE Trans. Power Electron. 2017, 33, 4045–4060. [Google Scholar] [CrossRef]

- Roncero-Clemente, C.; Romero-Cadaval, E.; Pires, V.F.; Martins, J.F.; Vilhena, N.; Husev, O. Efficiency and Loss Distribution Analysis of the 3L Active NPC qZS Inverter. In Proceedings of the 2018 IEEE 12th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG 2018), Doha, Qatar, 10–12 April 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, Y.; Hu, S. Stator Current Harmonic Reduction in a Novel Half Quasi-Z-Source Wind Power Generation System. Energies 2016, 9, 770. [Google Scholar] [CrossRef]

- Wang, B.; Tang, W. A New CUK-Based Z-Source Inverter. Electronics 2018, 7, 313. [Google Scholar] [CrossRef]

- Priyadarshi, N.; Padmanaban, S.; Ionel, D.M.; Mihet-Popa, L.; Azam, F. Hybrid PV-Wind, Micro-Grid Development Using Quasi-Z-Source Inverter Modeling and Control—Experimental Investigation. Energies 2018, 11, 2277. [Google Scholar] [CrossRef]

- Wang, B.; Tang, W. A Novel Three-Switch Z-Source SEPIC Inverter. Electronics 2019, 8, 247. [Google Scholar] [CrossRef]

- Choi, W.-Y.; Yang, M.-K. Transformerless Quasi-Z-Source Inverter to Reduce Leakage Current for Single-Phase Grid-Tied Applications. Electronics 2019, 8, 312. [Google Scholar] [CrossRef]

- Husev, O.; Shults, T.; Vinnikov, D.; Roncero-Clemente, C.; Romero-Cadaval, E.; Chub, A. Comprehensive Comparative Analysis of Impedance-Source Networks for DC and AC Application. Electronics 2019, 8, 405. [Google Scholar] [CrossRef]

- Noman, A.; A Al-Shamma’a, A.; Addoweesh, K.; Alabduljabbar, A.; Alolah, A. Cascaded Multilevel Inverter Topology Based on Cascaded H-Bridge Multilevel Inverter. Energies 2018, 11, 895. [Google Scholar] [CrossRef]

- Hammami, M.; Rizzoli, G.; Mandrioli, R.; Grandi, G. Capacitors Voltage Switching Ripple in Three-Phase Three-Level Neutral Point Clamped Inverters with Self-Balancing Carrier-Based Modulation. Energies 2018, 11, 3244. [Google Scholar] [CrossRef]

- Wu, M.; Song, Z.; Lv, Z.; Zhou, K.; Cui, Q. A Method for the Simultaneous Suppression of DC Capacitor Fluctuations and Common-Mode Voltage in a Five-Level NPC/H Bridge Inverter. Energies 2019, 12, 779. [Google Scholar] [CrossRef]

- Tran, V.-T.; Nguyen, M.-K.; Ngo, C.-C.; Choi, Y.-O. Three-Phase Five-Level Cascade Quasi-Switched Boost Inverter. Electronics 2019, 8, 296. [Google Scholar] [CrossRef]

- Mookken, J.; Agrawal, B.; Liu, J. Efficient and Compact 50kW Gen2 SiC Device Based PV String Inverter. In Proceedings of the PCIM Europe 2014; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 20–22 May 2014; pp. 1–7. [Google Scholar]

- Öztürk, S.; Canver, M.; Çadırcı, I.; Ermiş, M. All SiC Grid-Connected PV Supply with HF Link MPPT Converter: System Design Methodology and Development of a 20 kHz, 25 kVA Prototype. Electronics 2018, 7, 85. [Google Scholar] [CrossRef]

- Choi, W.-Y.; Yang, M.-K. High-Efficiency Design and Control of Zeta Inverter for Single-Phase Grid-Connected Applications. Energies 2019, 12, 974. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, J.; Zhou, J.; Wang, B. A New Single-Phase Transformerless Current Source Inverter for Leakage Current Reduction. Energies 2018, 11, 1633. [Google Scholar] [CrossRef]

- Nguyen, M.-K.; Choi, Y.-O. Voltage Multiplier Cell-Based Quasi-Switched Boost Inverter with Low Input Current Ripple. Electronics 2019, 8, 227. [Google Scholar] [CrossRef]

- Nguyen, M.; Choi, Y. PWM Control Scheme for Quasi-Switched-Boost Inverter to Improve Modulation Index. IEEE Trans. on Power Electron. 2018, 33(5), 4037–4044. [Google Scholar] [CrossRef]

- Fernández, E.; Paredes, A.; Sala, V.; Romeral, L. A Simple Method for Reducing THD and Improving the Efficiency in CSI Topology Based on SiC Power Devices. Energies 2018, 11, 2798. [Google Scholar] [CrossRef]

- Wolski, K.; Zdanowski, M.; Rabkowski, J. High-frequency SiC-based inverters with input stages based on quasi-Z-source and boost topologies—Experimental comparison. IEEE Trans. Power Electron. 2019. [Google Scholar] [CrossRef]

- Tiku, D. Modular Multilevel MMI(HB) Topology for Single-Stage Grid Connected PV Plant. In Proceedings of the 11th IET International Conference on AC and DC Power Transmission, Birmingham, UK, 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Keyhani, H.; Toliyat, H.A. Single-Stage Multistring PV Inverter With an Isolated High-Frequency Link and Soft-Switching Operation. IEEE Trans. Power Electron. 2014, 29, 3919–3929. [Google Scholar] [CrossRef]

- Strache, S.; Wunderlich, R.; Heinen, S. A Comprehensive, Quantitative Comparison of Inverter Architectures for Various PV Systems, PV Cells, and Irradiance Profiles. IEEE Trans. Sustain. Energy 2014, 5, 813–822. [Google Scholar] [CrossRef]

- Stepenko, S.; Roncero-Clemente, C.; Husev, O.; Makovenko, E.; Pimentel, S.P.; Vinnikov, D. New interleaved single-phase quasi-Z-source inverter with active power decoupling. In Proceedings of the 2018 IEEE 12th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG 2018), Doha, Qatar, 10–12 April 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Makovenko, E.; Husev, O.; Romero-Cadaval, E.; Vinnikov, D.; Stepenko, S. Single-Phase Three-Level qZ-Source Inverter Connected to the Grid with Battery Storage and Active Power Decoupling Function. In Proceedings of the 2018 IEEE 59th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 12–13 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Stepenko, S.; Husev, O.; Pimentel, S.P.; Makovenko, E.; Vinnikov, D. Small Signal Modeling of Interleaved Quasi-Z-Source Inverter with Active Power Decoupling Circuit. In Proceedings of the 2018 IEEE 59th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 12–13 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Roncero-Clemente, C.; Husev, O.; Stepenko, S.; Romero-Cadaval, E.; Vinnikov, D. Interleaved single-phase quasi-Z-source inverter with special modulation technique. In Proceedings of the 2017 IEEE First Ukraine Conference on Electrical and Computer Engineering (UKRCON), Kiev, Ukraine, 29 May–2 June 2017; pp. 593–598. [Google Scholar] [CrossRef]

- Roncero-Clemente, C.; Stepenko, S.; Husev, O.; Romero-Cadaval, E.; Vinnikov, D. Maximum boost control for interleaved single-phase Quasi-Z-Source inverter. In Proceedings of the IECON 2017-43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 7698–7703. [Google Scholar] [CrossRef]

- Nguyen, M.-K.; Choi, Y.-O. Maximum Boost Control Method for Single-Phase Quasi-Switched-Boost and Quasi-Z-Source Inverters. Energies 2017, 10, 553. [Google Scholar] [CrossRef]

- Roncero-Clemente, C.; Stepenko, S.; Husev, O.; Miñambres-Marcos, V.; Romero-Cadaval, E.; Vinnikov, D. Three-Level Neutral-Point-Clamped Quasi-Z-Source Inverter with Maximum Power Point Tracking for Photovoltaic Systems. In Technological Innovation for the Internet of Things. DoCEIS 2013. IFIP Advances in Information and Communication Technology; Camarinha-Matos, L.M., Tomic, S., Graça, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 394, pp. 334–342. [Google Scholar] [CrossRef]

- Pimentel, S.P.; Husev, O.; Stepenko, S.; Vinnikov, D.; Roncero-Clemente, C.; Makovenko, E. Voltage Control Tuning of a Single-Phase Grid-Connected 3L qZS-Based Inverter for PV Application. In Proceedings of the 2018 IEEE 38th International Conference on Electronics and Nanotechnology (ELNANO), Kiev, Ukraine, 24–26 April 2018; pp. 692–698. [Google Scholar] [CrossRef]

- Pimentel, S.P.; Husev, O.; Vinnikov, D.; Roncero-Clemente, C.; Stepenko, S. An Indirect Model Predictive Current Control (CCS-MPC) for Grid-Connected Single-Phase Three-Level NPC Quasi-Z-Source PV Inverter. In Proceedings of the 2018 IEEE 59th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 12–13 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Types of Solar Inverter Efficiency - Peak, Euro, and CEC-Solar Selections. Available online: http://www.solarselections.co.uk/blog/types-of-solar-inverter-efficiency-peak-vs-euro (accessed on 10 May 2019).

- SolarHub-PV Module Details: SPR-200-BLK-U-by SunPower. Available online: http://www.solarhub.com/product-catalog/pv-modules/764-SPR-200-BLK-U-SunPower (accessed on 13 May 2019).

- Husev, O.; Chub, A.; Romero-Cadaval, E.; Roncero-Clemente, C.; Vinnikov, D. Voltage Distortion Approach for Output Filter Design for Off-Grid and Grid-Connected PWM Inverters. J. Power Electron. 2015, 15, 278–287. [Google Scholar] [CrossRef]

- Model 62150h 600s/1000s-Chroma Systems Solutions. Available online: http://www.chromausa.com/pdf/Br-62150H-600S+1000S-dcsupply-112011.pdf (accessed on 24 May 2019).

- WT1800 High Performance Power Analyzer | Yokogawa Test & Measurement Corporation. Available online: https://tmi.yokogawa.com/us/solutions/products/power-analyzers/wt1800-high-performance-power-analyzer/ (accessed on 24 May 2019).

- MSO/DPO4000B Mixed Signal Oscilloscope | Tektronix. Available online: https://www.tek.com/oscilloscope/mso4000-dpo4000 (accessed on 24 May 2019).

- Cyclone IV Device Handbook-Intel. Available online: https://www.intel.com/content/dam/www/programmable/us/en/pdfs/literature/hb/cyclone-iv/cyclone4-handbook.pdf (accessed on 24 May 2019).

- Fluke Ti10 Infrared Camera | Fluke. Available online: https://www.fluke.com/en-us/product/thermal-cameras/ti10 (accessed on 27 May 2019).

- HM8118 LCR Bridge/Meter | Overview | Rohde & Schwarz. Available online: https://www.rohde-schwarz.com/pk/product/hm8118-productstartpage_63493-44101.html (accessed on 28 May 2019).

| References | Inverter Topology | Rated Power, kW | Input Voltage, V | Semiconductor Devices and Switching Frequency | Output Rms Voltage and Frequency | Peak/CEC Efficiency, % |

|---|---|---|---|---|---|---|

| [1] | SAF with FB VSI | 2 | 450 | 900 V SiC MOSFET/45 kHz 650V Si IGBT/45 kHz | 240 V, 60 Hz | 97.75/97.2 97.0/96.4 |

| [2] | FB VSI | 0.5 | 280 | Si MOSFET/19.2 kHz | 110 V, 60 Hz | 96/- |

| [4] | 3-Phase ZSI | 4.5 | 150 | IGBT/10 kHz | 208 V, 60 Hz | -/- |

| [5] | 3-Phase QZSI | 4.3 | 189–400 | 600 V diode & 600 V IGBT/10 kHz | 208 V, 60 Hz | -/- |

| [6] | 3l NPC QZSI | 1 | 220–325 | 600 V diode and 600 V Si MOSFET/100 kHz | 230 V, 50 Hz | 94/- |

| [11] | CUK-based ZSI | 0.4 | 90 | 1200 V IGBT K40T1202/20 kHz | 110 V, 50 Hz | -/- |

| [13] | 3-switch ZSI SEPIC | 0.5 | 100 | 1200 V IGBT K40T1202/20 kHz | 124 V, 50 Hz | 91.7/- |

| [14] | QZSI +2 bi- directional switches | 1 | 250 | SiC diode C4D20120D and SiC MOSFET C2M0080120D/10 kHz 1200 V IGBT IKW25T120/10 kHz | 220 V, 60 Hz | 95.1/- 92.9/- |

| [20] | Interleaved boost DC–DC + T-type 3L 3-phase DC–AC | 50 | 450-800 | 1.2kV SiC C4D20120D + 1.2kV SiC MOSFET C2M0025120D + 600V SiC C3D16060D + 1.2kV SiC MOSFET C2M0025120D/75 kHz | 480 V, 50 Hz | 99.4/- |

| [21] | HF link DC–AC–DC + 3-phase 2L VSI | 25 | 533 | SiC HB module CAS120M12BM2 + SiC diodes C4D40120D and 3 Phase SiC module CCS050M12CM2 | 400 V, 50 Hz | 98.5/- |

| [22] | Zeta inverter | 0.22 | 48 | 300 V MOSFET IXFK150N30P3 + 1200 V SiC MOSFET UJC1206k/50 kHz | 220 V, 60 Hz | 95/- |

| [24] | QSBI | 0.35 | 50–72 | Diodes STPS60SM200C and IXYS30-60A + MOSFETs IRFP4668 and IRFP460/20 kHz | 110 V, 50 Hz | 91.3/- |

| [25] | QSBI | 0.4 | 58–100 | Diodes DSEP 30–06A + MOSFETs IRFP460/10 and 20 kHz | 110 V, 50 Hz | 94/- |

| [27] | QZSI BC+VSI IBC+VSI | 6 | 400–600 | 1 × C4D20120D diodes + 6 × C2M0080120D/100 kHz 1 × C4D20120D diodes + 1 × C2M0080120D + 6 × C2M0080120D/100 kHz 2 × C4D20120D diodes + 1 × C2M0080120D + 6 × C2M0080120D/100 kHz | 220 V, 50 Hz | 95.97/- 95.96/- 96.11/- |

| PV panel parameters | Values | System parameters | Values |

|---|---|---|---|

| Standard Test Conditions (STCs): Air Mass (AM) 1.5, Irradiance 1000 W/m², cell temperature 25 °C | Nominal power | Pnom = 1800 W | |

| Nominal voltage | Vnom = 200–400 V | ||

| Nominal power (+/−5%) | Pnom = 200 W | Nominal current | Inom = 5 A |

| Rated voltage | Vmpp = 40.0 V | Load RMS voltage | Vload = 230 V |

| Rated current | Impp = 5.00 A | Output current THD | THDI < 3% |

| Open circuit voltage | Voc = 47.8 V | Min operating power | Pmin = 90 W |

| Short circuit current | Isc = 5.40 A | Max operating power | Pmax = 2000 W |

| Nominal Operating Cell Temperature (NOCT): Air Mass (AM) 1.5, Irradiance 800 W/m², cell temperature 46 °C +/−2 °C | Min operating voltage | Vmin = 180 V | |

| Max operating voltage | Vmax = 480 V | ||

| Nominal power | Pnom = 146 W | Voltage ripple | ΔV < 5% |

| Rated voltage | Vmpp = 36.5 V | Max input current | Imax = 10 A |

| Rated current | Impp = 4.01 A | Current ripple | ΔI < 10% |

| Open circuit voltage | Voc = 44.5 V | Number of PV panels | N = 5…10 |

| Short circuit current | Isc = 4.38 A | Case study PV panels | SPR-200-BLK |

| Components | 2L QZSI | 3l NPC QZSI |

|---|---|---|

| QZS-stage inductors | L1 = L2 = 1.8 mH | L1 = L2 = L3 = L4 = 0.9 mH |

| QZS-stage capacitors | EKMS3B1VSN122MA50S, C1 = 1200 µF, 105 °C, 315 V, 3000 Hrs, 3.25 A, ESR 100 mΩ; ALC10(1)681DL500, C2 = 680 µF, 85 °C, 500 V, 2000 Hrs, 3.65 A, ESR 244 mΩ | ESMQ201VSN122MQ40S, C1 = C4 = 1200 µF, 85 °C, 200 V, 2000 Hrs, 3.5 A, ESR 166 mΩ; B43504G2158M80, C1 = C4 = 1500 µF, 105 °C, 200 V, 3000 Hrs, 3.4 A, ESR 100 mΩ; B43545C9397M000, C2 = C3 = 390 µF, 105 °C, 400 V, 5000 Hrs, 2.3 A, ESR 150 mΩ; LPW471M2GQ45M, C2 = C3 = 470 µF, 85 °C, 400 V, 2000 Hrs, ESR 420 mΩ |

| Output filter | LF1 = 0.56 mH, LF2 = 0.2 mH, CF = 15 µF | |

| QZS-stage and clamping diodes | D1: SiC C4D02120A, VRRM = 1200 V | D1–D6: SiC C3D10065A, VRRM = 650 V |

| Inverter bridge switches | S1–S4: C2M0080120D MOSFETs SiC, VDS = 1200 V, RDS = 80 mΩ | S1–S8: IPW65R041CFD MOSFETs Si , VDS = 650 V, RDS = 41 mΩ |

| Gate drivers | ACPL-H342 (2.5 A max peak output current) | |

| Power Checkpoints, % of Nominal | Input Power, W | 2L QZSI Efficiency, % | 3l NPC QZSI Efficiency, % |

|---|---|---|---|

| 10 | 180 | 90.8 | 90.0 |

| 20 | 360 | 94.9 | 94.0 |

| 30 | 540 | 96.2 | 95.7 |

| 50 | 900 | 97.0 | 96.6 |

| 75 | 1350 | 97.1 | 96.8 |

| 100 | 1800 | 96.5 | 96.1 |

| - | CEC efficiency | 96.6 | 96.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stepenko, S.; Husev, O.; Vinnikov, D.; Roncero-Clemente, C.; Pires Pimentel, S.; Santasheva, E. Experimental Comparison of Two-Level Full-SiC and Three-Level Si–SiC Quasi-Z-Source Inverters for PV Applications. Energies 2019, 12, 2509. https://doi.org/10.3390/en12132509

Stepenko S, Husev O, Vinnikov D, Roncero-Clemente C, Pires Pimentel S, Santasheva E. Experimental Comparison of Two-Level Full-SiC and Three-Level Si–SiC Quasi-Z-Source Inverters for PV Applications. Energies. 2019; 12(13):2509. https://doi.org/10.3390/en12132509

Chicago/Turabian StyleStepenko, Serhii, Oleksandr Husev, Dmitri Vinnikov, Carlos Roncero-Clemente, Sergio Pires Pimentel, and Elena Santasheva. 2019. "Experimental Comparison of Two-Level Full-SiC and Three-Level Si–SiC Quasi-Z-Source Inverters for PV Applications" Energies 12, no. 13: 2509. https://doi.org/10.3390/en12132509

APA StyleStepenko, S., Husev, O., Vinnikov, D., Roncero-Clemente, C., Pires Pimentel, S., & Santasheva, E. (2019). Experimental Comparison of Two-Level Full-SiC and Three-Level Si–SiC Quasi-Z-Source Inverters for PV Applications. Energies, 12(13), 2509. https://doi.org/10.3390/en12132509