Exploring the Introduction of Plug-In Hybrid Flex-Fuel Vehicles in Ecuador

Abstract

:1. Introduction

2. Materials and Methods

NH3(gas) + HNO3 (gas) ⇔ NH4NO3 (particle)

NH3(gas) + HCl (gas) ⇔ NH4Cl (particle)

2.1. Reference Scenario-100% ICEV Diesel Fleet

2.2. Hypothetical Scenarios HEV with ED95

2.3. Hypothetical Scenarios PHEV with E20 and E100

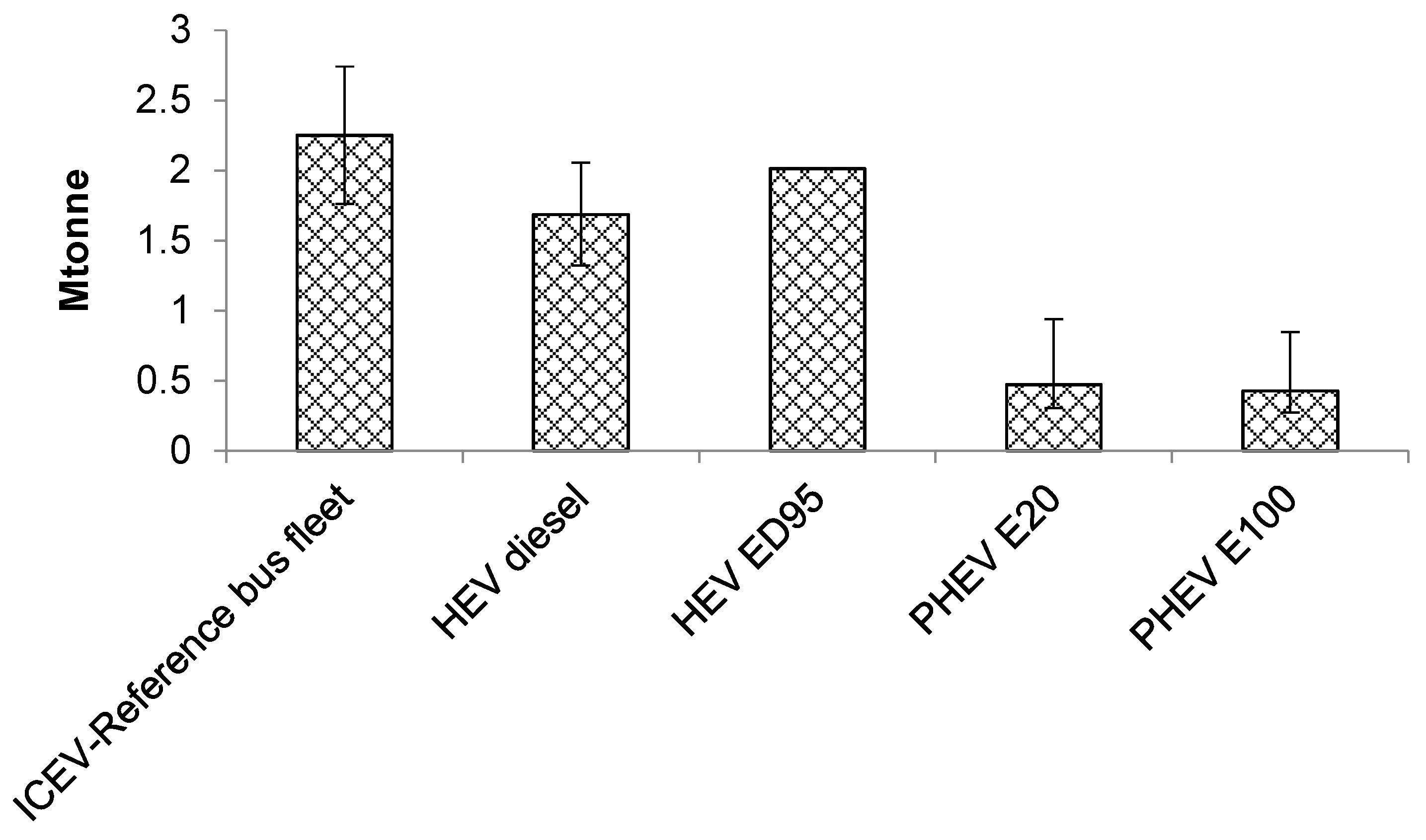

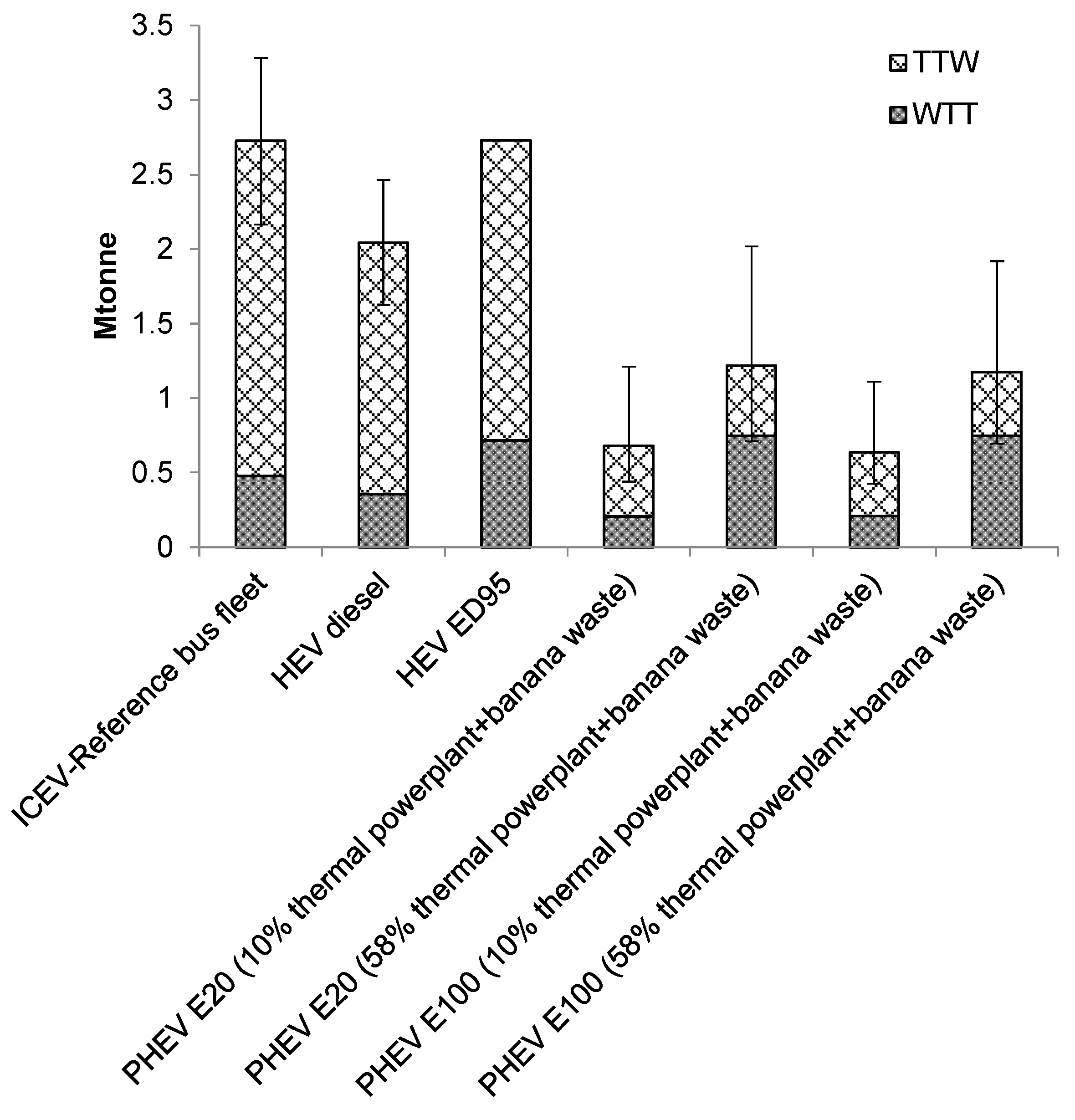

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Oliveira, M.L.M.; Silva, C.M.; Moreno-Tost, R.; Farias, T.L.; Jiménez-López, A.; Rodríguez-Castellón, E. Modelling of NOx emission factors from heavy and light-duty vehicles equipped with advanced aftertreatment systems. Energy Convers. Manag. 2011, 52, 2945–2951. [Google Scholar] [CrossRef]

- Stelwagen, U.; Ligterink, N. NH3 Emission Factors for Road Transport; TNO: Ultrecht, The Netherlands, 2015. [Google Scholar]

- Baek, B.H.; Koziel, J.A.; Aneja, V.P. A preliminary review of gas-to-particle conversion monitoring and modelling efforts in the USA. Int. J. Glob. Environ. Issues 2015. [Google Scholar] [CrossRef]

- INEC. Anuario de Transporte 2015. Inf. Anu. 2015, 46. [Google Scholar]

- Graefe, S.; Dufour, D.; Giraldo, A.; Muñoz, L.A.; Mora, P.; Solís, H.; Gonzalez, A. Energy and carbon footprints of ethanol production using banana and cooking banana discard: A case study from Costa Rica and Ecuador. Biomass Bioenergy 2011, 35, 2640–2649. [Google Scholar] [CrossRef]

- Guerrero, A.B.; Muñoz, E. Life cycle assessment of second generation ethanol derived from banana agricultural waste: Environmental impacts and energy balance. J. Clean. Prod. 2018. [Google Scholar] [CrossRef]

- Ponce-Jara, M.A.; Castro, M.; Pelaez-Samaniego, M.R.; Espinoza-Abad, J.L.; Ruiz, E. Electricity sector in Ecuador: An overview of the 2007–2017 decade. Energy Policy 2018. [Google Scholar] [CrossRef]

- MEER. Plan Nacional De Eficiencia Energética—PLANEE (Versión 2016–2035); Ministerio de Eletricidade y Energia Renovable: Quito, Ecuador, 2017. [Google Scholar]

- Samaniego, M.P.; Abad, J.E. Eficiencia energética y ahorro de energía en el Ecuador; Universidad Cuenca: Cuenca, Ecuador, 2015. [Google Scholar]

- Ribau, J.P.; Silva, C.M.; Sousa, J.M.C. Plug-in hybrid vehicle powertrain design optimization: Energy consumption and cost. Lect. Notes Electr. Eng. 2013, 191, 595–613. [Google Scholar]

- Silva, C.M.; Farias, T.L.; Frey, H.C.; Rouphail, N.M. Evaluation of numerical models for simulation of real-world hot-stabilized fuel consumption and emissions of gasoline light-duty vehicles. Transp. Res. Part D Transp. Environ. 2006, 11, 377–385. [Google Scholar] [CrossRef]

- Markel, T.; Brooker, A.; Hendricks, T.; Johnson, V.; Kelly, K.; Krämer, B.; O’Keefe, M.; Sprik, S.; Wipke, K. ADVISOR: A systems analysis tool for advanced vehicle modeling. J. Power Sources 2002, 110, 255–266. [Google Scholar] [CrossRef]

- Cooney, G.; Jamieson, M.; Marriott, J.; Bergerson, J.; Brandt, A.; Skone, T.J. Updating the U.S. life cycle GHG petroleum baseline to 2014 with projections to 2040 using open-source engineering-based models. Environ. Sci. Technol. 2017. [Google Scholar] [CrossRef]

- DieselNet. 2014. Available online: www.dieselnet.com (accessed on 1 May 2019).

- Kouridis, C.; Samaras, C.; Hassel, D.; Mellios, G.; Mccrae, I.; Hickman, J.; Zierock, H.; Keller, M.; Rexeis, M.; Andre, M.; et al. EMEP/EEA Air Pollutant Emission Inventory Guidebook; European Environment Agency: Luxemburg, 2018. [Google Scholar]

- Kogo, T.; Hamamura, Y.; Nakatani, K.; Toda, T.; Kawaguchi, A.; Shoji, A. High Efficiency Diesel Engine with Low Heat Loss Combustion Concept—Toyota’s Inline 4-Cylinder. SAE Int. 2016. [Google Scholar] [CrossRef]

- Thiruvengadam, A.; Pradhan, S.; Thiruvengadam, P.; Besch, M.; Carder, D.; Delgado, O. Heavy-Duty Vehicle Diesel Engine Efficiency Evaluation and Energy Audit. In Center for Alternative Fuels, Engines & Emissions: West Virginia University Final Report; West Virginia University: Morgantown, WV, USA, 2014. [Google Scholar]

- Zheng, J.; Song, C.; Peng, Q.; Wang, Z. Experimental Study on Transmission Efficiency of Hybrid Electric Bus Transmission with Synthetic Box Assembly. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: Singapore, 1988. [Google Scholar]

- Nylund, N.O.; Laurikko, J.; Laine, P.; Suominen, J.; Anttonen, M.P.A. Benchmarking heavy-duty ethanol vehicles against diesel and CNG vehicles. Biomass Convers. Biorefin. 2013. [Google Scholar] [CrossRef]

- Leone, T.G.; Anderson, J.E.; Davis, R.S.; Iqbal, A.; Reese, R.A.; Shelby, M.H.; Studzinski, W.M. The Effect of Compression Ratio, Fuel Octane Rating, and Ethanol Content on Spark-Ignition Engine Efficiency. Environ. Sci. Technol. 2015. [Google Scholar] [CrossRef]

- Edwards, K.D.; Wagner, R.M.; Briggs, T.E.; Theiss, T.J. Defining Engine Efficiency Limits. In Proceedings of the 17th DEER Conference, Detroit, MI, USA, 3–6 October 2011. [Google Scholar]

- Wang, R.; Wu, Y.; Ke, W.; Zhang, S.; Zhou, B.; Hao, J. Can propulsion and fuel diversity for the bus fleet achieve the win–win strategy of energy conservation and environmental protection? Appl. Energy 2015, 147, 92–103. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Zardini, A.A.; Keuken, H.; Astorga, C. Impact of ethanol containing gasoline blends on emissions from a flex-fuel vehicle tested over the Worldwide Harmonized Light duty Test Cycle (WLTC). Fuel 2015, 143, 173–182. [Google Scholar] [CrossRef]

- Hubbard, C.P.; Anderson, J.E.; Wallington, T.J. Ethanol and air quality: Influence of fuel ethanol content on emissions and fuel economy of flexible fuel vehicles. Environ. Sci. Technol. 2014. [Google Scholar] [CrossRef] [PubMed]

- Mueller, S.; Unnasch, S.; Keesom, B.; Mohan, S.; Goyal, L. The Impact of Higher Ethanol Blend Levels on Vehicle Emissions in Five Global Cities; University of Illinois: Chicago, IL, USA, 2018. [Google Scholar]

- Silva, C.; Ross, M.; Farias, T. Analysis and simulation of “low-cost” strategies to reduce fuel consumption and emissions in conventional gasoline light-duty vehicles. Energy Convers. Manag. 2009, 50, 215–222. [Google Scholar] [CrossRef]

- Eaves, S.; Eaves, J. A cost comparison of fuel-cell and battery electric vehicles. J. Power Sources 2004. [Google Scholar] [CrossRef]

- Righolt, H.C.; Rieck, F.G. Energy chain and efficiency in urban traffic for ICE and EV. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition, Barcelona, Spain, 17–20 November 2013. [Google Scholar] [CrossRef]

- Kappel, J.; Mathiesen, B.V. Screening of Tank-to-Wheel Efficiencies for CNG, DME and Methanolethanol Fuel Blends in Road Transport; Aalborg University: Aalborg, Denmark, 2013. [Google Scholar]

- Kouridis, C.; Gkatzoflias, D.; Kioutsioukis, I.; Ntziachristos, L.; Pastorello, C.; Dilara, P. Uncertainty Estimates and Guidance for Road Transport Emission Calculations; European Commission Joint Research Centre, Institute for Environment and Sustainability: Ispra, Italy, 2010. [Google Scholar]

- Bradley, M.J. Bus Technology & Alternative Fuels Demonstration Project; FINAL Phase 1—TEST PROGRAM REPORT; M.J. Bradley & Associates: Washington, DC, USA, 2006. [Google Scholar]

- Zhang, S.; Wu, Y.; Liu, H.; Huang, R.; Yang, L.; Li, Z.; Fu, L.; Hao, J. Real-world fuel consumption and CO2 emissions of urban public buses in Beijing. Appl. Energy 2014, 113, 1645–1655. [Google Scholar] [CrossRef]

- Keramydas, C.; Papadopoulos, G.; Ntziachristos, L.; Lo, T.S.; Ng, K.L.; Wong, H.L.; Wong, C. Real-World Measurement of Hybrid Buses’ Fuel Consumption and Pollutant Emissions in a Metropolitan Urban Road Network. Energies 2018, 11, 2569. [Google Scholar] [CrossRef]

- Hallmark, S.L.; Wang, B.; Sperry, R. Comparison of on-road emissions for hybrid and regular transit buses. J. Air Waste Manag. Assoc. 2013, 63, 1212–1220. [Google Scholar] [CrossRef] [PubMed]

- Cavalett, O.; Chagas, M.F.; Seabra, J.E.A.; Bonomi, A. Comparative LCA of ethanol versus gasoline in Brazil using different LCIA methods. Int. J. Life Cycle Assess. 2013. [Google Scholar] [CrossRef]

- Corrêa do Lago, A.; Bonomi, A.; Cavalett, O.; Pereira da Cunha, M.; Pinheiro Lima, M.A. Sugarcane as a carbon source: The Brazilian case. Biomass Bioenergy 2012. [Google Scholar] [CrossRef]

| Technology/Fuel | Diesel | E20 | E100 | Electricity |

|---|---|---|---|---|

| ICEV compression ignition (CI) | x | |||

| HEV (CI) | x | x | ||

| PHEV spark ignition (SI) | x | x | x |

| Energy Source | Min | Max |

|---|---|---|

| Diesel [13] (gCO2eq/MJ) | 17.5 (621.1 *) | 23.5 (834.0 *) |

| Gasoline [13] (gCO2eq/MJ) | 19.7 (654.4 *) | 26.3 (873.4 *) |

| electricity (10% thermal based) g/kWh | 34.1 (natural gas) | 102.4 (coal) |

| electricity (58% thermal based) g/kWh | 198.0 (natural gas) | 593.9 (coal) |

| ethanol from banana waste [6] (g/MJ) | 23.6 (540.2 *) | 23.6 (540.2 *) |

| Electric Motor | Voith TFM Max 150 kW/Max 2750 Nm |

| Energy Storage System | Maxwell supercapacitor 0.4 kWh |

| Passenger Capacity | 114 |

| Curb weight | 16 ton |

| Engine | Max. output 270 hp (198 kW) Max. torque between 1250 Nm No. of cylinders 6 Displacement 9 dm3 Compression ratio of 28:1 |

| [24] | [25] | |||||

|---|---|---|---|---|---|---|

| NOx (mg/km) WLTP Cycle | NH3 (mg/km) WLTP Cycle | PM2.5 (mg/km) WLTP Cycle | NOx (g/mile) FTP Cycle | NH3 (g/mile) FTP Cycle | PM2.5 (g/mile) FTP Cycle | |

| E0 | NA | NA | NA | 0.0544 | 0.0353 | NA |

| E5 | 62 | 6 | NA | NA | NA | NA |

| E10 | 42 | 16 | NA | 0.0472 | 0.0408 | NA |

| E15 | 51 | 14 | NA | NA | NA | NA |

| E20 | NA | NA | NA | 0.0316 | 0.0638 | NA |

| E30 | NA | NA | NA | 0.0245 | 0.0642 | NA |

| E40 | NA | NA | NA | 0.0209 | 0.0705 | NA |

| E55 | NA | NA | NA | 0.0293 | 0.0968 | NA |

| E80 | NA | NA | NA | 0.0261 | 0.0896 | NA |

| E85 | 19 | 26 | NA | NA | NA | NA |

| NOx | NH3 | PM2.5 | |

|---|---|---|---|

| E10 | −12% | +10% | −6% |

| E20 | −17 | +52% | −36% |

| E80 | −49 | +153% | –36% |

| E100 | −49 | +153% | –36% |

| Electric Motor | Max 160 kW/Max 1200 Nm |

| Energy Storage System | Lithium ion battery 76 kWh |

| Transmission | Volvo 2-speed automatic transmission |

| Charging System | Opportunity charging—conductive charging system—roof mounted. Fully automatic, fast charging. Fast charging time: up to six minutes. |

| Passenger Capacity | 83 |

| Curb weight | 12 ton |

| Engine Volvo D5K240 EU6 | Max. output 240 hp (177 kW) Max. power at 2200 rpm Max. torque between 1200–1600 rpm 918 Nm No. of cylinders 4 Bore 110 mm Stroke 135 mm Displacement of 5.1 dm3 Compression ratio of 17.5:1 Oil-change volume, including oil filters approx. 18.7 L |

| Technology y | Standard z | Fuel m | M Annual mileage (km/y) | N Number of Buses | FI L/km or kWh/km 1) | EFNOx 2) (g/km) | EFPM2.5 (g/km) | EFNH3 (g/km) |

|---|---|---|---|---|---|---|---|---|

| conventional ICEV (compression ignition) | Euro III | Diesel | 78,767 | 23,056 | 0.4–0.56 [32] 0.36 tier 2 0.46 VTT Capturing variations with the driving cycle | 9.38 | 0.207 | 0.0029 |

| conventional ICEV (compression ignition) | Euro V | Diesel | 78,767 | 23,056 | 3.09 | 0.0462 | 0.011 | |

| HEV (compression ignition) | - | Diesel | 78,767 | 23,056 | 0.3–0.42 (less 25% than FIDiesel [33]) | 0.98 [34] | 0.0231 less 50% than conventional ICEV [35] | 0.0046 [34] |

| HEV compression ignition | Euro V | E95 | 78,767 | 23,056 | 0.73 [20] | 5.58 [20] | 0.037 [20] | NA 3) |

| ICEV (spark ignition) reference for applying Table 3 | - | - | - | - | - | 2.5 (spark ignition urban bus [15]) | 0.005 (spark ignition urban bus [15]) | 0.0019 (spark ignition heavy-duty vehicle [15]) |

| PHEV | - | electricity | 80% of 78,767 | 23,056 | 0 | 0 | 0 | |

| PHEV | - | E20 | 20% of 78,767 | 23,056 | 2.0 applying Table 3 | 0.003 applying Table 3 | 0.0029 applying Table 3 | |

| PHEV | - | E100 | 20% of 78,767 | 23,056 | 1.3 applying Table 3 | 0.003 applying Table 3 | 0.0048 applying Table 3 |

| Electricity GWh | Diesel ML | Gasoline ML | Ethanol ML | |

|---|---|---|---|---|

| ICEVdiesel-Reference Euro III bus fleet | - | 835.38 (654–1017) | - | - |

| HEVdiesel | - | 626.54 (490–763) | - | - |

| HEVED95 | - | - | - | 1325.72 |

| PHEVflexE20 | 2215.99 (1642–4385) | - | 164.73 (105–326) | 41.18 (26–82) |

| PHEVflexE100 | 2215.99 (1624–4385) | - | - | 281.34 (179–557) |

| NO2 | PM2.5 | NH3 | PM2.5 Equivalent | |

|---|---|---|---|---|

| ICEV-Reference Euro III bus fleet | 17,034.6 (14,309–19,760) | 375.9 (318–434) | 5.3 | 396.5 (338–455) |

| HEV diesel | 1779.7 (1495–2065) | 42.0 (35–49) | 83.5 | 368.3 (364–376) |

| HEV ED95 | 10,133.6 (8512–11,755) | 67.2 (78–95) | 95.3 | 439.7 (429–450) |

| PHEV E20 | 753.7 (633–874) | 1.2 (1–1.3) | 1.0 | 5.3 (5.1–5.4) |

| PHEV E100 | 463.1 (389–537) | 1.2 (1–1.3) | 1.7 | 8.0 (7.8–8.2) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arcentales, D.; Silva, C. Exploring the Introduction of Plug-In Hybrid Flex-Fuel Vehicles in Ecuador. Energies 2019, 12, 2244. https://doi.org/10.3390/en12122244

Arcentales D, Silva C. Exploring the Introduction of Plug-In Hybrid Flex-Fuel Vehicles in Ecuador. Energies. 2019; 12(12):2244. https://doi.org/10.3390/en12122244

Chicago/Turabian StyleArcentales, Danilo, and Carla Silva. 2019. "Exploring the Introduction of Plug-In Hybrid Flex-Fuel Vehicles in Ecuador" Energies 12, no. 12: 2244. https://doi.org/10.3390/en12122244

APA StyleArcentales, D., & Silva, C. (2019). Exploring the Introduction of Plug-In Hybrid Flex-Fuel Vehicles in Ecuador. Energies, 12(12), 2244. https://doi.org/10.3390/en12122244