H∞ Mixed Sensitivity Control for a Three-Port Converter

Abstract

:1. Introduction

2. Modeling of Isolated TPC

2.1. Power Delivery

2.2. Small Signal Model of TPC

3. Controller Design of TPC

3.1. Fundamental of H∞ Mixed Sensitivity Design

- (1)

- Considerations of W1 Selection. W1 represents the performance metric of the control system for disturbance rejection. For the sensitivity function matrix, S denotes the relationship between tracking error e and external disturbance d, while W1 influences the tracking performance. It is desired that W1 has a high gain in low frequency to reduce steady state error. And a steep declining slope of W1 in high frequency is required for interference attenuation. Therefore, W1 is usually selected as a high gain first order transfer function. Furthermore, the crossover frequency, fw1 of W1 should be lower than the desired crossover frequency of the corrected control subsystem.

- (2)

- Considerations of W2 Selection. The strength or effectiveness of control signal u in Figure 8 can be limited by W2, which is beneficial for keeping u in its allowable range, therefore controller saturation and overshooting can be effectively avoided. The amplitude of u will be reduced if the gain of W2 is increased. The gain of W2 can be rationally high according to the required control performance. The bandwidth of control system can be influenced by W2, the control bandwidth will be reduced if the gain of W2 is increased and vice versa. Therefore, W2 should be appropriately designed by taking into account the effectiveness of the control signal and control bandwidth requirement. In order to avoid high order of the resulted controller, W2 is often selected as a constant in practices.

- (3)

- Considerations of W3 Selection. W3 is selected as a metric for multiplicative perturbation. Generally, the nominal transfer function can used to represent the characteristics of control plant accurately in low frequency, while the accuracy will be degraded in high frequency range, deviations in gain and phase will be resulted accordingly. This type of deviation can be expressed as multiplicative uncertainty, which is usually used to describe parameter uncertainty and high frequency unmodeled dynamic of the system. Multiplicative uncertainty, Δ(s) can be obtained by solving (22).

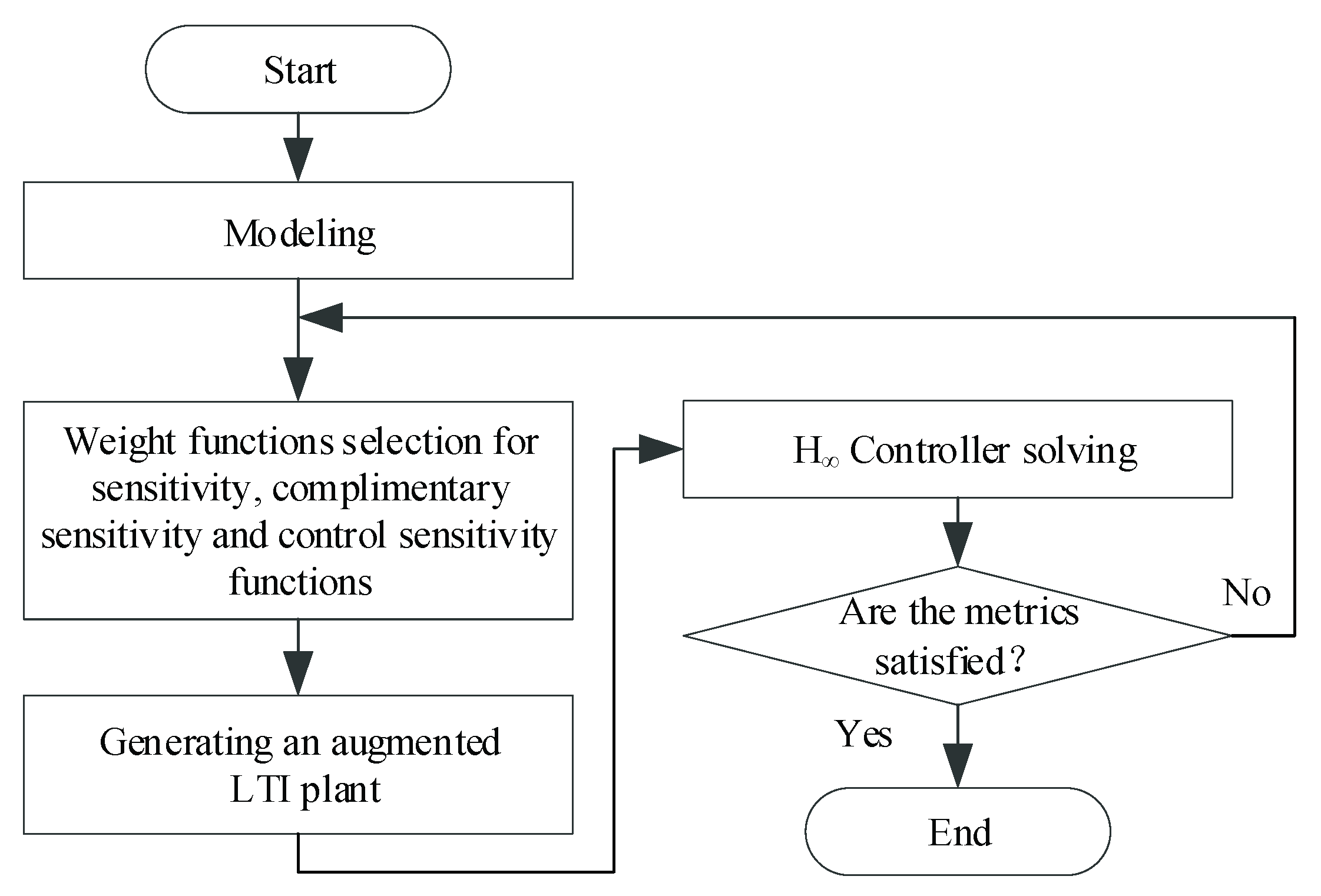

3.2. H∞ Controller Design

4. Simulation and Experimental

4.1. Simulation Results

4.2. Experiment Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tao, H.; Kotsopoulos, A.; Duarte, J.L.; Hendrix, M.A.M. Family of multiport bidirectional DC-DC converters. IEE Proc. Electr. Power Appl. 2006, 153, 451–458. [Google Scholar] [CrossRef]

- Vázquez, N.; Sánchez, C.M.; Hernández, C.; Vázquez, E.; Lesso, R. A three port converter for renewable energy applications. In Proceedings of the IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011; pp. 1736–1740. [Google Scholar]

- Wu, H.; Sun, K.; Ding, S.; Xing, Y. Topology derivation of non-isolated three-port DC-DC converters from DIC and DOC. IEEE Trans. Power Electron. 2013, 28, 3297–3307. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, D.; Zhang, B.; Zhou, Z. A non-isolated three-port DC-DC converter and three-domain control method for PV-battery power systems. IEEE Trans. Ind. Electron. 2015, 62, 4937–4947. [Google Scholar] [CrossRef]

- Phattanasak, M.; Ghoachani, R.G.; Martin, J.P.; Mobarakeh, B.N.; Pierfederici, S.; Davat, B. Control of a hybrid energy source comprising a fuel cell and two storage devices using isolated three-port bidirectional DC-DC converters. IEEE Trans. Power Electron. 2015, 51, 491–497. [Google Scholar] [CrossRef]

- Liu, R.; Xu, L.; Kang, Y.; Hui, Y.; Li, Y. Decoupled TAB Converter with Energy Storage System for HVDC Power System of More Electric Aircraft. J. Eng. 2018, 2018, 593–602. [Google Scholar] [CrossRef]

- Jakka, V.N.S.R.; Shukla, A.; Demetriades, G.D. Dual-Transformer-Based Asymmetrical Triple-Port Active Bridge (DT-ATAB) Isolated DC–DC Converter. IEEE Trans. Ind. Electron. 2017, 64, 4549–4560. [Google Scholar] [CrossRef]

- Zhao, C.; Kolar, J.W. A novel three-phase three-port UPS employing a single high-frequency isolation transformer. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference, Aachen, Germany, 20–25 June 2004. [Google Scholar]

- Zhao, C.; Round, S.D.; Kolar, J.W. An Isolated Three-Port Bidirectional DC-DC Converter with Decoupled Power Flow Management. IEEE Trans. Power Electron. 2008, 23, 2443–2453. [Google Scholar] [CrossRef]

- Tao, H.; Kotsopoulos, A.; Duarte, J.L.; Hendrix, M.A.M. Transformer-Coupled Multiport ZVS Bidirectional DC–DC Converter with Wide Input Range. IEEE Trans. Power Electron. 2008, 23, 771–781. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Z.; Li, H. Asymmetrical Duty Cycle Control and Decoupled Power Flow Design of a Three-port Bidirectional DC-DC Converter for Fuel Cell Vehicle Application. IEEE Trans. Power Electron. 2012, 27, 891–904. [Google Scholar] [CrossRef]

- Falcones, S.; Ayyanar, R. LQR control of a quad-active-bridge converter for renewable integration. In Proceedings of the 2016 IEEE Ecuador Technical Chapters Meeting (ETCM), Guayaquil, Ecuador, 12–14 October 2016. [Google Scholar]

- Tao, H.; Kotsopoulos, A.; Duarte, J.L.; Hendrix, M.A.M. A soft-switched three-port bidirectional converter for fuel cell and supercapacitor applications. In Proceedings of the IEEE 36th Power Electronics Specialists Conference, Recife, Brazil, 12–16 June 2005; pp. 2487–2493. [Google Scholar]

- Falcones, S.; Ayyanar, R.; Mao, X. A DC–DC multiport-converter-based solid-state transformer integrating distributed generation and storage. IEEE Trans. Power Electron. 2013, 28, 2192–2203. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, H.; Cao, F.; Zhu, L.; Xing, Y. Modeling and Decoupling Control of Three-port Half-bridge Converters. Proc. CSEE 2015, 35, 671–678. [Google Scholar]

- You, J.; Liao, M.; Chen, H.; Ghasemi, N.; Vilathgamuwa, M. Disturbance Rejection Control Method for Isolated Three-Port Converter with Virtual Damping. Energies 2018, 11, 3204. [Google Scholar] [CrossRef]

- Doyle, J.C.; Glover, K.; Khargonekar, P.P.; Francis, B.A. State-space solutions to standard H2 and H∞ control problems. IEEE Trans. Autom. Control 1989, 34, 831–847. [Google Scholar] [CrossRef]

- Zhou, K.; Doyle, J.C.; Glover, K. Robust and Optimal Control; Prentice Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Wu, X.; Xie, X. Weight Function Matrix Selection in H∞ Robust Control. J. Tsinghua Univ. 1997, 37, 27–30. [Google Scholar]

- Hu, J.; Unbehauen, H.; Bohn, C. A practical approach to selecting weighting functions for H∞ control and its application to a pilot plant. In Proceedings of the UKACC International Conference on Control ’96, Exeter, UK, 2–5 September 1996; pp. 998–1003. [Google Scholar]

| Parameter/Unit. | Value |

|---|---|

| vd1/V | 24 |

| vd2/V | 50 |

| vd3/V | 36 |

| Turns ratio N1:N2:N3 | 1:1:1 |

| L1/μH | 55 |

| L2/μH | 55 |

| L3/μH | 55 |

| Ld1/μH | 100 |

| RL/Ω | 90/30 |

| Cd1/μF | 1200 |

| Cd2/μF | 1000 |

| Switching frequency/kHz | 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, J.; Liu, H.; Fu, B.; Xiong, X. H∞ Mixed Sensitivity Control for a Three-Port Converter. Energies 2019, 12, 2231. https://doi.org/10.3390/en12122231

You J, Liu H, Fu B, Xiong X. H∞ Mixed Sensitivity Control for a Three-Port Converter. Energies. 2019; 12(12):2231. https://doi.org/10.3390/en12122231

Chicago/Turabian StyleYou, Jiang, Hongsheng Liu, Bin Fu, and Xingyan Xiong. 2019. "H∞ Mixed Sensitivity Control for a Three-Port Converter" Energies 12, no. 12: 2231. https://doi.org/10.3390/en12122231

APA StyleYou, J., Liu, H., Fu, B., & Xiong, X. (2019). H∞ Mixed Sensitivity Control for a Three-Port Converter. Energies, 12(12), 2231. https://doi.org/10.3390/en12122231