Application of Water Fracturing in Geothermal Energy Mining: Insights from Experimental Investigations

Abstract

1. Introduction

2. Background

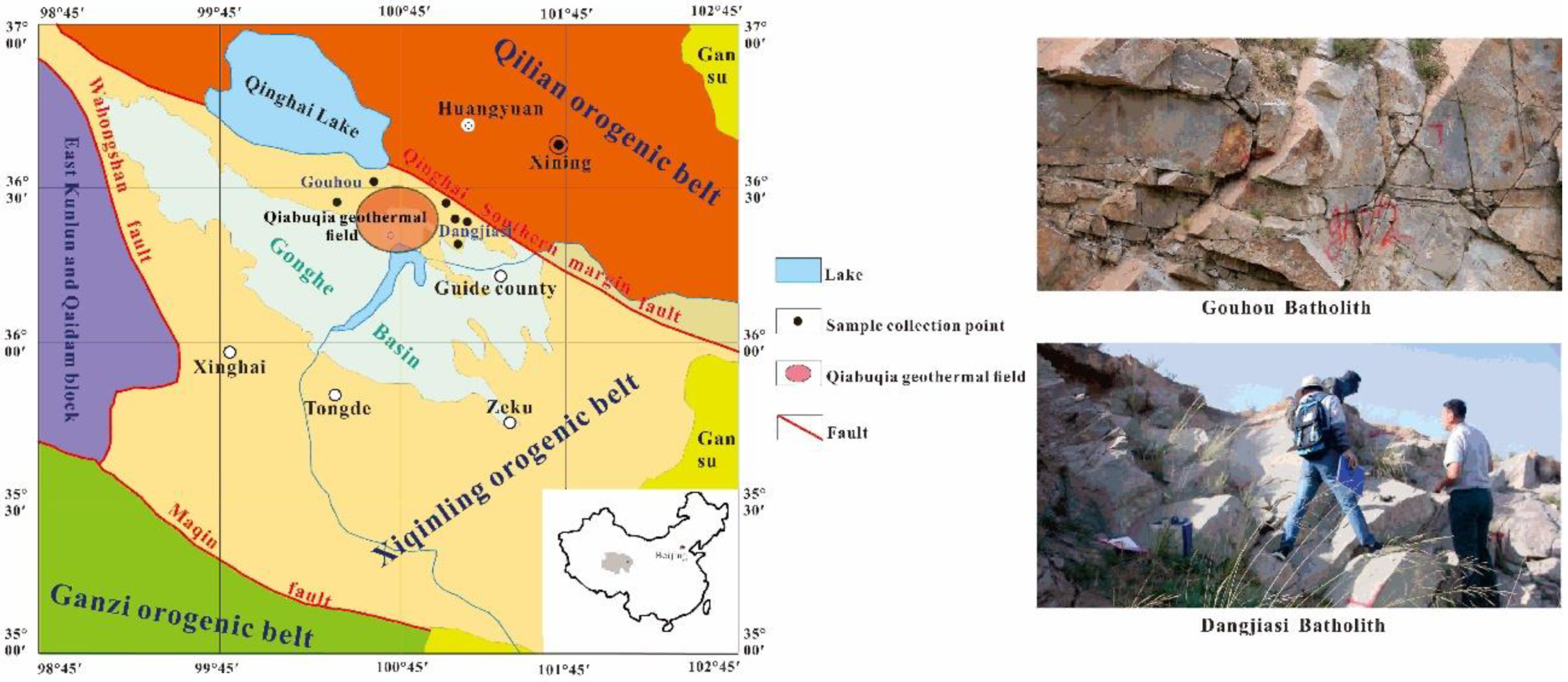

2.1. Geological Setting

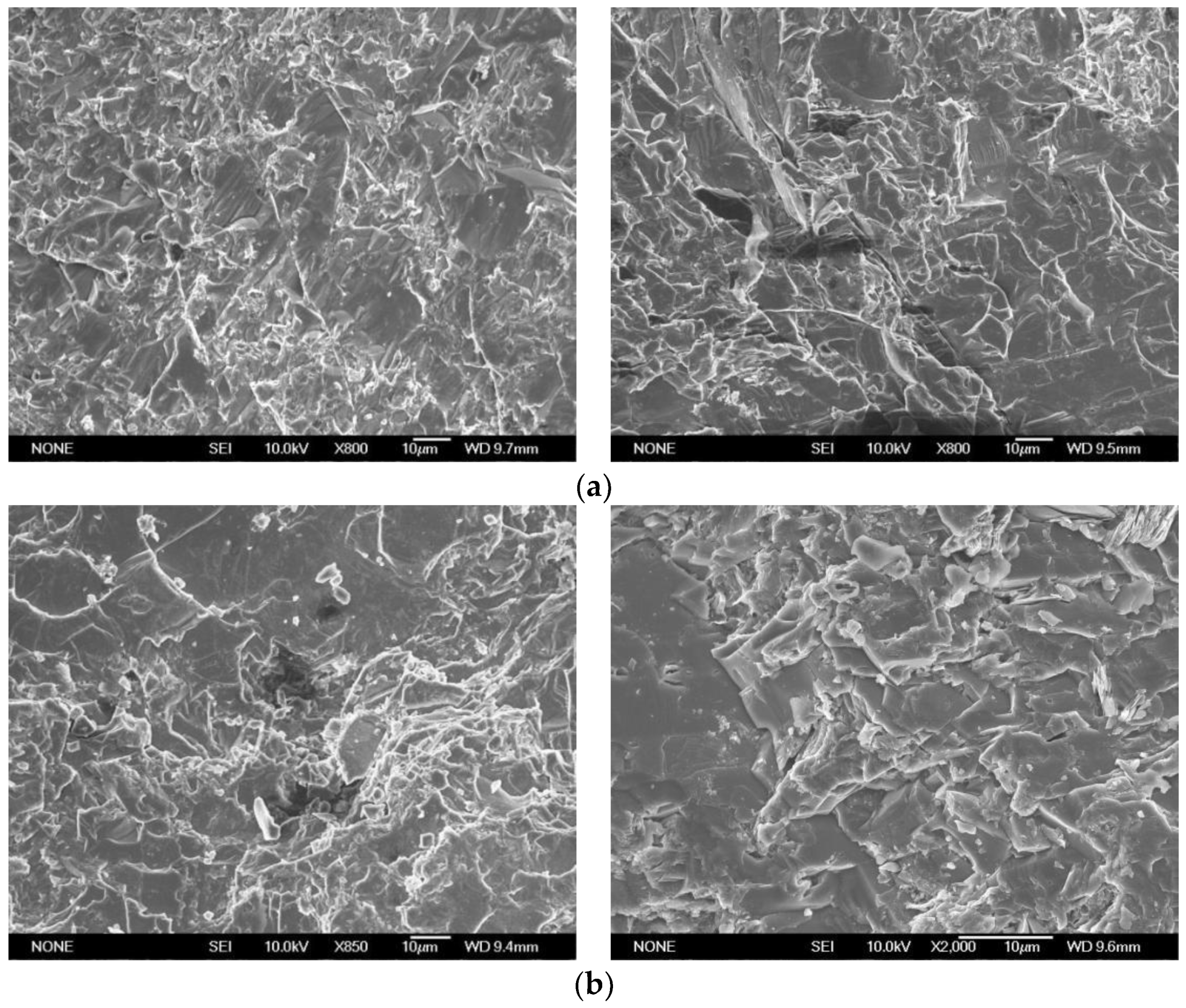

2.2. Experiment Material

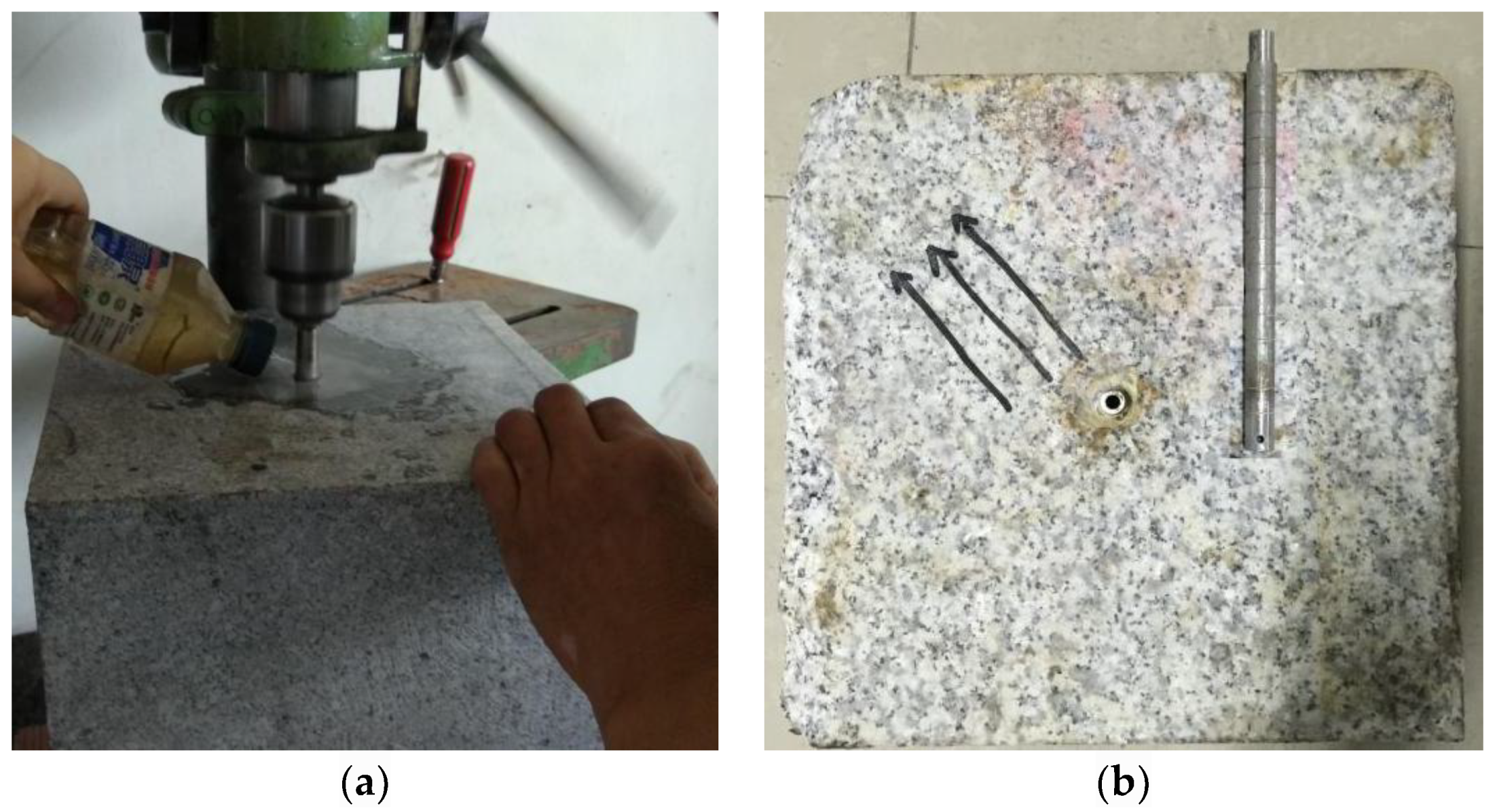

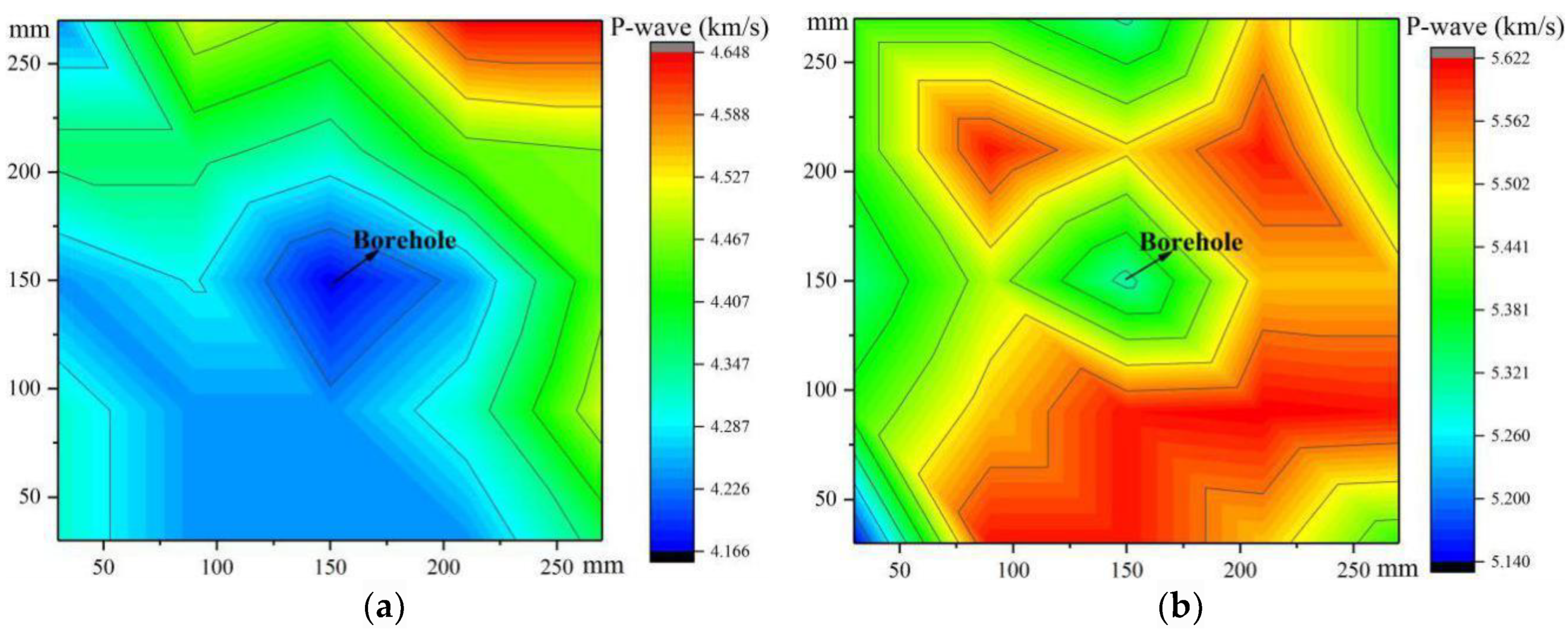

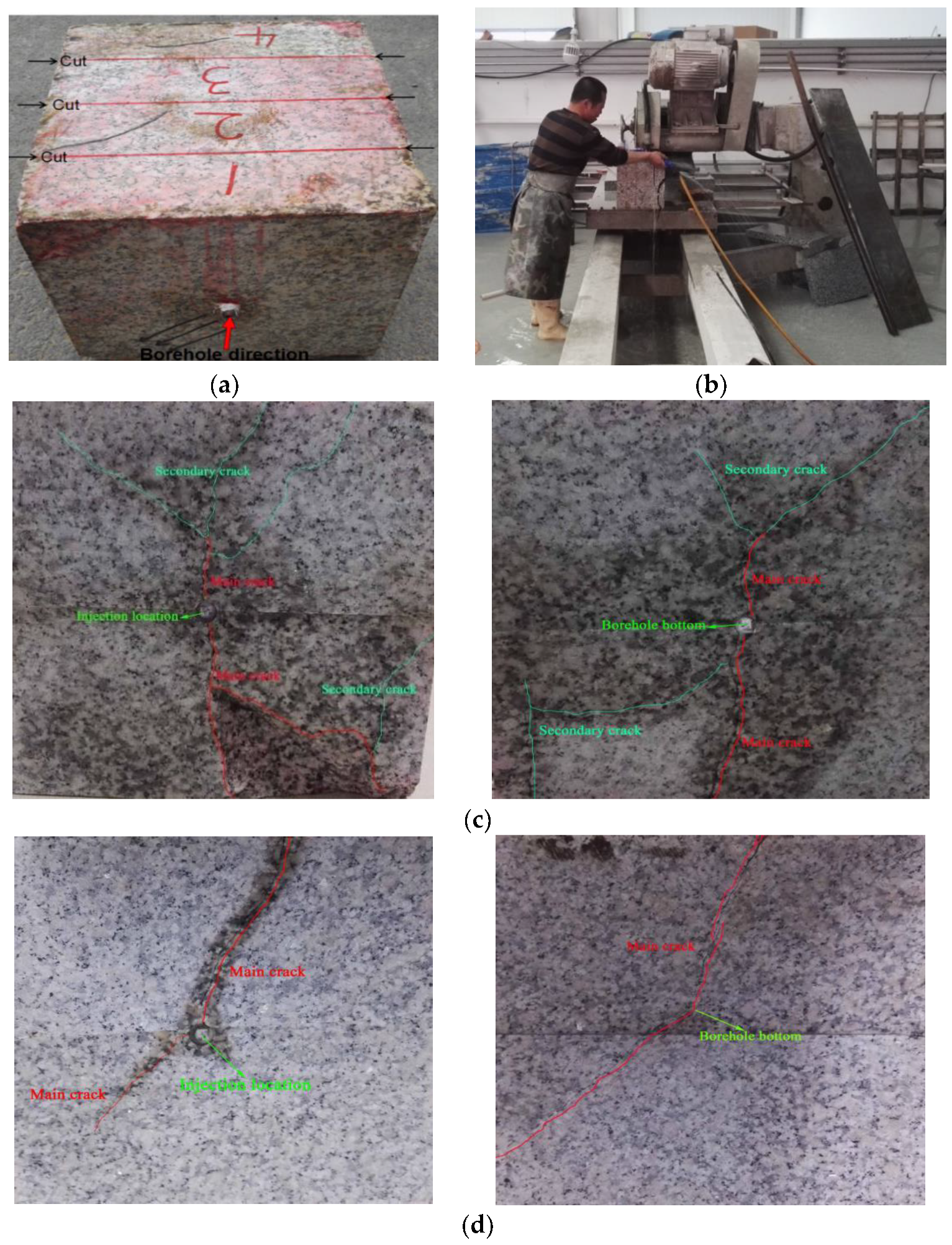

2.3. Sample Preparation

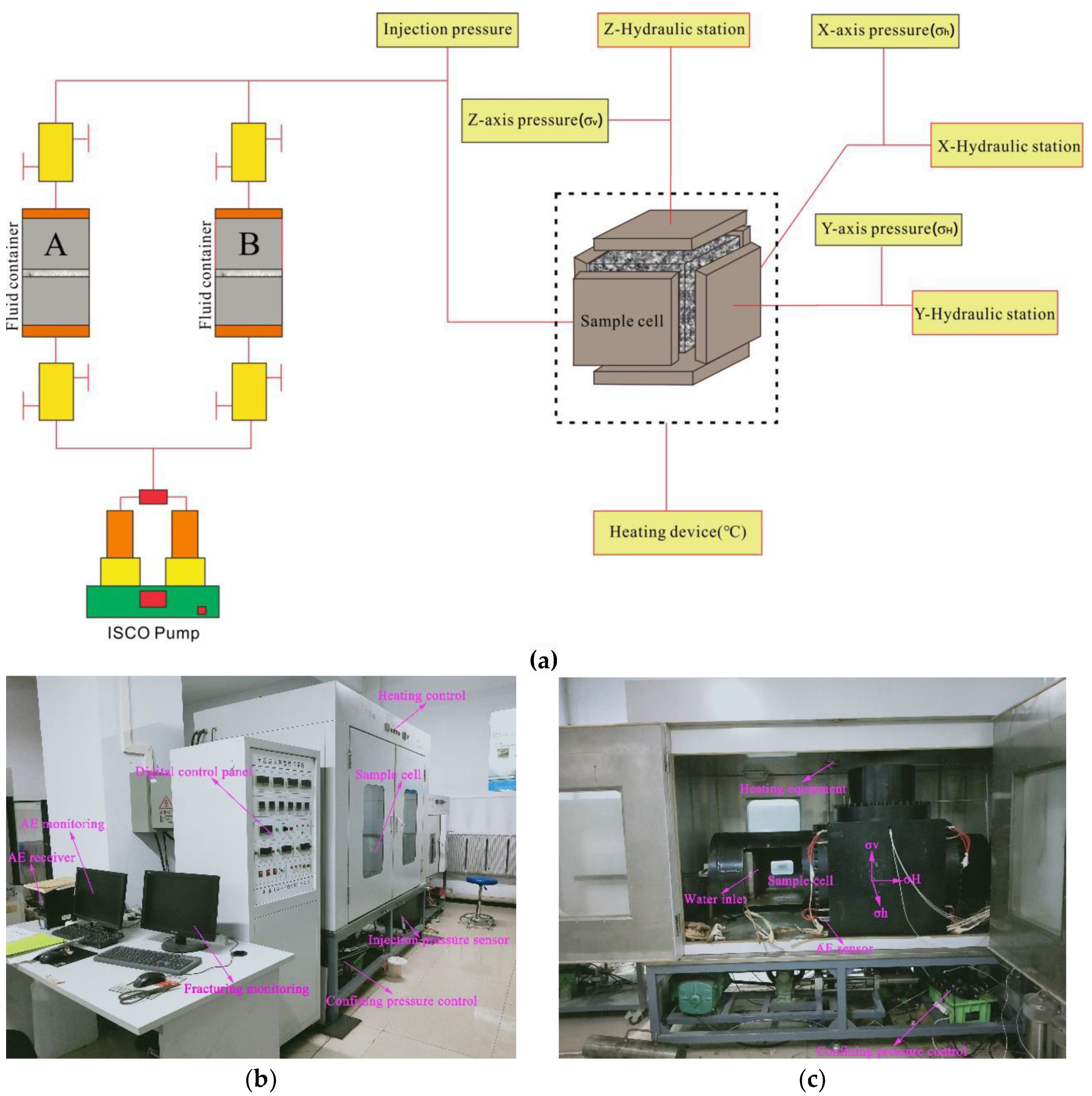

2.4. Hydraulic Fracturing Equipment

2.5. Hydraulic Fracturing Experiments

3. Experimental Results

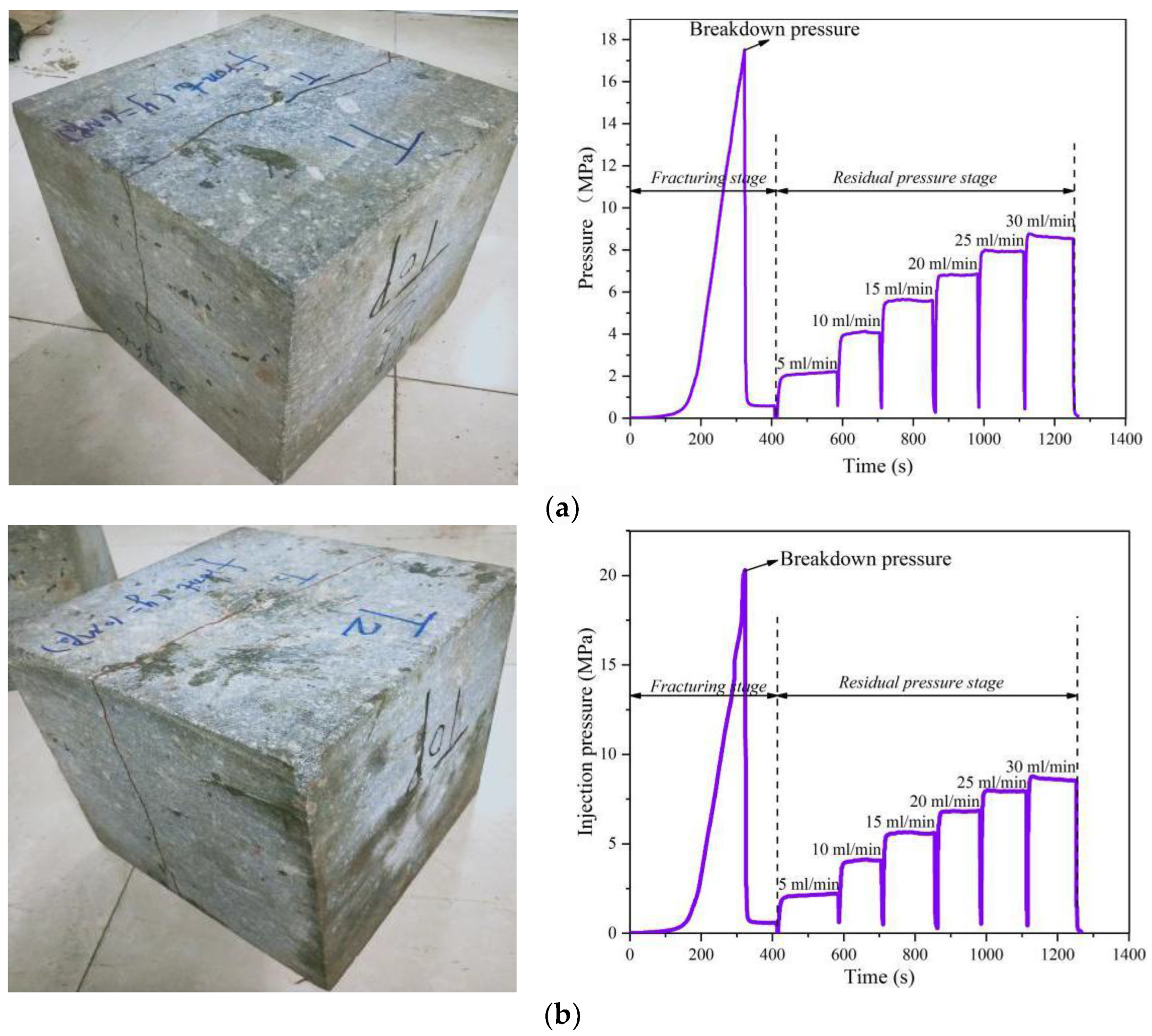

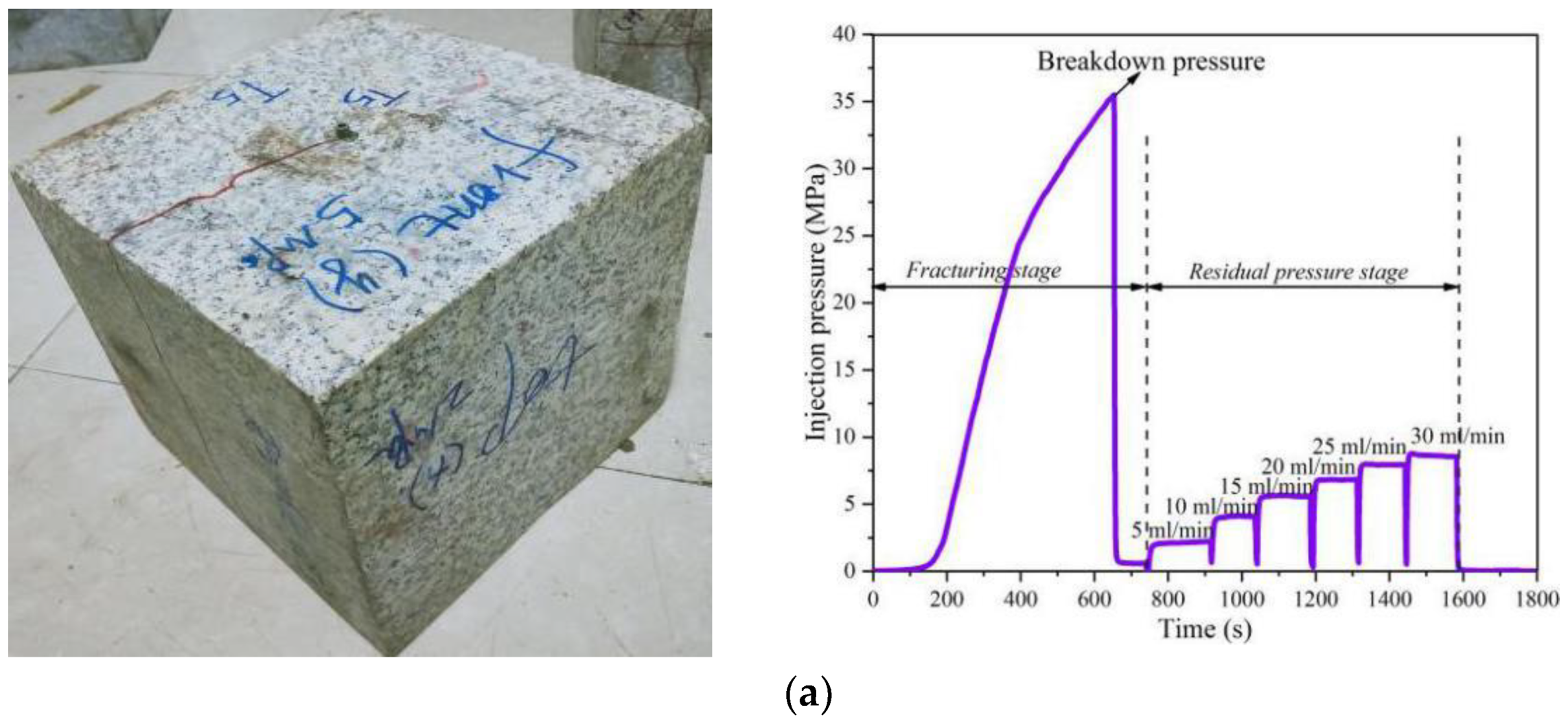

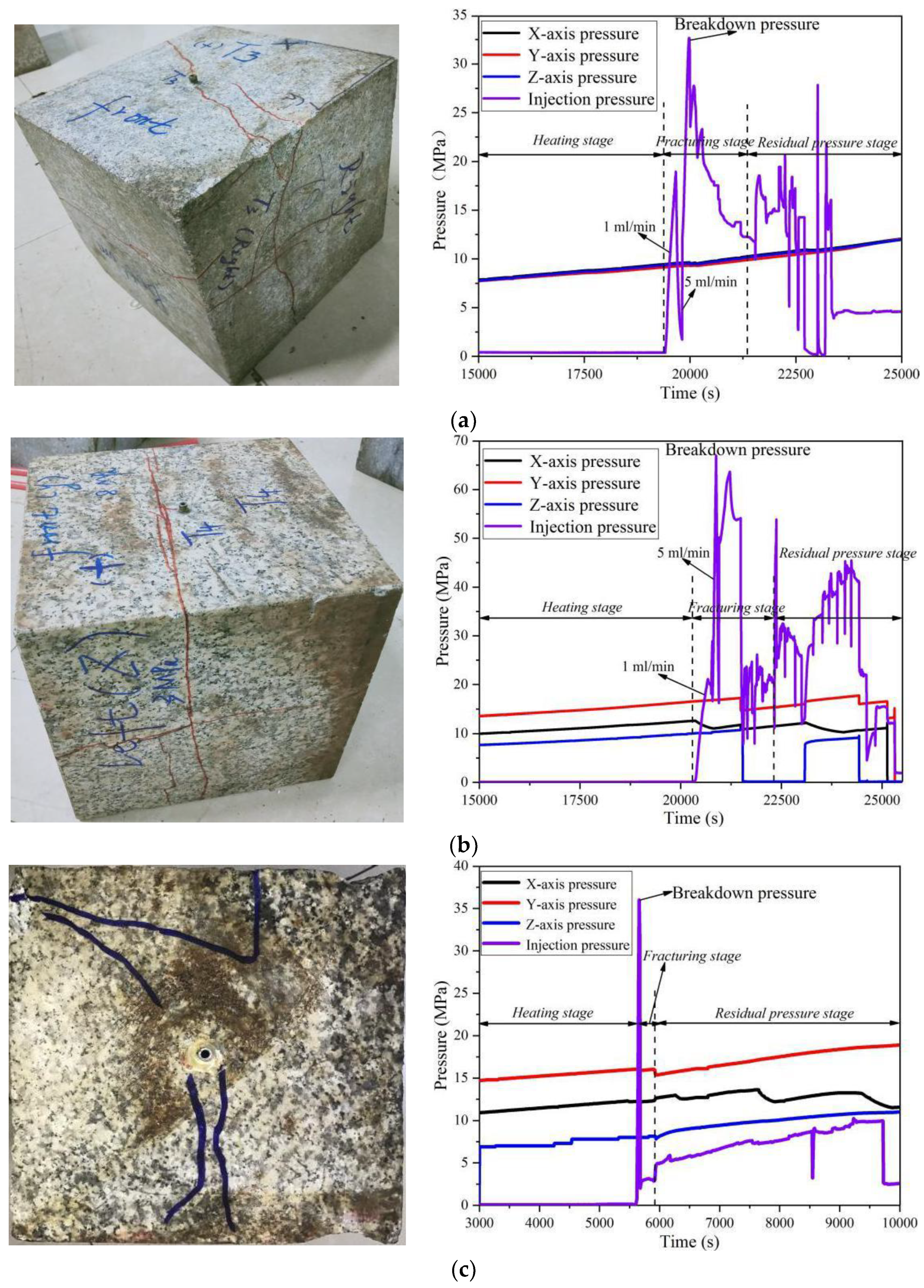

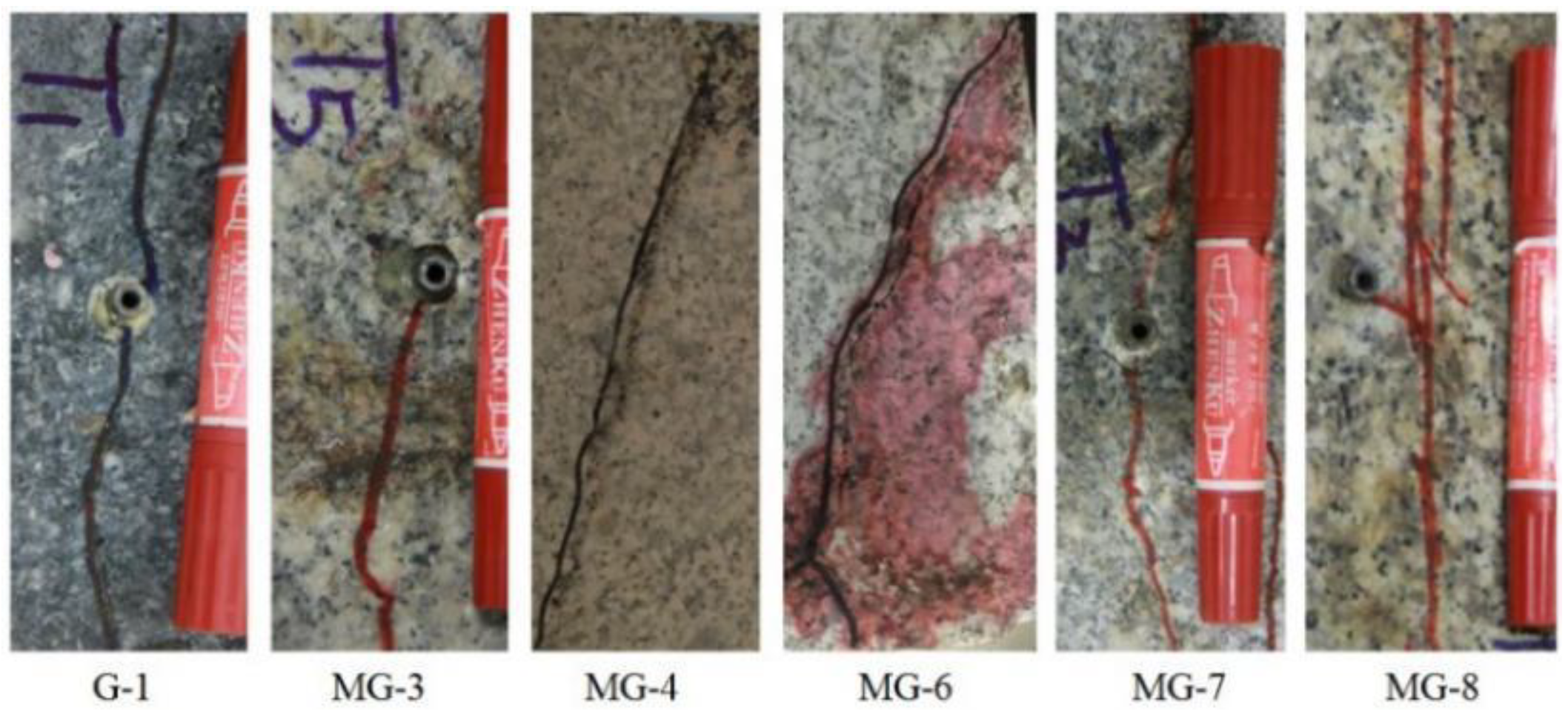

3.1. Room-Temperature Fracturing Test

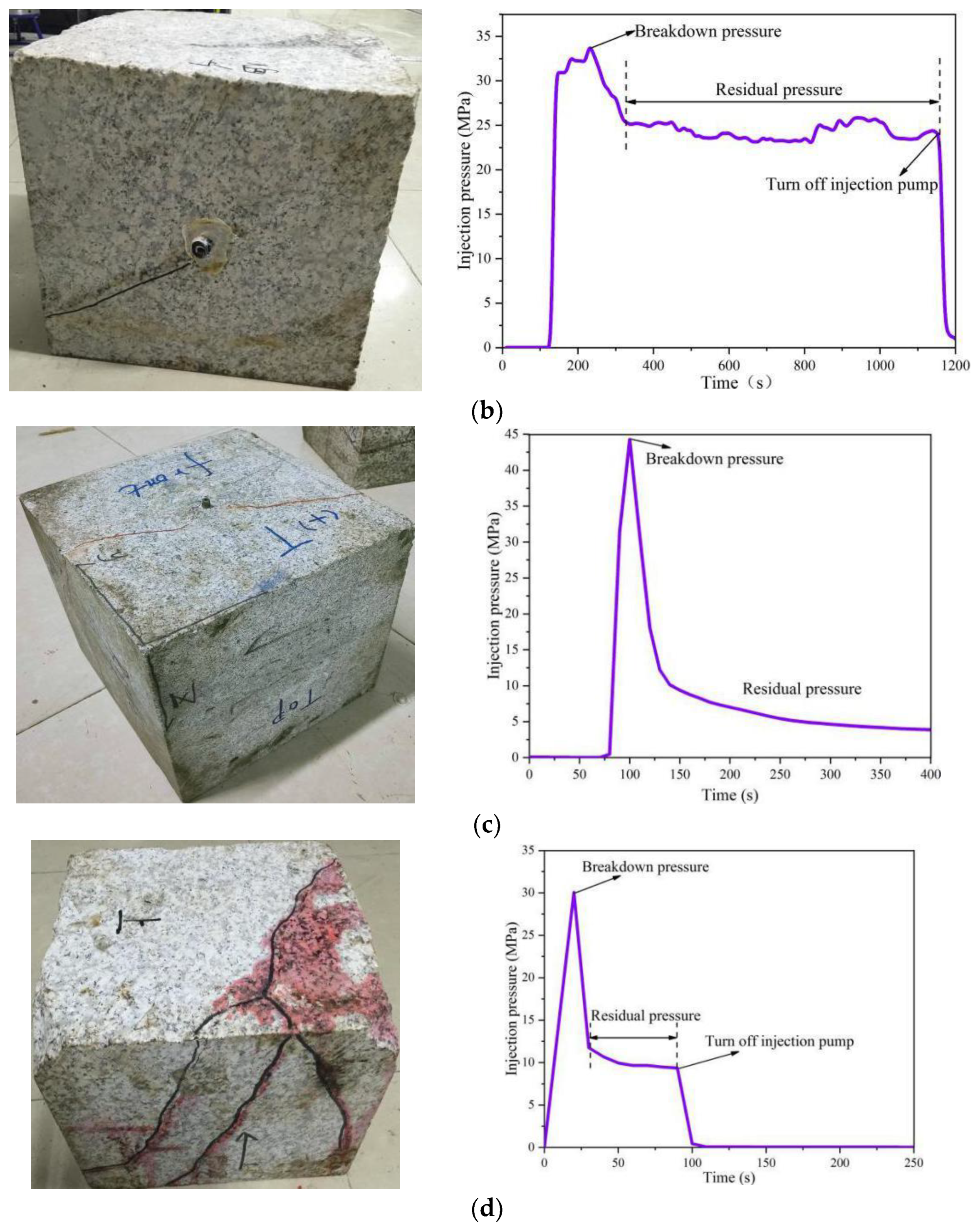

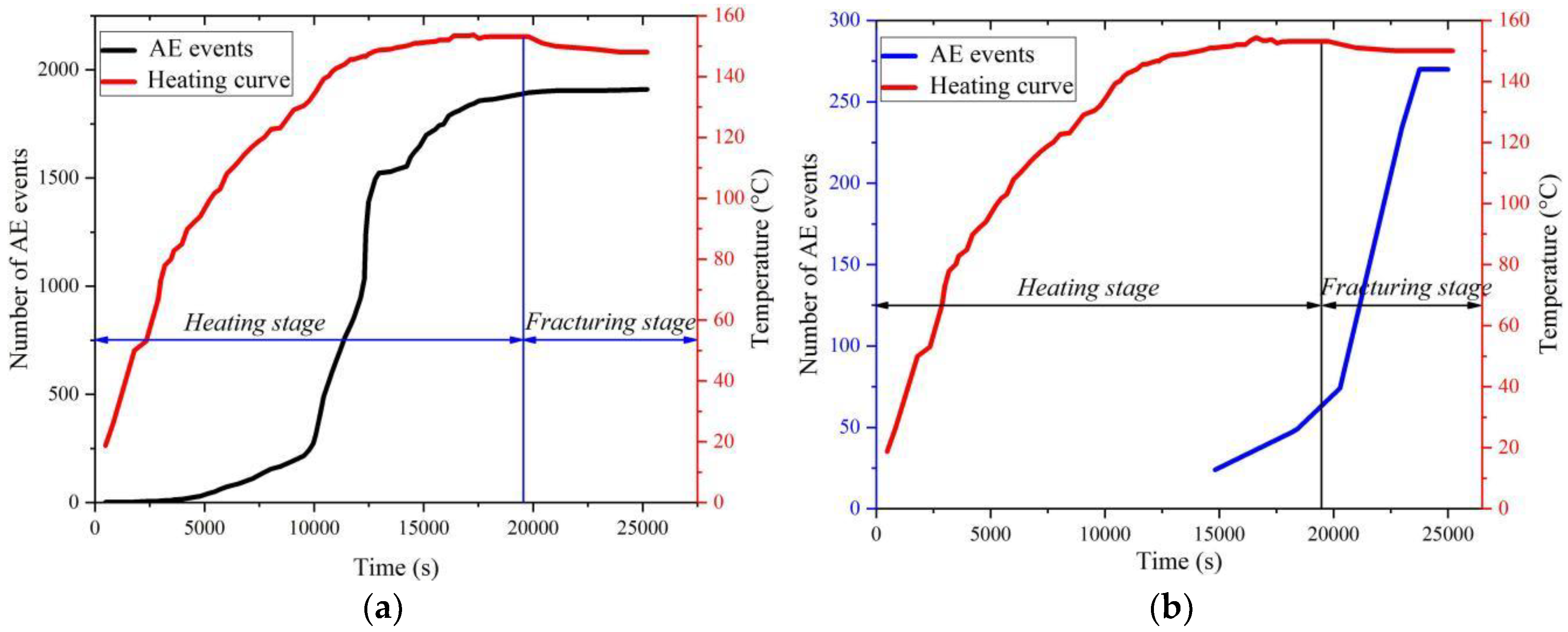

3.2. High-Temperature Fracturing Test

4. Analysis

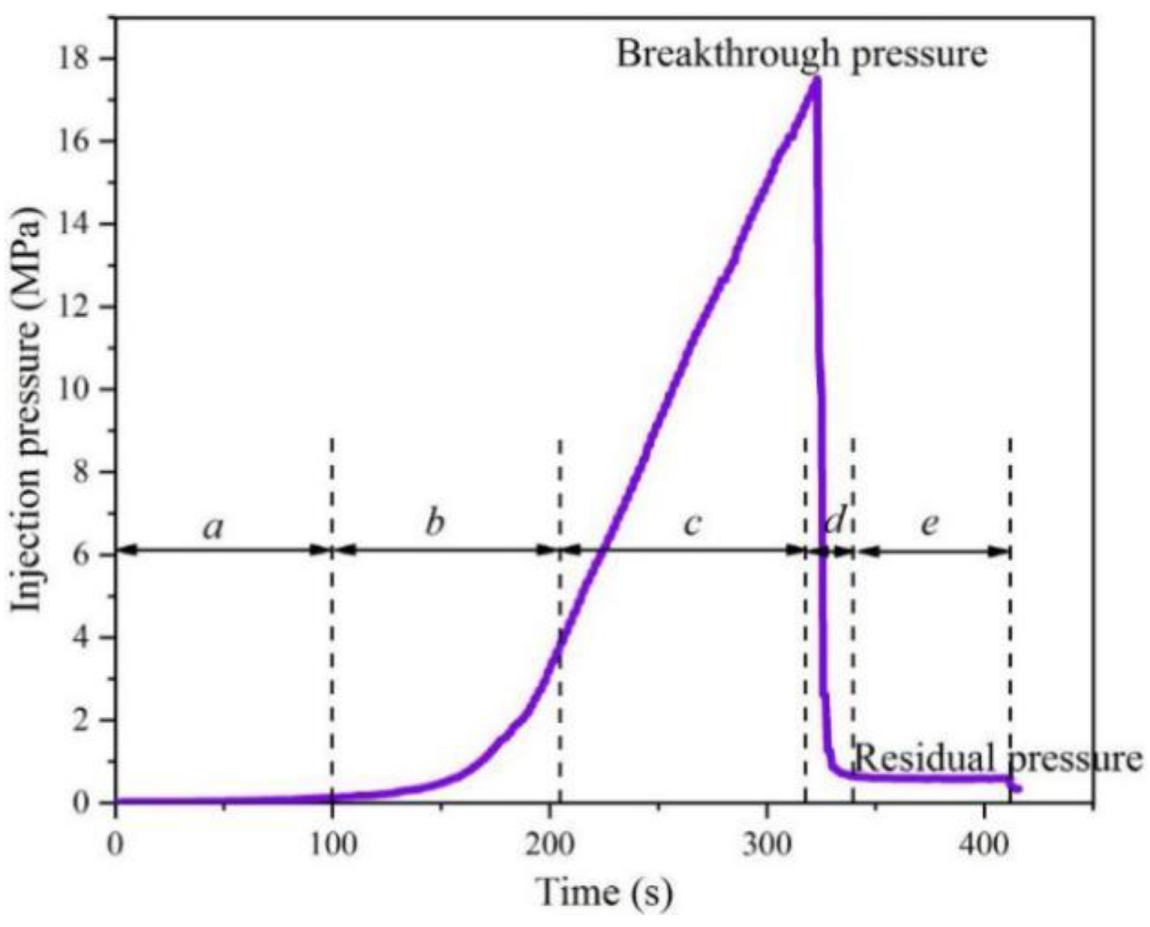

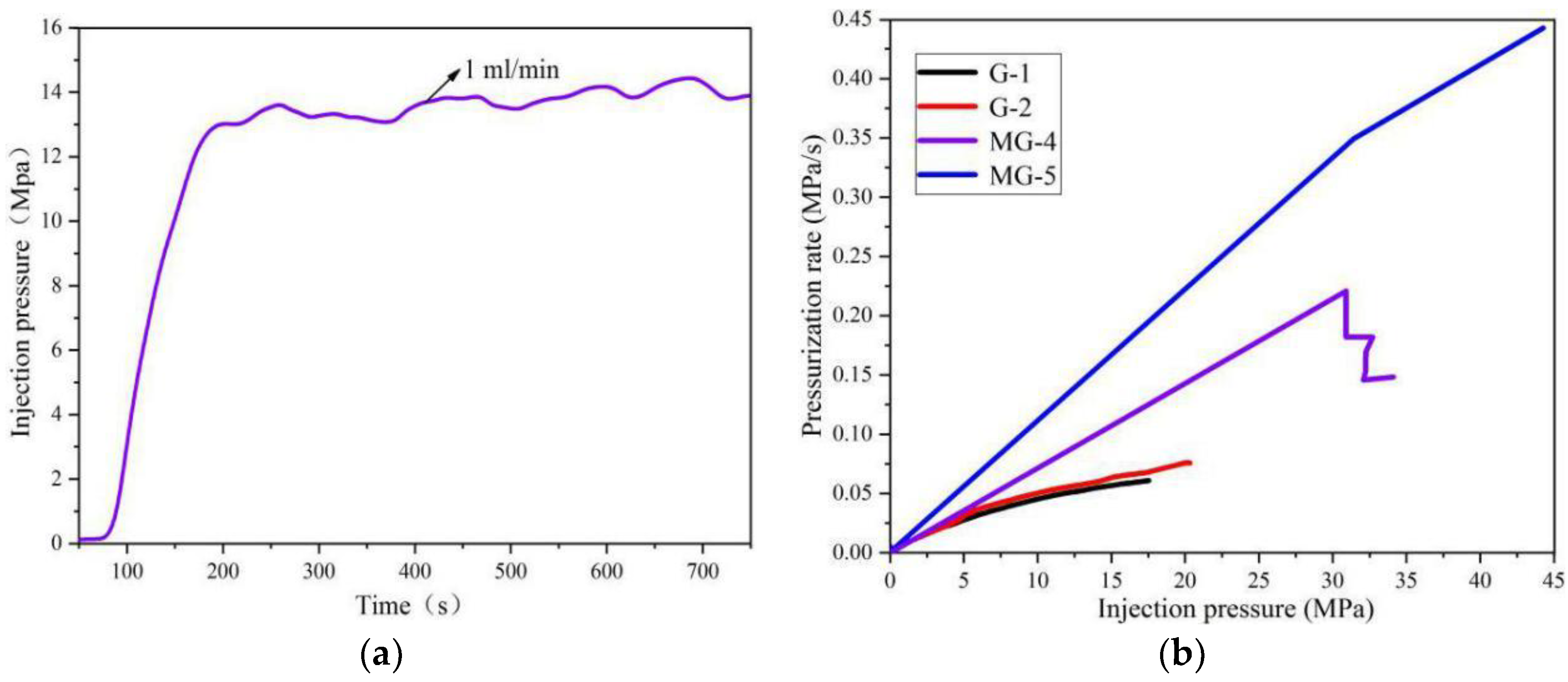

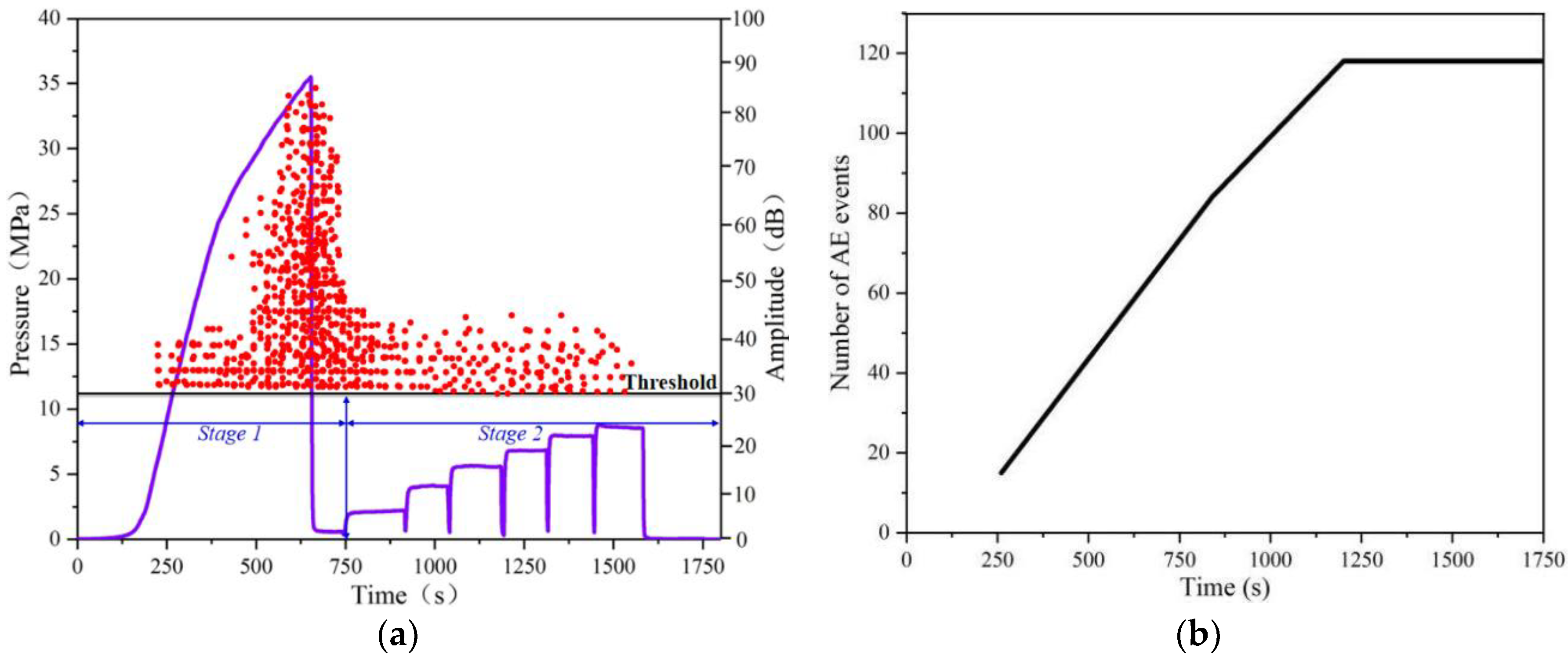

4.1. Injection Pressure Curve

4.2. Effect of Rock Properties on Hydraulic Fracturing

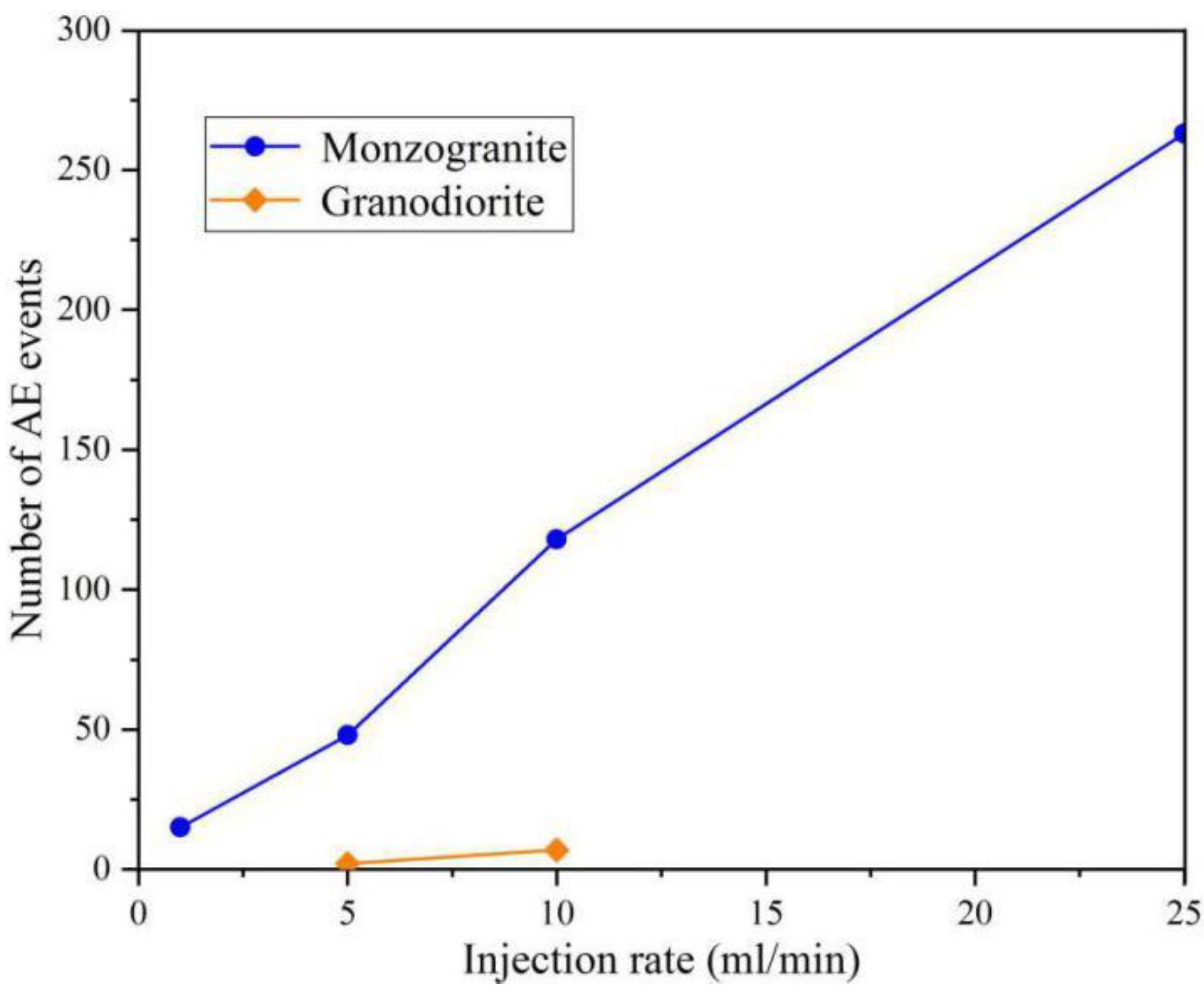

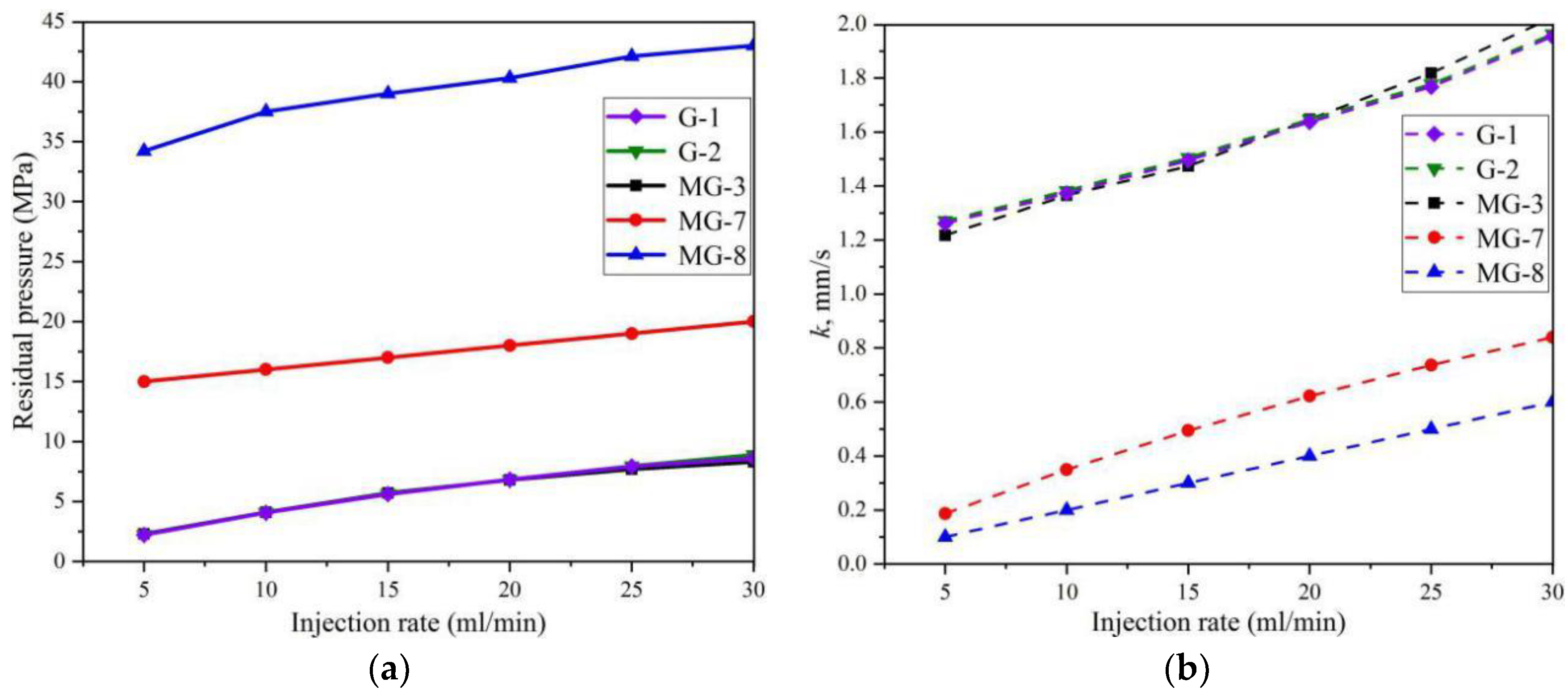

4.3. Effect of Injection Rate on Hydraulic Fracturing Behavior

4.4. Effect of Temperature on Hydraulic Fracturing Behavior

5. Discussion

5.1. Geometric Characteristics of Hydraulic Cracks

5.2. Seepage Characteristics of Hydraulic Crack

5.3. Application for Geothermal Energy Mining

6. Conclusions

- (1)

- The rock properties that had a significant impact on hydraulic fracturing included hydraulic (mainly permeability) and mechanical parameters (mainly rock strength). Due to the heterogeneity of the samples (different strength characteristics, different mineralogy, different grain size distribution, pre-existing cracks, and different permeability), the breakdown pressure, injection rate threshold, and pressurization rate were different. High-strength rock exhibits high breakdown pressures under the same fracturing test conditions. For example, in the present study, the breakdown pressure of the high-strength monzogranite (samples MG-4 and MG-5) was significantly higher than that of the low-strength granodiorite (samples G-1 and G-2) under the same fracturing test conditions. The hydraulic parameters determined the injection rate threshold and affected the pressurization rate, which in turn affected the hydraulic fracturing behavior.

- (2)

- The injection rate was a key factor in distributing the fluid between existing cracks and developing cracks, thereby affecting the complexity of the hydraulic crack networks. A high injection rate simultaneously caused the propagation of multiple pre-existing microcracks in the rock block and multiple hydraulic cracks were induced at the same time.

- (3)

- The anisotropy of the mineral components resulted in a large number of microcracks in the granite during heating, which enhanced the permeability of the rock and increased the injection rate threshold. The existence of these microcracks induced by heating led to the hydraulic crack network complexity. This suggests that it may be a viable approach to use the thermal differential effect between the fluid and rock to thermally stimulate the HDR reservoir to increase the complexity of the hydraulic crack network.

- (4)

- In our experimental investigation, the geometric and seepage characteristics of the hydraulic cracks were clearly affected by factors such as the rock properties, injection rate, and temperature. The crack aperture changed along the propagation path and there was greater variability in the crack aperture in the samples with larger grain size distribution. In addition, a higher injection rate and higher temperature resulted in a greater number of microcracks initiated in the rock mass, resulting in a larger crack aperture. The fluid conductivity in the induced cracks was maintained at 0.1–0.8 mm/s at a closure pressure of 12 MPa and was mainly controlled by the confining pressure state.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tester, J.W.; Livesay, B.; Anderson, B.J.; Moore, M.C.; Bathchelor, A.S.; Nichols, K. The Future of Geothermal Energy: Impact of Enhanced Geothermal Systems (EGS) on the United States in the 21st Century; An assessment by an MIT-led interdisciplinary panel; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Hofmann, H.; Babadagli, T.; Zimmermann, G. Hot water generation for oil sands processing from enhanced geothermal systems: Process simulation for different hydraulic fracturing scenarios. Appl. Energy 2014, 113, 524–547. [Google Scholar] [CrossRef]

- Law, R. Deep geothermal UK-United downs project, Redruth. In Proceedings of the Ground Source Live Workshop, Manchester, UK, 8 June 2011. [Google Scholar]

- Wyss, R.; Rybach, L. Developing deep geothermal resources in Switzerland. In Proceedings of the 2010 World Geothermal Congress, Bali, Indonesia, 25–29 April 2010. [Google Scholar]

- Baria, R.; Baumgärtner, J.; Gérard, A.; Jung, R.; Garnish, J. European HDR research programme at Soultz-sous-Forets (France) 1987–1996. Geothermics 1999, 28, 655–669. [Google Scholar] [CrossRef]

- Durham, W.B.; Bonner, B.P. Self-propping and fluid flow in slightly offset joints at high effective pressures. J. Geophys. Res. Solid Earth 1994, 99, 9391–9399. [Google Scholar] [CrossRef]

- Chen, Z.; Narayan, S.P.; Yang, Z.; Rahman, S.S. An experimental investigation of hydraulic behaviour of fractures and joints in granitic rock. Int. J. Rock Mech. Min. Sci. 2000, 37, 1061–1071. [Google Scholar] [CrossRef]

- Kamali-Asl, A.; Ehsan, G.; Nicolas, P.; Nicholas, B. Experimental study of fracture response in granite specimens subjected to hydrothermal conditions relevant for enhanced geothermal systems. Geothermics 2018, 72, 205–224. [Google Scholar] [CrossRef]

- Caulk, R.A.; Ghazanfari, E.; Perdrial, J.N.; Perdrial, N. Experimental investigation of fracture aperture and permeability change within Enhanced Geothermal Systems. Geothermics 2016, 62, 12–21. [Google Scholar] [CrossRef]

- Taherdangkoo, R.; Tatomir, A.; Anighoro, T.; Sauter, M. Modeling fate and transport of hydraulic fracturing fluid in the presence of abandoned wells. J. Contam. Hydrol. 2019, 221, 58–68. [Google Scholar] [CrossRef]

- Taherdangkoo, R.; Tatomir, A.; Taylor, R.; Sauter, M. Numerical investigations of upward migration of fracking fluid along a fault zone during and after stimulation. Energy Procedia 2017, 125, 126–135. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Guo, L.L.; Li, Z.W.; Yu, Z.W.; Xu, T.F.; Lan, C.Y. Electricity generation and heating potential from enhanced geothermal system in Songliao Basin, China: Different reservoir stimulation strategies for tight rock and naturally fractured formations. Energy 2015, 93, 1860–1885. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Li, X.; Li, L.; Chen, B.; Isaka, B.A.; De Silva, V. Hydraulic fracturing under high temperature and pressure conditions with micro CT applications: Geothermal energy from hot dry rocks. Fuel 2018, 230, 138–154. [Google Scholar] [CrossRef]

- Zoback, M.D.; Rummel, F.; Jung, R.; Raleigh, C.B. Laboratory hydraulic fracturing experiments in intact and pre-fractured rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1997, 14, 49–58. [Google Scholar] [CrossRef]

- Warpinski, N.; Teufel, L. Influence of geologic discontinuities on hydraulic fracture propagation (Includes associated papers 17011 and 17074). J. Pet. Technol. 1987, 39, 209–220. [Google Scholar] [CrossRef]

- Morgan, S.P.; Li, B.Q.; Einstein, H.H. Effect of injection rate on hydraulic fracturing of Opalinus clay shale. In Proceedings of the 51st US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 25–28 June 2017; pp. 17–873. [Google Scholar]

- Solberg, P.; Lockner, D.; Byerlee, J.D. Hydraulic fracturing in granite under geothermal conditions. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1980, 17, 25–33. [Google Scholar] [CrossRef]

- Zeng, Z.; Roegiers, J.C. Experimental observation of injection rate influence on the hydraulic fracturing behavior of a tight gas sandstone. In Proceedings of the SPE/ISRM Rock Mechanics Conference, Irving, TX, USA, 20–23 October 2002. [Google Scholar]

- Solberg, P.; Lockner, D.; Byerlee, J.D. Shear and tension hydraulic fractures in low permeability rocks. Pure Appl. Geophys. 1977, 115, 191–198. [Google Scholar] [CrossRef]

- Zhuang, L.; Kim, K.Y.; Jung, S.G.; Diaz, M.; Min, K.B. Effect of Water Infiltration, Injection Rate and Anisotropy on Hydraulic Fracturing Behavior of Granite. Rock Mech. Rock Eng. 2019, 52, 575–589. [Google Scholar] [CrossRef]

- Jones, C.; Keaney, G.; Meredith, P.G.; Murrell, S.A.F. Acoustic emission and fluid permeability measurements on thermally cracked rocks. Phys. Chem. Earth 1997, 22, 13–17. [Google Scholar] [CrossRef]

- Rutqvist, J.; Freifeld, B.; Min, K.B.; Elsworth, D.; Tsang, Y. Analysis of thermally induced changes in fractured rock permeability during 8 years of heating and cooling at the Yucca Mountain drift scale test. Int. J. Rock. Mech. Min. Sci. 2008, 45, 1373–1389. [Google Scholar] [CrossRef]

- Keshavarz, M.; Pellet, F.L.; Loret, B. Damage and changes in mechanical properties of a Gabbro thermally loaded up to 1000 °C. Pure Appl. Geophys. 2010, 167, 1511–1523. [Google Scholar] [CrossRef]

- Nasseri, M.H.B.; Schubnel, A.; Young, R.P. Coupled evolutions of fracture toughness and elastic wave velocities at high crack density in thermally treated Westerly Granite. Int. J. Rock Mech. Min. Sci. 2007, 44, 601–616. [Google Scholar] [CrossRef]

- Reuschlé, T.; Haore, S.G.; Darot, M. The effect of heating on the microstructural evolution of La Peyratte granite deduced from acoustic velocity measurements. Earth Planet. Sci. Lett. 2006, 243, 692–700. [Google Scholar] [CrossRef]

- Yavuz, H.; Demirdag, S.; Caran, S. Thermal effect on the physical properties of carbonate rocks. Int. J. Rock Mech. Min. Sci. 2010, 47, 94–103. [Google Scholar] [CrossRef]

- Deng, J.; Lin, C.; Yang, Q.; Liu, Y.; Tao, Z.; Duan, H. Investigation of directional hydraulic fracturing based on true tri-axial experiment and finite element modeling. Comput. Geotech. 2016, 75, 28–47. [Google Scholar] [CrossRef]

- Fan, T.G.; Zhang, G.Q. Laboratory investigation of hydraulic fracture networks in formations with continuous orthogonal fractures. Energy 2014, 74, 164–173. [Google Scholar] [CrossRef]

- Lei, Z.H.; Zhang, Y.J.; Yu, Z.W.; Hu, Z.J.; Li, L.Z.; Zhang, S.Q.; Fu, L.; Zhou, L.; Xie, Y.Y. Exploratory research into the enhanced geothermal system power generation project: The Qiabuqia geothermal field, Northwest China. Renew. Energy 2019, 139, 52–70. [Google Scholar] [CrossRef]

- Mao, R.B.; Feng, Z.J.; Liu, Z.H.; Zhao, Y.S. Laboratory hydraulic fracturing test on large-scale pre-cracked granite specimens. J. Nat. Gas Sci. Eng. 2017, 44, 278–286. [Google Scholar] [CrossRef]

- Sarmadivaleh, M.; Joodi, B.; Nabipour, A.; Rasouli, V. Steps to conducting a valid hydraulic-fracturing laboratory test. APPEA J. 2013, 53, 347–354. [Google Scholar] [CrossRef]

- Guo, L.L. Test and Model Research of Hydraulic Fracturing and Reservoir Damage Evolution in Enhanced Geothermal System. Ph.D. Thesis, Jilin University, Changchun, China, 2016. [Google Scholar]

- Meyer & Associates. Mayer Fracturing Simulators. User’s Guide Meyer Fracturing Simulators; Unicode Inc.: Mountain View, CA, USA, 2011. [Google Scholar]

- Al-Busaidi, A. Distinct element modeling of hydraulically fractured Lac du Bonnet granite. J. Geophys. Res. 2005, 110. [Google Scholar] [CrossRef]

- Homand-Etienne, F.; Houpert, R. Thermally induced microcracking in granites: Characterization and analysis. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1989, 26, 125–134. [Google Scholar] [CrossRef]

- Shao, S. Coupled Thermo-Hydro-Mechanical (THM) Behaviour of Rock Relevant to the Geothermal Industry. Ph.D. Thesis, Monash Univerisity, Melbourne, Australia, 2015. [Google Scholar]

- Li, Z.W. Research on Hot Dry Rock Fracture Seepage Heat Transfer Experiment and Reservoir Modeling Evaluation. Ph.D. Thesis, Jilin University, Changchun, China, 2016. [Google Scholar]

- Barla, G. Comprehensive study including testing, monitoring and thermo-hydro modelling for design and implementation of a geothermal system in Torino, Italy. Geomech. Geophys. Geo-Energy Geo-Resour. 2017, 3, 175–188. [Google Scholar] [CrossRef]

- Grant, M.A.; Clearwater, J.; Quinao, J.; Bixley, P.F.; Le Brun, M. Thermal stimulation of geothermal wells: A review of field data. In Proceedings of the Thirty-Eight Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 11–13 February 2013. [Google Scholar]

| Parameter | Granodiorite | Monzogranite |

|---|---|---|

| Bulk Density, ρ | 2623 kg/m3 | 2590 kg/m3 |

| Porosity, ϕ | 4.59% | 2.49% |

| Permeability, K | 0.7 mD | 0.26 mD |

| Elasticity modulus, E | 32.6–35.6 GPa | 40.7–43.5 GPa |

| Poisson’s ratio, μ | 0.28–0.33 | 0.19–0.25 |

| Uniaxial compressive strength (UCS), σc | 109.0 MPa | 131.0 MPa |

| Tensile strength, σb | 11.5–13.9 MPa | 16.5–19.9 MPa |

| Specific heat capacity, C | 720–750 J/(kg·K) | 740–800 J/(kg·K) |

| Thermal Conductivity, λ | 2.25–3.0 W/m/K | 2.25–3.0 W/m/K |

| Main minerals | Plagioclase feldspar (45%), quartz (32%), K-feldspar (10%), biotite (10%), other minerals (approximately 3%) | Quartz (35%), plagioclase feldspar (30%), K-feldspar (23%), and biotite (11%), other minerals (1%) |

| Grain size distribution | 0.2–2.0 mm | 0.2–3.0 mm |

| Specimen Number | Confining Pressure, σh/σH/σv, MPa | Injection Rate, mL/min | Temperature Setting, °C | Lithology |

|---|---|---|---|---|

| G-1 | 6/10/4 | 5 | Room temperature, 20 °C | Gr. |

| G-2 | 10 | Room temperature, 20 °C | Gr. | |

| MG-3 | 1 | Room temperature, 20 °C | MGr. | |

| MG-4 | 5 | Room temperature, 20 °C | MGr. | |

| MG-5 | 10 | Room temperature, 20 °C | MGr. | |

| MG-6 | 25 | Room temperature, 20 °C | MGr. | |

| MG-7 | 6/6/6 | 5 | High temperature, 150 °C | MGr. |

| MG-8 | 6/10/4 | 5 | High temperature, 150 °C | MGr. |

| MG-9 | 6/10/4 | 25 | High temperature, 150 °C | MGr. |

| Specimen size | 300 × 300 × 300 mm, cube. | |||

| Fracturing fluid | Distilled water | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Z.; Zhang, Y.; Hu, Z.; Li, L.; Zhang, S.; Fu, L.; Yue, G. Application of Water Fracturing in Geothermal Energy Mining: Insights from Experimental Investigations. Energies 2019, 12, 2138. https://doi.org/10.3390/en12112138

Lei Z, Zhang Y, Hu Z, Li L, Zhang S, Fu L, Yue G. Application of Water Fracturing in Geothermal Energy Mining: Insights from Experimental Investigations. Energies. 2019; 12(11):2138. https://doi.org/10.3390/en12112138

Chicago/Turabian StyleLei, Zhihong, Yanjun Zhang, Zhongjun Hu, Liangzhen Li, Senqi Zhang, Lei Fu, and Gaofan Yue. 2019. "Application of Water Fracturing in Geothermal Energy Mining: Insights from Experimental Investigations" Energies 12, no. 11: 2138. https://doi.org/10.3390/en12112138

APA StyleLei, Z., Zhang, Y., Hu, Z., Li, L., Zhang, S., Fu, L., & Yue, G. (2019). Application of Water Fracturing in Geothermal Energy Mining: Insights from Experimental Investigations. Energies, 12(11), 2138. https://doi.org/10.3390/en12112138